Miller Electric PRO 300 User Manual

PRO 300

|

Industrial Applications |

Processes |

|

Pipe Welding |

Stick (SMAW) |

Quick |

Structural Steelwork |

MIG (GMAW) |

Fabrication |

Flux Cored (FCAW) |

|

Maintenance |

DC TIG (GTAW) |

|

Specs |

Repair |

Rated: 3/16 in (4.8 mm) carbons, |

|

Air Carbon Arc (CAC-A) |

|

|

|

Capable: 1/4 in (6.4 mm) carbons |

|

|

Air Plasma Cutting and Gouging with |

|

|

optional Spectrum models |

|

|

|

Issued May 2008 • Index No. ED/5.21

Engine-Driven Welder/

AC Generator

Output Range DC Stick 40 – 410 A

DC TIG 20 – 410 A

FCAW/MIG 14 – 40 V

Generator Output Rated at 104˚ F (40˚ C)

12,000 Watts Peak

10,000 Watts Continuous

Accu-Rated™– Not Inflated

Generator Power

The Power of Blue®.

The Professional Welder’s Choice — designed with the professional in mind, the PRO 300 is the best for ease of

use, reliability and fuel economy.

Superior arc performance

•Four preset DIG settings (Stick)

•Hot Start™ (Stick)

•Lift-Arc™ TIG with Auto-Stop™ and Crater-out

•MIG/FCAW arc performance

Tailored Arc Control (DIG) allows the arc characteristics to be changed for specific applications and electrodes. Smooth running 7018 or stiffer, more penetrating 6010 electrodes.

Simple-to-set controls require no elaborate procedure — just select process and weld!

Auto Remote Sense (ARS) detects if a remote control is plugged into the 14-pin receptacle and eliminates confusion of a remote/panel switch.

The Vault — ultimate control board reliability. See page 4.

Superior Arc

Performance!

Standard features include: Stick, Lift-Arc™ TIG, Flux Cored and MIG. Other features include digital preset weld meters, output contactor control, and automatic idle.

Welder/generator is warranted by Miller for 3 years, parts and labor. Engine is warranted 3 years by engine manufacturer.

Heavy-Duty Low-Speed

Industrial Engine Choices!

CATERPILLAR C1.5, 21.7 HP @ 1800 RPM industrial engine

Deutz D2008 L04,

24.3 HP @ 1800 RPM

24.3 HP @ 1800 RPM

industrial engine

industrial engine

Designed to operate over 10,000 hours before the first basic overhaul. Backed by worldwide support and service.

Meter maintenance displays.

•Hour meter function

•Oil change interval

•High coolant temperature and low oil pressure shutdowns

•Low fuel shutdown — engine shuts downs before system runs out of fuel, making restarts easy.

Quiet operation: Improves work site communication.

Thermal overload protection prevents machine damage if the duty cycle is exceeded or airflow is blocked.

Optional Stainless Steel Appearance Package provides additional exterior protection to withstand corrosive environments.

|

|

|

|

|

Miller Electric Mfg. Co. |

International Headquarters |

Web Site |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

An Illinois Tool Works Company |

Phone: 920-735-4505 |

www.MillerWelds.com |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

1635 West Spencer Street |

USA FAX: 920-735-4134 |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Appleton, WI 54914 USA |

Canadian FAX: 920-735-4169 |

|

|

|

|

|

|

|

|

|

|

International FAX: 920-735-4125 |

|

|

|

|

Specifications (Subject to change without notice.)

Weld |

Weld Output |

Weld Output Rated |

Max. Open- |

Generator Power Output |

Sound Levels at Rated |

|

Net Weight |

|

Mode |

Range |

at 104˚ F (40˚C) |

Circuit Voltage |

Rated at 104˚ F (40˚C) |

Output, 7 m (23 ft) |

|

Dimensions |

(without fuel)* |

|

|

|

|

|

|

|

|

|

CC/DC |

20 – 410 A |

400 A, 20 VDC, |

65 |

12,000 Watts Peak |

CAT: |

|

H: 32 in |

CAT: |

|

|

30% Duty Cycle |

|

10,000 Watts Continuous |

71 dB (96 Lwa) |

|

(813 mm) |

Net: 1128 lb (512 kg) |

|

|

300 A, 32 VDC, |

|

Single-phase, 120/240 VAC, |

Deutz: |

|

W: 26-1/4 in |

Ship: 1150 lb (522 kg) |

|

|

60% Duty Cycle |

|

83/42 A 60 Hz |

73 dB (98 Lwa) |

|

(667 mm) |

Deutz: |

CV/DC |

14 – 40 V |

|

|

|

|

|

D: 56 in |

Net: 1208 lb (548 kg) |

|

|

|

|

|

(1422 mm) |

Ship: 1230 lb (558 kg) |

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

CSA approved. Meets NEMA and IEC output ratings. |

|

|

*Additional 82 lb (37 kg) when fuel tank is full. |

|||||

Engine Specifications (Engines warranted separately by the engine manufacturer.)

|

|

|

|

Engine |

Fuel |

Oil |

Coolant |

Automatic Engine |

Engine Brand |

Features |

HP |

Type |

Speeds |

Capacity |

Capacity |

Capacity |

Shutdown |

|

|

|

|

|

|

|

|

|

CATERPILLAR |

EPA Tier III indirect-injected liquid-cooled |

21.7 |

3-cylinder, industrial |

1850 RPM weld |

11.5 gal |

6 qt |

6 qt |

Low Oil Pressure, |

C1.5 |

engine. Right side service access with |

|

liquid-cooled, diesel |

(1500 RPM idle) |

(43.5 L) |

(5.7 L) |

(5.7 L) |

High Coolant |

|

intervals of 250 hrs for oil and filters. |

|

|

|

|

|

|

Temperature, |

|

|

|

|

|

|

|

|

Low Fuel Level |

Deutz D2008 |

EPA Tier IVi indirect-injected liquid-cooled |

24.3 |

4-cylinder, industrial |

1800 RPM weld |

|

|

|

|

|

|

|

|

|||||

L04 |

engine. Right side service access with |

|

liquid-cooled, diesel |

(1500 RPM idle) |

|

|

|

|

|

intervals of 250 hrs for oil and filters. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

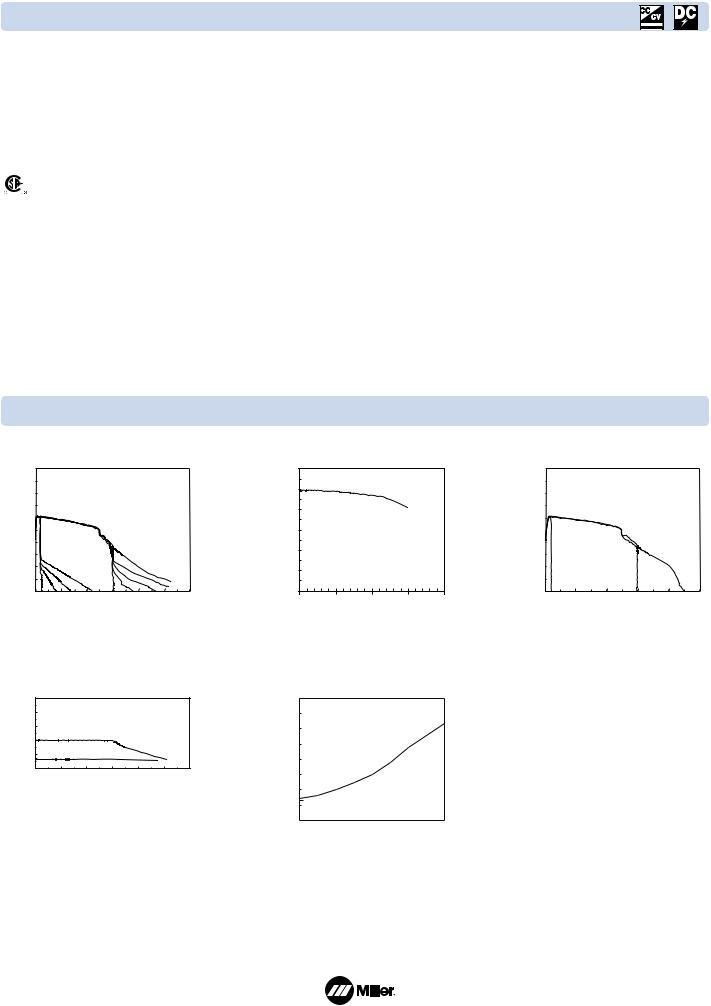

Performance Data

STICK MODE V/A CURVE – MAX DIG

|

100 |

|

|

|

|

|

|

|

90 |

|

|

|

|

|

|

VOLTS |

80 |

|

|

|

|

|

|

70 |

|

|

|

|

|

|

|

|

60 |

|

|

|

|

|

|

DC |

50 |

|

|

|

|

|

|

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

MIN |

|

300 |

|

|

|

|

20 |

|

|

|

MAX |

|

|

|

|

|

|

|

|

||

|

10 |

|

|

|

|

|

|

|

0 |

100 |

200 |

300 |

400 |

500 |

600 |

|

0 |

||||||

|

|

|

DC AMPERES |

|

|

||

MIG MODE V/A CURVE

100

VOLTS |

80 |

|

40 |

|

|

|

60 |

MAX |

|

|

|

DC |

20 |

MIN |

|

0 |

|

0 100 200 300 400 500 600

DC AMPERES

GENERATOR POWER CURVE

|

150 |

300 |

|

|

|

|

|

VOLTS |

125 |

250 |

|

|

|

|

|

100 |

200 |

|

|

|

|

|

|

|

|

|

|

|

|

||

AC |

75 |

150 |

|

|

|

|

|

50 |

100 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

25 |

50 |

|

|

|

|

|

|

0 |

0 |

0 |

20 |

40 |

60 |

80 |

|

|

|

|

AC AMPERES IN 240 V MODE |

|

||

|

|

|

0 |

40 |

80 |

120 |

160 |

|

|

|

|

AC AMPERES IN 120 V MODE |

|

||

FUEL CONSUMPTION CURVE

|

2.00 |

|

GAL/HR. |

1.75 |

|

1.50 |

|

|

|

|

|

|

1.25 |

|

U.S. |

1.00 |

|

0.75 |

|

|

|

0.50 |

|

|

0.25 |

IDLE |

0.00

0 50 100 150 200 250 300 350 400

0 50 100 150 200 250 300 350 400

DC WELD AMPERES

AT 100% DUTY CYCLE

DC TIG MODE V/A CURVE

|

100 |

|

|

|

|

|

|

90 |

|

|

|

|

|

VOLTS |

80 |

|

|

|

|

|

70 |

|

|

|

|

|

|

|

60 |

|

|

|

|

|

DC |

50 |

|

|

|

|

|

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

MIN |

|

300 |

|

|

|

20 |

|

MAX |

|

||

|

|

|

|

|||

|

|

|

|

|

||

|

10 |

|

|

|

|

|

|

0 |

100 |

200 |

300 |

400 |

500 |

|

0 |

|||||

|

|

|

DC AMPERES |

|

|

|

SIMULTANEOUS WELDING AND POWER

Weld |

Total Power |

|

|

Amperes |

Available (Watts) |

120 V |

240 V |

|

|

|

|

225 |

3000 |

25 |

12.5 |

175 |

5000 |

41.6 |

20.8 |

125 |

5900 |

49.2 |

24.6 |

75 |

7300 |

60.8 |

30.4 |

25 |

10,000 |

83.5 |

41.7 |

|

|

|

|

2

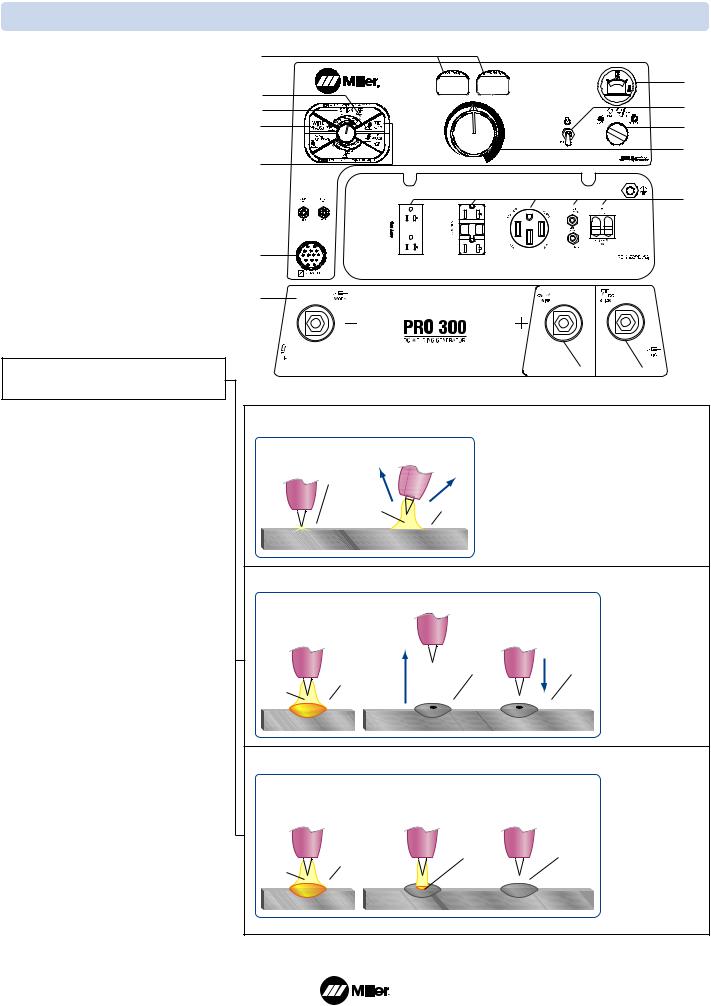

Function Guide

1.Self-calibrating digital weld meters with meter maintenance displays.

2.Four Preset DIG Settings offer the best arc characteristics for different electrodes and joint designs. The amount of DIG determines how much amperage (heat) varies with Stick arc length. The combined Process switch along with preset DIG settings make the PRO 300 easy to set

without the complication of multiple switches.

3.Hot Start™ provides positive Stick electrode starts making it easy to start all types of electrodes and it also works great for bead tie-ins.

4.Great MIG/FCAW Performance and Arc Starts make the PRO 300’s arc best in its class. Easy to run all wires from .023 in solid wires to large diameter 5/64 in

flux cored wires.

5.Lift-Arc™ TIG with Auto-Stop™ and Crater-out (patents pending)

6.Standard 14-Pin Receptacle for simple connection of remote controls and wire feeders. It features Auto Remote Sense™ which automatically switches from Panel to Remote Amperage/Voltage (A/V) control with remote connected. Eliminates confusion of the Panel/Remote A/V switch.

7.Weatherproof Lexan® Nameplate is super durable and resists cracking and fading. Color coding is for ease of operation.

8.Fuel Gauge displays engine hours and oil change interval information.

Low Fuel Shutdown shuts engine off prior to running out of fuel to prevent loss of fuel in the system, and make restarts easy.

Display will read noFUEL. Turn the machine off, add fuel, and restart.

9.Glow Plugs assist in cold weather starting.

10.Engine Control Switch is used to start the engine and then select between Auto Idle and High Speed Lock.

11.Amperage/Voltage Adjust Control

12.120 VAC and 240 VAC Receptacles with Circuit Breakers (optional 120 VAC GFCI receptacles available).

Note: For matching plug, order #119 172.

13.Weld Output Terminals

1

2 |

3 |

4 |

5 |

6

8

9

10

11

12 |

7

13

13

ARC STARTwith Lift-Arc™

Touch or scratch |

Lift at any angle |

|

Shielding |

|

|

gas |

|

|

|

Arc |

Shielding |

|

|

gas |

•Reduces or eliminates sticking

•Reduces or eliminates electrode/ work contamination

•Low open-circuit voltage (approximately 10 volts)

Workpiece

ARC ENDwith Auto-Stop™

While welding |

|

For Auto-Stop, lift up to terminate arc |

• |

Eliminates need for |

|

|

|

|

|

|

a remote control |

|

|

|

Move back |

• |

Maintains shielding |

|

Lift up |

Arc ends |

|

gas coverage |

|

|

down to |

• |

Eliminates tungsten |

||

|

until arc |

without |

maintain gas |

||

Shielding |

|

and workpiece |

|||

ends |

flare |

coverage |

|

||

gas |

|

|

|

|

contamination |

Arc |

|

|

|

• |

Eliminates |

|

|

|

|

|

unwanted arc |

Workpiece |

|

|

|

|

strikes outside the |

|

|

|

|

weld area |

|

|

|

|

|

|

|

ARC ENDwith Crater-out

While welding |

To start Crater-out, press |

|

|

momentary contact switch |

|

|

Welding |

Maintain |

|

current |

shielding |

Shielding |

ramps |

gas |

down |

coverage |

|

gas |

|

|

Arc |

|

|

Workpiece |

|

|

•Maintains shielding gas coverage

•Eliminates tungsten and workpiece contamination

•Crater-out time allows for addition of filler

•Eliminates unwanted arc strikes outside the weld area

3

Loading...

Loading...