Mikro X10 User Manual

X10 Earth Leakage Relay Quick Reference Guide

g

j

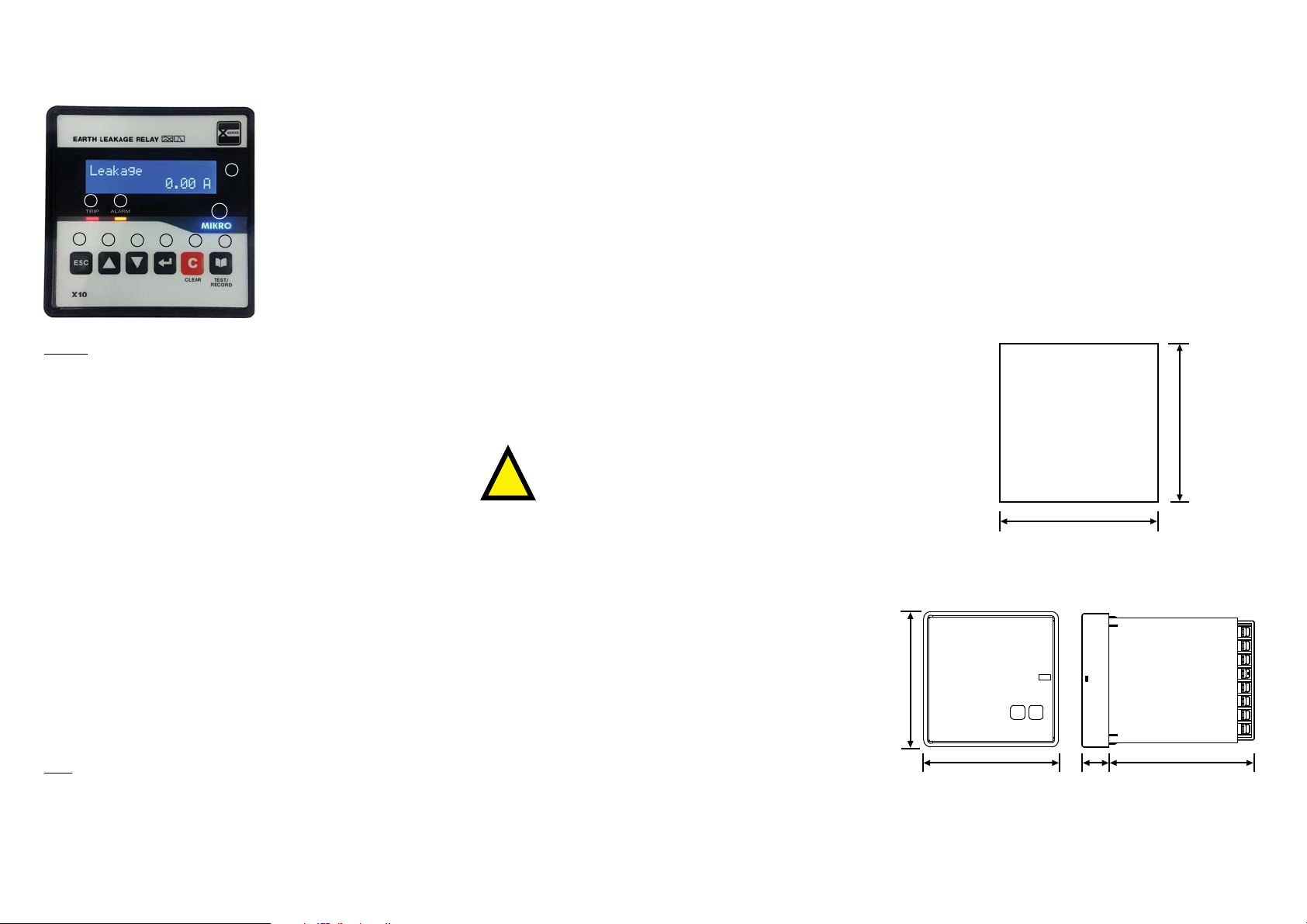

A Brief Overview

a) Trip LED

b) Alarm LED

c) 2x16-digit LCD with

c

a

b

d

e

f

Keypad

UP, DOWN, ENTER and ESC keys are used to navigate through the

menus and adjust the settings.

ESC :

UP :

DOWN :

ENTER :

CLEAR :

TEST/ :

RECORD

To exit from menus, submenus or to cancel the setting

value change. Press and hold for 1.5 seconds to return to

the default display from any submenu.

Scroll up the menus or increase the setting value.

Scroll down the menus or decrease the setting value.

To enter submenus or to conrm the setting value change.

To clear/reset the user resettable alarms. When the alarm

record is empty and the “CLEAR” Scroll is enabled (under

Congurations->Display menu), it can be used to scroll

through the protection settings. To return to the default

display from any submenu press and hold for 1.5 seconds.

To display the alarm records. To display successive records,

press the RECORD key again. If there’s no alarm press and

hold for 5 seconds to run the test function.

h

i

backlight display

d) “ESC” key

e) “UP” key

f) “DOWN” key

g) “ENTER” key

h) “CLEAR” key

i) “TEST/RECORD” key

j) Mikro logo and power

on indicator

1. General Description

Mikro X10 is an earth leakage relay with built-in advanced

features and functions for leakage protection, programmable

input and output control function, remote monitoring and etc. It

works together with Mikro’s zero-phase current transformer

(ZCT) to perform the protection function.

The relay provides the user with a 2x16 character LCD for

real-time display of leakage current, fault records, event record,

alarm record, various internal settings and etc.

The relay extends its connectivity by adopting the Modbus-RTU

protocol. Through the use of RS485 standard protocol, the user

will be able to network the relay with other slave devices, linked

to a central monitoring station.

The relay provides 2 programmable output contacts. There is

another output contact which is used for the relay’s internal fault

indication. Besides that, it also provides 1 conguration logic

input for various functions.

2. Precaution

Please observe the following safety precautions

before and during the installation of the relay :

!

Only competent and trained personnel should install, operate,

service and maintain this device.

Disconnect ALL power sources to the relay before performing

installation, inspection, tests and maintenance.

Do not perform megger, hi-pot or any high voltage stress test

with the relay connected to the system.

Install in a suitable enclosure where relay connections are

inaccessible with sucient clearance from other live parts.

Please note that incorrect installation may impair the operation

or even damage the relay. There is no user servicable part in the

relay. Tampering with it may damage the relay, result in injury

and also voiding any warranty.

3. Things included in the packing box

a) 1 x X10 protection relay

b) 2 x black colour retainer clips

c) 1 x X10 quick reference guide

4. Installation Guide

Before installing the relay, please check that the environment

meets the following conditions:

- Operating temperature: -5°C to +55°C

- Humidity: 5% to 95%, non-condensing

- Dust free environment away from electrical noise and radiation.

5. Mounting

Insert the relay through a 91mm x 91mm cutout on a switch-gear

panel as shown below:

Panel

Cutout

91mm +/- 0.5mm

91mm +/- 0.5mm

6. Dimension

96mm

Front

View

Side

View

LEDs

Trip LED :

Alarm :

LED

Indicates tripping.

Blinks to indicate unacknowledged alarm and continuously ON when the alarm is acknowledged by pressing

any key.

Before power up the relay, make sure the auxiliary voltage

supply is within the specication of 85 - 265 VAC or 110 - 370 VDC.

After powering up the relay, please ensure the LCD display and

the AUX Led indicator are turned on.

96mm

* For more details, please download the full set of X10 user

manual from the http://itmikro.com/contents/view/122

webpage.

20mm

105mm

7. Change Setting

There are two ways to change setting in X10.

Method 1: Change setting through rear RS485 communication port

User can use X-series toolkits software to change setting in PC.

The toolkits can be downloaded from website http://itmikro.com/contents/view/122

Method 2: Change setting through relay front panel

User must unlock the password rst then only allow to change the setting. The default password is “0000”.

The following ow chart shown an example on how to change date:

Main Page

Leakage

0.00 A

0 fourth digit start blinks

Enter password

0000

“Press”

Menu Page

1. MEASUREMENT

ESC

Enter password

0000

0 Third digit start blinks

or

3. CONFIGURATION

Goto

0 second digit start blinks

Enter password

0000

3.1 OP Parameter

ESC

0 rst digit start blinks

Enter password

0000

or

3.2 Date & Time

Goto

Date

xx/xx/xxxx

ESC

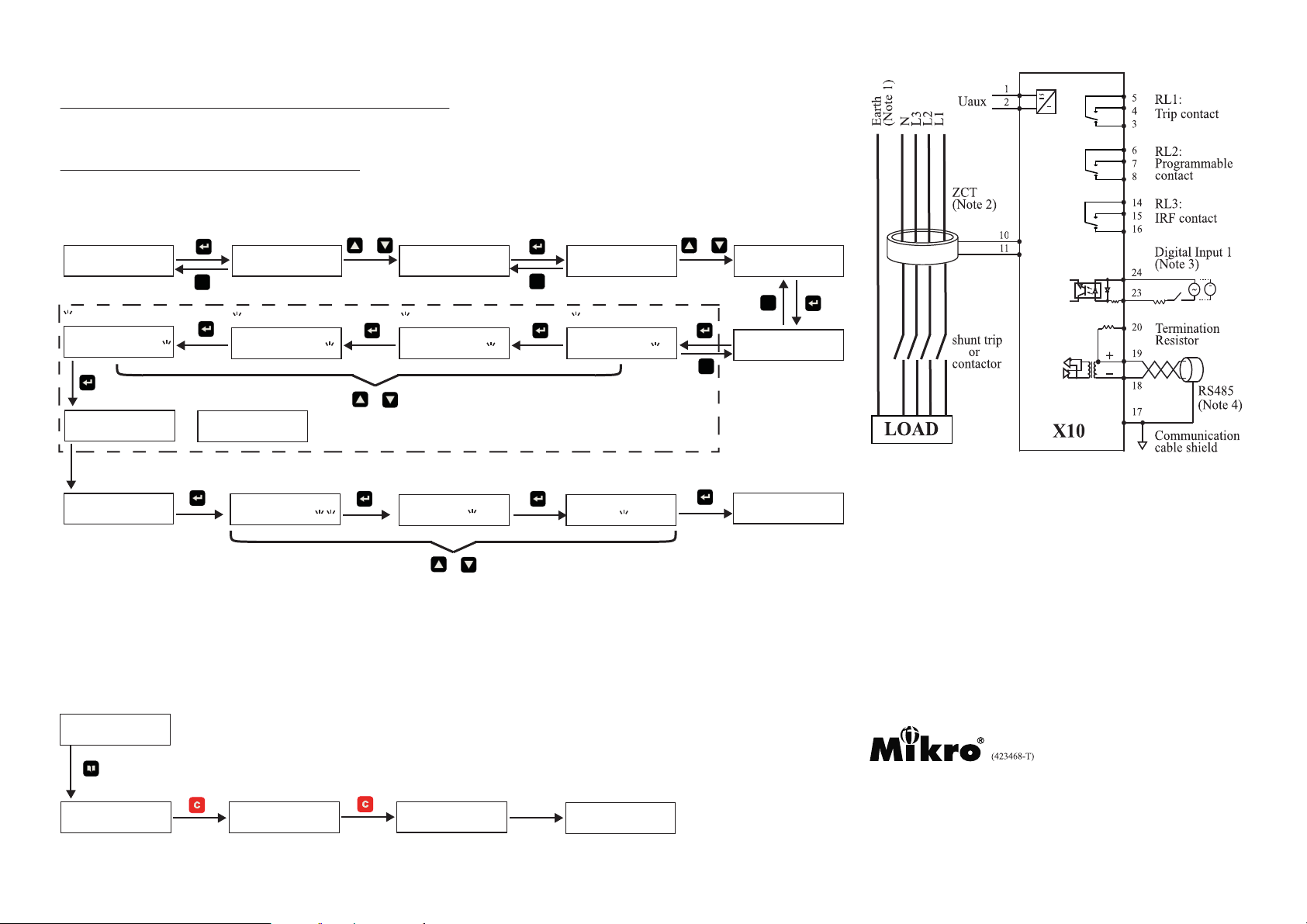

9. Connection Diagram

+

ESC

“ If display no show letter P on right top corner,

then user is required to unlock password for

changing setting. The factory default password is

set as 0000”

Day number blinks

Date p

xx/xx/xxxx

or

Save Data

Date p

xx/xx/xxxx

Password OK

Back to date page after few second.

“p” shows password is unlock

or

Date p

xx/xx/xxxx

If entering wrong password

Password ERROR

Year number blinks

Date p

xx/xx/xxxx

or

Press up or down button

to vary the number

Month number blinks

Date p

xx/xx/xxxx

Press up or down button to vary the number

8. Alarm Record

Alarms are divided into two catogories: user resettable and non-resetable types.

For the user non-resettable type, the alarm is self reset by the relay once the alarm condition is removed.

For the user resettable type, the user must ensure the cause of the alarm is removed before the the alarm can be cleared.

The following ow chart shown an example on how to clear fault alarm:

Main Page

Leakage

“Press”

Alarm Page

Relay 1 1/2

On

* For more detail information, please download full set of X10 user manual from http://itmikro.com/contents/view/122 webpage

0.00 A

“Press”

In1 Trip 1/1

50mA

No record

Back to main page after

few second.

Leakage

0.00 A

Note 1 :

Note 2 :

Note 3 :

The EARTH wire must not pass through the ZCT.

The relay must work together with Mikro’s ZCT.

External series resistor 18k ohm, 2W is required for input

voltage greater than 94Vac or 132Vdc

Note 4 :

Short terminals 18 and 20 for communication data lines

termination. Applicable only for relays located at the head

and tail ends of the communication lines.

No. 1, Jalan TP7/7, Sime UEP Industrial Park

40400 Shah Alam,

Selangor Darul Ehsan, Malaysia

Tel: +603-51927155

Fax: +603-51927166

Website: wwwitmikro.com

E-mail: salas@itmikro.com

Loading...

Loading...