Milnor 30010CGE, 30015C4E, 30015CGE, 30022C4E, 36021C4E User Manual

Published Manual Number: MTCEXB01

• Specified Date: 20040120

• As-of Date: 20040120

• Access Date: 20040120

• Depth: detail

• Applicability: CEX

• Language Code: ENG01, Purpose: publication, Format: 1colA

General—

Electronic Coin Washer-

extractor Control with

Seven Formulas

PELLERIN MILNOR CORPO RAT ION

POST OFFICE BOX 400, KENNER, LOUISIANA 70063 - 0400, U.S.A.

Applicable Milnor® products by model number:

30010CGE 30015C4E 30015CGE 30022C4E 36021C4E

Preface

BICEUK01 (Published) Book specs- Dates: 20040120 / 20040120 / 20040120 Lang: ENG01 Applic: CEX

i. About This Manual

i. 1.

Scope

This manual provides commissioning, operating, and troubleshooting instructions for Milnor

washer-extractors in the C_E model line, which are equipped with the Milnor® electronic seven

formula coin washer-extractor control. See the installation manual for information on machine

installation procedures and mechanical requirements. See the service manual for preventive

maintenance, service procedures, and mechanical parts identification. See the schematic manual

for electrical parts identification and electrical troubleshooting instructions.

Preface

®

i. 2.

How to Identify this Manual and its Included Documents

BIUUUD13]

[Document

A complete identification of this manual or any document in this manual must include all

specifications shown on the front cover, as defined below:

Published manual number—Primary identification number for the manual or any variation of it.

Specified date—The approximate date of introduction of the product or product change this

manual covers.

As-of date—When a manual for an old product is generated, any new information about the old

product developed up to this date will be included in the manual.

Access date—The date the manual was generated (assembled and formatted).

Applicability—Code(s) that represent a group of machines this manual applies to and/or actual

model numbers of applicable machines. The complete list of applicable models is provided

inside the front cover. If “not used” appears here, this is not a product manual, but has another

purpose such as to provide administrative procedures.

Language Code—A code representing the specific language and dialect of this manual. “Eng01”

identifies the language/dialect of the manual as United States English, which is that of the

Milnor factory.

When referring to any document used in this manual (as identified by an eight-character

document number such as BIUUUD13 at the start of the document), a complete identification of

the document must include all specifications shown on the front cover, except substituting the

document number for the published manual number.

i. 3.

Trademarks of Pellerin Milnor Corporation

The following, some of which may be used in this publication, are trademarks of Pellerin Milnor

Corporation:

[Document BIUUUD14]

PELLERIN MILNOR CORPORATION

Preface

Table 1: Trademarks

Ampsaver® E-P Express® Hydro-Cushion® Milnor® Totaltrol®

Autolint® E-P OneTouch® Mentor® Miltrac

Autovac E-P Plus® Mildata® Staph-Guard®

CBW® Gear Guardian® Milnet® System 7®

— End of BICEUK01 —

BICEXS04 (Published) Book specs- Dates: 20040120 / 20040120 / 20040120 Lang: ENG01 Applic: CEX

ii. General Safety Requirements—Vital Information for Coin

Laundry Owners/Managers and Employees

Notice 1 : Important Safety Instructions

—Read and save all instructions

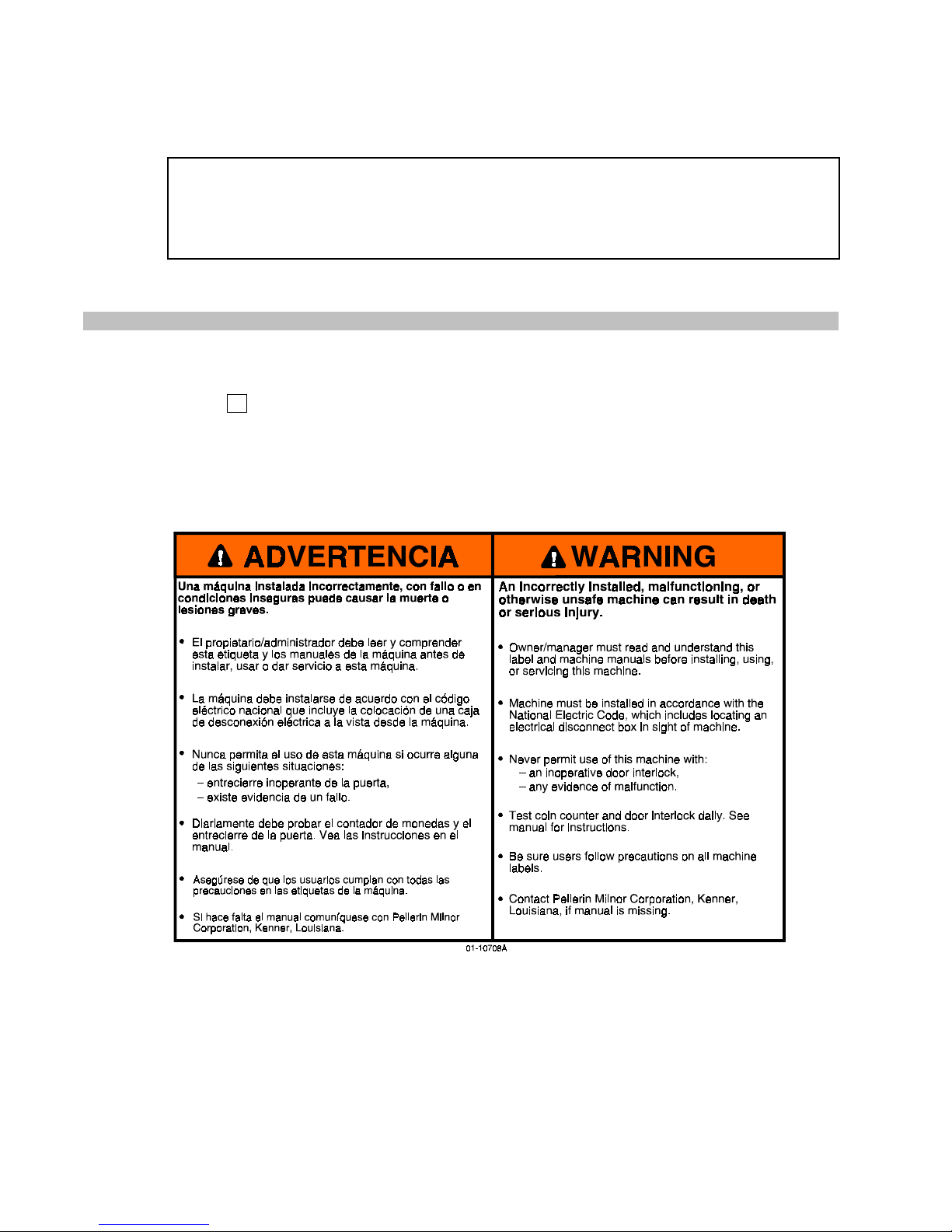

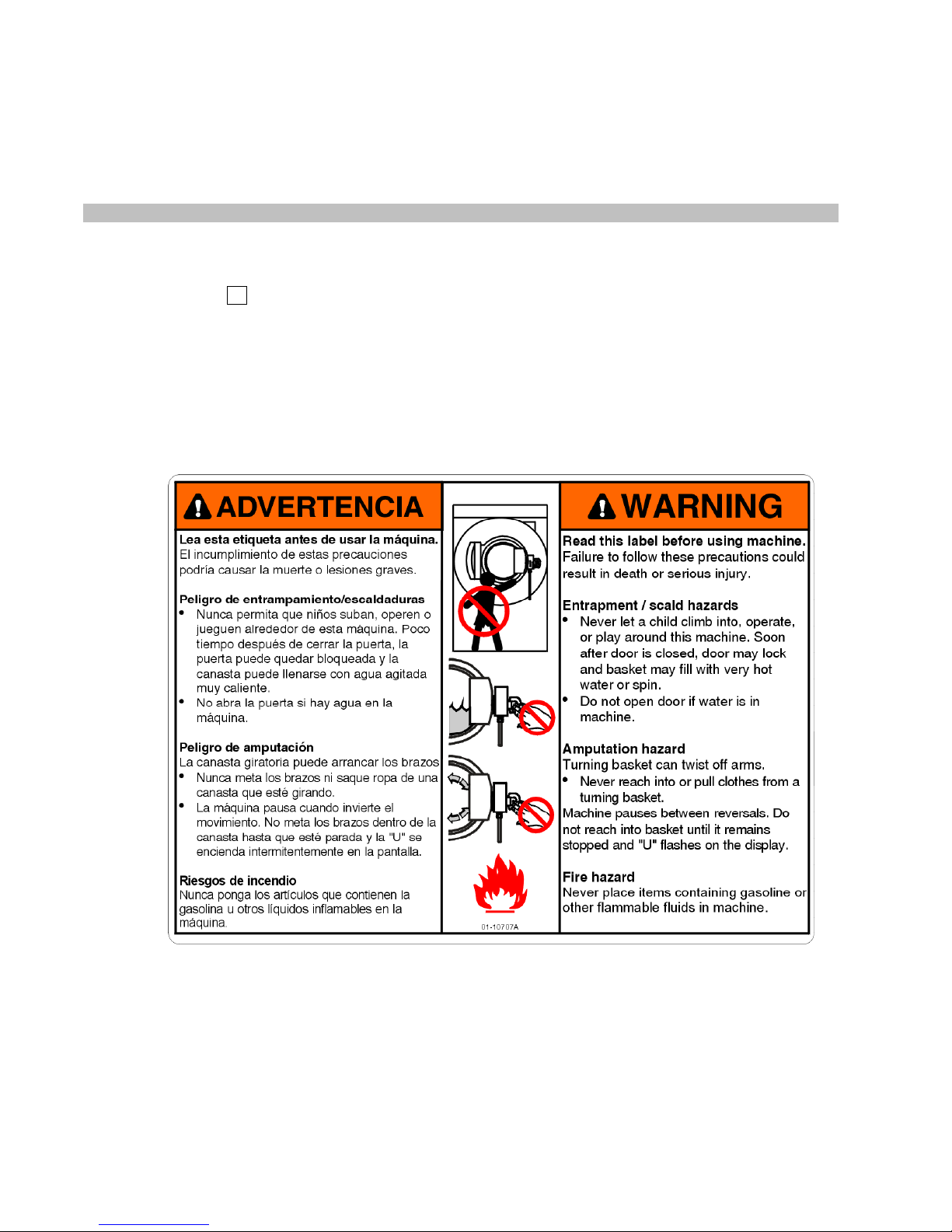

The placard shown in Figure 1 instructs laundry owners, their managers and employees about

installing, maintaining, testing, and providing instructions to users for safe operation of the

machine. The instructions on this placard and other general safety requirements are described in

more detail following the figure.

Figure 1: C4E and CGE Warning Placard for Owners, Managers, and Employees

Incorrect installation, neglected preventive maintenance, abuse, and/or improper repairs or

changes to the machine can cause unsafe operation and personal injuries, such as multiple

fractures, amputations, or death. The owner/manager is responsible for understanding and

ensuring the proper operation and maintenance of the machine. The owner/manager must be

familiar with the contents of all machine instruction manuals, and verify that the machine is

operated as described in this manual and all other manuals pertaining to this machine. The

owner/manager should direct any questions about these instructions to a Milnor

®

Milnor

PELLERIN MILNOR CORPORATION

Customer Service department.

®

dealer or the

ii. 1.

Laundry Facility

Provide a supporting floor that is strong and rigid enough to support—with a reasonable safety

factor and without undue or objectionable deflection—the weight of the fully loaded machine and

the forces transmitted by it during operation. Provide sufficient clearance for machine movement.

The laundry facility must provide protection from the elements. Do not install the machine

where it will be exposed to the weather.

As of this writing, the National Electrical Code requires a clearly marked electric disconnect

switch within sight of the machine and no farther away from the machine than 50 feet. Local

codes may have additional requirements.

You are urged to consult your licensed electrician and take immediate steps to comply if your

installation does not meet the National Electrical Code requirement and/or local codes.

Under certain conditions, hydrogen gas may be produced in a hot water system that has not been

used for 2 weeks or more. Hydrogen gas is explosive. if the hot water system has not been used

for such a period, before using a washing machine, turn on all hot water faucets and let the water

flow from each for several minutes. This will release any accumulated hydrogen gas. As the gas

is flammable, do not smoke or use an open flame during this time.

Preface

ii. 2.

Maintenance

Ensure the machine is inspected and serviced in accordance with good practice and the preventive

maintenance schedule. Replace belts, pulleys, bearing seals, etc. before they are severely worn.

Do not permit inspection, service or maintenance by unqualified personnel.

ii. 2.1.

The Danger from Operating a Damaged Machine

—The door interlock must permit

the door to be opened for a short time after the start of the cycle then prevent it from being

opened for the remainder of the cycle. Test this mechanism daily, as explained in Section iv.

“Daily Test of Door Interlock”.

Immediately investigate any evidence of impending failure and make needed repairs. Conditions

indicating that service is required include, among others, leaking seals, valves, and hoses, motor

or bearings making whining or grinding noises or becoming abnormally hot, and cracks or bends

in the cylinder, shell, or frame.

WARNING 2 : Multiple Hazards

—Operating a damaged machine can kill or injure

personnel, further damage or destroy the machine, damage property, and/or void the warranty.

• Do not permit the machine to be operated with any evidence of damage or malfunction.

• Do not disable any safety device or permit the machine to be operated with a

malfunctioning safety device.

WARNING 3 : Explosion Hazards

—Cylinder—A damaged cylinder can rip apart during

extraction, puncturing the shell and discharging metal fragments at high speed.

• Do not permit the machine to be operated with any evidence of damage or malfunction.

ii. 2.2.

The Danger of Exposing Normally Guarded Hazards

panel on the machine exists to isolate energized or moving parts from machine users and

bystanders and must be securely in place for safe operation.

WARNING 4 : Electrocution and Electrical Burn Hazards

will electrocute or burn you. High voltage is present at the machine unless the main machine

power disconnect is off.

—Every guard and access

—Contact with high voltage

PELLERIN MILNOR CORPORATION

Preface

• Do not service machine unless qualified and authorized.

• Lock out and tag out power at the main machine disconnect before servicing, or in

accordance with factory service procedures.

• Replace guards and covers before returning the machine to service and do not permit the

machine to be operated with guards or covers removed.

WARNING 5 : Entangle and Crush Hazards

—Contact with moving components normally

isolated by guards, covers, and panels, can entangle and crush your limbs. These components

move automatically.

• Do not service machine unless qualified and authorized.

• Lock out and tag out power at the main machine disconnect before servicing, or in

accordance with factory service procedures.

• Replace guards and covers before returning the machine to service and do not permit the

machine to be operated with guards or covers removed.

CAUTION 6 : Burn Haza rd s

—Contact with hot goods or machine components can burn you.

• Do not service machine unless qualified and authorized.

• Lock out and tag out power at the main machine disconnect before servicing, or in

accordance with factory service procedures.

• Replace guards and covers before returning the machine to service and do not permit the

machine to be operated with guards or covers removed.

An attendant key is provided with the machine. This key permits an attendant to bypass the coin

acceptor and start a wash program without coins. The key also provides access to the testing and

maintenance functions described in “Testing and Troubleshooting” in the reference manual.

WARNING 7 : Multiple Hazards

—Only knowledgeable service personnel can safely

perform the testing and maintenance functions provided by the attendant key. Unauthorized or

unknowledgeable users can be seriously injured or killed.

• Never leave key in lock.

• Understand the consequences of using the testing and maintenance functions.

ii. 3.

Disposal

The discarded machine must not pose an entrapment hazard. Before disposal, remove the

cylinder door.

ii. 4.

Customer Awareness

A customer safety placard on the machine alerts the customer to immediate hazards from misuse.

The placard is illustrated and described in Section iii. “The Customer Safety Placard—Vital

Information for Coin Laundry Customers, Owners/Managers and Employees”. Keep the safety

placards clean so that the pictures and words are plainly visible. Replace placards

immediately if lost or damaged. See the “Safety Placard Use and Placement” page in the service

manual to identify the placards and properly locate them on the machine.

Use whatever effective means are available, such as monitoring customer activity and posting

signs prominently in the facility, to ensure a safe environment. Customers must understand:

1. the nature of the potential hazards,

2. how to avoid the hazards, and

PELLERIN MILNOR CORPORATION

3. what to do in the event of an emergency.

— End of BICEXS04 —

BICEXS05 (Published) Book specs- Dates: 20040120 / 20040120 / 20040120 Lang: ENG01 Applic: CEX

iii. The Customer Safety Placard—Vital Information for Coin

Laundry Customers, Owners/Managers and Employees

Preface

Notice 8 : Important Safety Instructions

The customer safety placard shown in Figure 2 was affixed to your Milnor

—Read and save all instructions.

®

machine in a location

that is easily visible to customers. This placard warns customers who are about to use the

machine of hazards that can result from improper use. Safety placards help to ensure a safe work

environment and, as with any other machine part, must be properly maintained. Placards must

be kept clean so that the pictures and words are plainly visible. Placards must be replaced

immediately if lost or damaged. See the “Safety Placard Use and Placement” page in the service

manual to identify the placards and properly locate them on the machine.

Figure 2: Customer Safety Placard

Laundry owners, managers and employees must familiarize themselves with these hazards and

actively prevent any condition in their facility which might make accidents from these hazards

more likely. These hazards are described in more detail below.

PELLERIN MILNOR CORPORATION

Preface

iii. 1.

The Danger of Child Entrapment and Scalding

There have been child entrapment incidents with machines from various manufacturers. In

each instance, a small child was placed, climbed, or was helped to climb into a front loaded

coin machine and the door was closed behind him. The door locked, the machine started

running, and in one instance, the child was scalded to death.

WARNING 9 : Entrapment/Scald Hazards

—

• Never let a child climb into, operate, or play around this machine. Soon after door is

closed, door may lock and basket may fill with very hot water or spin.

• Do not open door if water is in machine.

®

Milnor

C4E and CGE coin operated washer-extractors have a door interlock which, to protect

against entrapment, permits opening the door during the first 60 seconds after closing the door

and starting the wash program. As additional protection against entrapment, once the door

locks, it may be unlocked by removing power at the wall-mounted disconnect switch or

circuit breaker, which must be part of the installation. The owner/manager must determine,

based on laundry operation, how to best address such an entrapment emergency. For example, the

owner/manager may wish to post clearly visible signs alerting customers to this, or, if an

attendant is always on duty, to make the attendant responsible for responding to such an

emergency.

iii. 2.

The Danger of Amputation Related to a Rotating Cylinder

A tremendous amount of energy exists in the rotating cylinder of any washer-extractor,

even at slow speeds. If someone tries to pull goods from a turning basket, the goods can

wrap around his/her arm, entangling the arm and twisting it off.

WARNING 10 : Amputation Hazard

—Turning basket can twist off arms.

• Never reach into or pull clothes from a turning basket.

• Machine pauses between reversals. Do not reach into basket until it remains stopped and

“U” flashes on display.

To protect against child entrapment, the controller used on coin machine models in the Milnor

®

C4E and CGE lines permit opening the door during the first 60 seconds after closing the door and

starting a wash program. The door locks after 60 seconds (see Note 1).

Note 1:

halts, the drain valve opens immediately, the motor stops driving the basket, and—if the machine still has

electric power—a brake is immediately applied to the basket. If the machine did not lose power, closing the

door will cause the wash program to resume where it was interrupted and the door lock delay time to be

reset so that the door can again be opened for 60 seconds from when the door was subsequently closed.

During the first 60 seconds of the cycle, the door may be opened. If this occurs, the wash program

Once the door locks, it remains locked, until one of the two following conditions occurs:

• When the wash cycle runs to completion without interruption, the door unlocks after the cycle

ends and the safety delay time expires. The safety delay allows time for the machine to coast

to a complete stop before allowing the user to open the door and retrieve the goods inside.

• If power is lost during the wash cycle, the door unlocks to allow the user to open the door and

retrieve the goods (see Note 2).

Note 2:

power is restored and the door is closed, the customer can start the wash cycle from the beginning by

inserting more coins, or the attendant can turn the

starting the machine without coins.

PELLERIN MILNOR CORPORATION

In C4E and CGE models, a wash program interrupted by a power loss cannot be restarted. When

Attendant

switch to the horizontal position to allow

iii. 3.

The Danger from Flammable Materials

Preface

WARNING 11 : Fire Hazard

—Never place items containing gasoline or other flammable

fluids in machine.

Washer-extractors are not designed to handle flammable materials. This includes goods

containing flammable substances as well as flammable cleaning materials such as solvents. In

either case, highly flammable vapors can be given off, especially when the material is heated.

Any source of spark or flame, such as the machine's motor, can then ignite the vapors, resulting in

fire or explosion. Additionally, washing with water and detergent may not fully remove

flammable materials from the goods, posing a severe risk of fire when those goods are placed in a

dryer.

— End of BICEXS05 —

BICEXS03 (Published) Book specs- Dates: 20040120 / 20040120 / 20040120 Lang: ENG01 Applic: CEX

iv. Daily Test of Door Interlock

The C_E door interlock is designed to lock the door after the machine has been running 60

seconds with the door closed. Test this vital safety mechanism daily to verify that it is functioning

properly.

Notice 12

: Daily test of coin counter not required.

placards used on some older coin-operated models, is not required on current C_E models.

Current models require only the daily door interlock test.

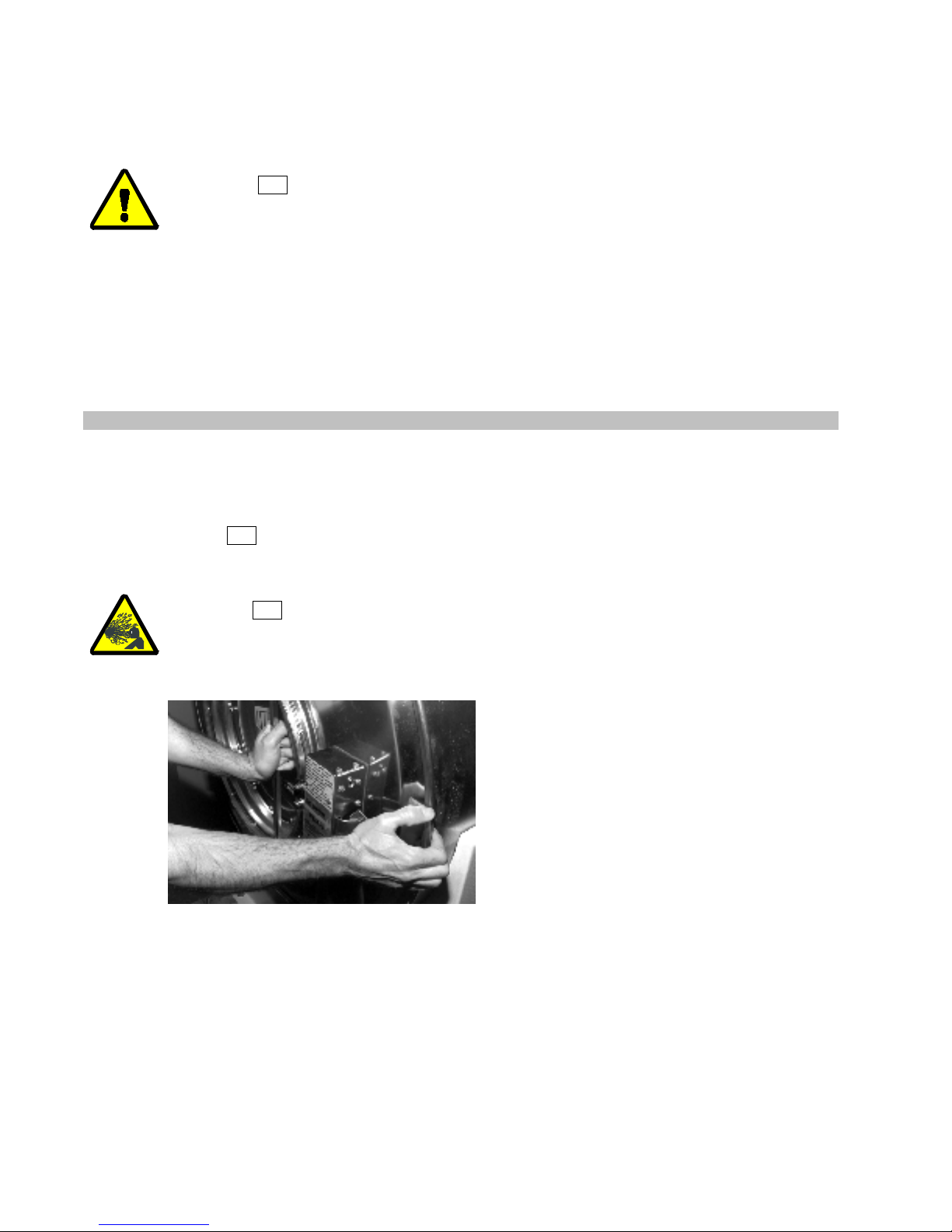

CAUTION 13 : Scald Hazards

—Contact with hot bath liquor can scald you.

• During the following test, hold the door firmly closed as shown in Figure 3 to prevent the

door from springing open if the latch retracts during this test.

—This test, referred to in safety

Figure 3: Hold Door Shut when Testing the Door Latch Interlock

Verify the door locks as follows:

1. Permit the wash program to progress for 90 seconds, but not much longer.

2. Holding the door closed, attempt to depress the door latch handle.

a. If the latch retracts (if the door unlocks), remove the machine from service until the

problem is identified and corrected.

b. If the latch does not retract (if the door is locked), and assuming no other evidence of

safety problems exists, return the machine to normal operation.

— End of BICEXS03 —

PELLERIN MILNOR CORPORATION

Preface

BIUUUK06 (Published) Book specs- Dates: 20040120 / 20040120 / 20040120 Lang: ENG01 Applic: CEX

v. Contacting Milnor

®

Your first contact with any question should be your authorized Milnor dealer, but problems or

special situations encountered in the field may require consultation with the Milnor factory.

Written correspondence can be mailed to this address:

Pellerin Milnor Corporation

Post Office Box 400

Kenner, Louisiana 70063-0400

Telephone: 504-467-9591

www.milnor.com

v. 1.

Ordering Replacement Parts

In most cases your authorized Milnor dealer can provide any necessary parts for equipment you

purchased from them. If your dealer is not available or able to help you acquire parts, contact the

Milnor parts group.

Milnor Parts

Telephone: 504-467-2787

Fax: 504-469-9777

E-mail: parts@milnor.com

v. 2.

Customer Service and Technical Support

For your technical questions or comments about Milnor equipment, contact your Milnor dealer

first. If your dealer is unable to respond, the Milnor customer service group has many years of

collective experience with our equipment. These men and women will give you the best possible

answer to your question.

Milnor Customer Service

Telephone: 504-464-0163

Fax: 504-469-9777

E-mail: service@milnor.com

www.milnor.com (Customer Service)

v. 3.

Warranty Informa t ion

Your Milnor dealer can address most warranty claims. However, if you have concerns or

questions beyond the scope of your dealer, please contact our warranty group.

Milnor Warranty Administrator

Telephone: 504-712-7735

Fax: 504-469-9777

E-mail: service@milnor.com (Attention: Warranty)

v. 4.

Equipment Manuals

If you have suggestions or questions about any part of this manual or any other documentation

included with your machine, the Milnor technical publications group can assist you.

Milnor Technical Publications

Telephone: 504-712-7636

Fax: 504-469-1849

PELLERIN MILNOR CORPORATION

E-mail: techpub@milnor.com

Preface

— End of BIUUUK06 —

PELLERIN MILNOR CORPORATION

Table of Contents

Preface

Table of Contents

Sections Figures, Tables, and Supplements

i. About This Manual

(Document BICEUK01)

i.1. Scope

i.2. How to Identify this Manual and its Included Documents

(Document BIUUUD13)

i.3. Trademarks of Pellerin Milnor Corporation

BIUUUD14)

(Document

ii. General Safety Requirements—Vital Information for Coin

Laundry Owners/Managers and Employees

BICEXS04)

(Document

ii.1. Laundry Facility

ii.2. Maintenance

ii.2.1. The Danger from Operating a Damaged Machine

ii.2.2. The Danger of Exposing Normally Guarded Hazards

ii.3. Disposal

ii.4. Customer Awareness

iii. The Customer Safety Placard—Vital Information for Coin

Laundry Customers, Owners/Managers and Employees

(Document BICEXS05)

iii.1. The Danger of Child Entrapment and Scalding

iii.2. The Danger of Amputation Related to a Rotating Cylinder

iii.3. The Danger from Flammable Materials

Table 1: Trademarks

Figure 1: C4E and CGE Warning Placard

for Owners, Managers, and Employees

Figure 2: Customer Safety Placard

iv. Daily Test of Door Interlock

v. Contacting Milnor

®

(Document BIUUUK06)

v.1. Ordering Replacement Parts

v.2. Customer Service and Technical Support

v.3. Warranty Information

v.4. Equipment Manuals

Table of Contents

Chapter 1. Commissioning

1.1. Important Owner/User Information

1.1.1. Ensure Safety of All Personnel

1.1.2. Customize the Machine Controller

PELLERIN MILNOR CORPORATION

(Document BICEXS03)

(Document BICEUK02)

Figure 3: Hold Door Shut when Testing

the Door Latch Interlock

Table of Contents

Sections Figures, Tables, and Supplements

1.2. About the Forces Transmitted by Milnor® Washerextractors

(Document BIWUUI02)

1.2.1. Foundation Considerations

1.2.2. How Strong and Rigid? Figure 4: How Rotating Forces Act on the

Foundation

1.3. Important Instructions for Pumped Chemical Inlets

(Document BIWUUI01)

1.3.1. How Pumped Chemical Systems can Internally Damage

the Washer-extractor

1.3.2. Locating Chemical System Components to Reduce the

Risk of Internal Damage

1.3.3. Preventing Leaks Which Can Injure Personnel and Cause

External Damage

Supplement 1: Preventing Dribbling by

Purging Chemical Lines

Figure 5: Proper Routing of Chemical

Tubing

Figure 6: Rear-mounted Water and Liquid

Supply Injector

Figure 7: Rear-mounted Water Inlet

Assembly (C_E Models)

1.4. Electrical Connections for Liquid Chemical Systems

(Document BICEUI01)

1.4.1. Pump Signal Connections Table 2: Chemical Injection Signals

Figure 8: Pump Signal Connections

1.4.2.

Timer Stop

Connections

Chapter 2. Configuring

2.1. Setting the Coin Counts

(Document BICEXC01)

Figure 9: Example Coin Count Settings

Figure 10: Processor Board as Viewed in

Machine

Table 3: DIP Switch Settings for Coin

Counts

Chapter 3. Operating

3.1. Control Panel

(Document BICEXO01)

3.1.1. Control Functions During Normal Operation

3.1.2. Control Functions in

3.2. Determining Load Size

3.3. Using the Machine

(Document BICEXO02)

Attendant

(Document BIWUUO01)

Mode

3.3.1. Normal Operation (Coins Required) Supplement 2: The Three-Compartment

3.3.2. Attendant Operation (Attendant Key Required)

3.3.3. Viewing and Clearing the Accumulator

3.3.3.1. Viewing the Accumulator Figure 12: Wash Cycle Accumulator

3.3.3.2. Clearing the Accumulator

Figure 11: C_E Control Panel (Typical)

Supply Injector (Optional)

PELLERIN MILNOR CORPORATION

Table of Contents

Sections Figures, Tables, and Supplements

3.3.4. Error Recovery Supplement 3: Recycle Sequence to

Reduce Vibration During Extract

3.4. Standard Wash Cycles

(Document BICEXP01)

Table 4: Wash Cycles for Software

Version WUC4E1A/20001-20006

Table 5: Standard Coast and Delay Times

(in seconds)

Chapter 4. Testing and Troubleshooting

4.1. Error Codes

(Document BICEXT01)

4.1.1. How to Clear Error Conditions Figure 14:

4.1.2. Explanations of Error Codes

4.2. Controller Inputs and Outputs

(Document BICEXT02)

4.2.1. Resuming Normal Operation

4.2.2. Viewing Inputs Figure 16: Viewing Inputs in

4.2.3. Actuating Outputs and Functional Tests Table 8: Output Signals

4.2.4. Functional Tests

4.2.4.1. Functional Test 12

4.2.4.2. Functional Test 13

Figure 13: Error Code Display

Normal

Position of Attendant

Switch

Figure 15:

Attendant

Position of Attendant

Switch

Table 6: Quick Reference for Error Codes

Mode

Table 7: Input Signals

Attendant

PELLERIN MILNOR CORPORATION

Loading...

Loading...