Page 1

MiIIe~

November1996

Effective

With Serial

Form:

No.

TM-1571

JJ507797

TECHNICAL

Service

And

MANUAL

Parts

coverjml—SB-124

A

SERVICING

•

Have

qualified

practices.

U

For

help,

Service

414-735-4505

467

WARNING

canbehazardous.

all

service

procedures

persons

call

Factory

Department:

following

performed only

~U~r

Wire

standard

©

S-21E

Feed

Equipment

by

safety

FAX:

14-735-4136

1996

MILLER Electric

Mfg.

Co.

Use

MILLER

150

853)

Use

only genuine

parts.

L................J

Testing Booklet

when

servicing

MILLER

U

Or

write

MILLER

RO.

Box

Appleton,WI54912

this

unit.

replacement

to:

Electric

1079

PRINTEDINUSA

(Part

Mfg.

No.

Co.

USA

Page 2

Page 3

TABLEOFCONTENTS

OM-1571B—3/91

Section

SECTION

SECTION2-SHIPPING

No.

1-SAFETY

1-1.

1-2.

1-3.

General

Safety

Safety

PRECAUTIONS AND

Information And

Alert

Precautions

2-1. Preparation

Symbol And

AND

STORAGE

For

Reshipment

Safety

Signal

SIGNAL

Words

2-2. Storage

SECTION3—SPECIFICATIONS

3-1.

Description

SECTION4-INSTALLATIONORRELOCATION

4-1.

4-2.

4-3.

4-4. Shielding

4-5.

4-6.

4-7.

4-8.

4-9.

4-10.

Location

Drive

Roll

Installation

Welding Gun Connections

Gas

Installation

14-Pin

Welding

Welding

Adjust

Welding

Feeding Welding

Plug

Wire

Wire

The

Cable

Hub

Connection

Installation

Threading

Tension

Connection

Wire

WORDS

Page

No.

1

1

1

2

2

3

3

3

5

5

6

6

7

8

8

8

SECTION

5-OPERATOR

5-1.

5-2.

Power

Wire

Switch

Speed

CONTROLS

Control

SECTION6—SEQUENCEOFOPERATION

6-1.

6-2.

Gas

Metal Arc (GMAW)

Shutting

Down

And

Flux Cored

SECTION7-THEORYOFOPERATION

7-1.

Diagram

Diagram

Theory Of

7-1.

Block

7-2.

Block

Operation

Diagram

Diagram

For

Wire Feeder

For

SpotlBurnback

Arc

(FCAW) Welding

Time

Control

Option

9

9

9

10

10

11

12

Page 4

Section

SECTION8-TROUBLESHOOTING

No.

Page

No.

8-1.

8-2.

8-3.

Diagram

8-4. Motor

Diagram

8-5.

Diagram

SECTION9-COMPONENT

Figure

SECTION

10-1.

10-2.

10-3.

10-4.

10-5.

SECTION

Testing

Circuit

Troubleshooting

Optional

9-1.

10—

Routine

Aligning

ReinstallationOfHub

Brush

Overload

11-ELECTRICAL

Instruments And Information

Board

Handling

8-1.

8-2.

8-3.

MAINTENANCE

Troubleshooting

Board

PCi

Troubleshooting

Board

SpotlBurnback

Troubleshooting

Board PC2

Component

Maintenance

Drive

Roll And

Inspection

Protection

Precautions

Circuit

Testing

Circuit

PCi

Board PC2 Testing

Circuit

IDENTIFICATION

Identification And

Wire

Assembly

And

Replacement

DIAGRAMS

Diagram For

Information

Diagram For

Diagram For

Guide

AND

LOCATION

Location

Wire Feeder

Motor Control

Information

Optional Spot/Burnback

14

14

14

16

17

18

20

22

24

25

26

26

27

27

Diagram

Diagram

Diagram

Diagram

Diagram

SECTION

Table 3-1.

Table 8-1.

Table

Table

11-1.

11-2.

11-3.

11-4.

11-5.

12—

PARTS

Specifications

Troubleshooting

10-1.

Maintenance

11-1.

ListOfCircuit Diagrams

Circuit

JJ507797

Wiring

JJ507797

Circuit

With Serial

Circuit

Effective

Circuit

Effective

Diagram For

Diagram

Diagram For

Diagram

With Serial

Diagram For

With Serial

LIST

LISTOFCHARTS AND

S-21EEffective

And Following

For

S-21EEffective

And Following

No.

Schedule

Motor Control

JJ507797 And Following

For

Optional

No.

JJ507797

Optional Spot/Burnback

No.

JK742029

And

Wiring

With Serial

With

Serial

Board

PCi

SpotlBurnback

Thru

JK742028

And Following

TABLES

Diagrams

No.

29

No.

29

Effective

30

Board PC2

31

Board PC2

32

3

15

25

28

Page 5

SECTION

1-SAFETY

PRECAUTIONS

AND

SIGNAL WORDS

1-1.

This

specific

dures.Italso includes

vanttothese

tive toolinthe

ever,itdoes

training

arises

sented,orif

manual,

proceeding

1-2.

The

used

identify

tions.

A

A

A

IMPORTANT

GENERAL

manual

about

following safety alert

throughout

provides

operating,

procedures.

handsofa

not

nor

safety-conscious service

the

problems

contact

further.

SAFETY

WORDS

different

This safety alert

words

WARNING and

tionto

the

WARNING statements identify

practices which

ous personal injury

CAUTION

practices which

personal injuryordamagetothis

statements identify special

necessary

for

the

INFORMATION

testing, and

and

cannot

specific

arise

the

factory

ALERT

this

levels of

safety

statements identify procedures

most efficient

ment.

1-3.

SAFETY

PRECAUTIONS

AND SAFETY

theoryofoperation

troubleshooting

precautionary information

This

manual

trained

application

which

symbol

manual to

hazard

symbolisused

statements.

mustbefollowedtoavoid

mustbefollowedtoavoid

serviceperson.

take

the

work.Ifany

of procedures

are

not

Service Department

SYMBOL AND

and signal

call

and

CAUTIONtocall

or loss of

along

can

be an

placeofprevious

covered

SIGNAL

words

attention

special

with

the

procedures

life.

equipment.

instructions

operationofthis

with

proce-

rele-

effec

How-

doubt

pre

in this

before

are

to and

instruc

signal

atten

or

seri

or

minor

equip

•

Shut

down

unit

and

disconnect

when

servicing

cally

requiresanenergized

•

Do

not

leave

-

-

ARC

RAYS,

can

burn eyes

hearing.

•

Wear

FUMES

your

health.

•

Keep

•

Ventilate to

correct

AND

your

unless

live

SPARKS,

and

eye,

GASES can

the

unit

unattended.

AND HOT

skin; NOISE

ear,

and body

head outofthe

keep

from

breathing

input

procedure

unit.

SURFACES

can

damage

protection.

seriously

fumes.

fumes

power

specifi

harm

and

-

gases.

•Ifventilationisinadequate,

breathing

•

-

Read Material

and

materials

-

WELDING

wounds.

•

Do

any

-

HOT

cause

•

Watch

•

Haveafire

howtouse

•

Do

•

-

Allow

device.

Safety

manufacturer’s

used.

WIRE

not

point

gun towardany

conductive

METAL,

fire

and

for

surface,orother

SPATrER,

burns.

fire.

extinguisher

it.

not

use

near

flammable

work

and

Data

instructions

can

equipmenttocool

use

Sheets

cause

part of

AND

nearby

material.

approved

(MSDSs)

for

any

puncture

the

body,

personnel.

SLAG

and

can

know

before

handling.

MOVING

•

Keep

PARTS

away

can

from

cause

moving

serious

parts.

injury.

A

5-21E

W

ARNING: ELECTRIC

S

Do

not

touch

live

•

Protect

and

•

Insulate

rubber9loves

power is

yourself

clothing.

yourself

and

appliedtothe

SHOCK

electrical

with

dry

from

groundbyusing

insulating

unit.

can kill.

parts.

insulating

floormats

gloves

when

HOT

SURFACES

•

Allow

cooling

MAGNETIC

can

affect

pacemaker

•

Wearers

going near

mentorany

can

period

FIELDS

should

consult

the

servicingofarc

arc

welding

cause

before

FROM

HIGH CURRENTS

operation.

their

operations.

severe

burns.

servicing.

doctor

welding

TM-1571

before

equip

Page

1

-

Page 6

SECTION2-SHIPPING

AND

STORAGE

PREPARATION

WARNING:

•

Do

not

A

•

Shut

source,

ing

touch

down wire

and

lockout/tagging

preparing unit

Lockout/tagging

sistofdisconnecting

for

welding

line

disconnect switch

ing

fuses

from

tagging circuit breaker or

device.

(—)

erators.

1.

Disconnect

feeder.

2.

Disconnect

3.

Disconnect and remove

devices.

4.

Disconnect

ble)

5.

Disconnect gun

6.

Secure

wire

7.

Tape

8.

Securely

around

if

available.

IMPORTANT:

Not

onlydocosts increase

more

subjecttolossordamage

9.

If

sending

factory

Department.

Stop

battery

hoses from

spoolorreel

cable

interconnecting

weld

shielding

welding

plastic

tie

sidesofunit.

Do

not

unittofactory,

Service

FOR

RESHIPMENT

ELECTRIC

live

disconnect

SHOCK

electrical

feeder

and

input

can

parts.

welding

power

procedures

for

shipping.

procedures

power

source

fuse

box,

engine, and

from

cable

gas

wire

feeder.

from

wire

wiretospool/reel,

from

around

and/or tape cardboard over

top

Use

ship without

dramatically

forwire

interconnecting

consistofpadlocking

in open

or shutting

other

disconnect

batteryonwelding

cord

from drive

any

remote

(and

feeder.

wire

feeder.

and

sidesofunit.

original

feedercon

position,

off

disconnecting

from

rearofwire

assembly.

controls

waterifapplica

and

shipping carton

a cardboard

but

cord,

the

withoutacarton.

ship

unitasdirected

DepartmentorTransportation

kill.

power

employ

before

and

remov-

and rednegative

gen

remove

top

and

carton.

unit

or

by

is

STORAGE

WARNING:

•

A

-

Do

•

Shut

source,

ing

ELECTRIC

not

touch

live

electrical

down

wire

feeder

and

disconnectinput power

lockout/tagging

procedures

SHOCK

parts.

and

can

kill.

welding

employ

before

power

-

storing

unit.

-

-

-

10.

11.

12.

13.

Lockout/tagging

sistofdisconnecting

for

welding

line

disconnect switch

ing

fuses

tagging circuit

device. Stop

(—)

battery

erators.

1.

Disconnect

feeder.

2.

Disconnect weld

3.

Disconnect and remove

devices.

4.

Disconnect

ble)

hoses

5.

Disconnect gun

6.

Secure

wire

spoolorreel

7.

Clean outside of

8.

Remove

9.

Using

Reinstall wrapper.

Selectastorage

unittowide

corrosive

Carry

Cover

power

from

cable

interconnecting

shielding

from

welding

wrapper.

dry

compressed

temperature

vapors.

unit

to storage

unit

with

procedures

source consistofpadlocking

fuse box,

breakerorother

engine, and

from

cable

gas

wire

feeder.

from

wire

wiretospool/reel,

from

unit.

location that

location.

plastic

forwirefeedercon

interconnecting

in open

or shutting

disconnect negative

batteryonwelding

cord

from drive

any

remote

(and

feeder.

wire

feeder.

air,

clean

least

variation,

or suitable

cord,

position,

off and

disconnecting

from

rearofwire

assembly.

controls

waterifapplica-

and remove

inside of

subjects

dust,

tarp.

and

remov-

red-

gen

unit.

the

dirt,

and

-

-

or

TM-1571

Page

2

5-21E

Page 7

SECTION3-SPECIFICATIONS

Input

Power

Requirements

24

VAC

3.5

Amps

50/60

Hz

Electrode

Diameter

.O23thru

(0.6 thru

10-112

(267

Wire

Capacity

.045

in.

1.1

mm)

In.

mm)

Table 3-1.

Wire

Capacity

10to20

(4.5 to9kg)

8

in.

(203mm)

upto60

(27.2

Specifications

Spool

lb.

spools

lb.

kg)_coils

Electrode

(1.9-15.2

22-1(2

(572

Wire

Feed Speed

75-600 ipm

mom)

at24VA~

in.

mm)

Net

30

(13.6

Weight

lbs.

kg)

Ship

33

lbs.

(15 kg)

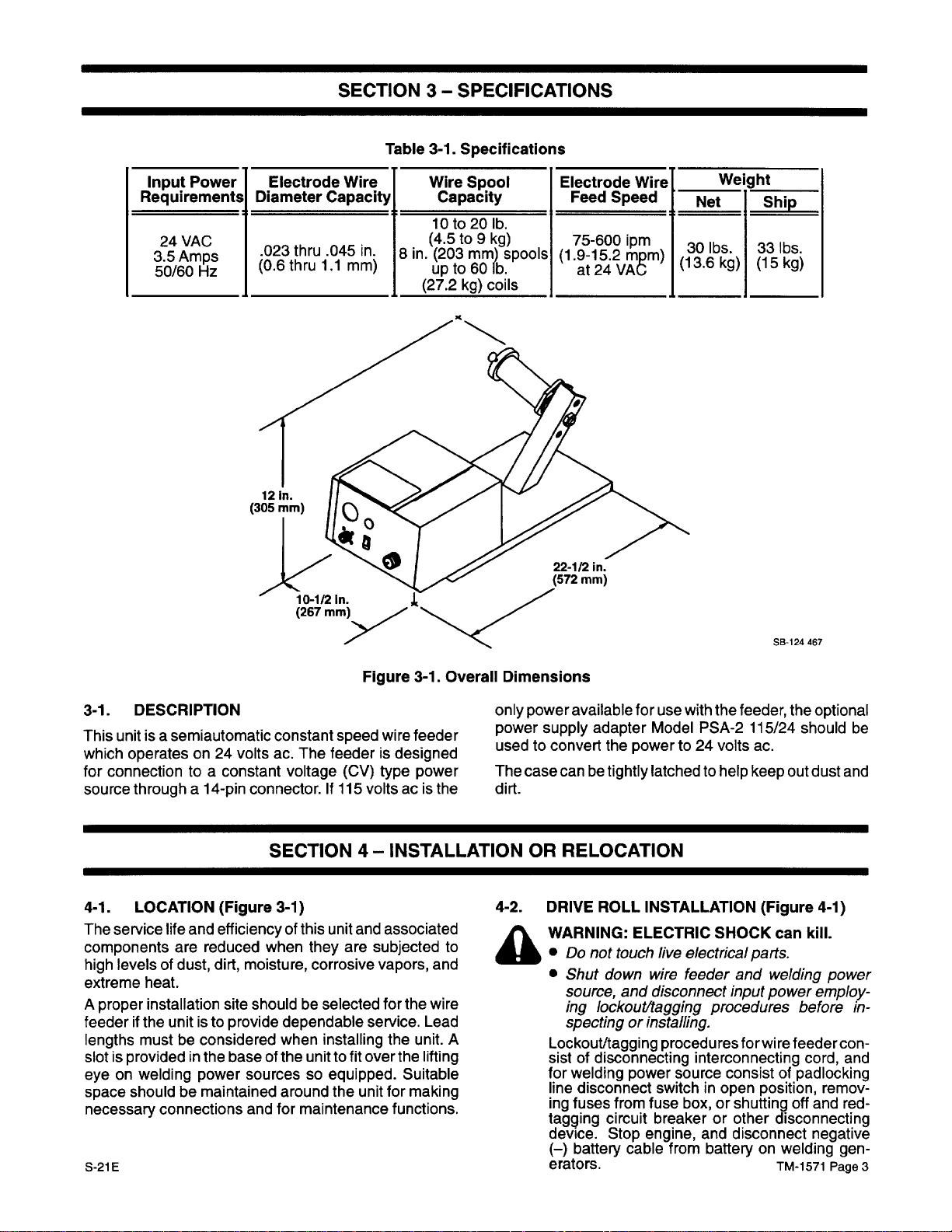

3-1. DESCRIPTION

This

unitisa

which

for

connection toaconstant

source

4-1.

The

service

components

high

levels of

extreme

A

proper installation

feederifthe

lengths

slotisprovided in

eyeonwelding

space

necessary

S-21E

semiautomatic

operates

througha14-pin

LOCATION

heat.

mustbeconsidered

shouldbemaintained

on 24

volts

(Figure 3-1)

life

and

efficiencyofthis unit

are

reduced

dust,

dirt, moisture,

site shouldbeselected

unitisto provide

the

baseofthe

power

connections

Figure

constant speed wire feeder

ac.

The

feederisdesigned

voltage (CV)

connector.If115

volts acisthe

3-1. Overall Dimensions

only

power supply

used

type

power

The

dirt.

SECTION4-INSTALLATION OR

4-2.

and

associated

when

they

are

subjected to

corrosive

dependable

when

installing

unittofit

sourcessoequipped. Suitable

around

and

for

maintenance

the

vapors, and

for

the

service.

the

over

the

unit

for

making

functions.

wire

Lead

unit.

lifting

A

A

power

available

to convert

case

canbetightly

for

adapter

the

powerto24

use

Model

latched to

RELOCATION

DRIVE

WARNING: ELECTRIC

•

•

Lockout/tagging

sistofdisconnecting

for

line

ing

tagging

device.

(—)

erators.

ROLL

INSTALLATION (Figure 4-1)

Do

not

touch

live

Shut

down

wire

source,

ing

and

disconnect

lockout/tagging

spectingorinstalling.

welding

disconnect switch

fuses

battery

power

from

circuit

Stop

cable

fuse

breakerorother

engine, and

SB-124

467

with

the

feeder,

PSA-2

volts

help

SHOCK

electrical

feeder and

input

procedures

procedures

source consistofpadlocking

box,

from

for

interconnecting

in open

or shutting

disconnect negative

batteryonwelding

the

optional

115/24 should

ac.

keep

out

dust

can kill.

parts.

welding

power

power

employ

beforein-

wire feeder

cord,

position,

remov-

off

and

disconnecting

TM-1571

Page

be

and

con

and

red-

gen

-

-

-

3

Page 8

Wire

•

Spring

Hub

Pressure

(ShownInOpen

9

Roll

Assembly

PosItion)

Retaining

Ring

•

OPTIONAL

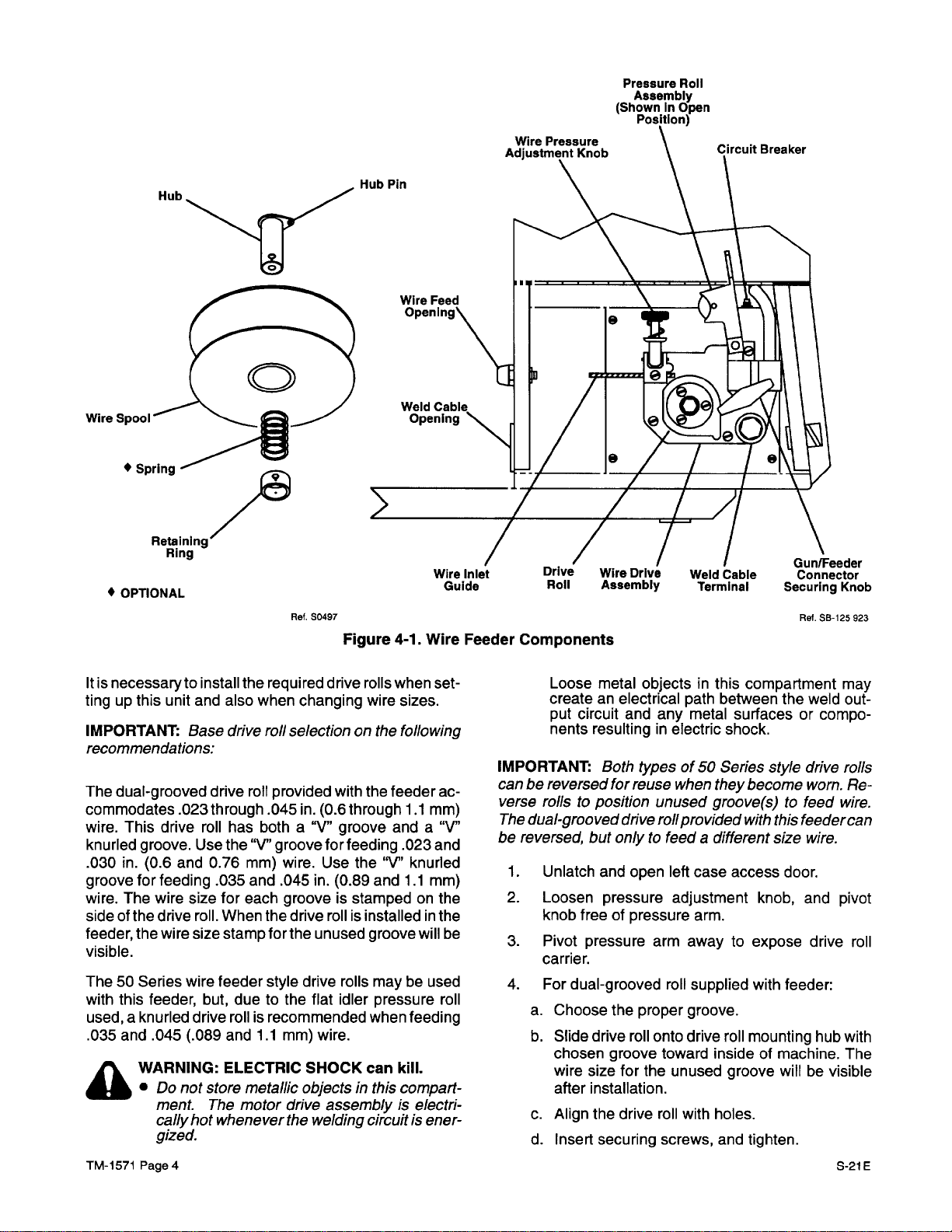

Itisnecessarytoinstall

tingupthis unit

IMPORTANT:

Base drive

and

the

also

recommendations:

The

dual-grooved drive

commodates

wire.

This

knurled

.030

in.

groove

wire.

The

sideofthe

feeder,

visible.

The50Series wire feeder

with

this feeder,

used,aknurled

.035

and

A

.023

drive

groove.

(0.6 and

for

feeding

wire

drive

the

wire

.045

(.089

W

ARNING:

Do

not

ment. The

cally

Use

size

roll.

size

drive

hot

roll

through

roll

has

the “V”

0.76

mm)

.035

and

for

each

When

stamp

but,

due to

roll is

and

ELECTRIC

store metallic

motor

whenever

gized.

TM-1571

Page

4

Ret.

50497

Figure

required

when

roll

provided

.045

both

groove

the

for

style

recommended

1.1

drive

changing

selectiononthe

with

in.

(0.6 through

a

“‘I”

groove

for

wire.

Use

.045

in.

(0.89

grooveisstampedonthe

drive

roll is

the

unused

drive

rolls

the flat

mm)

idler pressure

wire.

SHOCK

4-1.

rolls

when

wire

the

feederac-

and

feeding

the

“V”

and

installedinthe

groove

maybeused

when

can

objectsinthis

drive

assemblyiselectri

the

welding

circuitisener

Wire

set

sizes.

following

1.1

mm)

a

“‘I”

.023

and

knurled

1.1

mm)

will

be

roll

feeding

kill.

compart

Feeder

-

IMPORTANT:

can

verse

The

be

1.

2.

3.

4.

-

-

-

Components

Loose

createanelectrical

put

nents

metal

circuit and

resulting in

Both

be reversed

for

rollstoposition

dual-grooved

reversed,

a.

b.

c.

d.

but

Unlatch

Loosen

knob

Pivot

carrier.

For

and

pressure

free of

pressure

dual-grooved

Choose

Slide

drive

chosen

wire

size

after

installation.

Align

the

Insert

securing

the

groove

objects

path

any

metal

electric

typesof50

reuse

when

unused

drive

roll

pro

onlytofeed a

open

left

case

adjustment

pressure

proper

roll onto

for

the

drive

arm.

arm

away

roll

supplied

groove.

drive

toward

unused

roll

with

screws, and tighten.

GunlFeeder

connector

Securing

Ref.

in this

compartment

between

surfacesorcompo-

shock.

Series

they

the

style

become

groove(s)tofeed

vided

with

this

feedercan

different

inside of machine.

holes.

size

access

to expose

roll

groove

door.

knob,

with

feeder:

mounting hub with

willbevisible

Knob

SB-125

923

may

weld

out

drive

rolls

worn.Re-

wire.

wire.

and

pivot

drive

roll

The

5-21E

-

Page 9

5.

For50Series

a.

Slide

b.

Align

c.

Insert

6.

For50Series

a.

Align holesonpair of split

b.

Insert

c.

Slide

d.

Align

e.

Insert

IMPORTANT:

the drive

set

becomes

7.

4-3.

A

roll

and

should

necessary,

Close

WELDING

And

WARNING:

•

Do

•

Shut

mounting

and

5-1)

source,

ing

ingonfeeder.

Lockout/tagging

sistofdisconnecting

for

welding

line

disconnect switch

ing

fuses

tagging circuit

device.

(—)

battery

erators.

IMPORTANT:

stallationofa

gas

line.

Remove snap-in

style

one-piece

drive

roll

onto

drive

drive

roll

with

holes.

securing

securing

drive

drive

securing

Horizontal

not

not

down

lockout/tagging

Stop

A

gun

screws, and tighten.

style

screw.

rolls

onto

rolls

with

screws, and tighten.

hub

require

secure

GUN

touch

readjustment.Ifreadjustment

see

Section 10-2.

left

CONNECTIONS

ELECTRIC

live

wire

and

disconnect

procedures

power

from

fuse box,

breakerorother

engine, and

cable

from

hole

ispro

requiring an

split

drive

holes.

alignmentofthe drive

with

case

electrical

feeder

procedures

interconnecting

source consistofpadlocking

videdinthe

blank

drive

rolls:

roll

drive

rolls:

drive

roll

the

wire

access

SHOCK

mounting

rolls.

mounting

guideisfactory

hub.

door.

(Figures

can kill.

parts.

and

welding

input

power

employ

before

for

wire feeder

cord,

in open

batteryonwelding

position,

or shutting

disconnecting

disconnect

remov-

off

and red-

negative

nameplate

opening

before

foranexternal

installation.

hub.

roll

on

4-1

power

work

con

and

gen

form-

B.

Connect

front

into

clockwise.

4-4.

A

A.

-

Chain

-

prevent

the

-

secure gas

B.

1.

-

IMPORTANT:

leaks.Donot

Gun

Trigger (Figure 5-1)

‘9=

TRIGGER

RECEPTACLE

gun

trigger plugtotrigger receptacleonthe

panelasfollows:

trigger

receptacle,

SHIELDING

4-2

And

4-3)

WARNING:

rupture

lossoflife;

serious

•

causing serious

injury

Keep

cylinders

electrical circuits.

•

Never

allow

cylinder.

•

Always fasten

gear

bracket,awall,orother

port.

Gas

Cylinder (Customer

the

cylindertoa

the

cylinder

valve.Ifoptional

cylinder

Regulator/Flowmeter

With

the

cylinder

cylinder

and

inder,

or

valve

open

dirt

cap,

valve

close

that

seat.

A

use

align

and

GAS

PRESSURIZED

FALLING

and

a welding

wall or

from

power

to running

stand

slightly.

valve.

may

have

gasket shouldbeinstalledtoprevent

lubricantsorsealing

keyways,

rotate

threaded

INSTALLATION

CYLINDERS can

personal

CYLINDERS

equipment

away

from

electrodetotouch

cylinder

falling

source

(Customer

securely

to one

This procedure

securelytorunning

Supplied)

other

stationary

over

running

gear

with

installed,

sideofcylinder

When

gas

accumulated

insert

gun

plug

collar

fully

(Figures

injury

and

can

cause

damage.

weldingorother

any

stationary

and

breaking

gear is

supplied

Supplied)

remove

flows

blows

support

used,

chain.

valve,

from

out

around

sup-

to

off

the

cyl

dust

the

agents.

-

A.

1.

2.

3.

4.

5.

S-21E

Gun

ConnectorToDrive

Unlatch and

Loosen

the

wire

Insert

holeinthe

Insert

with

the

as

possible

curing

Close and

open

gun/feeder

drive

housing.

gun/feeder connector

front

panel.

gun/feeder

outlet

wire

without touching,

knob.

secure

Assembly

left

case

access

connector securing

through

connector

guideasclosetothe

left

case

access

into

and

tighten

(Figure 4-1)

door.

drive

door.

knob

the

housing

drive

on

access

rolls

these-

2.

The

regulator/flowmeter

equipped withastem,

ket

for

use

type

cylinders.

3.

Install

gas

regulator/flowmeter onto

valve;

securelytogas

4.

A

the

keep

gaugeinvertical

shielding

wire

feeder.

5/8-18

gas

gas

right- hand

hosetothis

hosetothe

must

nut

connectors,

with

either

CO

2

cylindersorinert

the

faceofthe

position,

cylinder

gas fittingisprovidedonthe

Obtainasuitable

fitting.

fitting.

regulator/flowmeter.

and

valve.

Attach

Attach the

be

gas

regulator/flowmeter

tighten

one end of

other

TM-1571

properly

and

cylinder

stem

rear of

hose

end of

Page

gas

gas

nut

with

the

the

-

5

Page 10

Flow

Adjustment

CO

2

Washer

CO2

Installation

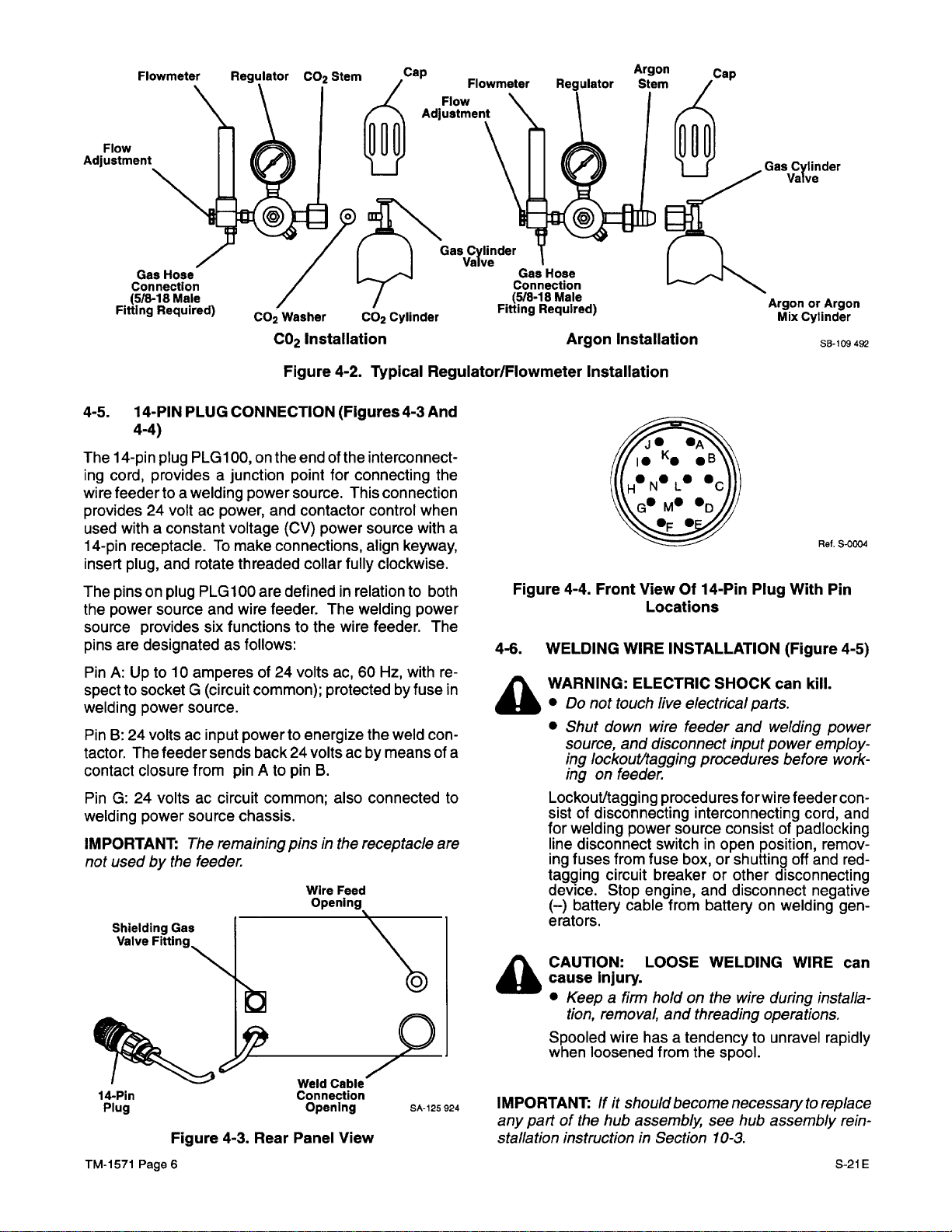

Figure

CO2

cylinder

4-2. Typical

Argon

RegulatorlFlowmeter

Installation

Installation

Gas

cylinder

Valve

ArgonorArgon

Mix

cylinder

SB-109

492

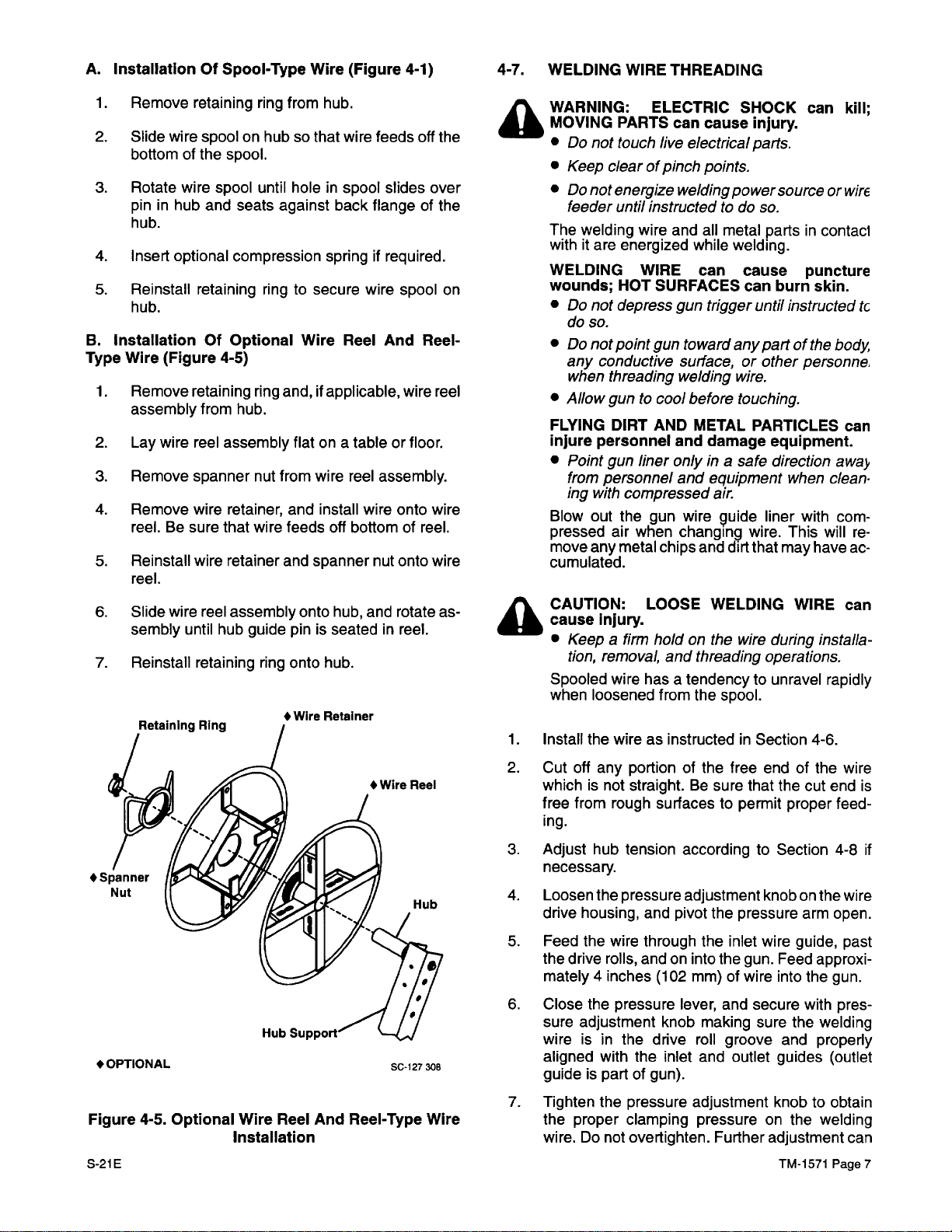

4-5.

The

ing

wire

provides24voltacpower,

used

14-pin

insert

The

the

source

pins

PinA:Upto10

specttosocket

welding

PinB:24

tactor.

contact closure

PinG:24

welding

IMPORTANT:

not

14-PIN

4-4)

14-pin

cord,

feedertoa

withaconstant

receptacle.Tomake

plug,

pinsonplug

power

are

The

usedbythe

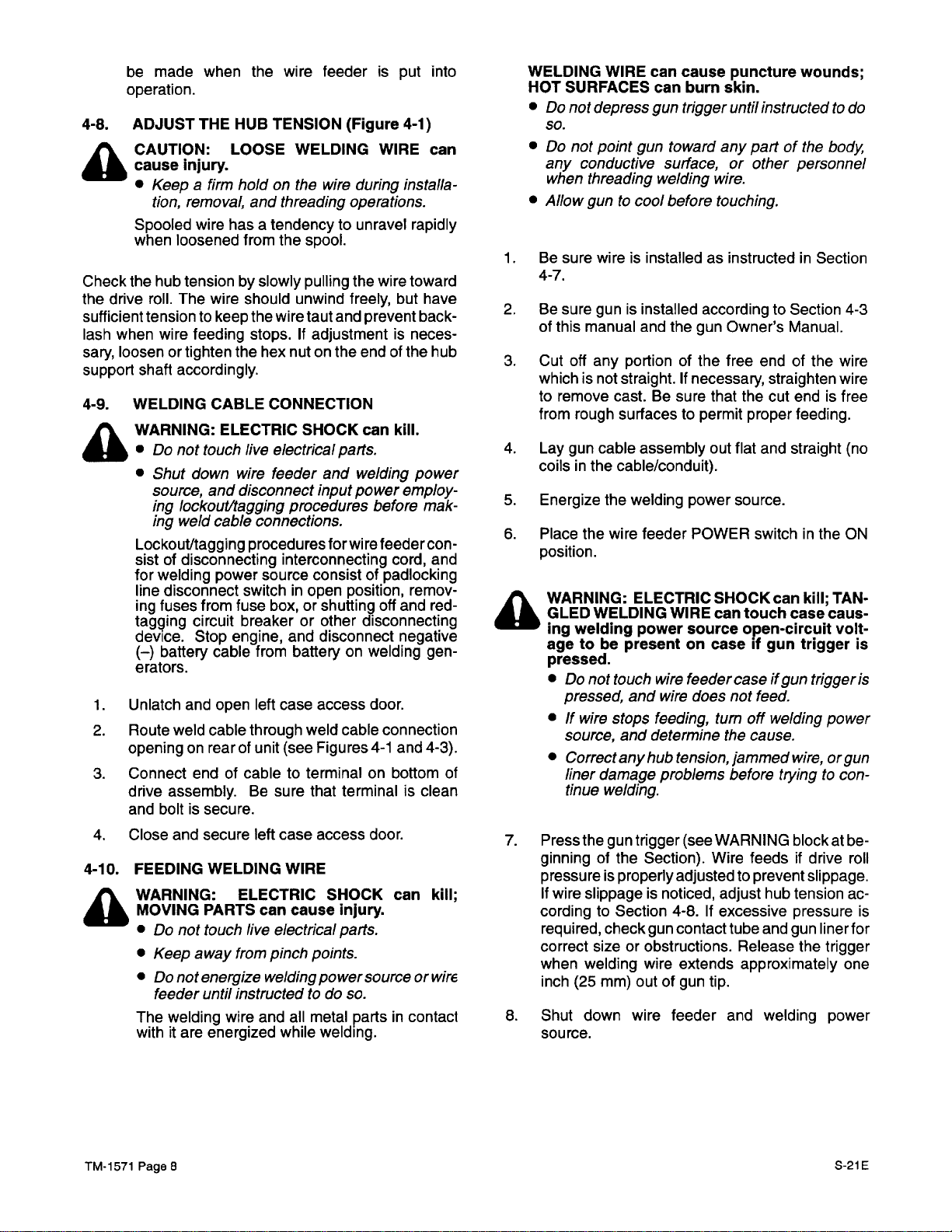

Shielding

valve

PLUG CONNECTION

plug

PLG1

providesajunction

welding

and

rotate

PLG

source

provides

designated as

power

volts ac

volts ac

power

and

six

amperesof24

G (circuit

source.

input

feeder

sends

from pin Atopin

circuit common;

source

The

remaining

feeder.

Gas

Fitting,

00,onthe

power

voltage

threaded

100

wire

functionstothe

follows:

common);

powertoenergize

back24volts ac by

chassis.

(Figures

end of

the

interconnect

point

for

connecting

source.

and

contactor

(CV)

connections,

are

definedinrelationtoboth

feeder.

volts

pinsinthe

This

control when

power

source

align

collar

fully

The

welding

wire

feeder.

ac,60Hz,

protected by

the

B.

also connected

receptacle are

Wire

Feed

connection

clockwise.

weld

meansofa

4-3

And

the

with

a

keyway,

power

The

withre-

fuse

in

con

to

-

Ref.

S-0004

Figure

4-6.

A

-

4-4. Front

WELDING

WARNING: ELECTRIC

•

Do

not

•

Shut

source,

ing

lockout/tagging

ViewOf14-Pin

Locations

WIRE

INSTALLATION

touch

live

down

wire

and

disconnect

electrical

feeder and

procedures

Plug

SHOCK

parts.

input

With

Pin

(Figure

can kill.

welding

4-5)

power

poweremploy

before

work

-

-

ingonfeeder.

A

Lockout/tagging

sistofdisconnecting

for

welding

line

disconnect

ing

fuses

tagging

device.

(—)

erators.

CAUTION: LOOSE

cause

•

Spooled wire

when

circuit

Stop

battery cable

Injury.

Keepafirm

tion,

removal,

loosened

procedures

power

source consistofpadlocking

switch

from

fuse

box,

breakerorother

engine, and

from batteryonwelding

holdonthe

and

hasatendencytounravel

from

forwire

interconnecting

in open

or shutting

disconnect

WELDING

wire

threading

the

spool.

feeder

cord,

position,

during

remov-

off and

disconnecting

negative

WIRE can

installa

operations.

rapidly

con

and

red-

gen

-

-

-

14-Pin

Plug

TM-1571

Page

Figure

6

4-3.

Rear

Weld

Cable

Connection

Opening

Panel

View

SA-125

924

IMPORTANT:

any

part of

If

it should become

the

hub

assembly

stallation instructioninSection

necessarytoreplace

see

hub

assembly

10-3.

rein

5-21E

-

Page 11

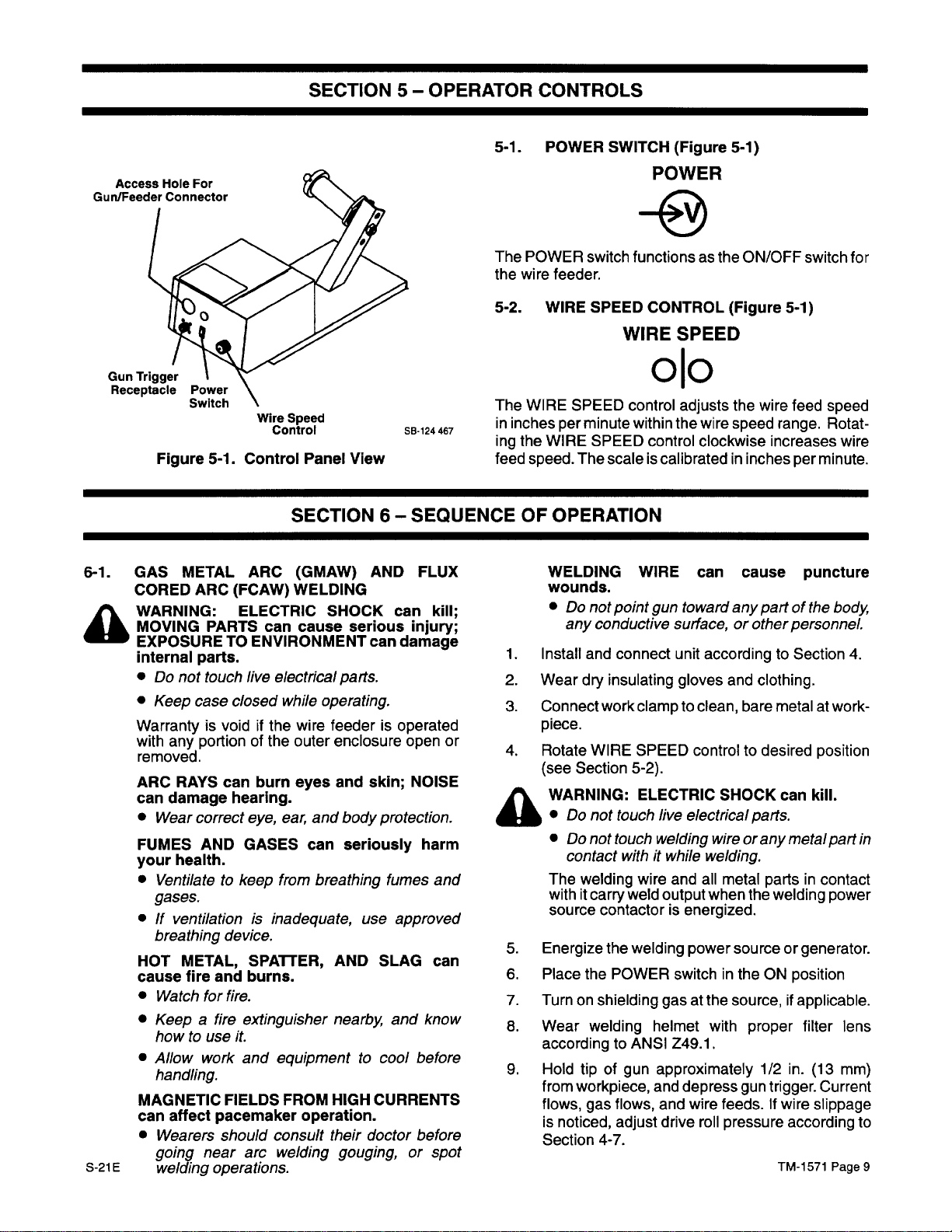

A.

InstallationOfSpool-Type

1.

Remove

2.

Slide

bottomofthe

3.

Rotate

pininhub and

hub.

4.

Insert optional

5.

Reinstall retaining

hub.

B.

InstallationOfOptional

Type

Wire

1.

Remove

assembly

2.

Lay

3.

Remove

4.

Remove wire

reel.Besure

5.

Reinstall

reel.

6.

Slide

sembly

7.

Reinstall retaining

retaining

wire

spoolonhubsothat

spool.

wire

spool

seats

compression springifrequired.

(Figure 4-5)

retaining

from hub.

wire

reel

assembly

spanner

retainer,

that

wire

retainer and

wire

reel

assembly

until

hub

Wire

ring

from

hub.

until

hole

in spool

against back

ringtosecure

Wire

ring

and,ifapplicable,

flat

on a

nut

from

wire

and

install

wire

feeds

spanner

onto

guide

pin is

ring

onto

hub.

•Wlre

Retainer

(Figure 4-1)

wire

feeds

slides

flangeofthe

wire

spool

Reel

And

tableorfloor.

reel

assembly.

wire onto wire

off

bottomofreel.

nut

onto wire

hub,

and

rotateas-

seated in

reel.

off

wire

the

over

on

Reel-

reel

4-7.

A

A

WELDING

WARNING:

MOVING

•

Do

•

Keep

•

Do

feeder

The welding

withitare

WELDING

Wounds;

•

Do

do

•

Do

any

WIRE

ELECTRIC

PARTS

not

touch

clearofpinch

not

energize welding

until

instructedtodo

wire

energized

WIRE can

HOT

not

depress

so.

not

point

gun towardany

conductive

when threading

•

Allow

guntocool before

FLYING

injure personnel

•

Blow

pressed

move

cumulated.

CAUTION:

cause

•

Spooled wire

when

1.Install

DIRT

Point

gun

from

personnel

ing with

compressed

out the

air

when

any

metal

Injury.

Keepafirm

tion,

removal,

loosened

the

wireasinstructedinSection 4-6.

AND

liner onlyina

gun

LOOSE

hasatendencytounravel

THREADING

SHOCK

can

live

electrical

cause

injury.

parts.

points.

power

sourceorwirE

so.

and

all

metal

partsincontaci

while

welding.

cause puncture

SURFACES

gun

can

trigger

burn skin.

untll

part of

surface,orother

welding

wire.

touching.

METAL PARTICLES can

and

damage equipment.

safe direction

and

equipment when

air.

wire

9uide

liner

changing

chips

and

holdonthe wire

and

threading

from

the

wire.

dirt

that

WELDING

during

operations.

spool.

may

can

kill;

instructed

the

body

personne.

awaj~

clean~

with

com

This

willre-

haveac-

WIRE

can

installa

rapidly

tc

-

-

•

Spanner

Nut

•

OPTIONAL

Figure

S-21E

4-5.

Optional Wire

Reel

Installation

And

Reel-Type

SC-127

306

Wire

2.

Cut

off

any

portionofthe

whichisnot straight.Besure

free

from

rough

surfacestopermit

ing.

3.

Adjust

necessary.

4.

Loosen

drive

5.

Feed

the

mately4inches

6.

Close

sure

wireisin

aligned with

guideispart of

7.

Tighten

the

wire.Donot

hub

tension according to Section

the

pressure

housing,

the

drive

the

adjustment knob

proper

and

wire

through

rolls,

andoninto

(102

pressure

the

drive

the

gun).

the

pressure

clamping

overtighten. Further

free

endofthe

that

the

cut

proper

adjustment knobonthe

pivot

the

pressure

the

inlet

the

gun.

mm)ofwire

lever,

and

secure

making

roll

groove

inlet

and

outlet

adjustment knobtoobtain

pressureonthe

arm open.

wire

guide, past

Feed

into

the

with

sure

the

and

guides

adjustment

TM-1571

wire

end

is

feed

4-8

wire

approxi

gun.

pres

welding

properly

(outlet

welding

can

Page

-

if

-

-

7

Page 12

be

operation.

4-8.

A

Check

the

sufficient

lash

sary,

support

4-9.

A

4-10.

A

ADJUST

CAUTION: LOOSE

:ause

Spooled

when

the

drive

when

loosen or

shaft

WELDING

WARNING: ELECTRIC

•

•

Lockout/tagging

sistofdisconnecting

for

line

ing

tagging

device.

(—)

erators.

1.

Unlatch and

2.

Route

openingonrearofunit

3.

Connect

drive

and

4.

Close and

FEEDING WELDING

WARNING: ELECTRIC

MOVING

•

•

•

The

withitare

made

Keepafirm

tion,

hub

roll.

tensiontokeep the

Do

Shut

source,

ing

ing

Do

Keep

Do

feeder

when

THE

Injury.

removal,

wire

loosened from

tensionbyslowly

The

wire

feeding

tighten

accordingly.

not

touch

down

lockout/tagging

weld

welding

disconnect switchinopen

fuses

from

circuit

Stop

battery

weld

end of

assembly.Besure

boltissecure.

secure

PARTS

not

touch

away

not

energize

until

welding

the

wire

HUB

TENSION

WELDING

holdonthe wire

and

threading

hasatendencytounravel

the

wire

should

the

CABLE

live

wire

and

disconnect

cable

power

fuse box,orshutting

breakerorother

engine,

cable

open

cable

cabletoterminalonbottom

live

from

instructedtodo

wire

energized

unwind

wire

stops.Ifadjustmentisneces

hex

nutonthe

CONNECTION

SHOCK

electrical

feeder and

procedures

connections.

procedures

interconnecting

source

and

from

batteryonwelding

left

case

through weld

(see

left

case

WIRE

can

cause

electrical

pinch

welding

and

all

while

feederisput

(Figure 4-1)

WIRE can

during

operations.

spool.

pulling

the

wire

freely,

taut and

consistofpadlocking

that

points.

metal

prevent

end of

can

parts.

welding

input

power

before

forwire

disconnect negative

access

Figures

access

SHOCK

powersourceorwirE

welding.

feedercon

position,

off

disconnecting

door.

cable

connection

4-1

terminalisclean

door.

Injury.

parts.

so.

partsincontaci

into

installa

rapidly

toward

but have

back

the

hub

kill.

power

employ

mak

cord,

and

remov

and

red-

gen

and

4-3).

can kill;

of

WELDING

HOT

•

Do

so.

•

Do

any

-

-

-

-

-

-

-

A

-

when threading

•

Allow

1.

Be

4-7.

2.

Be

of

this

3.

Cut

whichisnot straight.Ifnecessary,

to remove cast.Besure

from

4.

Lay

coilsinthe

5.

Energize the

6.

Place

position.

WARNING: ELECTRIC

GLED

ing Welding power

agetobe

pressed.

•

•Ifwire

•

7.

Press

ginningofthe Section).

pressureisproperly

If

wire

cordingtoSection

required,

correct

when

inch

8.

Shut

source.

WIRE

can

cause

SURFACES

not

depress

not

point

conductive

guntocool

sure

wireisinstalledasinstructedinSection

sure

gunisinstalled

manual

off

any

rough

gun

cable

the

WELDING

Do

not

pressed,

source,

Correctanyhub

liner

damage

tinue

welding.

the

gun

slippageisnoticed,

check

sizeorobstructions.

welding

(25

mm)

down

can

gun

gun

toward

surface,orother personnel

welding

before

and

the

portionofthe

surfacestopermit proper

assembly

cable/conduit).

welding

wire

feeder POWER switchinthe

WIRE can

presentoncaseifgun

touch

wire

and

wire does

stops

feeding,

and

determine

tension,

problems

trigger

adjustedtoprevent

4-8.Ifexcessive

gun

contact

wire extends

outofgun tip.

wire

feeder

puncture

burn skin.

trigger until

according

gun

that

out flat

power

source

feeder

(see

Wire feedsifdrive

instructedtodo

any

part of

wire.

touching.

to Section

Owner’s

free

source.

SHOCK

caseifgun

not

tum

the

jammed

before

WARNING blockatbe

adjust

tube

Release

approximately

and

Manual.

end of

straighten

the

cut

and

can kill;

touch

open-circuit

feed.

off

welding

cause.

tryingtocon-

hub

and gun

welding

endisfree

feeding.

straight

case

wire,orgun

tensionacpressure

Wounds;

the

body

4-3

the

wire

wire

(no

ON

TAN

caus-

volt

trigger

slippage.

the

trigger

power

roll

liner

for

trigger

one

power

is

is

is

-

-

-

TM-1571 Page

8

S-21E

Page 13

SECTION5-OPERATOR

CONTROLS

Access

Gun/Feeder

Gun

Trigger

Receptacle

6-1.

A

GAS

CORED

WARNING: ELECTRIC

MOVING

EXPOSURETOENVIRONMENT

internal parts.

•

•

Warrantyisvoidifthe

with

removed.

ARC

can

•

FUMES

your

•

•Ifventilationisinadequate,

HOT

cause

•

•

•

MAGNETIC

can

•

5-21

E

Hole

For

Connector

Wire

Figure

Do

Keep

Wear

5-1.

Control

METAL

ARC

not

case

any

portionofthe

RAYS

damage hearing.

correct

AND

health.

ARC

(FCAW)

PARTS

touch

live

closed

can

eye,

GASES can

burn

Ventilatetokeep

gases.

breathing

Watch

Keepafire

howtouse

Allow

device.

METAL,

fire

and

for

fire.

work

SPATrER,

burns.

extinguisher

it.

and

handling.

FIELDS

affect

pacemaker operation.

Wearers

going

welding

should

near

arc

operations.

Speed

Control

Panel

View

SECTION

(GMAW)

WELDING

can

cause

electrical

while operating.

wire

outer

eyes

ear,

and body

from

breathing

equipmenttocool

FROM

consult

welding

AND

SHOCK

serious

can

parts.

feederisoperated

enclosure open

and

skin; NOISE

seriously

use

AND

nearby

HIGH

CURRENTS

their

doctor

gouging,orspot

5-1.

The

the

5-2. WIRE SPEED

The

88-124

467

in

ing

feed

6—

SEQUENCEOFOPERATION

FLUX

can kill;

injury;

damage

POWER

POWER switch

wire

feeder.

WIRE

SPEED

inches per

the WIRE

speed.

minute

The

WELDING

Wounds.

•

Do

any

1.

Install

2.

Wear

dry

3.

Connect

SPEED

not

conductive

and

piece.

or

protection.

harm

4.

A

Rotate

(see

WIRE

Section

WARNING:

•

Do

not

•

Do

not

contact

fumes

and

The

welding

withitcarry

approved

SLAG

and

know

can

source

5.

Energize

6.

Place

the

7.

Turnonshielding

8.

Wear

welding

accordingtoANSI Z49.1.

before

before

9.

Hold

from

flows,

is

Section 4-7.

tip

workpiece,

gas

noticed,

SWITCH

(Figure 5-1)

POWER

functions as

CONTROL

the

ON/OFF switch

(Figure 5-1)

WIRE SPEED

ojo

control

scaleiscalibratedininches per

point

connect

insulating gloves

work

touch

touch welding

withitwhile

weld

contactorisenergized.

the

welding

POWER switchintheONposition

of gun

flows,

adjust drive

adjusts

within

the

control

WIRE can

gun

wire

clockwise

toward

surface,orother

unit

according

clamptoclean,

SPEED

controltodesired

5-2).

ELECTRIC

live

SHOCK

electrical

wireorany

welding.

wire

and all

metal

output when

power

gasatthe

helmet with

approximately

and

depress

and

wire

feeds.Ifwire

roll

pressure

the

wire

feed

speed

range.

increases

minute.

cause

any

part of

puncture

the

personnel.

to Section

and

clothing.

bare metalatwork-

position

can kill.

parts.

metal

partsincontact

the

welding

sourceorgenerator.

source,ifapplicable.

proper filter lens

1/2 in.

gun

(13

trigger.

Current

slippage

according

TM-1571

for

speed

Rotat

wire

body

4.

part

in

power

mm)

to

Page

9

-

Page 14

WARNING: ELECTRIC

A

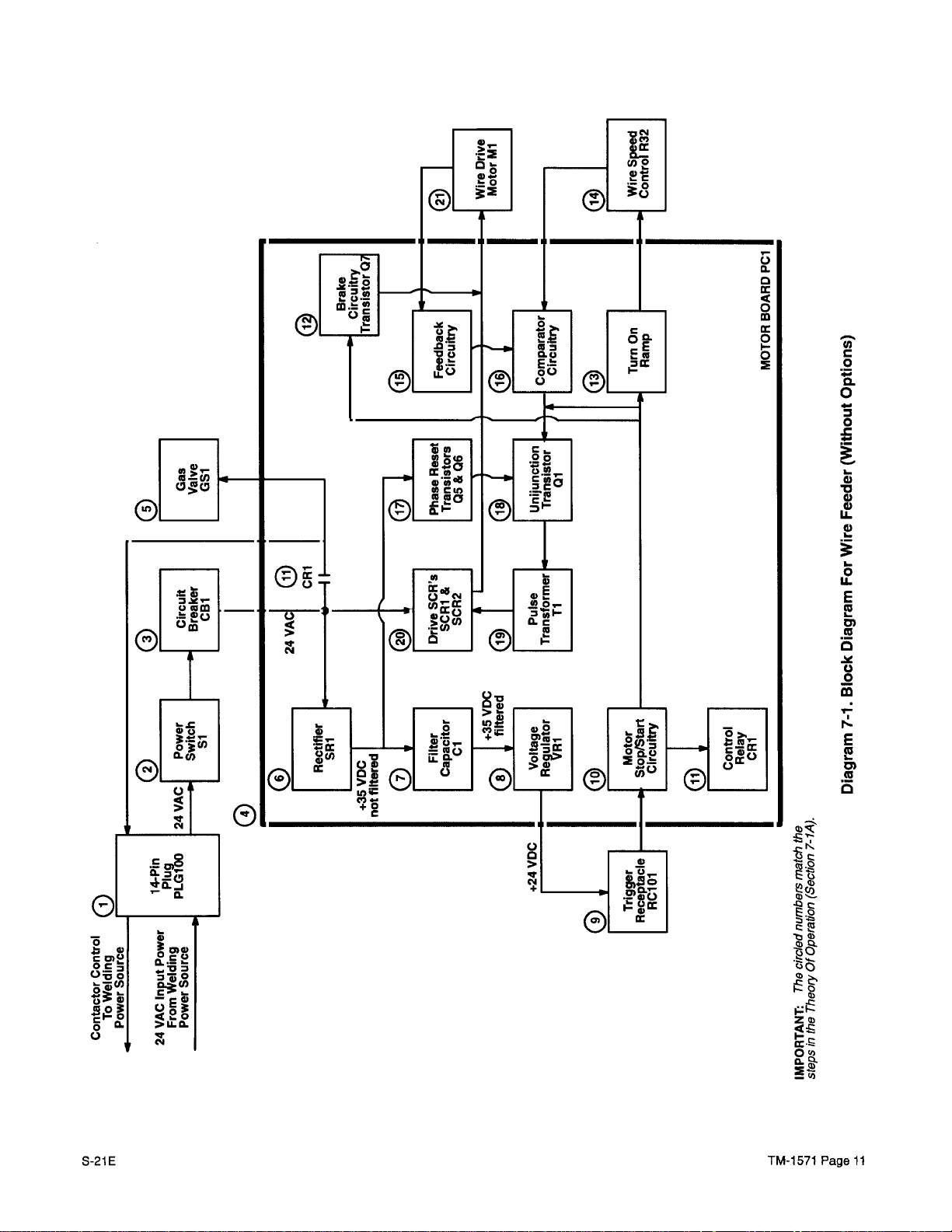

7-1.

IMPORTANT:

writteninsteps

grams

A.

TANGLED

causing

voltagetobe

pressed.

•

Do

pressed

•Ifwire

source,

•

Correctanyhub

liner

continue

THEORYOFOPERATION

7-1

and

Wire

Feeder

The

1.

2.

3.

4.

5.

6.

7.

8.

9.

14-pin

connecting cord

from

the

tactor

POWER switch51provides

volts ac

Circuit

for

the

Motor

drive

R32.

PCi

ing

power

CR1.

Gas

valve

weld

cycle.

Integrated

input

CapacitorClprovides

Voltage regulator

put

voltageto24

PCi

and

Trigger receptacle

put signaltothe

WELDING

welding

presentoncaseifgun

not

touch

and

stops

and

damage

welding.

The

following

which

match

7-2.

Without

plug PLG100onthe

welding

controltothe

input

powertothe

breaker

wire

Board

motorMlas

powertoa

CB1

feeder.

PCi

also

controls

source

051

rectifier

trigger

provides

SHOCK

WIRE can

power

wire

wire does

feeding,

determine

tension,jammed

problems

source

feeder

not

turn

the

caseifgun

feed.

off

welding

cause.

before

SECTION7-THEORYOFOPERATION

TheoryOfOperation

the

circled

Options

provides24volts ac

power

source

welding

provides

regulates

setbyWIRE

gas

contactor

shielding

SRi

converts

rectified35volts

filtering

VR1

reduces the35volts dcin-

volts dc

receptacle

RC101provides

motor

stop/start

numbersonDia-

(Diagram 7-1)

end of

and

power

on/oft

wire

feeder.

overload

the speedofwire

SPEED

valve

051

via

gas

the24volts ac

dc.

for

the35volts

for

control

RC1

01.

circuitry.

can kill;

touch

open-circuit

provides

source.

controlof24

control relay

the

case

trigger

wire,orgun

trying

the

input

protection

and

during

circuitry

triggerin-

trigger

power

inter

power

con-

control

weld-

the

dc.

is

is

to

is

on

6-2.

A

-

SHUTTING

1.

Stop

welding.

2.

Place

3.

Shut

down

4.

Turn

off

WARNING: HIGH

SHIELDING

•

Shut

10.

Motor

brake turnonramp,

trol relay circuitries.

11.

Control

welding

plug

PLG100.

12.

Brake

cal

path

13.

Turnonramp

control

14.

WIRE

the

comparator circuitrytocontrol the

15.

Feedback circuitry

with

a feedback

16.

Comparator circuitry compares feedback

to

R32

tion

circuitry

17.

Phase

ingofphase modulation.

18.

Unijuction

lation

19.

Pulse

lated

signaltothe

20.

Drive

phase

wire

drive

21.

Wire

drive

DOWN

POWER switchinthe

welding

shielding

off

gas

stop/start

relay

power

circuitry

for

motor

R32.

SPEED

control signal

reset

transistorsQ5and

transistorQicreates

from

the

transformerTitransfers

SCR’s

modulation

motor

motorMlfeeds

power

gasatsource,ifapplicable.

GAS

can

supply

circuitry

phase modulation,

CR1

controls

source

transistorQ7providesanelectri

current

provides

control

provides

signalofactual

and

accordingly.

charging of

gatesofSCRi

SCRi

and

signal

Mi.

OFF

sourceorgenerator.

CONCENTRATION

harm healthorkill.

when

provides

gas

contactor

during

powertoWIRE

R32

providesasignal

comparator circuitry

adjusts

capacitor ClO.

SCR2

and

the

position.

notinuse.

inputtothe

and

valve

051

through

braking.

wire

motor

voltage.

phase

Q6 reset the

the phase

the phase

and SCR2.

turnonfrom

supply

welding

power

wire.

OF

con-

and

the

14-pin

SPEED

to

speed.

signal

modula

tim

modu

modu

the

to

-

-

-

-

-

TM-1571

Page

10

S-21E

Page 15

0

4-

0.

0

•1~

0

4-

1~

4)

4)

LI

-

4)

I

-

0

U

-

E

(U

I

-

0)

(U

0

0

1~

E

(U

0)

(U

0

S-21E

-A

c~

.~

~(i)

.~Q)

tb~.

~3O

c~o

I—0

ZQ)

TM-1571

Page

11

Page 16

B.

SpotlBurnback

7-2)

1.

Optional

controlofspot

back

2.

Burnback

of

the

onds.

Time

Spot/Burnback

weld

time.

potentiometer

burnback

time between

Control

time

and

R26 allows

Option (Diagram

Board PC2

provides

adjustmentofburn-

adjustment

0.02

and

0.25

sec-

3.

Spot

time potentiometer R25 allows

of

spot time

seconds

DIP

Switch

4.

Spot/Continuous

mal

untimed

cycle.

5.

Spot

time

short

range

(0.25to5

from

0.12to2.5

dependingonthe

secondsor0.25to5

settingofSpot

Sl.

switch

weld

DIP

switch51provides

S51

allows

cycleora timed

(0.12to2.5 seconds)orlong

seconds)

spot

time.

adjustment

Time

either a

spot

nor

weld

a selection

range

-

of

Diagram 7-2.

Block

Diagram

For

Spot/Burnback

Time

Control

Option

TM-1571

Page

12

S-21E

Page 17

Notes

S-21E

TM-1571 Page 13

Page 18

SECTION

8—

TROUBLESHOOTING

8-1.

The

testing

ohmmeter

greater

for

fied,

pedanceorgreater.

TESTING

TION

INSTRUMENTS

service proceduresinthis

instruments.

(DVM)

and

variable

useagood

diode

resistor

Useagood quality

with

one

megohm

check capability

testing). Ifanoscilloscopeisspeci

quality

If a

unit

circuit

with

coating,itwillbenecessary

needle probesinthe

Recoat

Digital

areasifnecessary

volt-ohmmeters

larity attention

meter

may

indicate

procedure specified

rect

polarity

appearsonthe

connectionstotest

8-2.

A

CIRCUIT

WARNING:

•

Do

not

•

Shut

source,

ing

inspecting,

test

areatoobtain

to retain

(DVM’s)donot

when making connections.

a—(negative)

a+(positive) voltage.Ifthe

display, reverse

points.

BOARD

touch live

down

and

HANDLING

ELECTRIC

electrical

wire

feeder

disconnect

lockout/tagging

maintaining,orservicing.

Lockout/tagging procedures

sistofdisconnecting

for

welding

line

disconnect switchinopen

ing

fuses

tagging

device.

(—)

battery

power

source

from

fuse box,orshutting

circuit

Stop

cable

breakerorother

engine,

from

erators.

A

MOVING

•

Keep

HOT

•

Allow

CAUTION:

(ESD)

•

Put

BEFORE

•

Transport

shielding

•

Perform

INCORRECT

plugs

•

Be

PARTS

away

from

SURFACES

cooling

can

on

period

ELECTROSTATIC

damage

properly

handling

circuit

carriersorpackages.

work

onlyata static-safe

INSTALLATIONormisaligned

can

damage

sure

that

plugs

can

moving

can

aligned.

EXCESSIVE

board.

•

Use

ment

board

TM-1571 Page

14

PRESSURE

only

minimal pressure and

when

plugs

disconnectingorconnecting

and

removingorinstalling

AND

INFORMA

manual

require

digital

input

impedance

(useananalog VOM

one

megohm

board

has

a protective

to remove

coatingoruse

proper

corrosion

protection.

require

However,

voltage

when

meter

PRECAUTIONS

SHOCK

can

parts.

and

welding

input

power

procedures

forwirefeedercon

interconnecting

cord,

consistofpadlocking

position,

off

disconnecting

and

disconnect

batteryonwelding

cause serious

parts.

cause

severe burns.

before servicing.

circuit

grounded

circuit

DISCHARGE

boards.

wrist

boards.

boardsinproper

work

circuit board.

are

properly

can

installed

break

gentle

-

proper

volt-

or

-

inputim-

contact.

leadpo-

the

the

test

incor

-

lead

kill.

power

employ

-

before

-

and

remov

and

-

red-

negative

gen

-

injury.

strap

static-

area.

and

circuit

move

-

board.

8-3.

A

TROUBLESHOOTING

gram

8-1)

WARNING:

•

Do

not

touch

•

Shut

down

source,

ing

and

lockout/tagging

inspecting,

Lockout/tagging procedures

sistofdisconnecting

for

welding

line

disconnect

ing

fuses

from

tagging

device.

(—)

circuit

Stop

battery

erators.

MOVING

•

Keep away

HOT

•

Allow

PARTS

SURFACES

cooling

Troubleshootingtobe

qualified

The

troubleshooting

of

the

troubles

circuit

normally

persons.

that

tiedtoground mustbeat

tial.

Use

the tableinconjunction

manual

in

ubleshooting

When replacing

replacement

ranty

Resistance

made

fore

IMPORTANT:

dures,

overheating

winding(s) failure

smoke,

are

ers,

rosion,

saves

IMPORTANT: Be

and

and

with

and

the exploded

the

Service

Parts Manual

procedures.

components,

parts.

repair by

with the

making

authorized

and

continuity

unit

resistance

Before beginning troubleshooting

visually

examine

and

failure.

are

and

smell.

relatively

incorrect

simple:

switch positions, loose

and

the

like.Acomplete,

considerable

secure according

switches

areinproper

troubleshooting.

ELECTRIC

live

electrical

wire

feeder

disconnect

(Table

SHOCK

8-1

And

can

parts.

and

welding

input

power

procedures

Dia

kill.

power

employ

before

maintaining,orservicing.

forwire

interconnecting

feeder

cord,

con-

and

power source consistofpadlocking

switchinopen

fuse box,orshutting

breakerorother

engine,

cable

from

from

can

moving

can

period

and

batteryonwelding

cause

cause

before servicing.

position,

off

remov

and

red-

disconnecting

disconnect negative

gen

serious

injury.

parts.

severe

performed

burns.

only

by

tableisdesignedtodiagnose some

can

developinthis

with the

views

use

MILLER parts

warranty

measurements

shut

down.

Isolate

and

continuity

wire

feeder.

ground

poten

diagramsinthis

and

component

values

while performing

only

genuine

are

required

service

MILLER

for

agency.

must

components

measurements.

Any

tro

war-

be

be-

proce

internalcomponents

Many

major problems,

usually

Fortunately

blown

apparentbydiscoloration,

most

fuses,

tripped

careful

time,

sure

money

that

and

all connections

to Section4and

positions

elect

before

for

signs

such

rical

pro

blems

circuit

break

connections,

inspection

cor

often

frustration.

are

correct

that

all

controls

proceeding

S-21E

of

as

-

-

-

-

-

-

-

-

-

Page 19

Table 8-1.

Troubleshooting

TROUBLE

Wire

does not feed.

Wire feeds

Wire feeds

erratically. Pressureondrive

but thereisno

flow.

Wire

does not

is

pulled

but

continuestofeed

after

triggerisreleased.

Gun nozzle

The

gas

rattling

ble

erraticorslow

opening

valveinthe

loudly

speed.

Motor

runs

but

gized

with

Spot/Burnback

tion

installed.

feed

until

restricted. Weld

feeder

along

with possi-

wire

wireisnot

gas

trigger

feed

ener-

Op-

CAUSE REMEDY

Circuit

breaker

CB1.

Looseorimproperly

trigger

Welding

connection.

Gun

trigger. See

gun

shorted.

Motor

Ml.

Motor

Control

Board

poor connectionstoPCl.

ficient.

Drive

roll

wrong size

size

used.

Drive rolls

Dirt in

Motor

poor

Gas valve

Motor

poor

Welding

tween

and

worn.

drive

rolls.

Control

Board

connectionstoPCi.

GSl.

Control

Board

connectionstoPCl.

gunisshorted

one of

the

weld

cable.

spatterorforeign

accumulation.

is

Welding

tween

and

gunisshorted

one of

the

weld

cable.

Spot/Burnback

poor connectionstoPC2.

made gun

PCi

or

rollisinsuf-

for wire

PCl

or

PCl

or

be-

trigger leads

matter

be-

trigger leads

Board PC2

Check

pressure

tion

Check

gun

(see

10-5).

gun

4-3).

gun

Owner’s

Repairorreplace

Check

connections

motor brushes

if

necessary.

Check

Check

tion

Rotate

connections

PCi

8-4.

Replace

pressure adjustment

clockwisein1/4

stops

slipping

Changetocorrect

4-2).

Replace

drive rolls

Clean drive rolls

Check

Check

tion

Check

tions

Replace

tion

8-4.

(see

Check

Check

8-4.

connections

PCi

Replace

GS1

GSlifnecessary.

connections

PCl

Replace

Repairorreplace

Carefully

matter

nozzle

metal

remove

which

opening.

tool.

Repairorreplace

or

Check

connections

PC2

according

Replace

PC2ifnecessary.

liner,

hub

Section

trigger

tension,

4).

connection

and

Reset

(see

CBl

Manual.

welding

(see

gun.

for

continuitytoMl.

Section

for

10-4).

continuitytoPCl.

accordingtoDiagram

PClifnecessary.

knob

turn

increments

(see

Section

size drive

(see

(see

for

4-2).

roll

(see

Section

Section

4-2).

l0-lC).

continuitytoPCi.

accordingtoDiagram 8-2

PCiifnecessary.

for

proper

Diagram

coil

voltage

8-1).

Check

continuityofcoil.

for

continuitytoPCl.

accordingtoDiagram

PClifnecessary.

welding

any

may accumulate

Use

welding

to Diagram

gun.

weld spatterorforeign

around the

a hardwood

gun.

for

continuitytoPC2.

8-3

and Section 8-5.

drive

(see

Section

Replace

8-2

and

counter

until

the

Section

and

and

8-2

and

stick,

roll

Sec

Check

Ml

Sec

wire

Sec

connec

Sec

never

a

Check

5-21E

TM-i

571

Page

15

Page 20

~

~

~U)

~Z

~

&E

~

a~

~

~e

!FI

—

—

~

C’J CO

O

O

O

O~,

~

..~

— —

ow

~

~

+oO

o1t~0

~

—

U)

L

O~

~

N

(oIr-~0)

a

c

~ ~

ca

a~

0

zz:~~

O~

~ ~

— — —

0

CO

; ;

s.a

~

~

—

~

21

—

—

in

0,

=

Ci)

—

in

0)

LI

-

4)

I

-

I-

0

IL

E

(U

I-

0)

0

4-

0

I

-

(n

I—

0.

C,

z

0

U

o

o

0

1110 ~-0)0)

UJ:

0~

•c~~—-a-

Q~0~n~

~

• ~

~

0

—

S

0..o

~ ~

Oc~

=0

q~00

~-n’

0

0)

4-

0

L

0

.~

.-

Ci)

0)

.~

~Q)

0.

~0

~

•~

S

0

~

Ci)~

a

0.

-.

0

a

a

S

-

~

0

~

-~

0

S

0

(0

4

.0

0

I

-

E

(U

I..

0)

(U

OJ

I

TM-1571

)

Page 16

> >

CO

S-21E

Page 21

8-4.

A

MOTOR BOARD

TION

(Figure

W

ARNING:

Do

not

•

Shut

ELECTRIC

touch

down

8-1

wire

sourceorstop

changing

meter

disconnectingorconnecting

A

MOVING

•

Keep

HOT

•

Allow

This

~

ized.

ollowing

form this

CAUTION:

(ESD)

•

Putonproperly

FORE

•

shielding

•

Perform

INCORRECT

plugs

•

Be

PARTS

away

from

SURFACES

cooling

procedure requires the

Only

qualified

standard

testing

ELECTROSTATIC

can

damage

handling

Transport

circuit

carriersorpackages.

work

INSTALLATIONormisaligned

can

damage

sure

that

aligned.

EXCESSIVE

board.

•

Use

ment

board

IMPORTANT:

the

continuityofleads between

where

checkisperformed.

the

connections

so

that

bad

connectionsorleads

the

problem.

PRESSURE

only

minimal pressure and

when

plugs

and

For all checks,besuretotest

and be

PCi

TESTING

And

Diagram 8-2)

SHOCK

live

electrical

feeder and

engine

before

leadconnections

can

cause

moving

can

period

parts.

cause

before servicing.

persons

safety practices

INFORMA

can

kill.

parts.

welding

power

making

and

before

any

leads.

serious

severe burns.

unittobe

familiar

injury.

ener

with

aretoper-

or

and

procedure.

DISCHARGE

circuit

grounded

circuit

boardsinproper

onlyata static-safe

circuit board.

plugs

boards.

are

properly

boards.

wrist

installed

can

break

gentle

strap

static-

work

area.

circuit

move

BE-

and

disconnectingorconnecting

removing

All

actual

checks

orin

the

stalling

board

and

and

the

board.

verify

area

shouldgothrough

terminal-to-terminal

and

corrosion

are

tests

not

-

A.

Preliminary

1.

Check

tacle

2.

Check

Checks

that

RC1onMotor

that

RC2onMotor

3.

Check

that

RC3onMotor

4.

Check

that

RC3onMotor

B.

Power

Supply

Input powerof24

pinsAandBof

present,

-

CBl

An

output

pin A

If

+24

Control

An

output voltageof+6.5 volts dc

check

for

proper operation

of receptacle

volts dc

Board

receptacle

POWER

voltage

are

PCl.

pin Cofreceptacle

with

gun

trigger

pressed.

at

pin C,

C.

Trigger

When

replace

the

gun

Motor

Circuit

triggerispressed, +19

presentatpin Bofreceptacle

common

dc

is

start/stop

ceptacle

control relay

-

D.

The0to

signal

wire

current

providing the

to

otherwise

when

the

gun

triggerisnot

then

suppliedtopin Aofreceptacle

control signal

RCltocontrol

CR1onPCi.

Wire

Feed Speed

+6.5 volts dc

shouldbepresentatpin Dofreceptacle

feed

speed

and

voltage

proper

wire

drive

motorMlthrough

(negative)ofreceptacle

present

Control

between pinsCandDof

Board

PCi.

jumper

volts ac

plug