Pellicon® 2 and 3 Mini Holder

User Guide

Notice

The information in this document is subject to change without notice and should not be

construed as a commitment by Millipore Corporation. Millipore Corporation assumes no

responsibility for any errors that may appear in this document. This manual is believed

to be complete and accurate at the time of publication. In no event shall Millipore

Corporation be liable for incidental or consequential damages in connection with or

arising from the use of this manual.

Pellicon-2 and 3 Mini Holder User Guide 3

Contents

Unpacking ...............................................................................................5

Plumbing and Instrumentation ..............................................................6

Assembling the Pellicon 2 and 3 Mini Holder ......................................7

Feed and Retentate Fitting Connections ................................ 7

Permeate Fitting Connections ................................................7

Connecting Pressure Gauge Adapter Fittings

to FEED and RETENTATE Fittings .........................................8

Connecting the Pressure Gauge ............................................9

Connect the Permeate Fittings ............................................. 10

Inserting the Pellicon Cassettes ...........................................10

Attaching the End Plate ........................................................ 11

Setup for Autoclaving ..........................................................................13

Ordering Information ............................................................................14

Spare Parts and Accessories ...............................................14

General Limited Warranty .................................................................... 15

T echnical Assistance ...........................................................................16

4 www.millipore.com

Pellicon-2 and 3 Mini Holder User Guide 5

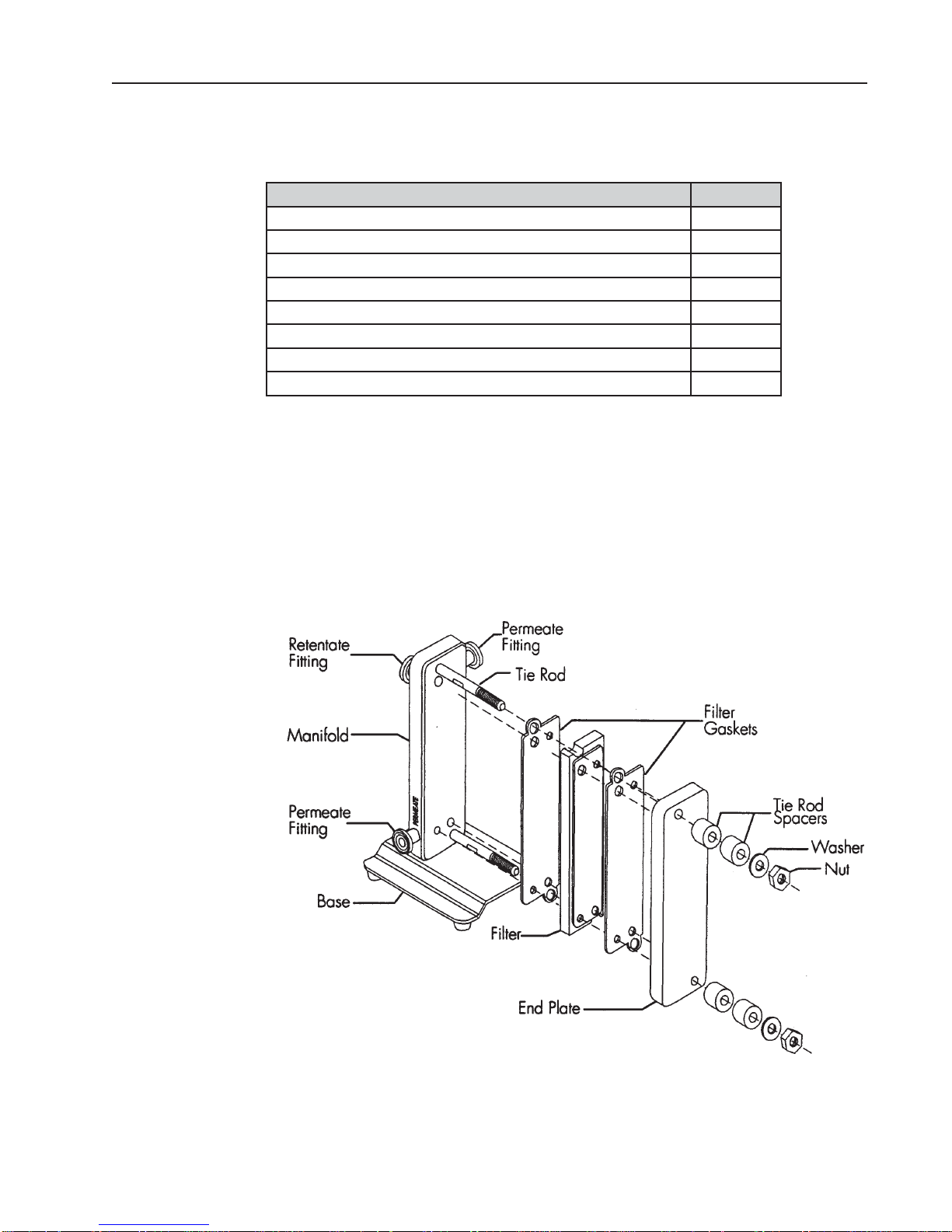

Unpacking

The Pellicon 2 and 3 Mini Holder comes packed in a box and includes the following items:

Description Quantity

Manifold with two tie rods, attached to a base 1

End plate 1

Tie rod spacer 4

3/8 inch Flat washer 2

3/8-16 UNC Hex nut, silicon bronze 2

½-inch Sanitary gasket 4

Fractional sanitary clamp 4

9/16 inch Deep socket 1

Unpack the holder and deep socket. 1.

Remove the FEED and RETENTATE fittings from the holder.2.

Loosen and remove the two nuts on the tie rods. 3.

Remove the washers, spacers, and end plate from the holder. Remove the shipping 4.

insert located between the holder manifold and end plate.

Place the holder base on a level surface.5.

Exploded view of Pellicon 2 and 3 Mini HolderFigure 1:

6 www.millipore.com

Plumbing and Instrumentation

The concentration mode is the most commonly used mode for the concentration of

proteins and viruses and is shown in Figure 2 without the diafiltrate. During this mode,

material retained by the membrane (retentate) flows out of the retentate fitting and is

recirculated to the original product container. The material passing through the membrane

(permeate) flows out of the permeate outlet fitting onto the permeate collection container.

The constant volume diafiltration mode, shown in Figure 2, is used for washing product

that is retained by the membrane or for recovering additional product that is passed

through the membrane. The mode involves the addition of water or buffer to the feed

container at the same rate as permeate is being removed from the process.

Plumbing and Instrumentation DiagramFigure 2:

Pellicon-2 and 3 Mini Holder User Guide 7

Assembling the Pellicon 2 and 3 Mini Holder

Feed and Retentate Fitting Connections

Configurations for connecting fittings to the FEED and the RETENTATE fittings, shown

in Figure 3, include:

Connecting a pressure and sanitary diaphragm valve to the RETENTATE fitting, 1.

and a pressure gauge to the FEED fitting.

Connecting separate tubing to the FEED and the RETENTATE fittings.2.

Feed and Retentate Fitting ConnectionsFigure 3:

Permeate Fitting Connections

Configurations for connecting fittings to the PERMEATE fittings, shown in Figure 4,

include:

Connecting the two PERMEATE fittings together with tubing using a tee or Y 1.

connection.

Connecting separate tubing to the two PERMEATE fittings.2.

Permeate Fitting ConnectionsFigure 4:

8 www.millipore.com

Connecting Pressure Gauge Adapter Fittings to FEED

and RETENTATE Fittings

The Pellicon 2 and 3 Mini Holder Pressure Gauge Adapter Fittings are short-leg tees to

keep the working fluid volume low and avoid non-sanitary low-flow areas in the piping.

Two ¾-inch sanitary gaskets and two sanitary fitting clamps are supplied with each

pressure gauge adapter fitting.

Seat a 3/4-inch sanitary gasket in the groove on the FEED fitting.1.

Hold the sanitary gasket in place and press the pressure gauge adapter fittings flange 2.

against the FEED fitting flange so the fitting branch is parallel to the holder case

and oriented as shown in Figure 5.

Note The gasket moves easily if not held in place when pressing the pressure gauge

adapter fittings fl ange against the holder fi tting fl ange.

Installing the Gasket and Positioning the Pressure Gauge Adapter FittingsFigure 5:

Secure the Pressure Gauge Adapter Fittings to the FEED fitting with the sanitary 3.

clamp, as shown in Figure 6.

Open the sanitary clamp by moving the swing bolt out of the clamp slot.4.

Place the sanitary clamp over the FEED fitting connection and close the sanitary 5.

clamp by moving the swing bolt into the clamp slot.

Hand tighten the sanitary clamp closure.6.

Repeat steps 1-3 to connect a pressure gauge adapter fittings to the RETENTATE 7.

fitting.

Pellicon-2 and 3 Mini Holder User Guide 9

Clamping the Pressure Gauge Adapter Fittings to the Mini Holder FittingFigure 6:

Connecting the Pressure Gauge

Analog and digital pressure gauges are available from Millipore.

Seat the ¾-inch sanitary gasket in the groove on the pressure gauge adapter fittings.1.

Hold the gasket in place and press the pressure gauge diaphragm against the ¾-inch 2.

side branch of the pressure gauge adapter fittings, as shown in Figure 7.

Attaching the Pressure Gauge to the Pressure Gauge Adapter FittingsFigure 7:

10 www.millipore.com

Secure the pressure gauge to the Pressure Gauge Adapter Fittings with the sanitary clamp.3.

Open the sanitary clamp by moving the swing bolt out of the clamp slot.4.

Place the sanitary clamp over the Pressure Gauge Adapter Fittings-PRESSURE GAUGE 5.

connection and close the sanitary clamp by moving the swing bolt into the clamp slot.

Hand tighten the sanitary clamp closure.6.

Repeat steps 1-3 to connect a Pressure Gauge Adapter Fittings to the 7.

RETENTATE fitting.

Connect the Permeate Fittings

Two gaskets and two clamps are supplied for attaching fittings to the two PERMEATE

fittings located on the sides of the manifold plate. The PERMEATE fittings accommodate

standard ½-inch or ¾-inch sanitary fittings and adapters.

Inserting the Pellicon Cassettes

Use one to three cassettes depending on the desired permeate flow rate. Permeate flow

rate increases as filter area increases.

Inspect the tie rods and nuts for signs of burrs or stripped threads. 1. Nuts should

turn freely on the tie rods for proper tightening of the holder.

Holding the manifold with one hand, slide the filter gasket (Pellicon 2 Cassettes only) tabs 2.

over the tie rods and press the filter gasket against the manifold, as shown in Figure 8.

Note Pellicon 2 Cassettes ONLY

The large feed and retentate holes on the fi lter gasket must align to the large feed

and retentate holes on the manifold.Millipore supplies two fi lter gaskets with each

fi lter. One fi lter gasket must be installed between each pair of fi lters, and one gasket

must be installed between each end of the fi lter and the adjacent stainless steel plate.

Inserting the Filter Gaskets and FilterFigure 8:

Pellicon-2 and 3 Mini Holder User Guide 11

Align the filter cut-outs with the tie rods, and insert the filter so it is parallel with the 3.

manifold as, shown in Figure 8.

Note The fi lter will extend beyond the edges of the manifold and end plate if the fi lter

does not properly align to the feed, retentate, and permeate holes.

Holding the manifold with one hand, slide the filter gasket (Pellicon 2 Cassettes 4.

only) tabs over the tie rods and press the filter gasket (Pellicon 2 Cassettes only)

against the filter, as shown in Figure 8.

Repeat steps 3–5 for additional cassettes.5.

Attaching the End Plate

Holding the manifold gaskets (Pellicon 2 Cassettes only) and filter(s) in place with 1.

one hand, slide the end plate holes over the tie rods, as shown in Figure 8, and press

the end plate against the filter.

Place an equal number of spacers on each tie rod depending on the number of 2.

filters in use.

Place one washer and one nut on each tie rod, as shown in Figure 8, and hand 3.

tighten.

Tighten the holder with the torque wrench and socket. The torque wrench setting 4.

for 180-200 inch-pounds (20.3-22.6 Newton-meters). Check the torque wrench

(not supplied with the holder) setting for 180-200 inch-pounds (20.3-22.6 Newtonmeters) prior to use. Refer to the next section to set the torque wrench.

Attaching the end plateFigure 9:

12 www.millipore.com

Attach the deep socket to the torque wrench by firmly pressing the deep socket onto 5.

the torque wrench drive. Attaching the deep socket may require force.

Hand tighten the nuts evenly by alternating from one nut to the other.6.

Brace the holder with one hand. With a continuous motion, turn each nut ¼ turn 7.

with the torque wrench, alternating from one nut to the other until torque wrench

“clicks” when it reaches 180-200 inch-pounds (20.3-22.6 Newton-meters).

Wait 5-10 minutes; re-torque to 180-200 inch-pounds (20.3-22.6 Newton-meters).8.

Waiting allows gasket(s) to relax before re-torquing.

Re-torque to a maximum of 200 inch-pounds (22.6 Newton-meters) as needed to 9.

create a liquid-tight seal. The torque wrench may have a fi xed head or a ratchet-style

head. If your wrench has a ratchet-style head, move lever to the right lock position

to tighten nuts and mover the lever to the left lock position to loosen the nuts.

Note Non-uniform tightening of the nuts can damage the fi lter. Non-parallel plates or

compression of the fi lter(s) at one end can cause leakage.

Setting the Torque Wrench

Pull down the spring-loaded lock collar to unlock the torque wrench.1.

Hold down the spring-loaded lock collar while turning the handle until the 180-200 2.

inch-pound (20.3-22.6 Newton-meters) mark on the wrench handle aligns with the

zero mark on the sleeve die.

Note One side of the torque wrench handle displays units as inch-pounds and the other

side displays units as Newton-meters.

Rotate the handle slightly so the lock collar springs back and locks into place. 3. When

the lock collar locks into place the handle will not rotate.

Setting the Torque WrenchFigure 10:

Pellicon-2 and 3 Mini Holder User Guide 13

Setup for Autoclaving

Remove all filters and filter gaskets from the Pellicon 2 and 3 Mini Holder before 1.

autoclaving.

Rest the holder FEED and RETENTATE fittings and the end plate on a soft 2.

material to protect the fitting faces and end plate from being scratched in the

autoclave.

Do not autoclave with the holder in an upright position, because the feet will

compress and become loose.

Autoclave the Pellicon 2 and 3 Mini Holder at 121º C to 125º C for 30 minutes per 3.

cycle.

14 www.millipore.com

Ordering Information

Description Catalogue Number

Pellicon 2 and 3 Mini Holder

Includes holder, 4 sanitary gaskets, 4 sanitary clamp fi ttings, and

assembly instructions

Spare Parts and Accessories

XX42PMINI

Description Catalogue Number

Kits for short tie rods including 2 tie rods XX42PMIST 2

Kits for long tie rods including 2 tie rods XX42PMILG 2

Stainless Steel Spacer

Stainless Steel spacers XX42PMSP 4

Nuts and Washer

4 washers 3/8 and 4 HEX silicone Bronze nuts 3/8-16 XX42MT073 4

Pressure Gauge

Pressure gauge.(0-4 bars) B26524 1

Pressure gauge (-1 / +6 bars) YFS7PGV34 1

Pressure gauge (0-2 bars) XX42PGM02 1

Stainless Steel TC Clamp

Fitting kit for pressure gauge: 2 tees/4 gaskets/4

clamps

TC Clamps 3/4 in. Stainless steel XX42T1900 4

TC Gasket

TC gasket silicone. FTPF03342 10

TC gasket EPDM. MSD1169W7 10

Valve

Stainless steel valve EPDM, diaphragm 3/4 in. TC YFS7ETC34 1

Hoses and Blank Caps

hose connector 12.5mm /TC FTPF0251 3

hose with 3/4” TC fi ttings XX42P60TC 1

TC blank cap 3/4 in. FTPF02247 4

Torque Wrench and Accessory: Socket/Rachet

torque wrench XX42PMITW 1

Socket 9/16 in. XX42PMISR 1

XX42PM001 N/A

Qty

(per kit)

Pellicon-2 and 3 Mini Holder User Guide 15

General Limited Warranty

Millipore Corporation (“Millipore”) warrants its products will meet their applicable

published specifications when used in accordance with their applicable instructions

for a period of one year from shipment of the products. MILLIPORE MAKES NO

OTHER WARRANTY, EXPRESSED OR IMPLIED. THERE IS NO WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The warranty

provided herein and the data, specifications and descriptions of Millipore products

appearing in Millipore’s published catalogues and product literature may not be altered

except by express written agreement signed by an officer of Millipore. Representations,

oral or written, which are inconsistent with this warranty or such publications are not

authorized and if given, should not be relied upon.

In the event of a breach of the foregoing warranty, Millipore’s sole obligation shall be

to repair or replace, at its option, the applicable product or part thereof, provided the

customer notifies Millipore promptly of any such breach. If after exercising reasonable

efforts, Millipore is unable to repair or replace the product or part, then Millipore shall

refund to the customer all monies paid for such applicable product or part. MILLIPORE

SHALL NOT BE LIABLE FOR CONSEQUENTIAL, INCIDENTAL, SPECIAL

OR ANY OTHER DAMAGES RESULTING FROM ECONOMIC LOSS OR

PROPERTY DAMAGE SUSTAINED BY ANY CUSTOMER FROM THE USE OF

ITS PRODUCTS.

Technical Assistance

For more information, contact the Millipore office nearest you. In the U.S., call

1-800-MILLIPORE (1-800-645-5476). Outside the U.S., see your Millipore catalogue for

the phone number of the office nearest you or go to our web site at www.millipore.com/

offices for up-to-date worldwide contact information. You can also visit the tech service

page on our web site at http://www.millipore.com/techservice.

Millipore and Pellicon are registered trademarks of Millipore Corporation. The M logo is a trademark of Millipore Corporation.

Copyright © 1994, 2009 Millipore Corporation. All rights reserved.

P35447 Rev C, 09/2009

Loading...

Loading...