Mikro DPM380 User Manual

v1.0

Digital Power Meter User Manual

DPM380

No.1, Jalan TP7/7, Sime UEP Industrial Park,

40400 Shah Alam, Selangor, Malaysia.

Website: www.itmikro.com

Tel: +(603)51927155 Fax: +(603)51927166

HAZARD CATAGORIES AND SPECIAL SYMBOL

Read all instruction carefully and check the device before

installing or service it. The following safety alert symbol may

appear throughout this manual or on device to warn any

potential hazards or to call for attention.

PLEASE NOTE

The power meter should be installed, operated, serviced and

maintained only by qualifi ed personnel. No responsibility is

assumed by the manufacturer for any consequences arising

out of the use of this material.

DISCLAIMER

Mikro shall not be liable for errors contained herein including

any incidential and/or consequential damages arising from

the use of this material. Mikro also reserves the right to vary

the product from that described in this material without prior

notice.

COPYRIGHT

The licensed software contaioned in the product is proprietary

software owned by Mikro or its third party suppliers and shall

be used solely in connection with the product.

BEFORE YOU BEGIN

• Apply appropriate personal protective equipment and

follow safe electrical work practices.

• NEVER work alone.

• Turn-off all power supplying the power meter and the

equipment in which it is installed before working on it.

• Always use a properly rated voltage sensing device to

confi rm that all power is off .

• Before closing all covers and doors, carefully inspect the

work area for tools and objects that may have been left

inside the equipment.

• NEVER bypass external fusing.

• NEVER open circuit a CT; use the shorting block to short

circuit the leads of the CT before removing the connection from the power meter.

• Before performing hi-pot testing on any equipment in

which the power meter is installed, disconnect all input

and output wires to the power meter. High voltage testing may damage electronic components contained in

the power meter.

• The power meter should be installed in a suitable electrical enclosure.

Failure to follow this instruction may result in serious

injury.

CONTENTS

1. Introduction

1.1.Content of box

1.2.Part of power meter

2. Installation Guide

2.1.Precautions

2.2.Mounting

2.3. Wiring

3. Meter parameters

4. Display and Buttons

1

1

2

4

4

4

7

11

12

5. Function

6. Setting up

6.1.Access programming mode

6.2.Setup CT ratio

6.3.Setup PT ratio

6.4.Neutral current

6.5.Setup communication confi guration

6.6.Demand setting

6.7.System setting

6.8. Reset all energy register

6.9. Reset demand register

6.10. Reset maximum & minimum value

13

15

15

16

17

18

19

20

21

22

23

24

6.11. Remote set

6.12. Scroll mode setting

25

26

6.13. Scroll delay setting

27

6.14. Reset Hour on register

6.15. Backlight setting

6.16. Exit from programming mode

6.17. Setup new password

7. Specifi cations

8. Modbus table

9. Maintenance and troubleshooting

10. Dimensions

28

29

30

31

33

36

50

51

11. Appendix

11.1. Demand calculation

11.2. Data read format from modbus

53

53

54

FIGURES

1. Parts of power meter

2. Recommendation cut-out

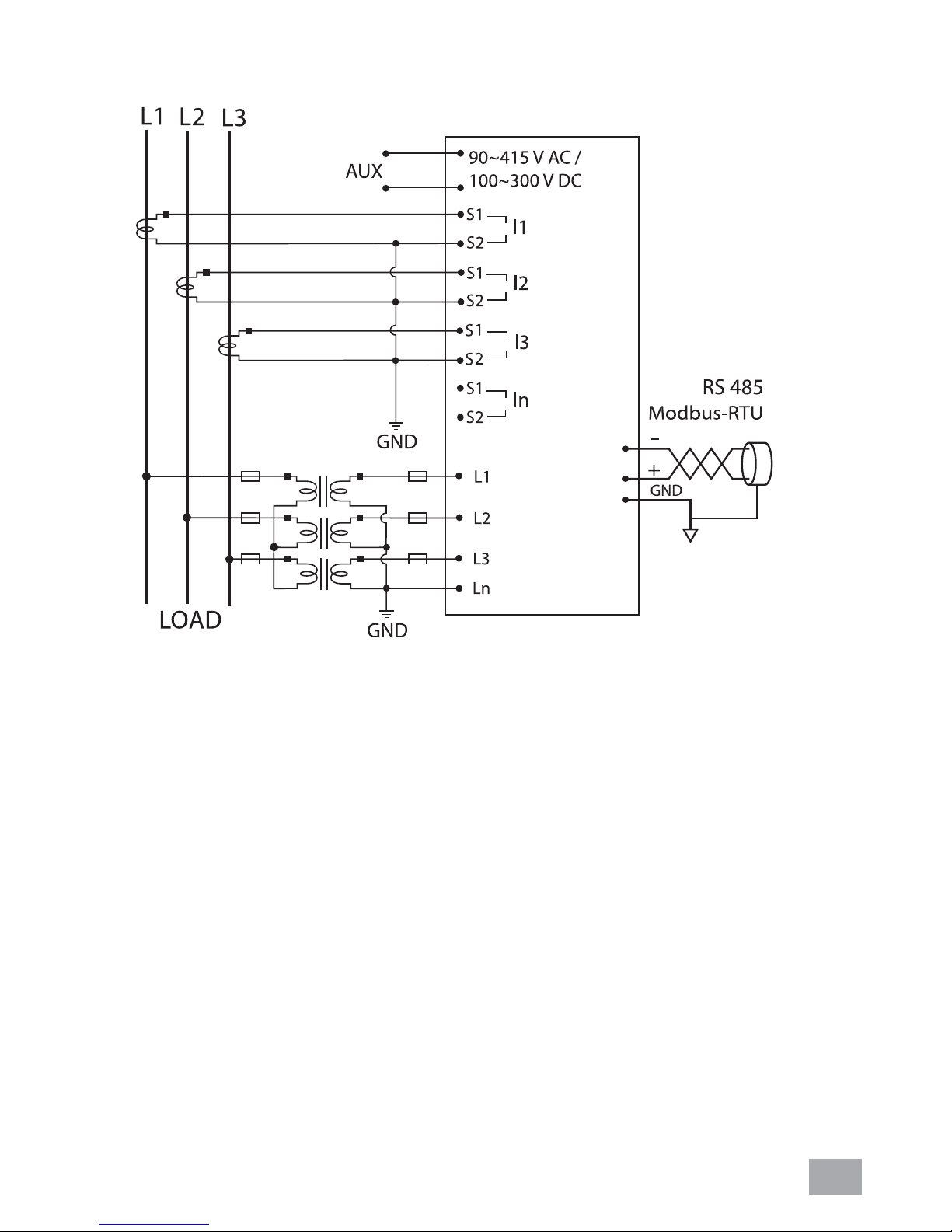

3. 3-phase 4-wire system with 4 CTs

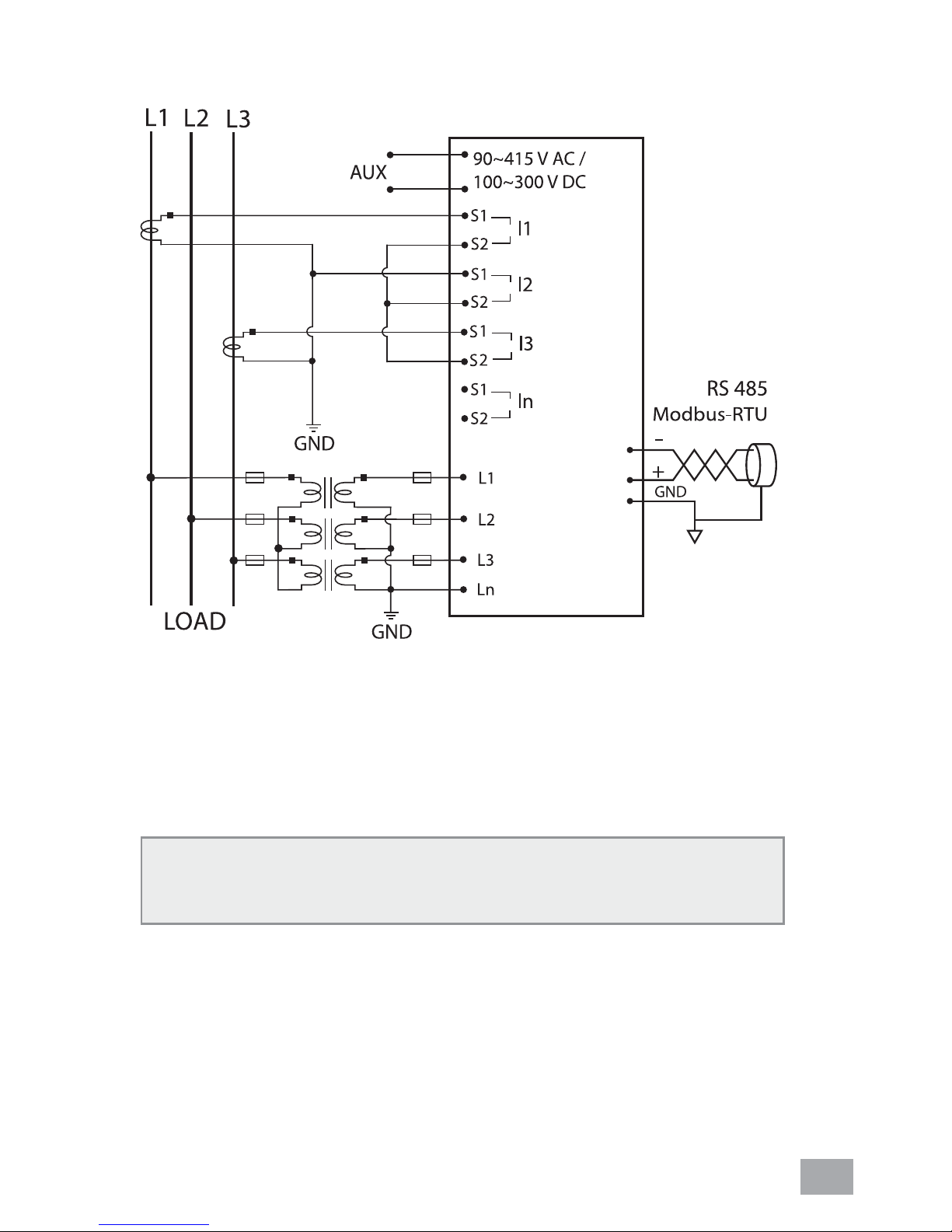

4. 3-phase 4-wire system with 3 CTs

5. 3-phase 3-wire with 3CTs and 3VTs

6. 3-phase 3-wire with 2CTs and 3VTs

7. Menu map for the normal mode

8. Flow map for the programming mode

2

4

7

8

9

10

13

14

TABLE

1. Parts list

2. Location and part label

3. Model information

4. Specifi cation

5. Data length nomenclature

6. Device and communication register

7. Operation data registers

8. Setting data registers

1

2

3

33

36

37

37

49

1.Introduction

Thank you for purchasing the DPM380 Digital Power Meter.

This multifunction power meter measuring the following

parameters:

• True RMS phase voltage ( L-N )

• True RMS line voltage (L-L )

• True RMS phase and neutral current

• Active, reactive and apparent power

• Total active, reactive and apparent energy

• Total and displacement power factor

• Frequency

• Voltage and current total harmonic distortion (THD)

• Demand and maximum demand for total active, reactive

and apparent power

• Maximum and minimum phase and line voltage

• Maximum and minimum phase and neutral current

• Maximum and minimum total active, reactive ad apparent power

1.2. CONTENT OF BOX

Upon opening this box, you should fi nd the following item

shown in table 1:

No Description Quantity

1 DPM380 power meter 1

2 Retainer clip 2

3 Quick guide 1

Table 1 : Parts list

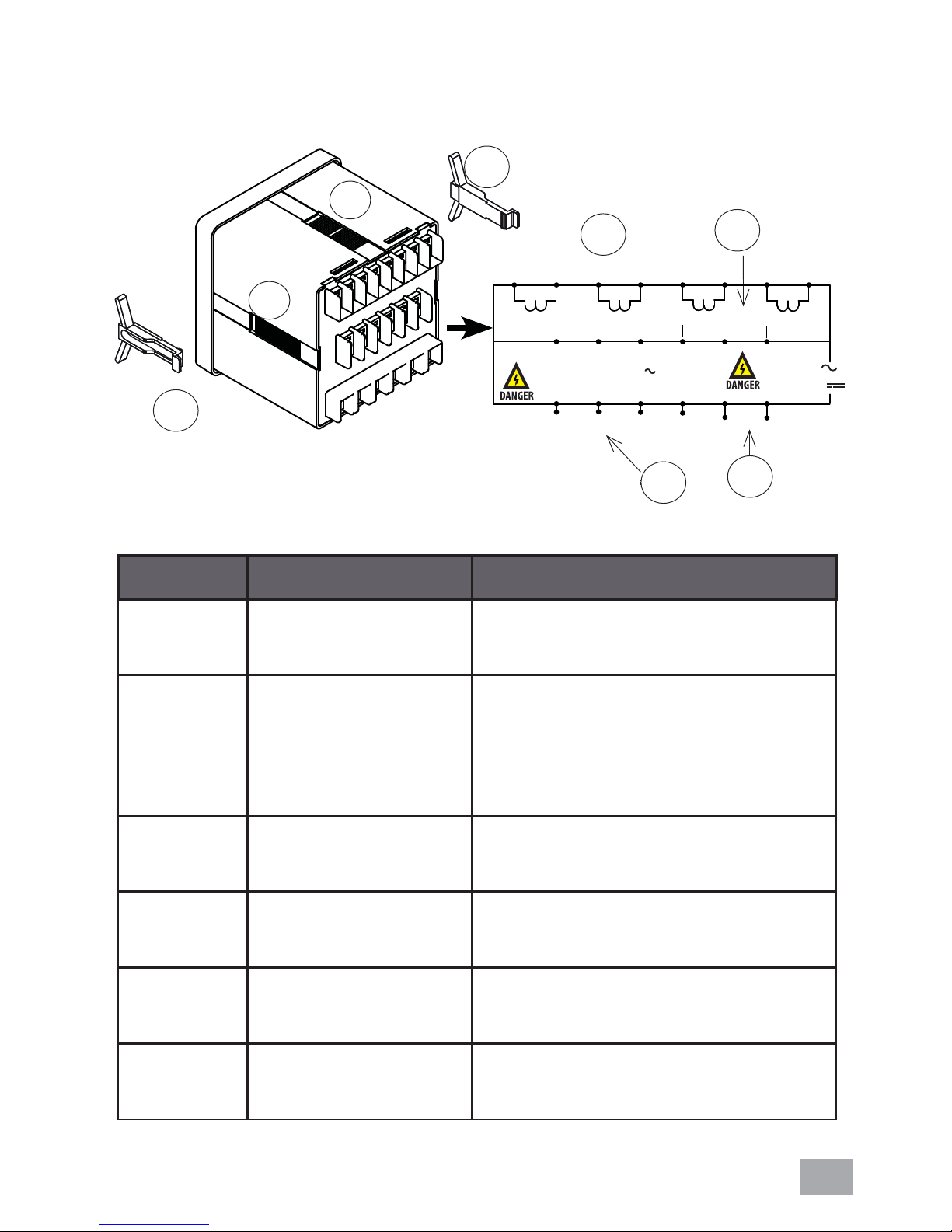

1.3. PARTS OF POWER METER

5

6

1

CURRENT INPUTS ... / 5A (6A MAX.)

5

6

I1 I2 I3 In

1

VOLTAGE INPUT L-N 300V MAX. 50/60Hz

Category III

3

2

S2 S2

L1

S1S1

11

109

1615

L2

4

57 8

S1

Modbus RTU RS485

Gnd

L3 Ln

Figure 1 : Parts of power meter

4

Table 2: Location and part label

Number Part Description

1 Current inputs Current metering connec-

tions.

2

6

S2

1312

-

-

AUX

S1

14

+

90V~415VAC

50/60Hz

100V~300VDC

3VA

20191817

+

S2

3

2 RS485 port The RS485 port is used for

communication with remote

monitoring and control

system.

3 Power supply

input

Connection to power the

meter

4 Voltage inputs Voltage metering connec-

tions.

5 Retainer clips Used to hold power meter

in place.

6 Retainer clips

slot

To slot in retainer clips in

place

2

Model Information

DPM380-415AD Auxiliary 90~415VAC or

100~300VDC; with Modbus

Table 3: Model information

3

2. Installation Guide

2.1. PRECAUTIONS

Before installing the power meter,please check that the

environment meets the following condition:

• Operating temperature -10 Celcius to +55 Celcius.

• Humidity 5% to 95%, non-condensing

• Dust free environmental away from electrical noise and

radiation

2.2. MOUNTING

a) Provide a cut out hole on the switchgear panel according

to the dimension below.

91 0.5mm

91 0.5mm

Figure 2:Recommended out-cut.

4

b) Insert the power meter through the hole and slide in the

retainer clip along the slots on left and right sides or bottom

and top sides of the power meter until the device is tightly

secured on the switchgear panel. The orientation of the

retainer clips is shown in fi gure 1.

The retainer clip can be removed by lifting the tab lightly at

the handle end.

c) Connect the metering voltage input, current input,

communcation and auxiliary according to the wiring schemes

shown in section 2.2 fi gure 3 to 6 on the next page.

d) The recomended wire size is as below:

• voltage input and auxiliary - AWG16~22

• current input - AWG12~18

• Modbus-RTU - AWG22 or thicker, shielded twisted pair

NOTE:

for CTs (S1 and S2).

Please make sure the power to the current metering input is totally shunted. Under no circumstances

can the CT connection be left open circuit. Use a

Polarity marks must be followed as shown

CT shorting block if necessary.

5

e) When connecting the power meter, please make sure the

polarity to the terminal is correctly aligned.

f) If the Modbus-RTU is used, it can be connected up to 32

devices in a daisy chain fashion and the cable total length

should not be more than 1000m.

NOTE:

the cable near sources of electrical noise. The

network cable sheild should be grounded at only

one end.

For Modbus-RTU connection, avoid running

6

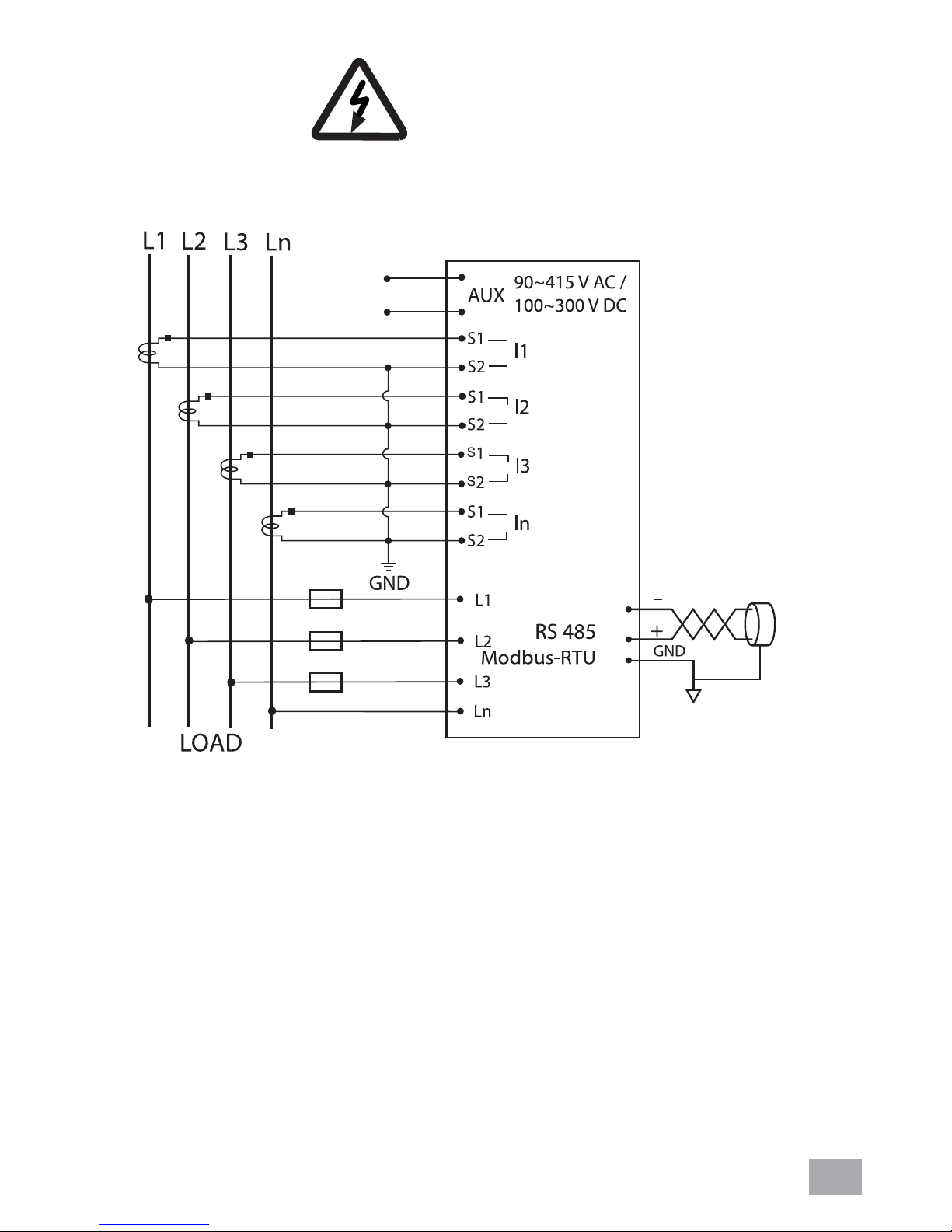

2.3. WIRING

19

20

1

2

3

4

5

6

7

8

15

13

16

17

18

14

12

Figure 3: 3 Phase 4-Wire System with 4CTs connection,

direct voltage input.

7

19

20

15

16

17

18

1

2

3

4

5

6

7

8

13

14

12

Figure 4: 3-Phase 4-Wire System with 3CTs connection,

direct voltage input.

NOTE: Neutral current measurement is based on the

vector sum of 3 CTs.

8

19

20

15

16

17

18

1

2

3

4

5

6

7

8

13

14

12

Figure 5: 3-phase 3-wire with 3CTs and 3VTs connection.

9

19

20

1

2

3

4

5

6

7

8

15

16

17

18

13

14

12

Figure 6: 3-phase 3-wire with 2CTs and 3VTs connection.

NOTE: I2 current measurement is based on the vector

sum of

2 CTs.

10

3. Meter parameters

Before commencing operation, the meter has to be set up. To

do this, the meter must be powered up by the meter control

power supply.

Under section 6, the following parameters should be reviewed

against the default value if necessary:

• CT ratio

• PT ratio

• Neutral current input

• Modbus-RTU setting

• Demand setting

• System setting

• Scroll mode setting and delay time

• Backlight setting

The fl ow maps for the meter is under section 5. It is guideline

for the user to fl ip to the desire window whether in normal

mode or programming mode.

11

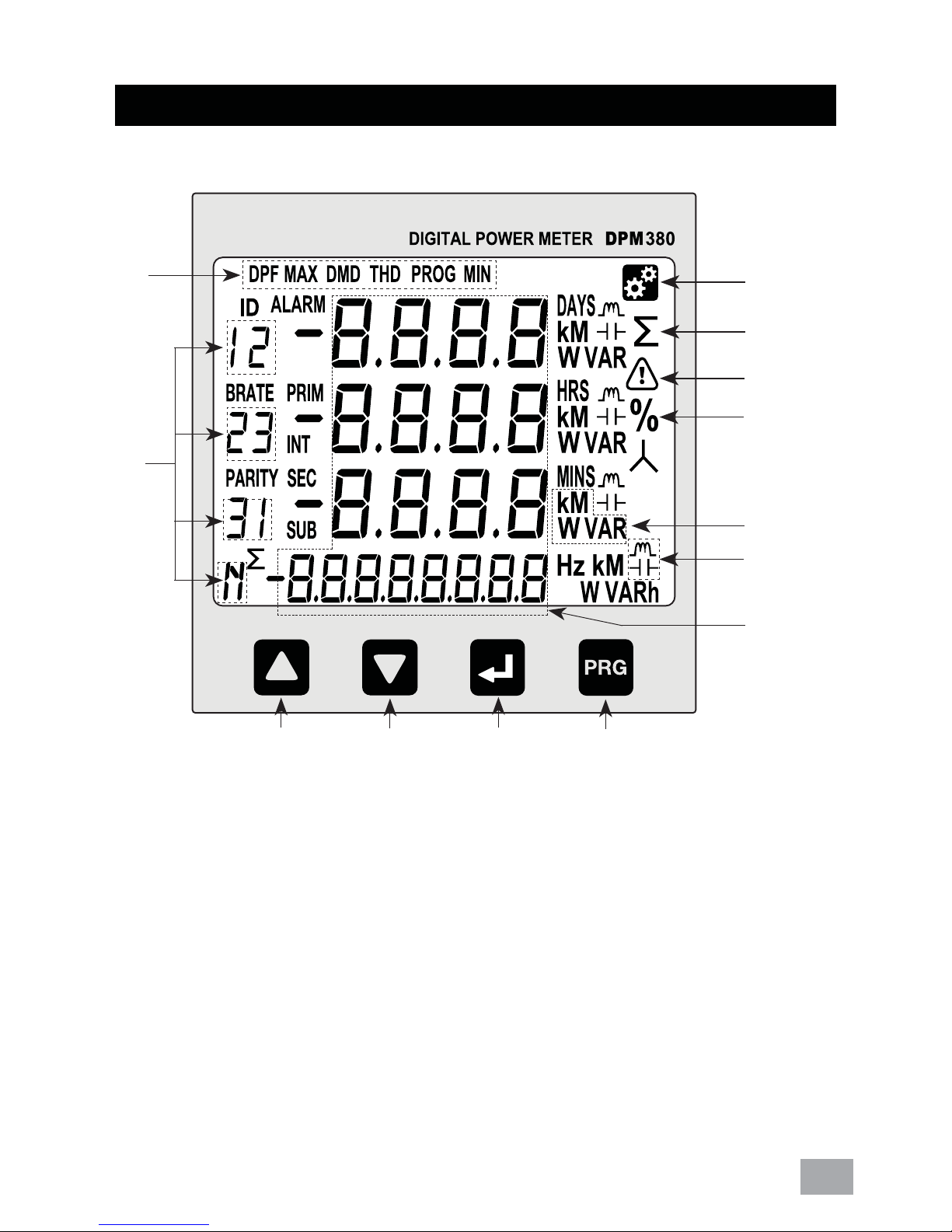

4. Display and Buttons

m

l

a

b

c

d

e

f

g

k

a. Setting Indicator h. ‘PROG’ button

b. Total Indicator i. ‘NEXT’ button

c. Alarm Indicator j. ‘DOWN’ button

d. Percentage Indicator k. ‘UP’ button

e. Unit Indicator l. Phase Indicator

f. Capasitive/Inductive Indicator m. Window Indicator

g. Digit Display

j

i

h

12

Loading...

Loading...