Page 1

Ef

f. w/Serial Number JJ487350

April 1993

Multiprocess W

Remote Pendant Control

RPC-IP

elding

V

isit our website at

Page 2

SECTION 1 – INTRODUCTION

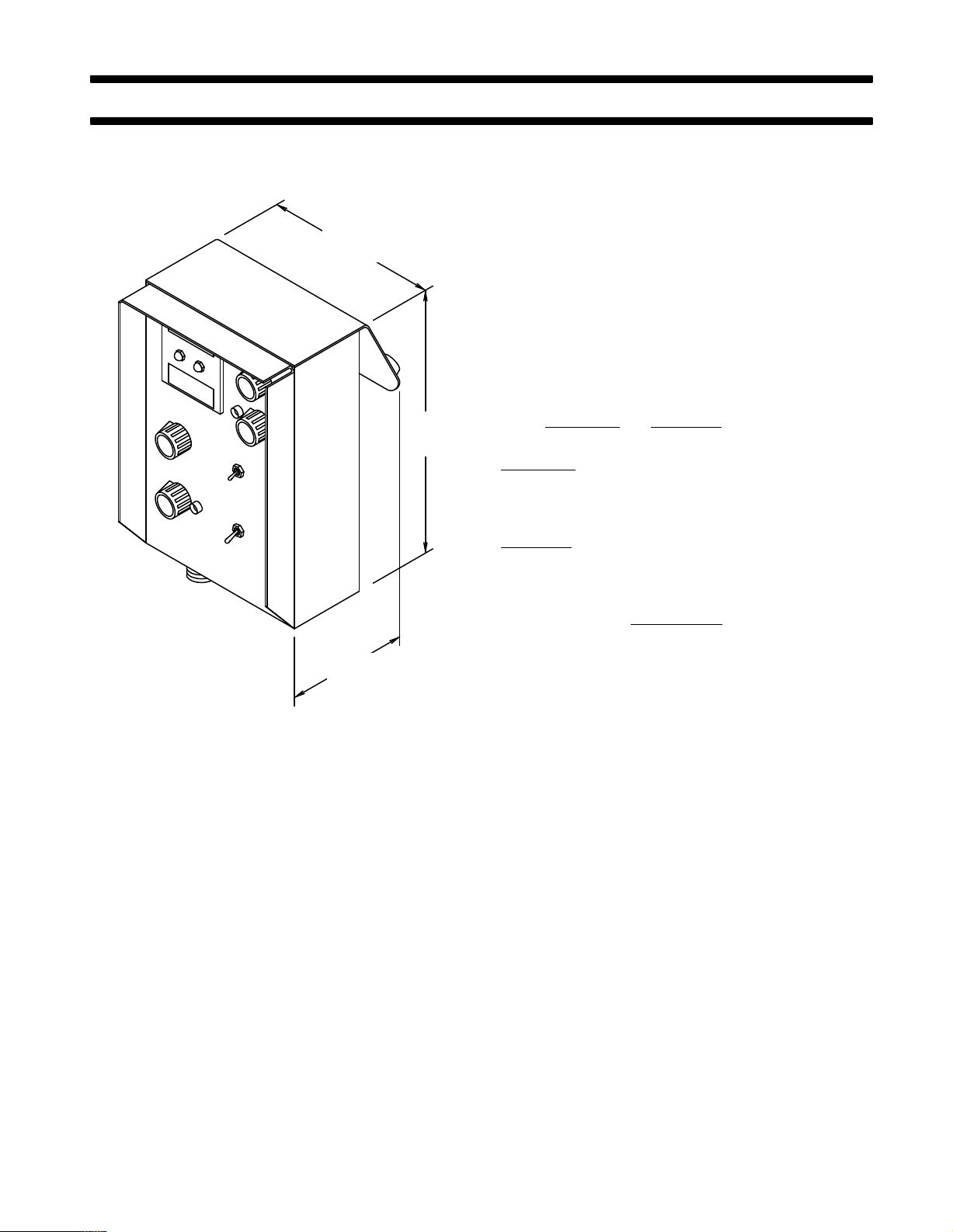

5-3/4 in.

(141 mm)

9-3/8 in.

(238 mm)

5 in.

(123 mm)

ST-109 521-A

Figure 1-1. Dimensions

1-1. GENERAL INFORMATION AND SAFETY A. General

Information

presented in this manual and on various

bels, tags, and plates provided on this unit pertains to

equipment

and

design,

troubleshooting which should be read,

installation, operation, maintenance,

understood,

la

and

followed for the safe and ef

fective use of this equip

ment.

B. Safety

The installation, operation, maintenance, and troubleshooting of arc welding equipment requires practices

and procedures which ensure personal safety and the

safety of others. Therefore, this equipment is to be

installed, operated, and maintained only by qualified

persons

ble

Welding

in accordance with

codes such as, but not limited to, those listed in Arc

Safety Precautions Section in the welding pow

this manual and all applica

er source Owner’s Manual.

instructions specifically pertaining to this unit ap

Safety

pear throughout this manual highlighted by the signal

words

WARNING

and

CAUTION

which identify dif

levels of hazard.

WARNING

statements include installation, operation,

and maintenance procedures or practices which if not

carefully

followed could result in serious personal injury

or loss of life.

CAUTION

statements include installation, operation,

and maintenance procedures or practices which if not

carefully

followed could result in minor personal injury or

damage to this equipment.

A

third signal word,

which

need special emphasis to obtain the most ef

IMPORTANT

, highlights instructions

operation of this equipment.

1-2. RECEIVING-HANDLING

unpacking equipment,

Before

check carton for any dam

age that may have occurred during shipment. File any

claims for loss or damage with the delivering carrier.

Assistance for filing or settling claims may be obtained

from the distributor and/or the equipment manufacturer’s Transportation Department.

When requesting information about this equipment, al-

provide the Model Description and Serial Number

ways

1-3.

DESCRIPTION

This

unit is a Remote Pendant Control for the Intellipulse

-

welding

welding

tactor

power source. When properly connected to

power source this unit provides arc control, con

control, voltage/amperage control, CV/CC selec

tion, and pulse frequency selection.

-

-

-

-

ferent

ficient

-

.

the

-

-

OM-533 Page 1

Page 3

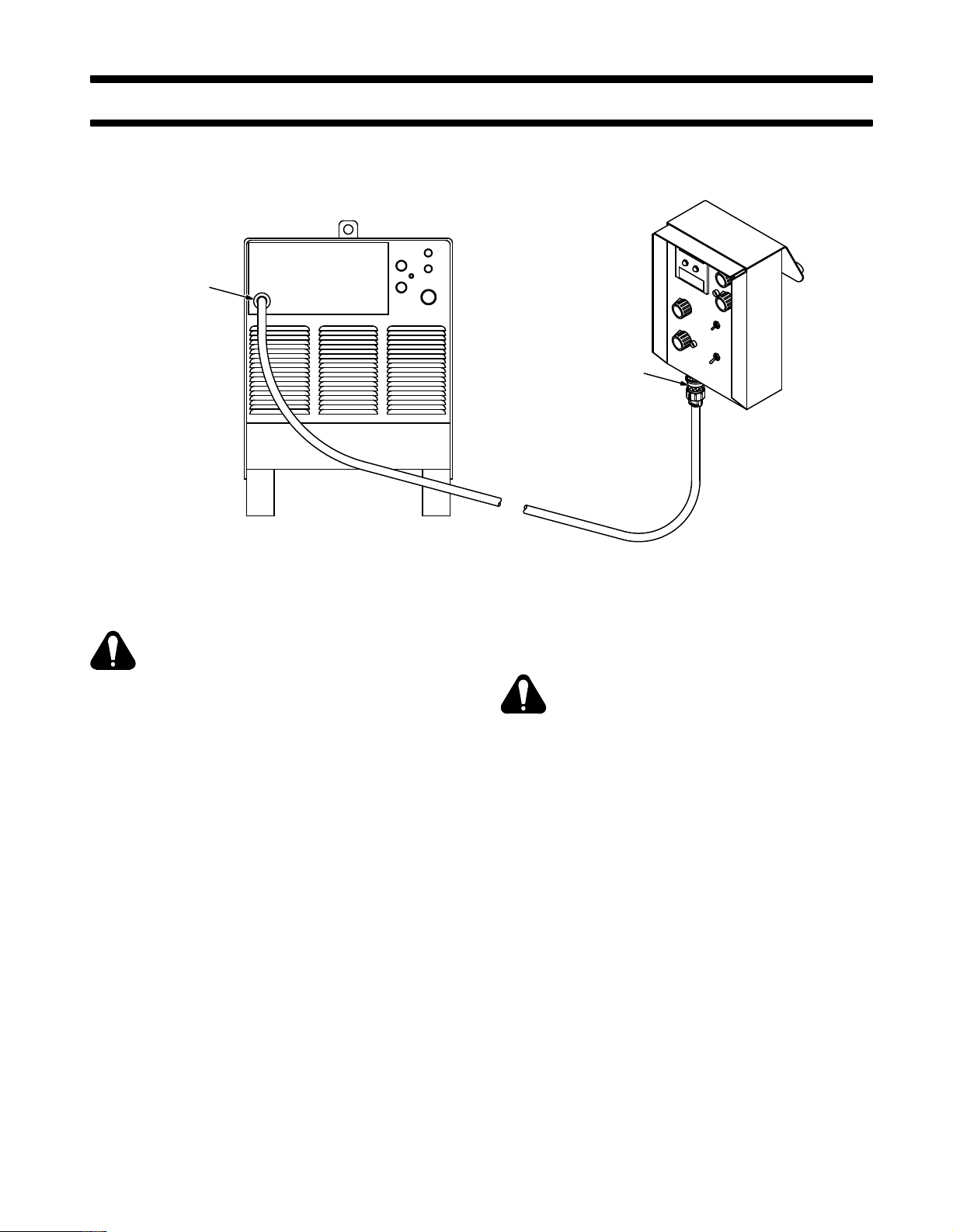

W

elding Power

Source Remote

Control Receptacle

SECTION 2 – INSTALLATION

RPC-IP

Receptacle

Figure 2-1. Power Source/Remote Control Connections

WARNING: ELECTRIC SHOCK can kill.

•

Do not touch live electrical parts.

•

Shut down welding power source, and be

sure it cannot be accidentally energized before

making remote Pendant Control connections.

•

Place CONTACTOR switch in OFF position.

2-1. WELDING POWER SOURCE REMOTE CONTROL

RECEPT

The Remote Pendant Control connects to a 17-socket

Amphenol

panel

(see OM-286). Insert 17-pin Amphenol plug

the interconnecting cable fully into the receptacle and

rotate collar clockwise.

2-2. RPC-IP RECEPTACLE CONNECTIONS (Figure 2-1)

The interconnecting cable from the welding power

source connects to a 17-pin Amphenol receptacle on

remote control. Insert the 17-socket plug from the

the

terconnecting

collar clockwise.

OM-533 Page 2

ACLE CONNECTIONS (Figure 2-1)

receptacle on the welding power source

cable fully into the receptacle, and rotate

front

from

in

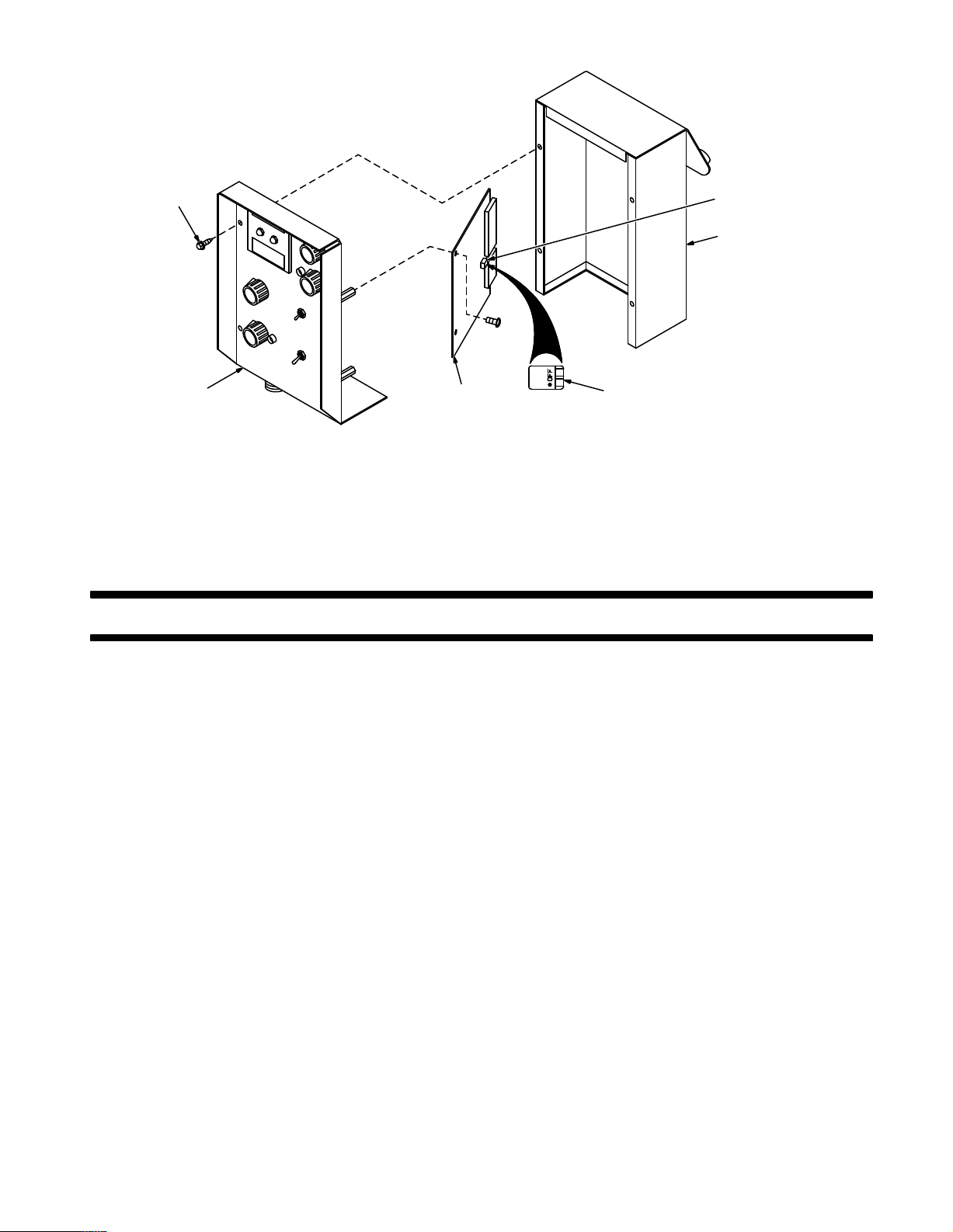

2-3. 650/1000 AMPERE MODEL SELECTOR SWITCH

WARNING: ELECTRIC SHOCK can kill.

•

Do not touch live electrical parts.

•

Shut down welding power source, and dis-

connect the Remote Pendant Control before

changing position of dip switches.

ELECTROSTATIC DISCHARGE (ESD) can

damage circuit boards.

•

Put on properly grounded wrist strap BE-

FORE handling circuit boards.

•

Perform

This Remote Pendant Control is designed to be used

with either a 650 or 1000 ampere intellipulse welding

power source. A dip switch is located on circuit board

to set up the Remote Pendant Control for operation

PC5

with 650 or 1000 ampere models. The unit is shipped

the factory set up for

from

models.

dant Control for operation with 1000 ampere models:

1. Remove cover.

2. Place

-

3. Reinstall cover.

Proceed as follows to set up the Remote Pen

both dip switches in the down position for op

eration with 1000 ampere models. Place both dip

switches in up position for operation with 650 ampere models (see Figure 2-2).

work only at a static-safe work area.

operation with the 650 ampere

ST-109 782-B

-

-

Page 4

Mounting

Screws (5)

Dip

Switch

Cover

Front

Panel

Figure 2-2. Dip Switch Positions And Locations

SECTION 3 – OPERATOR CONTROLS

3-1. MODE

The Mode Selector switch allows selection of CC

(constant

put from the welding power source.

The

CC position provides a constant current output spe

cifically designed for Shielded Metal Arc (SMAW) and

Gas

T

position

(CAC-A) and gouging processes.

The

CV position provides a constant voltage output de

signed

Arc (GMAW), Flux Cored Arc (FCAW), or Submerged

Arc

(SA

SELECT

current), CV (constant voltage),

ungsten Arc (GTAW) W

OR SWITCH (Figure 3-1)

or pulsed out

elding processes. The CC

is also normally used for Air Carbon Arc Cutting

for wire feeding applications such as Gas Metal

W) Welding.

Circuit

Board

PC5

Both dip switches down for

1000 ampere model operation

Both dip switches up for

650 ampere model operation

approached. When this control is set at some value

above 0, the current begins to increase when arc voltage drops below 20 volts.

When the control is set at 10 (MAX.), the short-circuit

current

rent (see welding power source volt-ampere curve for

CC

out-of-position

is considerably

higher than normal welding cur

mode). This provides extra current for arc starting in

welds as well as for certain types of elec

trodes.

the control is set at 0 (SOFT), short-circuit current

When

is the same as normal welding current. The 0 position

provides

current characteristics associated

Tungsten Arc Welding (GTAW) process.

ST-113 509-A

-

-

with the Gas

When

pulsed output is desired for Gas Metal Arc W

ing

- Pulsed Arc (GMAW-P), place switch at the desired

eld-

number of pulses per second: 60, 90, 120 or 180.

3-2. ARC

IMPORTANT:

pilot

CONTROL AND PILOT LIGHT

The ARC CONTROL potentiometer and

light are disabled in the CV (Constant V

(Figure 3-1)

oltage) and

pulsed modes.

The ARC CONTROL potentiometer provides variable

selection of short-circuit current to suit individual welding conditions. Rotating this control clockwise causes

the current to increase as the short-circuit condition is

When the control is set at 5, short-circuit current is

approximately

higher

than normal welding current. The 5 position pro

half that of the 10 (MAX.) position but still

vides a moderate current increase for arc starting necessary

for certain types of electrodes and

applications.

Select a setting best suited for the application.

The Arc Control pilot light turns on when the Mode Se-

lector

switch is in the CC position indicating that the ARC

CONTROL is active.

IMPORTANT:

The ARC CONTROL can be adjusted

while welding.

OM-533 Page 3

-

Page 5

Voltmeter

Ammeter

Volts/Peak

Control And

Pilot Light

Mode

Selector

Switch

Ammeter

Switch

Arc

Control

Arc Control

Pilot Light

Contactor

Switch

Figure 3-1. Front Panel View

Amps/Bkgd

Control And

Pilot Light

ST-109 521-A

3-3. CONTACTOR SWITCH (Figure 3-1)

WARNING: ELECTRIC SHOCK can kill.

•

Do not touch live electrical parts.

•

Do

not touch the weld output terminals when

the contactor is energized.

•

Do not touch electrode holder (or gun wire)

and work clamp at the same time.

If

the Remote

position,

Control CONT

ACT

OR switch is in the ON

open-circuit voltage will be present at the out

put terminals whenever the welding power source

POWER switch ON button is depressed.

IMPORTANT:

on

the nameplate and throughout this manual, the

Although the term CONT

ACT

OR is used

weld

output is not switched on or off by a physical secondary

contactor;

rather

, the weld output is controlled by

solid-

state circuitry in the welding power source.

If

contactor control by means of

a wire feeder is desired,

place the Remote Control CONTACTOR switch in the

OFF

position. Open-circuit voltage will be present at the

weld output terminals whenever the gun switch is

closed.

The

OFF position is normally used with all wire feeding

processes (GMAW, GMAW-P, FCAW, SAW) and the

Gas Tungsten Arc Welding (GTAW) process. The ON

position is normally used with the Shielded Metal Arc

Welding

(SMA

W) and the Air Carbon Arc (CAC-A)

Cut

-

ting and gouging processes.

Lift end of toggle switch to change switch positions.

OM-533 Page 4

3-4. AMMETER SWITCH (Figure 3-1)

The AMMETER switch provides selection of reading

PEAK weld amperage or Average (AVG) weld amperage on the Remote Control digital ammeter.

Normally the AVG switch position is used for reading

weld amperage during Gas Metal Arc (GMAW), Flux

Cored Arc (FCAW), Submerged Arc (SAW), Shielded

Metal

Arc (SMA

W), Gas T

ungsten Arc (GTAW) W

elding

and Air Carbon Arc (CAC-A) Cutting and gouging processes.

While

welding using the Gas

Arc (GMAW-P) process, the A

Metal Arc W

elding - Pulsed

VG switch position is

used

when display of the average (background and peak)

weld amperage is desired. The AMMETER switch can

be placed in the PEAK position when display of peak

weld amperage is desired.

3-5. AMPS/BKGD CONTROL AND PILOT LIGHT (Figure 3-1)

control presets weld amperage for constant current

This

applications and background amperage for GMAW-P

applications.

the Mode Selector switch is in the

When

CC position or

one of the pulses per second positions, the AMPS/

BKGD pilot light turns on.

control is disabled

This

when the Mode Selector switch

is in the CV position.

Rotating the control clockwise increases amperage.

IMPORTANT:

The AMPS/BKGD control can be ad-

justed while welding.

Page 6

3-6. VOLTS/PEAK CONTROL AND PILOT LIGHT (Figure 3-1)

This control presets weld voltage for constant voltage

applications and peak voltage for GMAW-P applications.

the Mode Selector switch is in the

When

one of the pulses per second positions, the VOLTS/

PEAK pilot light turns on.

This

control is disabled

is in the CC position.

Rotating the control clockwise increases voltage.

when the Mode Selector switch

CV position or

SECTION 4 – SEQUENCE OF OPERATION

IMPORTANT:

justed while welding.

3-7. METERS (Figure 3-1)

The

voltmeter displays weld

of a volt while welding and preset voltage when unit is

idling.

When welding using the pulsed GMA

the meter displays peak voltage.

The ammeter displays weld amperage to the nearest

ampere

idling.

the meter displays background amperage.

while welding and preset amperage

When welding using the pulsed GMA

The VOLTS/PEAK control can be ad-

voltage to the nearest tenth

W process,

when unit is

W process,

WARNING: ELECTRIC SHOCK can kill;

MOVING PARTS can cause serious injury;

IMPROPER AIR FLOW AND EXPOSURE TO

ENVIRONMENT can damage internal parts.

•

Keep

all covers and panels in place while

erating.

Warranty is void if the welding power source is

operated

removed.

ARC RAYS, SPARKS, AND HOT SURFACES

can

hearing.

•

FUMES AND GASES can seriously harm

your health.

•

gases from the breathing zone.

WELDING WIRE can cause puncture

wounds.

•

or other personnel.

HOT METAL, SPATTER, AND SLAG can

cause fire and burns.

•

•

how to use it.

MAGNETIC

can affect pacemaker operation.

•

fore going near arc welding, gouging, or spot

welding operations.

See

the welding power source Owner’s Manual.

with any portion of the outer enclosure

burn eyes

Wear correct eye, ear, and body protection.

Use enough ventilation to keep fumes and

Do

not point gun toward any part of the body

Watch for fire.

Have a fire extinguisher nearby and know

Wearers should consult with their doctor be-

Arc W

and skin; NOISE can damage

FIELDS

elding Safety Precautions Section in

FROM HIGH CURRENTS

op

4-1. GAS METAL ARC WELDING - PULSED ARC (GMAW-P)

WARNING:

-

1. Install

2. Install Remote Control as instructed in Section 2.

3. Install

4. Wear dry insulating gloves and clothing, and wear

5. Prepare for welding as follows:

6. Depress

7. Place Mode Selector switch to desired pulses per

8. Place CONTACTOR switch in OFF position (see

9. Place

10. Preset

tion at beginning of entire Section 4 before

proceeding.

and prepare welding power source according

to its Owner’s Manual.

and prepare wire feeder according to its Own

er’s Manual.

welding helmet with proper filter lens according to

ANSI Z49.1.

a. Connect work clamp to clean, bare metal at

workpiece.

b. Select and obtain proper welding wire, and

thread as instructed in wire feeder Owner’s

Manual.

welding power source POWER switch

button.

second (60, 90, 120, or 180) position (see Section

3-1).

Section 3-3).

AMMETER switch in the desired position (see

Section 3-4).

AMPS/BKGD control to desired

amperage setting (see Section 3-5). Pilot light

should be on.

Read and follow safety informa

-

-

ON

background

OM-533 Page 5

Page 7

11. Preset VOLTS/PEAK control to desired peak voltage setting (see Section 3-6). Pilot light should be

on.

12. Make adjustments to wire feeder.

13. Turn on shielding gas supply.

14. Begin welding.

4-2. GAS METAL ARC AND FLUX CORED ARC WELDING (GMAW AND FCAW)

WARNING:

Read and follow safety informa

tion at beginning of entire Section 4 before

proceeding.

1. Install

and prepare welding power source according

to its Owner’s Manual.

2. Install Remote Control as instructed in Section 2.

3. Install

and prepare wire feeder according to its Own

er’s Manual.

4. Wear dry insulating gloves and clothing, and wear

welding helmet with proper filter lens according to

ANSI Z49.1.

5. Prepare for welding as follows:

a. Connect work clamp to clean, bare metal at

workpiece.

4. Place Mode Selector switch in CC position (see

Section 3-1).

5. Place

ARC CONTROL to desired position (see

tion 3-2). Pilot light should be on.

6. Place CONTACTOR switch in ON position (see

Section 3-3).

7. Place

AMMETER switch in A

VG (A

verage) position

(see Section 3-4).

8. Preset

-

AMPS/BKGD

control to desired weld amper

age setting (see Section 3-5). Pilot light should be

on.

9. Wear dry insulating gloves and clothing, and wear

welding helmet with proper filter lens according to

ANSI Z49.1.

10. Prepare for welding as follows:

a. Connect work clamp to clean, bare metal at

-

workpiece.

b. Select and obtain proper electrode, and insert

into electrode holder.

11. Begin welding.

4-4.

SUBMERGED ARC WELDING (SA

WARNING:

Read and follow safety informa

tion at beginning of entire Section 4 before

proceeding.

W)

Sec

-

-

-

b. Select and obtain proper welding wire, and

thread as instructed in wire feeder Owner’s

Manual.

6. Depress

welding power source POWER switch

ON

button.

7. Place Mode Selector switch in CV position (see

Section 3-1).

8. Place CONTACTOR switch in OFF position (see

Section 3-3).

9. Place

AMMETER switch in A

VG (A

verage) position

(see Section 3-4).

10. Preset VOLTS/PEAK control to desired weld voltage setting (see Section 3-6). Pilot light should be

on.

11. Make adjustments to wire feeder.

12. Turn on shielding gas supply if applicable.

13. Begin welding.

4-3. SHIELDED METAL ARC WELDING (SMAW)

WARNING:

Read and follow safety informa

tion at beginning of entire Section 4 before

proceeding.

1. Install

and prepare welding power source according

to its Owner’s Manual.

2. Install Remote Control as instructed in Section 2.

3. Depress

button.

OM-533 Page 6

welding power source POWER switch

ON

1. Install

and prepare welding power source according

to its Owner’s Manual.

2. Install Remote Control as instructed in Section 2.

3. Install

4. Install

flux system according to its Owner’s Manual.

and prepare wire feeder according to its Own

er’s Manual.

5. Wear dry insulating gloves and clothing, and wear

safety

goggles with correct filter shade according to

ANSI Z49.1.

6. Prepare for welding as follows:

a. Connect work clamp to clean, bare metal at

workpiece.

b. Select and obtain proper welding wire, and

thread as instructed in wire feeder Owner’s

Manual.

c. Select and obtain proper flux, and put into flux

system.

7. Depress

welding power source POWER switch

button.

8. Place Mode Selector switch in CV position (see

-

Section 3-1).

9. Place CONTACTOR switch in OFF position (see

Section 3-3).

10. Place

AMMETER switch in A

VG (A

verage) position

(see Section 3-4).

11. Preset VOLTS/PEAK control to desired weld voltage setting (see Section 3-6). Pilot light should be

on.

-

ON

Page 8

12. Make adjustments to wire feeder.

13. Turn on flux supply system.

14. Begin welding.

4-5. GAS TUNGSTEN ARC WELDING (GTAW)

4-6. AIR CARBON ARC CUTTING AND GOUGING (CAC-A)

WARNING:

tion at beginning of entire Section 4 before

proceeding.

Read and follow safety informa

-

WARNING:

tion at beginning of entire Section 4 before

proceeding.

1. Install

2. Install Remote Control as instructed in Section 2.

3. Install

4. Depress

5. Place Mode Selector switch in CC position (see

6. Set

7. Place CONTACTOR switch in ON position (see

8. Place

9. Preset

10. Wear dry insulating gloves and clothing, and wear

11. Prepare for welding as follows:

12. Turn on shielding gas and water supplies as appli-

13. Turn on and adjust High-Frequency unit if applica-

14. Begin welding.

and prepare welding power source according

to its Owner’s Manual.

and prepare High-Frequency unit according

to its Owner’s Manual if applicable. Scratch start

GTAW

does not require the use of external high fre

quency.

button.

Section 3-1).

ARC

light should be on.

Section 3-3).

AMMETER switch in A

(see Section 3-4).

AMPS/BKGD

age setting (see Section 3-5). Pilot light should be

on.

welding helmet with proper filter lens according to

ANSI Z49.1.

a. Connect work clamp to clean, bare metal at

workpiece.

b. Select and obtain proper tungsten electrode.

c. Prepare tungsten electrode according to weld-

ing power source Owner’s Manual, and insert

into torch.

cable.

ble.

Read and follow safety informa

welding power source POWER switch

CONTROL to MIN. (see Section 3-2). Pilot

VG (A

verage) position

control to desired weld amper

ON

-

1. Install

2. Install Remote Control as instructed in Section 2.

3. Connect compressed air supply.

4. Depress

5. Place Mode Selector switch in CC position (see

-

6. Set ARC CONTROL to desired position (see Sec-

7. Place CONTACTOR switch in ON position (see

8. Place

9. Preset AMPS/BKGD control to desired amperage

10. Wear dry insulating gloves and clothing, and wear

11. Prepare for welding as follows:

-

12. Turn on air supply.

13. Begin cutting/gouging process.

4-7. SHUTTING DOWN

1. Stop welding.

2. Depress

3. Turn

4. Turn

and prepare welding power source according

to its Owner’s Manual.

welding power source POWER switch

button.

Section 3-1).

tion 3-2). Pilot light should be on.

Section 3-3).

AMMETER switch in A

(see Section 3-4).

setting (see Section 3-5). Pilot light should be on.

welding helmet with proper filter lens according to

ANSI Z49.1.

a. Connect work clamp to clean, bare metal at

workpiece.

b. Select

OFF button.

cable.

plicable.

and obtain proper carbon electrode,

insert into torch.

the welding power source POWER switch

of

f the shielding gas and water supplies if appli

WARNING: HIGH CONCENTRATION OF

SHIELDING GASES can harm health or kill.

•

Shut off gas supply when not in use.

of

f flux

supply and compressed air supply if ap

VG (A

verage) position

ON

and

-

-

OM-533 Page 7

Page 9

SECTION 5 – MAINTENANCE & TROUBLESHOOTING

5-1. MAINTENANCE

Usage

and shop conditions will determine the frequency

and

type of maintenance. Inspect equipment as follows:

WARNING: ELECTRIC SHOCK can kill.

•

Do not touch live electrical parts.

•

Shut down welding power source, and dis-

connect

taining, or servicing unit. Power to the remote

control

ing repair or replacement of internal components.

1. Inspect interconnecting cord for damage to or

breaks in the insulation jacket, particularly at the

plugs. Repair or replace cord as necessary.

2. Remove

ture from electrical parts and cable.

5-2. TROUBLESHOOTING

WARNING: ELECTRIC SHOCK can kill.

•

•

connect

taining, or servicing unit. Power to the remote

control

ing repair or replacement of internal components.

CAUTION: ELECTROSTATIC DISCHARGE

(ESD) can damage circuit boards.

•

FORE handling circuit boards.

•

shielding carriers or packages.

•

INCORRECT INSTALLATION or misaligned

plugs can damage circuit board.

•

aligned.

EXCESSIVE PRESSURE can break circuit

board.

•

ment when disconnecting or connecting board

plugs and removing or installing board.

remote control before inspecting, main

should be disconnected before

grease

Do not touch live electrical parts.

Shut down welding power source, and dis-

Put on properly grounded wrist strap BE-

Transport circuit boards in proper static-

Perform

Be sure that plugs are properly installed and

Use

and grime from components; mois

remote control before inspecting, main

should be disconnected before

work only at a static-safe work area.

only minimal pressure and gentle move

attempt

attempt

A. General

It is assumed that proper installation has been made,

according

has been functioning properly until trouble developed.

B. Troubleshooting

Troubleshooting to be performed only by qualified persons.

-

The following information is supplied to diagnose and

-

provide

velop

Manual

source malfunctions.

Use this information in conjunction with the circuit diagram while performing troubleshooting procedures. If

the trouble is not remedied after performing these pro-

cedures, the nearest Factory Authorized Service Sta-

tion/Service Distribuitor should be contacted. In all

cases of equipment malfunction, the manufacturer’s

recommendations should be strictly followed.

Problems with this unit fall into four categories:

1. Front panel components

-

2. Circuit board PC5

-

3. Interconnecting cable

4. Welding power source.

If everything on the remote control functions except a

particular

attributed to a broken component. Replace the broken

component.

If

the problem is still present,

control

conditions occur and the welding power source was

working properly, replace PC5.

A

break in the

or

command signal between welding power source

remote

continuity is suspected.

Printed circuit board PC1 in the welding power source

sends

-

other components of the system are functioning, replace welding power source PC1 according to instructions in welding power source Owner’s Manual.

to

Section 2 of this manual, and that the unit

remedies for some of the troubles that may

in

this unit. Check welding power source Owner

for possible problems caused

switch, meter

is entirely non-functional, replace

interconnecting cable can interrupt power

control. Replace interconnecting cable

and receives signals from the remote control. If

, or control, the problem can be

replace PC5. If the remote

by welding power

de

’s

PC5. If erratic

and

if lack of

all

-

OM-533 Page 8

Page 10

SECTION 6 – ELECTRICAL DIAGRAMS

Circuit Diagram No. SB-107 993-B

Diagram 6-1. Circuit Diagram For Pendant Control

Circuit Diagram No. SB-124 223

Diagram 6-2. Circuit Diagram For Circuit Board PC5

OM-533 Page 9

Page 11

Wiring Diagram No. SC-122 538-B

OM-533 Page 10

Diagram 6-3. Wiring Diagram For Pendant Control

Page 12

SECTION 7 – PARTS LIST

Item

No.

Dia.

Mkgs.

Part

No.

Description

Figure 7-1. Main Assembly

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 108 056 CASE SECTION, front end 1.

2 109 779 CASE 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 R6,7 603 856 POTENTIOMETER, WW 10 turn 2 watt 10K ohm 2.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 S7 011 770 SWITCH, toggle SPDT 5 amp 125 volts 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 S8 079 722 SWITCH, toggle SPDT 0.4 amp 2-4 volts dc 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 LED1-3 083 850 LIGHT, indicator - red lens 2 volts 3.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 RC3 097 867 RECEPTACLE, 17 pin MS-3102A-20-29P 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 NAMEPLATE (order by model & style number) 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 R8 009 156 POTENTIOMETER, carbon 1 turn 2 watt 2.5K ohm 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 S6 108 944 SWITCH, rotary - 0.5 amp 115 volts ac 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 108 903 SHIELD, meter 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 A&V 108 453 METER, DC 0-200 MV 2.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . .

PC5 124 002 CIRCUIT CARD, pendant 1.

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

108 904 ANCHOR, meter 1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

038 785 STRIP, terminal 3 pole 1.

072 566 CONNECTOR, rect 8skt plug Amp 87159-8 1.

081 380 CONNECTOR, rect 14skt plug Amp 1-87159-3 1.

108 907 CONNECTOR, rect 13skt 1 row plug Amp 2-87499-3 2.

097 922 KNOB, pointer 4.

019 663 MOUNT, 15/16 OD x 3/8 2.

097 132 STAND-OFF, No. 6-32 x 3/8 inches 4.

094 484 STAND-OFF, No. 6-32 x 1 inch 4.

108 863 CABLE, interconnecting (consisting of) 1.

097 868 CONNECTOR, circ 17skt plug Amphenol MS-3106A-20-29S 1.

039 734 CONNECTOR, circ clamp str rlf Amphenol AN-3057-12 2.

090 263 CABLE, pwr No. 18ga 18/c (order by ft) 15ft.

097 866 CONNECTOR, circ 17 pin plug Amphenol MS-3106A-20-29P 1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

Quantity

.

Hardware

not available unless listed.

is common and

12

11

10

1

2

3

9

8

7

6

5

4

ST-109 521

Figure 7-1. Main Assembly

To maintain the factory original performance of your equipment, use only Manufacturer’s Suggested

Replacement Parts. Model and serial number required when ordering parts from your local distributor.

OM-533 Page 1

1

Loading...

Loading...