Miller Electric 302 User Manual

Processes (X-Ray Quality)

Stick (SMAW)

MIG (GMAW)

with voltage-sensing feeder

Flux Cored (FCAW)

with voltage-sensing feeder

DC TIG (GTAW)

Air Carbon Arc (CAC-A) Cutting

and Gouging (3/16 in carbons)

Output Range

DC Stick 25 – 300 A

DC TIG 10 – 300 A

MIG/FCAW 13 – 35 V

Generator Power Output Rated at 104˚ F (40˚ C)

5500 Watts Peak — 5000 Watts Continuous

Industrial Applications

Fabrication

Structural Steel Work

Process Plant Piping

Maintenance

Quick

Specs

Miller Legend®302

Gas/LP Engine-Driven

Welder/AC Generator

Issued January 2008 • Index No. ED/4.2

Superior arc performance

• Four preset DIG settings

• Adaptive Hot Start

™

• Lift-Arc™with Auto-Stop

™

• MIG/FCAW

See page 2 for more information.

Increased fuel capacity to

12 gallons means many hours

of run time before refueling.

See page 3 for fuel

consumption information.

Exclusive!

Digital meters use SunVision

™

technology so they are easy to read in

direct sunlight or shade.

The Power of Blue®.

Self-calibrating digital weld meters with

meter maintenance functions.

• Preset and actual weld amperage/voltage

• Hour meter function

• Oil change interval

Miller Electric Mfg. Co.

An Illinois Tool Works Company

1635 West Spencer Street

Appleton, WI 54914 USA

Web Site

www.MillerWelds.com

International Headquarters

Phone: 920-735-4505

USA FAX: 920-735-4134

Canadian FAX: 920-735-4169

International FAX: 920-735-4125

Welder/generator is warranted for 3 years, parts and labor.

Engine is warranted separately by the engine manufacturer.

Reduced sound level of 75.5 dB

(100.5 Lwa) at rated load. Quietest in its

class and quieter than most engine drives

in the industry!

More horsepower — 23 HP gas/

20 HP LP Kohler

®

. Fully enclosed case

provides: reduced sound levels, fully

protected engine, and utilizes the same

hole mounting pattern as past models.

Exclusive!

Low-speed

generator produces 5500

watts peak, 5000 watts

continuous at 1800 RPMs,

2400 watts (60 –120 Hz) at

all speeds.

Exclusive!

Multi-speed

welding to reduce noise.

Up to 240 amps at a quiet

3000 RPMs and powerful

300 amps at 3600 RPMs.

See pages 2 and 3 for more

machine features/benefits.

Exclusive!

High-Impact Protective Armor

• Protective armor with receptacle and

output stud covers provides a virtually

indestructible barrier from damage

• High-impact resistance in all temperatures

Other applications include: automotive

bumpers, tractor hoods and panels, lawn

mower decks, large structural parts, etc.

Output stud and receptacle covers required

by OSHA and CSA for job site safety.

Accu-Rated

™

– Not Inflated

Generator Power

2

Weld

Speed

3600 RPM

3000 RPM

1800 RPM

Welding

Mode

CV/DC

CC/DC

CV/DC

CC/DC

CV/DC

CC/DC

Process

MIG/FCAW

Stick/TIG

MIG/FCAW

Stick/TIG

MIG/FCAW

Stick/TIG

Weld Output Rated at

25 V (at 104°F/40°C)*

300 A, 100% Duty Cycle

280 A, 100% Duty Cycle

240 A, 100% Duty Cycle

240 A, 100% Duty Cycle

120 A, 100% Duty Cycle

120 A, 100% Duty Cycle

Amp/Volt

Ranges

13 –35 V

10–300 A

13–27 V

10 – 240 A

13–22 V

10 – 120 A

Single-Phase

Generator Power

Peak: 5500 watts

Continuous: 5000 watts

120/240 VAC, 42/21 A,

60 Hz at 1800 RPM

2400 watts, 120 VAC,

60 –120 Hz at all speeds

Sound Levels at

Rated Output,

7 m (23 ft)

75.5 dB

(100.5 Lwa)

73 dB

(98 Lwa)

66 dB

(91 Lwa)

Net

Weight**

580 lb

(263 kg)

Dimensions

H: 33 in (838 mm)

W: 20 in (508 mm)

D: 45-1/2 in (1156 mm)

Specifications (Subject to change without notice.)

Engine Brand/

Warranty

Kohler:

3-year mfg.

Horsepower (HP)

23 HP (gas),

20 HP (LP) at 3600 RPM

Weld Speed

3600 RPM

3000 RPM

Idle Speed

2400 RPM

1800 RPM

Type

Twin-cylinder, 4-cycle overhead valve,

industrial air-cooled gasoline or LP

Fuel

Capacity

12 gal

(45 L)

Low Oil Pressure

Shutdown

Standard

Oil Capacity

1.75 qt (1.7 L),

2 qt (1.9 L) with filter

Engine Specifications (Engines warranted separately by the engine manufacturer.)

*Rated at sea level. **Net weight without fuel.

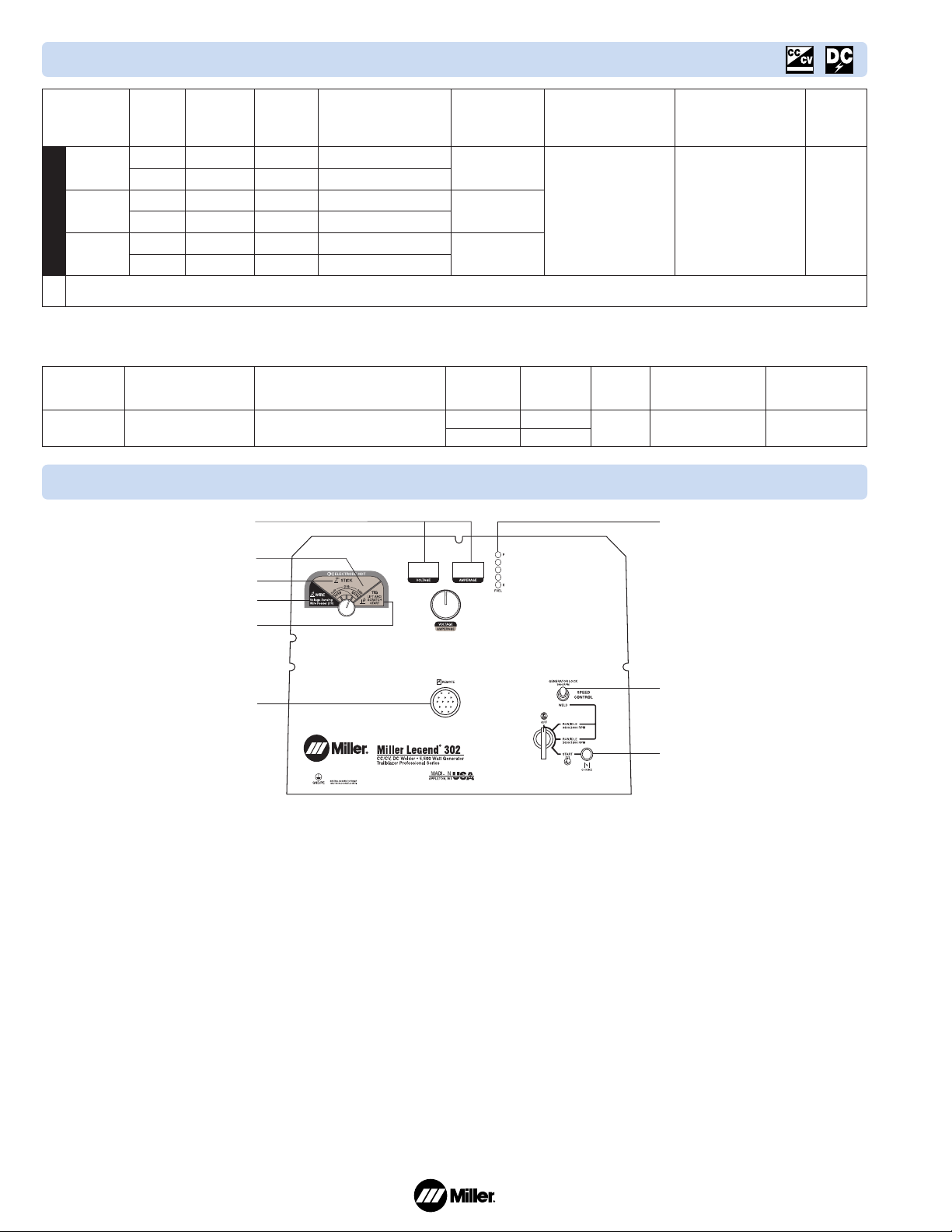

1 7

8

9

2

4

5

6

3

Function Guide

1. Digital Meters display preset amperage or

voltage while not welding. Displays actual

amperage and voltage while welding and for

5 seconds after welding has stopped.

Meter Maintenance Functions*

• Hour Meter: with engine off, place Engine

Control switch in the first RUN/IDLE

position to view engine hours.

• Oil Change Interval: with engine off, place

Engine Control switch into the second

RUN/IDLE position to see hours before next

oil change. Oil hours start at 100 and count

down to 0 (oil change due).

Note: Negative hours indicated when past

recommended oil change interval.

To Reset: Flip Engine Control switch from the

RUN/IDLE to RUN position 3 times.

2. Four Preset DIG Settings* offer the best arc

characteristics for different electrodes and

joint designs. The combined DIG and

Process switch along with preset DIG

settings makes it easy to set without the

complication of multiple switches.

DIG Settings

• Soft arc and smooth 7018 performance.

• Medium-soft driving arc.

• Medium-stiff driving arc.

• Driving arc such as pipe welding.

3. Adaptive Hot Start

™

* (Stick) automatically

sets starting amperage for great arc starts.

4. Great MIG/FCAW Performance with

voltage-sensing wire feeders.

5. Lift-Arc

™

/Scratch Start TIG* with Auto-Stop

™

provides great DC starts with both starting

techniques. Auto-Stop allows the arc to be

stopped without the loss of shielding gas.

6. Standard 14-Pin Receptacle for simple

connection of remote controls (not for wire

feeder usage). It features Auto Remote

Sense™* which automatically switches from

Panel to Remote Amperage/ Voltage (A/V)

control with remote connected. Eliminates

confusion of the Panel/Remote A/V switch.

7. Front Panel Fuel Gauge* LEDs indicate

fuel level. The “E” LED lights only when

fuel is low.

8. Speed Control Switch locks engine speed

at 1800 RPM for uninterrupted 60 Hz

generator power and light welding loads.

9. Engine Choke Control

*Category Exclusive

GasolineLP

Derate outputs up to 5% when using LP fuel.

Loading...

Loading...