Page 1

Quick

Specs

Quiet at only 70 dB (95 Lwa) when idle,

79 dB (104 Lwa) at maximum output.

Improves work site communications.

NEW!

Meter maintenance display

• Hour meter function

• Oil Change interval

• Diesel: High coolant temperature

and low oil pressure shutdowns

• Diesel: Low fuel shutdown —

engine shuts down before

system runs out of fuel making

restarts easy

Low maintenance with easy single-side

access to engine and 500 hour oil changes for

both engine and compressor.

Arc-Drive makes welding easy.

Automatically enhances Stick

welding, especially on pipe, by

focusing the arc and preventing

the electrode from going out.

Optional

AC/DC/battery charge/

jump-start for AC TIG welding

and 12 or 24 volt batteries. Simply

select the battery voltage and

connect cables to the separate

battery output studs.

(High-frequency unit required for

AC TIG.)

Big Blue®Air Pak

™

Engine-Driven Welder/

AC Generator/Air Compressor

Issued April 2008 • Index No. ED/10.5

Hot Start™provides positive stick

electrode starts to make it easy to

start all types of electrodes.

Enclosed robust case design protects

internal components from impact and

allows air flow to cool and prolong the life

of the engine. Also reduces sound levels.

Welder/generator/air compressor.

One machine that will do it all. Designed

and built to be the most reliable highoutput system in the world.

Weatherproof Lexan

®

nameplate

resists cracking and fading, and is

color-coded for ease of operation.

GFCI receptacle as required on most job sites

to protect operators from electrical hazards.

turbocharged four-cylinder diesel

engine provides ample power at high altitudes.

Independent compressor controls.

On/off switch for applications not

requiring compressed air. At idle

speed will produce 100 PSI at 40 CFM.

ultra-reliable

industrial rotary screw air compressor.

Belt-driven with automatic belt tensioner

with a life expectancy of 30,000 hrs.

The Power of Blue®.

Welder/Generator/Air Compressor is warranted

by Miller for 3 years, parts and labor.

Engine is warranted by Deutz for 3 years.

Miller Electric Mfg. Co.

An Illinois Tool Works Company

1635 West Spencer Street

Appleton, WI 54914 USA

Web Site

www.MillerWelds.com

International Headquarters

Phone: 920-735-4505

USA FAX: 920-735-4134

Canadian FAX: 920-735-4169

International FAX: 920-735-4125

Heavy Industrial Applications

Railroad Maintenance

Mining Maintenance

Maintenance and Repair Rigs

Processes

Stick (SMAW)

MIG (GMAW)

Flux Cored (FCAW)

Submerged Arc (SAW)

AC TIG (GTAW)*

DC TIG (GTAW)

Stud Welding — 1/2 in (12.7 mm)

Air Plasma Cutting

with Optional Spectrum Models

Air Carbon Arc (CAC-A)

1/2 in (12.7 mm) Carbons

Battery Charging/Jump-Starting*

Air Compressor

Output Range

DC Stick 45–750 A MIG/FCAW 14–40 V

DC TIG 20–450 A AC 20–575 A*

Battery Charge 12/24 V, 50–750 A*

*Deluxe Model Only.

Weld Output Rated at 104°F (40°C)

Stick 600 A, 44 V, 26.4 kW, 40% Duty Cycle

Stick 550 A, 42 V, 23.1 kW, 60% Duty Cycle

MIG/FCAW 500 A, 40 V, 20 kW, 100% Duty Cycle

AC TIG 400 A, 26 V, 10.4 kW, 100% Duty Cycle*

Generator Output Rated at 104°F (40°C)

5,500 Watts Peak — 4,000 Watts Continuous

20,000 Watts 3-Phase/12,000 Watts 1-Phase

Continuous*

Air Compressor 100 PSI, 60 CFM, 100% Duty Cycle

Weight Net: 1931 lb (876 kg)

Ship: 1982 lb (899 kg)

Improved!

Maintenance Displays!

Page 2

Welding

Mode

CC/DC

CV/DC

CC/AC*

Battery*

Charge

Jump-Start

Weld Output Rated at 104˚ F (40˚ C) NEMA

Amperage and Voltage

600 A, 44 V, 26.4 kW, 40% Duty Cycle

550 A, 42 V, 23.1 kW, 60% Duty Cycle

500 A, 40 V, 20 kW, 100% Duty Cycle

500 A, 40 V, 20 kW, 100% Duty Cycle

400 A, 36 V, 14.4 kW 100% Duty Cycle

750 A, 12 V, Jump-Start

750 A, 24 V, Jump-Start

Weld

Output

Range

20 – 750 A

14 – 40 V

20 – 575 A

12/24 V

Max. OpenCircuit

Voltage

95

56

64

14/28

Meets NEMA and IEC output ratings. *Only available on deluxe model. **Additional 7 in (178 mm) to top of exhaust. ***Additional 190 lb (86 kg) when fuel tank is full.

CSA approved.

Compressor

Brand

Ingersoll-Rand

CE55 G1

Free Air

Delivery at

1850 RPM

60 cfm

(1.70 m

3

/min)

Free Air

Delivery at

1235 RPM

40 cfm

(1.13 m3/min)

Idle

Features

Rotary screw with electric clutch for on/off.

Oil change intervals 500 hrs (same as engine).

Life expectancy 30,000 hrs.

Working

Pressure

Constant

100 psig

7 bar

Duty

Cycle

100%

Oil

Capacity

5 qt (4.7 L)

Automatic

Compressor

Shutdowns

Oil temperature

Engine Brand

Deutz, BF4M

2011 Diesel

Features

EPA certified, turbocharged direct-injected,

liquid-cooled (oil) engine. Right side service

access with 500 hr intervals for oil and filters.

MSHA approved with purchase of certificate

from Deutz dealer.

Type

Four-cylinder,

industrial, liquidcooled engine

Engine

Speeds

1850 Run

1235 Idle

HP

63.4

Fuel Capacity

25 gal (95 L)

Automatic Engine

Shutdowns

Oil pressure

Oil temperature

Oil

Capacity

11 qt

(10.4 L)

Engine

7

8

9

18

19

20

21

22

7

23

International Model

1

2

10

11

12

13

4

3

5

6

15

16

17

14

2

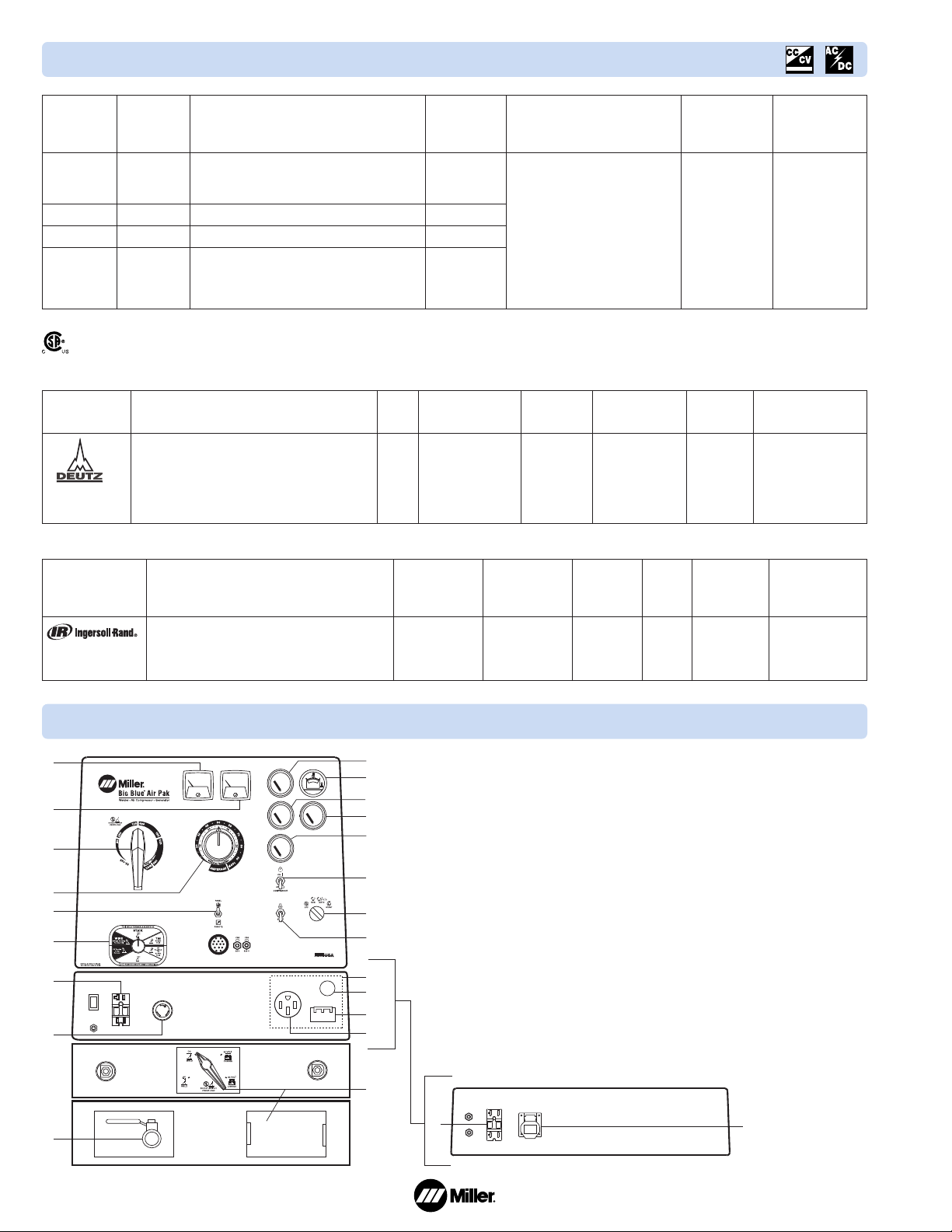

Control Panel

Weight

Without Fuel***

Net: 1931 lb

(876 kg)

Ship: 1982 lb

(899 kg)

Deluxe Model

Net: 1956 lb

(887 kg)

Ship: 2007 lb

(910 kg)

Dimensions**

H: 43 in

(1092 mm)

W: 28-1/2 in

(724 mm)

D: 67-1/2 in

(1715 mm)

Generator Output Rated

at 104˚ F (40˚ C)

Peak: 5500 watts

Continuous: 4000 watts,

120/240 VAC, 34/17 A, 60 Hz

while welding

Optional kW

3-phase, 20 kW, 36 A, 240 VAC

1-phase, 12 kW, 50 A,

120/240 VAC while not welding

Specifications

(Subject to change without notice.)

1. AC/DC Voltmeter*

2. AC/DC Ammeter*

3. Amperage Range Switch

4. Amperage/Voltage Adjust Control

5. Amperage/Voltage Adjust Switch

and Remote Amperage/Voltage

Adjust 14-Pin Receptacle

6. Process/Contactor

Selector Switch

7. 120 VAC, 20 A GFCI

Duplex Receptacle

8. 240 VAC, 30 A TwistLock

Receptacle (NEMA L6-30)

9. Air Outlet Valve 3/4 in NPT

10. Engine Oil Pressure Gauge

11. Fuel Gauge—displays engine

hours and oil change intervals

12. Engine Coolant Temperature Gauge

13. Battery Voltmeter

14. Air Compressor Pressure Gauge

15. Air Compressor On/Off Switch

16. Engine Control Switch

17. Starting Aid Switch*

18. 20 kW, 3-Phase Generator*

19. Strain Relief*

20. 50 A, 3-Phase Circuit Breaker*

21. 50 A, 1-Phase 120/240 V

Receptacle (NEMA 14-50)*

22. AC/DC/Battery Charge/

Jump-Start Switch*

23. International Model—240 VAC,

16 A Pin and Sleeve Receptacle

*On Select Models

Air Compressor

Page 3

3

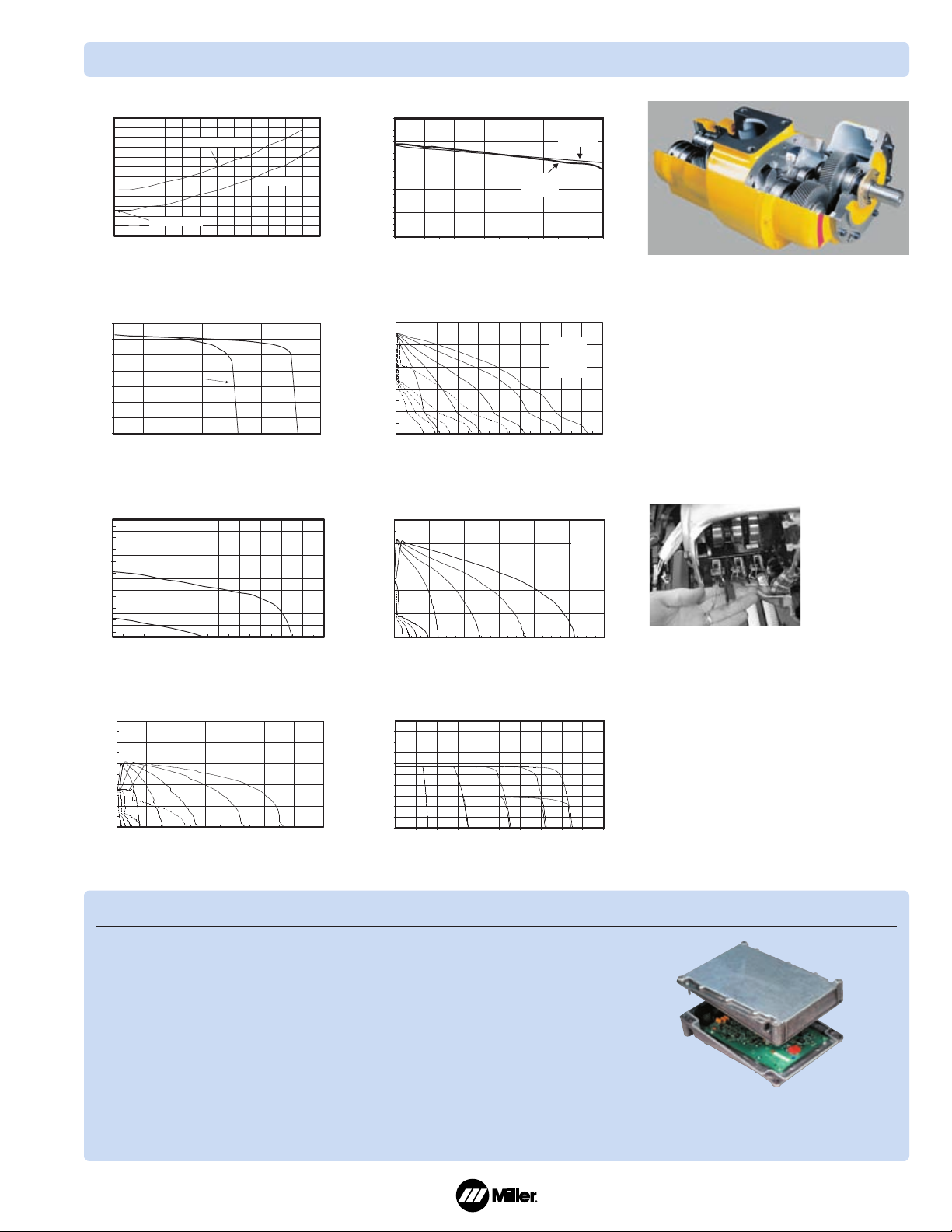

Performance Data

FUEL CONSUMPTION CURVE

0.00

0.25

0.50

0.75

1.00

1.25

1.50

1.75

2.00

2.25

2.50

2.75

3.00

0 50 100 150 200 250 300 350 400 450 500 550 600

DC WELD AMPERES AT 100% DUTY CYCLE

US Gal./Hr.

VOLT/AMP CURVE – STICK MODE

0

20

40

60

80

100

0 100 200 300 400 500 600 700 800 900 1000

DC AMPERES

DC VOLTS

VOLT/AMP CURVE – AC TIG MODE

0

20

40

60

80

100

0 100 200 300 400 500 600 700

AC AMPERES

AC VOLTS

WELD AND AIR

WELD ONLY

IDLE WITH AIR

IDLE

AIR SUPPLY CURVE

0

20

40

60

80

100

120

140

0 10203040506070

CFM

PSI

IDLE

300–Max

185–525

125–400

55–125

VOLT/AMP CURVE – MIG MODE

0

10

20

30

40

50

60

70

80

90

100

0 100 200 300 400 500 600 700 800 900 1000

DC AMPERES

DC VOLTS

MAX

MIN

VOLT/AMP CURVE – DC TIG MODE

0

20

40

60

80

100

0 100 200 300 400 500 600

DC AMPERES

DC VOLTS

60– 450

40– 330

30– 220

20– 110

GENERATOR POWER CURVE OPTION

180

200

220

240

260

280

0 10203040506070

AC AMPERES

AC VOLTS

12 kW

1-PHASE

BATTERY CHARGE OUTPUT

0

5

10

15

20

25

30

35

40

45

50

0 100 200 300 400 500 600 700 800 900 1000

DC AMPS

DC VOLTS

20 kW

3-PHASE

Ingersoll-Rand Rotary Screw Air

Compressor

This industrial grade compressor, has a life

expectancy of 30,000 hours, is belt driven and

utilizes an electric clutch control to allow the

compressor to be turned off if not needed.

This design increases efficiency, reduces fuel

consumption and saves you money at the

pump. An automatic belt tensioner provides

proper belt tension even after years of service.

The compressor is protected by a high

temperature shutdown switch.

Toolless

Generator

Brushes

100% copperwound

generator

features quick

and easy brush and slip ring inspection.

Brushes can be removed and/or replaced

in a matter of seconds.

The Vault

Superior Circuit Board Design

Miller’s critical circuit boards are engineered

to carry

low power

and

low heat

to reduce

thermal stress and minimize expansion and

contraction. In contrast, our competitor’s

boards carry

high power

and

high heat

, making

them more vulnerable to failure.

“The Vault” Makes Upgrading to Miller CC/CV

Units Worry-Free

Concerns with circuit board reliability have

resulted in some operators steering clear of

CC/CV welder/generators — even though they

offer a superior arc and multiple welding

processes. Miller’s circuit board reliability isn’t

a concern since all PRO 300 and Big Blue

multiprocess industrial engine drives feature

the Vault.

Created out of two aluminum halves sealed

with silicone, as well as watertight harness

connections, the Vault provides a clean circuit

board environment, protecting the electronics

— and controlling output — in heavy industrial

applications. No other competitor protects their

electronics with a sealed vault, leaving critical

circuit boards exposed to harsh elements that

can disrupt the machine’s electronics, and

therefore, its operation.

Page 4

4

Genuine Miller Accessories

Field Kit Accessories

Desiccant Air Dryer System #195 117

A regenerating inline air dryer system

that eliminates moisture in the air stream

to prevent air tool freeze-ups in cold

climates. Internal thermostat and heating

elements insure good air quality in all

climates. The system can be mounted on

the side of the machine or remotely for

truck mount installations.

AC/DC/Battery Charge/Jump-Start Switch

#195 148 Field

AC TIG welding and 12/24 V battery charge/

jump-starting system.

FA-1D Lockable Flame

Arrestor Fuel Cap #043 947

Fuel cap can be padlocked to

prevent vandalism. A built-in

flame arrestor prevents

flames or sparks from

entering the fuel tank.

Cold Weather Starting Aids*

#043 959 Field 12 V intake manifold heater.

#195 086 Field 120 V oil pan heater element.

*Note: for extreme cold weather both starting aids

can be used in conjunction.

Weld Ammeter and Voltmeter

#195 131 Field

Panel-mounted AC/DC analog meters to

monitor weld output.

Vandalism

Lockout Kit

#195 118 Field

Lockable hinged

steel panels cover

and protect name

plate gauges and

ignition switch

(padlock included).

Also includes engine

compartment door

lock and key.

Cable Holder

#043 946

Saddle-bag-style

cable holder.

Convenient wraparound storage of

coiled cable for

transportation.

Stores 100 ft of

2/0 cable

on each side.

Note: For best results do not weld when cable is

coiled! Canvas cover cannot be used with cable

holder.

Battery Lockout/Tagout

Disconnect Switch

#195 120 Field

Lockable battery

disconnect switch for safe

routine maintenance.

Stick (SMAW) Welding

Weld Leads

#173 851 2/0, 350 A, 100% duty cycle,

50 ft stinger, 50 ft work cable

#043 952 2/0, 300 A, 100% duty cycle,

100 ft stinger, 50 ft work cable

Plasma Cutting

Spectrum®375 X-TREME™#907 303

Spectrum®375 X-TREME™with X-CASE

™

#907 339 (not shown)

See Lit. Index No. PC/9.2.

Spectrum

®

625 #907 058

See Lit. Index No. PC/9.5.

Spectrum 2050 #903 777-01-2

See Lit. Index No. PC/7.0.

MIG/Flux Cored Welding

Millermatic®Passport®Plus

#907 401

Portable, all-in-one MIG package features

ultimate arc performance, self-contained

gas bottle, and flexibility to plug into 115 or

230 V power with Miller exclusive MultiVoltage Plug. See Lit. Index No. DC/12.53.

SuitCase

™

X-TREME™8VS

Wire Feeder #300 093

SuitCase

™

X-TREME™12VS

Wire Feeder #195 500

Lightweight, portable, voltage-sensing

wire feeders include secondary contactor

and gas valve. Require drive roll kit.

See Lit. Index No. M/6.41.

Page 5

5

Genuine Miller Accessories (continued)

MIG/Flux Cored Welding (continued)

SuitCase™8RC Wire Feeder #194 938

SuitCase™12RC Wire Feeder #194 940

Lightweight, modular design and flexible

enough to run a variety of wires up to 5/64 in

diameter. Comes standard with remote

voltage control. See Lit. Index No. M/6.5.

S-32SL Wire Feeder #109 294

Simple to use, but with all the features

needed for heavy-duty applications up to

7/64 in wire diameter. See Lit. Index

No. M/6.21.

Spoolmatic

®

30A Spool Gun

#130 831

Air-cooled, 200-amp, 1-lb spool gun for

aluminum MIG. See Lit. Index No. M/1.73.

WC-24 Control #137 549

Use with Spoolmatic 30A.

XR

™

Wire Feeders and Guns

Push-pull system designed to handle

difficult-to-feed soft alloy wires such as

aluminum. See Lit. Index No. M/1.7,

M/1.71, and M/1.73.

TIG (GTAW) Welding

Dynasty®200 Series

For premium portable AC/DC TIG arc

quality. See Lit. Index No. AD/4.8.

HF-251 Series #042 388

HF-251D-1, 115 VAC

High-frequency arc starter and stabilizer.

See Accessory Lit. Index No. AY/5.0.

Remote Controls

RHC-14 Hand Control

#129 340

Miniature hand control for

remote current and contactor

control. Dimensions: 4 x 4 x

3-1/4 in (102 x 102 x 82 mm). Includes

20 ft (6 m) cord and 14-pin plug.

RFCS-14 HD Foot

Control #194 744

Heavy-duty foot current

and contactor control.

Includes 20 ft (6 m)

cord and 14-pin plug.

RMLS-14 #129 337

14-pin plug Momentary- and maintainedcontact rocker switch for contactor control.

Push forward for maintained contact and

back for momen tary contact. Includes 20 ft

(6 m) cord.

RCC-14 Remote Contactor and Current

Control #151 086 14-pin plug

Rotary-motion fingertip control fastens to

TIG torch using two Velcro

®

straps.

Includes 28 ft (8.5 m) control cord.

Extension Cords for 14-Pin

Remote Controls

#122 973 25 ft (7.6 m)

#122 974 50 ft (15.2 m)

#122 975 75 ft (23 m)

Page 6

6

A. 20 in (508 mm)

B. 16-1/2 in (419 mm)

C. 1-3/4 in (44 mm)

D. 6-1/16 in (154 mm)

E. 32-3/4 in (832 mm)

F. 45-3/8 in (1153 mm) (Gas)

52 in (1321 mm) (Diesel)

G. 13/32 in (10 mm) diameter

Height:

(to top of exhaust)

33 in (838 mm) (Gas)

34-1/4 in (870 mm) (Diesel)

Width: 20 in (508 mm)

Depth: 45-7/8 in (1164 mm) (Gas)

52-1/2 in (1334 mm) (Diesel)

4 Holes

Engine End

G

A

B

C

D

E

F

Mounting Specifications

HWY-224 Trailer #043 805 For highway use.

OFR-224 Trailer #043 802 For off-road use.

A 2650 lb (1202 kg) capacity trailer. Welded

steel tubing frame, heavy-duty axle with roller

bearing hubs and leaf-spring suspension.

Includes jack stand, 2 in (50 mm) ball hitch.

HWY-224 also includes fenders and lights.

Note: Trailer is shipped unassembled.

Cable Tree #043 826

Provides an area to conveniently wrap weld

cables and extension cords.

Lunette Eye 2-1/2 in (64 mm) #043 824

HWY-430 Tandem Axle Trailer #043 806

Smooth riding with 3750 lb (1701 kg) capacity.

Includes hand-operated parking brake, hydraulic

brake system, and a break-away device to lock

brakes if the trailer comes loose. Includes jack

stand, fenders and lights. (Hitch must be

ordered separately.)

Note: Some assembly required.

Cable Tree #043 826

Provides an area to conveniently wrap weld

cables and extension cords.

Ball Hitch 2 in (50 mm) #043 864

Lunette Eye 3 in (76 mm) #043 863

4 West Four-Wheel Steerable

Off-Road Trailer #042 801

A heavy-duty 2570 lb (1166 kg) capacity trailer

designed for use in mines, quarries, and other

rough terrain. Has narrow 22 ft (6.7 m) turning

radius. Includes 3 in lunette eye, universal hitch

and safety chains.

Note: Trailer is shipped unassembled.

Trailers and Hitches (Note: Trailers are shipped unassembled.)

Trailer Specifications (Subject to change without notice.)

Net

Payload

2570 lb

(1166 kg)

2650 lb

(1202 kg)

3750 lb

(1701 kg)

Gross Vehicle

Weight Rating

3000 lb

(1361 kg)

2960 lb

(1343 kg)

4280 lb

(1941 kg)

Gross Axle

Weight Rating

2000 lb/axle

(907 kg/axle)

3500 lb

(1588 kg)

2200 lb/axle

(998 kg/axle)

Model

4 West

HWY-224

OFR-224

HWY-430

Height

of Bed

21-1/4 in

(540 mm)

18-1/2 in

(470 mm)

19-1/4 in

(489 mm)

Road

Clearance

8 in

(203 mm)

7-1/2 in

(191 mm)

8-1/2 in

(216 mm)

Net

Weight

430 lb

(195 kg)

355 lb

(161 kg)

530 lb

(240 kg)

Track (Center

to center of

tires)

55-1/4 in

(1403 mm)

52 in

(1321 mm)

52 in

(1321 mm)

Standard Tires

(Standard rating

or P-size rating)

B78-13

B78-13B

B78-13B

Dimensions

Length: 91 in (2311 mm)**

Width: 61-1/4 in (1556 mm)

Length: 122-1/2 in (3112 mm)

Width: HWY– 61 in (1549 mm)*

OFR–58-1/2 in (1486 mm)

Length: 156-1/2 in (3975 mm)

Width: 61 in (1549 mm)*

*

Width at outside of fenders.

**

Does not include tongue.

Page 7

7

MIG Gun

Work

SuitCase

8RC/12RC

Work

Stick Electrode

Work

Flux Cored Gun

Aluminum MIG with

Spoolmatic 30A Gun

Work

Cutting Torch

Work

Spectrum

14-Pin

14-Pin

WC-24

TIG

Torch

Work

14-Pin

HF-251D-1

X-TREME 8VS/

X-TREME 12VS

Feeder

Plasma Basic Equipment

Spectrum®375 X-TREME™#907 303

Spectrum®375 X-TREME™with X-CASE

™

#907 339

Spectrum

®

625 #907 058

Spectrum®2050 #903 777-01-2

Stick (SMAW) Basic Equipment

Flux-Cored (FCAW) Basic Equipment

SuitCase™X-TREME™ 8VS #300 093

SuitCase

™

X-TREME™12VS #195 500

MIG (GMAW) Basic Equipment

SuitCase™8RC #194 938

SuitCase™12RC #194 940

Aluminum MIG (GMAW) Basic Equipment

Spoolmatic®30A #130 831

WC-24 #137 549

TIG (GTAW) Basic Equipment

Dynasty®200 Series

HF-251D-1 #042 388*

*TIG power cable adapter required

Typical Installations

Page 8

Litho in USA

Distributed by:

Equipment and Factory Options Stock No. Description Qty. Price

Big Blue

®

Air Pak™CC/CV Base Model #907 062 Automatic Idle, Engine Gauges, 5.5 kW AC Generator

International Model #907 062-01-1 50/60 Hz, Dry Battery, Automatic Idle, Engine Gauges, 5.5 kW AC Generator

Cold Weather Model #907 062-04-1 Automatic Idle, Engine Gauges, 5.5 kW AC Generator, Weld Meters,

Battery Lockout/Tagout Disconnect Switch, 12 V Intake Manifold Heater,

120 V Oil Pan Heater

Deluxe Model #907 062-07-1 Automatic Idle, Engine Gauges, 5.5 kW AC Generator, Weld Meters,

Battery Lockout/Tagout Disconnect Switch, 12 V Intake Manifold Heater,

120 V Oil Pan Heater, Vandalism Lockout Kit, 20 kW Generator,

AC/DC/Battery Charge/Jump-Start Switch

Field Kit Accessories

Weld Ammeter and Voltmeter Kit #195 131 AC/DC analog weld output meters

Lockable Fuel Cap Flame Arrestor #043 947 Padlock not included

Cold Weather Starting Aids #043 959 12 volt intake manifold heater

#195 086 120 volt oil pan heater

Desiccant Air Dryer System #195 117 Removes moisture from air supply

Vandalism Lockout Kit #195 118 Lockable front control panel and engine compartment

Battery Lockout/Tagout Disconnect Switch #195 120 Allows machine battery to be disconnected and locked

AC/DC/Battery Charge/Jump-Start Switch #195 148 Field

Cable Holder #043 946 Stores up to 200 ft of 2/0 weld cable

Protective Cover #195 159 Will not fit over machine with cable holder attached

Stick Accessories

Welding Leads #173 851 2/0, 350 A, 100% Duty Cycle, 50 ft stinger, 50 ft work clamp

#043 952 2/0, 300 A, 100% Duty Cycle, 100 ft stinger, 50 ft work clamp

Plasma Cutters

Spectrum®Plasma Cutter See page 4

Wire Feeders

SuitCase™X-TREME™ 8VS #300 093 Includes contactor and gas valve. See Lit. Index No. M/6.41

SuitCase™X-TREME™12VS #195 500 Includes contactor and gas valve. See Lit Index No. M/6.41

SuitCase™8RC #194 938 See Lit Index No. M/6.5

SuitCase™12RC #194 940 See Lit Index No. M/6.5

S-32SL Wire Feeder #109 294 See Lit. Index No. M/6.21

Spoolmatic®30A Spool Gun #130 831 Requires WC-24 Control. See Lit. Index No. M/1.73

Guns and Consumables See Lit. Index No. M/10.0 and M/13.4

TIG Accessories

HF-251D-1 #042 388 High frequency unit for AC TIG welding

Water Coolant System See Lit. Index No. AY/7.2

TIG Torch, Consumables

Remote Controls

RHC-14 #129 340 Hand control

RFCS-14 HD #194 744 Foot control

RMLS-14 #129 337 Momentary and maintained contact switch

RCC-14 #151 086 Fingertip control

Extension Cords #122 973 25 ft (7.6 m)

#122 974 50 ft (15.2 m)

#122 975 75 ft (22.9 m)

Trailers and Hitches

HWY-224 Trailer #043 805 Highway trailer with 2650 lb (1202 kg) capacity

OFR-224 Trailer #043 802 Off-road trailer with 2650 lb (1202 kg) capacity

HWY-430 Tandem Axle Trailer #043 806 Highway trailer with 3750 lb (1701 kg) capacity.

4-West Trailer #042 801 Off-road steerable trailer with 2570 (1166 kg) capacity

Lunette Eye #043 824 2-1/2 in (64 mm). For 224 trailers only

#043 863 3 in (76 mm). For 430 trailer only

Ball Hitch #043 864 2 in (51 mm). For 430 trailer only

Clevis #043 823 For 430 trailer only

Cable Tree #043 826 Works on 224 and 430 trailers

Date: Total Quoted Price:

Ordering Information

Loading...

Loading...