Miller Electric MWG 160, MWG 160B Owner's Manual

February

1989

OWN

ERS

MANUAL

AUTOi~J

MILLER

ELECTRIC

MFG.

Co.

718

S.

BOUNDS

ST.

P.O.

Box

1079

APPLETON,

WI

54912

USA

ADDITIONAL

COPY

PRICE35CENTS

IMPORTANT

Read

and

understand

the

entire

contents

of

this

manual,

with

special

emphasis

on

the

safety

material

throughout

the

manual,

before

installing,

operating,

or

maintaining

this

equip

ment.

This

unit

and

these

instructions

are

for

use

only

by

persons

trained

and

experienced

in

the

safe

operation

of

welding

equipment.

Do

not

allow

un

trained

persons

to

install,

operate,

or

maintain

this

unit.

Contact

your

distributor

if

you

do

not

fully

understand

these

instructions.

FORM:

112934

Effective

With

Style

No.

JG-20

MODEL

AUTO

ARC

MWG

160

MWG

160B

NWSA

CODE

NO.

4579

PRINTED

IN

U.S.A.

ONEYEARLIMITEDWARRANTY

COVERAGE

-

Miller

Electric

Mfg.

Co.

warrants

to

the

buyer

REMEDY

FOR

DEFECTIVE

WELDER

-

Upon

receipt

of

any

who

purchases

this

Auto

Arc

Welder

(Welder)

for

personal,

defective

Welder.

Miller

Electric

will,

at

its

option,

repair

or

(4

family

or

household

purposes

(Consumer)

that

this

Welder

replace

the

defective

Welder

at

its

expense,

refund

or

credit

~?

will

be

free

from

defects

in

material

and

workmanship

for

a

the

purchase

price

(less

reasonable

depreciation

based

on

ac-

(

period

of

one

year

from

the

date

of

purchase.

This

warranty

tual

use),

or

reimburse

the

Consumer

for

the

cost

of

repair

or

covers

only

the

original

purchaser

of

this

Welder.

Miller

Electric

replacement

at

an

approved

Miller

Electric

warranty

station,

does

not

authorize

any

party,

including

its

authorized

provided

that

the

purchaser

of

that

Welder

has

followed

the

distributors,

to

offer

any

other

warranty

on

behalfofMiller

procedure

for

obtaining

warranty

performance

set

forth

below.

Electric.

Upon

expiration

of

the

warranty

period,

Miller

Electric

The

Welder

so

repaired

or

used

as

a

replacement

will

be

ship

~

shall

have

no

further

liability

related

to

the

Welder,

except

on

ped

to

the

purchaser

of

the

defective

Welder,

with

transporta

(

warranty

claims

made

during

the

warranty

period.

tion

charges

prepaid

to

any

destination

in

the

continental

United

States

(transportation

charges

on

shipments

to

Alaska

c~

THIS

WARRANTY

IS

OFFERED

IN

LIEUOFANY

OTHER

or

Hawaii

will

be

paid

only

to

the

nearest

port

of

export).

~

EXPRESS

WARRANTY;

AND,

EXCEPT

TO

THE

EXTENT

(4

PROHIBITED

BY

APPLICABLE

LAW,

THE

DURATION

OF

ALL

IMPLIED

WARRANTIES,

INCLUDING

BUT

NOT

THE

PURCHASERS

REMEDIES

FOR

A

DEFECTIVE

LIMITED

TO

THE

IMPLIED

WARRANTIES

OF

MERCHAN-

WELDER,

TO

THE

EXTENT

PERMITTED

BY

APPLICABLE

TABILITY

AND

FITNESS

FORAPARTICULAR

PURPOSE,

IS

LAW,

ARE

LIMITED

TO

THE

REMEDY

PROVIDED

BY

THIS

WARRANTY:

AND,

TO

THE

EXTENT

ENFORCEABLE

LIMITED

TO

THE

DURATION

OF

THIS

WARRANTY.

UNDER

APPLICABLE

LAW,

MILLER

ELECTRIC

SHALL

IN

4

Some

states

do

not

allow

limitations

on

how

long

an

implied

NO

EVENT

BE

LIABLE

FOR

CONSEQUENTIAL,

INCIDENTAL

~

warranty

lasts,

so

the

above

limitation

may

not

apply

to

you.

OR

SPECIAL

DAMAGES

ARISING

OUTOFTHE

USE

OF,

OR

(4

This

warranty

gives

you

specific

legal

rights,

and

you

may

also

INABILITY

TO

USE,

THE

WELDER,

WHETHER

BASED ON

have

other

rights

which

vary

from

state

to

state.

BREACH

OF

THIS

WARRANTY,

MILLER

ELECTRICS

NEGLIGENCE

OR

OTHER

TORT,

OR

ON

ANY

THEORY

OF

STRICT

LIABILITY.

Except

as

specified

below,

Millers

warranty

does

not

apply

to

components

having

normal

useful

life

of

less

than

one

(1)

year,

such

as

spot

welder

tips,

relay

and

contactor

points,

Some

states

do

not

allow

the

exclusionorlimitation

of

con

~

parts

that

come

in

contact

with

the

welding

wire

including

sequential

or

incidental

damages,

so

the

above

limitations

may

~

nozzles

and

nozzle

insulators

where

failure

does

not

result

from

not

apply

to

you.

defect

in

workmanship

or

material.

Miller

shall

be

required

to

honor

warranty

claims

on

war-

PROCEDURE

FOR

OBTAINING

WARRANTY

PERFORMANCE

~

ranted

Equipment

in

the

event

of

failure

resulting

from

a

defect

As

soon

as

any

defect

in

a

Welder

becomes

known,

the

pur

within

the

following

periods

from

the

date

of

deliveryofEquip-

chaser

of

the

Welder

must,

within

thirty

(30)

days,

notify

an

ment

to

the

original

user:

approved

Warranty

StationorMiller

Electric

in

writing

of

the

~

1.

Arc

welders,

power

sources,

and

components

1

year

period.

return

the

WeldertoMiller

Electricatthe

following

ad-

defect.

The

purchaser

must

then,

within

the

one

year

warranty

2

Original

main

power

rectifiers

3

years

dress:

(labor

-

1

year

only)

3.

All

welding

guns,

feeder/gunsand

plasma

torches...

BOdeyS

Miller

Electric

Mfg.

Co.

4.

Replacement

or

repair

parts,

exclusive

of

labor

..

60

days

718

South

Bounds

Street

WHAT

IS

NOT

COVERED

-

This

warranty

does

not

extend

Box

1079

Appleton,

Wisconsin

54912

to

any

Welder

subjected

to

misuse,

neglect,

accident,

or

in-

warranty

repair

by

anyone

except

Miller

Electric.

Further,

this

All

transportation

charges

to

Warranty

Station

or

Miller

Electric

~Q

warranty

only

extendstothose

purchasing

the

Welder

for

per-

must

be

prepaid.

sonal,

family

or

household

purposes.

Commercial

and

in

dustrial

users

are

given

a

different

warranty.

TABLE

OF

CONTENTS

Section

No.

Page

No.

SECTION

1

INTRODUCTION

1-1.

General

Information

And

Safety

1

1-2.

Receiving-Handling

1

1-3.

Description

1

1-4.

Duty

Cycle

1

SECTION

2

INSTALLATION

2-1.

Gun/Feeder

Connector

Installation

2

2-2.

Gun

Trigger

Connections

2

2-3.

Changing

Wire

Size

2

SECTION

3

SEQUENCE

OF

OPERATION

3-1.

Gas

Metal

Arc

Welding

(GMAW)

3

3-2.

Flux

Cored

Arc

Welding

(FCAW)

3

3-3.

Shutting

Down

4

SECTION

4

MAINTENANCE

4-1.

Inspection

And

Upkeep

4

4-2.

Contact

Tube

Replacement

5

4-3.

Liner

Replacement

5

SECTION

1

-

INTRODUCTION

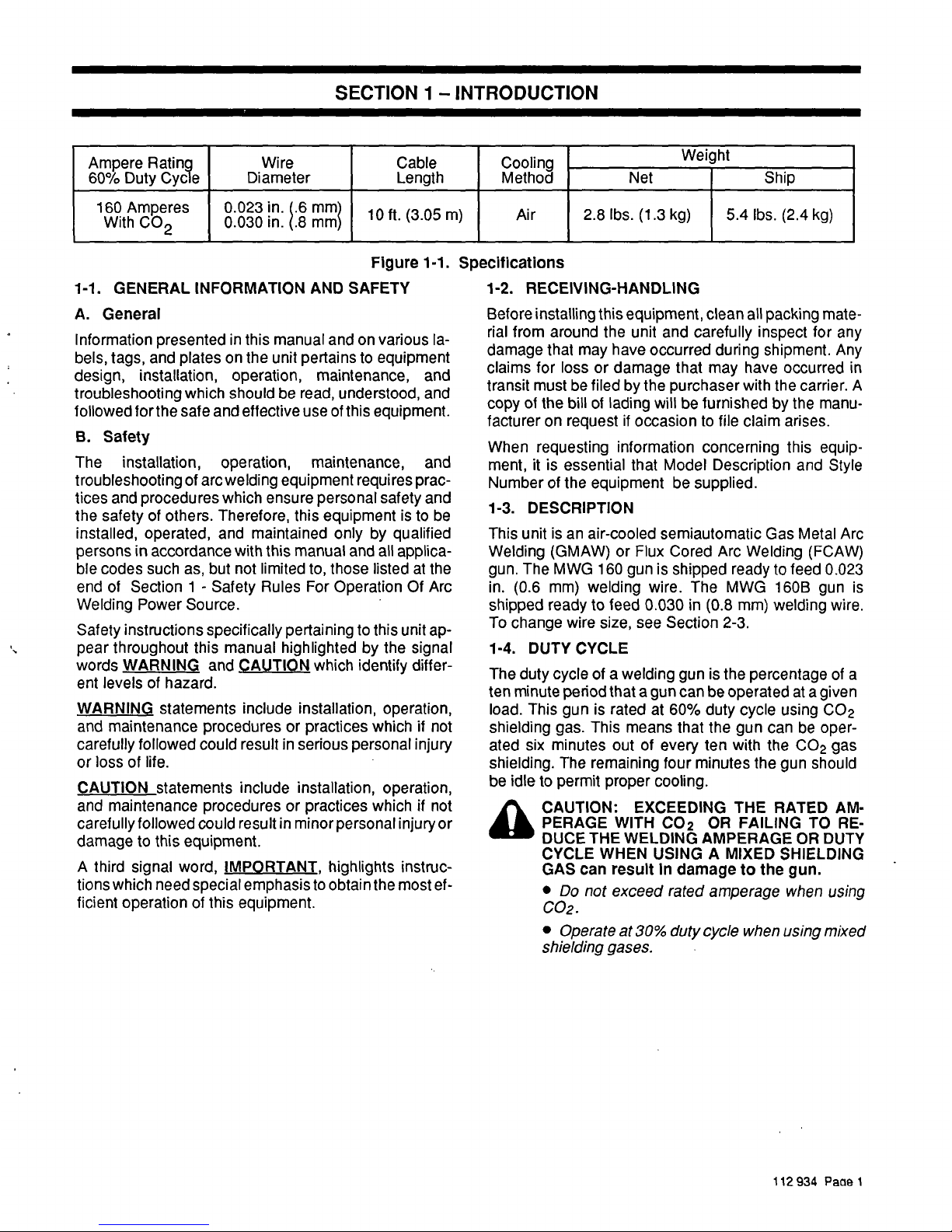

Ampere

Rating

60/~

Duty

Cycle

Wire

Diameter

Cable

Length

Cooling

Method

Weight

Net

I

Ship

I

2.8

lbs.

(1.3

kg)

5.4

lbs.

(2.4

kg)

160

Amperes

With

CO2

0.023

in.

(.6

mm)

0.030

in.

~.8

mm)

10

ft.

(3.05

m)

Air

Figure

1-1.

Specifications

1-1.

GENERAL

INFORMATION

AND

SAFETY

A.

General

Information

presented

in

this

manual

andonvarious

la

bels,

tags,

and

plates

on

the

unit

pertains

to

equipment

design,

installation,

operation,

maintenance,

and

troubleshooting

which

should

be

read,

understood,

and

followed

forthe

safe

and

effective

use

of this

equipment.

B.

Safety

The

installation,

operation,

maintenance,

and

troubleshooting

of

arc

welding

equipment

requires

prac

tices

and

procedures

which

ensure

personal

safety

and

the

safety

of

others.

Therefore,

this

equipment

istobe

installed,

operated,

and

maintained

onlybyqualified

persons

in

accordance

with

this

manual

and

all

applica

ble

codes

such

as,

but

not

limited

to,

those

listedatthe

end

of

Section

1

-

Safety

Rules

For

Operation

Of

Arc

Welding

Power

Source.

Safety

instructions

specifically

pertaining

to

this

unit

ap

pear

throughout

this

manual

highlighted

by

the

signal

words

WARNING

and

CAUTION

which

identify

differ

ent

levelsofhazard.

WARNING

statements

include

installation,

operation,

and

maintenance

procedures

or

practices

which

if

not

carefully

followed

could

resultinserious

personal

injury

or

lossoflife.

CAUTION

statements

include

installation,

operation,

and

maintenance

procedures

or

practices

which

if

not

carefully

followed

could

result

in

minor

personal

injury

or

damage

to

this

equipment.

A

third

signal

word,

IMPORTANT

highlights

instruc

tions

which

need

special

emphasis

to

obtain

the

most

ef

ficient

operation

of this

equipment.

1-2.

RECEIVING-HANDLING

Before

installing

this

equipment,

clean

all

packing

mate

rial

from

around

the

unit

and

carefully

inspect

for

any

damage

that

may

have

occurred

during

shipment.

Any

claims

for

loss

or

damage

that

may

have

occurred

in

transit

must

be

filed

by

the

purchaser

with

the

carrier.

A

copy

of

the

bill

of

lading

will

be

furnished

by

the

manu

facturer

on

request

if

occasion

to

file

claim

arises.

When

requesting

information

concerning

this

equip

ment,

itisessential

that

Model

Description

and

Style

Number

of

the

equipmentbesupplied.

1-3.

DESCRIPTION

This

unit

is

an

air-cooled

semiautomatic

Gas

Metal

Arc

Welding

(OMAW)

or

Flux

Cored

Arc

Welding

(FCAW)

gun.

The

MWG

160

gun

is

shipped

ready

to

feed

0.023

in.

(0.6

mm)

welding

wire.

The

MWG

160B

gun

is

shipped

ready

to

feed

0.030

in

(0.8

mm)

welding

wire.

To

change

wire

size,

see

Section

2-3.

1-4.

DUTY

CYCLE

The

duty

cycle

of

a

welding

gun

is

the

percentage

of

a

ten

minute

period

that

a

gun

can

be

operated

at

a

given

load.

This

gun

is

rated

at

60%

duty

cycle

using

CO2

shielding

gas.

This

means

that

the

gun

can

be

oper

ated

six

minutes

out

of

every

ten

with

the

CO2

gas

shielding.

The

remaining

four

minutes

the

gun

should

be

idle

to

permit

proper

cooling.

4A

CAUTION:

EXCEEDING

THE

RATED

AM

PERAGE

WITH

CO2

OR

FAILING

TO

RE

DUCE

THE

WELDING

AMPERAGE

OR

DUTY

CYCLE

WHEN

USING

A

MIXED

SHIELDING

GAS

can

result

In

damage

to

the

gun.

Do

not

exceed

rated

amperage

when

using

C02.

Operate

at

30%

duty

cycle

when

using

mixed

shielding

gases.

112934

Paael

Loading...

Loading...