User Guide

Direct Detect® Spectrometer

C

Made in Germany

The M logo, Millipore, Direct Detect, and Amicon are registered trademarks

of Merck KGaA, Darmstadt, Germany.

All trademarks of third parties are the property of their respective owners.

© 2014 EMD Millipore Corporation, Billerica, MA, U.S.A. All rights reserved.

00000833, Rev. D, 05/14

Notice

The information in this document is subject to change without notice and should not be construed

as a commitment by EMD Millipore Corporation (“Millipore”) or an affiliate. Neither EMD Millipore

Corporation nor any of its affiliates assumes responsibility for any errors that may appear in this

document.

Contents

1 Introduction ............................................................................................................... 1

2 Components Supplied ............................................................................................... 2

3 Symbols Used in this User Guide .............................................................................. 3

4 Product Labeling ........................................................................................................ 3

5 Safety Precautions .................................................................................................... 4

6 Installation ................................................................................................................. 4

6.1 Packaging ........................................................................................................................................................4

6.2 Site Requirements .........................................................................................................................................5

6.3 Installation Configuration ..........................................................................................................................6

6.4 Unpacking and Setting up the Computer ...............................................................................................6

6.5 Unpacking and Setting Up the Direct Detect® Spectrometer ...........................................................6

7 Direct Detect® Spectrometer Parts and Functions .................................................. 8

7.1 General Technical Features .........................................................................................................................8

7.2 Direct Detect® Computer and Software .............................................................................................. 10

8 General Guidelines .................................................................................................. 11

8.1 Buffer components .................................................................................................................................... 11

8.2 Materials Required but Not Supplied ................................................................................................... 11

9 Direct Detect® Assay-free Card and Sample Preparation .....................................12

9.1 Direct Detect® Assay-free Card ............................................................................................................12

9.2 Sample Preparation ................................................................................................................................... 13

10 How to Use the Direct Detect® Spectrometer ....................................................... 14

10.1 Accessing Direct Detect® Software ....................................................................................................... 14

10.2 Loading and Installing the Card ............................................................................................................. 15

10.3 Measurement .............................................................................................................................................. 16

10.4 Removing the Card .................................................................................................................................... 18

11 Switching from Direct Connection to Intranet Connection (Networking) ..........19

11.1 Reconfiguration Requirements ............................................................................................................... 19

11.2 Changing from Direct Connection to Intranet Connection............................................................ 20

11.3 Changing from Intranet Connection to Direct Connection............................................................ 22

11.4 Changing Computer Network Settings Manually ............................................................................. 24

12 Troubleshooting ....................................................................................................... 26

12.1 General Information .................................................................................................................................. 26

12.2 Problems Indicated by Hardware Diagnostics Icon .......................................................................... 27

12.3 Problems Indicated by Instrument Status Light (top of instrument) .......................................... 28

12.4 Problems Indicated by Instrument Validation Icon .......................................................................... 29

12.5 Problem Indicated by Instrument Internal Humidity Icon.............................................................. 29

13 Maintenance ............................................................................................................ 30

13.1 Replacing the IR Source ........................................................................................................................... 30

13.2 Replacing the Desiccant ........................................................................................................................... 33

13.3 Cleaning ........................................................................................................................................................ 35

13.4 Description of Instrument Validation Tests ......................................................................................... 36

13.5 Running the Instrument Validation OQ and PQ Tests ...................................................................... 39

13.6 Storage .......................................................................................................................................................... 39

14 Installation, Operation, and Process Qualification Protocol (Optional) .............. 40

14.1 Installation Qualification Protocol (IQ) ................................................................................................ 40

14.2 Instrument Hardware Diagnostic Protocol..........................................................................................40

14.3 Operation Qualification Protocol (OQ) ................................................................................................. 42

14.4 Performance Qualification Protocol (PQ) ............................................................................................ 42

14.5 Protein Measurement Verification ........................................................................................................ 42

14.6 Direct Detect® System IQ/OQ/PQ Report Summary ......................................................................... 44

15 Specifications........................................................................................................... 45

16 Ordering Information .............................................................................................. 46

17 Technical Assistance ................................................................................................ 47

18 EC Representative .................................................................................................... 47

19 Standard Warranty .................................................................................................. 47

Contents, continued

Direct Detect® Spectrometer User Guide

1

1 Introduction

The Direct Detect® infrared (IR)-based quantification system is an innovative combination of softwarecontrolled instrumentation and EMD Millipore Corporation’s advanced membrane technology, optimized

for biomolecule detection, quantification of proteins, and analysis of lipids/detergents. Biomolecules

are applied directly to a card-based hydrophilic polytetrafluoroethylene (PTFE) membrane that is

transparent in most of the infrared spectral region.

The Direct Detect® system measures amide bonds in protein chains, accurately quantifying an intrinsic

component of every protein without relying on amino acid composition, dye binding properties, or

redox potential. Protein concentrations from 0.25 to 5 mg/mL can accurately be determined from a

minimal sample volume (2 µL) without bio- or immuno-chemical staining. Sample analysis takes only

minutes and in most cases can be performed directly from the buffered or native solution.

Quantification of lipids and detergents requires a user-defined standard curve. Unknown mixtures can

be analyzed by determining the relative IR absorbance.

The system has been validated with proteins and cell lysates representative of those currently in use in

research laboratories.

Direct Detect® Spectrometer User Guide

2

2 Components Supplied

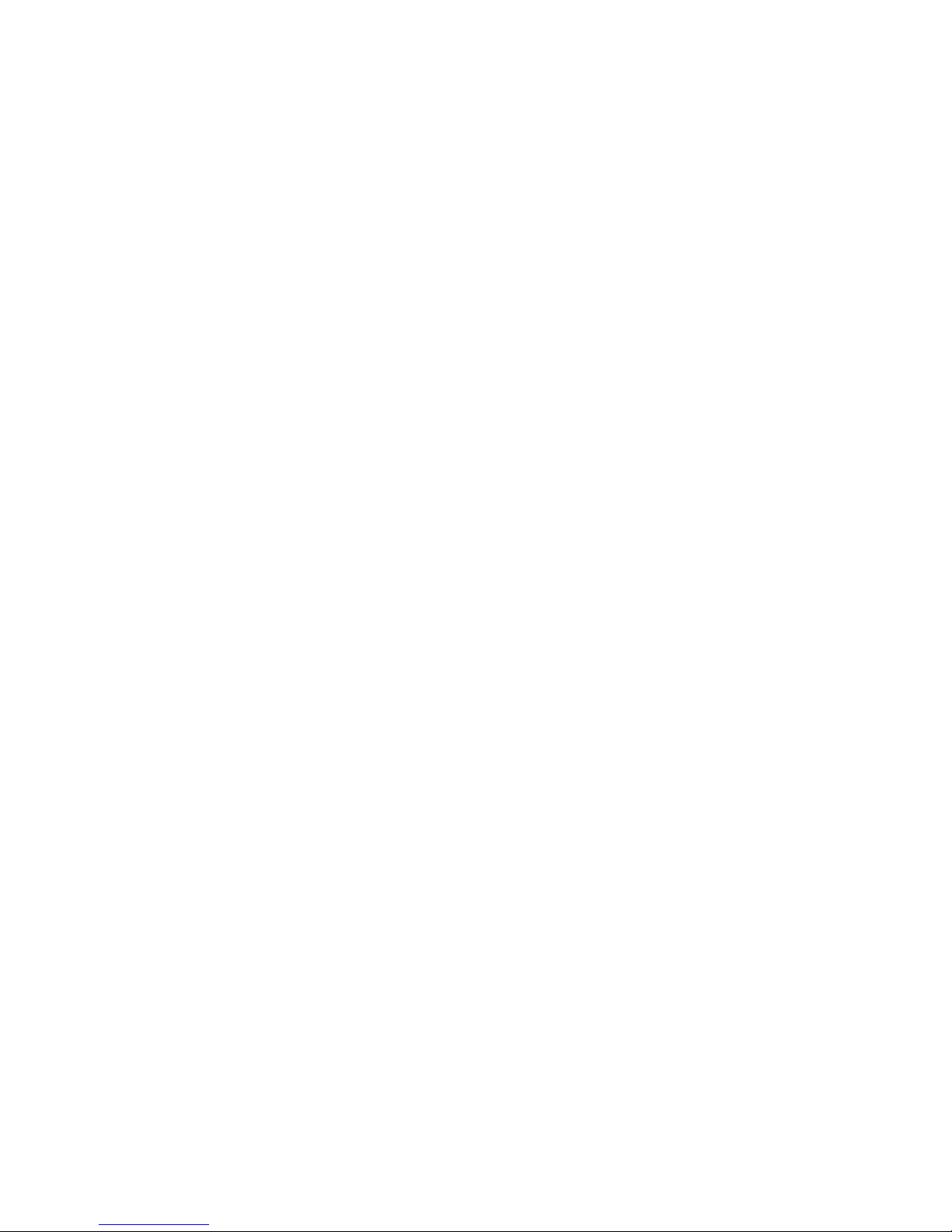

The Direct Detect® system includes the following components:

Figure 1. Components supplied

1A

1B

1C

1D

1E

1F

1G

1H

1A Direct Detect® spectrometer

1B Instrument power adapter with 4 power cord/plug configurations (EU, UK, US, Japan)

1C Data cable (crossover, 10Base-T Ethernet with RJ45 connectors)

1D Dell® Netbook computer with Direct Detect® Software installed

1E Computer power adapter with world-wide plug adapter

1F Netbook stand

1G Direct Detect® Assay-free cards (package of 50)

1H Direct Detect® spotting tray

Desiccant pack replacement (1, not shown)

Torx® TX20 screw driver for replacing the IR source (not shown)

Direct Detect® Spectrometer Quick Start Card (not shown)

Direct Detect® Spectrometer User Guide

3

3 Symbols Used in this User Guide

The following symbols are used throughout this user guide and/or on product labels, and the user shall

abide by indicated requirements:

Symbol Definition

Y

Warning alerts you to actions that may cause personal injury or pose a

physical threat.

Class I Laser

Product

Class I Laser product, complies with 21 CFR Chapter 1, Subchapter J

i

Read the documentation

h

Catalogue number

f

Serial number

M

Manufacturer

C

CE conformity marking. Reference Declaration of Conformity for specific directives.

Do not discard with common solid waste at end of life. Segregate with other waste

electrical and electronic equipment (WEEE) and send to an appropriate facility for

recycling. For information on recycling electrical and electronic products in the

European Union, please visit www.millipore.com/weee.

Hot Surface

4 Product Labeling

Figure 2. Product label appears on both the back and the bottom of the instrument

Direct Detect® Spectrometer User Guide

4

5 Safety Precautions

Review and understand the safety precautions below before installing and operating the Direct Detect®

spectrometer.

Y

WARNING

● To avoid danger of electric shock, do not install the instrument in an area with a high humidity

level. Refer to Site Requirements in section 6.2.

● Do not touch the Ethernet cable or universal power adapter plugs with wet hands.

● To avoid potential shock hazard, choose the correct plug configuration and make sure that the

power adapter is plugged securely into a properly grounded AC power outlet. Make sure that

the connection between the cable and the instrument is secure.

● Always ensure that the power supply input voltage matches the voltage available in your

location.

● Use only the power supplies that were supplied by EMD Millipore Corporation for use with the

Direct Detect® system. Use of other power supplies may damage the system.

● Minimize power draw from other instruments on the same power circuit.

● Do not use with flammable or explosive liquids. Cards that have been spotted with samples in

flammable solvents must be dried prior to insertion into the instrument.

6 Installation

NOTE: For a full installation, operation, and process qualification protocol and checklist, refer to

section14.

6.1 Packaging

Inspect the packaging for damage upon receipt. If there are any signs of damage, contact

the responsible shipping company.

Y

WARNING: Do not put a spectrometer showing signs of damage into operation as this

may result in severe personal injuries and/or property damage.

Keep the original shipping boxes in case you need to return the spectrometer for servicing

or repair.

NOTE: Instruments will not be accepted for repair if not in original packaging. EMD

Millipore Corporation will provide shipping boxes for a charge if original packaging

has been discarded.

Direct Detect® Spectrometer User Guide

5

6.2 Site Requirements

The user must provide an installation site that meets the following requirements:

Space requirement Stable and horizontal base which is able to bear the weight of

at least 8 kilograms (kg)

A clearance of at least 25 centimeters (cm) at the

spectrometer rear side

Environment Temperature range: 18–35 °C

Humidity (non-condensing): less than 35% (relative humidity)

Temperature variation: less than 1 °C/hour

Humidity variation: less than 3%/hour

Do not install devices such as large electric motors, heaters,

welding equipment, radio transmitting equipment, units emitting pulsed NMRs, or high-powered lasers in close proximity

to the Direct Detect® spectrometer. These devices can cause a

spectrometer malfunction.

Make sure that these types of devices are not connected to the

same electrical circuit as the Direct Detect® spectrometer.

Vibration Do not locate the Direct Detect® spectrometer near vibration

sources (centrifuges, vortexes, ventilation hoods, air

conditioners, etc.), or in rooms with intense floor vibrations.

Inductive electrical

interference

Do not install the Direct Detect® spectrometer near any

sources of potential inductive electrical interference (e.g.,

pumps, switching motors, microwave ovens, etc.), sources of

high energy pulses, or sources that might cause magnetic or

radio frequency interference.

Power supply Voltage range: 100–240 VAC

Frequency range: 50–60 Hz

Protection class: I

The power supply unit automatically adapts to most power

sources commonly used.

Make sure that the power supply is easily accessible at all

times.

Connect the Direct Detect® spectrometer only to a grounded

power outlet.

Take precautions to ensure uninterrupted power supply if there

is the potential for power supply issues (e.g., brownouts, power

surges, frequent thunderstorms, etc.)

Direct Detect® Spectrometer User Guide

6

6.3 Installation Configuration

The Direct Detect® spectrometer is configured to operate as a stand-alone unit

connected to the supplied Netbook computer (PC) using the factory-set standard IP

address (10.10.0.1).

6.4 Unpacking and Setting up the Computer

Unpack the Netbook computer, power adapter, and world-wide plug adapter from

the shipping box. Choose the plug adapter with the correct configuration for local

requirements and attach it to the plug. Plug the low voltage (round) end of the power

adapter into the power port of the PC, but do not plug the computer into a power outlet at

this time.

6.5 Unpacking and Setting Up the Direct Detect® Spectrometer

Remove all components from shipping boxes and lay out on work surface.

6.5.1 Positioning and Connecting Components (Figure 3)

1. Place instrument on bench and put Netbook stand on top of instrument. The

front tab of the stand fits into the slot on top of the instrument (5B in Figure5).

2. Place Netbook computer on stand.

Figure 3. Rear side - Connection ports

3A

3B

3C

3. Turn the instrument/computer assembly so that the rear of the instrument is

facing you (Figure 3).

4. Connect one end of the provided Ethernet cable to the instrument ETH/LAN

port (3A) and the other end to the PC network/LAN port (3B).

Direct Detect® Spectrometer User Guide

7

6.5 Unpacking and Setting Up the Direct Detect® Spectrometer, cont.

5. Connect the low voltage (round) end of the instrument power adapter to the

power port of the instrument (3C). Secure the connector with the clamp.

6. Choose the instrument power cord with the correct plug configuration for local

requirements and plug it into the power adapter.

7. Plug both the PC and instrument power cords into a grounded power outlet. A

surge protector is recommended.

Y

WARNING: To avoid personal injuries and/or property damage caused by

electrical power, connect the spectrometer and computer to

a grounded power outlet. Make sure that this power outlet

complies with IEC (International Electrotechnical Commission)

regulations.

8. Turn on the PC.

NOTE: The instrument is powered through the computer and does not have

a separate ON/OFF switch. It should be left on and powered up at all

times.

6.5.2 Initializing the Direct Detect® Spectrometer

1. Refer to the Direct Detect® Software User Guide for instructions on starting up

the software and logging in (section 1.2).

2. During initialization, the laser, IR source, and detector are switched on. The IR

source warms up, the scanner moves forward and backward several times, and

tones once. This phase takes several minutes, and the hardware diagnostics

icon is yellow. After the initialization has been completed successfully, the

hardware diagnostics icon turns to green, but the instrument validation icon

will be yellow (Figure 4). This indicates that the PQ test has expired and needs

to be run. Refer to section 13.5 for instructions on running the PQ test.

Figure 4. Instrument status icons

Instrument validation icon

Instrument internal humidity icon

Hardware diagnostics icon

NOTE: If the status indicator on either the instrument or the software is red or

remains yellow after initialization is complete and the PQ test has been

run, refer to section12, Troubleshooting.

Direct Detect® Spectrometer User Guide

8

7 Direct Detect® Spectrometer Parts and Functions

7.1 General Technical Features

7.1.1 The Instrument

The Direct Detect® spectrometer is a small compact FTIR spectrometer designed for

measuring IR absorbance.

Figure 5. Direct Detect® spectrometer

5A

5B

5C

5E

5G

5F

5D

Definition

5A Instrument module (with integrated electronics and optics)

5B Slot for Netbook stand tab

5C Direct Detect® automated card holder

5D Card insertion alignment arrow

5E Status light

5F Sample drying indicator light

5G Card insertion light

7.1.2 The Direct Detect® Automated Card Holder

The automated card holder (5C) accepts only 4-sample Direct Detect® Assay-free cards.

The top of the card holder module contains two LED lights located at the bottom right

corner (5F and 5G as viewed from the top).

The bottom LED light (5G) is green whenever an Assay-free card is inserted properly.

The top LED light (5F) is yellow whenever the drying system heater and fan are active.

Periodically (default setting is 15 minutes) the software will initiate a reference measurement which must be performed without a sample card inserted in the card holder. If a card

is found in the card holder, the software will prompt you to remove it.

Direct Detect® Spectrometer User Guide

9

7.1.3 Connecting Ports and LEDs

The connecting ports (e.g., power, Ethernet) and the system diagnostic LEDs are on the

back of the instrument.

Figure 6. Direct Detect® Spectrometer rear side - Connecting ports and LEDs

6A

6B 6C 6E 6F 6G 6H 6I 6J 6K

6D

Type Definition

6A

USB port Not available to user. For instrument service use only.

6B

ETH/LAN port The ETH/LAN port connects the spectrometer to the Netbook

computer, using the supplied data cable (crossover, 10Base-T with

RJ45 ports).

6C TKD LED The green TKD LED indicates that the interferometer mirror is

within the data acquisition range. When data acquisition is

occurring, the light is bright green. The abbreviation TKD means

Take Data.

6D ACC LED The yellow ACC LED indicates that the network is accessing the

optics. During transition of measuring data the LED is light yellow.

The abbreviation ACC means Access.

6E DIR/ERR LED In normal operation mode the DIR/ERR LED flashes pale red and

indicates scanner movement. If the LED lights permanently bright

red, there is an interferometer problem, e.g., missing laser signal.

When this LED is permanently red no data acquisition is possible.

The abbreviation DIR means Direction and ERR means Error.

6F External

accessory port

Not available to user. For instrument service use only.

6G TAP port Not available to user. For instrument service use only.

7.1 Direct Detect® Spectrometer General Technical Features, continued

Direct Detect® Spectrometer User Guide

10

Type Definition

6H CFG switch CFG is a four-fold DIP switch:

#1 ON and #2 OFF: DHCP mode - use last DHCP address

#1 OFF and #2 ON: use ON-IP address 10.10.0.1

#3: stay in boot loader, do not load the application program

#4: reserved

The abbreviation CFG means Configuration.

6I SBY/RES button Pressing this button for approximately 2 seconds, activates/

deactivates the stand-by mode. Pressing this button for more

than 6 seconds resets the spectrometer to the original state. The

abbreviation SBY means Standby and RES means Reset. Do not use

unless instructed to do so by service personnel.

6J POWER port This port connects the spectrometer to the power supply via the

supplied power adapter and power cord. The POWER port is for

extra low-voltage connectors. Use only power cords/supplies that

have been supplied by EMD Millipore Corporation.

6K Kensington lock

slot

The lock slot is an anti-theft lock for mobile hardware. Lock and

cable are not supplied.

7.2 Direct Detect® Computer and Software

The Direct Detect® spectrometer is designed to operate with the Direct Detect® Software

that is pre-installed on the Netbook computer. For computer specifications, refer to

section 15.

Direct Detect® Software may be updated periodically. For information on the most up-todate software, go to www.millipore.com/directdetect. Register your instrument in order to

receive notification about relevant software upgrades.

WARNING: Do not install third-party software (screen savers, etc.), as this may impact the

performance of the Direct Detect® system.

7.1 Direct Detect® Spectrometer General Technical Features, continued

Direct Detect® Spectrometer User Guide

11

8 General Guidelines

The Direct Detect® spectrometer is recommended for use with protein samples ranging from 0.25 to

5mg/mL. Although the instrument can measure protein concentrations from 0.1 mg/mL to around

30mg/mL, the most accurate results are achieved within the recommended concentration range. The

instrument is also capable of detecting and analyzing lipids and detergents. Analysis is performed with

a user-defined calibration method. Samples to be analyzed are introduced to the system using the

Assay-free card which contains a novel IR-compatible membrane. The recommended sample volume is

2 µL per spot position.

8.1 Buffer components

The Direct Detect® system is compatible with most commonly used buffers, detergents, and

reducing agents, however, use of buffers which contain amides or amine functional groups

may affect quantification.

Buffers containing more than 5% glycerol, SDS, and/or Tween® 20 surfactant should be

avoided due to the excessive time required to achieve dryness.

The instrument comes with preloaded protein calibration files, prepared using National

Institute of Standards & Technology (NIST) bovine serum albumin (BSA) in phosphatebuffered saline (PBS). However, preparation of a fresh calibration method with the

buffer used for protein preparation is recommended. The Direct Detect® spectrometer is

compatible with most solvents used in lipid research.

8.2 Materials Required but Not Supplied

● Protein standards (Bovine Serum Albumin - National Institute of Standards &

Technology SRM 927d (optional))

● Protein sample(s)

● Lipid/detergent standards

● Lipid/detergent sample(s)

● Fixed-volume precision pipette capable of precisely dispensing 2 µL, and pipette tips

NOTE: To minimize pipetting error, we recommend the use of a fixed-volume precision

pipette capable of dispensing 2 µL, for applying samples to the Assay-free card.

Adjustable pipettes are not recommended.

● Water, PBS, or other buffer

● Chloroform or other lipid compatible solvent

● Printer (optional)

Direct Detect® Spectrometer User Guide

12

9 Direct Detect® Assay-free Card and Sample Preparation

9.1 Direct Detect® Assay-free Card

All concentration measurements are performed using the Assay-free card.

Figure 7. Direct Detect® Assay-free card

The card contains four hydrophilic polytetrafluoroethylene (PTFE) membrane positions,

sized for easy sample application and surrounded by a hydrophobic ring that retains the

sample to be analyzed within the IR beam. A 2 µL sample volume is recommended in order

to assure proper sample application, drying, and measurement.

By design, the positions on the card are numbered from 1 to 4, starting from the bottom.

Position 1, by software default, is reserved for the “blank” measurement. The “blank” is the

buffer/solvent used to resuspend the sample, but contains no protein or lipid/detergent.

One or more of the remaining card positions are used for the protein and/or lipid/detergent

samples.

The Assay-free card can be inserted into the system and analyzed immediately after

preparation. The Direct Detect® spectrometer has a built-in drying system that

automatically dries the sample to the point where it gives an accurate reading. The first

sample position typically takes the longest period of time to dry, with subsequent positions

taking less time. Including drying time, the total measurement time for a card loaded with

2 µL samples does not exceed 5 minutes.

The Direct Detect® Assay-free card is intended for one-time protein and/or lipid/detergent

spotting. However, already prepared cards can be stored and read again.

Direct Detect® Spectrometer User Guide

13

9.2 Sample Preparation

In general, analysis of protein samples within the concentration range of 0.25–5 mg/mL

can be performed directly from the buffered solution. Buffers containing more than 5%

glycerol, SDS, and/or Tween® 20 surfactant should be avoided due to the excessive time

required to achieve dryness.

For analysis of samples with protein content above 5 mg/mL, single step dilution is

recommended.

Concentration determination of samples below 0.25 mg/mL can be achieved after a simple

spin concentration step using a centrifugal filter (e.g., Amicon® Ultra-0.5 device).

Use of centrifugal filters is also recommended for buffer exchange when the original buffer

contains a high concentration of components with amide- or amine-containing functional

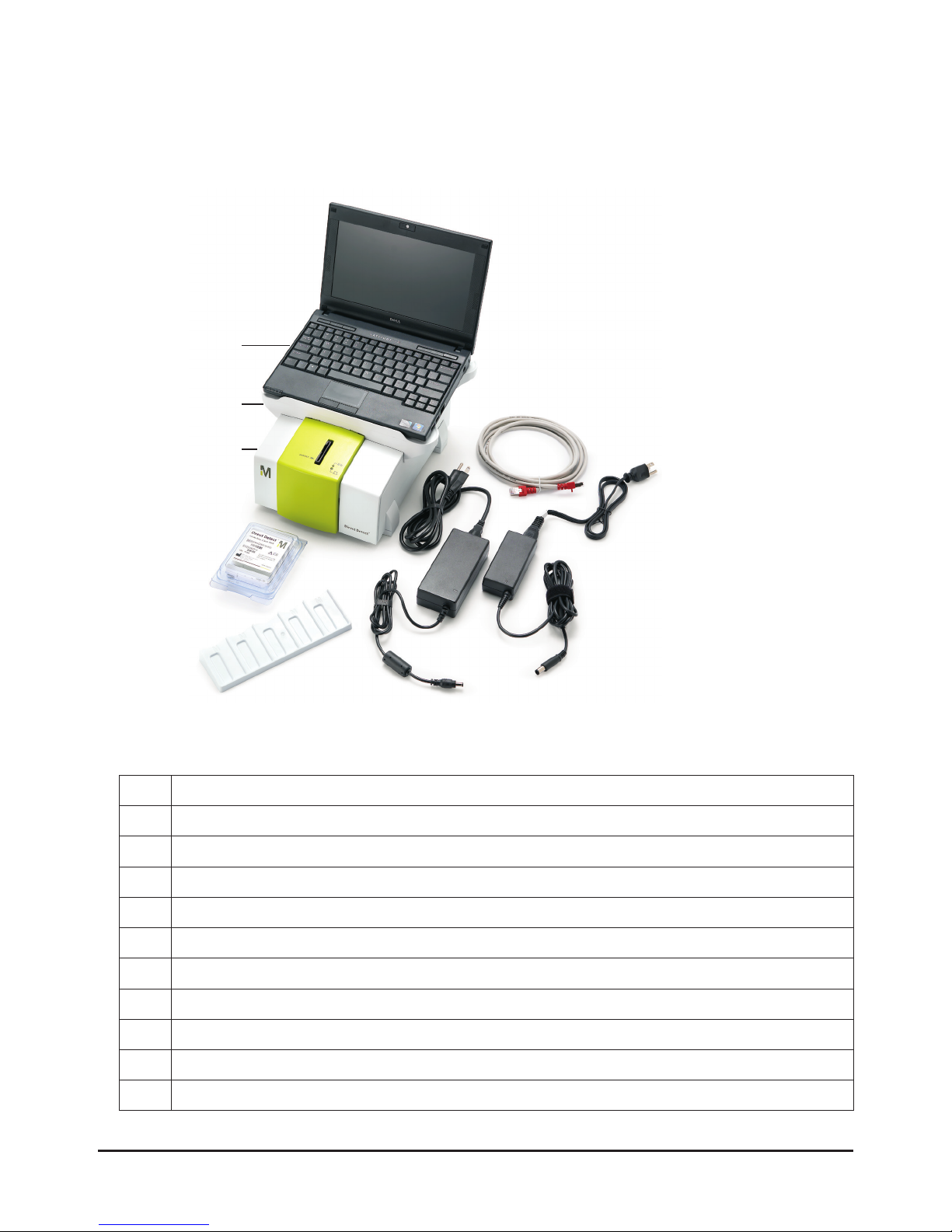

groups. Figure 8 is an example of a diafiltration protocol that concentrates the sample and

reduces the Tris buffer concentration.

500 µL of

0.1 mg/mL

protein in

50 mM Tris

50 µL of

1 mg/mL

protein in

50 mM Tris

50 mM

Tris

50 µL of

1 mg/mL

protein in

PBS with 9.5

mM Tris

PBS with

9.5 mM Tris

Add 450 µL of

1X PBS or

exchange buffer

500 µL of

0.1 mg/mL

protein in

PBS with 9.5

mM Tris

Spin to

concentrate

Spin to

concentrate

Figure 8. Buffer exchange and concentration using an Amicon® Ultra-0.5 device

In general, lipid sample preparation involves solvent extraction. Neutral lipids may be

extracted by relatively nonpolar solvents such as hexane, chloroform, or toluene while

membrane-associated lipids require polar solvents like methanol or ethanol.

Lipids dissolved in organic solvents may be applied directly onto the Assay-free card.

Special care in the application of highly volatile solvents (chloroform, hexane, etc.) is

recommended in order to contain the samples within the hydrophobic embossing.

Analysis of detergents can be performed directly from buffer. Due to the excessive time

required to achieve dryness, samples containing more than 5% of the analyzed detergent

should be avoided.

The limits of lipid and detergent detection and quantification should be established

experimentally for each compound analyzed.

Direct Detect® Spectrometer User Guide

14

10 How to Use the Direct Detect® Spectrometer

The instrument is controlled and operated by Direct Detect® Software installed on the Netbook

computer. Samples are introduced to the instrument module by inserting the Direct Detect® Assay-free

card into the card holder (Figure 11). An alignment notch on one corner of the card ensures correct

card insertion into the card holder.

10.1 Accessing Direct Detect® Software

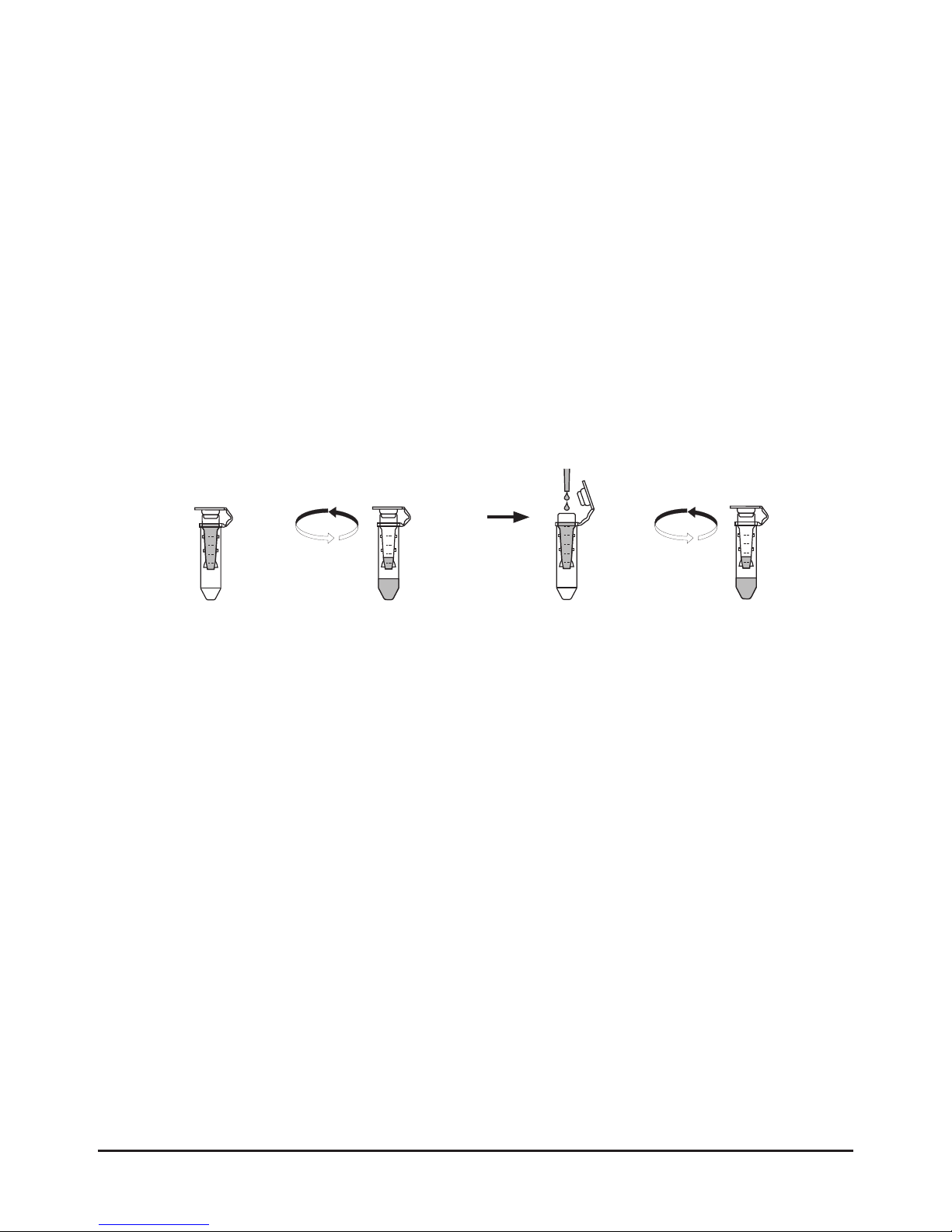

The Direct Detect® Software can be accessed through the icon on the Netbook desktop.

Figure 9. Direct Detect® Software desktop icon

Each instrument user can be assigned a unique name and optional password (Figure 10).

NOTE: If 21CFR11 mode is enabled, a password is mandatory. Refer to section 1.3 in the

Direct Detect® Software User Guide.

The measurements performed by each user are stored and recalled based upon the user

name.

Figure 10. Direct Detect® login screen

For detailed instructions on starting up the software, refer to section 1.2 of the Direct

Detect® Software User Guide.

NOTE: A seven minute warm-up cycle is required after initial power-up and software

activation. The software will wait for seven minutes before allowing a sample

measurement to begin.

Direct Detect® Spectrometer User Guide

15

10.2 Loading and Installing the Card

1. Place the Assay-free card(s) on the spotting tray or other clean surface. Select an

appropriate buffer/solvent blank, preferably the same solution in which the protein

or lipid/detergent has been prepared. If that buffer/solvent is not fully characterized,

select the closest buffer/solvent possible. Pipette 2 µL of the buffer/solvent solution to

the default blank position on the card (position1).

2. Pipette 2 µL of sample to sample positions 2 through 4 as needed. Unused positions can

be loaded and read at a later time as long as the buffer/solvent blank is appropriate for

them. Card positions can be labeled if desired.

NOTE: Cards spotted with samples in flammable solvents must be dried at ambient

conditions prior to inserting the Assay-free card into the instrument. However,

for nonflammable samples, the Direct Detect® spectrometer has a built-in

drying system that can automatically dry the sample to the point where it will

give an accurate reading.

3. Insert the card vertically into the slot in the top of the card holder module with the

card facing left and the alignment notch in the corner of the card oriented towards the

center of the instrument.

Figure 11. Inserting sample card

The arrow on the bottom right side of the card should be aligned with the arrow on

the Direct Detect® card holder module (5D in Figure 5). Gently release the card and the

instrument will accept it for analysis.

When the card is inserted properly the instrument will respond by jogging the card

holder up and down briefly. The bottom green LED on Direct Detect® card holder

module will light and the system will produce a brief tone confirming correct

placement of the Assay-free card.

NOTE: The software will not allow sample measurement if the card is not inserted

properly.

Direct Detect® Spectrometer User Guide

16

10.3 Measurement

For detailed instructions on setting up a sample measurement, refer to section 2.2 of the

Direct Detect® Software User Guide.

10.3.1 General Measurement Procedure

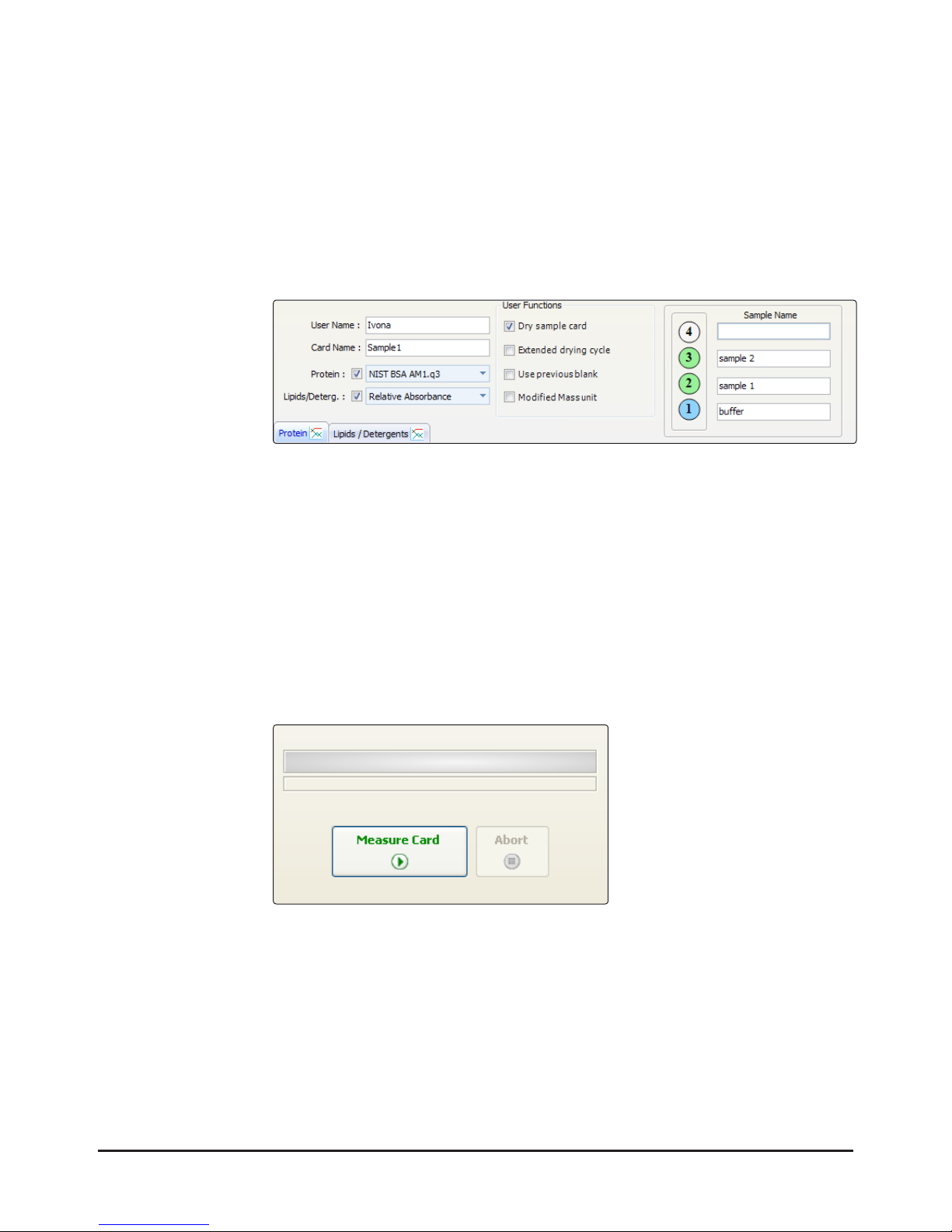

1. Complete the sample measurement setup (Figure 12). Check the Dry sample

card box to allow the instrument to dry the sample.

Figure 12. Sample information

NOTE: The Direct Detect® system comes with three preloaded protein

calibration methods. These pre-existing methods may be used for

all future measurements, however, for accurate quantification, we

recommend preparation of a fresh calibration method for each buffer

used in sample preparation (refer to section 4.2 in the Direct Detect®

Software User Guide). Lipids and detergents can be analyzed using a

Relative Absorbance mode.

2. Click on the Measure Card button (Figure 13). The sample measurement takes

about a minute and the measurement progress is shown in the lower status bar.

Figure 13. Measure sample

Direct Detect® Spectrometer User Guide

17

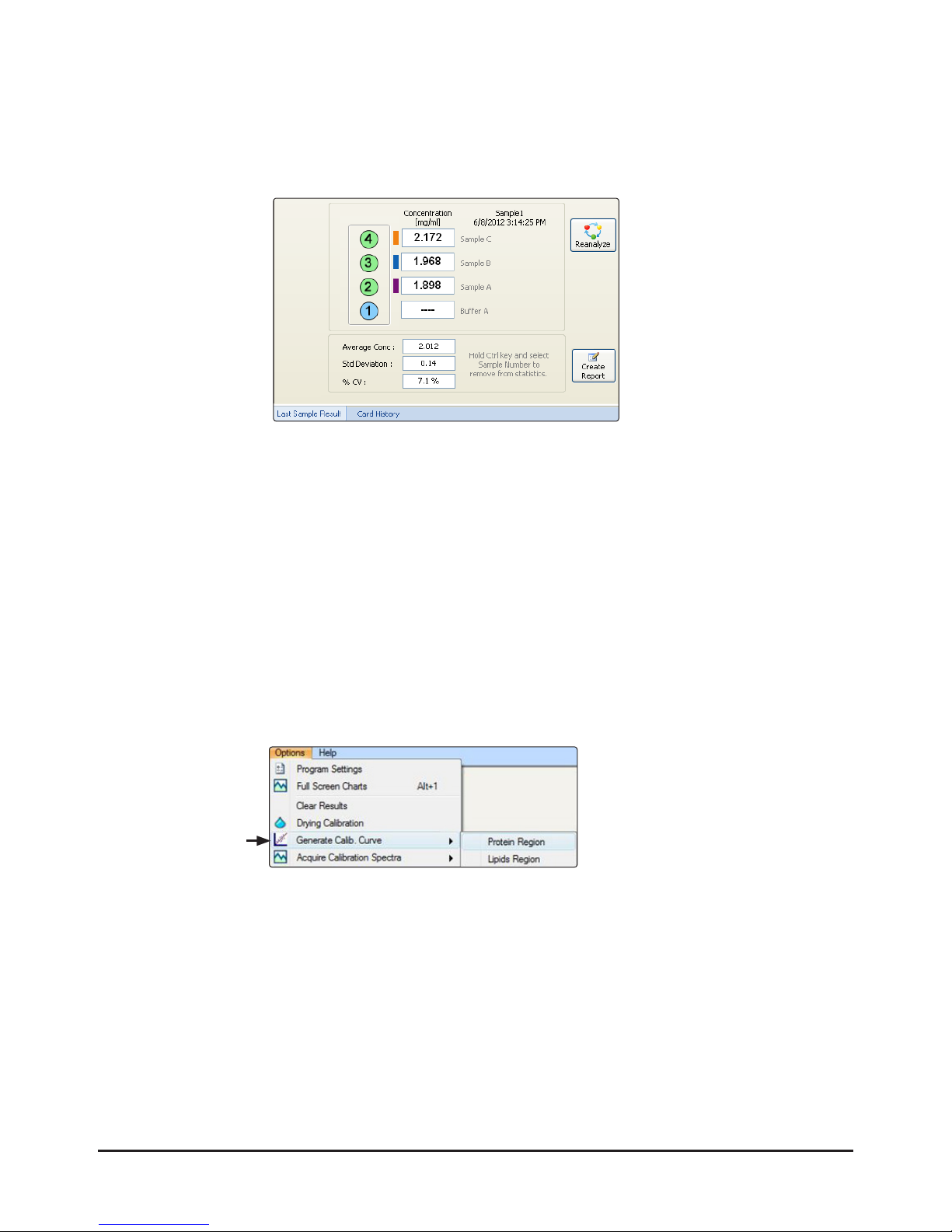

The result from each measured sample position is displayed in the Last Sample

Result tab (Figure 14) of the main Direct Detect® screen.

Figure 14. Last sample results screen

3. For reporting options, refer to sections 2.4–2.7 of the Direct Detect® Software

User Guide.

NOTE: Periodically the software will initiate a reference measurement which

must be performed without a sample card inserted in the card holder.

If a card is found in the card holder, the software will prompt you to

remove it.

10.3.2 Calibration

The Calibration Method Wizard (Options menu, Generate Calib. Curve) is used to

create or modify calibration method files that will be used to perform the analysis

of the Assay-free cards.

Figure 15. Calibration mode

To create a calibration method you need previously collected spectra from a series

of known protein or lipid/detergent concentrations. To compile these files, select

Acquire Calibration Spectra; Protein Region or Lipids Region from the Options

menu and follow the instructions for collecting calibration spectra in section 4.2 of

the Direct Detect® Software User Guide.

10.3 Measurement, continued

Direct Detect® Spectrometer User Guide

18

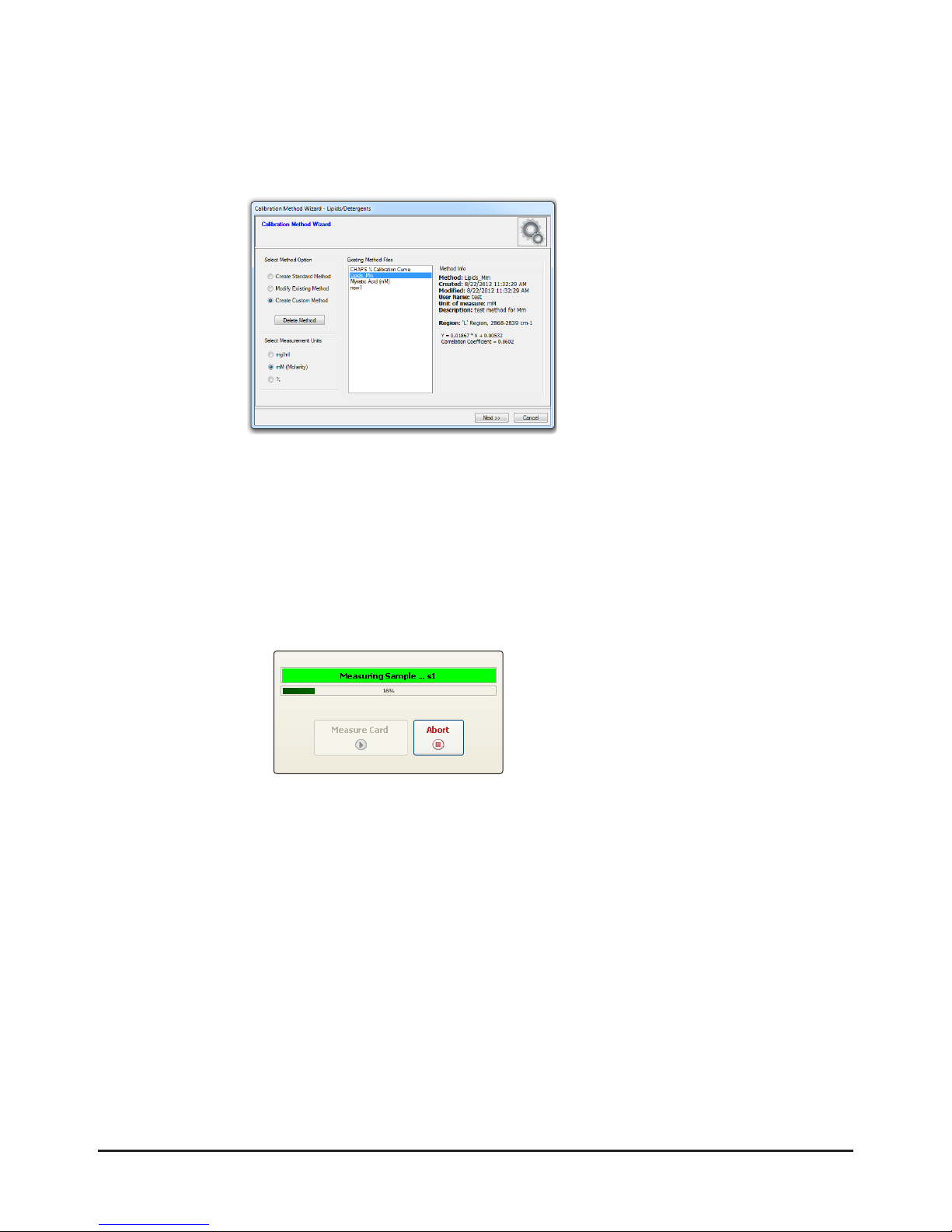

Section 4.2 of the Direct Detect® Software User Guide details how to use the

Calibration Method Wizard to create or modify a calibration method file.

Figure 16. Calibration Method start page

10.4 Removing the Card

After all 4 positions on the card have been read, the instrument will sound a tone. The card

will rise to the initial insertion position and can be removed.

CAUTION: Do not remove card during the reading. To stop a reading in progress, click on

the Abort button.

Figure 17. Abort button

When a measurement has been aborted, the progress bar will display Measurement

Aborted. After a short period of time, the instrument will return to Measure Card status.

10.3 Measurement, continued

Direct Detect® Spectrometer User Guide

19

11 Switching from Direct Connection to Intranet

Connection (Networking)

During initial setup, the Direct Detect® instrument is connected directly to the computer running

the Direct Detect® software using the crossover 10Base-T cable with RJ45 connectors provided with

the instrument (direct connection). After verification of instrument and software functionality, the

instrument can be configured to run directly from your company’s intranet (intranet connection), if

desired.

11.1 Reconfiguration Requirements

1. Confirm that the system initializes and run the PQ test (refer to section 13.5). If a full

Installation, Operation, and Process Qualification Protocol is required, perform all tests

prior to changing the connections (refer to section 14).

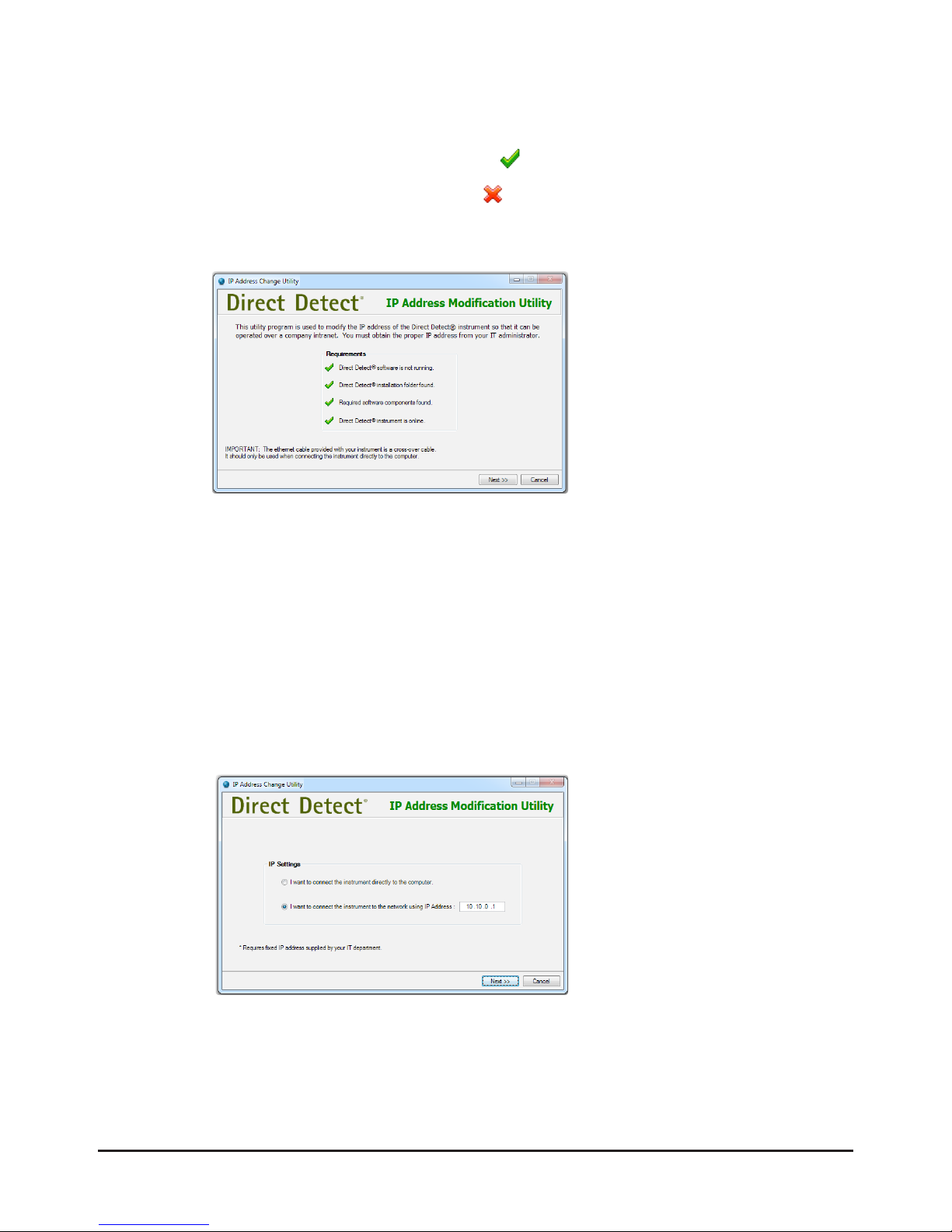

2. The IP Address Change Utility is located in C:\directdetect\IPAddressChanger. This

utility assists in the transition between direct connection to the computer and

connection via the intranet and vice versa. Two standard RJ45Cat5e Ethernet cables

(not provided) are required to switch to an intranet connection.

When the IP Address Change Utility starts, the screen lists the requirements necessary

to perform the change in operating mode (Figure 18):

● The Direct Detect® software is not running on the computer.

● The instrument is powered on and connected, either directly to the instrument or to

the intranet.

● The software is able to locate the Direct Detect® installation folder and files

required to reconfigure the instrument.

Figure 18. IP address change utility requirements

3. Select the Next button and the software will check the validity of each requirement.

Direct Detect® Spectrometer User Guide

20

11.1 Reconfiguration Requirements, continued

4. If a requirement is found to be valid, a appears next to the requirement in the list.

If a requirement is not valid then an will appear next to the requirement. A message

indicating the cause of the failure will appear.

You can continue to the next step in the utility only if all requirements are valid.

Figure 19. Status of requirements

11.2 Changing from Direct Connection to Intranet Connection

IMPORTANT: This section assumes that the Direct Detect® instrument is currently

connected directly to the computer using the supplied crossover 10Base-T cable with RJ45

connectors.

1. If the requirements are valid (all check marks are green) select the Next button to

proceed to the IP Settings selection screen of the utility.

2. Select the second option, I want to connect the instrument to the network using

IPAddress.

Figure 20. Selecting network IP address

3. An IP address URL field will become active to the right of this option. Enter the fixed IP

address issued by your IT department. The URL must be fixed for this instrument.

4. Select the Next button to proceed.

Direct Detect® Spectrometer User Guide

21

5. The software will now make the necessary modifications to the Direct Detect® software

and instrument, as well as the host computer. If the modifications are successful you

will be informed that your instrument settings have been updated.

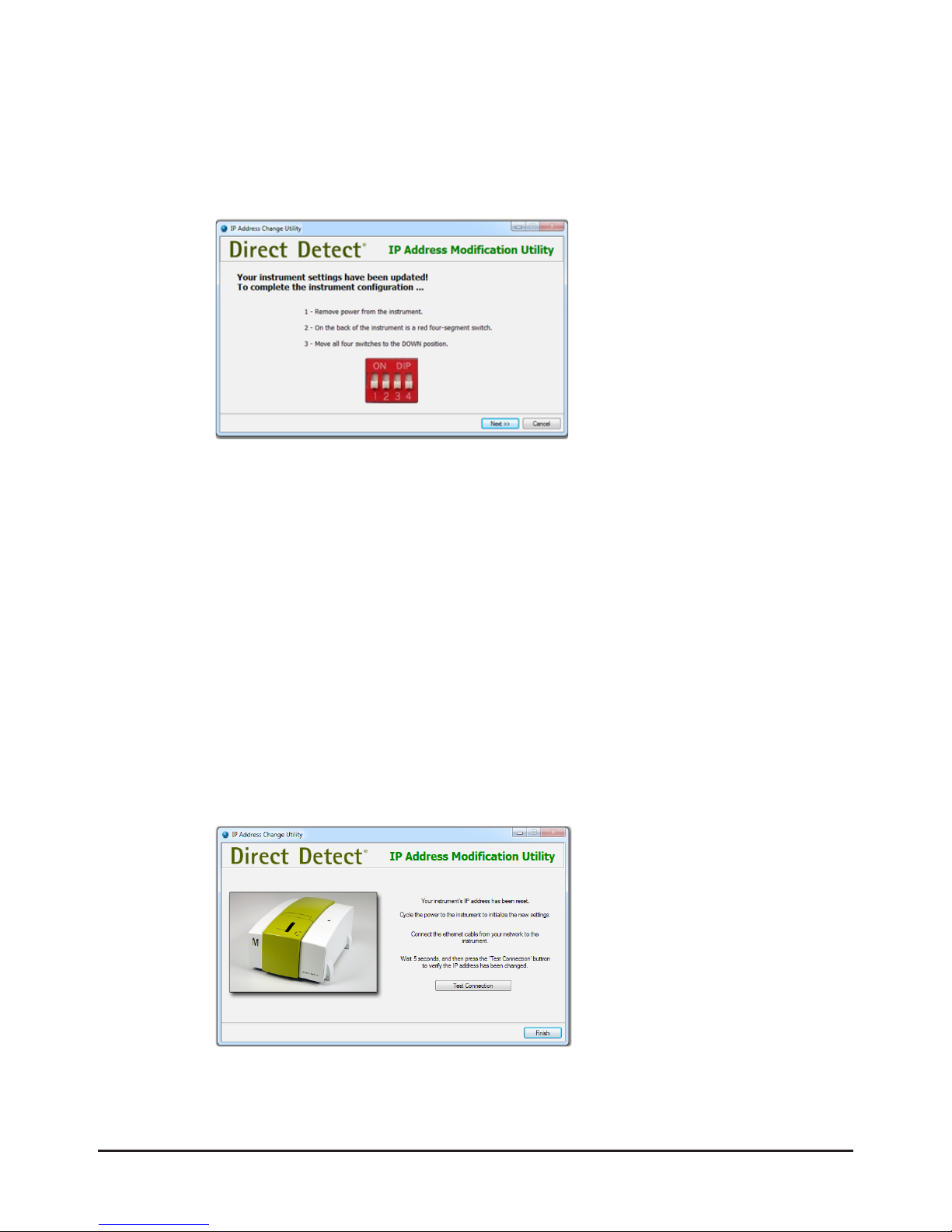

Figure 21. Successful reconfiguration to intranet connection

6. Unplug the instrument from the power source, then change the switches in the red

4-position DIP switch (6H in Figure6) on the rear of the instrument so that all four are

in the DOWN position (refer to Figure 21).

7. Select the Next button to proceed.

8. Run one of the standard RJ45 Cat5e Ethernet cables between the ETH/LAN port on the

rear of the instrument (6B in Figure 6), and your intranet hub. Run the other standard

RJ45 Cat5e Ethernet cable between the PC network/LAN port (3B in figure 3) of the

Netbook computer and your intranet hub. The supplied crossover 10Base-T cable with

RJ45 connectors is not required for this configuration.

9. Reconnect power to the instrument.

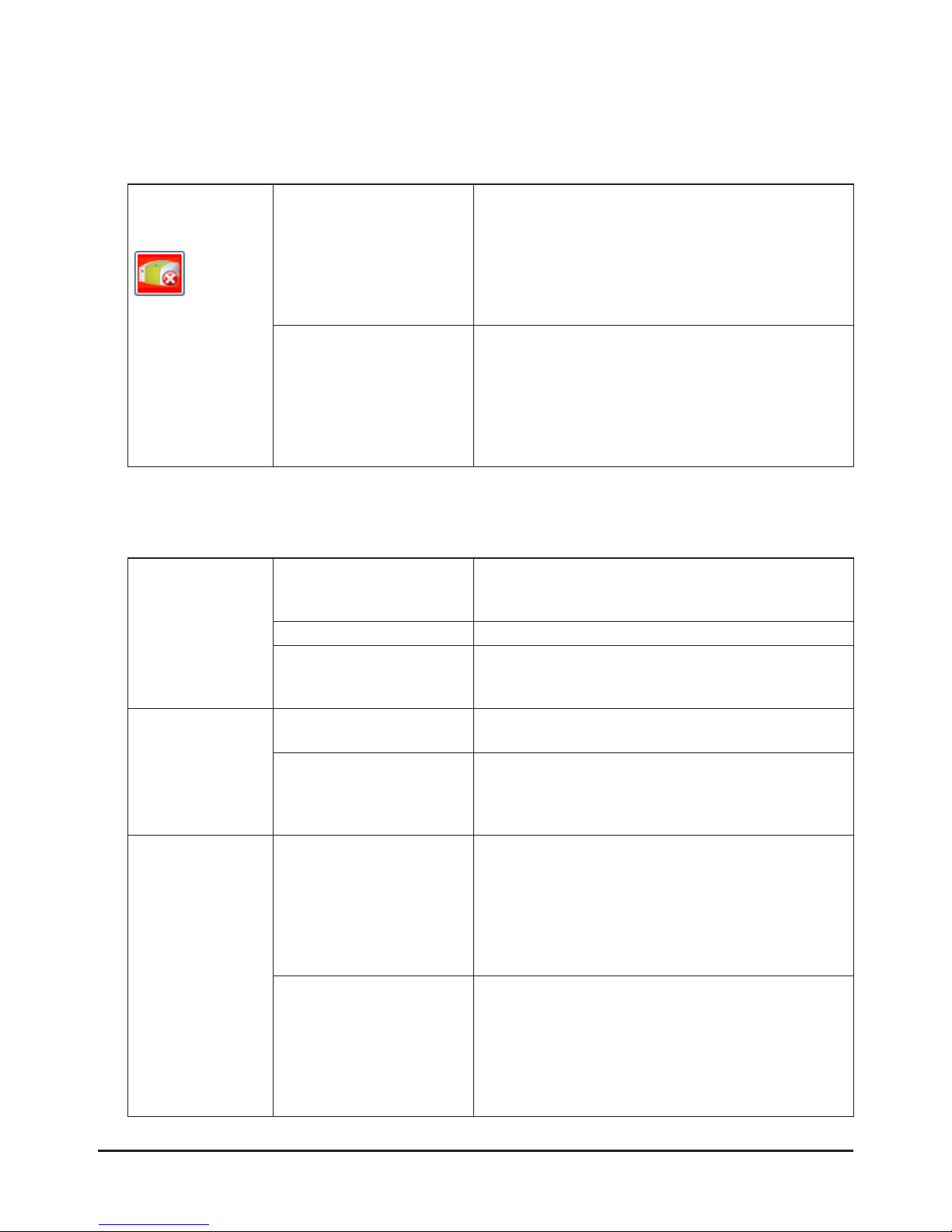

10. Wait for the instrument to initialize and then select the Test Connection button on the

utility screen.

Figure 22. Testing the connection

11.2 Changing from Direct Connection to Intranet Connection, continued

Direct Detect® Spectrometer User Guide

22

11.2 Changing from Direct Connection to Intranet Connection, continued

11. If the connection was successful, the instrument will produce a tone and a message

box will appear to inform you that the connection was successful. If an error message

appears, check with your IT department or contact Technical Service (section 17).

12. Select the Finish button to close the software. You should now be able to perform

measurements using the Direct Detect® instrument connected to your intranet.

11.3 Changing from Intranet Connection to Direct Connection

IMPORTANT: This section assumes that the Direct Detect® instrument and Netbook

computer are currently connected to your intranet using two standard RJ45 Cat5e

Ethernet cables.

1. Run the IP Address Change Utility (section 11.1) and confirm that the requirements

are all valid (green check marks).

2. Select the Next button to proceed to the IP Settings screen of the utility and select the

first option, I want to connect the instrument directly to the computer.

Figure 23. Selecting direct connection

3. Select the Next button to proceed.

4. The software will now make the necessary modifications to the Direct Detect® software

and instrument, as well as the host computer. If the modifications are successful you

will be informed that your instrument settings have been updated (Figure 24).

Direct Detect® Spectrometer User Guide

23

Figure 24. Successful reconfiguration to direct connection

5. Unplug the instrument from the power source, then change the switches in the red

4-position DIP switch (6H in Figure6) on the rear of the instrument so that the second

switch from the left is in the UP position, and all other switches are in the DOWN

position (refer to Figure 24).

6. Select the Next button to proceed.

7. Run the crossover 10Base-T cable with RJ45 connectors supplied with your instrument

between the ETH/LAN port on the rear of the instrument (6B in Figure 6) and the

network/LAN port on the computer (3B in Figure 3).

8. Reconnect power to the instrument.

9. Wait for the instrument to initialize and then select the Test Connection button on the

utility screen (Figure 25).

Figure 25. Testing the connection

10. If the connection was successful, the instrument will produce a tone and a message

box will appear to inform you that the connection was successful. If an error message

appears, check with your IT department or contact Technical Service (section 17).

11. Select the Finish button to close the software. You should now be able to perform

measurements using the Direct Detect® instrument connected directly to the computer.

11.3 Changing from Intranet Connection to Direct Connection, continued

Direct Detect® Spectrometer User Guide

24

11.4 Changing Computer Network Settings Manually

Typically the IP Address Changer software makes the appropriate modifications

automatically, however, in some cases you may need to do it manually.

1. To access the settings in the Windows® 7 operating

system, enter TCPIP in the search field. Select the

View network connections option in the control

panel section.

Figure 26. Accessing network connections in the Windows® 7 operating system

2. Select your network connection, and then select option Change settings of this

connection.

3. This opens the Local Area Connection Properties dialog. Select the connection

Internet Protocol Version 4(TCP/IPv4) and then select the Properties button to view

this connection’s properties.

Figure 27. Accessing the connection’s properties

Direct Detect® Spectrometer User Guide

25

4. Depending on the desired configuration, choose one of the following options:

For a direct connection between the Direct Detect® instrument and the computer,

enter the custom IP address 10.10.0.100 and subnet mask setting 255.255.255.0

(Figure28).

IMPORTANT: Do not change the settings on your computer until after you have run the

IP Address Change Utility to change the IP address on the instrument and the Direct

Detect® software (section 11.2).

Figure 28. IP address and subnet mask settings for direct connection

OR

For a connection between the Direct Detect® instrument and the computer via

your intranet, consult with your IT department. Typically the settings are set to obtain

the IP address automatically. However, some IT departments may issue fixed addresses.

Figure 29. IP address and subnet mask settings

IMPORTANT: Do not change the settings on your computer until after you have run the

IP Address Change Utility to change the IP address on the instrument and the Direct

Detect® software (section 11.3).

11.4 Changing Computer Network Settings Manually, continued

Direct Detect® Spectrometer User Guide

26

12 Troubleshooting

12.1 General Information

The status of the Direct Detect® spectrometer is indicated by both the instrument

status light (located on the top right side of the instrument under the Netbook tray (5E

in Figure5)) and the hardware diagnostics icon (located in the upper right corner of

the Direct Detect® Software user interface (Figure 30)). The status light and hardware

diagnostics icon colors are typically the same at any given time, and indicate the

following:

Green Instrument is in proper operating condition (flashing green on the instrument

indicates stand-by mode)

Yellow Instrument is initializing or indicating a warning (e.g., IR source has not yet

reached its operating temperature, the validity period of the instrument has

expired, the air humidity inside the spectrometer is too high)

Red Instrument has malfunctioned, or has a defective component, or an OQ/PQ test

has expired or failed

Figure 30. Direct Detect® Software user interface

Instrument internal

humidity icon

Instrument validation icon

and OQ/PQ initiator

Hardware diagnostics icon

Direct Detect® Spectrometer User Guide

27

Click on the hardware diagnostics icon and the hardware diagnostics dialog opens.

Figure 31. Hardware diagnostics dialog - Instrument Status

More information on hardware diagnostics is available in section 5.1 of the Direct Detect®

Software User Guide. If an issue cannot be resolved with the help of this diagnostics

section and/or the following troubleshooting tables, refer to section17 for information on

how to contact Technical Service.

12.2 Problems Indicated by Hardware Diagnostics Icon

Symptom Cause Corrective Action

Hardware

diagnostics icon

is yellow

Spectrometer is still in the

initialization phase.

Wait until spectrometer initialization is completed

(several minutes).

IR source has not yet

reached its operating

temperature.

The warm-up takes about 7 minutes. As soon as the

IR source has reached its operating temperature, the

hardware diagnostics icon will automatically turn

green. Wait until the warm-up is completed.

IR source is nearing end of

operational lifetime.

To confirm IR source issue, click on the hardware

diagnostics icon (Figure 30) to open the hardware

diagnostics dialog (Figure 31). If IR source is indicated,

refer to section 13.1 for instructions on how to replace

it.

Instrument internal

humidity is above tolerance

(also indicated by the

yellow internal humidity

icon, see section 12.5).

Wait 30 minutes to 24 hours for desiccant to remove

the humidity. If after 24 hours the icon is still yellow,

refer to section 13.2, Replacing the Desiccant.

12.1 General Information, continued

Direct Detect® Spectrometer User Guide

28

Symptom Cause Corrective Action

Hardware

diagnostics icon

is red

Instrument test has failed. To determine which instrument component is causing

the test failure, click on the hardware diagnostics icon

(Figure 30) to open the hardware diagnostics dialog

(Figure 31). If the laser, interferometer, electronics,

automation, or detector is defective, contact Technical

Service. If the IR source is defective, refer to section

13.1 for instructions on how to replace it.

A spectrometer component

is defective.

To find out which component is defective, click on

the hardware diagnostics icon (Figure 30) to open the

hardware diagnostics dialog (Figure 31). If the laser,

interferometer, electronics, automation, or detector is

defective, contact Technical Service. If the IR source is

defective, refer to section 13.1 for instructions on how

to replace it.

12.3 Problems Indicated by Instrument Status Light (top of instrument)

Symptom Cause Corrective Action

Spectrometer

status light does

not light

Spectrometer is not

connected properly to the

power supply.

Check the power cord connection at the power outlet

and the power port on the back of the spectrometer

(Figure 3).

No voltage is applied. Confirm proper voltage at the power outlet.

Short circuit in the adapter

or power cable.

A short circuit is accompanied by a “ticking” sound in

the power adapter. Unplug the power cord immediately

and contact Technical Service.

Spectrometer

status light is

yellow

Spectrometer is still in the

initialization phase.

Wait until spectrometer initialization is completed

(several minutes).

IR source has not yet

reached its operating

temperature.

The warm-up takes about 7 minutes. As soon as the

IR source has reached its operating temperature the

status light will automatically turn green. Wait until

the warm-up is completed.

Spectrometer

status light is red

Instrument test has failed. To determine which instrument component is causing

the test failure, click on the hardware diagnostics icon

(Figure 30) to open the hardware diagnostics dialog

(Figure 31). If the laser, interferometer, electronics,

automation, or detector is defective, contact Technical

Service. If the IR source is defective, refer to section

13.1 for instructions on how to replace it.

A spectrometer component

is defective.

To find out which component is defective, click on

the hardware diagnostics icon (Figure 30) to open the

hardware diagnostics dialog (Figure 31). If the laser,

interferometer, electronics, automation, or detector is

defective, contact Technical Service. If the IR source is

defective, refer to section 13.1 for instructions on how

to replace it.

12.2 Problems Indicated by Hardware Diagnostics Icon, continued

Direct Detect® Spectrometer User Guide

29

12.4 Problems Indicated by Instrument Validation Icon

Instrument validation problems are indicated by the Instrument Validation Icon (Figure 30).

Symptom Cause Corrective Action

Instrument

validation icon

is yellow

An instrument validation

test has expired.

To find out which instrument validation test has

expired, click on the instrument validation icon to

open the instrument validation dialog. Refer to section

5.2 of the Direct Detect® Software User Guide for

details on instrument validation.

Instrument

validation icon

is red

An instrument validation

test has failed.

To find out which instrument validation test has failed,

click on the instrument validation icon to open the

instrument validation dialog. Refer to section 5.2 of

the Direct Detect® Software User Guide for details on

instrument validation.

12.5 Problem Indicated by Instrument Internal Humidity Icon

Symptom Cause Corrective Action

Internal humidity

icon is yellow

Instrument internal

humidity is above

tolerance.

Click on the internal humidity icon to see what the

current humidity level is. If the instrument has been

on for more than 60minutes, and the humidity

warning is still displayed, replace the desiccant packets

in the rear compartment of the instrument. Refer to

section 13.2.

Direct Detect® Spectrometer User Guide

30

13 Maintenance

The Direct Detect® spectrometer is a low-maintenance instrument and the operator can replace

components with a limited service life. Replacing the IR source and desiccant are described in this

section.

Y

WARNING

Perform only the maintenance procedures described in this manual and observe the relevant safety

precautions. Failure to do so may cause property damage or personal injury.

Maintenance or repair procedures not described in this manual should be performed only by an

EMD Millipore Corporation service engineer. Refer to the Technical Assistance section for contact

information.

13.1 Replacing the IR Source

13.1.1 IR Source Status Indicator

The Direct Detect® spectrometer is equipped with a highly-efficient, low-power,

air-cooled infrared source with an average life span of 44,000 hours. As the end

of this life span is approached, the hardware diagnostics icon turns yellow. When

you click on the hardware diagnostics icon (Figure 30), the hardware diagnostics

dialog appears and displays the message End of lifetime is nearly reached

(Figure31). Samples can still be measured, but performance and reliability may

be compromised and the IR source (cat. no. DDSP00010-LA) should be replaced as

soon as possible.

If the source is defective, the hardware diagnostics icon turns red. When you click

on this icon, the hardware diagnostics dialog appears and displays the message No

source is connected. Samples can no longer be measured, and the IR source must

be replaced.

13.1.2 Replacing the IR Source

WARNING: During spectrometer operation the light source becomes very

hot. To avoid burns, wait until the light source has cooled down

before replacing it.

1. Unplug the instrument power plug.

2. On the back of the instrument, loosen the 4 cover plate Torx® screws with the

Torx®TX20 screw driver supplied (Figure32).

Direct Detect® Spectrometer User Guide

31

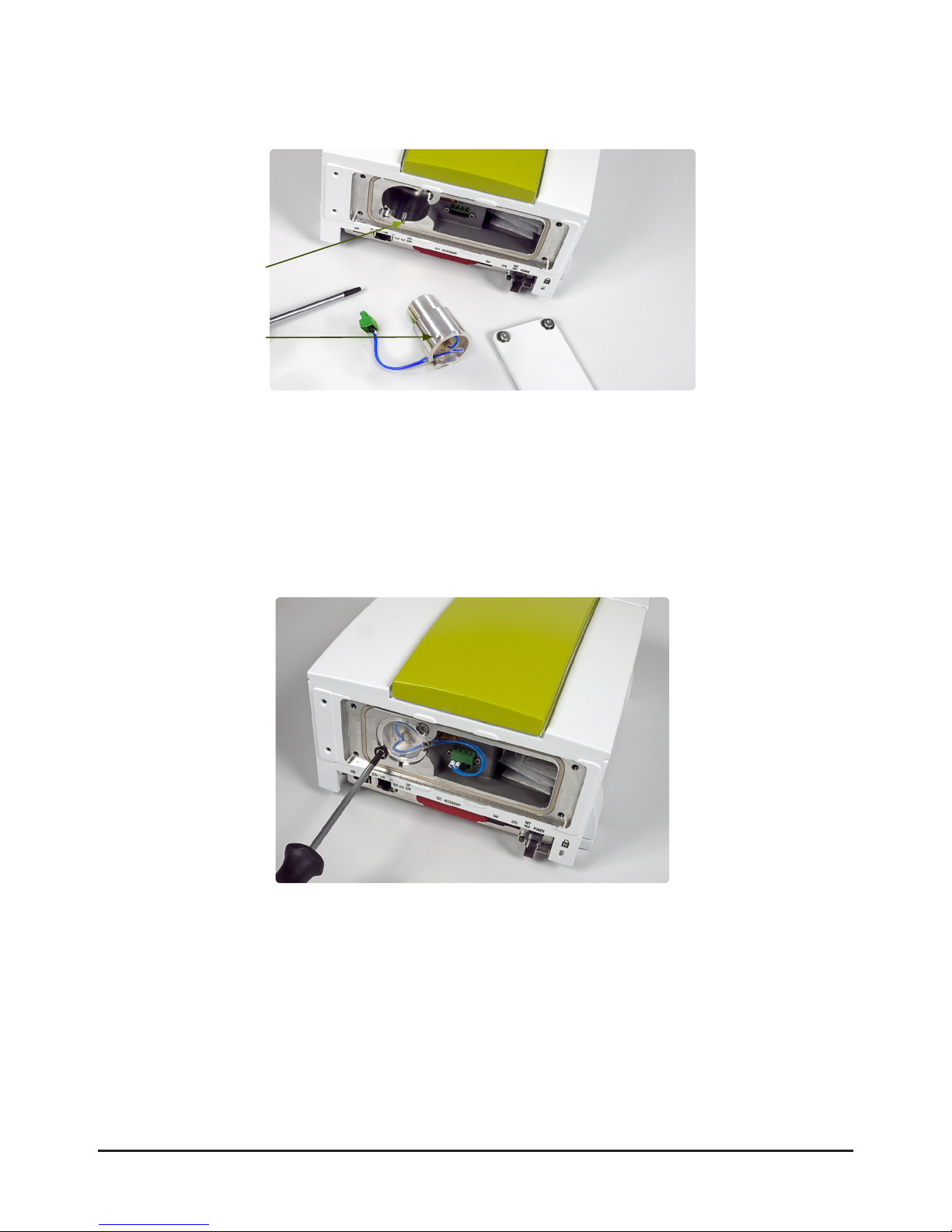

Figure 32. Removing the cover plate

Torx® screws

3. Take off the cover plate.

Figure 33. Removing the IR source

IR source

Source plug

IR source

Torx® screws

Alignment

groove

4. Loosen the two mounting screws on the IR source (Figure33) with the Torx®

screw driver.

5. Disconnect the green source plug (Figure33).

6. Pull the source out from the spectrometer housing.

13.1 Replacing the IR Source, continued

Direct Detect® Spectrometer User Guide

32

Figure 34. IR source removed from instrument

Alignment

groove

Alignment

pin

7. Insert the new IR source into the spectrometer housing. Make sure that the

alignment pin fits into the alignment groove (Figure 34).

8. Secure the source by fastening the two Torx® screws (Figure35) .

9. Plug the green source plug into the SRC female connector.

Figure 35. Replacing IR source Torx® screws

10. Attach the cover plate and fasten the 4 Torx® screws (Figure 32). Plug the

power plug into the power outlet again.

13.1 Replacing the IR Source, continued

Direct Detect® Spectrometer User Guide

33

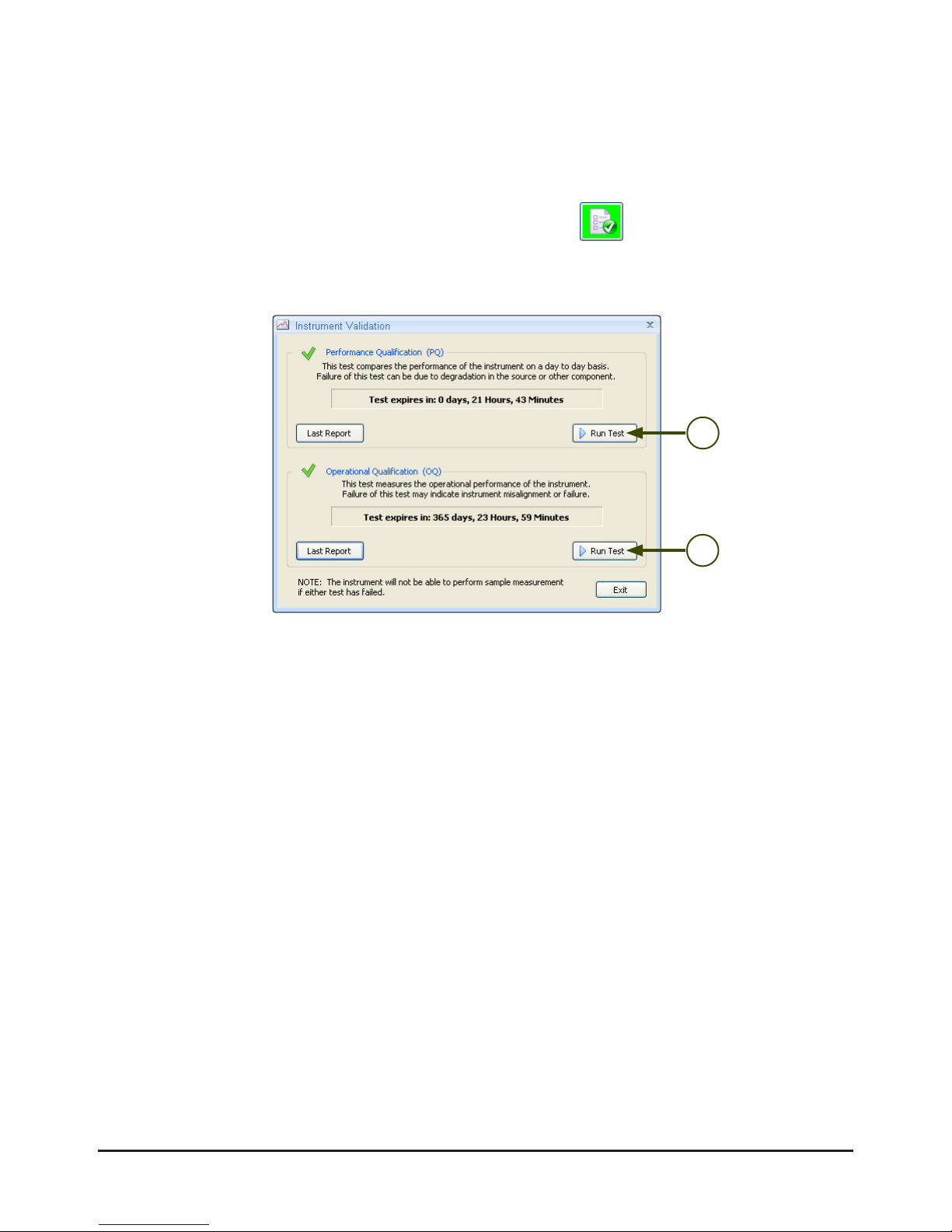

After replacing the IR source, perform the Performance Qualification and

Operational Qualification instrument tests as follows:

11. Click on the instrument validation button .

12. When the instrument validation dialog appears, click on the Performance

Qualification Run Test button (1 in Figure36). The test takes about 5 minutes.

Figure 36. Instrument validation dialog

2

1

13. After the test has finished, run the Operational Qualification test by clicking on

the Operational Qualification Run Test button (2).

14. If the instrument passes the test, the hardware diagnostics icon turns green.

If the instrument fails, refer to section 5.1 in the Direct Detect® Software User

Guide.

13.2 Replacing the Desiccant

Excessive humidity inside the spectrometer may cause H2O bands in the spectrum. To

reduce H2O bands to a minimum, the air inside the Direct Detect® instrument module is

convectively dried with a desiccant enclosed in a small, removable, multichambered pack.

If the desiccant is saturated and can no longer absorb humidity, it must be replaced.

Both the internal humidity icon (Figure 37) and instrument status light (on top of the

instrument, 5E in Figure 5) will turn yellow. When you click on the internal humidity icon,

a warning message with the current humidity level is displayed (Figure 37).

13.1 Replacing the IR Source, continued

Direct Detect® Spectrometer User Guide

34

Internal humidity icon

Figure 37. Instrument internal humidity warning

Measuring is still possible if the status light is yellow, but the desiccant should be replaced

as soon as possible.

Replace the desiccant as follows:

1. Unplug the power plug.

2. The desiccant is accessible from the rear side of the spectrometer. Loosen the 4Torx®

screws (Figure 32) with the Torx® screw driver supplied and take off the cover plate.

Figure 38. Replacing the desiccant

Desiccant

pack

3. Pull out the used desiccant pack. A pair of tweezers may be helpful.

13.2 Replacing the Desiccant, continued

Direct Detect® Spectrometer User Guide

35

13.2 Replacing the Desiccant, continued

4. Remove the external packaging from the replacement desiccant pack.

5. Insert the desiccant pack properly into the spectrometer as shown in Figure38.

Y

CAUTION: Do not cut or tear the pack into single pieces or ingest the desiccant.

6. Attach the cover plate and fasten the 4 Torx® screws again (Figure32).

7. Plug the power plug into the power outlet again. After the new desiccant removes the

moisture from the chamber (approximately 30 minutes), the instrument status light

and hardware diagnostics icon will turn back to green.

13.3 Cleaning

The outer spectrometer surface can be cleaned with a damp or dry cloth. Do not use

detergents with organic solvents, acids, or bases!

Y

CAUTION: Do not try to clean the interior of the spectrometer as this may lead to

serious spectrometer damage.

Direct Detect® Spectrometer User Guide

36

13.4 Description of Instrument Validation Tests

13.4.1 Performance Qualification Test (PQ)

The Performance Qualification test evaluates the spectroscopic performance and

confirms proper function of the IR spectrometer. To ensure that the instrument is

working properly, it is recommended that the PQ test be run on a weekly basis.

The factory default interval for the PQ test is one week. One week from the last PQ

test, the software will alert you to run the instrument PQ test again. You can use

the instrument with an expired PQ test, but the software will query you each time

a measurement is initiated, asking if you wish to proceed under the expired PQ

condition.

The PQ test protocol consists of the following three tests:

●Signal-to-noise test: The signal-to-noise ratio determines the sensitivity of

the spectrometer by calculating the average signal-to-noise ratio of ten 100%

spectra. A 100% spectrum is the ratio of two successively acquired singlechannel spectra with no sample in the sample compartment. The ratio of these

two single-channel spectra is used to generate a transmission spectrum.

●100% Line Test: This test verifies that the 100% line does not shift over time.

It measures the maximum deviation of a 100% line within a larger frequency

range. The average of ten measurements must not exceed the predefined limit.

●Wavenumber Accuracy Test: - This test ensures that the frequency calibration

of the instrument is within the defined limits using an internal polystyrene

standard sample.

Direct Detect® Spectrometer User Guide

37

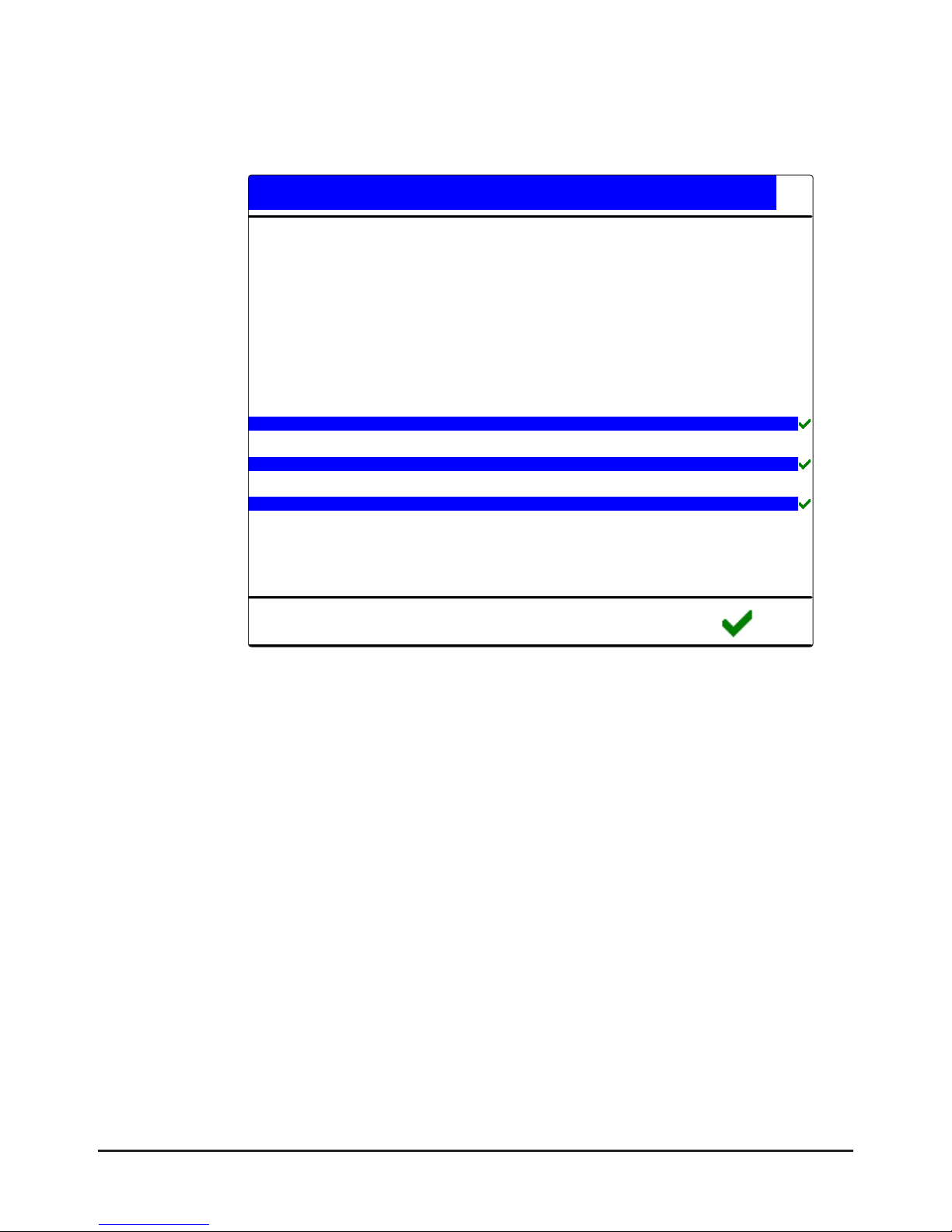

Figure 39 shows a successful PQ test report.

OVP - PQ Test Protocol

Company :

Operator:

Instrument Ty pe:

Optics Configuration:

Accessory:

Instrument Serial Number:

Instrument Fir mwar e Ver sion:

OPUS/DB Version:

Overall Tes t Result

Test expires:

Test Date/Time:

Test Spectra Path:

Date of last PQ Ref erenc e Measurement

Comment:

MILLIPORE

Default

Alpha Sample Compartment RT-DLaTGS ZnSe

Fibre 1 w ith: MIR, KBr, RT- DLATGS [Internal Pos.1]

Millipore Dir ect-Det ec t

M3

1.320_MDD_01 Oct 27 2011

OPUS 7.0 Build: 7, 0, 122 / DB: 7.0.105.1106 for OPUS 7.0

PA SSED

12/25/2011, 3:12:41 PM (GMT-5)

12/15/2011, 3:12:41 PM (GMT-5)

C:\Dire ct Detect\V alidation\Data\20111215\151241

Signal to Noise Te st

Minim um Signal to Noise L imit (are a 1): 1000 Signal to Noise m eas ured: 3458

100% Line T es t

Maxim um 100% Line Deviation: 2.0 M eas ured 100% Line Deviation: 0.29

Wavenum ber Accur acy Te st - Polystyr ene (35.5 Deg. C, Pe ak is T. cor r.)

Sample Mater ial:

Specifie d Peak:

Measured Peak:

Cor re cted Pe ak:

1601.45 cm -1

1601.13 cm -1

1601.25 cm -1

Polys tyren e

Maxim um Deviation:

Me asu re d Deviation :

0.50 cm -1

0.20 cm -1

Overall Test Result = PASSED

Figure 39. PQ test report

13.4.2 Operational Qualification Test (OQ)

The Operational Qualification test checks instrument performance and compares

this performance to the instrument specifications. The OQ test is performed during

final testing before an instrument is delivered to the customer. It should also be

performed after each major repair, after replacement of optical components which

may influence the instrument performance, and after maintenance has taken place.

The factory default interval for the OQ test is 12 months. Twelve months from the

last OQ test, the software will alert you to run the instrument OQ test again. You

can use the instrument with an expired OQ test, but the software will query you

each time a measurement is initiated, asking if you would like to proceed under the

expired OQ condition.

The OQ test protocol consists of the following four tests:

●Wavenumber Resolution Test: This test verifies the achievable spectrometer

resolution by measuring a single-channel (single-beam) spectrum of the water

vapor available inside the spectrometer, using the maximum available resolution.

13.4 Description of Instrument Validation Tests, continued

Direct Detect® Spectrometer User Guide

38

●Signal Sensitivity Test: This test is the same as the PQ signal-to-noise test,

except that the spectra are measured in a very small region (2,200–2,100 cm-1).

●Energy Distribution Test: This test verifies the achievable frequency range and

the energy at the maximum position of the single-channel spectrum. Absolute

values of energy are measured at different wavenumber positions. These values

are divided by the maximum value achieved, and compared to acceptance values

indicated in percent. Optical components (e.g., detector, source, and beam

splitter) as well as the card holder have an effect on the limits of the frequency

range.

●Wavenumber Accuracy Test: The wavenumber accuracy test verifies that the

frequency calibration of the spectrometer is within defined limits. Water vapor

is used for this test because it has extremely narrow bands, and the position of

these bands can be measured with a very high degree of accuracy.

Figure 40 shows a successful OQ test report.

OVP - OQ Test Protocol

Company :

Operator:

Instrument Ty pe:

Optics Configuration:

Accessory:

Instrument Serial Number:

Instrument Fir mwar e Ver sion:

OPUS/DB Version:

Overall Tes t Result

Test expires:

Test Date/Time:

Test Spectra Path:

Comment:

MILLIPORE

Default

Alpha Sample Compartment RT-DLaTGS ZnSe

Fibre 1 w ith: MIR, KBr, RT- DLATGS [Internal Pos.1]

Millipore Dir ect-Det ec t

M3

1.320_MDD_01 Oct 27 2011

OPUS 7.0 Build: 7, 0, 122 / DB: 7.0.105.1106

PA SSED

12/16/2012, 9:32:23 AM (GMT- 5)

12/16/2011, 9:32:23 AM (GMT- 5)

C:\Dire ct Detect\V alidation\Data\20111216\093223

Resolu tion Te st

Water Vapor Band:

Maxim um Reso lution:

1554.35 cm -1

2.00 cm -1 Measure d Resolution: 1.63 cm-1

Sens itivity Te st

Me asu re m ent Region , Start:

Minim um S/N:

2200.00 cm -1

2000

Meas urem ent Re gion, End:

Me asu re d S/N:

2100.00 cm -1

3446.07

Ener gy Dis tr ibution Tes t

Minim um Energy Value :

Minim um Energy Value :

Energ y at 7500.00 cm -1

5.00%

0.20%

0.01%

Energ y at 5000.00 cm -1

Ener gy at 500.00 cm- 1

9.14%

4.67%

Wavenu m be r Accuracy T es t Water Vap or

Expecte d Band:

Maxim um Deviation:

1576.130 cm -1

0.050 cm -1

Meas ured Band:

Me asu re d Deviation :

1576.129 cm -1

0.001 cm -1

Figure 40. OQ test report

13.4 Description of Instrument Validation Tests, continued

Direct Detect® Spectrometer User Guide

39

13.5 Running the Instrument Validation OQ and PQ Tests

1. Make sure card holder is empty.

2. To run OQ and/or PQ tests, click on the instrument validation icon .

3. When the instrument validation dialog appears, click on the Performance Qualification

(PQ) Run Test button (1 in Figure41). The test takes about 5 minutes.

Figure 41. Running OQ/PQ tests

2

1

Instrument validation

icon and OQ/PQ

Initiator

4. To run the Operational Qualification (OQ) test click on the Operational Qualification

Run Test button (2). The test takes about a minute to run.

For information on interpreting test failures, refer to section 12.4.

13.6 Storage

Store the Direct Detect® spectrometer and Assay-free cards in a clean, dry environment

at 15–30 °C.

Direct Detect® Spectrometer User Guide

40

14 Installation, Operation, and Process Qualification

Protocol (Optional)

NOTE: A 2 mg/mL protein standard (e.g., Thermo Scientific Pierce® or Bio-Rad® Bovine Serum

Albumin Standard ) is required for the protein verification test (section 14.5).

14.1 Installation Qualification Protocol (IQ)

NOTE: The installation qualification should be performed prior to making any local

modifications to the PC software.

1. Set up the system as instructed in section 6.5.1.

2. Verify that the Direct Detect® system starts the initialization sequence and that

successful completion is indicated by the status indicator light (5E in Figure 5) turning

green. Document results on the IQ/OQ/PQ Report Summary page found in section14.6.

14.2 Instrument Hardware Diagnostic Protocol

1. Access the Direct Detect® software by double-clicking on

the icon on the Netbook desktop.

2. Log into the instrument using the “Administrator” user name and password

“directdetect”. Once in the User Management screen, create a user name with

administrator privileges to run the OQ/PQ tests below. Refer to section 1.2.4, User

Management, in the Direct Detect® Software User Guide.

3. Click on the hardware diagnostics icon to open the hardware diagnostics dialog

(Figure42).

Direct Detect® Spectrometer User Guide

41

Figure 42. Instrument status

Hardware diagnostics icon

4. A green check mark indicates that each of the systems is functioning correctly. If

any systems do not have a green check mark, refer to section 5, Diagnostics, in the

Direct Detect® Software User Guide. Correct the problem, then click on the hardware

diagnostics icon to verify that all of the check marks are green.

Select the save button to save the hardware diagnostics report file to the

hard drive (C:\DirectDetect\Validation\Reports).

Select the print button to print the report to an installed printer.

5. Document results on the IQ/OQ/PQ Report Summary.

14.2 Instrument Hardware Diagnostic Protocol, continued

Direct Detect® Spectrometer User Guide

42

14.3 Operation Qualification Protocol (OQ)

1. Click on the instrument validation icon to open the instrument validation dialog box.

Figure 43. Instrument validation dialog

2

1

2. Click on the Operational Qualification (OQ) Run Test button (2). This starts a system

check that takes several minutes to complete. Run this test regardless of the test

expiration date. A report displaying the OQ test results will be generated and stored in

C:\DirectDetect\Validation\Reports. The report can be viewed and printed by clicking on

the button. Document results on the IQ/OQ/PQ Report Summary.

14.4 Performance Qualification Protocol (PQ)

1. After the OQ test has been successfully completed, run the PQ test by clicking on the

Performance Qualification (PQ) Run Test button (1). Run this test regardless of the

test expiration date. A report displaying the PQ results will be generated and stored in

C:\DirectDetect\Validation\Reports. The report can be viewed and printed by clicking on

the button. Document results on the IQ/OQ/PQ Report Summary.

14.5 Protein Measurement Verification

1. After successful completion of the OQ and PQ tests, the system is ready to verify that a

protein spotted on the card is equivalent to a standard.

2. Open a new vial of BSA standard.

3. Place the Assay-free card(s) on the spotting tray or other clean surface. Select an

appropriate buffer blank, preferably the same solution in which the BSA standard has

been prepared. The majority of commercially available BSA standards use NaCl (with

NaN3) as a buffer; check manufacturer specifications. Pipette exactly 2 µL of the buffer

solution to the default blank position on the card (position1).

Direct Detect® Spectrometer User Guide

43

14.5 Protein Measurement Verification, continued

4. Pipette exactly 2 µL of sample to sample positions 2 through 4. Card positions can be

labeled if desired.

5. In the Direct Detect® Software main screen, complete the measurement setup as

indicated in Figure 44. Choose NIST BSA AM1 from the protein drop down menu and

check the Dry sample card box. Sample location 1 should be blue, indicating that the

buffer solution is in this location. Sample locations 2–4 should be green, indicating

that there is a sample to be measured.

Figure 44. Sample information

6. Follow the instructions in section 10.2 for inserting the sample card into the

instrument, then click on the button.

7. The sample measurement results are displayed on the Last Sample Result tab of the

main screen.

8. Measure the BSA standard concentration using a UV reader at 280 nm.

DO NOT use standard curves built into the UV reader. Use the sequence-based

extinction coefficient 42,925 M-1cm-1 or ABS 1 mg/mL = 0.646. Zero the UV instrument

with the correct buffer and read absorbance at 280 nm.

9. Manually calculate the correct concentration using the sequence-based numbers. The

system passes the protein verification test if the results from the UV reader and the

Direct Detect® system are within 10% of one another. Document results on the

IQ/OQ/PQ Report Summary.

NOTE: The Direct Detect® system comes pre-loaded with standard curves that

were generated from phosphate-buffered saline (PBS). Analysis from buffers

like NaCl with NaN3 delivers accurate quantification if the measurement is

performed in a room with humidity level below 35%. Humidity levels above

35% will affect sample drying, resulting in artificially increased concentration

estimates.

Direct Detect® Spectrometer User Guide

44

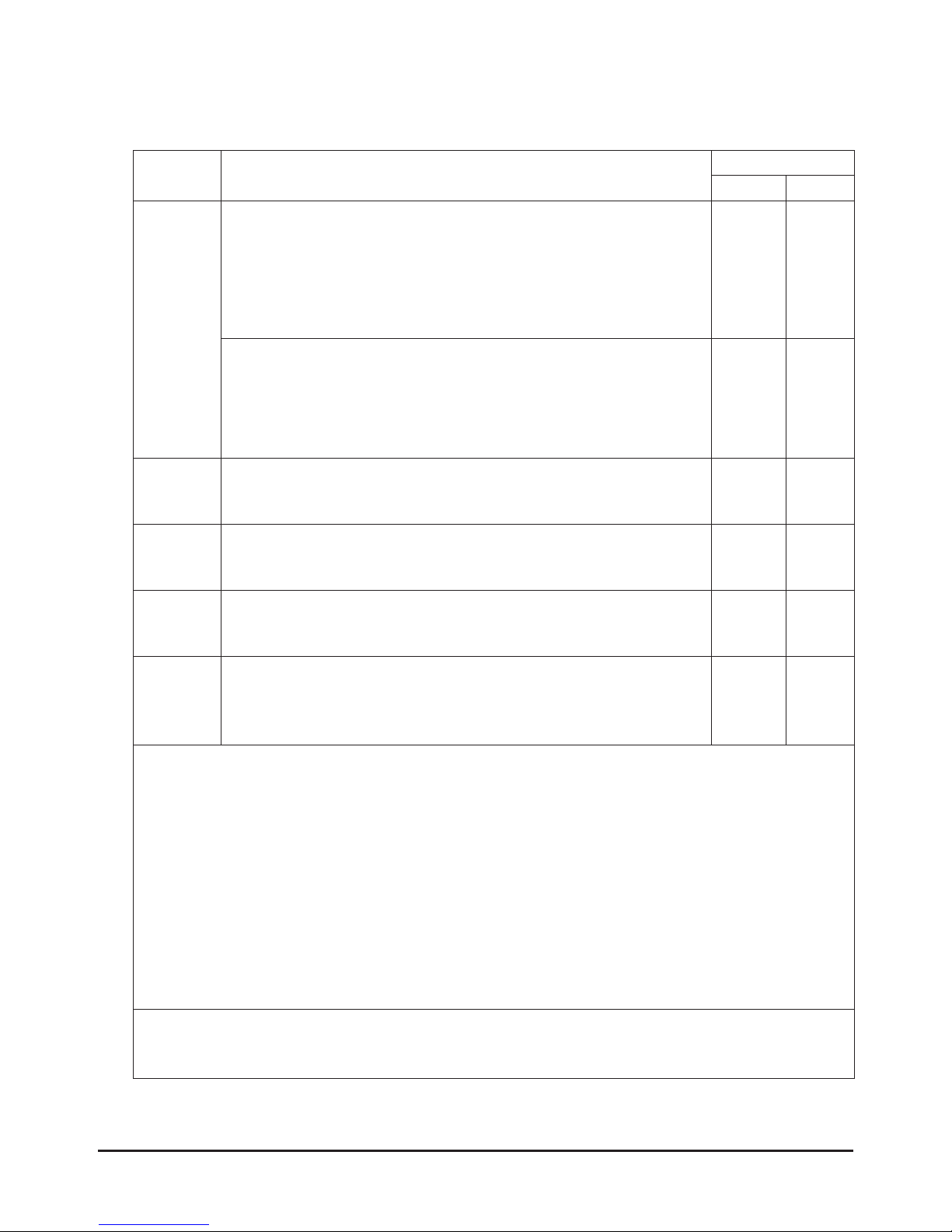

14.6 Direct Detect® System IQ/OQ/PQ Report Summary

Reference

Section

Checklist Result

Pass Fail

14.1 Verify power and cable connections

● Power adapters are connected to Netbook computer and

Direct Detect® instrument

● Verify connection between Netbook computer and Direct

Detect® instrument (cross over cables)

Verify Software communication

● Direct Detect® Software launches successfully

● Login successful

● Instrument detected

14.2 Instrument Hardware Diagnostic

● All functions have green check mark

14.3 System OQ

● OQ test report indicates Overall Test Result = PASSED

14.4 System PQ

● PQ test report indicates Overall Test Result = PASSED

14.5 Verification of Protein Measurement

● Direct Detect® measurement and UV reader measurement

are within 10% of one another for a 2 mg/mL BSA standard.

Testing completed by:

Date:

Direct Detect® Spectrometer User Guide

45

15 Specifications

General

Dimensions 22 cm wide x 30 cm deep x 15.2 cm high (including tray)

(8.7 x 11.8 x 6.0 in.)

NOTE: Overall height with Netbook computer opened will vary,

but is typically less than 40.6 cm (16 in.).

Weight (approximate) 7 kg (15.4 lb)

Power consumption Maximal: 100–240 VAC, 50–60 Hz (max 2 A)

Electronics Class 1 laser product (contains 850 nm laser diode)

Environmental conditions Operational temperature range: 18–35 °C (64–95 °F)

Temperature variation: max. 1 °C/h and max. 2 °C/day

Humidity (non-condensing): less than 35% (relative humidity)

Humidity variation: less than 3%/hr

Installation site: in a closed room, max. 2,000 m above sea level

Installation overvoltage category: II

Pollution degree: 2

Safety regulations Complies with EN/IEC 61010-1/08.2002 (Safety requirements for

electrical equipment for measure ment, control and laboratory use)

EMI regulations Complies with EN/IEC 61326/05.2004 (Electrical equipment for

measurement, control and laboratory use - EMC requirements)

Performance

Spectral range 6,000–500 cm

-1

Resolution Better than 2 cm

-1

Wave number accuracy Better than 0.05 cm

-1

Wave number reproducibility Better than 0.01 cm

-1

Photometric accuracy 0.1% T

Optics

Design Sealed optics housing, convective desiccating

IR Source Low voltage, air cooled, can be replaced

(lifetime 44,000 operating hours)

Computer Specifications

Operating System Microsoft® Windows® 7

Software Framework Microsoft®.NET Framework 2.0

Screen Resolution 1,024 x 600 or greater

Ethernet Cable Crossover, 10Base-T (10 or 10/100 MBit) with RJ45 connectors

Processor Intel® Pentium® III, 800 MHz or greater

Random Access Memory (RAM) 2 GB

Graphics Card XVGA, 256 Mb RAM, 32-bit color depth, Open GL, GDI+

Direct Detect® Spectrometer User Guide

46

16 Ordering Information

This section lists catalogue numbers for the Direct Detect® spectrometer and replacement parts. See

Technical Assistance section for contact information. You can purchase these products on-line at

www.millipore.com/products.

Product Description Cat. No. Qty/Pk

Direct Detect® Spectrometer

Direct Detect® Spectrometer (includes instrument with power

adapter*, Dell® Netbook computer with power adapter*,

Ethernet crossover cable, Netbook computer stand, 50-pack

of Assay-free cards, spotting tray, spare desiccant bag, Torx®

screw driver, Quick-Start Guide)