Miller Electric 700 User Manual

Processes

TIG (GTAW)

Pulsed TIG (GTAW-P)

Stick (SMAW)

Air Carbon Arc (CAC-A)

350: 1/4 in maximum

700: 3/8 in maximum

Input Power 208 – 575 V, 3- or 1-Phase

Amperage Range 350: 5–350 A

700: 5–700 A

Rated Output 350: 300 A at 32 V, 60% Duty Cycle

700: 600 A at 44 V, 60% Duty Cycle

Weight 350: 135.5 lb (61 kg)

700: 198 lb (90 kg)

Industrial Applications

Precision Fabrication

Heavy Fabrication

Pipe and Tube Fabrication

Aerospace

Aluminum Ship Repair

Anodized Aluminum Fabrication

Quick

Specs

Dynasty®350 and 700

TIG/Stick Welding

Power Source

Issued Oct. 2008 • Index No. AD/5.0

The Power of Blue®.

Miller Electric Mfg. Co.

An Illinois Tool Works Company

1635 West Spencer Street

Appleton, WI 54914 USA

Web Site

www.MillerWelds.com

International Headquarters

Phone: 920-735-4505

USA FAX: 920-735-4134

Canadian FAX: 920-735-4169

International FAX: 920-735-4125

Power source is warranted for 3 years, parts and labor.

Original main power rectifier parts are warranted for 5 years.

Allows for any

input voltage

hookup (208–575 V) with no manual linking,

providing convenience in any job setting.

Ideal solution for dirty or unreliable power.

NEW!

Meter Calibration allows meters to

be calibrated for certification.

120 V auxiliary power receptacle for

cooling system or small tools.

Wind Tunnel Technology

™

protects internal

electrical components from airborne

contaminants, extending the product life.

Fan-On-Demand

™

power source cooling

system operates only when needed,

reducing noise, energy use and the amount

of contaminants pulled though the machine.

TIGRunner

®

packages feature a

3.5 gallon (13.2 L) cooling system. The

cart is equipped with cylinder carrying

capabilities, filler rod holder, foot pedal

holder, torch and cable holders. A pullout

drawer provides additional storage for torch

consumables and tools. See page 6.

Programmable start parameters allow

independent starting conditions based

on process and memory selections

(amperage, time and polarity).

Program memory features 9 independent

program memories that maintain/save

your parameters.

High-frequency arc starter for

non-contact arc initiation.

Lift-Arc

™

start provides AC or DC arc

starting without the use of high frequency

Auto-Postflow calculates the length of

postflow time based on the amperage setting.

This eliminates the need to independently set

the postflow time for different amperages.

This feature preserves your tungsten and

prevents porosity.

Stick Features (AC/DC)

Tailored arc control (DIG) allows the arc characteristic

to be changed for specific applications and electrodes.

Smooth running 7018 or stiffer, more penetrating 6010.

Hot Start

™

adaptive control provides positive arc starts

without sticking.

AC frequency control adds additional stability when Stick

welding in AC for smoother welds.

AC TIG Features

Independent Amplitude/Amperage

Control allows EP and EN

amperages to be set independently

to precisely control heat input to the

work and electrode.

Extended AC balance (30–99%)

controls the amount of oxide

cleaning (amperage time in EN)

which is essential for high quality

welds on aluminum.

AC frequency (20–400 hz) controls

the width of the arc cone and the

force of the arc.

AC Waveforms

Advance Squarewave, fast

freezing puddle, deep

penetration and fast travel speeds.

Soft Squarewave for a soft

buttery arc with maximum

puddle control and good wetting action.

Sine wave for customers

that like a traditional arc.

Quiet with good wetting.

Triangular wave reduces the

heat input and is good on

thin aluminum. Fast travel speeds.

DC TIG Features

Exceptionally smooth and precise

arc for welding exotic materials.

High-Speed DC TIG Pulse Control

Pulse frequency capable of pulsing

5000 pulses per second. Pulsing

adds arc stability, reduces heat input

and warpage and can increase travel

speeds. Other parameters include

peak amperage, peak time and

background amperage.

Dynasty 700

Dynasty 350

2

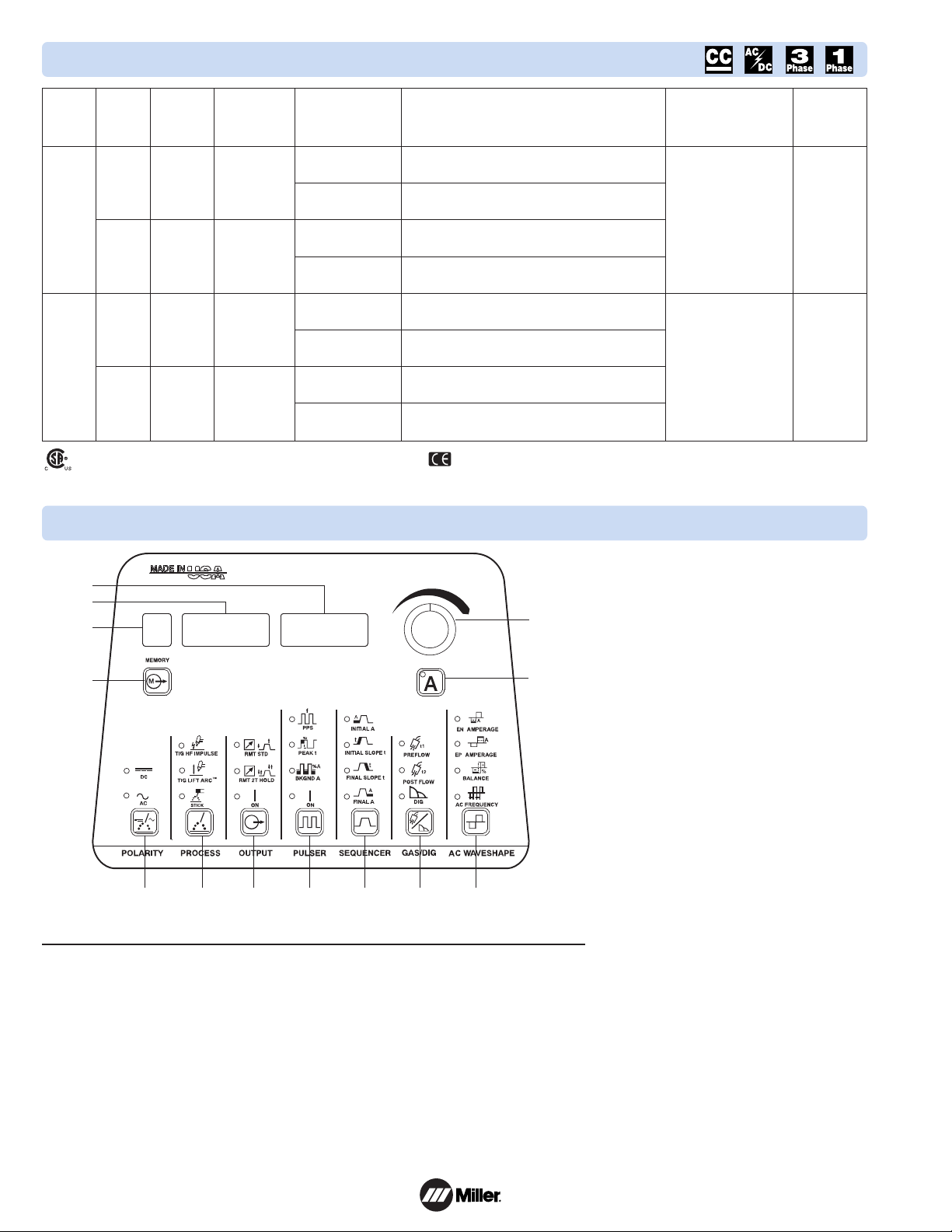

Control Panel

Input

Power

ThreePhase

SinglePhase

ThreePhase

SinglePhase

Rated

Output

250 A at 30 V,

100% Duty Cycle

300 A at 32 V,

60% Duty Cycle

180 A at 27.2 V,

100% Duty Cycle

225 A at 29 V,

60% Duty Cycle

500 A at 40 V,

100% Duty Cycle

600 A at 44 V,

60% Duty Cycle

360 A at 34 V,

100% Duty Cycle

450 A at 38 V,

60% Duty Cycle

Welding

Amperage

Range

5 – 350 A

5 – 350 A

5 – 700 A

5 – 700 A

Model

Dynasty

350

Dynasty

700

Max.

Open-Circuit

Voltage

75 VDC

10 –15 VDC*

75 VDC

10 –15 VDC*

75 VDC

10 –15 VDC*

75 VDC

10 –15 VDC*

Net

Weight

135.5 lb

(61 kg)

with

TIGRunner

®

308 lb

(140 kg)

198 lb

(90 kg)

with

TIGRunner

®

370 lb

(168 kg)

Specifications (Subject to change without notice.)

Amps Input at Rated Load Output, 50/60 Hz

208

V 230 V 400 V 460 V 575V KVA KW

29 26 15 13 10 10.3 9.9

35 32 18 16 13 12.7 12.1

35 32 — 15 12 7.4 6.8

47 43 — 21 17 9.8 9.1

75 68 39 34 27 27 26

97 88 51 44 35 35 34

82 74 — 37 30 17 16

115 104 — 52 42 24 22

Dimensions

H: 24-3/4 in (629 mm)

W: 13-3/4 in (349 mm)

D: 22 in (559 mm)

with TIGRunner

®

H: 45-1/8 in (1146 mm)

W: 23-1/8 in (587 mm)

D: 43-3/4 in (1111 mm)

H: 34-5/8 in (879 mm)

W: 13-3/4 in (349 mm)

D: 22 in (559 mm)

with TIGRunner

®

H: 55-1/8 in (1400 mm)

W: 23-1/8 in (587 mm)

D: 43-3/4 in (1111 mm)

*Indicates sense-voltage for Lift-Arc TIG and Low OCV Stick.

1. Memory 36 Combinations

(9 AC TIG)

(9 AC Stick)

(9 DC TIG)

(9 DC Stick)

2. Polarity AC/DC

3. Process/ TIG: HF Impulse, Lift Arc

Arc Starting STICK: Adaptive Hot Start

4. Output Control Standard Remote,

2T Trigger Hold,

Output ON

5. Pulser Control

Pulses per Second DC : 0.1 –5000 PPS

AC: 0.1– 500 PPS

Peak Time 5 – 95%

Background Amps 5 – 95%

6. Sequencer Control

Initial Amps Dynasty 350: 5 –350 A

Dynasty 700: 5–700 A

Initial Slope 0.0 – 50.0 Seconds

Final Slope 0.0–50.0 Seconds

Final Amps Dynasty 350: 5 –350 A

Dynasty 700: 5–700 A

7. Gas/DIG Preflow 0.0 – 25.0 Seconds

Postflow Auto Postflow,

Adjust 0.0–50 Seconds

DIG 0–100%

8. AC Waveshape

EN Amperage 5–350 A /5 – 700 A

EP Amperage 5 –350 A/5–700 A

Balance 30 – 99%

AC Frequency 20– 400 Hz

9. Amperage Control

10. Encoder Control

11. Ammeter Display

12. Voltmeter Display

Additional Setup Parameter Values

Programmable Starts

Amperage 5–200 A

Time 1– 200 Milliseconds

Polarity EP, EN

Additional Triggers 3T, 4T, Mini Logic,

4T Momentary

Waveshapes Advance Squarewave,

Soft Squarewave, Sine

Wave, Triangular wave

Amplitude Lock EN EP Same,

EN EP Independent

Spot/Weld Timer 0.0–999 Seconds

OCV Low OCV, Normal OCV

Lockouts Four levels

Arc Timer 0.0– 9999 Hours

and 0–59 Min

Cycle Counter 0 – 999,999 Cycles

Meter Calibration ±0–20.0 Amps

±0–20.0 Volts

Control Panel Parameter Values

Certified to both the Canadian and U.S. Standards for welding equipment.

Conforms to European standards.

11

12

13

1

23 64 5 78

10

f

9

UPGRADE

UPGRADE

UPGRADE

UPGRADE

UPGRADE

UPGRADE

UPGRADE

UPGRADE

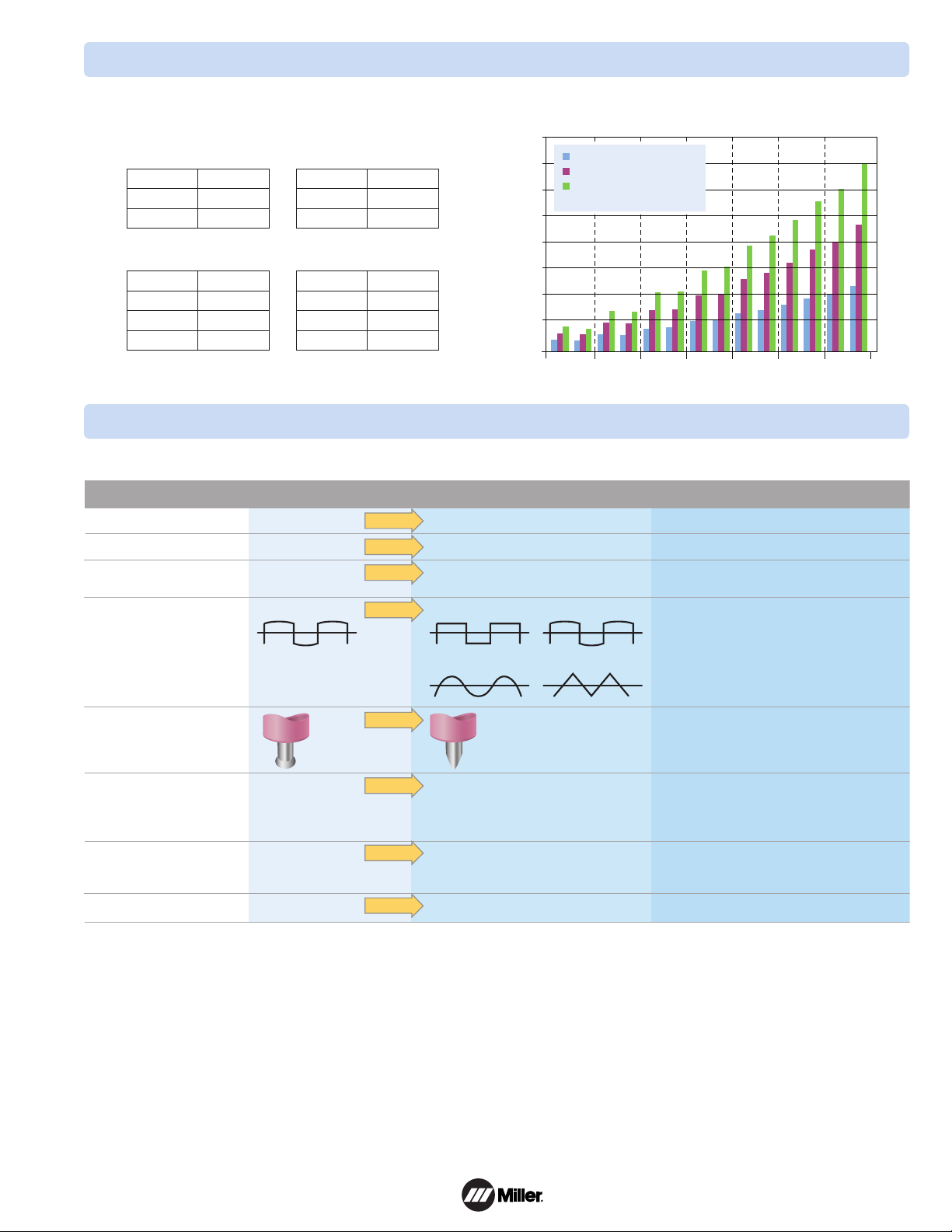

1/2 in Aluminum

Continuous HF

Fixed at 60 Hz

Soft Squarewave

496 lb

Manual Links

208/230/460 V

Single-Phase

110 A at 230 V

Single-Phase

Some Digital Controls

Maximum Thickness Capacity

High Frequency Arc Starting

Frequency Control

AC Output Control

AC Waveforms

Weld Aluminum

with Pointed Tungsten

Portability

Power Draw at 300 Amps

Precise Controls

Increases aluminum thickness.

Start Only limits HF interference issues.

Higher frequencies provide better arc control

and faster travel speeds.

Advanced Squarewave=Travel faster

Soft Squarewave= Maximum puddle control

Sine Wave= Traditional characteristics

Triangular Wave= Reduced heat input

Waveshaping controls maintain the point. The

benefits are: reduced heat input into your part,

smaller weld beads, better starting and more

control of the arc.

Easier to move because of size and weight.

Auto-Line™ allows the unit to operate on any

voltage. Single- or three-phase. Even generators!

Power requirement to operate is much less.

Smaller electrical service needed, smaller

breaker/fuses and power cord.

Accuracy and repeatability with all digital controls.

5/8 in Aluminum

Start Only

Variable 20– 400 Hz

Advanced Squarewave Soft Squarewave

Sine Wave Triangular Wave

135 lb

Auto-Line™

208–575 V

Single-Phase or Three-Phase

32 A at 230 V

Three-Phase

All Digital Controls

Why Upgrade? Syncrowave 350 Dynasty 350 Dynasty 350 Benefits

3

TIG Upgrade Chart

Performance Data

Which Machine is Right for You?

DUTY CYCLE

Maxstar 350

3-PHASE

%

0 – 30%

60%

100%

%

0 – 10%

30%

60%

100%

AMPERAGE

350 A

300 A

250 A

1-PHASE

AMPERAGE

350 A

250 A

225 A

180 A

Maxstar 700

%

0 – 30%

60%

100%

%

0 – 10%

30%

60%

100%

3-PHASE

AMPERAGE

1-PHASE

AMPERAGE

700 A

600 A

500 A

700 A

500 A

450 A

360 A

$1,600

$1,400

$1,200

$1,000

$800

$600

$400

$200

ANNUAL POWER COST OF OPERATION

Annual power costs based on one 8 hour shift (40 hrs/wk).

25% ARC ON= 2 HOURS/SHIFT

50% ARC ON= 4 HOURS/SHIFT

75% ARC ON= 6 HOURS/SHIFT

D= Dynasty T= Traditional

DT

$-

50 100 150 200 250 300 350

Power cost of $0.08/kWh.

T

D

DT

AMPERAGE

T

D

T

D

T

D

T

D

Loading...

Loading...