Page 1

Invision™350 MPa System

MIG Welding

Power Source

Issued Nov. 2007 • Index No. DC/23.5

Lightweight, aerospace-grade aluminum

case offers protection with the benefit of

reduced weight.

SharpArc

™

technology changes welding arc

characteristics in Pulsed MIG welding mode.

Auto-Line

™

Power Management

Technology allows for any input voltage

hook-up (208 – 575 V) with no manual

linking required, providing convenience

in any job setting. Ideal solution for dirty

or unreliable input power.

Easy setup for MIG and Pulsed MIG

applications.

Inverter arc control technology provides

greater puddle control for outstanding MIG

weld performance.

Fan-On-Demand

™

cooling system

operates only when needed, reducing

noise, energy use and the amount of

contaminants pulled through machine.

The Power of Blue®.

Dynamic Pulsed MIG — highly-engineered

pulse programs default to give a tight

productive pulse arc. The operator can

fine tune the arc if desired.

Processes

Invision 350 MPa

MIG (GMAW)/Pulsed MIG (GMAW-P)

Flux Cored (FCAW)

Air Carbon Arc Cutting and Gouging

(CAC-A) (1/4 in carbons max.)

S-74 MPa

MIG (GMAW)

Flux Cored (FCAW)

Pulsed MIG (GMAW-P)

Invision 350 MPa

Input Power

Requires 3- or 1-Phase Power, 50/60 Hz

Rated Output 10 – 38 V, 5 – 425 A

Weight

Net: 80 lb (36.3 kg) Ship: 89.1 lb (40.4 kg)

S-74 MPa

Input Power

24 VAC, 10 A, 50/60 Hz

Electrode Wire Dia. Capacity

.023 –5/64 in (0.6 –2

mm)

Wire Speed 50–780 IPM (1.3–19.8 m/min)

Weight Net: 58 lb (26 kg)

Heavy Industrial Applications

Invision 350 MPa

Railroad

Truck/Trailer Manufacturing

Light Gauge and Tube

Lawn and Garden Equipment

Recreational Vehicles

S-74 MPa

Heavy/Light Manufacturing

Metal Fabrication

Miller Electric Mfg. Co.

An Illinois Tool Works Company

1635 West Spencer Street

Appleton, WI 54914 USA

Web Site

www.MillerWelds.com

International Headquarters

Phone: 920-735-4505

USA FAX: 920-735-4134

Canadian FAX: 920-735-4169

International FAX: 920-735-4125

Power source is warranted for 3 years, parts and labor.

Original main power rectified parts are warranted for 5 years.

Gun warranted for 90 days, parts and labor.

Quick

Specs

Line voltage compensation keeps welding

output constant even if input power varies

by +/-10%. XMT 350 models further expand

line voltage compensation on 460 VAC to

an amazing +37%, -59%.

Large, dual digital meters are easy to

view and are presettable to ease setting

weld output.

Invision 350 MPa System

Add the new S-74 MPa feeder for a

package that gives you the benefit of

Synergic-Pulsed MIG. As you increase/

decrease the wire feed speed, the pulse

parameters increase/decrease matching

the right amount of power output to

the wire speed.

Page 2

2

Certified to both the Canadian and U.S. Standards for welding equipment.

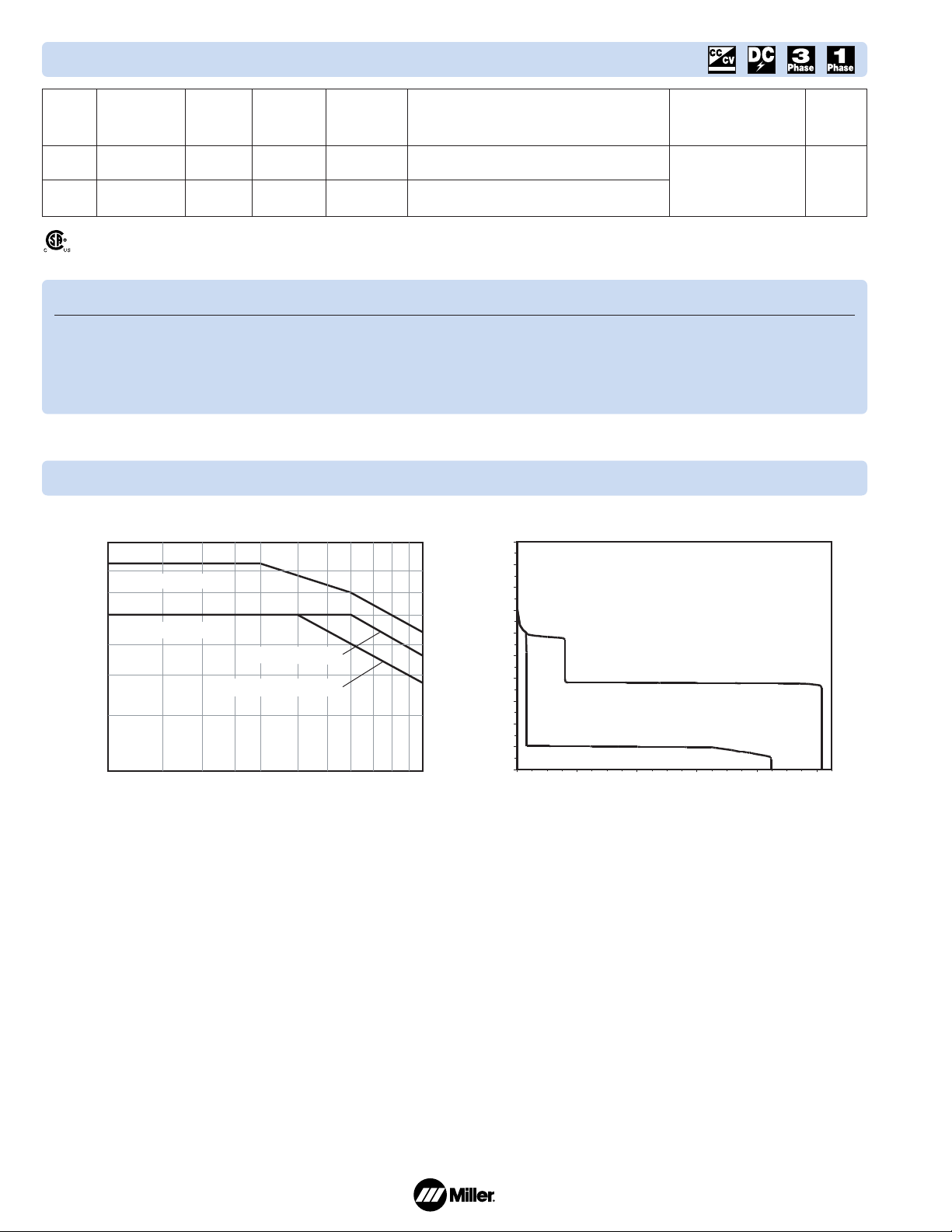

Performance Data

Input

Power

ThreePhase

SinglePhase

Rated Out put

at 60%

Duty Cycle

350 A at

34 VDC

300 A at

32 VDC

Amperage

Range in

CC Mode

5–425 A

5–425 A

Voltage

Range in

CV Mode

10–38 V

10–38 V

Max. OpenCircuit

Voltage

75 VDC

75 VDC

Amps Input at Rated Load Output, 60 Hz,

208 V 230 V 400 V 460 V 575 V KVA KW

40.4 36.1 20.6 17.8 14.1 14.2 13.6

60.8 54.6 29.7 24.5 19.9 11.7 11.2

Weight

80 lb

(36.3 kg)

Dimensions

H: 17 in (432 mm)

W: 12-1/2 in (318 mm)

D: 24 in (610 mm)

Specifications (Subject to change without notice.)

Additional Features

Exceptional electrical efficiency. At 400 A,

efficiency is 87.24%!

350 A of welding output at 60% duty cycle

with superior low-end performance.

Power factor of .95 enables smaller

fuses/breakers and primary wiring. Primary

amperage draw at rated output is 25% less

than the competition.

Ultra-tough, polycarbonate-blended cover

for control panel protects front controls

from damage.

DUTY CYCLE CHART

500

425

400

3-PHASE OPERATION

350

300

1-PHASE OPERATION

250

200

WELDING AMPERES

150

100

10 15 20 25

6 AWG POWER CORD

8 AWG POWER CORD

30

DUTY CYCLE

100

90

80

70

60

50

VOLTAGE

40

30

20

10

0

10040 50 60 70 9080

0 100 200 300 400 500

CV VOLT/AMP CURVE

MAX

MIN

AMPS

Page 3

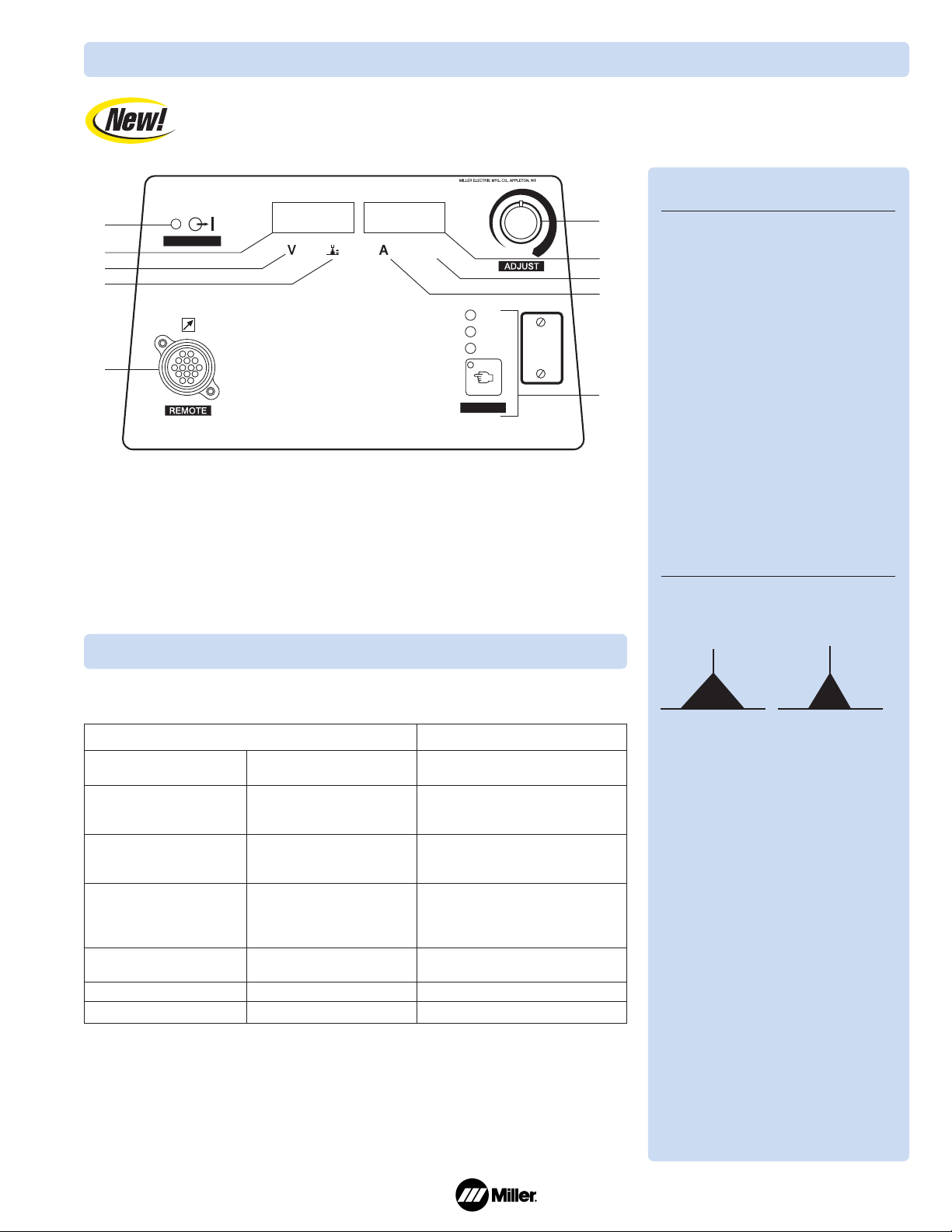

3

1. Output ON Indicator Light

2. Left Display

3. Voltage Indicator

4. Arc Length Indicator

5. Wire Feeder Receptacle

6. Adjustment Control

7. Right Display

8. Setup Indicator

9. Amperage Indicator

10. Setup Indicator Lights

• Arc Control Indicator

• Process Indicator

• Wire/Gas Type Indicator

• Setup Button

Control Panel

Additional Features

SharpArc

™

Changes welding arc characteristics in

Pulsed MIG (GMAW-P) welding mode.

If a gas is used other than what is listed

on the Pulsed MIG welding program

chart (below left), the SharpArc

™

can be

adjusted to help customize your arc to the

gas being used.

Lower SharpArc

™

settings widen the arc

cone, increase puddle fluidity and flattens

the weld bead.

Auto Remote Sense

™

Enables unit to automatically use remote

control if connected to remote control

receptacle.

Dinse International-style weld disconnects

Provide high-quality weld cable connections.

Dinse and Tweco connectors are available.

When Dinse connectors are specified, two

connectors are supplied with the unit.

Optional 115 VAC auxiliary power

Provides 10 amps of circuit-breakerprotected power for water circulators, etc.

MPa

MPa: M (MIG), P (Pulse), a (Advanced

Arc Control). Advanced arc control

enables an improved pulse welding arc.

The operator has more control over puddle

and bead characteristics using SharpArc

™

.

In addition, the unit provides a more robust

and stable arc at very low arc length, reducing

heat input, and providing the ability to weld

on a wider range of material thickness.

Synergic pulsing is available only with the

S-74 MPa dedicated wire feeder.

What are some benefits of

Synergic-Pulsed MIG?

1. Easier to set up

2. No more changing wire speed, and

then having to go back to reset the

welding output.

The Invision 350 MPa has built-in dynamic Pulsed MIG capabilities. See the table below for the wide

range of Pulsed MIG (GMAW-P) welding applications the Invision 350 MPa can handle.

The Invision™350 MPa and S-74 MPa combine for a synergic system that simplifies and

improves MIG and Pulsed MIG welding applications for industrial manufacturing.

(0 setting) (50 setting)

Low Setting High Setting

Note: Setting has a subtle effect on arc that is

exaggerated in graphic for visual emphasis.

Steel

Metal Core

Stainless Steel

Aluminum

Nickel

Silicon Bronze

Copper Nickel

.035 STL

.045 STL

.035 MCOR

.045 MCOR

.052 MCOR

.035 SSTL

.045 SSTL

.035 AL4X (4000 Series)

3/64 AL4X (4000 Series)

.035 AL4X (5000 Series)

3/64 AL4X (5000 Series)

.035 NI

.045 NI

.035 SIBR

.045 CUNI

Gas Types

ARGN CO2(Argon/Carbon Dioxide)

ARGN OXY (Argon/Oxygen)

ARGN CO

2

(Argon/Carbon Dioxide)

TRI MIX (Tri-gas mixture)

ARGN OXY (Argon/Oxygen)

ARGN CO

2

(Argon/Carbon Dioxide)

ARGN (Argon)

ARGN HE (Argon/Helium)

ARGN (Argon)

HE ARGN (Helium/Argon)

Built-In Pulsed MIG Programs

Wire Types

1

OUTPUT ON

2

3

4

5

Setup

Arc Control

Process

Wire/Gas

SETUP

6

7

8

9

10

Page 4

4

S-74 MPa Single Feeder Features

Dual tension control adds flexibil ity

for the operator to fine-tune the

pressure on the wire independently

when feeding a variety of wires.

Tool-less rotatable drive assem bly

allows operator to rotate the drive

housing, eliminating severe bends in the

wire feed path which reduce gun liner

life. Also aids in feeding difficult wires.

1. Voltage Display Meter

2. Wire Speed Display Meter

3. Wire Feed Speed Select

4. Trigger Hold

5. Voltage Select

6. Jog/Purge

Input Power

24 VAC, 10 A, 50/60 Hz

Wire Speed

50–780 IPM (1.3–19.8 m/min)

Optional High Speed Motor:

90–1440 IPM (2.3–36.6 m/min)

Electrode Wire Diameter Capacity

.023–5/64 in (0.6–2 mm)

Net Weight

58 lb (26 kg)

Dimensions

H: 14 in (356 mm)

W: 12 in (305 mm)

D: 26-1/2 in (673 mm)

Specifications

(Subject to change without notice.)

(Use with CV

Power Sources.)

Posifeed™Wire Drive Assembly Features

(Synergic Pulsed MIG when connected to the Invision 350 MPa)

24 VDC high-torque, permanent-magnet motor.

Quick-change drive rolls.

Quick-release, calibrated drive-roll pressure adjustment arm allows drive roll change

without losing spring preload setting.

Four sealed ball bearing all-gear-driven drive-roll carriers for smooth, positive and

accurate wire feed with long uninterrupted service life.

Easy loading and threading of welding wire with out having to release the drive-roll

pressure arm.

Solid-state speed control and brake circuit eliminates the need for electrical/

mechanical relays and increases service life.

Uses Miller standard 1-5/8 in (41 mm) diameter drive rolls.

Quick-connect for all Miller guns.

Covered drive rolls — easy access, heavy-duty, molded composite cover over

drive assembly.

Floating positive drive systems provide trouble-free feeding on a variety of wires.

Control Panel

1

2

3

4

S-74 MPa

24V Wire Feeder

5

6

Page 5

5

Invision™350 MPa System Components

Invision™350 MPa MIGRunner™#907 398

Comes Complete With:

Invision 350 MPa power source

S-74 MPa wire feeder

Bernard®Q™-Gun

Consumables

.035/.045 in drive roll kit

NEW!

Industrial MIG 4/0 Kit with

Dinse Connector

MIGRunner Cart with cylinder rack

Bottom tray will hold optional Coolmate 3

(sold separately)

Invision™350 MPa Push-Pull Aluminum

Package #951 115

Comes Complete With:

Invision 350 MPa power source

XR™-Control Box

25 ft (7.6 m) air-cooled XR-Aluma-Pro™Gun

Invision™350 MPa Stationary Package

#951 113

Comes Complete With:

Invision 350 MPa power source

S-74 MPa wire feeder

Bernard

®

Q™-Gun

Consumables

.035/.045 in drive roll kit

NEW!

Industrial MIG 4/0 Kit with

Dinse Connector

For Your Aluminum Welding Applications

Page 6

Industrial MIG 4/0 Kit with Dinse

Connector #300 405

This useful pulse-ready MIG kit can be

purchased separately. Includes Smith

®

flowmeter/regulator with 10 ft (3 m) gas

hose, 10 ft (3 m) 4/0 feeder weld cable with

Dinse connector on one end and a lug on

the other, 15 ft (4.6 m) work cable with

Dinse connector on one end and 600-amp

C-clamp on the other.

Process Selector Control #042 872

Designed for use with dual wire feeders,

applications where electrical isolation and/or

polarity revers ing of weld current is required,

and for welding process changes. Includes

115 VAC/2 amp recepta cle, two 14-pin

receptacles and a 10 ft (3 m) 14-pin cord.

Running Gear

MIGRunner™Cart

#195 445

Small footprint

and easily

maneuverable,

with cylinder

rack low enough

that you do not

have to lift bottles.

XMT Cylinder Cart

#042 537

Carries two 160 lb

(72.6 kg) gas

cylinders, or one

gas cylinder and

one coolant

system for TIG

(GTAW) welding.

Feeder mounts to

tray above power

source.

Universal

Carrying Cart and

Cylinder Rack

#042 934

Holds power

source, and gas

cylinder up to 56 in

(142.2 cm) high

mea sur ing 6 to 9 in

(15.2 to 22.8 cm)

in dia meter.

Protective Cover

#195 478

Mildew and water resistant, odor-free

cover protects your machine’s finish.

For 300/350 A inverters: Invision, XMT,

Maxstar and Dynasty.

Wire Feeders/Guns

70 Series

S-74 MPa #300 411*

S-74S #195 057

S-74D #195 058

S-74DX #195 059

Wire feeder features Posifeed

™

wire drive

assembly and handles a variety of wires up to

1/8 in. Comes with FREE Bernard®Q™-Gun.

See Lit. Index No. M/3.0.

*Designed exclusively for Invision 350 MPa for

Synergic Pulsed MIG benefits.

XR™-Control #181 538

Push-pull wire feed

system offers

unparalleled performance

for aluminum MIG

welding. See Lit.

Index No. M/1.7.

XR

™

-Aluma-Pro™Gun*

#300 000 15 ft (4.6 m) air-cooled

#300 001 25 ft (7.6 m) air-cooled

#300 264 35 ft (10.6 m) air-cooled

#300 003 15 ft (4.6 m) water-cooled

#300 004 25 ft (7.6 m) water-cooled

#300 265 35 ft (10.6 m) water-cooled

This easy-to-use and easy-to-maintain

gooseneck-style MIG gun is designed for

push-pull wire feed systems (with required

XR-Control). Available in air- or watercooled versions. Trigger hold reduces

operator fatigue (feature available when

paired with XR-Control). Gun design allows

for better access into tight spots. See Lit.

Index No. M/1.7.

*XR-Control is required to operate this gun with

the Invision 350 MPa System.

6

Genuine Miller Accessories

Page 7

22A #193 066

Simple, reliable, 24 VAC constant-speed

semiautomatic wire feeder, best suited for

small diameter wires. Accommodates up to

60 lb (27.2 kg) spool of welding wire when

using optional wire reel assembly. Comes

with FREE Bernard

®Q™

-Gun! See Lit. Index

No. M/11.0.

24A #195 112

Simple, reliable, 24 VAC constant-speed

semiautomatic wire feeder, best suited for

small diameter wires. Remote voltage is

standard. Features four gear-driven drive

rolls for larger wire sizes. Accommodates

up to 60 lb (27.2 kg) spool of welding wire

when using optional wire reel assembly.

Comes with FREE Bernard

®Q™

-Gun! See

Lit. Index No. M/11.0.

Spoolmatic

®

30A #130 831

A 1-lb, air-cooled spool gun that extends

the weld process range by adding a handy

portable system for small wire MIG. Rated

200 A at 100% duty cycle. Includes 30 ft

(9.1 m) cable assembly. (WC-24 #137 549

for 14 pin.)

WC-24 Weld Control

#137 549

Designed for use with

Miller CV power sources

supplying 24 VAC and

14-pin recep tacles. For

use with Spoolmatic

30A spool gun.

Water Coolant Systems

For more information, see the Miller Coolant

Systems literature sheet, Index No. AY/7.2.

Coolmate

™

3

#043 007 115 VAC

#043 008 230 VAC

For use with water-cooled torches rated up

to 600 amps. Unique paddle-wheel

indicator, external filter and easy-fill spout.

Coolmate

™

V3 #043 009 115 VAC

For use with water-cooled torches rated up

to 500 amps. Vertical design conveniently

mounts to Miller cylinder rack in place of

one cylinder.

Coolmate

™

4 #042 288 115 VAC

For use with water-cooled torches rated up

to 600 amps. Tough molded polyethylene

case with carrying handle.

Coolant #043 810

Sold in cases of four 1-gallon recyclable

plastic bottles. Miller coolants contain a

base of ethylene glycol and deionized water

to protect against freezing to -37˚F (-38˚C)

or boiling to 227˚F (108˚C). Also contains a

compound that resists algae growth.

International-Style Connectors

Note: XMT 350 power sources are equipped with

International-style connectors for secondary

connections. (Power source is shipped with two

50-mm male International-style plugs for use with

#1 or #2 AWG size cable.)

International/Tweco

®

Adapter #042 465

International/Cam-Lok

Adapter #042 466

One-piece adapter with International-style

male plug (to power source) on one end and

female receptacle (Tweco or Cam-Lok for

weld cable connection) on other end.

International-Style Connector Kit

#042 418 50 mm

Accepts #4 or #1/0 AWG cable size. Required

if male plugs shipped with power source must

be replaced, or if additional plugs are needed.

#042 533 70 mm

Accepts #1/0 or #2/0 AWG cable size.

Required if #1/0 or #2/0 AWG size cable is

to be used.

Kit includes one International-style male

plug which attaches to the work and/or weld

cables and plugs into the International-style

recep tacles on the power source.

Extension Kit for International-Style

Cable Connectors

#042 419 50 mm

Accepts #4 or #1/0 AWG size cable.

#042 534 70 mm

Accepts #1/0 or #2/0 AWG size cable.

Used to adapt or extend weld and/or work

cables. Kit includes one male Internationalstyle plug and one in-line female

International-style receptacle.

Genuine Miller Accessories (continued)

7

Page 8

Ordering Information

Litho in USA

Power Source and Options Stock No. Description Qty. Price

Invision™350 MPa #907 397 208 –575 VAC with Auto-Line

™

#907 397-01-1 208 – 575 VAC with Auto-Line™and Auxiliary Power

Invision™350 MPa System See page 5 for different packages and components

Accessories

Industrial MIG 4/0 Kit with Dinse Connector #300 405 See page 6

WC-24 #137 549 For use with Spoolmatic®30A and power sources with 14-pin

Process Selector Control #042 872

Extension Cords (For 24 VAC wire #043 690 25 ft (7.6 m)

feeders and remote controls) #043 691 50 ft (15 m)

Running Gear

MIGRunner™Cart #195 445

XMT Cylinder Cart #042 537

Universal Carrying Cart and Cylinder Rack #042 934

Protective Cover #195 478

Wire Feeders/Guns

70 Series #300 411 S-74 MPa. Designed exclusively for Invision 350 MPa for

Synergic Pulsed MIG benefits

#195 057 S-74S. See Lit. Index No. M/3.0

#195 058 S-74D. See Lit. Index No. M/3.0

#195 059 S-74DX. See Lit. Index No. M/3.0

XR™-Control #181 538 See Lit. Index No. M/1.7

22A #193 066 See Lit. Index No. M/11.0

24A #195 112 See Lit. Index No. M/11.0

Spoolmatic®30A Spool Gun #130 831 Includes 30 ft (9.1 m) cable assembly

XR-Aluma-Pro™Gun #300 000 15 ft (4.6 m) air-cooled

#300 001 25 ft (7.6 m) air-cooled

#300 264 35 ft (10.6 m) air-cooled

#300 003 15 ft (4.6 m) water-cooled

#300 004 25 ft (7.6 m) water-cooled

#300 265 35 ft (10.6 m) water-cooled

Water Coolant Systems See page 7. See Lit. Index No. AY/7.2

International-Style Connectors See page 7

Date: Total Quoted Price:

Distributed by:

Loading...

Loading...