Miller Electric OFR-210, HWY-210 User Manual

OM-699 189 553

February 1998

Description

Two-Wheel Trailer For Small EngineDriven Welding Generators

HWY-210 & OFR-210

Visit our website at

www.MillerWelds.com

From Miller to You

Thank you and congratulations on choosing Miller. Now

you can get the job done and get it done right. We know

you don’t have time to do it any other way.

That’s why when Niels Miller first started building arc

welders in 1929, he made sure his products offered

long-lasting value and superior quality. Like you, his

customers couldn’t afford anything less. Miller products

had to be more than the best they could be. They had to

be the best you could buy.

Today, the people that build and sell Miller products continue the

tradition. They’re just as committed to providing equipment and service

that meets the high standards of quality and value established in 1929.

This Owner’s Manual is designed to help you get the most out of your

Miller products. Please take time to read the Safety precautions. They will

help you protect yourself against potential hazards on the worksite. We’ve

made installation and operation quick and easy.

With Miller you can count on years of reliable

service with proper maintenance. And if for

some reason the unit needs repair, there’s a

Troubleshooting section that will help you

Miller is the first welding

equipment manufacturer in

the U.S.A. to be registered

to the ISO 9001 Quality

System Standard.

Miller Electric manufactures a full line

of welders and welding related equipment.

For information on other quality Miller

products, contact your local Miller distributor

to receive the latest full line catalog or

individual catalog sheets. To locate your nearest

distributor call 1-800-4-A-Miller.

figure out what the problem is. The parts list

will then help you to decide which exact part

you may need to fix the problem. Warranty and

service information for your particular model

are also provided.

Working as hard as you

do − every power source

from Miller is backed by

the most hassle-free warranty in the business.

Miller offers a Technical

Manual which provides

more detailed service and

parts information for your

unit. To obtain a Technical

Manual, contact your local

distributor. Your distributor

can also supply you with

Welding Process Manuals

such as SMAW, GTAW,

GMAW, and GMAW-P.

TRAILER TOWING SAFETY PRECAUTIONS

WARNING

TRAILER TOWING can be hazardous.

In trailer towing, as in most driving situations, exposure to certain hazards occurs. Trailer towing is safe when

precautions are taken. The following safety information is only a summary of the more complete information found in

the Safety Standards listed at the end of these precautions. Read and follow all Safety Standards. In addition, the

end user must check and comply with all federal, state, and local laws before use.

HAVE ALL INSTALLATION, OPERATION, MAINTENANCE, AND REPAIR WORK PERFORMED ONLY BY

QUALIFIED PEOPLE.

3

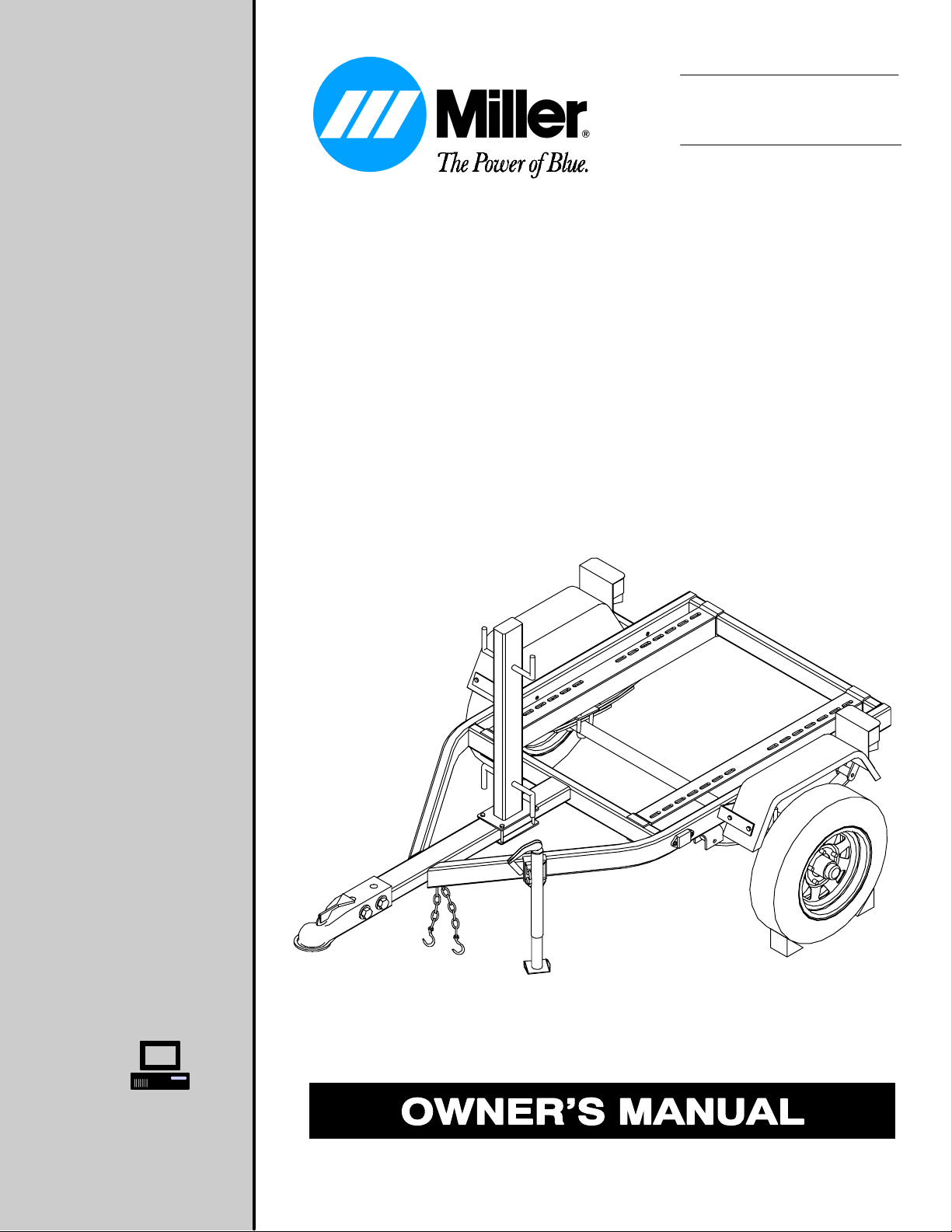

2

1

35

7

6

1. Use a towing vehicle prepared and capable of handling the load.

2. Towing any trailer requires special awareness because of the

changed driving situation.

1 Coupler

Hitch is on towing vehicle.

2 Tongue

3 Lights

4 Wheels And

3

4

Bearings

5 Rating Plate

6 Jack Stand

7 Safety Chains

3. When towing, it takes longer to start, stop, and pass − use

training and practice to avoid accidents.

4. Turning and backing up present new problems − plan ahead.

5. Require each driver to be fully trained and experienced in trailer

towing before going out on the road.

6. Holes are provided for mounting weld/power generator.

7. Be sure trailer is fully prepared and connected to towing vehicle.

8. Observe maximum speed of 45 mph (72 kph) when towing.

9. Do not modify or change the trailer in any way − changes void the

warranty. Read Owner’s Manual.

10. Use only genuine factory parts as replacements.

11. Adjust load on trailer so tongue weight is approximately 10% of

the gross trailer weight and center load side-to-side to reduce

fishtailing.

12. Tighten all parts, bolts, nuts, and mounting hardware.

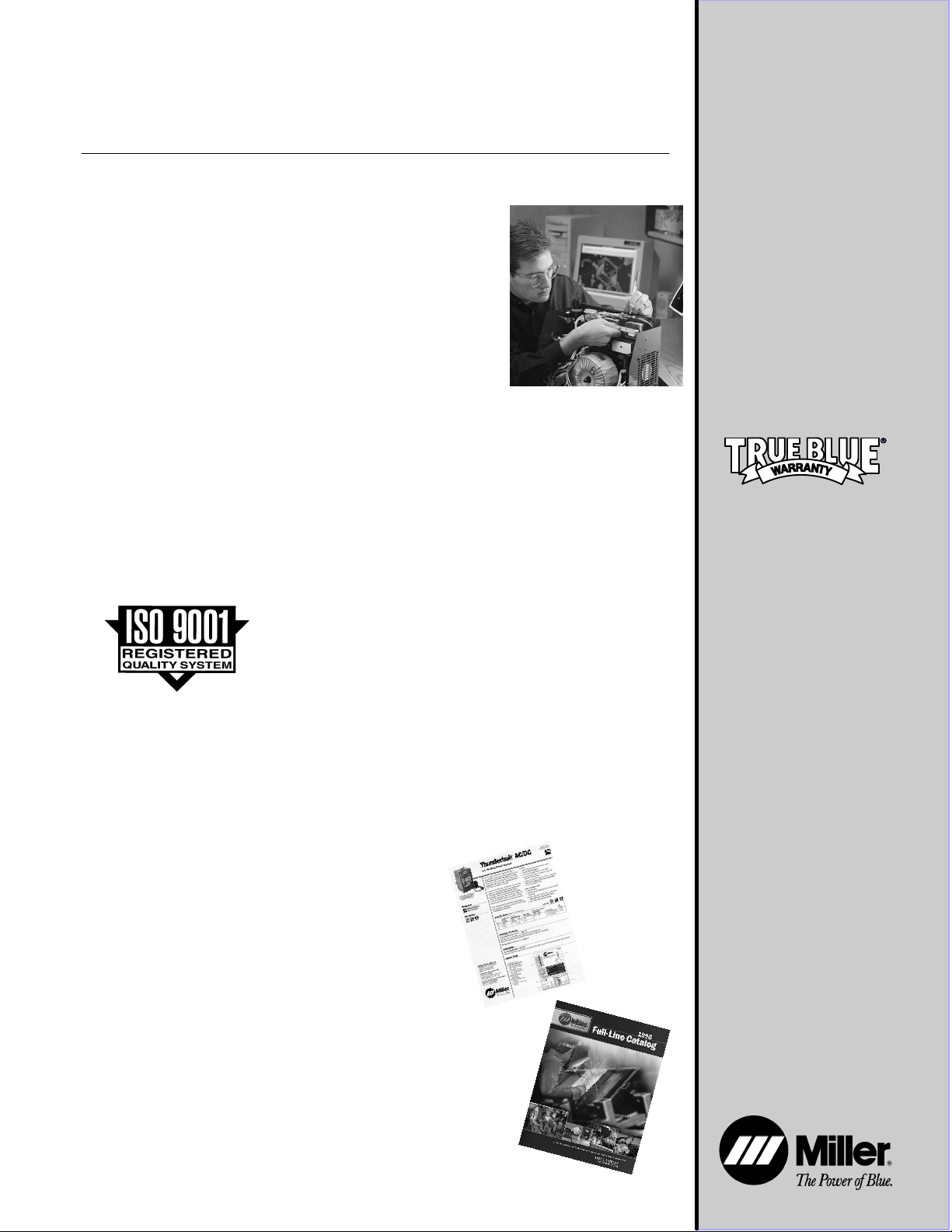

OVERLOADING can cause serious injury or

equipment damage.

1. Do not overload the trailer.

2. The Gross Vehicle Weight Rating (GVWR) is the maximum total

trailer weight with the engine driven welding generator and all

equipment, such as tools, cables, and shielding gas cylinder,

installed.

3. The Gross Axle Weight Rating (GAWR) is the maximum

load-bearing capacity of the axle(s).

4. Weigh trailer − adjust weight by removing accessory equipment if

necessary − call local authorities for nearest scale location.

5. Use gross trailer weight to select a proper towing vehicle.

Rating

Plate

GVWR − Gross Vehicle

Weight Rating (Maximum

Total Trailer Weight Including Its Load)

GAWR − Gross Axle

Weight Rating

VIN NO − Vehicle Identification Number

Trailer

And

Coupler

Class

1

2

3

Gross Vehicle

Weight Rating

GVWR

1

lb (kg)

Up to 2000

(Up to 910)

2000 to 3500

(910 to 1590)

3500 to 5000

(1590 to 2270)

Tongue − Level

Bathroom

Scale

Approximately

10% Of GTW

Gross Trailer Maximum

Weight GTW

1000 (455)

2000 (910)

2000 (910)

3500 (1590)

3500 (1590)

2

lb (kg)

Tongue Weight

lb (kg)

100 (45)

200 (90)

200 (90)

350 (158)

350 (158)

Pipe

Board

3

1

Information From SAE

J684 May 1987

2

Gross Trailer Weight

(Actual Loaded Weight)

3

10% Of GTW

Recommended

Bottom

View

Side

View

UNCONTROLLED TILTING OF TRAILER can result

in personal injury or equipment damage.

1. Install generator according to Owner’s Manual with engine end

toward hitch end of trailer.

2. Distribute weight so that trailer tongue weight is approximately

10% of the gross trailer weight.

INCORRECT TONGUE WEIGHT can cause

fishtailing and loss of control of towing vehicle

resulting in serious injury and equipment damage.

3. Tongue weight is the amount of trailer weight that rests on the

towing vehicle hitch − that is, the downward pressure on the

coupler.

4. Remove or adjust trailer load to get correct tongue weight.

5. Do not let tongue weight exceed coupler and hitch rating.

6. Use slower speeds when towing a trailer − never above 45 mph

(72 km/h) − to prevent fishtailing.

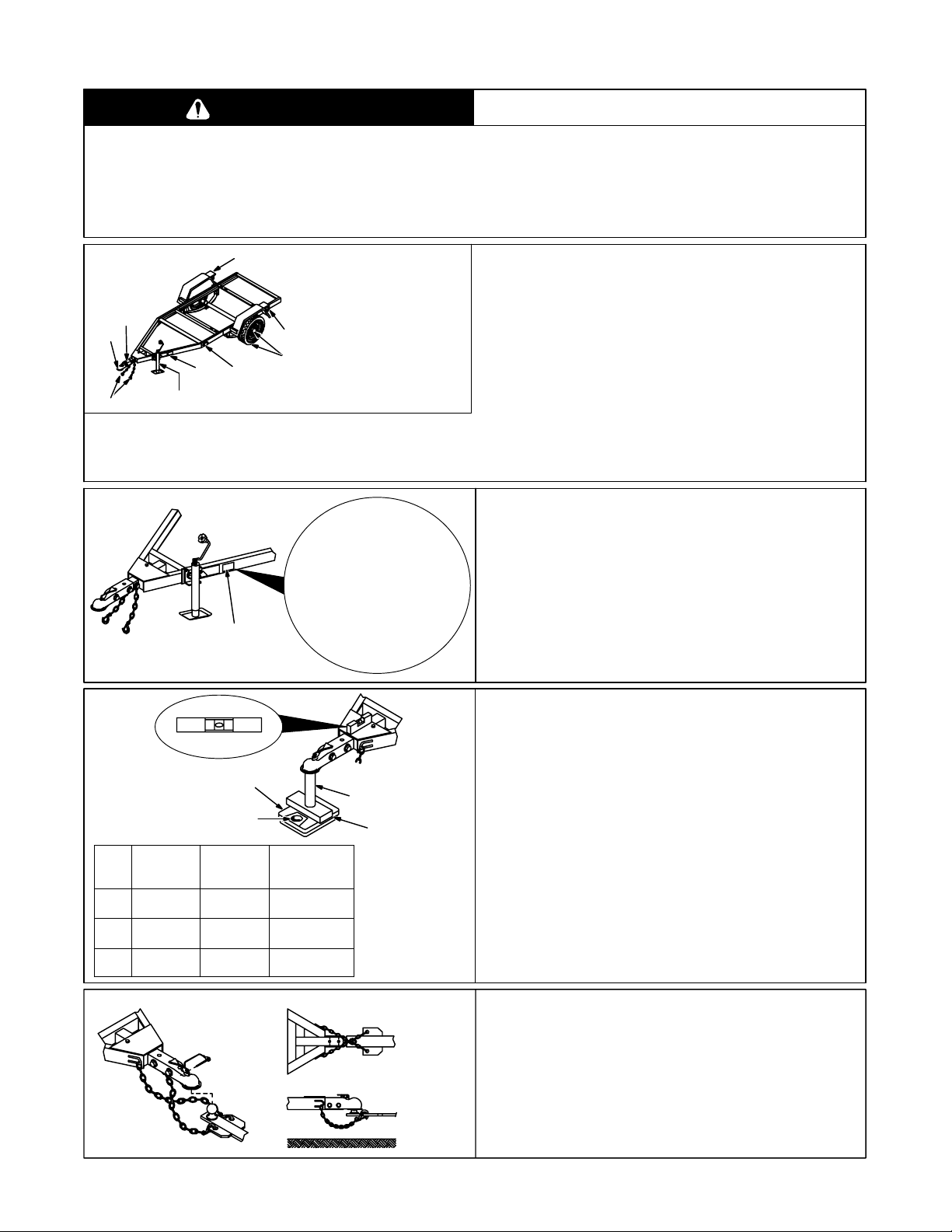

SAFETY CHAINS CAN PREVENT RUNAWAY

TRAILER in case hitch/coupler fails.

1. Always use safety chains when towing.

2. Cross safety chains under coupling to prevent tongue from

dropping to ground.

3. Allow only enough slack for tight turns.

4. Do not let safety chains drag on ground.

5. Twist safety chains equally from hook ends to take up slack.

6. Use safety chains rated equal to or greater than twice the

maximum gross trailer weight rating.

safety_trailer 10/96

Clevis

Lunette

Eye

Ball

Couplers

OR

Safety Pin

Trailer

Tongue

INCORRECT SIZE OR RATING OF HITCH can

cause trailer to break loose from towing vehicle.

1. Be sure towing vehicle hitch is correct type, size, and rating to

match coupler.

2. Be sure the hitch is properly installed onto towing vehicle.

3. On optional ball couplers, always insert hitch safety pin before

towing.

4. Make sure hitch and ball are properly sized and match each

other.

WHEELS MUST BE CHOCKED when trailer is

uncoupled from vehicle.

1. Chock in direction of grade.

2. Position chock snugly behind tire.

3. Place chock square to the tire.

4. Tap chock into place.

5. For added protection, chock both sides of tire.

UNEXPECTED TILTING OF TRAILER can cause

injury and damage.

1. When trailer is uncoupled from towing vehicle, use jack on front

and block rear to prevent tilting.

2. Use proper blocks that are large enough and able to support the

necessary weight.

3. Always chock the wheels when uncoupled.

Lug

Nuts

Breakaway

Surge-Type

Side Marker Lights

Torquing Sequence

Wheel

Bearings

Inside Hub

Self-Actuating Hydraulic

Brake System

Cable

Coupler

Bracket

INCORRECTLY WORKING LIGHTS can cause

accidents.

1. State and Federal regulations require trailers used on highways

Tail, Stop, And

Turn Lights

to have tail, stop, turn, and side marker lights.

2. Lights are not required for trailers designed for off-road use only.

3. Check all lights and connectors for proper installation and

operation before using the trailer.

4. Check condition of wiring harness leads, plugs, and connections

regularly. Repair or replace damaged parts or wires.

5. Replace any broken lenses, reflectors, or bulbs.

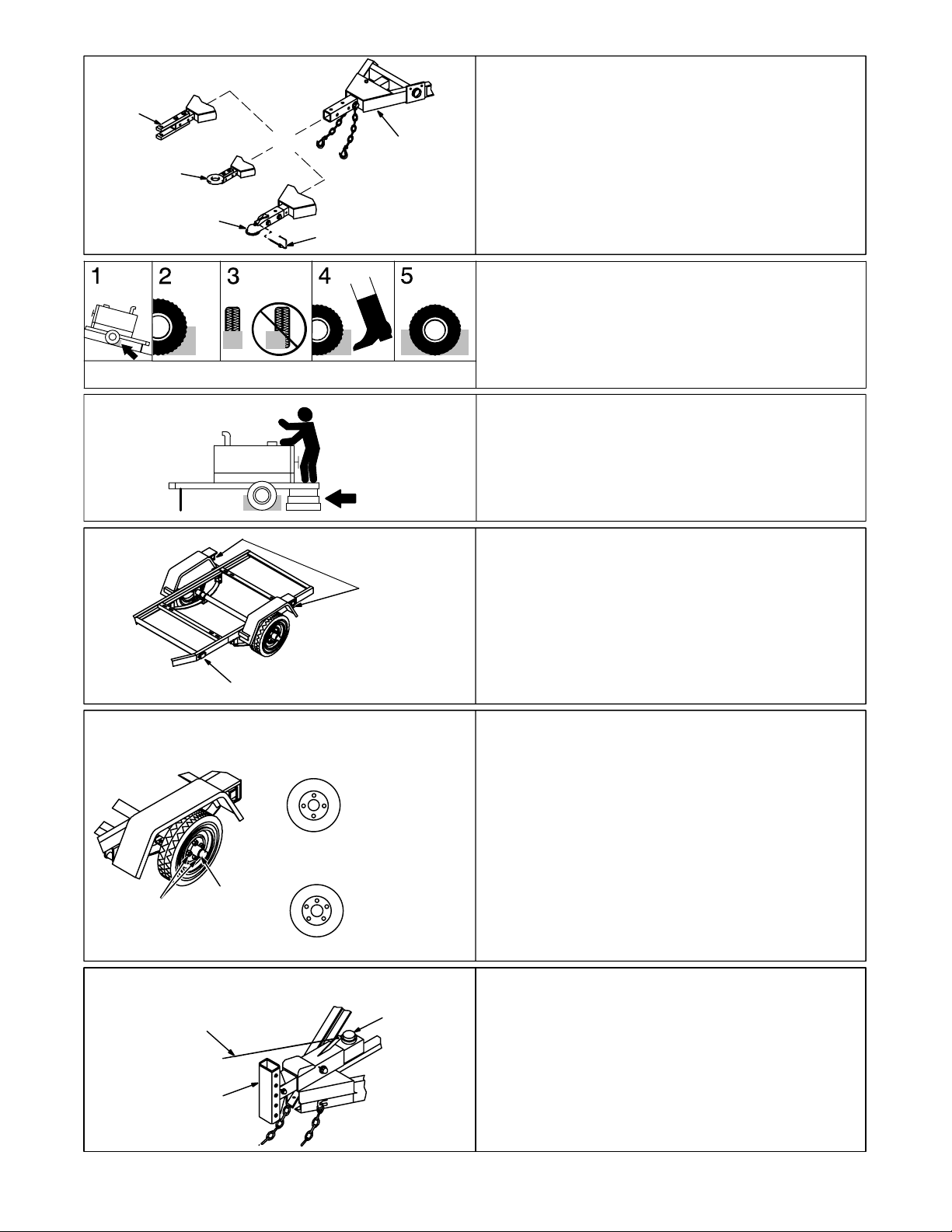

INCORRECT TORQUE on lug nuts or INCORRECT

TIRE PRESSURE or BEARING MAINTENANCE can

cause loss of control resulting in serious injury

1

3

2

1

3

5

4-Hole Wheels −

4

Torque Lug Nuts

To 60 ft-lbs (81 N·m)

4

5-Hole Wheels −

Torque Lug Nuts

To 70 ft-lbs (95 N·m)

2

and equipment damage.

1. Recheck lug nut torque after first 50 miles (80 km) and once each

year or every 12,000 miles (19,500 km) thereafter, whichever

comes first.

2. When checking lug nuts, keep them clean, dry, and unlubricated.

3. Check and repack wheel bearings once each year or every

12,000 miles (19,500 km), whichever comes first.

4. Maintain correct tire pressure according to sidewall data on tire −

underinflation is the most common cause of tire trouble.

5. Check tires for wear every six months.

6. Use only replacement tires of the same size, rating, and capacity.

INOPERATIVE SURGE-TYPE BRAKES OR

Brake Fluid

Reservoir

WRONG BREAKAWAY CABLE CONNECTION can

cause accidents.

1. Check brake fluid level before use.

2. Do not use sway control devices − keep coupler free to telescope

during braking.

3. Always connect breakaway cable to towing vehicle − be sure it

has a direct free pull.

4. Do not wrap cable around safety chains, tongue, wiring, or any

other parts.

5. The breakaway cable automatically applies the trailer brakes if

separation occurs.

safety_trailer 10/96

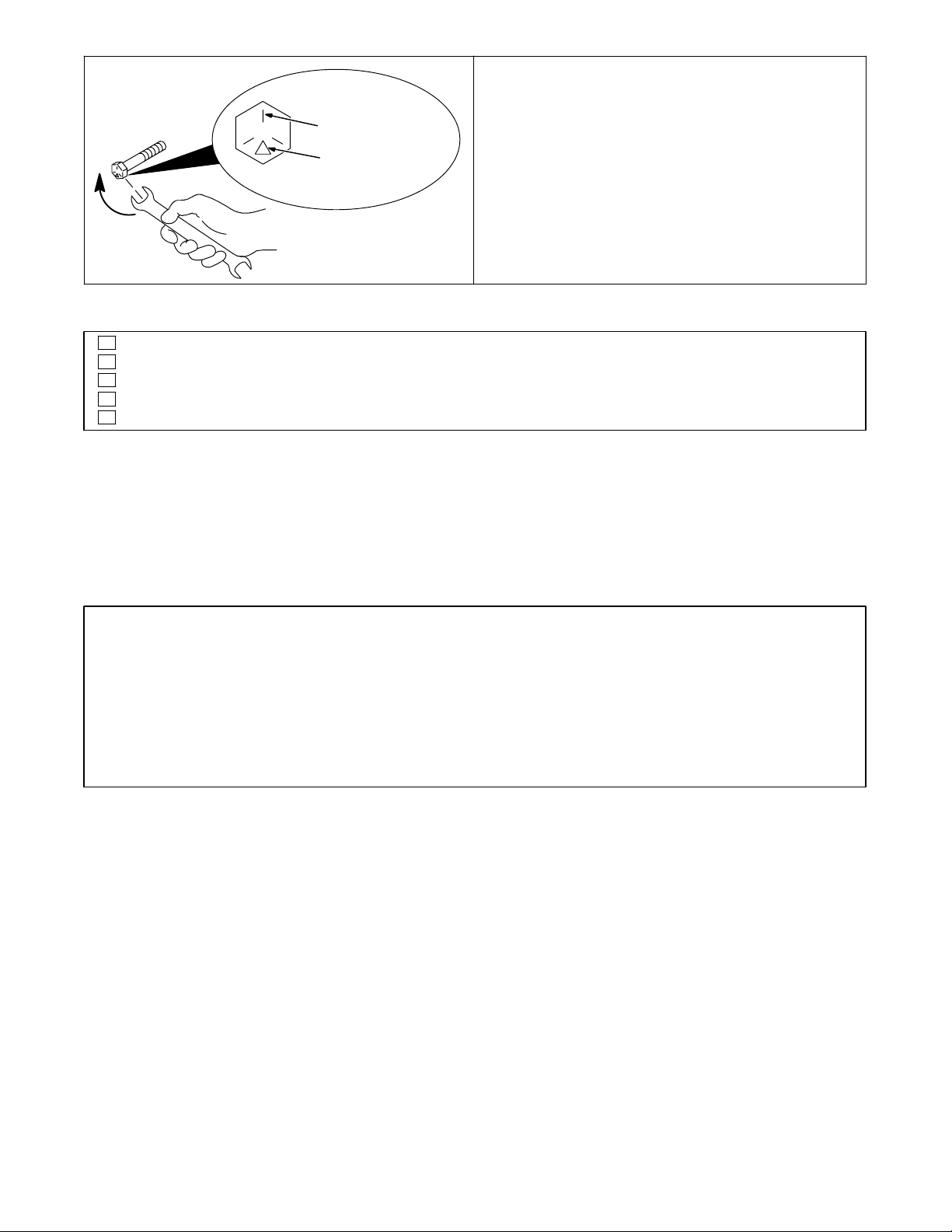

LOOSE OR INCORRECT HARDWARE AND

FASTENERS can cause injury and damage.

1. Periodically double-check all nuts and bolts for tightness and

Grade Marks.

Manufacturer’s

Identification Mark

condition.

2. If necessary, always replace any fastener with one of equal

size, grade, and type.

3. Be sure the grade marks on replacement fastener match the

original bolt. The manufacture’s identification mark is not critical

and does not matter for the replacement fastener.

PRE-TOWING CHECKLIST

Check gross trailer weight, tongue weight, and total weight distribution − do not overload this trailer.

Check that the correct hitch is properly installed on towing vehicle.

When coupling, check that coupler locking device (safety pin), safety chains, and breakaway cable (if applicable) are properly connected.

Check that tires are properly inflated and that wheel nuts are properly torqued.

If applicable, check that all lights are working properly.

PRINCIPAL SAFETY STANDARDS

Trailer & Camper Safety, Publication # DOT HS-802586, from U.S. Department of Transportation, National Highway Traffic Safety Administration, Washington, D.C. 20590

Safety and Health Standards, OSHA 49 CFR 200 to 999, from Superintendent of Documents, U.S. Government Printing Office, Washington,

D.C. 20402

SAE Handbook. 1996. Volume 4. On-Highway Vehicles and Off-High-

way Machinery, from Society of Automotive Engineers, Inc., 400 Commonwealth Drive, Warrendale, PA 15096-0001.

REPORTING SAFETY DEFECTS

If you believe that your vehicle has a defect which

could cause a crash or could cause injury or death,

you should immediately inform the National Highway

Traffic Safety Administration (NHTSA) in addition to

notifying MILLER Electric Mfg. Co.

If NHTSA receives similar complaints, it may open an

investigation, and if it finds that a safety defect exists

in a group of vehicles, it may order a recall and remedy

campaign. However, NHTSA cannot become

involved in individual problems between you, your

dealer, or MILLER Electric Mfg. Co.

To contact NHTSA, you may either call the Auto

Safety Hotline toll-free at 1-800-424-9393 (or

366-0123 in Washington, D.C. area) or write to:

NHTSA, U.S. Department of Transportation,

Washington D.C. 20590. You can also obtain other

information about motor vehicle safety from the

Hotline.

mod11.1 8/94

safety_trailer 10/96

Loading...

Loading...