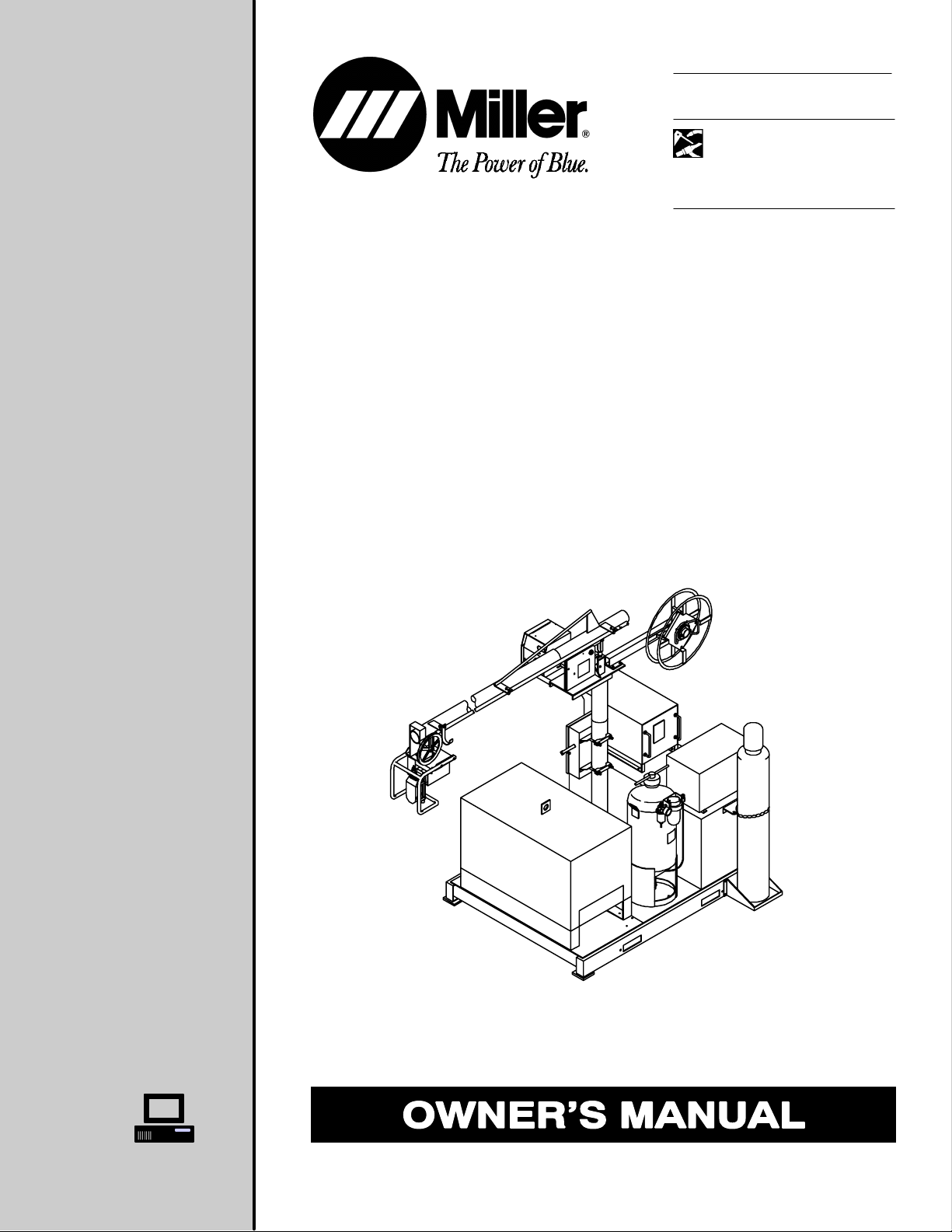

Page 1

OM-1102 113 214A

July 1995

Processes

Multiprocess Welding

Description

Semiautomatic Welding Platform

Swingpak 12 & 16

Visit our website at

www.MillerWelds.com

Page 2

From Miller to You

Thank you and congratulations on choosing Miller. Now

you can get the job done and get it done right. We know

you don’t have time to do it any other way.

That’s why when Niels Miller first started building arc

welders in 1929, he made sure his products offered

long-lasting value and superior quality. Like you, his

customers couldn’t afford anything less. Miller products

had to be more than the best they could be. They had to

be the best you could buy.

Today, the people that build and sell Miller products continue the

tradition. They’re just as committed to providing equipment and service

that meets the high standards of quality and value established in 1929.

This Owner’s Manual is designed to help you get the most out of your

Miller products. Please take time to read the Safety precautions. They will

help you protect yourself against potential hazards on the worksite. We’ve

made installation and operation quick and easy.

With Miller you can count on years of reliable

service with proper maintenance. And if for

some reason the unit needs repair, there’s a

Troubleshooting section that will help you

Miller is the first welding

equipment manufacturer in

the U.S.A. to be registered to

the ISO 9001 Quality System

Standard.

Miller Electric manufactures a full line

of welders and welding related equipment.

For information on other quality Miller

products, contact your local Miller distributor

to receive the latest full line catalog or

individual catalog sheets. To locate your nearest

distributor or service agency call 1-800-4-A-Miller,

or visit us at www.MillerWelds.com on the web.

figure out what the problem is. The parts list

will then help you to decide which exact part

you may need to fix the problem. Warranty and

service information for your particular model

are also provided.

Working as hard as you do

– every power source from

Miller is backed by the most

hassle-free warranty in the

business.

Miller offers a Technical

Manual which provides

more detailed service and

parts information for your

unit. T o obtain a Technical

Manual, contact your local

distributor. Your distributor

can also supply you with

Welding Process Manuals

such as SMAW, GTAW,

GMAW, and GMA W-P.

Page 3

TABLE OF CONTENTS

SECTION 1 – SAFETY PRECAUTIONS AND SIGNAL WORDS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1. General Information And Safety 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2. Safety Alert Symbol And Signal Words 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 – SPECIFICATIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1. Description 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 – INSTALLATION OR RELOCATION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1. Location 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2. Installation 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4 – PARTS LIST 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY

Page 4

Page 5

SECTION 1 – SAFETY PRECAUTIONS AND SIGNAL WORDS

1-1. GENERAL INFORMATION AND SAFETY

A. General

Information presented in this manual and on various labels, tags, and plates on the unit pertains to equipment

design, installation, operation, maintenance, and

troubleshooting which should be read, understood, and

followed for the safe and ef fective use of this equipment.

B. Safety

The installation, operation, maintenance, and troubleshooting of arc welding equipment requires practices

and procedures which ensure personal safety and the

safety of others. Therefore, this equipment is to be installed, operated, and maintained only by qualified persons in accordance with this manual and all safety precautions in the welding power source Owner’s Manual.

SECTION 2 – SPECIFICATIONS

Gas Cylinder Support Bracket Located

Here (SWINGPAK-12 Models Only)

1-2. SAFETY ALERT SYMBOL AND SIGNAL

WORDS

The following safety alert symbol and signal words are

used throughout this manual to call attention to and

identify different levels of hazard and special instructions.

This safety alert symbol is used with the signal

words WARNING and CAUTION to call attention to the safety statements.

WARNING statements identify procedures or

practices which must be followed to avoid serious personal injury or loss of life.

CAUTION statements identify procedures or

practices which must be followed to avoid minor

personal injury or damage to this equipment.

IMPORTANT statements identify special instructions

necessary for the most efficient operation of this equipment.

Coolant System

(Mounted Onto

SWINGPAK

Locker)

Resistance

Grid

(Mounted Onto

SWINGPAK

Locker)

**65 in. (1651 mm)

*66-7/8 in. (1699 mm) Swingpak-16

**79 in. (2007 mm) Swingpak-16

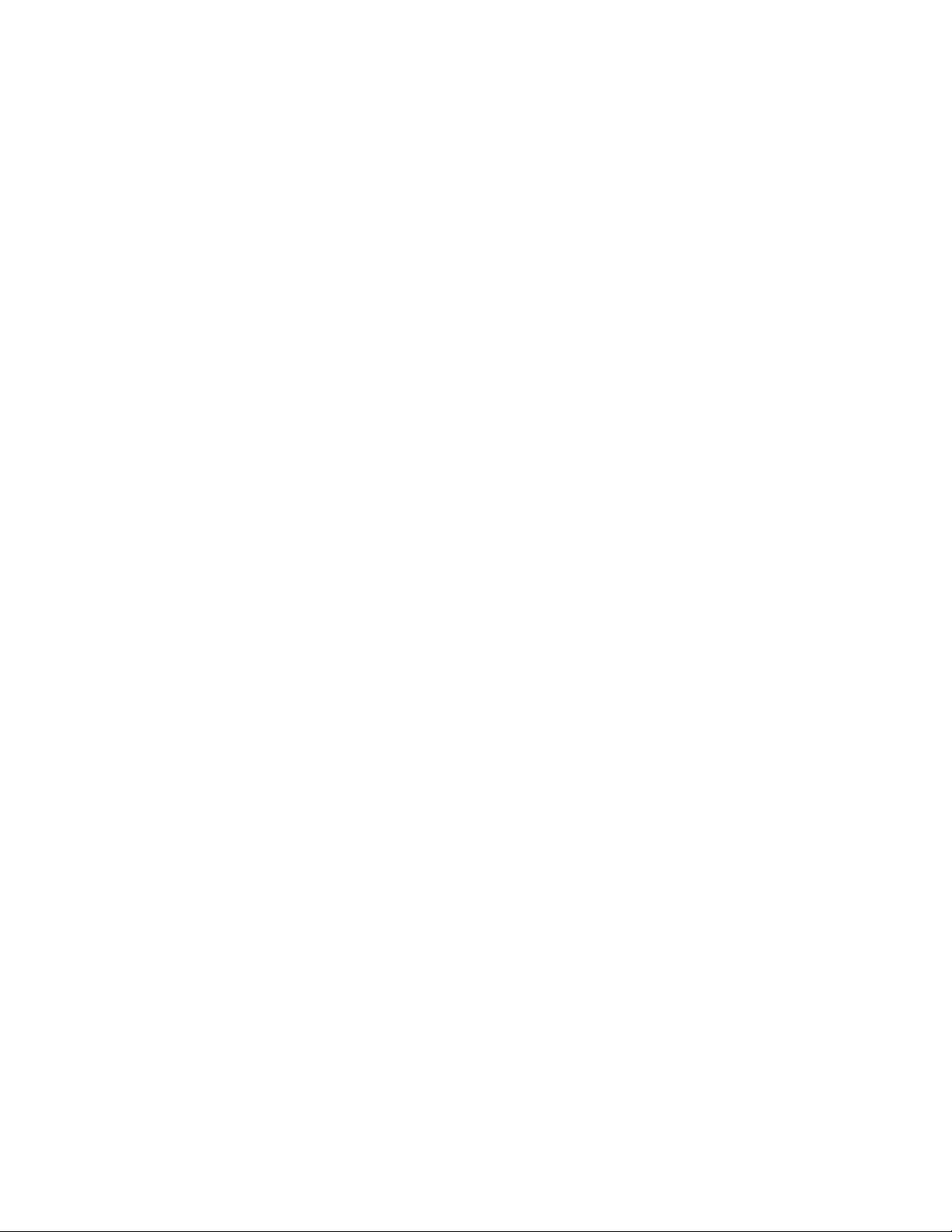

Figure 2-1. Overall Dimensions, Mounting Hole Layout, And Component Locations

Flux

Tank

Boom

Support

Base

Swingpak-12

Welding

Power

Source

K

G

H

J

FRONT

*50-7/8 in.

(1292 mm)

Swingpak-12

C

L

B

A

D

F

E

S-0458-A

Inches Millimeters

A

28

B

30

C

31

D

32-3/4

E

37

F

39

G

14-1/2

H

16-3/4

J

20

K 12-3/8 314

L 24-1/16 611

711

762

787

831

940

991

368

415

508

OM-1102 Page 1

Page 6

2-1. DESCRIPTION

The SWINGPAK-12 and SWINGPAK-16 provide a direct mounting facility for several welding power sources

(refer to welding power source Owner’s Manual for base

mounting hole layout), SWINGARC wire feeder or CB

boom, RADIATOR 1A or RADIATOR 2A coolant system, MPG-395B resistance grid, AFT-100 flux tank, and

shielding gas cylinder. If equipment other than that listed

is to be used, mounting hole locations may have to be

modified to accommodate equipment. A SWINGPAK

locker and brackets for mounting a disconnect switch to

the SWINGARC post support are also supplied.

SECTION 3 – INSTALLATION OR RELOCATION

Additional space is available on the base for mounting

customer supplied accessories.

Table 2-1. Specifications

Weight

Net Ship

SWINGPAK-12

SWINGPAK-16

412 lbs.

(187 kg)

504 lbs.

(229 kg)

418 lbs.

(190 kg)

510 lbs.

(231 kg)

WARNING: ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Disconnect equipment input power conduc-

tors from deenergized supply line BEFORE

moving unit.

3-1. LOCATION

When installing this unit, be sure to allow room for the

boom to swing horizontally in the desired arc, and to pivot upward to the desired angle. The location should allow room to remove panels of associated equipment for

installation, inspection, maintenance, and repair procedures. Consider the input power requirements as well a s

coolant (water) needs of optional equipment when

choosing a location.

The service life and efficiency of this unit and associated

equipment will be reduced if they are subjected to high

levels of dust, dirt, moisture, corrosive vapors, and extreme heat.

Mounting holes are provided in the SWINGPAK base for

installing equipment.

3-2. INSTALLATION (Figures 2-1 And 4-1)

IMPROPER LIFTING OR INSTALLING OF

EQUIPMENT can cause personal injury and

equipment damage.

• Use equipment of adequate capacity to lift

components.

• Use bolts and fasteners of adequate capacity

to assemble and install unit.

IMPORTANT: Refer to Figures 2-1 and 4-1 during assembly as necessary.

Mounting hardw a r e i s p a c k e d i n l o c k e r f o r s h i p p i n g p u r poses. Remove hardware kit from locker and proceed

as follows:

1. Install boom support base onto SWINGPAK base

using supplied 1/2-13 x 1-1/2 inch cap screws

(Item 23, Figure 4-1) and associated hardware

(see Figure 2-1 for mounting location).

2. Locate appropriate mounting holes on SWINGPAK base for welding power source, and install

power source onto SWINGPAK base using

supplied 3/8-16 x 1-1/4 inch cap screws (Item 20,

Figure 4-1).

3. Install boom into boom support base following

procedure outlined in appropriate Owner’s Manual.

WARNING: OVERTURNING BASE can result

in serious injury and equipment damage.

• Mount the welding power source on SWING-

PAK base before mounting SWINGARC wire

feeder into SWINGARC support base.

• Do not install or operate on an incline.

• Do not lift the SWINGPAK base with a fork lift

from the sides unless the lift forks extend far

enough under the base to ensure against tipping.

OM-1102 Page 2

4. If applicable, install AFT-100 flux tank onto

SWINGPAK base using supplied 5/16-18 x 1 inch

cap screws (Item 13, Figure 4-1) and associated

hardware.

5. Install SWINGPAK locker onto SWINGPAK base

using supplied 1/4-20 x 3/4 inch self-threading

screws (item 16, Figure 4-1).

6. If applicable, install coolant system mounting

brackets onto SWINGPAK locker using supplied

1/4-20 x 1inch cap screws (Item 7, Figure 4-1).

Page 7

IMPORTANT: If cooling system has mounting holes i n

base, do not install mounting brackets onto SWINGPAK

locker. Instead, install coolant system directly onto locker using supplied hardware.

7. If applicable, install grid onto SWINGPAK locker

using supplied 1/4-20 x 1 inch cap screws (Item 7,

Figure 4-1) and associated hardware.

8. If applicable, install gas cylinder support bracket

onto SWINGPAK locker using supplied 5/16-18 x

3/4 inch self-threading screws (item 12, Figure

4-1).

9. Install cylinder support bracket to SWINGPAK

locker using supplied 1/4-20 x 1 inch cap screws

and associated hardware. Secure gas cylinder in

bracket using supplied cylinder chain.

10. If applicable, install disconnect switch mounting

brackets onto disconnect switch (customer must

supply mounting hardware).

WARNING: ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Be sure input power is disconnected and

welding power source is shut down before

making connections to disconnect switch.

1 1. Install disconnect switch onto boom support, and

secure using supplied disconnect switch mounting clamps (Item 2, Figure 4-1) and 3/8-16 nuts

(Item 5) and associated hardware.

12. Make electrical input connections from welding

power source to disconnect switch according to

welding power source Owner’s Manual.

13. To make electrical connections from line disconnect switch to source of input power, consult local

electric utility or certified electrician.

OM-1102 Page 3

Page 8

. Hardware i s common and

not available unless listed.

SECTION 4 – PARTS LIST

AFT-100

Flux Tank

13

14

SD-113 627-A

Coolant System

RADIATOR 1 Or RADIAT OR 2

MPG-395B

Resistance Grid

Gas

Cylinder

8

Coolant System

7

6

7

6

5

4

3

2

10

Support

Cylinder

9

Mounting Bracket

Locker

SWINGPAK

Bracket

11

12

7

6

15

Gas Bottle

Support Bracket

16

17

Base

SWINGPAK

Figure 4-1. Complete Assembly

Wire Feeder

SWINGARC Digital

OM-1102 Page 4

1

Disconnect Switch

Mounting Brackets

Disconnect

Switch

Base

232221

Boom Support

201918

Page 9

Quantity

Item

No.

Part

No.

Description

Model

12 16

Figure 4-1. Complete Assembly

1 086 752 BRACKET, mtg disconnect switch 2 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 086 739 CLAMP, mtg disconnect switch 2 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 010 910 WASHER, flat SAE .375 8 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 602 213 WASHER, lock split .375 8 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 601 872 NUT, hex full .375-16 8 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 602 207 WASHER, lock split .250 10 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 604 631 SCREW, hexhd .250-20 x 1.000 10 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 099 038 BRACKET, mtg coolant system 2 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 085 940 LOCKER 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

085 840 DOOR 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 169 654 BRACKET, support tank 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 602 387 CHAIN, weldless 2/0 x 27 bright zinc pld 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 602 159 SCREW, hexwhd .312-18 x .75 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 601 948 SCREW, hexhd-pln .312-18 x 1.000 4 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14 602 211 WASHER, lock split .312 4 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15 087 876 BRACKET, support gas bottle 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 604 224 SCREW, hexwhd .50D .250-20 x .750 8 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17 085 939 BASE 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17 086 736 BASE 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18 602 241 WASHER, flat stl SAE .250 (used w/Maxtron) 4 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19 602 207 WASHER, lock split .250 (used w/Maxtron) 4 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20 601 927 SCREW, cap stl hexhd .250-20 x .750 (used w/Maxtron) 4 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18 010 910 WASHER, flat SAE .375 (all models except Maxtron 450) 4 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19 602 213 WASHER, lock split .375 (all models except Maxtron 450) 4 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20 604 657 SCREW, hexhd-pln .375-16 x 1.250 (all models except Maxtron 450) 4 4. . . . . . . . . . . . . . . . . . .

21 602 246 WASHER, flat .500 4 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22 602 216 WASHER, lock split .500 4 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23 604 467 SCREW, hexhd-pln .500-13 x 1.500 4 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To maintain the factory original performance of your equipment, use only Manufacturer’s Suggested

Replacement Parts. Model and serial number required when ordering parts from your local distributor.

OM-1102 Page 5

Page 10

Notes

Page 11

Warranty Questions?

Call

1-800-4-A-MILLER

for your local

Miller distributor.

Y our distributor also gives

you ...

Service

Y ou always get the fast,

reliable response you

need. Most replacement

parts can be in your

hands in 24 hours.

Support

Need fast answers to the

tough welding questions?

Contact your distributor.

The expertise of the

distributor and Miller is

there to help you, every

step of the way.

Effective January 1, 2000

(Equipment with a serial number preface of “LA” or newer)

This limited warranty supersedes all previous Miller warranties and is exclusive with no other

LIMITED WARRANTY – Subject to the terms and conditions

below, Miller Electric Mfg. Co., Appleton, Wisconsin, warrants

to its original retail purchaser that new Miller equipment sold

after the effective date of this limited warranty is free of defects

in material and workmanship at the time it is shipped by Miller.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE

WARRANTIES OF MERCHANTABILITY AND FITNESS.

Within the warranty periods listed below, Miller will repair or

replace any warranted parts or components that fail due to

such defects in material or workmanship. Miller must be

notified in writing within thirty (30) days of such defect or

failure, at which time Miller will provide instructions on the

warranty claim procedures to be followed.

Miller shall honor warranty claims on warranted equipment

listed below in the event of such a failure within the warranty

time periods. All warranty time periods start on the date that

the equipment was delivered to the original retail purchaser, or

one year after the equipment is sent to a North American

distributor or eighteen months after the equipment is sent to an

International distributor.

1. 5 Years Parts – 3 Years Labor

* Original main power rectifiers

* Inverters (input and output rectifiers only)

2. 3 Years — Parts and Labor

* Transformer/Rectifier Power Sources

* Plasma Arc Cutting Power Sources

* Semi-Automatic and Automatic Wire Feeders

* Inverter Power Supplies

* Intellitig

* Engine Driven Welding Generators

(NOTE: Engines are warranted separately by

the engine manufacturer .)

3. 1 Year — Parts and Labor

* DS-2 Wire Feeder

* Motor Driven Guns (w/exception of Spoolmate

185 & Spoolmate 250)

* Process Controllers

* Positioners and Controllers

* Automatic Motion Devices

* RFCS Foot Controls

* Induction Heating Power Sources

* Water Coolant Systems

* HF Units

* Grids

* Maxstar 140

* Spot Welders

* Load Banks

* Miller Cyclomatic Equipment

* Running Gear/Trailers

* Plasma Cutting Torches (except APT & SAF

Models)

* Field Options

(NOTE: Field options are covered under True

Blue for the remaining warranty period of the

product they are installed in, or for a minimum of

one year — whichever is greater.)

4. 6 Months — Batteries

5. 90 Days — Parts

* MIG Guns/TIG Torches

* Induction Heating Coils and Blankets

guarantees or warranties expressed or implied.

* APT, ZIPCUT & PLAZCUT Model Plasma Cutting

Torches

* Remote Controls

* Accessory Kits

* Replacement Parts (No labor)

* Spoolmate 185 & Spoolmate 250

* Canvas Covers

Miller’s True Blue Limited Warranty shall not apply to:

1. Consumable components; such as contact tips,

cutting nozzles, contactors, brushes, slip rings,

relays or parts that fail due to normal wear.

2. Items furnished by Miller, but manufactured by others,

such as engines or trade accessories. These items are

covered by the manufacturer’s warranty, if any.

3. Equipment that has been modified by any party other

than Miller, or equipment that has been improperly

installed, improperly operated or misused based upon

industry standards, or equipment which has not had

reasonable and necessary maintenance, or equipment

which has been used for operation outside of the

specifications for the equipment.

MILLER PRODUCTS ARE INTENDED FOR PURCHASE

AND USE BY COMMERCIAL/INDUSTRIAL USERS AND

PERSONS TRAINED AND EXPERIENCED IN THE USE

AND MAINTENANCE OF WELDING EQUIPMENT.

In the event of a warranty claim covered by this warranty, the

exclusive remedies shall be, at Miller’s option: (1) repair; or (2)

replacement; or, where authorized in writing by Miller in

appropriate cases, (3) the reasonable cost of repair or

replacement at an authorized Miller service station; or (4)

payment of or credit for the purchase price (less reasonable

depreciation bas e d u p o n a c tual use) upon return of the goods

at customer’s risk and expense. Miller’s option of repair or

replacement will be F.O.B., Factory at Appleton, Wisconsin, or

F.O.B. at a Miller authorized service facility as determined by

Miller. Therefore no compensation or reimbursement for

transportation costs of any kind will be allowed.

TO THE EXTENT PERMITTED BY LAW, THE REMEDIES

PROVIDED HEREIN ARE THE SOLE AND EXCLUSIVE

REMEDIES. I N N O EVENT SHALL MILLER BE LIABLE FOR

DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES (INCLUDING LOSS OF

PROFIT), WHETHER BASED ON CONTRACT, TORT OR

ANY OTHER LEGAL THEORY.

ANY EXPRESS WARRANTY NOT PROVIDED HEREIN

AND ANY IMPLIED WARRANTY, GUARANTY OR

REPRESENTATION AS TO PERFORMANCE, AND ANY

REMEDY FOR BREACH OF CONTRACT TORT OR ANY

OTHER LEGAL THEORY WHICH, BUT FOR THIS

PROVISION, MIGHT ARISE BY IMPLICATION,

OPERATION OF LAW, CUSTOM OF TRADE OR COURSE

OF DEALING, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR PARTICULAR

PURPOSE, WITH RESPECT TO ANY AND ALL

EQUIPMENT FURNISHED BY MILLER IS EXCLUDED AND

DISCLAIMED BY MILLER.

Some states in the U.S.A. do not allow limitations of how long

an implied warranty lasts, or the exclusion of incidental,

indirect, special or consequential damages, so the above

limitation or exclusion may not apply to you. This warranty

provides specific legal rights, and other rights may be

available, but may vary from state to state.

In Canada, legislation in some provinces provides for certain

additional warranties or remedies other than as stated herein,

and to the extent that they may not be waived, the limitations

and exclusions set out above may not apply. This Limited

Warranty provides specific legal rights, and other rights may

be available, but may vary from province to province.

miller_warr 7/00

Page 12

Owner’s Record

Please complete and retain with your personal records.

Model Name Serial/Style Number

Purchase Date (Date which equipment was delivered to original customer.)

Distributor

Address

City

State Zip

For Service

Call 1-800-4-A-Miller or see our website at www.MillerWelds.com

to locate a DISTRIBUTOR or SERVICE AGENCY near you.

Always provide Model Name and Serial/Style Number.

Contact your Distributor for:

Welding Supplies and Consumables

Options and Accessories

Personal Safety Equipment

Service and Repair

Replacement Parts

Training (Schools, Videos, Books)

Technical Manuals (Servicing Information

and Parts)

Circuit Diagrams

Welding Process Handbooks

Miller Electric Mfg. Co.

An Ill inoi s Tool Works Company

1635 West Spencer Street

Appleton, WI 54914 USA

International Headquarters–USA

USA Phone: 920-735-4505 Auto-At t ended

USA & Canada FAX: 920-735-4134

International FAX: 920-735-4125

European Headquarters –

United Kingdom

Phone: 44 (0) 1204-593493

FAX: 44 (0) 1204-598066

www.MillerWelds.com

Contact the Delivering Carrier for:

For assistance in filing or settling claims,

contact your distributor and/or equipment

manufacturer’s Transportation Department.

PRINTED IN USA 2000 Miller Electric Mfg. Co. 6/00

File a claim for loss or damage during

shipment.

Loading...

Loading...