Page 1

Processes

TIG (GTAW)

Stick (SMAW)

Pulsed TIG (GTAW-P)

(Optional)

Input Power Requires 1-Phase Power

Amperage Range 250: 3 – 310 350: 3 – 400

Max. Open-Circuit Voltage

80 VDC

Rated Output 250: 250 A at 30 VAC, 40% Duty Cycle

200 A at 28 VAC, 60% Duty Cycle

350: 350 A at 34 VAC, 40% Duty Cycle

300 A at 32 VAC, 60% Duty Cycle

Weight Standard: 250: 378 lb (172 kg) 350: 496 lb (225 kg)

TIGRunner

®

: 250: 478 lb (217 kg) 350: 596 lb (270 kg)

Industrial Applications

Precision Metal Fabrication

Maintenance and Repair

Light and Heavy Manufacturing

Aerospace

Shipbuilding

Tube and Pipe

Automotive

Vocational

Quick

Specs

See page 2 for

additional features

Syncrowave

®

250 DX/350 LX

TIG/Stick Welding

Power Source

Issued April 2008 • Index No. AD/4.2

The Power of Blue®.

Miller Electric Mfg. Co.

An Illinois Tool Works Company

1635 West Spencer Street

Appleton, WI 54914 USA

Web Site

www.MillerWelds.com

International Headquarters

Phone: 920-735-4505

USA FAX: 920-735-4134

Canadian FAX: 920-735-4169

International FAX: 920-735-4125

The balance control is adjustable to provide

additional oxide removal (more cleaning) or less

cleaning based on the condition of the material

being welded. See pg 2 for more information on

this feature.

Syncro Start

™

allows the choice of Soft, Standard

or Hot TIG starts based on the application, lead

lengths and tungsten size.

Dual inline high-frequency points provide

intense high frequency for arc starting and

stabilization. Internal machine components are

protected from HF interference with additional

grounding and filtering for extended product life.

Digital welding meters display both amperage

and voltage for viewing of the actual and preset

values for greater accuracy and repeatability in

your welding procedure.

Last procedure recall simplifies changing your

Syncrowave back and forth from aluminum TIG

to stainless TIG to stick welding. One switch

makes all the control panel changes.

Standard Machine

Syncrowave Complete

Package includes:

Syncrowave

®

Coolmate™3X cooler

No. 37 running gear

TIG torch kit with

accessories

Foot pedal

Four gallons of coolant

Power source is warranted for 3 years, parts and labor.

Original main power rectifier parts are warranted for 5 years.

Page 2

2

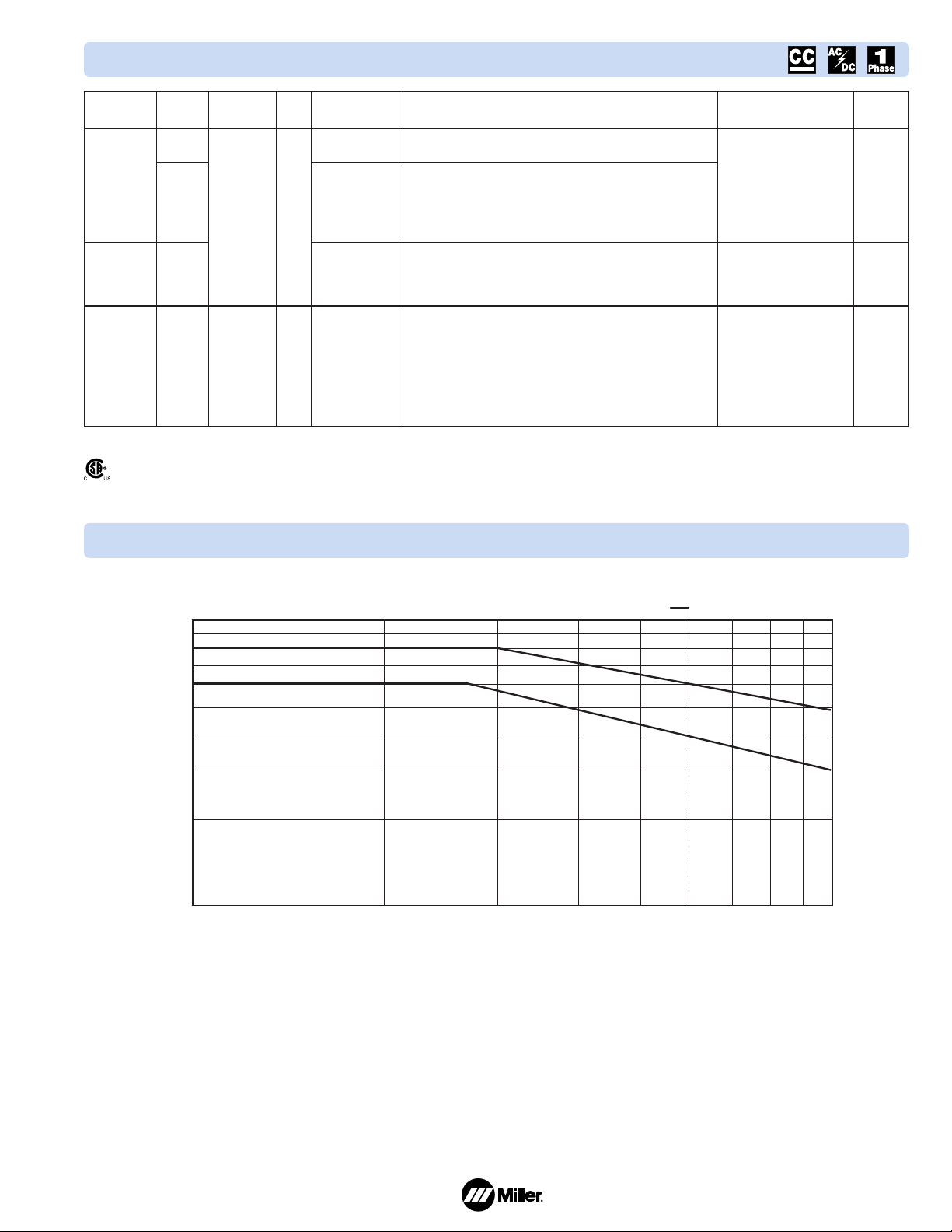

AC Output: Balance Control

Additional Features

Pulsed TIG control lowers the heat input into

the part and reduces warping and distortion

(optional on 250 DX models).

TIGRunner™system packages with

Coolmate™3X cooler. A 3-gallon cooling

system equipped with a visual flow indicator

ensures that the coolant is flowing. An external

coolant filter stops foreign objects from entering

the water cooled torch cable for better flow and

longer life. Extended cooling capacity ensures

maximum productivity. 3-year cooler warranty.

Stick welding features such as Adaptive

Hot Start

™

provide good arc strikes without

sticking. Once welding, the DIG control makes

dynamic adjustments to the welder to ensure

smooth E7018 and deep penetration E6010.

Tilted operator interface and built-in consumable

drawer provide added convenience to your

welding experience.

Arc timer/cycle counter records actual welding

time and number of arc starts. Great for estimating

job costs.

Squarewave technology developed and

patented by Miller Electric in 1976. Squarewave

technology was developed to improve your weld

quality and make TIG welding easier. Miller

Squarewave technology provides arc stability

when welding aluminum, prevents arc

rectification and eliminates tungsten erosion.

Welding aluminum? Oxides that form on

aluminum melt at temperatures over 3700° F.

The aluminum material that is located under

this layer of oxide melts at 1200° F. The

Syncrowave’s AC Squarewave welding current

automatically removes the layer of oxide which

is necessary for producing high quality welds.

Do you have power fluctuations?

The Syncrowave compensates for power

fluctuation without changing your welding

parameters. Line voltage compensation

works on fluctuating power ±10%.

NEW!

Easy Load Dual Cylinder Rack

➡

minimizes cylinder lifting. (Cylinder not included.)

AC Balance Balanced Wave Function

4

3

2

1

0

Balanced

4

3

2

1

0

Penetration

4

3

2

1

0

Max.

Cleaning

5

5

Max.

5

6

7

Medium bead

8

9

10

6

Narrower bead

7

for fillet welds

8

9

10

6

7

Wide bead

8

9

10

Narrow bead, with no

visible cleaning

No Visible Cleaning

Wider bead and

cleaning action

Bead

Cleaning

Bead

Bead

Cleaning

Balanced Wave

50%

Electrode

Positive

50%

Electrode

Negative

More Heat into Work

32%

Electrode

Positive

68%

Electrode

Negative

Greatest Cleaning Action

55%

Electrode

Positive

Electrode

Negative

45%

Page 3

3

Specifications (Subject to change without notice.)

Model

Syncrowave

250

Syncrowave

250 CE

220/400/

440/520

Syncrowave

350

All Models

Rated Output

250 A at 30 V,

40% Duty Cycle

225 A at 29 V,

40% Duty Cycle

250 A at 30 V,

40% Duty Cycle

350 A at 34 V,

40% Duty Cycle

Welding

Amp Range

3–310 A

3–400 A

Max

OCV

80 V

80 V

Input

Power

60 Hz,

1-Phase

50 Hz,

1-Phase

50 or

60 Hz,

1-Phase

50 or

60 Hz,

1-Phase

Amps Input at AC Balance, Rated Load

200V 220V 230V 400V 440V 460V 520V 575V KVA KW

110 — 96 — — 48 — 38 22 12

101 — 88 — — 44 — 35 20 10

— 100 — 55 50 — 42 — 22 12

146 120 128 66 60 65 51 50 30 14

Dimensions

H: 33-1/4 in (845 mm)*

W:22-1/2 in (572 mm)

D: 25 in (635 mm)**

with TIGRunner

®

H: 46 in (1168 mm)*

W:28-1/2 in (724 mm)

D: 40-1/2 in (1029 mm)**

H: 33-1/4 in (845 mm)*

W:22-1/2 in (572 mm)

D: 25 in (635 mm)**

H: 33-1/4 in (845 mm)*

W:22-1/2 in (572 mm)

D: 25 in (635 mm)**

with TIGRunner

®

H: 46 in (1168 mm)*

W:28-1/2 in (724 mm)

D: 40-1/2 in (1029 mm)**

Weight

378 lb

(172 kg)

478 lb

(217 kg)

378 lb

(172 kg)

496 lb

(225 kg)

596 lb

(270 kg)

Certified to both the Canadian and U.S. Standards for welding equipment.

Note: See pg 6 for power factor correction kit. *Add 3 in (76 mm) for lift eye. **Add 1-1/2 in (38 mm) for handle.

Performance Data

DUTY CYCLE CHART

500

450

400

350

300

250

200

150

WELDING AMPERES

100

50

10 20 30 40 50 60 70 80 90 100

Syncrowave 350 LX

Syncrowave 250 DX

% DUTY CYCLE

RATED OUTPUT

Page 4

4

Common Bottom Panel

Control Panels

1. Voltmeter Display

2. Start Mode Control

(Lift-Arc, HF Start, HF Continuous)

3. Output Control

4. Amperage Control (Panel/Remote)

5. Process Control (Stick/TIG)

6. Balance/Dig Control (0 –10)

7. Postflow Time Control (0 –50 sec)

8. Ammeter Display

9. Pulser Control*

10. Background Amps Control (0 –100%)*

11. Pulse-Per-Second Control (0.25 –10 Hz)*

12. Peak Time Control (5 –95%)*

13. Spot Time Control (0 –5 sec)*

14. Final Slope Control (0 –25 sec)*

15. Initial Time Control (0 –15 sec)*

16. Final Amperage Control (0 –100%)*

17. Initial Amperage Control (3 –310/400 A)*

18. Amperage Adjustment Control (3 –310/400 A)

19. Power Switch (On/Off)

20. Output Selector Switch (AC/DC-/DC+)

*Optional Pulser for 250 DX

**Optional Sequencer

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Pulser*

Module

Sequencer**

Module

20

Page 5

5

Packages

Syncrowave®Power Sources

Syncrowave®250 DX

#907 194 (200/230/460 VAC)

#907 195 (230/460/575 VAC)

#907 197 (220/400/440/520 VAC) CE

Syncrowave

®

350 LX

#907 198 (200/230/460 VAC)

#907 199 (230/460/575 VAC)

#907 200 (220/400/440/520 VAC) CE

Primary cord and TIG torch adapter

sold separately.

TIGRunner®Packages

Syncrowave®250 DX TIGRunner®3X

#907 194-03-2 (200/230/460 VAC)

#907 195-03-2 (230/460/575 VAC)

Syncrowave®350 LX TIGRunner®3X

#907 198-03-2 (200/230/460 VAC)

#907 199-03-2 (230/460/575 VAC)

Completely assembled. TIGRunner includes

Syncrowave, Coolmate

™

3X cooler, No. 37

running gear, RFCS-14 HD remote foot

control, and international-style connectors.

Primary cord, TIG torch adapter and TIG

coolant sold separately.

Syncrowave®Complete Packages

Syncrowave®250 DX Complete

#951 117 (200/230/460 VAC)

#951 118 (230/460/575 VAC)

Syncrowave

®

350 LX Complete

#951 119 (200/230/460 VAC)

#951 120 (230/460/575 VAC)

Completely assembled. Includes TIGRunner

above (Syncrowave, Coolmate

™

3X cooler,

No. 37 running gear, RFCS-14 HD remote

foot control, and international-style

connectors), plus four gallons of TIG

coolant and a water-cooled torch kit (see

kits to left) consisting of torch, cable cover,

accessory kit, regulator/flowmeter, gas

hose, torch adapter, and weld lead with

clamp and Dinse connector.

Primary cord sold separately.

Syncrowave Complete

(Syncrowave TIGRunner,

TIG Coolant and Torch Kit)

250 A Water-Cooled Torch Kit

for Syncrowave 250 DX TIGRunner

TIG Coolant TIG Coolant

Syncrowave TIGRunner

300 A Water-Cooled Torch Kit

for Syncrowave 350 LX TIGRunner

Standard Model

Page 6

No. 37 Running Gear #195 282

Includes two 10 in (254 mm) wheels, two

5 in (127 mm) casters, two-compartment

rack (for gas cylinder(s) or Coolmate V3

coolant system), and handles. Provides

excellent mobility and easy to install.

Protective Cover #195 320

Heavy-duty, water- and mildew-resistant.

Protects and maintains the finish of

the welder.

Remote Controls and Switches

RCCS-14 Remote Contactor and

Current Control #043 688 14-pin plug

North/south rotary-motion fingertip control

fastens to TIG torch using two Velcro

®

straps. Great for applications that require a

finer amperage control. Includes 26.5 ft (8

m) control cord.

RFCS-14 HD Foot Control #194 744

Maximum flexibility is accomplished with a

reconfigurable cord that can exit the front,

back or either side of the pedal. Foot pedal

provides remote current and contactor

control. Includes 20 ft (6 m) cord and 14pin plug.

RHC-14 Hand Control

#129 340

Miniature hand control

for remote current and

contactor control.

Dimensions:

4 x 4 x 3-1/4 in

(102 x 102 x 83 mm). Includes 20 ft (6 m)

cord and 14-pin plug.

RMLS-14 Switch #129 337

Momentary- and maintained-contact rocker

switch for contactor control. Push forward

for maintained contact and backward for

momentary contact. Includes 26.5 ft (8 m)

cord and 14-pin plug.

RMS-14 On/Off Control #187 208

Momentary-contact switch for contactor

control. Rubber-covered pushbutton dome

switch ideal for repetitive on-off

applications. Includes 26.5 ft (8 m) cord

and 14-pin plug.

Extension Cords for 14-Pin Remote Controls

#122 973 25 ft (7.6 m)

#122 974 50 ft (15.2 m)

#122 975 75 ft (23 m)

Gas Tungsten Arc (TIG) Welding Book

#170 555

To order this item, distributors can call

the Miller Literature Distribution Center at

1-920-735-4356, or FAX 1-920-735-4011.

86 pages — 8-1/2 x 11 in. A comprehensive

text on all aspects of the GTAW process.

Filled with figures and tables to illustrate

process technique and equipment setup.

Glossary of TIG terms also provided.

TIG Training CD #196 567

Designed for anyone who’s looking to

better understand the TIG process. Easy

to understand instruction, proven teaching

steps, and expert advice help to create a

more effective academic approach to training.

Subject areas covered include system

components, process fundamentals, electrical

theory, safety, power source operation.

Video – GTAW Setup Procedures #108 241

To order this item, distributors can call

the Miller Literature Distribution Center at

1-920-735-4356, or FAX 1-920-735-4011.

13:00 minutes. A detailed demonstration

on preparing your equipment for TIG

welding. Uses a Syncrowave 250 power

source, but topics fit any TIG setup

including air-or water-cooled systems.

In-depth discussion of tungstens and gases.

6

Genuine Miller Accessories

Genuine Miller Options

Field Options

Sequencer Module #195 345 Field Kit

Provides a starting current higher or lower

than the welding current. Provides final slope

and final current for trailing the weld. Provides

a spot timer for TIG spot application.

Pulser Module

#195 344 Field Kit for Syncrowave 250 DX

For welding of thin materials. Provides a

heating and cooling effect of the weld

puddle to reduce heat input and control

distortion of the material. Provides 0.25 to

10 pulses per second.

Power Factor Correction Kit

#194 692 Field Kit for Syncrowave 250 DX

#043 757 Field Kit for Syncrowave 350 LX

Reduces primary amperage draw by

approximately 25% allowing the use of

smaller breakers/fuses and smaller primary

cord. Power Factor

does not

reduce the

power consumption/electrical bill.

Page 7

7

TIG Welding Gloves

#227 813 Small

#227 814 Medium

#227 815 Large

#227 816 X-Large

Designed to meet the

specific requirements high-

quality TIG welding demands.

Made from soft grain goatskin. Sewn with

Kevlar

®

thread.

TIG (GTAW) Torch Adapters

Water-Cooled Dinse #195 377

Used to adapt a 250 or 350 A water-cooled

torch (WP20, WP18, CS310) to an

International-style connector.

Air-Cooled Dinse #195 379

Used to adapt a 1-piece 200 amp air-cooled

torch (WP26) to an International-style

connector.

Tungsten

Items below are available in packages of 10 and

are 7-in lengths.

2% Ceriated (orange) for AC/DC applications

#WC040X7 .040 in, 10–80 A

#WC116X7 1/16 in, 70–150 A

#WC332X7 3/32 in, 140–250 A

#WC018X7 1/8 in, 225 – 400 A

#WC532X7 5/32 in, 300 – 500 A

1.5% Lanthanum (gold) for AC/DC applications

#WL040X7 .040 in, 10–80 A

#WL116X7 1/16 in, 70–150 A

#WL332X7 3/32 in, 140–250 A

#WL018X7 1/8 in, 225 – 400 A

#WL532X7 5/32 in, 300 – 500 A

Pure (green) for AC applications only

#WP040X7 .040 in, 10–80 A

#WP116X7 1/16 in, 70–150 A

#WP332X7 3/32 in, 140–250 A

#WP018X7 1/8 in, 225 – 400 A

#WP532X7 5/32 in, 300 – 500 A

2% Thoriated (red) for DC applications only

#WT040X7 .040 in, 10–80 A

#WT116X7 1/16 in, 70–150 A

#WT332X7 3/32 in, 140–250 A

#WT018X7 1/8 in, 225 – 400 A

#WT532X7 5/32 in, 300 – 500 A

Water Coolant Systems

For more information, see the Miller Coolant

Systems literature sheet, Index No. AY/7.2.

Coolmate™V3

#043 009 115 VAC

#043 009-01-2 115 VAC, CE

For use with water-cooled

torches rated up to 500 amps.

Vertical design conveniently

mounts to Miller cylinder

rack in place of one cylinder.

3-gallon capacity.

Coolmate

™

3X with

Cart and Dual Cylinder

Rack #300 419

Includes: Easy Load

Dual Cylinder Rack,

running gear, and 3X

industrial water cooler — a perfect

solution for water-cooled TIG torches.

TIG Coolant

#043 810

Sold in multiples of 4.

Pre-mixed lowconductivity Miller

coolant contains

ethylene glycol and deionized water to

protect from freezing and boiling -37˚ to

227˚F (-38˚ to 108˚C). Coolant contains

2.4% algae growth inhibitor. 1-gallon plastic

recyclable bottles.

250 A Water-Cooled Torch Kit #300 185

Recommended for Syncrowave 250 DX

25 ft (7.6 m) Weldcraft®WP20 torch

Torch cable cover

AK4C torch accessory kit includes

shielding cups, collets, collet bodies and

2% cerium tungsten electrodes (1/16,

3/32 and 1/8 in)

Smith

®

regulator/flowmeter HM2051A-580

12 ft (3.7 m) rubber gas hose (regulator

to machine)

Water-cooled Dinse torch adapter

15 ft (4.6 m) 1/0 weld lead with clamp

(work or ground lead) and Dinse connector

300 A Water-Cooled Torch Kit #300 183

Recommended for Syncrowave 350 LX

25 ft (7.6 m) Weldcraft®CS310 torch

Torch cable cover

CS310AKC torch accessory kit includes

shielding cups, collets, collet bodies and

2% cerium tungsten electrodes (1/16,

3/32 and 1/8 in)

Smith

®

regulator/flowmeter HM2051A-580

12 ft (3.7 m) rubber gas hose (regulator

to machine)

Water-cooled Dinse torch adapter

15 ft (4.6 m) 1/0 weld lead with clamp

(work or ground lead) and Dinse connector

400 A Water-Cooled Torch Kit #300 186

25 ft (7.6 m) Weldcraft

®

WP18SC torch

Torch cable cover

AK18C torch accessory kit includes

shielding cups, collets, collet bodies and

2% cerium tungsten electrodes (3/32,

1/8 and 5/32 in)

Smith

®

regulator/flowmeter H1954D-580

12 ft (3.7 m) rubber gas hose (regulator

to machine)

Water-cooled thread lock torch adapters

12 ft (3.7 m) 4/0 weld lead with clamp

(work or ground lead)

Genuine Miller Accessories (continued)

Torch Kits

Includes Wheels

Page 8

Litho in USA

Distributed by:

Equipment and Options Stock No. Description Qty. Price

Syncrowave®250 DX #907 194 200/230/460 V, 50/60 Hz, Standard Model

#907 195 230/460/575 V, 50/60 Hz, Standard Model

#907 197 220/400/440/520 V, 50/60 Hz, CE, Standard Model

#907 194-03-2 200/230/460 V, 50/60 Hz, Syncrowave 250 DX TIGRunner® 3X

#951 117 200/230/460 V, 50/60 Hz, Syncrowave 250 DX Complete

#907 195-03-2 230/460/575 V, 50/60 Hz, Syncrowave 250 DX TIGRunner® 3X

#951 118 230/460/575 V, 50/60 Hz, Syncrowave 250 DX Complete

Syncrowave

®

350 LX #907 198 200/230/460 V, 50/60 Hz, Standard Model

#907 199 230/460/575 V, 50/60 Hz, Standard Model

#907 200 220/400/440/520 V, 50/60 Hz, CE

#907 198-03-2 200/230/460 V, 50/60 Hz, Syncrowave 350 LX TIGRunner® 3X

#951 119 200/230/460 V, 50/60 Hz, Syncrowave 350 LX Complete

#907 199-03-2 230/460/575 V, 50/60 Hz, Syncrowave 350 LX TIGRunner® 3X

#951 120 230/460/575 V, 50/60 Hz, Syncrowave 350 LX Complete

Sequencer Module #195 345 Field

Pulser Module #195 344 Field. For Syncrowave 250 DX

Power Factor Correction Kit #194 692 Field. For Syncrowave 250 DX

#043 757 Field. For Syncrowave 350 LX

TIG Torch Kits

Weldcraft®250 A Water-Cooled Torch Kit #300 185 See page 7. Recommended for Syncrowave 250 DX TIGRunner 3X

Weldcraft®300 A Water-Cooled Torch Kit #300 183 See page 7. Recommended for Syncrowave 350 LX TIGRunner 3X

Weldcraft®400 A Water-Cooled Torch Kit #300 186 See page 7

Consumables and Tungsten See page 7

Gas Cylinder, Hose and Fittings

Remote Controls

RCCS-14 #043 688 North/south fingertip control

RFCS-14 HD #194 744 Heavy-duty foot control

RHC-14 #129 340 Hand control

RMLS-14 #129 337 Momentary/maintained rocker switch

RMS-14 #187 208 Momentary rubber dome switch

Extension Cords #122 973 25 ft (7.6 m)

#122 974 50 ft (15.2 m)

#122 975 75 ft (22.9 m)

Accessories

No. 37 Running Gear #195 282

Protective Cover #195 320

Gas Tungsten Arc (TIG) Welding Book #170 555

Contact your distributor

TIG Training CD #196 567

Video – GTAW Setup Procedures #108 241

Contact your distributor

Torch Adapters #195 377 Adapts 250 or 350 A water-cooled torch to international-style connector

Supplied with power source and torch kits

#195 379 Adapts 1-pc 200 A air-cooled torch to international-style connector

Cable Connectors

Supplied with power source and torch kits

Dinse Connector 50 mm (1 male) #042 418 Used to connect weld lead to Dinse terminal machine

Dinse Connector 50 mm (1 male, 1 female) #042 419 Used to extend weld cables

Tweco Terminal Adapter #042 465 Male Dinse to female Tweco

Cam-Lok Terminal Adapter #042 466 Male Dinse to female Cam-Lok

TIG Coolant #043 810 Sold in multiples of 4. 1-gallon plastic bottles.

Water Coolant Systems See page 7

Miscellaneous

Stick Electrodes

Welding and Work Cables

Helmets

TIG Welding Gloves See page 7

Date: Total Quoted Price:

Ordering Information

Loading...

Loading...