Page 1

February 1992 FORM: OM-823G

Effective With Serial No. KB055102

MODEL: RHC-3

RHC-3-2

RHC-3GD9A

RHC-3GD25B

RHCS-3

RHC-3-GD34A

RHC-14

RHC-23

OWNER’S MANUAL

IMPORTANT: Read and understand the entire contents of both this manual

and the power source manual used with this unit, with special emphasis on

the safety material throughout both manuals, before installing, operating, or

maintaining this equipment. This unit and these instructions are for use only

by persons trained and experienced in the safe operation of welding equipment. Do not allow untrained persons to install, operate, or maintain this unit.

Contact your distributor if you do not fully understand these instructions.

SA-141 127 PRINTED IN U.S.A.

MILLER ELECTRIC Mfg. Co.

A Miller Group Ltd., Company

P.O. Box 1079

Appleton, WI 54912 USA

Tel. 414-734-9821

Page 2

Page 3

RECEIVING-HANDLING

OM-823G - 2/92

Before unpacking equipment, check carton for any

damage that may have occurred during shipment. File

any claims for loss or damage with the delivering car-

rier. Assistance for filing or settling claims may be obtained from the distributor and/or the equipment manufacturer’s Transportation Department.

When requesting information about this equipment, always provide the Model Description and Serial or Style

Number.

TABLE OF CONTENTS

Section No. Page No.

SECTION 1 − SAFETY PRECAUTIONS AND SIGNAL WORDS

1-1. General Information And Safety 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2. Safety Alert Symbol And Signal Words 1. . . . . . . . . . . . . . . . . . . . . . . . .

1-3. Description 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Use the following spaces to record the Model Designation and Serial or Style Number of your unit. The information is located on the rating label or nameplate.

Model

Serial or Style No.

Date of Purchase

SECTION 2 − INSTALLATION

2-1. Location 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2. Interconnections 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 − OPERATOR CONTROLS

3-1. Operation 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2. Contactor Switch 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4 − MAINTENANCE

SECTION 5 − ELECTRICAL DIAGRAMS

Diagram 5-1. Circuit Diagram For Remote Hand Control Used With

Transformer Arc Welding Power Source 3. . . . . . . . . . . . . . . .

Diagram 5-2. Circuit Diagram For RHCS-3 3. . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 5-3. Circuit Diagram For RHC-3-GD9A And RHC-3-GD34A 3. . . .

Diagram 5-4. Circuit Diagram For RHC-3-GD25B 4. . . . . . . . . . . . . . . . . . . .

Diagram 5-5. Circuit Diagram For RHC-14 And RHC-23 4. . . . . . . . . . . . . . .

SECTION 6 − PARTS LIST

Figure 6-1. Complete Assembly (RHC-3 Illustrated) 6. . . . . . . . . . . . . . . . . . . . .

LIST OF CHARTS AND TABLES

Table 2-1. Cord Conductor Length And Size 1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

SECTION 1 − SAFETY PRECAUTIONS AND SIGNAL WORDS

1-1. GENERAL INFORMATION AND SAFETY

A. General

Information presented in this manual and on various labels, tags, and plates on the unit pertains to equipment

design, installation, operation, maintenance, and

troubleshooting which should be read, understood, and

followed for the safe and effective use of this equipment.

The nameplate of this unit uses international symbols

for labeling the front panel controls. The symbols also

appear at the appropriate section in the text.

B. Safety

The installation, operation, maintenance, and troubleshooting of arc welding equipment requires practices

and procedures which ensure personal safety and the

safety of others. Therefore, this equipment is to be installed, operated, and maintained only by qualified persons in accordance with this manual and all applicable

codes such as, but not limited to, those listed at the end

of Section 1 − Safety Rules For Operation Of Arc Welding Power Source.

1-2. SAFETY ALERT SYMBOL AND SIGNAL

WORDS

The following safety alert symbol and signal words are

used throughout this manual to call attention to and

identify different levels of hazard and special instructions.

This safety alert symbol is used with the signal

words WARNING and CAUTION to call attention to the safety statements.

WARNING statements identify procedures or

practices which must be followed to avoid serious personal injury or loss of life.

CAUTION statements identify procedures or

practices which must be followed to avoid minor

personal injury or damage to this equipment.

IMPORTANT statements identify special instructions

necessary for the most efficient operation of this equipment.

1-3. DESCRIPTION

Remote Hand Controls are designed for use as remote

amperage or voltage controls in conjunction with a welding power source or welding generator having electric

control facilities. Remote Hand Controls with the letters

GD displayed in the model description are designed for

use with welding generators only.

SECTION 2 − INSTALLATION

Table 2-1. Cord Conductor Length And Size

Amperage or Voltage Control

Cord Length

Up to 20ft (6 m)

Up to 20ft (6 m) (GD Models)

21 to 100ft (6 to 30 m) (GD Models)

21 to 50ft (6 to 15 m)

51 to 100ft (16 to 31 m)

101 to 200ft (31 to 61 m)

*AWG-American Wire Guage

2-1. LOCATION

The Remote Hand Controls is equipped with a twenty

foot (6 m) interconnecting multi-conductor cord (unless

otherwise specified) which enables the Remote Hand

Control to be remotely located from the welding power

Conductor

Size*

No. 16

No. 14

No. 12

No. 14

No. 12

No. 10

source or welding generator. The Remote Hand Control

can be wall mounted or placed on a stand at the work

area.

If it is necessary to install a muti-conductor cord of longer length, refer to Table 2-1 for cord conductor size according to the desired length. Refer to Section 5 - Electrical Diagrams for connections

2-2. INTERCONNECTIONS

1. To make connections on models equipped with

the twistlock plug, fully insert the twistlock plug

that is attached to the Remote Hand Control cord

into Remote Amperage or Voltage Control Receptacle on the welding power source or welding

generator. Turn the cap in a clockwise direction,

as far as it will turn, to lock the connection.

2. To make connections on models equipped with

the 14-pin or 5-pin Amphenol plug, align keyway,

insert plug, and rotate threaded collar fully clockwise.

OM-823 Page 1

Page 5

SECTION 3 − OPERATOR CONTROLS

3-1. OPERATION

A. General

When a Remote Hand Control is being used, it should

be noted that on most welding power sources or welding

generators, the Remote Hand Control functions as a

fine amperage or voltage adjustment of the Amperage

or Voltage Adjustment Control setting on the welding

power source or welding generator. For example, if the

Amperage or Voltage Adjustment Control on the welding power source or welding generator is set at the midpoint position, the Remote Hand Control will provide

(from its minimum to maximum positions) fine adjustment of one half of the welding power source or welding

generator output. If full adjustment of the maximum output of the welding power source or welding generator

from the Remote Hand Control is desired, it will be necessary to rotate the Amperage or Voltage Adjustment

Control on the welding generator to the maximum position. The Remote Hand Control dial is calibrated in percentage in increments of ten from 0 to 100 percent.

On some welding power source or welding generators

the Amperage Voltage Adjustment Control on the Welding power source or welding generator is inoperative

when a Remote Hand Control is connected in the welding power source or welding generator control circuitry.

In this situation, the Remote Hand Control provides

complete control from the minimum to the maximum

output of the welding power source or welding generator

rather than fine adjustment of the Amperage or Voltage

Adjustment control setting on the welding power source

or welding generator.

To determine in which way the Remote Hand Control affects the operation of the welding power source or welding generator, refer to the welding power source or welding generator circuit diagram and/or instruction Manual.

B. Remote Hand Control Of Two Welding Power

Sources

Remote amperage or voltage control of two welding

power sources from one Remote Hand Control is made

possible through the use of Remote Hand Control having two rheostats. These Remote Hand Controls are

identified by a model suffix of -2, and are designed to simultaneously control two identical welding power

sources. These Remote Hand Controls have two rheostats coupled on a common control shaft. Rotating the

knob on the Remote Hand Control simultaneously adjusts each rheostat in the control to the same value,

thus making possible remote control of two welding

power sources from a single Remote Hand Control.

IMPORTANT: When a Remote Hand Control is used,

refer to the Instruction Manual of the welding power

source or welding generator for additional operational

information.

3-2. CONTACTOR SWITCH

WARNING: ELECTRIC SHOCK can kill.

• Do not touch live electrical parts

• Do not touch the weld output terminals when

the contactor is energized.

• Do not touch electrode and work clamp at the

same time.

IMPORTANT: To use the RHC-14 or RHC-23 contactor

switch, the OUTPUT (CONTACTOR) switch on the

welding power source must be in the Remote position

for proper remote control operation.

The RHC-14 or RHC-23 switch has two positions, ON

and OFF. Placing this switch in the ON position provides

open-circuit voltage. Placing this switch in the OFF position stops open-circuit voltage (ocv goes to zero).

SECTION 4 − MAINTENANCE

WARNING: ELECTRIC SHOCK can kill; HOT

SURFACES can cause severe burns.

• Do not touch live electrical parts.

• Disconnect plugs from power source before

inspecting or servicing.

• Allow unit to cool before servicing.

Once a month inspect the Remote Hand Control cord for

breaks in the insulating jacket particularly at the plug

OM-823 Page 2

and at the strain relief connector on the Remote Hand

Control base. Repair all breaks with electrical tape, or

replace the cord if necessary.

Daily, rotate the Remote Hand Control knob from the 0

to 100 percent position. This procedure will prevent oxidation from forming on the contacts, which could insulate the contacts from the brush, causing the control to

become inoperative. Refer to Table 2-1 for proper cord

conductor size and to Diagrams 5-1 through 5-5 for

proper cord conductor connections.

Page 6

SECTION 5 − ELECTRICAL DIAGRAMS

Circuit Diagram No. SA-150 670

Diagram 5-1. Circuit Diagram For Remote Hand Control Used With

Transformer Arc Welding Power Source

Circuit Diagram No. SA-150 671

Diagram 5-2. Circuit Diagram For RHCS-3

Circuit Diagram No. SA-094 231-A

Diagram 5-3. Circuit Diagram For RHC-3-GD9A And RHC-3-GD34A

OM-823 Page 3

Page 7

Circuit Diagram No. SA-094 232-A

Diagram 5-4. Circuit Diagram For RHC-3-GD25B

Circuit Diagram No. SA-053 656-A

OM-823 Page 4

Diagram 5-5. Circuit Diagram For RHC-14 And RHC-23

Page 8

SECTION 6 − PARTS LIST

OM-823 Page 5

Page 9

Quantity

-

Model

Item

No.

Dia.

Mkgs.

Part

No.

Description

RHC-3RHC-

3-2

RHC-14RHC-23RHCS

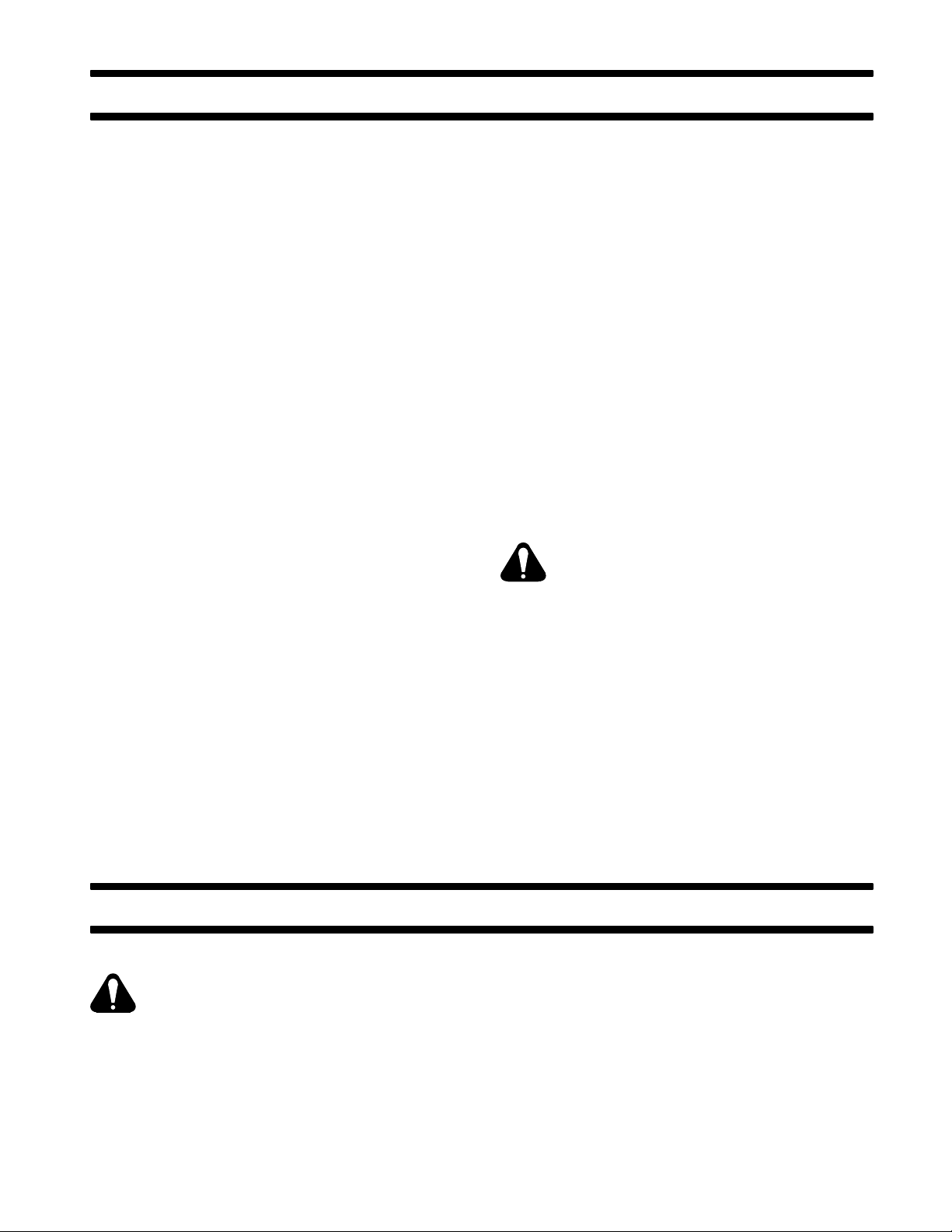

Figure 6-1. Complete Assembly

1 R1 030 653 RHEOSTAT, WW 150W 15 ohm 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 R1 107 363 RHEOSTAT, WW 150W 15 ohm 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 R1 035 897 POTENTIOMETER, C sltd sft 1/T 2W 1000 ohm 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 R1 039 272 RHEOSTAT, WW 150W 1250 ohm 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 +021 475 WRAPPER 1 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 +014 417 WRAPPER 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

085 220 LABEL, caution electric circuit 11111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 021 474 CASE SECTION, base/front/rear 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 106 952 CASE SECTION, base/front/rear 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 109 974 CASE SECTION, base/front/rear 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 PLG1 605 797 PLUG, twlk 3P3W 20A 125V 1 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 PLG1 144 310 HOUSING PLUG & PINS, (consisting of) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

134 732 TERMINAL, male 1 pin 24-20 wire 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

143 922 CLAMP, cable strain relief sz 17 & 20 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 PLG1 039 273 PLUG, 5 pin MS-3106A-16S-8P 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

039 685 CLAMP, cable AN-3057-8 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 600 733 CORD SET, pwr 115V 16ga 3/c 20ft 1 2 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 052 246 CABLE, pwr 20ga 5/c (order by ft) 20ft 20ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 010 659 CONNECTOR, clamp cable .375 90deg 1 2 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 070 654 BUSHING, strain relief .300 ID x .550mtg hole 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 097 926 KNOB, pointer 2.375dia x .250 ID 1 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 097 922 KNOB, pointer .875dia x .250 ID 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 039 411 NAMEPLATE 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 148 720 NAMEPLATE 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 130 214 NAMEPLATE 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 053 574 PLATE, ind current 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 148 716 NAMEPLATE 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S1 011 609 SWITCH, tgl SPDT 15A 125VAC 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

604 311 GROMMET, rbr .250 ID x .375mtg hole 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

1

2

8

3

7

4

5

6

Figure 6-1. Complete Assembly (RHC-3 Illustrated)

+When ordering a component originally displaying a precautionary label, the label should also be ordered.

BE SURE TO PROVIDE MODEL AND SERIAL NUMBER WHEN ORDERING REPLACEMENT PARTS.

OM-823 Page 6

SA-141 128

Page 10

Quantity

Model

RHC-3-GD

Item

No.

Dia.

Mkgs.

Part

No.

Description

9A 25B 34A

Complete Assembly (Use Fig 6-1 View)

1 R1 005 355 RHEOSTAT, WW 50W 9 ohm 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 R1 605 049 RHEOSTAT, WW 300W 25 ohm 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 R1 605 960 RHEOSTAT, WW 300W 34 ohm 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 R1 +021 475 WRAPPER 1 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

085 220 LABEL, caution electrical circuit 1 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 021 474 CASE SECTION, base/front/rear 1 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 PLG1 032 898 PLUG, twlk grd 2P3W 15A 125V 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 PLG1 039 621 PLUG, twlk armd 4P4W 20A 250V 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 600 349 CABLE, port No.14 3/c (order by ft) 20ft 20ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 604 834 CABLE, port No.14 4/c (order by ft) 20ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 010 659 CONNECTOR, clamp .375 90deg 1 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 097 926 KNOB, pointer 2.375dia x .250 ID 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 148 723 KNOB, pointer 2.375dia x .379 ID 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 006 101 PLATE, ind amperage 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 013 615 PLATE, ind amperage 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 148 717 NAMEPLATE 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

+When ordering a component originally displaying a precautionary label, the label should also be ordered.

BE SURE TO PROVIDE MODEL AND SERIAL NUMBER WHEN ORDERING REPLACEMENT PARTS.

1

OM-823 Page 7

Loading...

Loading...