Page 1

4

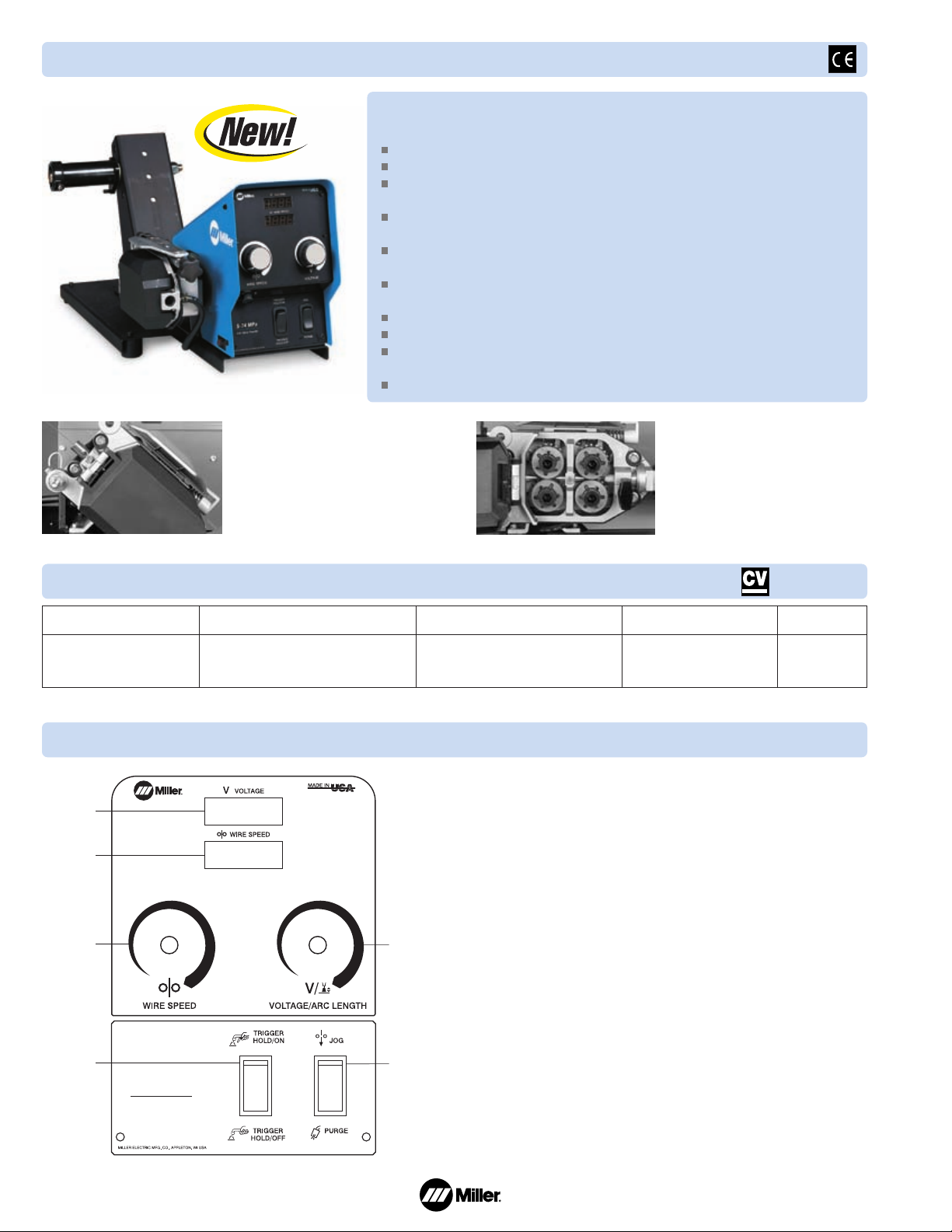

S-74 MPa Single Feeder Features

Dual tension control adds flexibil ity

for the operator to fine-tune the

pressure on the wire independently

when feeding a variety of wires.

Tool-less rotatable drive assem bly

allows operator to rotate the drive

housing, eliminating severe bends in the

wire feed path which reduce gun liner

life. Also aids in feeding difficult wires.

1. Voltage Display Meter

2. Wire Speed Display Meter

3. Wire Feed Speed Select

4. Trigger Hold

5. Voltage Select

6. Jog/Purge

Input Power

24 VAC, 10 A, 50/60 Hz

Wire Speed

50–780 IPM (1.3 –19.8 m/min)

Optional High Speed Motor:

90–1440 IPM (2.3 – 36.6 m/min)

Electrode Wire Diameter Capacity

.023–5/64 in (0.6 – 2 mm)

Net Weight

58 lb (26 kg)

Dimensions

H: 14 in (356 mm)

W: 12 in (305 mm)

D: 26-1/2 in (673 mm)

Specifications

(Subject to change without notice.)

(Use with CV

Power Sources.)

Posifeed™Wire Drive Assembly Features

(Synergic Pulsed MIG when connected to the Invision 350 MPa)

24 VDC high-torque, permanent-magnet motor.

Quick-change drive rolls.

Quick-release, calibrated drive-roll pressure adjustment arm allows drive roll change

without losing spring preload setting.

Four sealed ball bearing all-gear-driven drive-roll carriers for smooth, positive and

accurate wire feed with long uninterrupted service life.

Easy loading and threading of welding wire with out having to release the drive-roll

pressure arm.

Solid-state speed control and brake circuit eliminates the need for electrical/

mechanical relays and increases service life.

Uses Miller standard 1-5/8 in (41 mm) diameter drive rolls.

Quick-connect for all Miller guns.

Covered drive rolls — easy access, heavy-duty, molded composite cover over

drive assembly.

Floating positive drive systems provide trouble-free feeding on a variety of wires.

Control Panel

1

2

3

4

S-74 MPa

24V Wire Feeder

5

6

Loading...

Loading...