Page 1

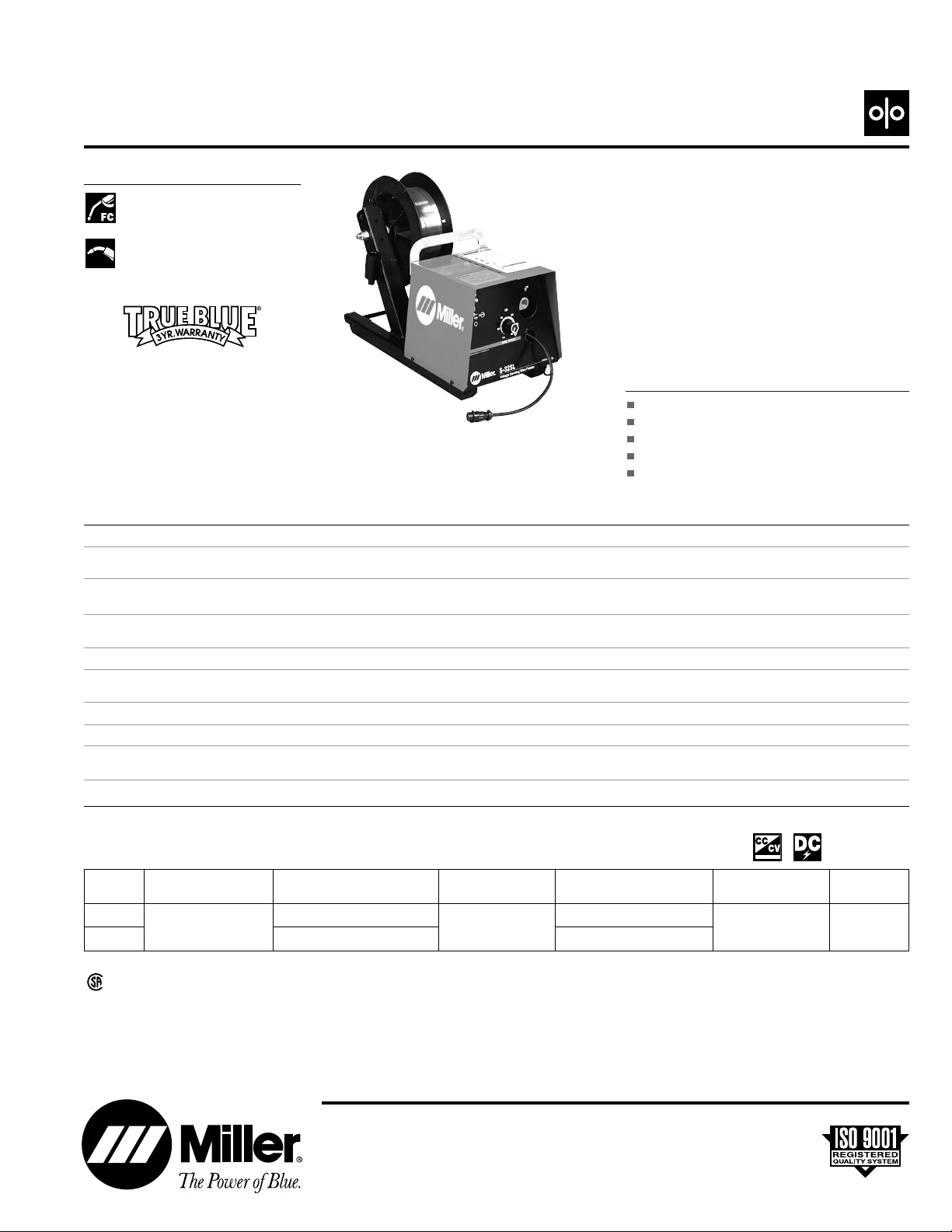

Simple to use but with all the features needed for

heavy-duty wire feed applications... that’s the S-32S

and S-32SL wire feeders from Miller. Built with the

strength and flexibility to handle the strenuous work

loads of field and fabrication shops, the S-32S and

S-32SL delivers proven reliability and performance.

These feeders operate off arc voltage, so a control

cord is not required. Operates with most CV and CC

DC-type power sources.

The S-32S and S-32SL handle the necessary highend speed for small diameter wires, and the lowend speed and

power for the more demanding larger

diameter wires.

Applications

Structural steel

Building construction

Bridge construction

Field maintenance and repair

Outdoor equipment repair and build-up work

(Use with CC/CV,

DC Power Sources.)

®

Certified by Canadian Standards Association to both Canadian and U.S. Standards.

NRTL/C

Index No. M/6.21

Issued Dec. 1999

S-32S and S-32SL

Voltage-Sensing Wire Feeders

Processes

Flux Cored (FCAW) Welding

(Gas and Self-shielded)

MIG (GMAW)

Welding

Features Benefits

Operates on open-circuit and arc voltages

Voltage-sensing control circuit with

CC/CV switch

S-32S wire speed range:

50 –700 IPM (1.3 –18 m/min)

S-32SL wire speed range:

25 – 325 IPM (0.6 – 8.2 m/min)

Polarity insensitive

High-torque, 24 VDC drive motor with two

gear-driven drive rolls

Solid-state speed control and brake circuit

Overload protection

Quick-change drive rolls and quick connect

for Miller guns

Insulated gun-holding bracket

Requires only the secondary weld cable to power feeder, no control cord needed.

Allows the feeder to be used with most constant-current and constant-voltage DC power sources.

Accommodates a wide variety of wire sizes and types, .023 – 5/64 in (0.6 –2.0 mm).

Designed for 5/64– 7/64 in (2.0 –2.8 mm) diameter wire.

Operates on straight (electrode negative) or reverse (electrode positive) polarity.

Offers excellent wire feeding performance and long uninterrupted service life.

Exceptional speed control and regulation; eliminates the need for electrical/mechanical relays and increases service life.

Protects motor and control circuit against possible damage due to overloading conditions.

No tools required. Easy attachment.

Convenient place for holding gun when not welding or when transporting the feeder.

Miller Electric Mfg. Co.

An Illinois Tool Works Company

1635 West Spencer Street

Appleton, WI 54914 USA

Web Site

www.MillerWelds.com

International Headquarters

Phone: 920-735-4505

USA FAX: 920-735-4134

Canadian FAX: 920-735-4169

International FAX: 920-735-4125

Ordering Information

☞

See back page.

Specifications

(Subject to change without notice.) Heavy Industrial

Model

S-32S

S-S32SL*

Input Power

Operates on open-circuit

voltage and arc voltage

15 to 100 V

Electrode Wire

Diameter Capacity

.023–5⁄64 in (0.6–2.0 mm)

5⁄64 –7⁄64 in (2.0 – 2.8 mm)

Maximum Spool Size

Capacity

60 lb (27 kg) coil

Wire Feed Speed**

50–700 IPM (1.3 –18 m/min)

25–325 IPM (0.6– 8.2 m/min)

Net

Weight

33 lb (15 kg)

Dimensions

L: 221⁄2 in (572 mm)

W: 103⁄4 in (273 mm)

H: 10 in (254 mm)

*When using an 8 in (203 mm) diameter spool of welding wire, compression spring #057 745 is required. **Actual range is dependent on arc voltage applied.

Page 2

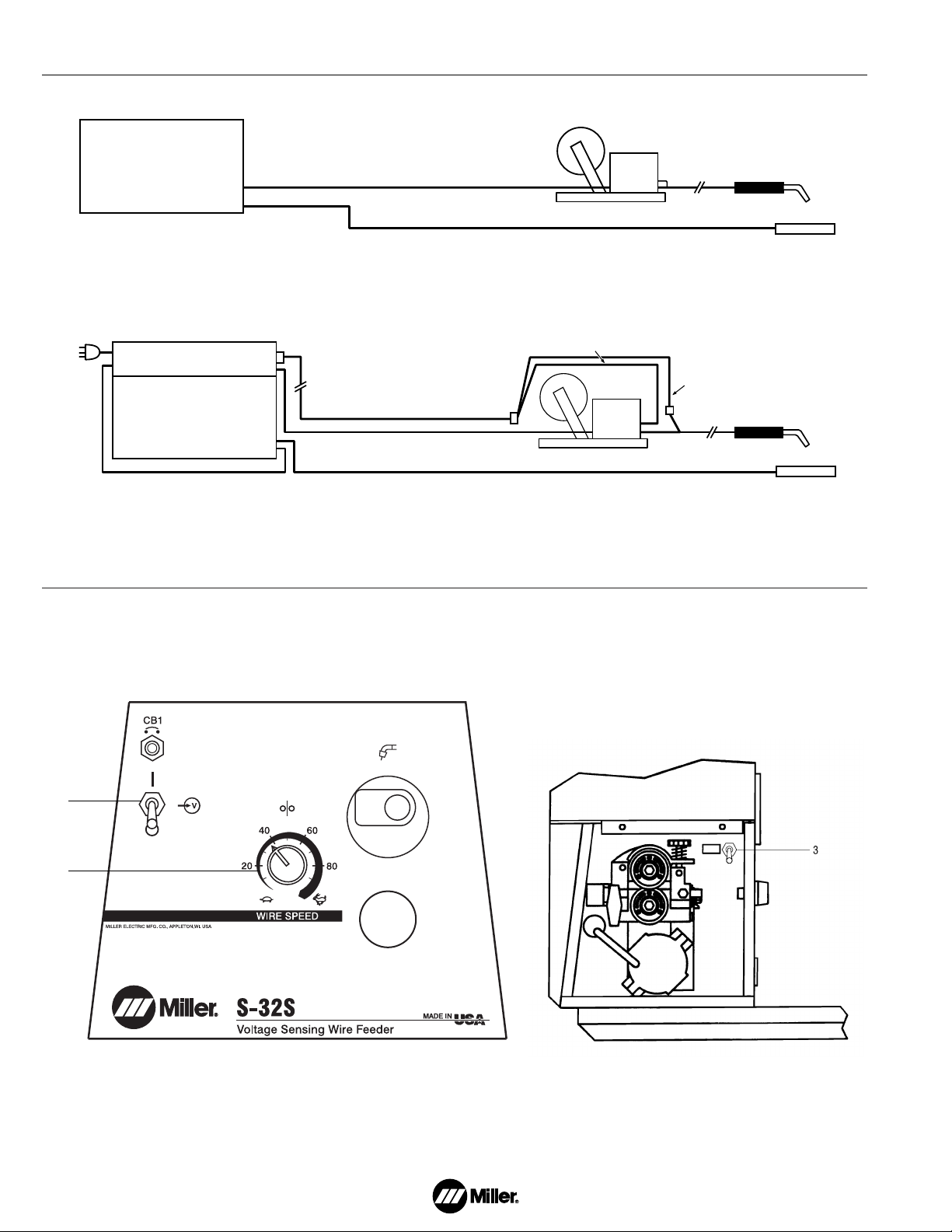

Control Panel

2

Work

BASIC SET-UP -– HOT WIRE

For MIG welding, use the

optional Gas Solenoid Valve.

Constant-Current

and Constant-Voltage

DC Power Sources

Electrode/Welding Cable

Electrode/Welding Cable

Remote Contactor Cord

Work

For MIG welding, use the

optional Gas Solenoid Valve.

WITH OPTIONAL EXTERNAL SECONDARY CONTACTOR -– COLD WIRE

Note: The secondary contactor can be wired to operate off 115 VAC or powered

off a 12 VDC battery of an engine driven welder.

10 ft. (3 m) 115 VAC Primary Cord (Connect to power source 115 VAC supply, if available.)

115 VAC/12 VDC

Secondary Contactor

Electrode/Welding Cable

To Wire Feeder Trigger Receptacle

To Gun Trigger

Constant-Current

DC Power Sources

Not Having a Weld

Output Contactor

2

1

Typical Installations

1. Power Control Switch

2. Wire Speed Control

3. CC/CV Switch

Page 3

3

Gas Solenoid Valve

#093 768 Field

[ A: 15 ]

Required when using gas-shielded type wires.

Includes purge control. Operates off the arc

voltage and is designed for use with hot wire

set-up or when using an external secondary

contactor.

External Secondary Contactor

#108 921

[ A: 10 ]

Contactor rating:

400 amps at 30% duty cycle

330 amps at 60% duty cycle

250 amps at 100% duty cycle

Allows the welding wire to be electrically

cold until the operator is ready to weld. The

contactor can be used with direct current

(DC) power sources operating in either reverse

(electrode positive) or straight (electrode

negative) polarity. The contactor will operate

off 115 VAC or can be connected to a 12 VDC

battery of an engine driven welder not having

115 VAC auxiliary power available. The gun

trigger switch controls the contactor and must

remain closed while welding.

Note: 25 ft (7.6 m), #108 925, or 50 ft (15.2 m), #108 926,

remote contactor cord required.

Wire Reel Assembly #108 008

For 60 lb (27.2 kg) coil of wire.

Spool Cover #090 389

For 12 in (305 mm) spool only.

Reel Cover #091 668

For 60 lb (27 kg) coil.

Compression Spring #057 745

Required when using 8 in (203 mm) diameter

10 lb (4.5 kg) and 15 lb (6.8 kg) spools of wire.

Spool Adapter #047 141

For use with 14 lb (6.4 kg) spool of Lincoln

self-shielding wire.

Remote Contactor Cables

#108 925 25 ft (7.6 m)

#108 926 50 ft (15.2 m)

Skill Level Index

The box following the stock number of field-installed

options contains a letter and number. The letter indicates

the skill level required to install the option. The number

indicates the approximate time required for installation (see

legend).

A– Easy. No previous experience needed.

B– Average. Requires removal of service panels.

Mechanical ability is helpful.

C– Difficult. May require the use of an ohmmeter and/or

splicing of electrical wires. Repair or replacement of

component parts is more difficult.

D– Technical. May require the use of an ohmmeter and the

ability to read a circuit diagram. Repair or replacement

of component parts is complex.

Example:

[ B: 30 ] Skill Level: B, Time: 30 minutes

Options and Accessories

“U” cogged for

extremely soft

“U” groove for wire or soft-

soft wire or “V” knurled shelled cored

“V” groove soft-shelled for hard-shelled wires (i.e., hard

Wire size for hard wire cored wires cored wires facing types)

.023 / .025 in (0.6 mm) #087 131 —— —

.030 in (0.8 mm) #079 594 —— —

.035 in (0.9 mm) #079 595 #044 749 #079 606 —

.040 in (1.0 mm) #161 189 —— —

.045 in (1.1/1.2 mm) #079 596 #079 599 #079 607 #083 318

.052 in (1.3/1.4 mm) #079 597 #079 600 #079 608 #083 317

1/16 in (1.6 mm) #079 598 #079 601 #079 609 #079 614

.068/.072 in (1.8 mm) ——#089 984 —

5/64 in (2.0 mm) — #079 602 #079 610 #079 615

3/32 in (2.4 mm) — #079 603 #079 611 #079 616

7/64 in (2.8 mm) — #079 604 #079 612 #079 617

Drive Roll Kits

(Order from Miller Service Parts.) Select drive roll kits from chart below according to type and wire size being used. Kit includes drive rolls and inlet guide.

Page 4

Litho in USA

Distributed by:

Equipment and Options Stock No. Description Qty. Price

S-32S #088 816

S-32SL #109 294

Drive Roll Kit See table on page 3

Gas Solenoid Valve #093 768

Power Sources

Dimension

™

See Lit. Index No. DC/19.2

Gold Star

®

See Lit. Index No. DC/8.1

Mark VI®, VIII®-2 See Lit. Index No. DC/9.8, DC/10

Bobcat

™

See Lit. Index No. ED/4.31

Trailblazer®251 See Lit. Index No. ED/4.5

Big 40®G or Diesel See Lit. Index No. ED/8.1, ED/9.6

Big Blue®251D See Lit. Index No. ED/5.2

Big Blue®600D See Lit. Index No. ED/10.3

Miller Air Pak

™

Accessories

External Secondary Contactor #108 921

Wire Reel Assembly #108 008

Spool Cover #090 389

Reel Cover #091 668

Compression Spring #057 745 For 8 in spool of wire

Spool Adapter #047 141

Remote Contactor Cables #108 925 25 ft (7.6 m)

#108 926 50 ft (15.2 m)

GA-40GL Gun See Lit. Index No. M/9.0

M-25, M-40 Guns See Lit. Index No. M/10.0

GW-500 Gun See Lit. Index No. M/13.4

Miscellaneous

Primary Power Cable

Secondary Power Cable

Ground Cable with Clamp

Gas Cylinder (if required)

Gas Hose with Fittings (if required)

Regulator/Flowmeter (if required)

Welding Wire

Helmet

Welding Gloves

Date: Total Quoted Price:

Ordering Information and System Checklist

Loading...

Loading...