Millipore Milli-Q Plus Installation And Operation Manual

iilli-Q* Plus

Water Purification System

Installation and Operation

M1LUPORE

MILLI-Q PLUS

A. Introduction

1. System Description

2.

External Features

3. Schematic

4.

Dimensions

5. Function of Components/Controls

B.

Installation

1. Unpacking

2.

Battery Insertion

3. Water Connection

4.

Electrical Connection

5. Bench/Wall Mounting

6. Pack Installation

7.

Initial Startup

C. Operation

1. Switch On - Auto Test

2.

Operate

3. Standby

4.

Auto Recirculation (Intermittent)

5. Temperature

6. Battery

7.

Remote Standby

8. Pack Replacement

9. Final Filter - (Millipak) - Replacement

0. Maintenance

1. Access to PC Board

2.

Battery Replacement

3. Fuse Replacement

4.

Set Point Adjustment

5. Pack Replacement Frequency Setting

6. Changing the Frequency of Automatic Recirculation

1. Troubleshooting

E.

Technical Information

1. Components

2.

Specifications

3. Ordering Information

4.

Warranty

Milli-Q Plus

A. INTRODUCTION

1. System Description

The Milli-Q Plus system is a state of the art water purification

system, designed to provide the final polish to water which has

been pretreated by primary purification methods such as

Reverse Osmosis (RO), Distillation, or Deionization (DI).

The system provides ultrapure water for the laboratory for use

in critical applications requiring the absence of interfering

inorganic, organic, particulate, or microbiological material.

As a result of attention to design detail, plus strict selection

and testing of materials of construction, resins, and other

purification media, the system consistently produces water which

exceeds Type 1 standards for Reagent Grade Water.

The Milli-Q Plus system utilizes a patented purification pack

concept.

The design of this pack ensures minimal dead water

volume and as a consequence extremely low TOC values in the

purified water. The pack is constructed of pure polypropylene and

is heat welded to minimize extractables associated with gluing.

The pack concept makes maintenance of the system extremely easy.

The system indicates when the pack requires to be changed and

this can be done quickly and easily without the use of any tools.

The control box of the system utilizes a membrane keypad combined

with an alphanumeric display. The alphanumeric display allows

the user to monitor the status of the Milli-Q Plus system at all

times.

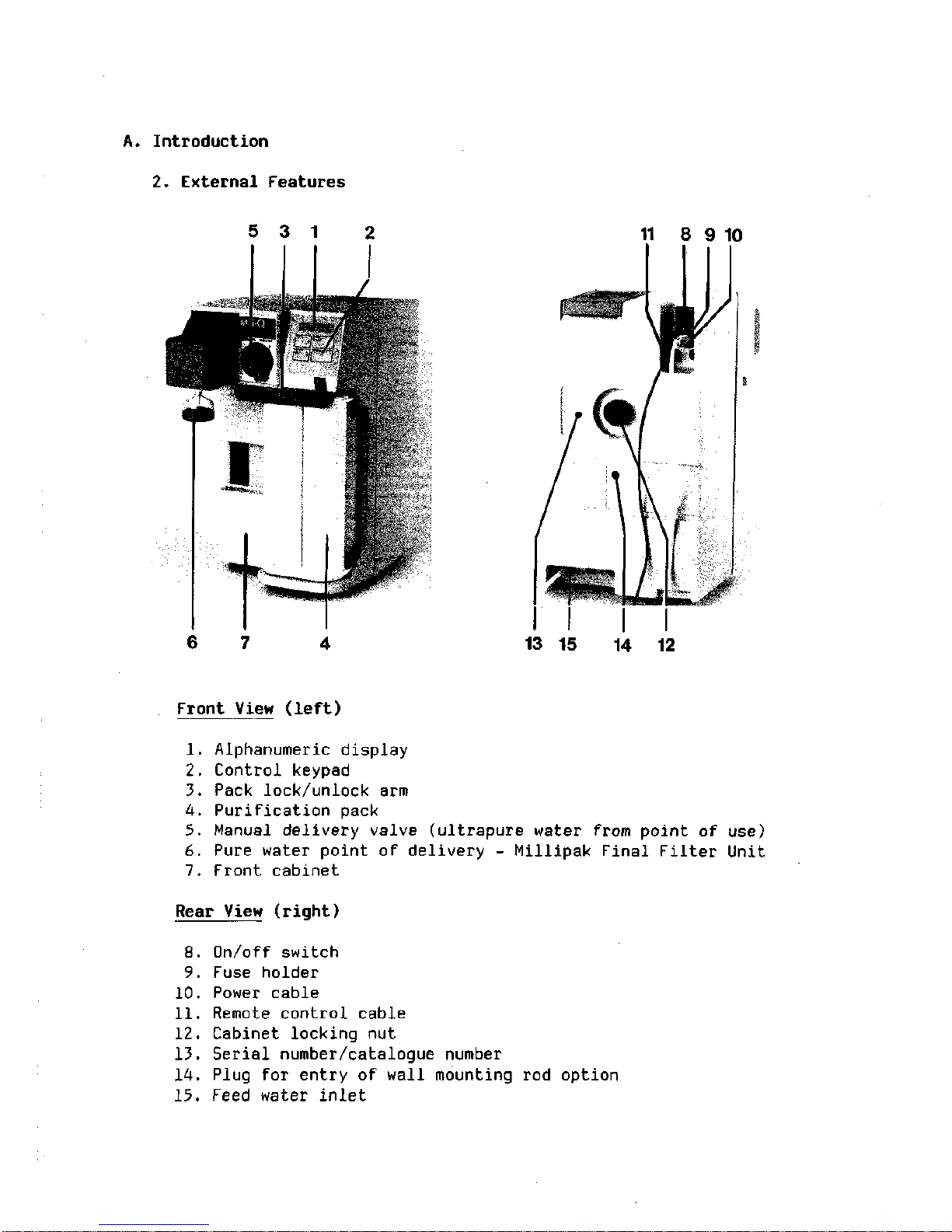

A. Introduction

2.

External Features

5 3 1

11 8 9 10

6 7

13 15 14 12

Front View (left)

1. Alphanumeric display

2.

Control keypad

3. Pack lock/unlock arm

4.

Purification pack

5. Manual delivery valve (ultrapure water from point of use)

6. Pure water point of delivery - Millipak Final Filter Unit

7.

Front cabinet

Rear View (right)

8. On/off switch

9. Fuse holder

10.

Power cable

11.

Remote control cable

12.

Cabinet locking nut

13.

Serial number/catalogue number

14.

Plug for entry of wall mounting rod option

15.

Feed water inlet

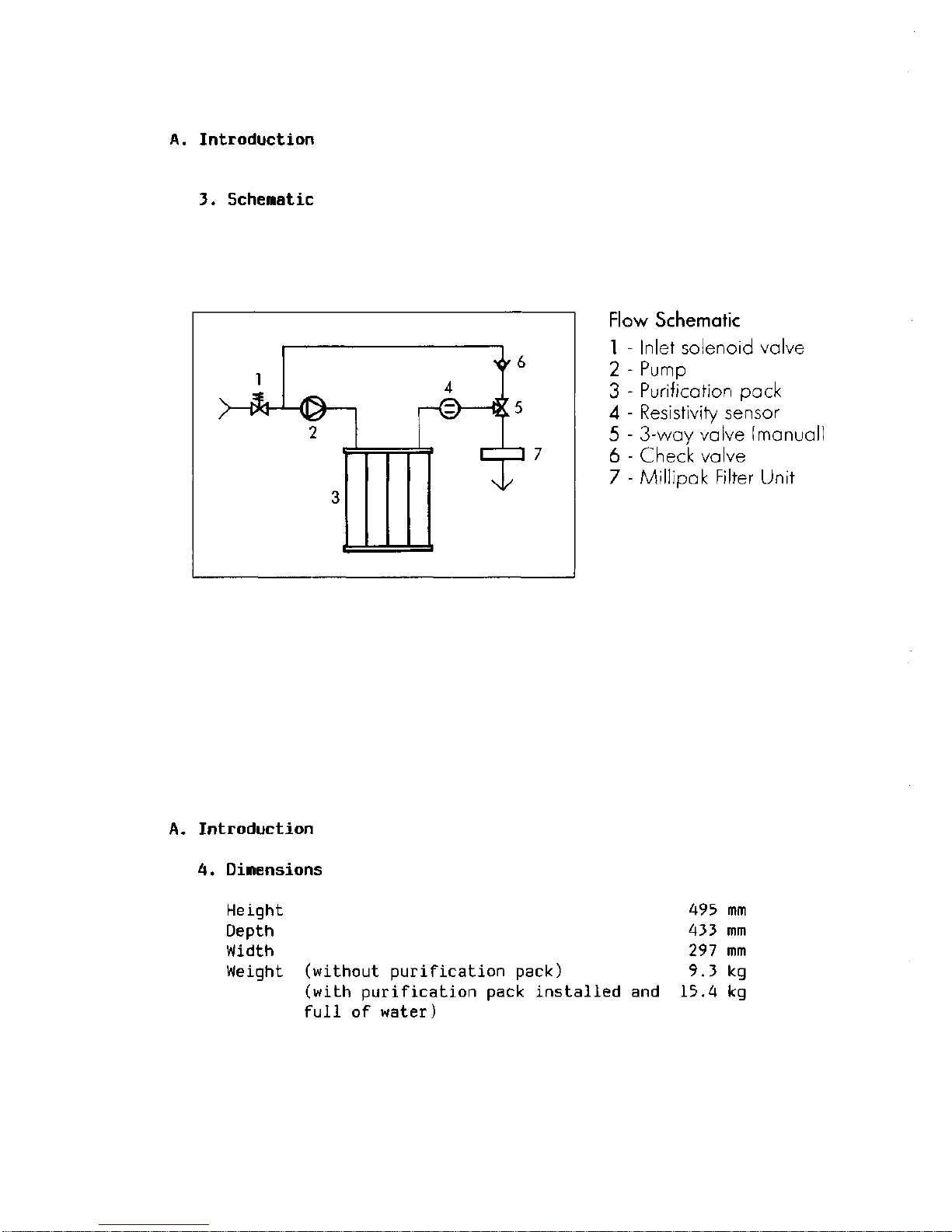

A. Introduction

3. Schematic

Flow Schematic

1

- Inlet solenoid valve

2 - Pump

3 - Purification pack

4 - Resistivity sensor

5 - 3-way valve (manual)

6 - Check valve

7 - Millipak Filter Unit

A. Introduction

4.

Dimensions

Height 495 mm

Depth 433 mm

Width 297 mm

Weight (without purification pack) 9.3 kg

(with purification pack installed and 15.4 kg

full of water)

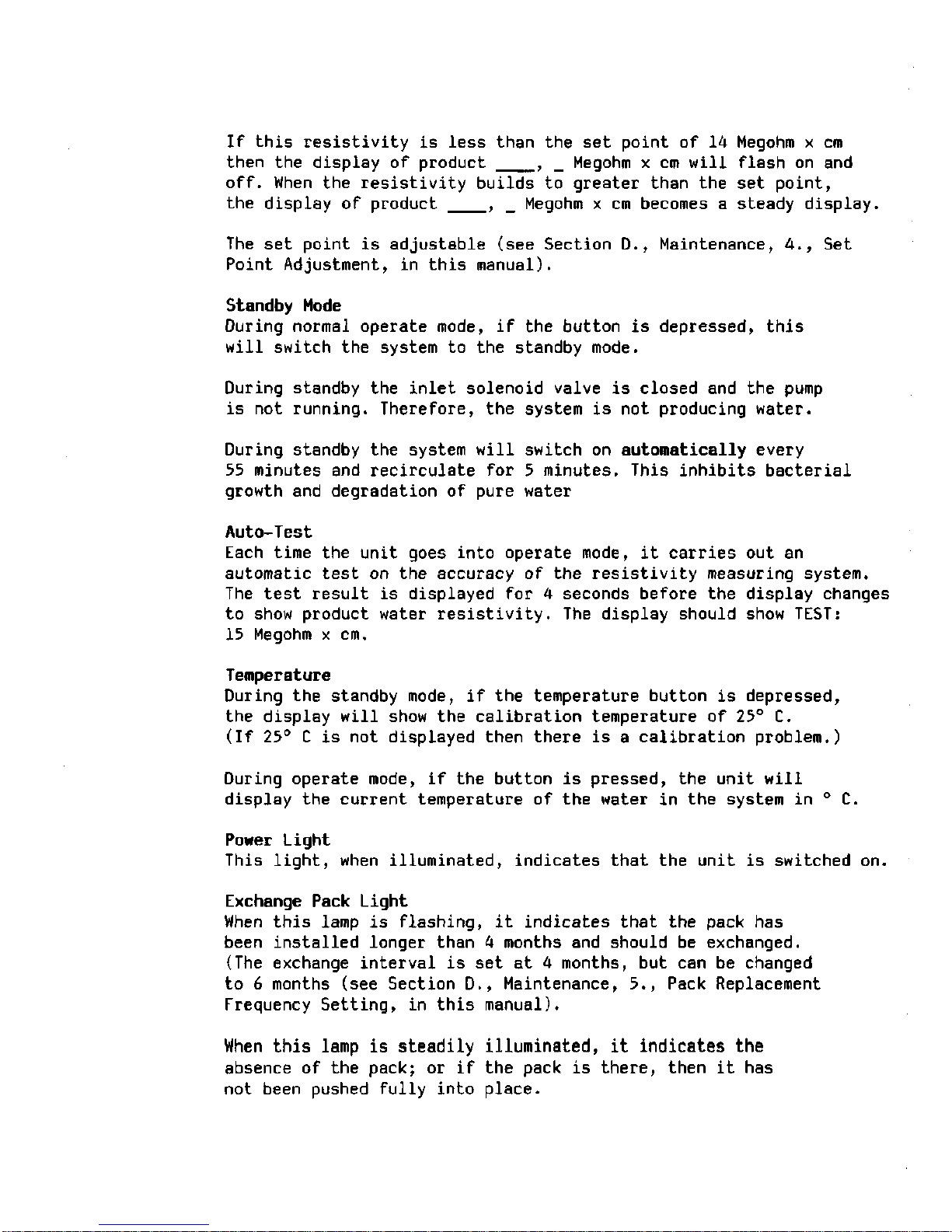

A. Introduction

5. Function of Components/Controls

On/Off Power Switch

This switch, located on the rear side of the unit, controls

the power to the control box. The power inlet socket is

located below the ON/OFF switch. This socket has a built

in fuse holder which contains the main fuse plus a spare.

Pump

This magnetic drive gear pump provides a draw-off flow rate of

1.5

1/min.

A built-in pressure relief valve regulates discharge

pressure to 2.8 bars (40 psi).

Sensor

The sensor, located at the outlet of the purification pack, is

electrically connected to the PC board. The sensor continuously

measures the resistivity of the product water as it exits the pack.

Meg-0-Meter Display

Resistivity of the water is displayed on the alphanumeric display

as product , Megohm x cm.

The unit is internally temperature-compensated to normalize readings

to 25° C.

Three Way Point-of-Use Valve

This PVDF valve, located behind the front panel of the unit, is

manually operated by the knob on the front panel of the unit.

This valve has two positions: RECIRCULATION - where the water

is directed through the system's recirculation loop; or

PRODUCTION - where the water is directed through the final

filter to the point-of-use.

CONTROL KEYBOARD

Operate/Standby, Operate Mode

This button, when first depressed, will switch the system to

the operate, mode. During operate mode the inlet solenoid valve

is open and the pump is running. If the manual point-of-use

valve is in the RECIRCULATION position, water will recirculate

around the system's internal recirculation loop. If the

point-of-use valve is open in the PRODUCTION position, water

will be delivered through the point-of-use. During operate,

the display will show the resistivity of the purified water

as product , Megohm x cm.

If this resistivity is less than the set point of 14 Megohm x cm

then the display of product , _ Megohm x cm will flash on and

off.

When the resistivity builds to greater than the set point,

the display of product , _ Megohm x cm becomes a steady display.

The set point is adjustable (see Section D., Maintenance, 4., Set

Point Adjustment, in this

manual).

Standby Mode

During normal operate mode, if the button is depressed, this

will switch the system to the standby mode.

During standby the inlet solenoid valve is closed and the pump

is not running. Therefore, the system is not producing water.

During standby the system will switch on automatically every

55 minutes and recirculate for 5 minutes. This inhibits bacterial

growth and degradation of pure water

Auto-Test

Each time the unit goes into operate mode, it carries out an

automatic test on the accuracy of the resistivity measuring system.

The test result is displayed for 4 seconds before the display changes

to show product water resistivity. The display should show TEST:

15 Megohm x cm.

Temperature

During the standby mode, if the temperature button is depressed,

the display will show the calibration temperature of 25° C.

(If 25° C is not displayed then there is a calibration problem.)

During operate mode, if the button is pressed, the unit will

display the current temperature of the water in the system in ° C.

Power Light

This light, when illuminated, indicates that the unit is switched on.

Exchange Pack Light

When this lamp is flashing, it indicates that the pack has

been installed longer than 4 months and should be exchanged.

(The exchange interval is set at 4 months, but can be changed

to 6 months (see Section D., Maintenance, 5., Pack Replacement

Frequency Setting, in this

manual).

When this lamp is steadily illuminated, it indicates the

absence of the pack; or if the pack is there, then it has

not been pushed fully into place.

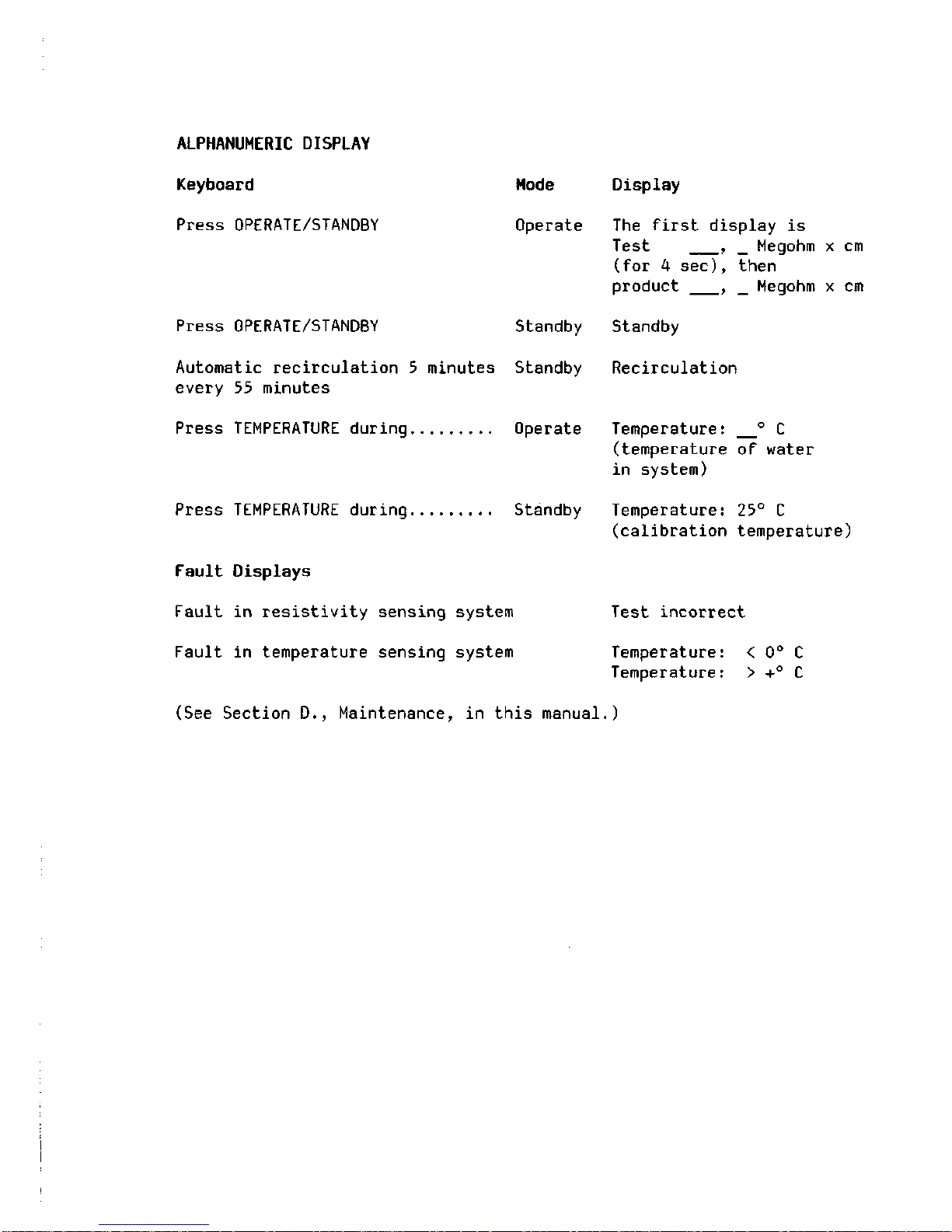

ALPHANUMERIC DISPLAY

Keyboard

Press OPERATE/STANDBY

Mode

Operate

Press OPERATE/STANDBY Standby

Automatic recirculation 5 minutes Standby

every 55 minutes

Press TEMPERATURE during Operate

Press TEMPERATURE during Standby

Fault Displays

Fault in resistivity sensing system

Fault in temperature sensing system

Display

The first display is

Test , _ Megohm x cm

(for 4 sec), then

product , _ Megohm x cm

Standby

Recirculation

Temperature: ° C

(temperature of water

in system)

Temperature: 25° C

(calibration temperature)

Test incorrect

Temperature:

Temperature:

< 0° C

> +° C

(See Section D., Maintenance, in this manual.)

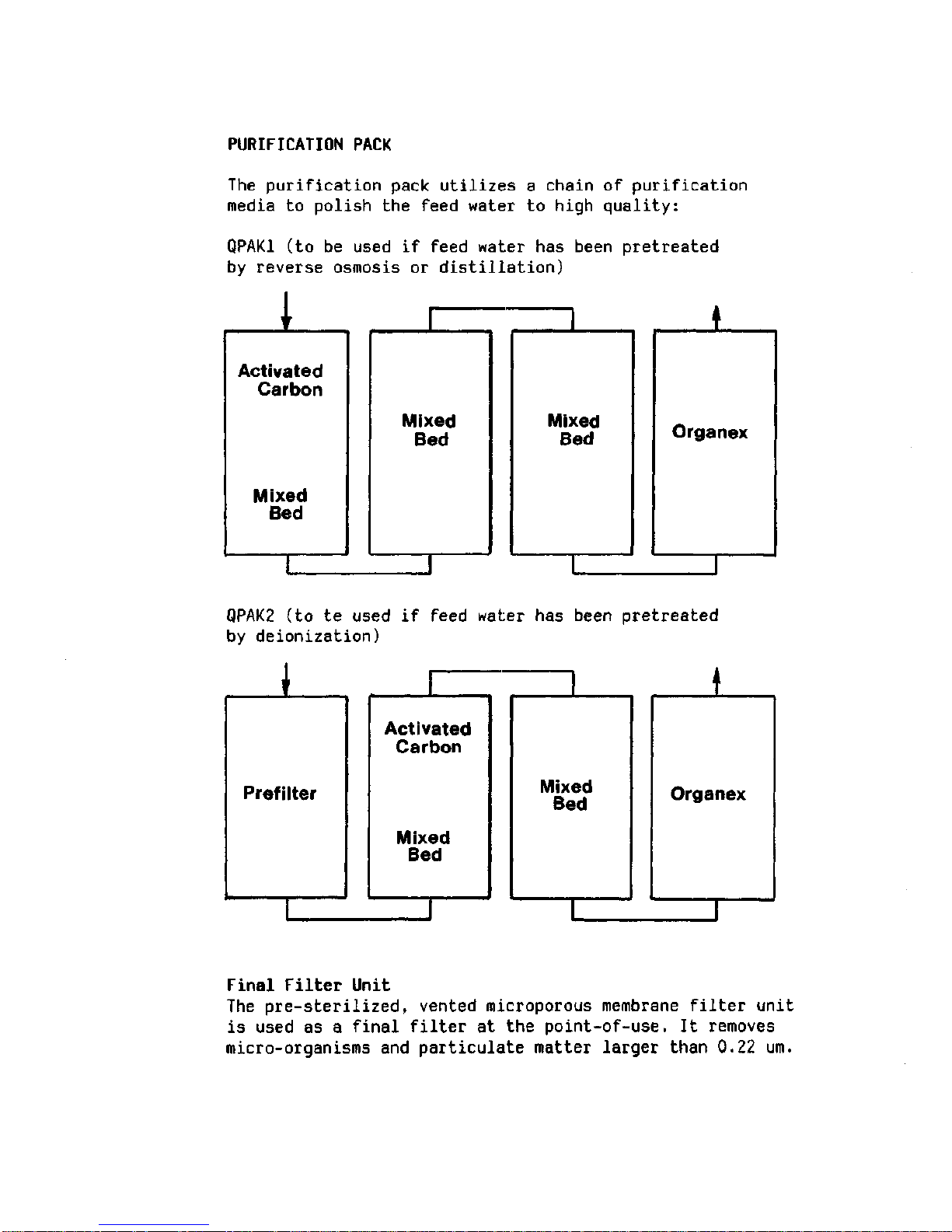

PURIFICATION PACK

The purification pack utilizes a chain

of

purification

media

to

polish

the

feed water

to

high quality:

QPAK1

(to be

used

if

feed water

has

been pretreated

by reverse osmosis

or

distillation)

I

Activated

Carbon

Mixed

Bed

Organex

QPAK2

(to te

used

if

feed water

has

been pretreated

by deionization)

I

Prefilter

I

Activated

Carbon

Mixed

Bed

Final Filter Unit

The pre-sterilized, vented microporous membrane filter unit

is used

as a

final filter

at the

point-of-use.

It

removes

micro-organisms

and

particulate matter larger than

0.22 um.

B.

Installation

1. Unpacking

Unpack the system carefully from its container.

Verify Contents: 1. Milli-Q Plus system

2.

Operation and maintenance manual

3. Power cable

4.

Cover for point-of-use

5. 3 meters of feed water tubing - white, 8 mm O.D.

6. Roll Teflon tape

7.

1/4" male - 8 mm diameter tubing adapter -

feed water

8. 1/2" female to 1/4" female reducing bushing with

stainless steel filter screen

9. 1/4" male - 1/4" hose barb

10.

2 meters tubing, 12 mm O.D.

Purification Pack

The system requires a purification pack which is not included

with the unit. The purification pack must be ordered separately,

The choice of purification pack depends on feed water quality.

Feed Water

Reverse Osmosis or distilled - use CPMQ 004 Rl

Deionized - use CPMQ 004 D2

Pack Contents 1. Purification pack

2.

Millipak final filter unit

B.

Installation

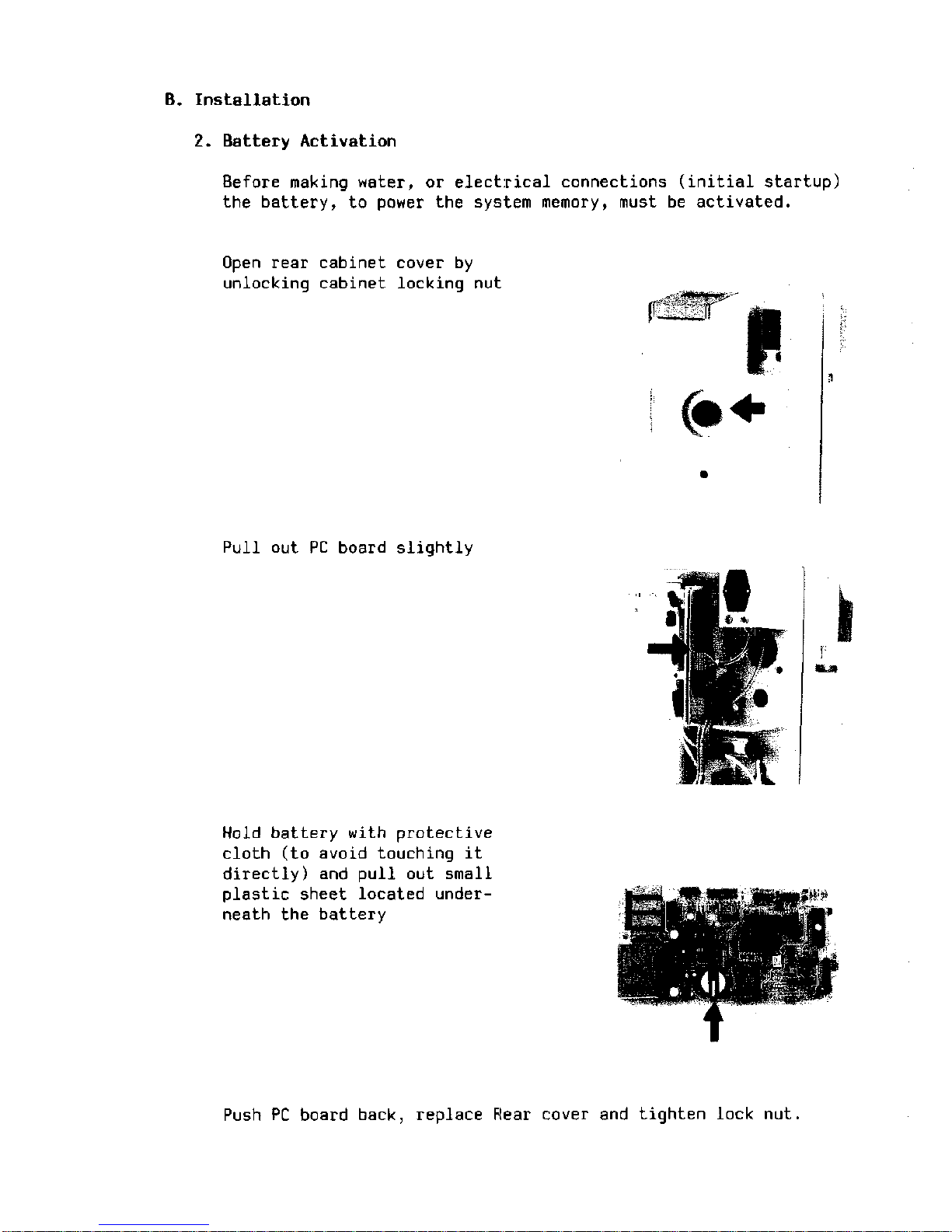

2.

Battery Activation

Before making water, or electrical connections (initial startup)

the battery, to power the system memory, must be activated.

Open rear cabinet cover by

unlocking cabinet locking nut

Pull out PC board slightly

•Ml

Hold battery with protective

cloth (to avoid touching it

directly) and pull out small

plastic sheet located underneath the battery

Push PC board back, replace Rear cover and tighten lock nut.

Note:

Switch on power immediately after battery activation.

Switch system to ON for a few seconds. This will

initialise the microprocessor and avoid discharging

the battery.

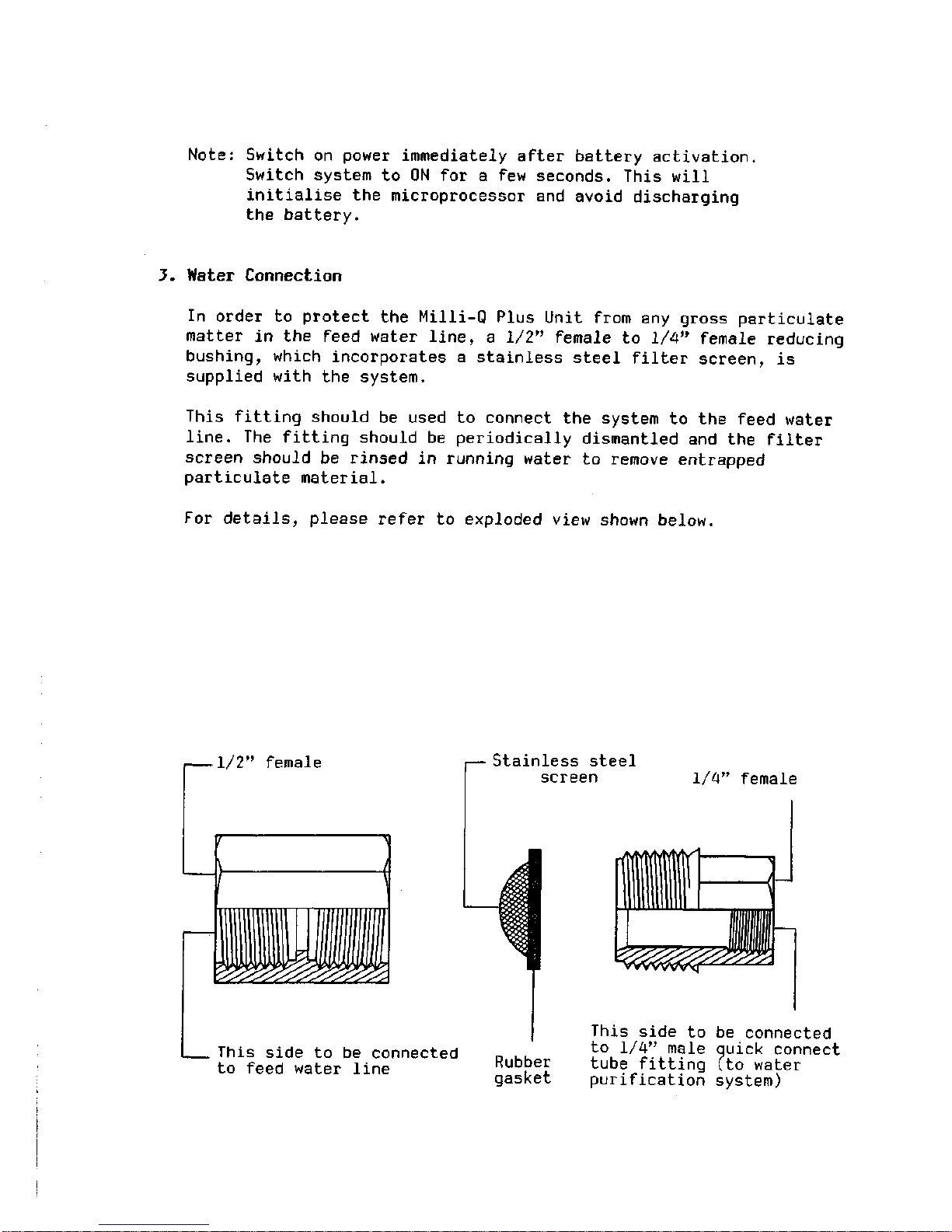

3. Water Connection

In order to protect the Milli-Q Plus Unit from any gross particulate

matter in the feed water line, a 1/2" female to 1/4" female reducing

bushing, which incorporates a stainless steel filter screen, is

supplied with the system.

This fitting should be used to connect the system to the feed water

line.

The fitting should be periodically dismantled and the filter

screen should be rinsed in running water to remove entrapped

particulate material.

For details, please refer to exploded view shown below.

, 1/2" female

Stainless steel

screen

1/4" female

This side to be connected

to feed water line

Rubber

gasket

This side to be connected

to 1/4" male quick connect

tube fitting (to water

purification system)

Loading...

Loading...