Page 1

REVERSIBLE COMPACTOR

INSTRUCTION MANUAL

402-04504

We thank you for selecting Mikasa

Vibration Compactor. For your safe

and proper operation, please read

this manual and be always sure to

keep it ready for reference.

MVH-R60

MVH-120

MVH-150

Contentsof“DeclarationofConformity”

Pleasereferthe

ECDECLARATIONOFCONFORMITY

inthismanualaswell.

Original

Page 2

Page 3

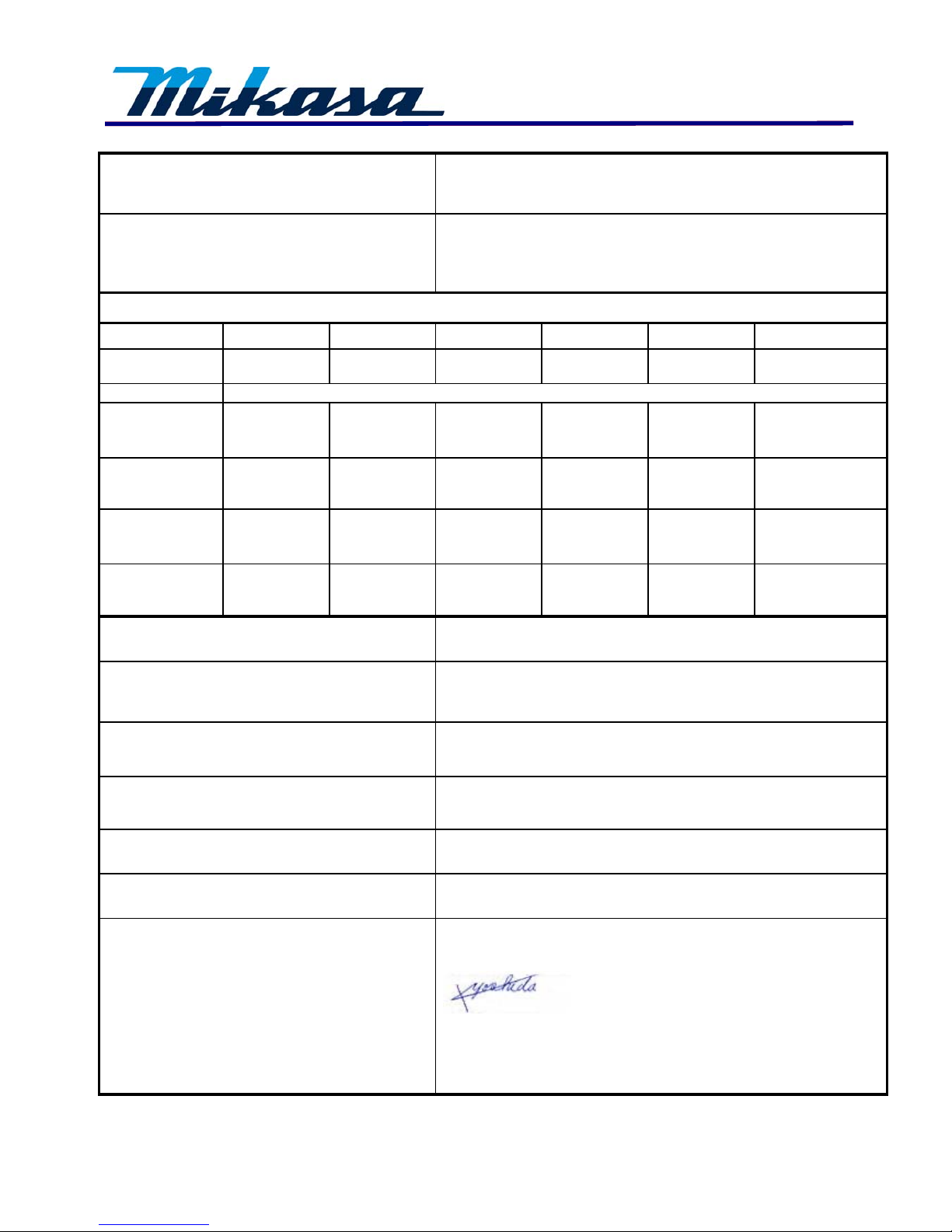

5) model

MVH-R60 MVH-120GH MVH-120GR MVH-150GH MVH-150GR MVH-150D

6) Equipmen

t

item numbe

r

452726 452732

452733

452802 452806

452814

452810 452811

452772 452776

452778

452762 452758

7) Serial number

8) power source

cont. output

<max.output>

Honda GX120

2.1kW

<2.6kW>

Honda GX160

2.9kW

<3.6kW>

Robin EH17

2.9kW

<3.7kW>

Honda GX200

3.7kW

<4.1kW>

Robin EH25

4.7kW

<5.9kW>

Yanmer L48N

3.1kW

<3.5kW>

9) Measured

sound power

l

evel(dB)

104 107 106 107 107 107

10) Guaranteed

sound power

level(dB)

105 108 108 108 108 108

11) Max. Sound

pressure

level

(dB)

90 94 94 94 97 95

For serial number, please refer it on front page.

2) Manufacturer’s name and address.

3) Name and address of the person who keeps the

technical documentation.

Mikasa Sangyo Co., Ltd.

4-3, Sarugaku-cho 1 chome, Chiyoda-ku, Tokyo101-0064, Japan

Yoshiharu Nishimaki, engineer

R. & D. Division, Mikasa Sangyo Co., Ltd.

Shiraoka-machi, Saitama, Japan

12) Conformity assessment according to Annex: VIII (Full Quality Assurance procedure)

13) Name and address of the Notified Body

Société Nationale de Certification et d’Homologation (SNCH)

11, route de Luxembourg

L-5230 Sandweiler LUXEMBOURG

15) Declaration

The equipment referred in this document, fulfills with all the

requirements of Directive 2000/14/EC

14) Related Directive

Directive 2000/14/EC and, to be followed by Directive 2005/88/EC,

relating to the noise emission in the environment by equipment for use

outdoors.

Signed by:

16) Other related Community Directives

2006/42/EC, 2005/88/EC, 2004/108/EC, 2002/88/EC(2004/26/EC)

EN500-1, EN500-4

17) EC Conformity Certificate No: e13*2000/14*2005/14*0472*01

1) DECLARATION OF CONFORMITY

4) Type: Vibratory Plates

Director, Product Control Division

Mikasa Sangyo Co., Ltd.

18) Place and date of the declaration

Keiichi YOSHIDA

Tokyo, Japan Jul, 2010

Page 4

TABLE OF CONTENTS

1. Preface

2. Applications, Warnings, Power Transmission of Machine

3. Warning Symbols

4. Safety Precautions

5. Specifications

6. Appearance

7. Inspection Before Operation

8. Operation

9. Stopping the Machine

10. Transportation

11. Storage

12. Regular Check and Adjustment

13. Troubleshooting

4-1 General Precautions

4-2 Refueling Precautions

4-3 Location and Ventilation Precautions

4-4 Precautions Before Starting

4-5 Precautions During Work

4-6 Lifting Precautions

4-7 Transportation and Storage Precautions

4-8 Maintenance Precautions

4-9 Labeling Positions

4-10 Description of Symbols Used on Warning Labels

6-1 Outside Dimensions

6-2 Parts and Component

8-1 Starting

Gasolime Engine

Diesel Engine

8-2 Operation

10-1 Loading and Unloading

10-2 Transportation Precautions

12-1 Inspection and Maintenance Schedule Table

12-2 Changing the Engine Oil

12-3 Cleaning the Air Cleaner

12-4 Checking/Changing the V-belt and Clutch

12-5 Checking/Changing the Vibrator Oil

12-6 Checking/Changing the Hydraulic Oil

13-1 Gasoline Engine

13-2 Diesel Engine

13-3 Main Body

.................................................................................... 1

....... 1

.................................................................... 3

.................................................................. 3

.................................................... 3

.................................................. 4

........................... 4

....................................... 4

............................................. 4

....................................................... 4

.................... 5

........................................... 5

....................................................... 6

...... 7

.......................................................................... 9

.............................................................................10

.....................................................10

................................................ 11

.................................................. 12

............................................................................... 13

..................................................................... 13

.................................................... 13

.......................................................... 16

.................................................................. 17

............................................................ 18

....................................................................... 19

............................................ 19

...................................... 19

...................................................................................19

............................................ 20

........... 20

........................................... 21

........................................... 21

................ 21

......................... 22

....................... 22

.................................................................... 24

....................................................... 24

........................................................... 25

................................................................ 26

Page 5

1. Preface

This operation manual describes the proper operation, basic inspection and maintenance

procedures of the reversible compactor. Please read this operation manual before use in order

to maximize the excellent performance of this machine and make your work more efficient and

effective.

After reading the manual, please keep it in a handy location for easy reference.

For the handling the engine, please refer to the separate engine operation manual.

For inquiries about repair parts, parts lists, service manuals, and repairs, please contact the

store where you purchased the product, our sales office, or the Mikasa Parts Service Center.

For parts lists, please visit our homepage at: http://www.mikasas.com/ where you can access

Mikasa WEB parts lists.

This machine, weighing more than 60kg to more than 150kg, is a compactor with back and forth

motion. The strong vibration from the two-axes pendulum structure inside the vibrator changes

the machine’s motion into straight back and forth motion. The machine compacts through this

motion.

The machine has tightening and compacting effect for all ground types other than the soft soil

with high water percentage. Because the machine is capable of straight back and forth movement, it works very effectively in grooved structures. Also, since the work efficiency of this

machine is high, it is suitable for compacting of a large area. The machine also works well for

flattening and leveling rough ground surface with irregularities created by the use of a powerful

tamping rammer.

The machine can be used widely for heavy compacting works such as base work as well as

finishing work for asphalt paving.

Do not use this machine on ground with a high water percentage and, in particular, do not use

on clay because the machine will not advance. Use this machine for compacting earth and

sand mixtures, soil, sand or gravel. Do not use this machine for other type of work.

The upper part of the machine consists of an engine, handle, belt cover and guard frame. The

upper part of the machine is fixed to the compacting board of the lower part via an anti-vibration

rubber. The lower part of the machine consists of a compacting board and a vibrator. Inside the

vibrator, there are two pendulums. The phase of those pendulums is changed by hydraulic

pressure.

The hydraulic cylinder for the vibrator is connected with a hydraulic hose to the hydraulic pump,

which is directly connected to the drive lever.

Power is provided by an air-cooled single-cylinder 4-cycle gasoline engine or diesel engine.

The engine output shaft is equipped with a centrifugal clutch. The centrifugal clutch is engaged

when the engine speed increases. A V-pulley is incorporated to the centrifugal clutch drum, and

power is transmitted via the V-belt to the V-pulley on the vibrator side.

The illustrations in this manual might slightly differ in part from the machine you

actually purchased due to design changes.

2. Application,Warnings,Power Transmission of Machine

Application

Warning about Incorrect Applications and Techniques

Structure

Power Transmission

1

Page 6

Through this process, the engine revolution is changed to the pendulum revolution suitable for

compacting.

The vibrator pulley rotates the pendulum axis of the drive side. The two pendulums inside the

vibrator are fixed to the two pendulum axes that are positioned in parallel and are connected

with the gear. The two axes rotate in opposite directions at the same speed to generate vibration.

There is a spiral groove on the inner periphery of the gear assembled on the pendulum axis to

be driven. This groove serves as a key groove to let the guide pin slide to the axis direction.

This guide pin is connecting the two pendulum axes. The phase of the two pendulums is

changed by the axial sliding of the guide pin. The change in phase causes the vibration to

change directions, thus changing the speed and travel direction of the machine.

Hydraulic pressure is used for the axial movement of the guide pin. At the end of the groove

where the guide pin is attached, a piston is installed. When the oil level rises inside the hydraulic cylinder on the vibrator side and the pressure increases, the piston is pushed. Then the axis

connected to the piston is pushed, which causes the guide pin attached to the axis to move,

resulting in a change in phase.

The operator of the machine, by using the back and forth motion lever of the handle, can adjust

the oil quantity and pressure by the connected hand pump to get the travel speed suitable for

the work.

2

Page 7

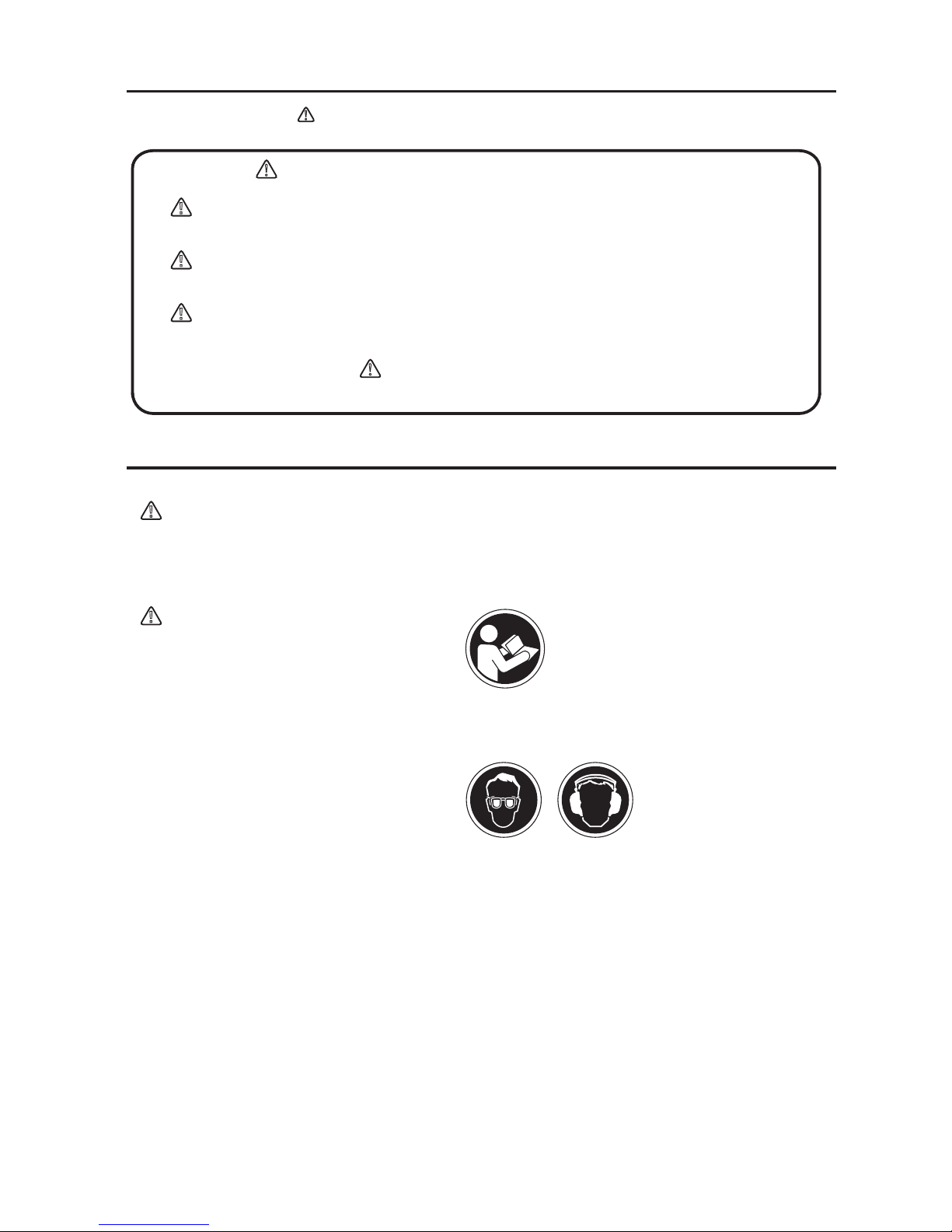

The triangle marks( ) used in this manual and on the decals on the machine

are warning symbols. Please follow these precautions.

Warning symbols indicating personnel hazards

DANGER:

!

WARNING:

!

CAUTION:

!

!

!

!

4-1. General Precautions

3. Warning Symbols

Extremely hazardous. If the warning is not followed, it is likely

to result in serious injury or death.

Hazardous. If the warning is not followed, it is likely to result in

serious injury or death.

Potential hazard. If the warning is not followed, it may result in

injury.

Precautions (without mark):

4. Safety Precautions

WARNING

!

DO NOT operate the machine,

- If you do not feel well due to overwork or illness.

- If you are taking any medicine.

- If you are under the influence of alcohol.

For details about the engine, refer the separate instruction manual for the engine.

Make sure you understand the structure of the machine well.

Always check the machine before your work to make sure it is in normal condition.ed.

Decals on the machine (operation method labels, warning labels, etc.) are very important for

your safety. Keep the machine clean so that the decals can be read all the time. Replace a

decal if it becomes illegible.

Before performing maintenance work, be sure to turn the engine off.

It is very dangerous if children come into close contact with the machine. Have the utmost

concern about how and where to store the machine. In particular, for an engine with a cell,

always remove the starter key and keep it in a designated place.

Before inspection and maintenance work, stop the engine, and do your work on a flat

surface area. If a cell is attached, remove the battery wiring before your work.

Mikasa does not accept any responsibility for accidents caused by remodeling or rework

done on the machine.

CAUTION

!

Read this manual carefully and

handle the machine as described to

ensure safe work.

For safe work, always wear protective

gear (helmets, safety shoes, ear

plugs, etc.) and work in appropriate

clothes.

■

■

■

■

■

■

■

■

■

■

■

3

If the warning is not followed, it may

result in property damage.

Page 8

4-2. Refueling Precautions

DANGER

!

When adding fuel,

Do not fill to the rim due to potential spillage.

After adding the fuel, tightly close the tank cap

Check each part to see if it is tightened properly. Vibration causes loosening of bolts, which

results in unexpected serious malfunctions of the machine. Tighten the bolts securely.

Before starting the machine, make sure it is safe to start by checking your surroundings for

people and objects.

Always pay attention to your footing. Work in an area where you can maintain a good

balance of the machine and a safe comfortable posture.

If you notice deterioration of machine operation during your work, stop your work

immediately.

Before moving away from the machine, be sure to turn the engine off. Also when the

machine is transported, stop the engine and close the fuel cock.

For unloading using a crane, a licensed crane operator is needed. An operator should be

qualified for crane and hooking work.

Before lifting, check the machine parts (especially the hook and anti-vibration rubber) for any

damage and loosened or missing bolts.

Take the machine to a clear flat location without any combustibles nearby.

Be careful not to spill the fuel. Wipe

well if any spill occurs.

■

■

■

■

■

■

■

■

■

■

■

■

Make sure you work in a well ventilated location.

Make sure the engine is stopped and wait until it cools down.

-

-

-

4-3. Location and Ventilation Precautions

DANGER

!

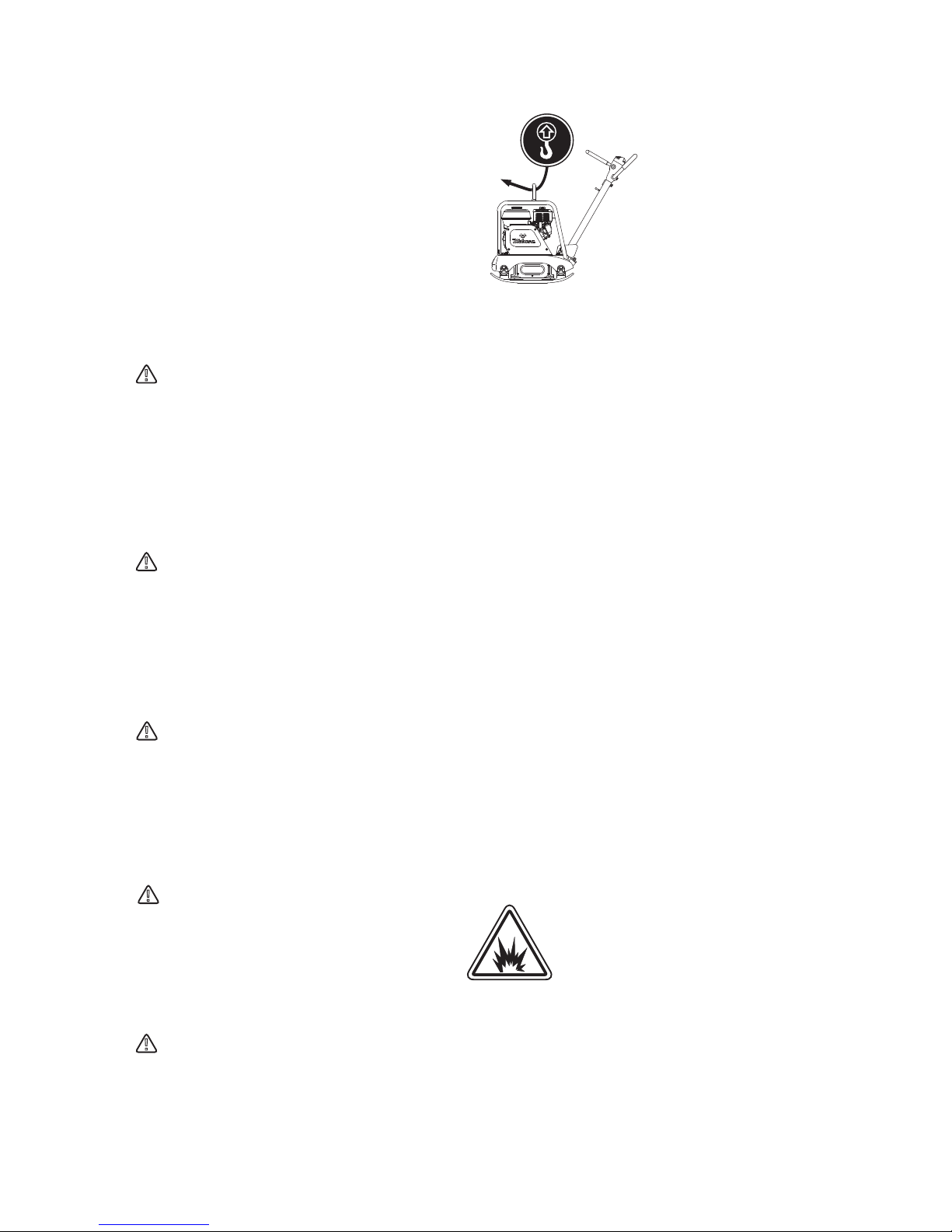

4-6. Lifting Precautions

DANGER

!

DO NOT run the machine in an

unventilated location, such as indoors

or inside a tunnel. The exhaust gas

from the engine contains toxic gases

such as carbon monoxide and is very

hazardous.

DO NOT operate the machine near

open flames.

The engine and muffler become very

hot. Do not touch immediately after

the machine stops because they are

still very hot.

4-4. Precautions Before Starting

CAUTION

!

4-5. Precautions During Work

CAUTION

!

4

Page 9

WARNING

!

For safety reasons, do not lift to a height that is higher than necessary.

Stop the engine during transportation.

Transport after the engine and the machine are cooled down.

Always drain the fuel before transporting.

Securely fix the machine to prevent it from moving or falling during transportation.

Appropriate maintenance is required to ensure safe and efficient operation of the machine.

Always pay attention to the machine’ s condition and keep it in good condition. Pay special

attention to the parts used for lifting, if they are not maintained properly, it might result in a

serious accident.

Start maintenance work after the machine has cooled down completely. The muffler, in

particular, becomes very hot, and there is a danger of burn. The engine, engine oil and

vibrator also become very hot. Be careful not to get burned.

Always stop the engine before inspection and adjustment. If you are caught in a rotating

part, serious injury might occur.

After maintenance work, check the security parts to see if they are securely installed.

Special attention should be paid when checking bolts and nuts.

If disassembly is involved in maintenance, refer to the maintenance instruction manual to

make your work safe.

Never put the positive terminal and negative terminal come into contact. Sparks will be

generated, and ignition might occur.

Be careful when handling the battery fluid because it is very toxic. If the battery fluid gets on

your skin, eye, or clothes, rinse it off with plenty of water and consult with a doctor.

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

4-7. Transportation and Storage Precautions

WARNING

!

WARNING

!

4-8. Maintenance Precautions

Stop the engine and shut the fuel

cock while lifting.

Use a sufficiently strong wire rope.

For lifting, use only one point hoisting

hook, and do not lift at any other part.

When the machine is hoisted, never

let people or animals come underneath.

The gas from the battery might cause

an explosion. Do not generate sparks

or bring flames near the battery.

5

Lifting Precautions (Continued)

DANGER

!

CAUTION

!

Page 10

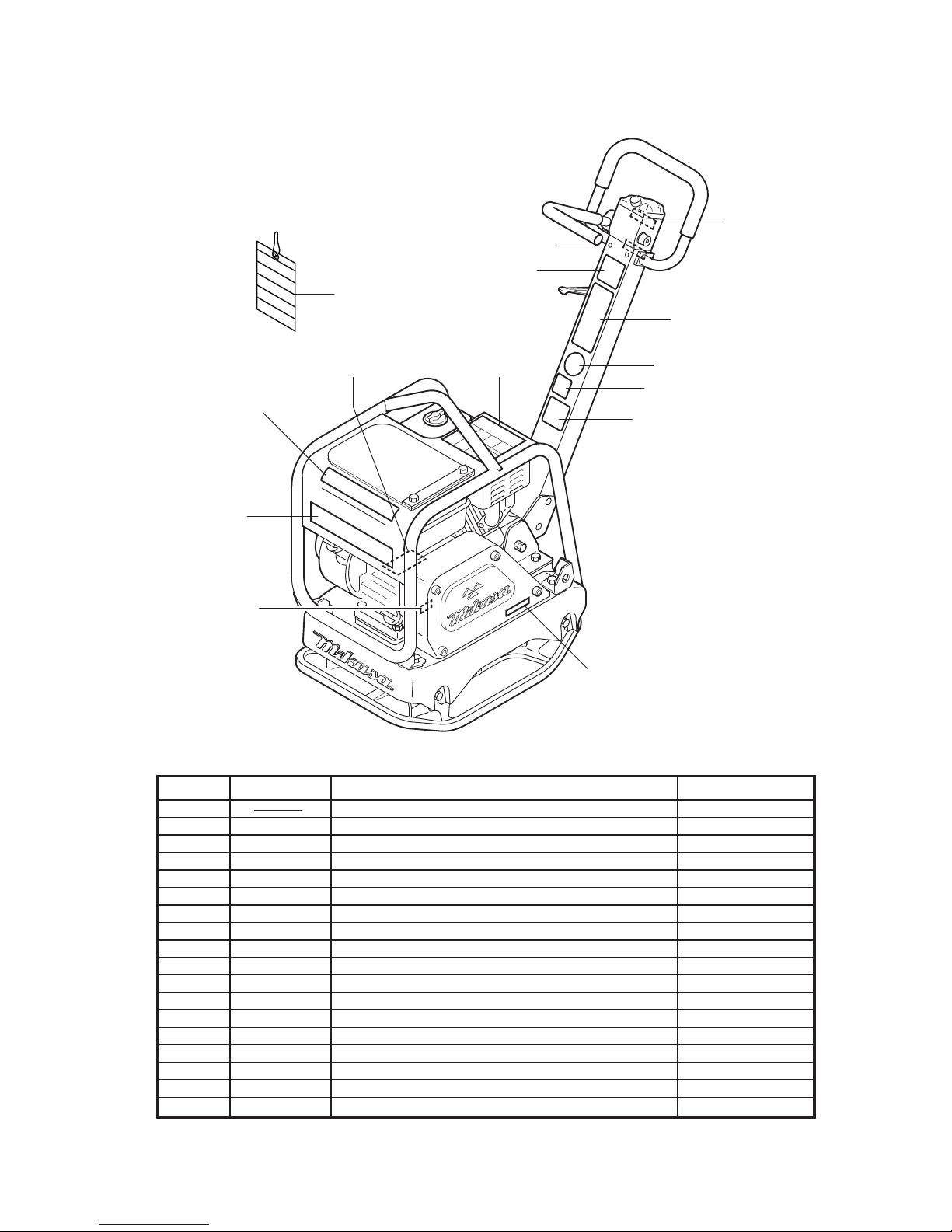

4-9. Labeling Positions

MVH-R60

-120

-150

7

2

1

5

5

8

10

6

11

9

12

3

4

13

6

Parts No. Parts Name Remarks

9201-10000

9202-07440

9202-07660

9202-09620

9202-07400

9202-07420

9202-07670

9202-07680

9202-07480

9202-00870

9202-01950

9202-10330

9202-10100

9202-07430

9202-03330

9202-07690

9202-09530

PLATE, SERIAL NO.

DECAL, MODEL/MVH-R60

DECAL, MODEL/MVH-120

DECAL, MODEL/MVH-150

DECAL, CAUTION/R60

DECAL, DANGER-CAUTION/MVH-150

DECAL, V-BELT RPF-3320

DECAL, V-BELT RPF-3350

DECAL, V-BELT RPF-3340

DECAL, SHELL TELLUS OIL 46

DECAL, WITHOUT ENGINE OIL

DECAL, OIL SAE 10W-30

DECAL, EC NOISE REQ.LWA105

DECAL, EC NOISE REQ.LWA108

DECAL, CAUTION/MVH-120

DECAL, EAR PROTECTION LABEL

DECAL, CAUTION/MANUAL

DECAL, CAUTION/COMBINATION

MVH-R60

MVH-120

MVH-150

MVH-R60

MVH-120/150

MVH-R60/120

MVH-150G

MVH-150D

MVH-R60

MVH-120/150

MVH-120/150

MVH-120/150

MVH-120/150

MVH-120/150

1

2

2

2

3

3

4

4

4

5

6

7

8

9

10

11

12

13

Label No.

Page 11

⑥

⑤

②

①

DANGER

OPERATIONAL CAUTION

FUEL

Fire risk

Operate only in well-

Wear ear protection

・ Prior to OPERATION, check engine oil and fuel levels.it not enough,add to proper levels.

・ Warm up engine at low speed for 3 to 5 minutes.

・ Operate machine at full throttle speed. (incorrect clutch engagement causes clutch to burn.)

・ Use travel lever for forward & reverse motion. Do not push or pull travel lever strongly.

Do not stand next to

Do not touch moving

ventillted area

Operate only in well-

ventillted area parts in operation

Read operator’s manual

carefully before use

machine while lifting

Do not use machine

handle

WARNING WARNING

NOISE

HOT TEMP. READ

CAUTION CAUTION

MOVING PARTS

DANGER

EXHAUST

DANGER

LIFTING

DANGER

LIFTING

③

⑧

④

⑦

4-10. Descriptions of Symbols Used on Warning Labels

Fire hazard

Stop the engine when refueling. Fire may occur if a flame is near the tank fuel port.

Danger: poisonous exhaust gas

Carbon monoxide poisoning may occur if the exhaust gas is inhaled. Do not operate the

machine in a poorly ventilated area.

Do not go under the lifted machine.

Do not let people or animals go under the lifted machine.

Lifting by the handle is prohibited.

Due to a falling risk, do not lift the machine by the handle.

Danger of hearing damage caused by noise

Always use ear plugs while operating the machine.

Be careful not to get burned.

Accidental burn may occur if you touch the hot parts (engine, muffler, etc.) during operation

or immediately after the machine stops.

Be careful not to be caught in rotating parts.

Make sure the engine is stopped when removing the belt cover during a belt change.

Read the manual carefully.

Always read the operation manual and have good understanding of operation before your

work.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

WARNING

NOISE

Wear ear protection

①

②

③

⑤

⑦

⑧

Wear ear protection

WARNING

NOISE

①

②

③

⑤

⑦

⑧

Label No.3 Pars No.9202-09620 (MVH-R60)

Label No.3 Pars No.9202-07400 (MVH-120/150)

Label No.13 Pars No.9202-09530 ( MVH-150

D[L48]

)

※

Engine type except L48

Part No.9209-00110

DECAL, SET /MVH, MRH /EXP, EU

Do not use.

(For rollers)

NPA-1473

Do not use.

(For rollers)

NPA-1475

NPA-1474

NPA-1476

(MVH-150D is

excluded.)

Decal for new European machine directives

7

Page 12

Caution Decals on Engine

Fire hazard

Stop the engine when refueling. Fire may occur if a flame is near the tank fuel port.

Danger: poisonous exhaust gas

Carbon monoxide poisoning may occur if the exhaust gas is inhaled. Do not operate the

machine in a poorly ventilated area.

Do not go under the lifted machine.

Do not let people or animals go under the lifted machine.

Lifting by the handle is prohibited.

Due to a falling risk, do not lift the machine by the handle.

Danger of hearing damage caused by noise

Always use ear plugs while operating the machine.

Be careful not to get burned.

Accidental burn may occur if you touch the hot parts (engine, muffler, etc.) during operation

or immediately after the machine stops.

Be careful not to be caught in rotating parts.

Make sure the engine is stopped when removing the belt cover during a belt change.

Read the manual carefully.

Always read the operation manual and have good understanding of operation before your

work.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Fire hazard

Stop the engine when refueling. Fire may occur if a flame is near the tank fuel port.

Danger: poisonous exhaust gas

Carbon monoxide poisoning may occur if the exhaust gas is inhaled. Do not operate the

machine in a poorly ventilated area.

Hot muffler

Do not touch the muffler and its surrounding area.

Read operation manual

For safe operation, always read the operation manual before use.

Fire, open flame and smoking prohibited.

(1)

(2)

(3)

(4)

(5)

8

Robin Honda

WARNING

!

STOP

WARNING

!

⑤

②

②

①

①

③

④

④

(1)

(2) (3)

(4)

(5)

(6)

(7) (8)

(MVH-150D is excluded. Refer to engine instruction manual for MVH-150D.)

Page 13

5. Specifications

Model

Dimensions(mm)

Overall Length

Overall Width

Overall Height

Plate Size

(W x L)

V-Belt Size

Lubrication Oil

in vibration case

(cc)

Weight

Operating

Weight

(kg)

Performance

Max, Travelling

Speed

Vibrating

Frequency

Centrifugal

Force

Power Source

Manufacturer

Model

Max.Output

Fuel Tank

Capacity

Set R.P.M

68

Honda

GX120

(petrol)

2.6kW(3.5PS)

/3600min

-1

2.0L

69

Robin

EX13

(petrol)

3.2kW(4.3PS)

/4000min

-1

2.7L

MVH-R60

886

350

880

350 x 480

RPF-3320

200

0-25m/min

100Hz

(6000v.p.m)

15kN

(1530kgf)

3600min

-1

(3600rpm)

105

104

7.6

105

104

7.5

108

107

5.5 [2.5]

108

106

5.2

108

107

8.8

108

107

5.8

111

110

8.7

108

106

9.2

MVH-120GR

1030

400

900

400 x 585

RPF-3320

350

118

0-23m/min

100Hz

(6000v.p.m)

22.5kN

(2300kgf)

Robin

EH17-2D

(petrol)

3.7kW(5.0PS)

/4000min

-1

3.6L

3600min

-1

(3600rpm)

MVH-150GH

1130

430

920

430 x 700

RPF-3350

350

150

0-25m/min

90Hz

(5400v.p.m)

27kN

(2750kgf)

Honda

GX200

(petrol)

4.1kW(5.6PS)

/3600min

-1

3.1L

3600min

-1

(3600rpm)

MVH-150GR

1130

430

920

430 x 700

RPF-3350

350

161

0-25m/min

90Hz

(5400v.p.m)

27kN

(2750kgf)

Robin

EH25-2D

(petrol)

5.9kW(8.0PS)

/3600min

-1

6.0L

3600min

-1

(3600rpm)

1130

430

920

430 x 700

RPF-3340

350

150

0-25m/min

90Hz

(5400v.p.m)

27kN

(2750kgf)

Robin

DY23-2D

(diesel)

3.7kW(5.0PS)

/3600min

-1

3.2L

3200min

-1

(3200rpm)

1130

430

920

430 x 700

RPF-3340

350

158

0-25m/min

90Hz

(5400v.p.m)

27kN

(2750kgf)

Yanmar

L48N6-VSMK

(diesel)

3.5kW(4.7PS)

/3600min

-1

2.5L

3200min

-1

(3200rpm)

MVH-150D

MVH-150D

(Silent Type)

9

Guaranteed sound

power level(dB)

(in comply with

2000/14/EC)

Measured sound

power level(dB)

(in comply with

2000/14/EC)

Hand Arm Vibration

(m/sec2)

(in comply with

2002/44/EC)

1030 [1120]

400

900 [990]

400 x 585

RPF-3320

350

116 [118]

0-23m/min

100Hz

(6000v.p.m)

22.5kN

(2300kgf)

Honda

GX160

(petrol)

3.6kW(4.9PS)

/3600min

-1

3.1L

3600min

-1

(3600rpm)

MVH-120GH

[VAS]

Page 14

6-1. Outside Dimension

(mm)

6. Appearance

400 (MVH-120)

430 (MVH-150)

900 (MVH-120)

990 (MVH-120 VAS)

920 (MVH-150)

585 (MVH-120)

700 (MVH-150)

1030 (MVH-120)

1120 (MVH-120 VAS)

1130 (MVH-150)

MVH-R60

350

880

480

886

MVH-R60

MVH-120

MVH-150

10

Page 15

ENGINE

GUARD FRAME

HANDLE

(WORKING

POSITION)

HANDLE

(STORING

POSITION)

LIFTING FOOK

THROTTLE LEVER

TRAVEL LEVER

BREATHER CAP

HAND PUMP

( )

Hydraulic oil :

Shell Terrace Oil #46 or equivalent

FORWARD

REVERSE

NEUTRAL

BELT COVER

STARTING KNOB

VIBRATION CASE

HANDLE GRIP

HANDLE LOCK

OIL GAUGE FOR VIBRATION CASE

( )

Lubrication oil :SAE 10W-30

6-2. Parts and Component

THROTTLE LEVER

11

Page 16

7. Inspection Before Operation

Clean each part of the machine well to maintain

dirt and dust-free condition. Pay special attention

to the soil attached to the bottom of the compacting board, engine cooling air inlet, and the carbu-

retor and air cleaner area to keep those parts clean.

Check each part for any looseness of bolts. Vibration causes bolts to loosen, which might result in

unexpected accident or malfunction.

Inspect the guard hook, belt cover and antivibration rubber to check the function of speed

adjustment wire and speed adjusting lever.

Check for oil leakage from the hydraulic pump and

hoses.

Check the V-belt tension. (See p.19.) The belt

should have about 10–15mm of flexibility when

pushed strongly with a finger at the mid-point

between the axes. If the V-belt is loosened, power

is not transmitted well, which reduces compacting

force and shortens the life of the V-belt.

Set the engine on a level surface to check the oil

level. If the oil level is low, add oil. Use the following engine oil.(Fig. 1)

Set the machine on a level surface, then remove

the oil gauge of the vibrator. Check the oil gauge

to see if the oil is at the specified level. Use engine

oil SAE10W-30 as lubrication oil.

Recommended oil quantity for MVH-R60 is 200cc

and MVH-120/150, 350cc. (Fig. 2)

Refueling

-Do not expose to open flames while refueling.

-Do

not fill to the rim because the fuel might spill.

-Wipe off well if a spill occurs.

Use clean automotive gasoline or automotive light

oil appropriate for the engine. Let the fuel run

hrough a filter when refueling.

Quality:

Grade CC or above

Grade SE or above

Viscosity:

SAE No. 30 at 20°C and above(summer)

SAE10W-30

Diesel engine oil,

Gasoline engine oil,

1.

2.

3.

4.

5.

6.

7.

8.

Upper Level

Lower Level

(refil needed)

Oil Gauge

fig.1

Effective

Measure oil volume

Not necessary to screw

fig.2

DANGER

!

12

OPERATIONAL CAUTION

Check engine oil and fuel level.

If not enough, add to proper level.

To START engine:

1.Warm up engine at low speed for 3 to 5 minutes.

2.Operate machine always at full speed to avoid

incorrect clutch engagement.

3.Use travel lever for forward and reverse motion.

Do not push or pull lever strongly.

To STOP engine:

Move stop switch to "OFF' position.

To LIFT machine by using lifting hook in center

To STORE machine covered with plastic sheet in a moisture.

Do not move travel lever

if engine stops (MVH-120/150)

Prior to OPERATION:

Page 17

Gasoline Engine

Set the fuel cock lever to the “Out” position to

let the fuel flow. (Fig. 3-1, 3-2, 3-3)

In cold weather or when the engine does not

start easily, set the choke lever to the “Start”

position. This is not necessary when the engine

is already warmed up. (Fig. 4-1, 4-2, 4-3)

1.

2.

8. Operation

8-1. Starting

Choke (HONDA)

fig.4-1

Start

Choke Lever

Choke (ROBIN EX-TYPE)

fig.4-2

Start

Choke Lever

Fuel Cock

(HONDA)

fig.3-1

Fuel Cock Lever

FLOW

Fuel Cock

(ROBIN EX-TYPE)

fig.3-2

Fuel Cock Lever

“

l

”

“

O

”

13

Fuel Cock

(ROBIN EH-TYPE)

fig.3-3

Fuel Cock Lever

“ l ”

“

O

”

Choke (ROBIN EH-TYPE)

fig.4-3

Start

Choke Lever

Page 18

Slightly move the throttle lever at the handle to

high. (Fig. 5)

Turn the engine switch to “ON (operation)”.

(Fig.6)

Hold the recoil starter grip, and pull it a little.

You will feel a slight resistance. Then, pull it

hard to run the engine. Be careful not to pull

too hard, or the rope might break or come off.

Allow the starter rope to slowly move back into

the case while keeping the grip grabbed.

(Fig. 7-1, 7-2)

After the engine has started, while you hear

some explosion loud noise, gradually move

back the choke lever until it is wide open.

(Fig. 8-1, 8-2)

-When the choke lever is set to “Start”,

gradually move it back toward the “Operation” direction while making sure the enginerevolution stabilizes.

3.

4.

5.

6.

Choke (HONDA)

fig.8-1

Operation

(Open)

Choke Lever

Starter Grip (HONDA)

fig.7-1

Starter Grip

Starter Grip (ROBIN)

fig.7-2

Starter Grip

14

fig.5

Throttle Lever

fig.6

“ON”

ON

“ON”

HONDA ROBIN

Engine Switch

Page 19

After the engine has started, warm up the

engine at low speed for 2 to 3 minutes. This is

especially important in cold weather. While

warming up, check for any abnormalities

suchas gas leakage.

-After the engine has started, return the

speed adjustment lever to the low speed

position. If it is left “half open”, the centrifugal clutch remains slipping. It might cause

the centrifugal clutch to fail, and abnormal

vibration of the machine might result and

create very dangerous situation.

7.

15

Choke (ROBIN EX-TYPE)

fig.8-2

Choke Lever

Operation(Open)

Choke (ROBIN EH-TYPE)

fig.8-3

Choke Lever

Operation(Open)

Page 20

Diesel Engine (MVH-150D)

Open the fuel cock lever. (Fig 9)

Open the throttle lever to about 30° for the

idling position. (Fig.10)

Recoil starter

Do not pull the rope completely. Allow the

start knob to slowly move back while keeping the knob grabbed. If you let the knob off

your hand, the rope will suddenly move

back, resulting in damage of the knob,

engine, or the main body.

After the engine has started, warm up the

engine at low speed for 2 to 3 minutes. This is

especially important in cold weather. While

warming up, check for any abnormalities such

as gas leakage.

1.

2.

3.

4.

fig.10

Throttle Lever

Open by about

30 degress

fig.9

Fuel Cock

Close

Open

CAUTION

!

If you pull the starting knob slowly, you will

feel some resistance at a point (the compression point). After you feel the resistance,

slowly return the starting knob.

Push down the decompressor lever.

Pull the starting knob hard to start the engine.

(Fig. 11)

a.

b.

c.

fig.11

Recoil Starter

16

Page 21

While the machine is in operation, make

sure there is no object or structure that

might cause injury or machine damage in

the direction that the machine is moving.

If the throttle lever is opened suddenly, the

machine starts to operate. At an engine revolution of around 2000 rpm, the clutch engages,

but if the engine revolution is increased gradually, slipping of the clutch occurs (halfclutching), which results in wear and malfunction of the clutch. So, the operation of the

speed adjustment level should be done quickly

and suddenly without a hesitation.

Use the back and forth travel lever to make the

machine move backward and forward. When

the lever is pushed forward, the machine

moves forward, when pulled backward, the

machine moves backward. At neutral, the

machine vibrates staying at the same location.

(Fig. 12)

When this machine is used on ground that

contains clay, the ground surface tends to stick

to the compacting board, and the machine

travel speed becomes slower. In this case,

check the bottom of the compacting board to

see if there is any clay adhered to the board.

This machine cannot perform well on clay and

other type of ground with a high water percentage. Drying the ground is recommended to

make the ground water percentage appropriate

for the machine to get good compacting performance.

-

1.

2.

3.

fig.12

Travel Lever

Reverse

Neutral

Forward

CAUTION

!

8-2. Operation

17

Page 22

Move the throttle lever from ON to OFF (for

diesel engine, to idle position). Run the engine

for 3 to 5 minutes at low speeds to cool it down

before stopping.

Diesel Engine

Move the throttle lever to the stop position to

stop the engine.

Gasoline Engine

Turn the engine switch to the OFF position,

then the engine stops. (Fig. 13)

If the engine is stopped while it is hot, burning of the oil film on the cylinder inner wall

occurs, leading to troubles such as accelerated engine wear.

For gasoline engine, shut the fuel cock.

(Fig. 14-1, 14-2)

1.

-

-

2.

fig.13

Engine Switch

“OFF”

HONDA ROBIN

ON

“OFF”

9. Stopping the Machine

Fuel Cock

(HONDA)

fig.14-1

OFF

Fuel Cock Lever

Fuel Cock

(ROBIN EX-TYPE)

fig.14-2

“ O ”

“

l

”

Fuel Cock Lever

CAUTION

!

18

Fuel Cock

(ROBIN EH-TYPE)

fig.14-3

Fuel Cock Lever

“ l ”

“

O

”

Page 23

10-1. Loading and Unloading

10-2. Transportation Precautions

10. Transportation

11. Storage

WARNING

!

WARNING

!

Make sure there is no breakage of guard frame and anti-vibration rubber nor

loosened or missing bolts.

Always stop the engine when lifting.

Use an intact wire rope without any deformation with sufficient strength.

Slowly lift upward without applying any impact. Never let people or animals go under

the lifted machine.

For safety reasons, do not lift to a height that is higher than necessary.

Stop the engine when the machine is transported.

Always drain the fuel before transportation.

Fix the machine securely to prevent the machine from moving or falling.

For loading and unloading using a

crane, an operator qualified for

cranes and hooking works is

needed.

Use a crane for loading and unloading the machine.

Designate a person to guide the loading and unloading, and always work

under the instruction of that person.

When lifting, always use a special

hook on the guard frame. (Fig. 15)

Never lift by using the hook on the

handle.

Wash with water to remove any dust

and dirt from all parts of the machine.

Store in a dry area away from direct

sunlight after putting the cover over

the machine to prevent dust and dirt

buildup.

Add fuel and oil or perform an oil

change. Remove the battery terminals or remove the battery from the

machine for storage.

Securely cover the air cleaner and

muffler air inlets and exhaust port.

Do not leave the machine outdoors.

Keep it indoors.

(When storing for a long period of time)

■

■

■

■

■

1.

2.

3.

■

■

■

1.

2.

3.

4.

5.

fig.15

Special Hook

19

Page 24

Check frequency

Check parts Check items Oils

Appearance

Fuel tank

Fuel system

Engine oil

Shock absorber

Hand pump

Vibrator oil

Hydraulic pipe system

Air cleaner

Guard frame

Back and forth motion

lever, linking parts

Back and forth motion

lever operation

Bolts and nuts

Engine oil

Engine oil filter

Engine oil

Engine oil filter

Vibrator oil

Hydraulic oil

Battery terminal

V-belt for vibrator

Clutch

Vibrator oil

Hydraulic oil

Fuel filter

Engine oil filter

Fuel pipes

Air cleaner element

Hydraulic hose

Daily

(before starting)

Every 20 hours

Every 100 hours

Every 200 hours

Every 300 hours

Every 2 years

Irregular

Flaw, deformation

Leakage

Leakage

Leakage, oil level, dirt

Crack, damage, wear

Leakage

Leakage

Leakage, looseness, flaw, wear

Dust on sponge

Breakage, flaw, loosened or

missing bolts and nuts

Missing, breakage, flaw, looseness or

missing bolts and nuts

Operation check, play

Looseness, missing

Replace only after the first 20 hours

Replace only after the first 20 hours

Change

Washing

Leakage, oil level, dirt

Leakage, oil level, dirt

Cleaning

Flaw, tension

Dirt, flaw, wear

Change

Change

Change

Change

Change

Change

Change

gasoline

Engine oil

Hydraulic oil

Engine oil

Hydraulic oil

Engine oil

Engine oil

Engine oil

Hydraulic oil

Engine oil

Hydraulic oil

6mm 8mm 10mm 12mm 14mm 16mm 18mm 20mm

4T (SS41) 70 150 300 500 750 1,100 1,400 2,000

6-8T (S45C)

100 250 500 800 1,300 2,000 2,700 3,800

11T (SCM3)

150 400 800 1,200 2,000 2,900 4,200 5,600

When the mating material is aluminum

100 300~350 650~700

Thread diameter

Material

(Bolts used on the machine are right-hand thread.)

12-1. Inspection and Maintenance Schedule Table

12. Regular Check and Adjustment

For details about the check and maintenance of the engine, please refer to the

attached engine operation manual.

Caution: The above table shows the check frequency for standard condition. The

check frequency may vary depending on the condition in which the machine is used.

For check of bolt and nut looseness and tightening, please see the following tightening torque list.

Tightening Torque List (unit: kgf-cm, 1kgf-cm=9.80665N-cm)

20

Page 25

Perform the first engine oil change after 20

hours of operation, then change at every 100

hours.

When the air cleaner element becomes dirty,

the engine does not start smoothly, and sufficient output cannot be obtained. Machine

operation will be affected and the engine life

will be shortened greatly. Do not forget to clean

the element. (For details, please see the separate engine operation manual.) If the element

cannot be cleaned, replace it with a new one.

Check of V-belt (Fig. 16)

At every 200 hours, remove the belt cover (top)

to check the tension of the V-belt. The flexibility

of the belt should be about 10 mm when

pushed strongly with your finger at the midpoint between the axes. When the V-belt is

loose, the engine power is not transmitted well,

resulting in poor compacting force and shortening the life of the V-belt.

Changing the V-belt

Removing the V-belt

Remove the top and bottom belt covers. Put a

wrench (19mm) on the tightening bolt of the

vibrator pulley (lower side). Put a piece of cloth

at the center of the left side of the V-belt, and

pull the belt strongly towards you. While pulling,

turn the wrench clockwise, then remove the

V-belt.

Installing the V-belt

Set the V-belt on the lower side of the vibrator

pulley. Push the V-belt to the left side of the

upper clutch. Similar to removing the V-belt,

turn the wrench clockwise to install.

Be careful not to get your hand caught

between the belt and clutch pulley. Injury

may occur. Wear gloves when performing

this operation. (Fig. 17)

Checking the Clutch

Check the clutch when checking the V-belt.

Remove the belt cover and check for any seizing on the clutch outside drum. Also visually

check for wear and damage on V-groove. If the

V-groove is dirty, clean it thoroughly.

Wear on the lining shoe can be checked by an

operation check. Wear on the shoe will result in

poor power transmission, causing slipping.

To stop the operation, perform the starting

steps in reverse. Return the throttle lever

quickly and suddenly to lower the revolution

speed.

1.

2.

-

-

3.

-

fig.16

Belt Cover(upper)

Clutch

Belt

Belt Cover (lower)

Vibration Pulley

fig.17

CAUTION

!

12-2. Changing the Engine Oil

12-3. Cleaning the Air Cleaner

12-4. Checking/Changing the V-belt and Clutch

21

Page 26

Changing the Clutch

Remove the V-belt. (See the belt removing

steps described in the previous page.)

Remove the bolt at the engine output shaft end

by applying an impact (hitting with a hammer)

to the spanner. (in a counterclockwise direction).

Remove the clutch with a pulley remover.

For installation, perform the previous steps in

reverse. When tightening the bolt, apply a

shock to the spanner to tighten securely.

If vibration becomes weaker during operation or when there is no vibration even

though the engine is running normally,

immediately check the V-belt and clutch with

disregard to the rule of every 200 hours

check.

At every 100 hours of operation, set the

machine on a level surface and remove the oil

gauge of the vibrator. Check the oil level to see

if it is within the allowable range. (Fig.18)

Change the vibrator oil at every 300 hours

operation. Drain the oil from the drain plug. For

draining, put a beam under the compacting

board at the other side of the drain plug to tilt

the machine.

Use engine oil SAE 10W-3D as lubrication

oil. The quantity used is 200cc for MVH-R60

and 350cc for MVH-120/150.

When checking the vibrator oil, clean the oil

port beforehand to prevent dust and other

foreign materials from falling into the oil.

Whenever there is an oil leakage from the

vibrator, check the oil level.

Check the Hydraulic Oil

Check the hydraulic oil at every 100 hours’

operation. By making the handle bar vertical

(done at the time of storage), remove the

breather plug at the top of the hydraulic hand

pump to see if the hydraulic oil is at the specified level (OIL LEVEL). (Fig. 19)

4.

-

-

-

-

※

1.

fig.18

Effective

For MVH-R60/120/150

Measure oil volume

Not necessary to screw

fig.19

Cap

Breather Plug

Hand Pump

OIL LEVEL

CAUTION

!

CAUTION

!

12-5. Checking/Changing the Vibrator Oil

(Fig.18)

12-6. Checking/Changing the Hydraulic Oil

22

Page 27

Changing the Hydraulic Oil (Fig. 20)

The level of the hydraulic oil in the hand

pump should always be at OIL LEVEL. If the

level is higher, the oil bursts out from the

breather plug.

Be careful not to let dust enter inside the

hand pump.

Remove the hand pump plug cap, then remove

the breather plug (with a 24 mm wrench).

Remove the hydraulic hose that is in the vibrator cylinder. Set the lever to the forward motion

to drain the hydraulic oil in the pump.

After the hydraulic oil is drained, install the

hydraulic hose to the vibrator.

Pour hydraulic oil from the hand pump breather

plug attachment hole.

(MVH-R60: 0.25L, MVH-120/150: 0.3L)

Remove the air releasing plug of vibrator cylinder. Then oil will come out from the air releasing plug. After air bubbles stop coming out,

attach the plug. Tighten securely.

Attach the hand pump breather plug, put on the

plug cap. After making sure the hydraulic oil in

the pump is at OIL LEVEL, attach the breather

plug.

Hydraulic oil: Shell Terrace Oil #46 or

equivalent

2.

-

-

a.

b.

c.

d.

e.

■

fig.20

Hydraulic Hose Breather Plug

Vibrator

CAUTION

!

23

Page 28

Revolution fluctuation

(1) Starting Problem

(2) Operation Problems

(3) Recoil Starter Operation not Good

13-1. Gasoline Engine

13. Troubleshooting

Bridging the igniter plug.

Carbon accumulated on the igniter plug.

Short circuit due to insulation problems of the igniter plug.

Inappropriate spark gap.

Short circuit of the ON-OFF switch

Ignition coil problems

Dirt of the point or inappropriate gap.

Breakage of ignition coil or short circuit

Intake/exhaust valve is stuck or pushed up

Piston ring, cylinder wear

Cylinder head, igniter plug tightening problem

Head gasket, igniter plug gasket breakage

Water mixed in fuel

Dirt of the igniter plug.

Ignition coil problem

Occasional short circuit of the ignition coil

No fuel in the fuel tank.

Fuel cock does not open properly.

Clogging of fuel filter.

Clogging of tank cap air hole

Air trapped in the fuel pipe.

The wrong fuel is used.

Mixing of water or foreign materials

The air cleaner not working

Dirt of air cleaner.

Carbon accumulated in the cylinder.

Carburetor oil level inappropriate.

Carbon accumulated inside combustion chamber and exhaust hole.

Spark plug thermal value inappropriate.

Dirt and breakage of the cooling fin.

Clogging of foreign materials at the rotating part.

Weakening of the spiral spring

Governor adjustment inappropriate

Governor spring problems

Fuel does not flow properly.

Air taken from intake pipe system

Fuel is supplied, but the igniter plug does not ignite.

■

■

■

■

■

■

Fuel supplied, and the igniter plug ignites.

Fuel does not reach the carburetor.

Lowered power.

Engine overheating

Compression is good and no firing problem.

Compression is good, but no firing.

Insufficient compression (see the item “compression is not good.” )

Compression is good

Compression is not good

Electricity reaches the high voltage cable.

Electricity does not reach the high voltage cable.

24

Page 29

Intake/exhaust valve upthrust

Decompressor adjustment problems

(1) Starting Problem

(2) Insufficient Output and Operation Problems

Contact with seat not close enough.

Piston ring wear

Cylinder wear

Cylinder, cylinder head mating surface problems

Nozzle seat looseness

No compression at all

Almost no compression

Clogging of the tank cap air hole.

Clogging of the fuel filter

Fuel cock not open

Air inside the fuel pipe

Fuel flow low or no flow

Injection pump barrel, plunger stuck

Nozzle hole clogging

Nozzle needle stuck

Fuel not injected inside the combustion chamber

Inappropriate starting operations

Engine oil viscosity high, engine oil is very dirty.

Air trapped inside the fuel pipe.

Does not reach the starting revolution.

Governor fork and sleeve mating surface problems

Governor spring problems

Fly plate and sliding part wear and operation problems

Revolution fluctuation

Valve open/close timing inappropriate

Clogged exhaust hole, muffler

Overload

Engine revolution does not increase.

Dirt and breakage of cooling fin

Mixing of water inside the fuel filter

Carbon accumulated in the combustion chamber or exhaust hole.

Smoke set inappropriate

Overload

Inappropriate injecting timing

Nozzle clogging

Engine overheating with black smoke

See the comment for insufficient compression.

Insufficient compression

No fuel in the fuel tank

Mixing of water or foreign materials

(A) In case of compression problems

(B) In case of inappropriate fuel injection inside the combustion chamber

(C) Fuel and compression pressure appropriate, but the engine does not start.

13-2. Diesel Engine

25

■

■

■

■

■

■

■

■

■

■

■

Page 30

Piston, cylinder ring wear

Nozzle hole clogging

Piston ring stuck

Wrong assembly (upside down) of piston ring

Inappropriate injection timing

Inappropriate valve open/close timing

Looseness of injection pump joint

Firing problem with white smoke (when unloaded)

Hand pump problems

Inappropriately installed forward/backward motion lever

Breakage of the oil hose

Mixing of air in the hydraulic oil

Clogging of foreign materials in the check valve inside the hand pump

Breakage of the piston bearing in cylinder

Move forward or backwards, but unable to switch between back and forth motion

Insufficient engine output and inappropriate high speed set revolution

Slipping of clutch

Slipping of V-belt

Too much vibrator oil

Failure inside vibrator

Low travel speed and vibration weak

Leakage from fuel passage

Clogging of the air cleaner element

Inappropriate fuel due to mixing of impurities

Overload

Fuel consumption too high (black smoke)

V-belt coming off, slipping and breakage

Slipping of the clutch

Locking of the vibrator

Breakage of the piston bearing in cylinder

No forward, backward motion

Piston inside the hand pump not moving smoothly

Vibrator cylinder piston does not move smoothly

Movement of lever heavy

Use of wrong oil

Failure to change oil

Breakage of the air cleaner element or failure to clean the air cleaner

Extensive wear on sliding parts or stuck piston rings

Too much oil

Wrong assembly of the governor system

Detached injection pump rack

Engine does not stop even though the fuel supply is cut (or over-running)

Searing or damage of the piston, rod, etc.

Stopped suddenly with abnormal noise

Wear on the injection pump barrel or plunger

Lubrication oil diluted and increased.

13-3. Main Body

■

■

■

■

■

■

■

■

■

■

26

Page 31

Page 32

Loading...

Loading...