Page 1

402-07403

MVH-308

MVH-408

MVH-508

INSTRUCTION MANUAL

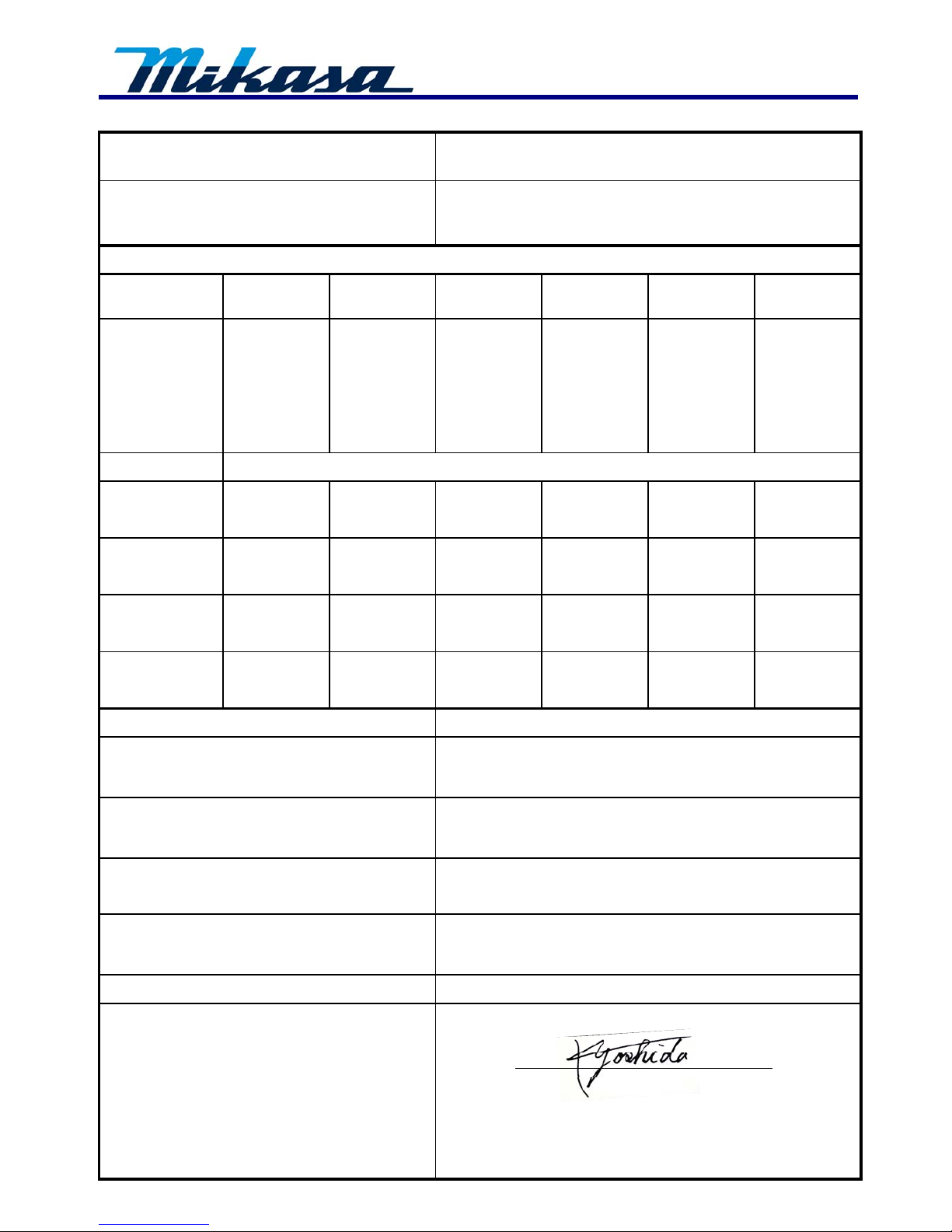

Contentsof“DeclarationofConformity”

Pleasereferthe

ECDECLARATIONOFCONFORMITY

inthismanualaswell.

REVERSIBLE COMPACTOR

Page 2

5) model MVH-308DSZ MVH-408DSZ MVH-508DSZ

6) Equipment

item number

454100, 454101,

454113, 454114,

454115, 454116,

454117, 454118,

454119, 454120,

454121, 454122

454136

454200, 454202,

454211, 454212,

454213, 454214,

454215, 454216,

454217, 454218,

454219, 454220

454234

454300, 454301,

454306. 454307,

454308, 454309,

454310, 454311,

454312, 454313,

454314, 454315,

454316, 454317

454333

7) Serial number

8) power source

cont. output

<max. output>

Hatz 1B30

4.9kW

<5.4kW>

Hatz 1B50

6.7kW

<7.3kW>

Hatz 1D81S

8.9kW

9) Measured

sound power

level(dB)

107 107 108

10) Guaranteed

sound power

level(dB)

108 108 109

11) Operator's

sound pressure

level(dB)

93 94 94

1) DECLARATION OF CONFORMITY

2) Manufacturer’s name and address.

Mikasa Sangyo Co., Ltd.

4-3, Sarugaku-cho 1 chome, Chiyoda-ku, Tokyo101-0064, Japan

3) Name and address of the person who keeps the

technical documentation.

Yoshiharu Nishimaki, engineer

R. & D. Division, Mikasa Sangyo Co., Ltd.

Shiraoka-city, Saitama, Japan

4) Type: Vibratory Plates

For serial number, please refer it on front page.

12) Conformity assessment according to Annex: VIII (Full Quality Assurance procedure)

13) Name and address of the Notified Body

Société Nationale de Certification et d’Homologation (SNCH)

11, route de Luxembourg

L-5230 Sandweiler LUXEMBOURG

14) Related Directive

Directive 2000/14/EC and, to be followed by Directive

2005/88/EC, relating to the noise emission in the environment by

equipment for use outdoors.

15) Declaration

The equipment referred in this document, fulfills with all the

requirements of Directive 2000/14/EC

16) Other related Community Directives

2006/42/EC, 2005/88/EC, 2004/108/EC,

2002/88/EC(2004/26/EC)

EN500-1, EN500-4

17) EC Conformity Certificate No: SNCH*2000/14*2005/88*0472*03

18) Place and date of the declaration

Tokyo, Japan December, 2013

Signed by:

Keiichi YOSHIDA

Director, Product Control Division

Mikasa Sangyo Co., Ltd.

Page 3

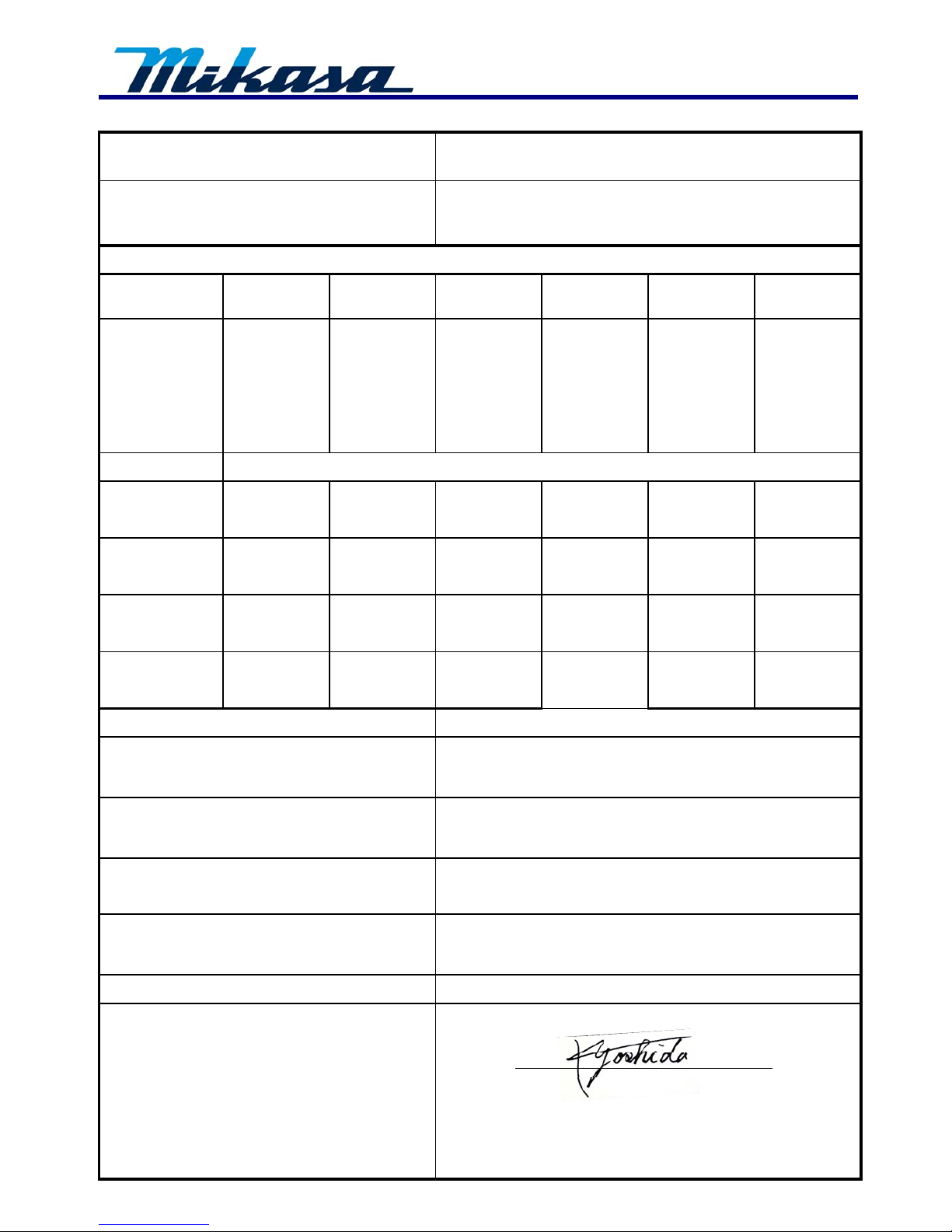

5) model MVH-308GH MVH-308GE MVH-408GH

6) Equipment

item number

454102, 454105,

454108, 454123,

454124, 454125,

454126

454111, 454112,

454127, 454128

454202, 454205,

454208, 454221,

454222, 454223

7) Serial number

8) power source

cont. output

<max. output>

Honda GX270

5.1kW

<6.0kW>

Subaru EX27

5.1kW

<6.6kW>

Honda GX390

6.6kW

<8.2kW>

9) Measured

sound power

level(dB)

105 106 106

10) Guaranteed

sound power

level(dB)

107 107 107

11) Operator's

sound pressure

level(dB)

93 94 94

18) Place and date of the declaration

Tokyo, Japan March, 2014

Signed by:

Keiichi YOSHIDA

Director, Product Control Division

Mikasa Sangyo Co., Ltd.

15) Declaration

The equipment referred in this document, fulfills with all the

requirements of Directive 2000/14/EC

16) Other related Community Directives

2006/42/EC, 2005/88/EC, 2004/108/EC,

2002/88/EC(2004/26/EC)

EN500-1, EN500-4

17) EC Conformity Certificate No: SNCH*2000/14*2005/88*0472*03

For serial number, please refer it on front page.

12) Conformity assessment according to Annex: VIII (Full Quality Assurance procedure)

13) Name and address of the Notified Body

Société Nationale de Certification et d’Homologation (SNCH)

11, route de Luxembourg

L-5230 Sandweiler LUXEMBOURG

14) Related Directive

Directive 2000/14/EC and, to be followed by Directive

2005/88/EC, relating to the noise emission in the environment by

equipment for use outdoors.

1) DECLARATION OF CONFORMITY

2) Manufacturer’s name and address.

Mikasa Sangyo Co., Ltd.

4-3, Sarugaku-cho 1 chome, Chiyoda-ku, Tokyo101-0064, Japan

3) Name and address of the person who keeps the

technical documentation.

Yoshiharu Nishimaki, engineer

R. & D. Division, Mikasa Sangyo Co., Ltd.

Shiraoka-city, Saitama, Japan

4) Type: Vibratory Plates

Page 4

Italian

1. DICHIARAZIONE “CE” DI CONFORMITÁ

2. Nome e indirizz o Fabbricante

3. Nome e indirizzo della persona che conserva la

documentazione tecnica

4. Tipo: Piastre vibranti

5. Modello

6. Codice macchina

7. Numeridi matricola

8. Potenza installata netta <resa massima>

9. Livello di potenza sonora misurato (dB)

10. Livello di potenza sonora garantito

11. Livello massimo di pressione sonora

12. Valutazione di conformità in accordo all'annesso VIII

( procedura Garanzia di Qualità totale

13. Nome dell'organismo notificato

14. Rappresentante Autorizzato in Europa

15. Direttiva di riferimento

Direttiva 2000/14/CE su l'emissione acustica ambientale

delle macchine ed attrezzature destinate a funzionare

all'aperto

16. Dichiarazione

Le attrezzature riportate nel documento soddisfano i requisiti

della Direttiva 2000/14/CE

17. Altre Direttive Comunitarie di riferimento

18. Certificato di Conformità CE No:

19. Luogo e data della dichiarazione

French

1. DECLARATION « CE » DE CONFORMITE

2. Non et adresse du Fabricant

3. Nom et adresse de la personne qui défient les documents

techniques

4. Type du materiel: Plaques vibrantes

5. Modello

6. Numero equipement

7. Numéro de série

8. Puissance reseau <rendement maximal>

9. Niveau sonore mesure(dB)

10. Niveau sonore garanti(dB)

11. Niveau sonore maximum

12. Certification de conformite selon l'annexe VIII ( procedura

Garanzia di Qualità totale )

13. Nom et adresse de l'organisme notifié

14. Mandataire dans la Communaute Europeenne

15. Directive concernee

Est egalement conforme aux dispositions de la directive

<<emission sonores des equipements utilises a l'exterieur

des batiments>> 2000/14/CE et aux legislations nationales

la transposant.

16. Declaration

L'équipement de référence satisfait aux exigences de la

Directive 2000/14/EC

17. Autres directives communautaires concernees

18. Certificate deConformite CE numero:

19. Lieu et date de la declaratio

Spanish

1. DECLARACIÓN “CE” DE CONFORMIDAD

2. Nombre y dirección del fabricante

3. Nombre y dirección de la persona que guarda la

documentación técnica.

4. Tipo: Bandejas vibrantes

5. Modelo

6. Número de referencia del equipo

7. Numeros de serie

8. Potencia neta instlada <rendimineto maximo>

9. Nivel sonoro medido del motor ( dB )

10. Nivel sonoro garantizado del motor ( dB )

11. Máximo nivel sonoro de presión ( dB )

12. Evaluación de la Conformidad de acuerdo al Anexo VIII

( Prcedimiento de total garantía asegurada )

13. Nombre y dirección de la Entidad Notificada

14. Representante autorizado

15. Directiva relacionada

Directiva 2000/14/CE en relación a la emisión sonora en el

ambiente por equipos que trabajan en espacios abiertos

16. Declaración

El equipo referido en este documento , cumple con todos los

requerimientos de la Directiva 2000/14/EC

17. Otras Directivas Comunitarias relacionadas

18. Certificado de Conformidad CE Nº

19. Lugar y fecha de la declaración

Page 5

Table of contents

1

1

2

2

2

3

3

3

3

3

3

4

5

7

8

9

11

12

12

12

12

13

13

13

16

16

18

19

19

19

19

20

20

21

22

22

22

23

23

24

26

29

General Cautions

Refueling Precautions

Location And Ventilation Precautions

Precautions Before Starting

Precautions During Work

Lifting Precautions

Transportation And Storage Precautions

Maintenance Precautions

Label Position

Descriptions Of Symbols Used On Warning Labels

Control Unit Positions And Names

Engine Oil

Vibration Case Oil

Refueling

Handle

Starting

Operation

Compaction Sensor (Compas)

Care

Transportation Precautions

Storage

Inspection And Maintenance Schedule Table

Open The Front Cover

Changing The Engine Oil

Cleaning The Air Cleaner

Checking/Changing The V-belt

Checking/Changing The vibrator Oil

Checking/Changing The Hydraulic Oil

Battery

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

7.1

7.2

7.3

7.4

8.1

8.2

8.3

10.1

10.2

10.3

11.1

11.2

11.3

11.4

11.5

11.6

11.7

11.8

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.11

INTRODUCTION ......................................................................................

APPLICATION, STRUCTURE AND POWER TRANSMISSION ..............

WARNING SIGNS ....................................................................................

CAUTIONS FOR SAFETY........................................................................

SPECIFICATION......................................................................................

APPEARANCE ........................................................................................

INSPECTION BEFORE OPERATION .....................................................

OPERATION ............................................................................................

STOPPING THE MACHINE......................................................................

TRANSPORTAION AND STORAGE........................................................

REGULAR CHECK AND ADJUSTMENT.................................................

TROUBLESHOOTING ............................................................................

WIRING DIAGRAM .................................................................................

Page 6

1

1.INTRODUCTION

2.APPLICATION, STRUCTURE AND POWER TRANSMISSION

This machine, weighing more than 200kg to more than 400kg, is a compactor with back and forth motion. The strong vibration from the two-axes pendulum structure inside the vibrator changes the machine’s motion into straight back and forth

motion. The machine compacts through this motion.

The machine has tightening and compacting effect for all ground types other than the soft soil with high water percentage.

Because the machine is capable of straight back and forth movement, it works very effectively in grooved structures. Also,

since the work efficiency of this machine is high, it is suitable for compacting of a large area. The machine also works well

for flattening and leveling rough ground surface with irregularities created by the use of a powerful tamping rammer.

The machine can be used widely for heavy compacting works such as base work as well as finishing work for asphalt paving.

Do not use this machine on ground with a high water percentage and, in particular, do not use on clay because the machine

will not advance. Use this machine for compacting earth and sand mixtures, soil, sand or gravel. Do not use this machine for

other type of work.

The upper part of the machine consists of an engine, handle, belt cover and exterior frame. The upper part of the machine

is fixed to the vibrating plate of the lower part via an anti-vibration rubber. The lower part of this machine consists of a vibrating plate that incorporates a vibrator, there are two pendulums. The phase of those pendulums is changed by hydraulic

pressure.

The hydraulic cylinder for the vibrator is connected with a hydraulic hose to the hydraulic pump, which is directly connected

to the drive lever.

Power is provided by an air-cooled single-cylinder 4-cycle gasoline engine or diesel engine. The engine output shaft is

equipped with a centrifugal clutch. The centrifugal clutch is engaged when the engine speed increases. V-pulley is incorporated to the centrifugal clutch drum, and power is transmitted via the V-belt to the V-pulley on the vibrator side.

Through this process, the engine revolution is changed to the pendulum revolution suitable for compacting.

The vibrator pulley rotates the pendulum axis of the drive side. The two pendulums inside the vibrator are fixed to the two

pendulum axes that are positioned in parallel and are connected with the gear. The two axes rotate in opposite directions at

the same speed to generate vibration.

There is a spiral groove on the inner periphery of the gear assembled on the pendulum axis to be driven. This groove serves

as a key groove to let the guide pin slide to the axis direction. This guide pin is connecting the two pendulum axes. The phase

of the two pendulums is changed by the axial sliding of the guide pin. The change in phase causes the vibration to change

directions, thus changing the speed and travel direction of the machine.

Hydraulic pressure is used for the axial movement of the guide pin. At the end of the groove where the guide pin is attached,

a piston is installed. When the oil level rises inside the hydraulic cylinder on the vibrator side and the pressure increases, the

piston is pushed. Then the axis connected to the piston is pushed, which causes the guide pin attached to the axis to move,

resulting in a change in phase.

The operator of the machine, by using the back and forth motion lever of the handle, can adjust the oil quantity and pressure

by the connected hand pump to get the travel speed suitable for the work.

This operation manual describes the proper operation, basic inspection and maintenance procedures of the reversible

compactor. Please read this operation manual before use in order to maximize the excellent performance of this

machine and make your work more efficient and effective.

After reading the manual, please keep it in a handy location for easy reference.

For the handling the engine, please refer to the separate engine operation manual.

For inquiries about repair parts, parts lists, service manuals, and repairs, please contact the store where you purchased

the product, our sales office, or the Mikasa Parts Service Center. For parts lists, please visit our homepage at:

http://www.mikasas.com/ where you can access Mikasa WEB parts lists.

●

●

●

●

Application

Warning About Incorrect Applications And Techniques

Structure

Power Transmission

The illustrations in this manual might slightly differ in part from the machine you actually

purchased due to design changes.

Page 7

2

3.WARNING SIGNS

4.CAUTIONS FOR SAFETY

The triangle shaped marks used in this manual and on the decals stuck on the main body

indicate common hazards. Be sure to read and observe the cautions described.

Do not work with this machine, when

Please read the operation manual well and work safely by using the machine properly.

For handling of the engine, please refer to the separate engine operation manual.

Please have a good understanding of the structure of this machine.

Make sure to do work start inspection, regular self inspection and specified self inspection.

To make your work safe, please use protective equipment (use specified helmet, protective shoes, etc.) and wear appropriate work clothes.

Always use noise protection equipment such as ear muffs or ear plugs.

Always check the machine to make sure it is in normal condition before operating the

machine.

The nameplates attached to the machine (nameplates showing operation method,

warning, etc.) are very important for your safety. Clean the machine so that the nameplates can be read easily. If it is difficult to read the nameplate, please replace the old

one with a new one.

It is dangerous for young children to come near the machine. Please pay careful attention to the method of storing and the storage location for this machine. Especially the

engine start key has to be taken out every time you finish your work, and keep it in a

designated location.

To do maintenance work, stop the engine and remove the battery wiring.

We are not responsible for accidents that have occurred after the machine was refurbished without approval from the manufacturer.

you are tired or sick and not feeling well,

you have taken medicine or drug, or

you have had a drink.

4.1 General Cautions

●

●

●

●

●

●

●

●

●

●

●

●

○

○

○

Warning labels indicating hazards to humans and to equipment.

DANGER

!

WARNING

!

CAUTION

!

CAUTION

!

Denotes an extreme hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or adhered to, is

likely to result in serious injury or death.

Denotes a hazard. It calls attention to a procedure, practice, condition

or the like, which, if not correctly performed or adhered to, could

result in serious injury or death.

Denotes a hazard. It calls attention to a procedure, practice, condition

or the like, which, if not correctly performed or adhered to, could

result in injury to people and may damage or destroy the product.

Failure to follow the instructions may result in damage to property.

!

(without at )

WARNING

!

CAUTION

!

Page 8

3

Always refuel in a well ventilated area.

Make sure to stop the engine and wait until the engine cools down when refueling.

Select a flat surface area with no flammable material around for refueling. Be careful

not to spill the fuel. Wipe off well if there is any spill.

Never put fire near the machine during refueling. (Especially, be careful about

smoking.)

If you fill to the top of the fuel tank inlet, fuel might spill out from the tank, and it

becomes dangerous

After refueling, tighten the tank cap well.

Do not run the machine in an unventilated location, such as indoors or inside a tunnel. The exhaust gas

from the engine contains toxic gases such as carbon monoxide and is very hazardous.

Do not operate the machine near open flames.

Check each part to see if it is tightened properly. Vibration causes loosening of bolts, which results in

unexpected serious malfunctions of the machine. Tighten the bolts securely.

Before starting the machine, make sure it is safe to start by checking your surroundings for people and

objects.

Always pay attention to your footing. Work in an area where you can maintain a good balance of the

machine and a safe comfortable posture.

The engine and muffler become very hot. Do not touch immediately after the machine stops because

they are still very hot.

If you notice deterioration of machine operation during your work, stop your work immediately.

Before moving away from the machine, be sure to turn the engine off. Also when the machine is

transported, stop the engine and close the fuel cock.

For a machine with cell starter specification, do not operate without the battery. If you operate without the

battery, electrical system failure might occur.

Before lifting, check the machine parts (especially the hook and anti-vibration rubber) for any damage

and loosened or missing bolts.

Stop the engine and shut the fuel cock while lifting.

Use a sufficiently strong wire rope.

For lifting, use only one point hoisting hook, and do not lift at any other part.

When the machine is hoisted, never let people or animals come underneath.

For safety reasons, do not lift to a height that is higher than necessary.

Stop the engine during transportation.

Transport after the engine and the machine are cooled down.

Always drain the fuel before transporting.

Securely fix the machine to prevent it from moving or falling during transportation.

4.2 Refueling Precautions

4.4 Precautions Before Starting

4.5 Precautions During Work

4.6 Lifting Precautions

4.7 Transportation And Storage Precautions

4.3 Location And Ventilation Precautions

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

DANGER

!

DANGER

!

DANGER

!

WARNING

!

CAUTION

!

CAUTION

!

Page 9

4

Appropriate maintenance is required to ensure safe and efficient operation of the

machine. Always pay attention to the machine’s condition and keep it in good

condition. Pay special attention to the parts used for lifting, if they are not maintained

properly, it might result in a serious accident.

Start maintenance work after the machine has cooled down completely. The muffler,

in particular, becomes very hot, and there is a danger of burn. The engine, engine oil

and vibrator also become very hot. Be careful not to get burned.

Always stop the engine before inspection and adjustment. If you are caught in a

rotating part, serious injury might occur.

After maintenance work, check the security parts to see if they are securely installed.

Special attention should be paid when checking bolts and nuts.

If disassembly is involved in maintenance, refer to the maintenance instruction

manual to make your work safe.

If the battery fixing bolts have been removed, put them back and tighten securely to

fix the battery.

If used with the battery not fixed properly, contact with the battery terminal might

occur, leading to electric shock and electric leak, or breakage of the battery might

occur by the impact and vibration from outside, resulting in battery fluid leakage.

The gas from the battery might cause an explosion. Do not generate sparks or bring

flames near the battery.

Never put the positive terminal and negative terminal come into contact. Sparks will

be generated, and ignition might occur.

Be careful when handling the battery fluid because it is very toxic. If the battery fluid

gets on your skin, eye, or clothes, rinse it off with plenty of water and consult with a

doctor.

4.8 Maintenance Precautions

About The Battery

●

●

●

●

●

●

●

●

●

DANGER

!

WARNING

!

WARNING

!

CAUTION

!

Page 10

5

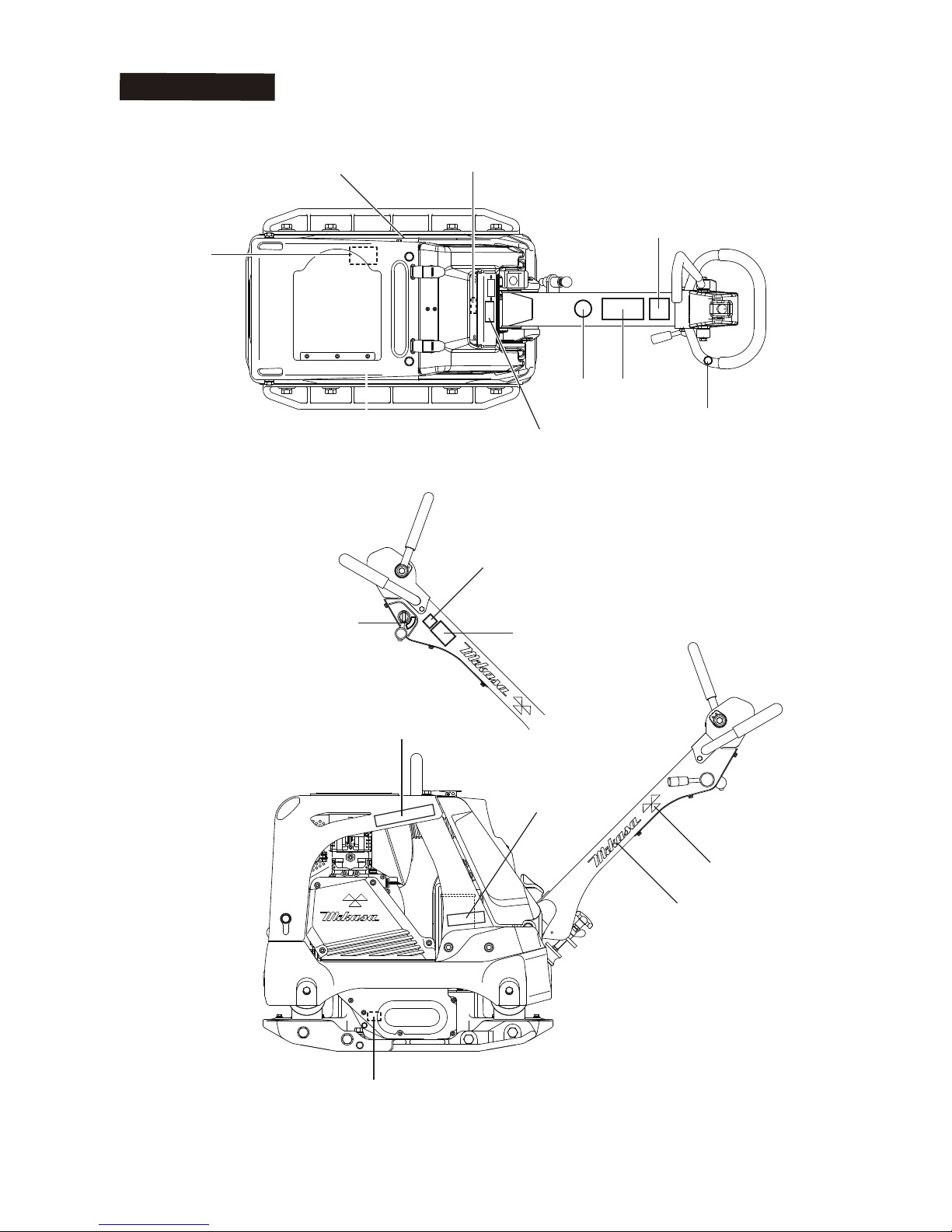

4.9 Label Position

2

18

17

1

7

15

15

14

5

16

3

4

6

10

12

13

※ The illustration is shown for model, "MVH-308"

Page 11

6

PART No. PART NAME Q’TY REMARKREF No.

9202-10100

9202-03330

9201-08800

9202-14960

9202-01950

9202-14950

9202-14730

9202-14740

9202-17640

9202-17650

9202-14750

9202-17130

9202-17110

9202-18140

9202-18130

9202-18150

9202-18160

9202-17870

9202-17880

9202-17890

9202-17730

9202-17770

9202-17810

9202-17740

9202-17780

9202-17820

Diesel Only

Diesel Only

308D

308G

408D,508D

408G

308

408

508

308

408

508

308

408

508

Not For Sale

1

1

1

1

1

1

1

1

1

2

1

2

2

1

1

1

1

1

1

1

2

2

2

1

1

1

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

14

14

14

15

15

15

16

16

16

17

17

17

18

DECAL,EC NOISE REQ.LWA108

EAR PROTECTION LABEL

DECAL, KEY SWITCH

DECAL, KEY OPERATION

DECAL,OIL SAE 10W-30

DECAL,REMOVE KEY

DECAL,DO NOT LIFTING

DEAL,LIFTING POSITION

DECAL COMPASS MARK 94MM

DECAL COMPASS MARK 110MM

DEAL,CAUTION ICONS/V-TYPE

DECAL,MIKASA MARK(W)200L

DECAL, MIKASA MARK 35X70

DECAL, E/G RPM 3400

DECAL, E/G RPM 3600

DECAL, E/G RPM 2400

DECAL, E/G RPM 3200

DECAL, MODEL MVH-308

DECAL, MODEL MVH-408

DECAL, MODEL MVH-508

DECAL,MODEL MVH-308 R-OR

DECAL,MODEL MVH-408 R-OR

DECAL,MODEL MVH-508 R-OR

DECAL,MODEL MVH-308 L-OR

DECAL,MODEL MVH-408 L-OR

DECAL,MODEL MVH-508 L-OR

PLATE,SERIAL NO.

9

8

16

Page 12

7

4.10 Descriptions Of Symbols Used On Warning Labels

Do not use.

(For rollers)

NPA-1473

Do not use.

(For rollers)

NPA-1475 NPA-1474

①Open Fuel Cock to start

②Turn Stop Switch to “I”(ON) position

③Close Choke Lever

④Pull Recoil Starter to start

⑤Return Choke Lever to open

①Return Throttle Lever fully until “O”(OFF) position

to stop work

②After cooling down enough, stop the engine to move Stop Switch to “O”(OFF) position

③Close Fuel Cock at the end

START

STOP

Starting, and stopping

P/N 9209-00110

DECAL, SET /MVH, MRH /EXP, EU

(NPA-1476 : “Diesel engine type

” is excluded.

)

(Refer to engine instruction manual for Diesel engine type)

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

Fire hazard

Stop the engine when refueling. Fire may

occur if a flame is near the tank fuel port.

⑧

Danger of hearing damage caused by

noise

Always use ear plugs while operating the

machine.

⑦

Be careful not to get burned.

Accidental burn may occur if you touch the hot

parts (engine, muffler, etc.) during operation or

immediately after the machine stops.

④

Be careful not to be caught in rotating parts.

Make sure the engine is stopped when removing the belt cover during a belt change.

③

Read the manual carefully.

Always read the operation manual and have

good understanding of operation before your

work.

①

Danger: poisonous exhaust gas

Carbon monoxide poisoning may occur if

the exhaust gas is inhaled. Do not operate

the machine in a poorly ventilated area.

②

⑩

⑨

NPA-1476

MVH-308GH

MVH-408GH

( )

⑤

Be careful not to approach danger

source.

During operation, Be careful not to approach

hot parts and rotating parts.

⑥

Refueling Hazard.

Don't fill the fuel tank while the engine is

running or hot.

Lifting position.

For lifting, use only one point hoisting hook,

and do not lift at any other part.

Do not lift the machine at this point.

Lifting by the handle is prohibited.

Page 13

8

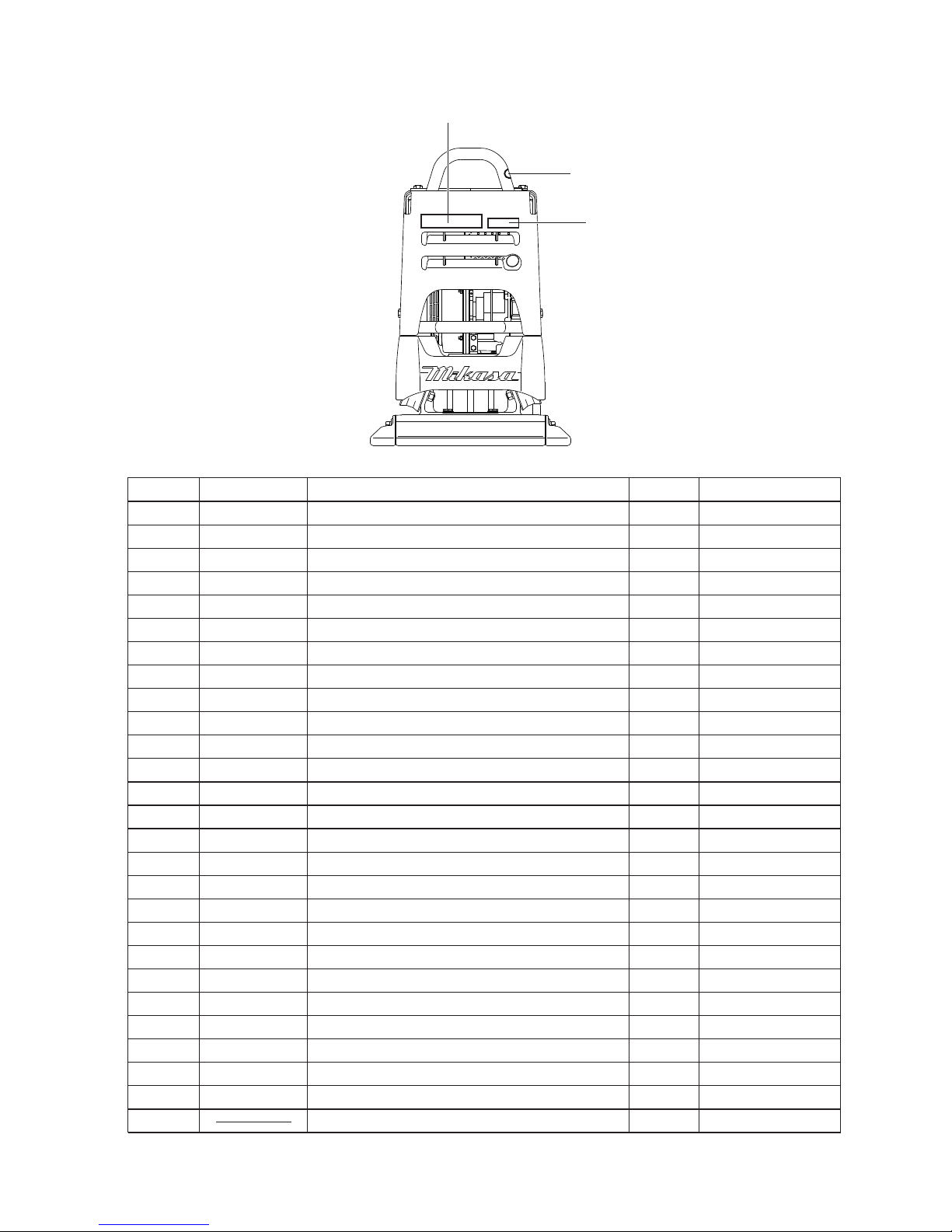

4.11 Control Unit Positions And Names

※ The illustration is shown for model, "MVH-308"

NPA−1764

A

A

NPA−1765

Oil filler for vibration case

(with oil gauge)

Oil filler for engine

(without oil gauge)

Rubber cover

Fuel tank cap

(Fuel inlet)

Hour / tacho meter

Cyclone cleaner

Hand pump

Key switch

Breather plug

(with plug cap)

Handle lock

(Stored position)

Grip

Compaction sensor

(COMPASS)

Oil drain plug for vibration case

Battery

Grip for adjusting handle height

Handle

(Stored position)

Rear cover

Center cover

Front cover

Vibrating plate

Extension plate (option)

Hook

Engine

Stopper for rear cover

Handle (Working position)

Throttle lever

Forward

Neutral

Reverse

Direction control lever

(variable speed adjustable)

Engine switch

(ON-OFF)

MVH-308GH

MVH-408GH

Page 14

9

5.SPECIFICATION

Main Dimensions

Compacting Board

Weight

Engine

Parformance

1540

1030

445(595,745)

445(595,745)

860

345(360,375)

HATZ,1B30

Air-cooled 4-cycle

diesel engine

4.9/3300

6.7/3300

3350

○

73/4400

45/4600

0~27

6.1

1540

1030

445(595,745)

445(595,745)

860

341(356,371)

YANMAR,L70N6

Air-cooled 4-cycle

diesel engine

4.9/3600

6.7/3600

3600

○

73/4400

45/4600

0~27

Overall Length

Overall Height (Handle)

Overall Width

Width

Length

Operating Weight

Manufacturer/Type

Type Of Engine

Maximum Power

Set Engine Revolution

Electric Start

Vibrating Frequency

Centrifugal Force

Max. Traveling Speed

Hand Arm Vibration

(Ahv)

mm

mm

mm

mm

mm

kg

kw/min

-1

PS/min

-1

r.p.m

Hz/VPM

kN/kgf

m/min

m/sec

2

mm

mm

mm

mm

mm

kg

kw/min

-1

PS/min

-1

r.p.m

Hz/VPM

kN/kgf

m/min

m/sec

2

MODEL

MVH-308DSY

MVH-308DSY-PAS

MVH-308DSZ

MVH-308DSZ-PAS

MVH-408DSY

MVH-408DSY-PAS

MVH-408DSZ

MVH-408DSZ-PAS

MVH-508DSZ

MVH-508DSZ-PAS

1570

1030

500(650,800)

500(650,800)

900

408(423,438)

HATZ,1B50

Air-cooled 4-cycle

diesel engine

6.7/2500

9.1/2500

2350

○

73/4400

55/5600

0~28

4.7

1570

1030

500(650,800)

500(650,800)

900

407(422,437)

YANMAR,L100N2

Air-cooled 4-cycle

diesel engine

7.0/3200

9.5/3200

3200

○

73/4400

50/5100

0~27

1600

1070

650(800)

650(800)

900

525(540)

HATZ,1D81

Air-cooled 4-cycle

diesel engine

8.9/2500

12.1/2500

2350

○

69/4150

65/6600

0~29

5.5

※

The number in parentheses is the dimension of the “extension plate(option)” with.

“( )” : MVH-308,408: (standard type, wide type)

MVH-508: (wide type)

Main Dimensions

Compacting Board

Weight

Engine

Parformance

Overall Length

Overall Height (Handle)

Overall Width

Width

Length

Operating Weight

Manufacturer/Type

Type Of Engine

Maximum Power

Set Engine Revolution

Electric Start

Vibrating Frequency

Centrifugal Force

Max. Traveling Speed

Hand Arm Vibration

(Ahv)

MODEL

Page 15

10

※

The number in parentheses is the dimension of the “extension plate(option)” with.

“( )” : MVH-308,408: (standard type, wide type)

MVH-508: (wide type)

Main Dimensions

Compacting Board

Weight

Engine

Parformance

Overall Length

Overall Height (Handle)

Overall Width

Width

Length

Operating Weight

Manufacturer/Type

Type Of Engine

Maximum Power

Set Engine Revolution

Electric Start

Vibrating Frequency

Centrifugal Force

Max. Traveling Speed

Hand Arm Vibration

(Ahv)

mm

mm

mm

mm

mm

kg

kw/min

-1

PS/min

-1

r.p.m

Hz/VPM

kN/kgf

m/min

m/sec

2

MODEL

MVH-308GE

1540

1030

445(595,745)

445(595,745)

860

310(325,340)

HONDA,GX270

Air-cooled 4-cycle

petrol engine

6.3/3600

8.6/3600

3600

×

73/4400

45/4600

0~27

2.8

1570

1030

500(650,800)

500(650,800)

900

364(379,394)

HONDA,GX390

Air-cooled 4-cycle

petrol engine

8.7/3600

11.9/3600

3200

×

73/4400

55/5600

0~28

3.7

1540

1030

445(595,745)

445(595,745)

860

307(322,337)

ROBIN,EX27

Air-cooled 4-cycle

petrol engine

6.6/4000

9.0/4000

3600

×

73/4400

45/4600

0~27

3.8

MVH-308GH MVH-408GH

Remarks:

Vibration Level is in comply with EU Directive 2002/44/EC and the

value is shown as 3 axix min vibration level.

Test course (Crushed gravel) is in comply with EN500-4.

The above values are sublect to change in case that the machine

is modified or/and the required regulations change.

Page 16

11

6.APPEARANCE

A

NPA−1765

NPA−1764

A

A

NPA−1765

MVH-308 (

Standard:595mm, Wide:745mm

)

MVH-408 (

Standard:650mm, Wide:800mm

)

MVH-308: 445mm

MVH-408: 500mm

MVH-308

MVH-408

MVH-508

MVH-308: 880mm

MVH-408: 930mm

MVH-308: 1540mm

MVH-408: 1575mm

1210mm

1360mm

1250mm

1400mm

1040mm

1600mm

900mm

MVH-308: 860mm

MVH-408: 900mm

Working position

Stored position

※ The illustration is shown for model, "MVH-308"

Extension plate (option)

Working position

Stored position

Standard

Extension plate (OPTION)

A

NPA−1765

(

500mm)

650mm

800mm

Page 17

Always stop the engine before inspection

Fig. 1

Upper level

Lower level

(refil needed)

Oil gauge

Fig. 2

Oil inlet at the top

Fig. 3

600cc

Effective

Oil gauge

(19mm wrench)

Drain plug

(14mm wrench)

7.INSPECTION BEFORE OPERATION

Part inspection sheet before work start

Check point

Visual inspection

Front cover & center cover

Fuel tank

Fuel system

Fuel filter

Engine oil

Vibration case oil

V-belt for vibrator

Oil pressure pipe line system

Traveling lever & part of system

Operation of traveling lever, rink origin

Bolt, nuts

Crack、Skewness

Falling off、Breakage、Crack、Looseness and falling off of bolt & nuts

Leak、Quantity of oil、 Dirt

Leak

Dirt

Leak、Quantity of oil、 Dirt

Leak、Quantity of oil、 Dirt

Crack、Tension

Leak、Looseness、Crack、Abrasion

Falling off、Breakage、Crack、Looseness and falling off of bolt & nuts

Operation check、Permissible error

Looseness、Falling off

Check item

The check is details of engine is referred to engine instruction manual independently.

Set the engine on a level surface to check

the oil level.If the oil level is low, add oil.

(Fig.1)

Only lubrication can be done from the top

for HATZ engine (1B and 1D). (There is no

oil gauge.) (Fig.2)

Use the following engine oil.

When pouring oil from the top (for 1B and

1D), oil might overflow if large amount of oil

is poured at one time. So, pour slowly.

●

※

Set the machine on a level surface, then

remove the oil gauge of the vibrator. Check

the oil gauge to see if the oil is at the specified level. Use engine oil SAE10W-30 as

lubrication oil.

Recommended oil quantity is 600cc. (Fig. 3)

Stop the engine when refueling.

Do not expose to open flames while refueling.

Do not fill to the rim because the fuel might

spill.

Wipe off well if a spill occurs.

Use clean automotive gasoline or automotive

light oil appropriate for the engine. Let the

fuel run through a filter when refueling.

Fuel inlet is located under the rubber cover

at the front cover top portion.

The fuel tank cap is equipped with a lock

lever. Unlock this lever before opening the

cap. (Only for HATZ engine)

(Fig.4)

●

●

●

●

●

●

●

●

7.1 Engine Oil

7.2 Vibration Case Oil

7.3 Refueling

CAUTION

!

DANGER

!

Quality: Diesel engine oil, Grade CC or above

Gasoline engine oil, Grade SE or above

Viscosity: SAE No. 30 at 20°C and above (summer)

SAE10W-30

12

Page 18

8.OPERATION

Set the fuel cock lever to the “ON” position

to let the fuel flow. (Fig. 6)

In cold weather or when the engine does

not start easily, set the choke lever to the

“Start” position. This is not necessary when

the engine is already warmed up. (Fig. 7)

1

The height of the handle is adjustable for

your comfort.(Fig.5)

Adjusting Handle height

Loosen the wing nut.Turn the grip clockwise

to raise the handle or counter clockwise to

lower the handle.When the handle is raised

to the desired height, tighten the wing nut.

2

8.1 Starting

Gasoline Engine

7.4 Handle

13

Fig. 4

Lock lever

Fuel tank cap

※

Only for HATZ engine

①

②

③

Put your finger at the lock lever

to pull it up towards you.

Unlock the lock lever.

Put your fingers to the tabs at

the two locations of the tank

cap to pull up towards you.

Grip

Wing nut

Fig. 5

Fig. 6

“ON”

Fuel cock lever

Fig. 7

Choke lever

Choke lever

“START”

“START”

“ON”

Fuel cock lever

HONDA (GX270,GX390) HONDA (GX270,GX390)

ROBIN (EX27) ROBIN (EX27)

Page 19

Move the throttle lever to the idle position.

(Fig. 8)

When the engine is stopped, the hour

tachometer is always showing "Cumulative

time".(Fig.9)

Turn on the engine switch on the rear cover.

(Fig.10)

Hold the recoil starter grip, and pull it a little.

You will feel a slight resistance. Then, pull it

hard to run the engine. be careful not to pull

too hard, or the rope might break or come

off. Allow the starter rope to slowly move

back into the case while keeping the grip

grabbed. (Fig.11)

3

4

5

6

After the engine has started, while you hear

some explosion loud noise, gradually move

back the choke lever until it is wide open.

(Fig.12)

When the choke lever is set to “Start”,

gradually move it back toward the “Operation” direction while making sure the

engine revolution stabilizes.

After the engine has started, warm up the

engine at low speed for 2 to 3 minutes. This

is especially important in cold weather.

“Rotation number” is displayed during operation.(Fig.13)

7

8

9

14

Fig. 10

Fig. 11

Starter grip

Recoil starter

Fig.13

Rotation number

Cumulative time

ENGINE TACH

HOUR&METER

HRS

TP-22

ENGINE TACH

HOUR&METER

RPM

TP-22

Idle position

Throttle lever

Handle

Fig. 8

ENGINE TACH

HOUR&METER

HRS

TP-22

Fig. 9

Choke lever

“OPERATION”

“OPERATION”

Choke lever

HONDA (GX270,GX390)

ROBIN (EX27)

Fig. 12

Page 20

Set the fuel cock lever to the “ON” position

to let the fuel flow.(Fig. 14)

(

Only for YANMAR engine

)

Starter motor

Insert the key to the key switch.

Open the throttle lever to the idling position.

(Fig.15)

Turn the key to "Run" position. (Fig.16)

The buzzer starts. After "HA" is displayed on

hour tachometer, the display will change immediately to "Cumulative time".(Fig.17)

Turn the key further to the “START” position

to start the engine. After the engine is

started, take your hand off the key.(Fig.16)

After the engine revolution rises, the buzzer

stops.

“Rotation number” is displayed during operation.(Fig.18)

After the engine has started, warm up the

engine at low speed for 2 to 3 minutes. This

is especially important in cold weather.

When the engine does not start, do not run

the cell motor continuously for more than

five seconds. Move the key back to the

“RUN” position, then wait for about 10 seconds to restart.

While the engine is running, never turn the

key switch to the “START” position.

Recoil motor

Insert the key to the key switch.

Open the throttle lever to the idling position.

(Fig.15)

Turn the key to "Run" position. (Fig.16)

The buzzer starts. After "HA" is displayed on

hour tachometer, the display will change immediately to "Cumulative time".(Fig.17)

Hold the recoil starter grip, and pull it a little.

You will feel a slight resistance. Then, pull it

hard to run the engine. be careful not to pull

too hard, or the rope might break or come

off. Allow the starter rope to slowly move

back into the case while keeping the grip

grabbed. (Fig.19)

●

1

2

3

4

5

6

●

●

●

1

2

3

4

Diesel Engine

15

Starter grip

Recoil starter

Fig. 19

DIESEL

ENGINE TACH

&HOUR

METER

HRS

DIESEL

ENGINE TACH

&HOUR

METER

RPM

Fig.18

Rotation number

Cumulative time

Diesel Engine

Fig.16

DIESEL

ENGINE TACH

&HOUR

METER

DIESEL

ENGINE TACH

&HOUR

METER

HRS

Fig.17

"HA" is displayed at the

operation position, then

immediately it will change

to "Cumulative time".

HA: 1B30 or 1B50

YA: L70 or

L100

1081: 1D81

Stop position

Throttle lever

Handle

Idle position

Fig.15

CAUTION

Fig. 14

“ON”

Fuel cock lever

YANMAR (L70N,L100N)

Page 21

16

When this machine is used on ground that contains clay, the ground surface tends to stick to

the vibrating board, and the machine travel

speed becomes slower. In this case, check the

bottom of the vibrating board to see if there is

any clay adhered to the board.

This machine cannot perform well on clay

and other type of ground with a high water

percentage. Drying the ground is recommended to make the ground water percentage appropriate for the machine to get good

compacting performance.

If you want to suspend the work, to return

quickly to the idle position the throttle lever.

(Fig.22)

Compaction sensor (Compas) is a system

that uses acceleration sensor to show realtime soil stiffness with LED (light-emitting

diode) lights based on the number of compactions done.

This compaction sensor improves efficiency

of compaction work because it can prevent

the area already properly compacted from

being compacted more than necessary and

to identify the area where more compaction

is needed. The sensor also has a function to

detect abnormality such as vibration trouble

(insufficient vibration frequency), ground

trouble (soft soil) and functional issues.

(Fig. 23)

NOTE

What is shown by the compaction

sensor (Compass) is not the absolute

value of the soil stiffness.

When using the sensor, always calculate

appropriate soil stiffness by conducting

plate load test and dynamic load test

(FWD), etc. to calibrate the LED lighting

level with the actual measurement value.

3

4

Throttle lever

Handle

Idle position

Operation

position

Fig.22

When you move to the idle position the

throttle lever, please do not return to the operating position rapidly the throttle lever before

the rotational speed is possible fall.

CAUTION

!

8.3 Compaction Sensor (Compas)

Reverse

Neutral

Forward

Fig.21

Direction

control lever

Throttle lever

Handle

Idle position

Operation

position

Fig.20

After the engine has started, warm up the

engine at low speed for 2 to 3 minutes. This

is especially important in cold weather.

Do not pull the starter knob all the length of

the rope.

After engine start, do not let the starter knob

off your hand, but return it slowly by holding it.

If you let the knob off at the position where it

is pulled, the rope retracts suddenly, leading

to breakage of the recoil starter and engine.

While the engine is running, never turn the

key switch to the “START” position.

During operation, pay sufficient attention to

dangerous objects, obstacles, in the direction of your work and surrounding area.

While in operation, never touch the moving

parts and high temperature parts of the machine.

If the throttle lever is opened suddenly, the

machine starts to operate. When you operate

the throttle lever slowly, it may cause failure

of the clutch causing the bad connection.

(Fig.20)

Use the back and forth movement direction

control lever to make the machine move

backward and forward. When the direction

control lever is pushed forward, the machine

moves forward, when pulled backward, the

machine moves backward.

At neutral, the machine vibrates staying at

the same location.(Fig.21)

5

●

●

●

●

●

1

2

CAUTION

8.2 Operation

CAUTION

!

Page 22

17

If that happens, because you cannot expect

sufficient compaction, do ground improvement work before proceeding with the compaction process. (Fig. 26)

Detection of vibration abnormality

During operation when appropriate vibration

frequency cannot be achieved because of

the specified engine revolution or the loosened drive belt, or when the vibration frequency is too high, it is indicated by the

flashing light. (Fig. 27)

Sensor wire disconnection

(Between acceleration sensor and sensor

panel)

If flashing of red LED and green LED alternates as shown in the figure, please check

the sensor wire because there is a possibility that it is disconnected. (Fig. 28)

Power cable disconnection

(Between battery and sensor panel)

If there is no power even when the key

switch is turned on, please check because

there is a possibility that the power cable is

disconnected.

Function to detect electric system abnormality

3-2

4

4-1

4-2

1

2

3

4

5

6

7

8

!

CM-01

Ground trouble or soft ground

(Red only: Lighted)

Compaction Analyzing System

Fig.26

1

2

3

4

5

6

7

8

!

CM-01

Compaction Analyzing System

Vibration abnormality due to insufficient revolution

(Green: Flashing)

Fig.27

(Red: Flashing)

(Alternating)

(Green: Flashing)

4

5

6

7

8

!

CM-01

4

5

6

7

8

!

CM-01

Fig.28

Function to detect abnormality

Normal compaction (during compacting)

Green LED lights up when the sensor finds

that the machine is in normal compaction

process. When the revolution goes up, and

compaction starts, the yellow LED ① lights

up, and as the compaction proceeds, the

number of the lighted LEDs increases from

②

to ⑧. After the LED light that was calibrated with the measured soil stiffness

value lights up, the compaction process

completes. (Fig. 24)

Normal compaction (Compaction limit)

Compaction limit is reached when all the

yellow LEDs from ① to ⑧ have lit up and

the red LED lights up. At this point, this machine cannot do any further compaction. If

higher soil stiffness value is required, please

use a machine of higher level. (Fig. 25)

Detection of ground trouble and soft ground

For a case of unstable ground or soft

ground (soil containing clay) for which the

use of this machine is not suitable, only the

red LED lights up, with no yellow LED illuminated.

1

2

3

3-1

Normal operation (Green: Lighted)

Vibration abnormality (Green: Flashing)

Compaction condition (Yellow (1 - 8): Lighted)

Compaction limit (Yellow + Red: Lighted)

Soil problem (Only red: Lighted)

1

2

3

4

5

6

7

8

!

CM-01

Compaction Analyzing System

Fig.23

Normal operation (Green: Lighted)

Initial compaction (Yellow ①: Lighted)

1

2

3

4

5

6

7

8

!

CM-01

Compaction Analyzing System

Fig.24

During compaction (Yellow ① to ④ : Lighted)

1

2

3

4

5

6

7

8

!

CM-01

Compaction Analyzing System

Fig.25

Page 23

Diesel Engine

18

34When the key switch is moved from “ON

(Operation)” to “OFF(Stop)”, the buzzer

stops. (Fig. 32)

Shut the fuel cock.(Fig. 33)

(

Only for YANMAR engine

)

Stop position

Throttle lever

Handle

Idle position

Fig.31

Fig.32

CAUTION

If the throttle lever is moved from the idling

position to the stop position, the engine revolution decreases. Before the engine stops

completely, do not move the throttle lever sud-

9.STOPPING THE MACHINE

Move the throttle lever to idle position.

Run the engine for 3 to 5 minutes at low

speeds to cool it down before stopping.

Turn the engine switch to the OFF position,

then the engine stops. (Fig. 29)

Shut the fuel cock.

(Fig. 30)

Move the throttle lever to idle position.

Run the engine for 3 to 5 minutes at low

speeds to cool it down before stopping.

Move the throttle lever to the stop position

to stop the engine.

In case of a diesel engine, when the engine

stops, the buzzer sounds.(Fig.31)

1

2

3

1

2

Fig.29

Gasoline Engine

Fig. 30

Fuel cock lever

“Close”

Fuel cock lever

HONDA (GX270,GX390)

ROBIN (EX27)

“Close”

Fig.33

YANMAR (L70N,L100N)

“Close”

Fuel cock lever

Page 24

19

10.TRANSPORTAION AND STORAGE

Make sure there is no breakage of guard

frame and anti-vibration rubber nor loosened or missing bolts.

Always stop the engine when lifting.

Use an intact wire rope without any deformation with sufficient strength.

Slowly lift upward without applying any

impact. Never let people or animals go

under the lifted machine.

For safety reasons, do not lift to a height

that is higher than necessary.

Use a crane for loading and unloading the

machine.

Designate a person to guide the loading and

unloading, and always work under the

instruction of that person.

When lifting, always use a hook. (Fig. 34)

Never lift by using the hook on the handle.

Stop the engine when the machine is transported.

Always drain the fuel before transportation.

Fix the machine securely to prevent the machine from moving or falling.

When putting the handle into the stored

condition (vertical condition), make sure it is

properly locked.

When transporting, remove the starter key.

Wash off dirt and soil from every part with

water. While washing, be careful not to let

the water splashed on the electric components such as the battery and the engine

muffler part.

●

●

●

●

●

1

2

3

●

●

●

●

●

●

●

●

●

●

Store in a dry area away from direct sunlight

after putting the cover over the machine to

prevent dust and dirt buildup.

Do not leave the machine outdoors. Keep it

indoors.

When not used for a long period of time,

drain the fuel from the fuel tank, and either

disconnect the battery terminal or remove

the battery itself.

When the machine is used after a long storage period, check the level of engine oil and

battery capacity.

10.1 Loading And Unloading

10.2 Transportation Precautions

10.3 Storage

WARNING

!

WARNING

!

Fig.34

Hook

Page 25

11.REGULAR CHECK AND ADJUSTMENT

11.1 Inspection And Maintenance Schedule Table

20

For details about the check and maintenance of the engine, please refer to the attached engine operation manual.

Caution: The above table shows the check frequency for standard condition.

The check frequency may vary depending on the condition in which the machine is used.

For check of bolt and nut looseness and tightening, please see the following tightening torque list.

Tightening torque list (unit: kgf-cm, 1kgf-cm=9.80665N-cm)

6mm

8mm 10mm

12mm 14mm

16mm 18mm 20mm

4T(SS41)

70

150

300

500 750

1,100

1,400

2,000

6-8T(S45C)

100

250

500

800 1,300

2,000

2,700

3,800

11T(SCM3)

150

400

800

1,200

2,000

2,900 4,200

5,600

When the mating material is aluminum.

100

300~350 650~700

Thread diameter

Material

(Bolts used on the machine are all right-hand thread.)

Check parts

Appearance

Fuel tank

Fuel system

Engine oil

Shock absorber

Hand pump

Vibrator oil

Hydraulic pipe system

Air cleaner

Guard frame

Back and forth motion

lever, linking parts

Back and forth motion

lever operation

Bolts and nuts

Duct hose

Engine oil

Engine oil filter

Engine oil

Engine oil filter

Vibrator oil

Hydraulic oil

Battery terminal

V-belt for vibrator

Clutch

Vibrator oil

Hydraulic oil

Fuel filter

Engine oil filter

Fuel

pipes

Air cleaner element

Hydraulic hose

Cyclone cleaner

Check frequency

Daily

(before starting)

Every 20 hours

Every 100 hours

Every 200 hours

Every 300 hours

Every 2 years

Irregular

Check items

Flaw, deformation

Leakage, oil level, dirt

Leakage, oil level, dirt

Leakage, oil level, dirt

Crack, damage, wear

Leakage

Leakage

Leakage, looseness,flaw,

wear

Dust on sponge

Breakage, flaw, loosenedor

missing bolts and nuts

Missing, breakage,

flaw,looseness or m

issing-

bolts and nuts

Operation check, play

Looseness, missing

Crack, damage

Replace only afterthe first

20 hours

Replace only afterthe first

20 hours

Change

Washing

Leakage, oil level, dirt

Leakage, oil level, dirt

Cleaning

Flaw, tension

Dirt, flaw, wear

Change

Change

Change

Change

Change

Change

Change

Cleaning

Oils

Light oil, gasoline

Engine oil

Hydraulic oil

Engine oil

Hydraulic oil

Engine oil

Engine oil

Hydraulic oil

Engine oil

Hydraulic oil

Page 26

For a comfortable maintenance work.

Do maintenance work in a place with a flat

and hard surface to keep the machine

stable.

Start your work after the machine and

engine cool down completely.

Be careful to catch the finger when opening

and closing the front cover.

Do not touch the hot part because the

engine and muffler become very hot.

Remove the bolts (M14x35) on the front

cover. Loosen the bolts (M14x35) on the

side of front cover. (Do not remove.) (Fig.35)

Hold the side of front cover, and pull up to

open position.(Fig.36)

Open the front cover slowly.(Fig.37)

●

●

●

●

1

2

3

Hold the hook and the front side of front

cover, and pull up to open position.(Fig.38)

Open the front cover slowly.(Fig.39)

Return the front cover to original position

slowly.Tighten the bolts in the specified

torque. (Fig.40)

Do not return the front cover in its open position.

Do not start the engine when opening the

front cover.

Tighten the bolts firmly.

2

3

4

●

●

●

21

11.2 Opening The Front Cover

CAUTION

!

Fig.38

Pull up

Fig.35

Top of front cover

bolts (M14×45)

Side of front cover

bolts (M14×45)

Fig.40

Front cover top

BOLTS (M14×45)

Side of front cover

BOLTS (M14×45)

Fig.37

OPEN

Fig.39

OPEN

CAUTION

!

Fig.36

Pull up

Diesel Engine

Gasoline Engine

Bolt M14X45

176.6N・m

(130.2ft・lbf)

Size

Apply Loctite

#243

Tightening

torque

Remarks

Open position

Open position

Page 27

22

Perform the first engine oil change after 20

hours of operation, then change at every

100 hours.(Fig.41)

The Engine Air Cleaner

When the air cleaner element becomes

dirty, the engine does not start smoothly,

and sufficient output cannot be obtained.

Machine operation will be affected and the

engine life will be shortened greatly. Do not

forget to clean the element. (For details,

please see the separate engine operation

manual.) If the element cannot be cleaned,

replace it with a new one.(Fig.42)

Cyclone Cleaner

Always clean Dust Pot. Clogged Dust Pot

leads to reduce cyclone effect with easy

wear of Cleaner Element.

How to clean Dust Pot

Latch off to remove Dust Pot. (Fig.43)

●

●

●

i)

ii)

iii)

1

2

●

11.3 Changing The Engine Oil

11.4 Cleaning The Air Cleaner

11.5 Checking/Changing The V-belt

And Clutch

Clean Dust Pot inside with water and neutral detergent.

Latch up securely to return Dust Pot to Air

Cleaner.(Fig. 44)

Check of V-belt (Fig. 45)

At every 200 hours, remove the belt cover

(top) to check the tension of the V-belt.

The flexibility of the belt should be about

10 mm when pushed strongly with your

finger at the mid-point between the axes.

When the V-belt is loose, the engine

power is not transmitted well, resulting in

poor compacting force and shortening the

life of the V-belt.

Changing the V-belt

Removing the V-belt

Remove the top and bottom belt covers.

Put a wrench (19mm) on the tightening

bolt of the vibrator pulley (lower side). Put

a piece of cloth at the center of the left

side of the V-belt, and pull the belt strongly

towards you. While pulling, turn the

wrench clockwise, then remove the V-belt.

Fig.44

1

2

Lock

Dust exhaust

Fig.41

Engine oil drain

(Drain bolt)

Fig.42

Engine air cleaner

Dust pot

Latch

Dust exhaust

Fig.43

CAUTION

!

Be careful to avoid pinched fingers.

CAUTION

!

Do not use organic solvent like paint thinner, which may cause damage or deformation of Dust Pot.

Clutch

V-belt

Vibration pulley

Fig.45

Page 28

●

●

●

●

●

●

●

●

●

1

2

23

11.6 Checking/Changing The vibrator Oil

11.7 Checking/Changing The Hydraulic Oil

Installing the V-belt

Set the V-belt on the lower side of the vibrator pulley. Push the V-belt to the left side of

the upper clutch. Similar to removing the

V-belt, turn the wrench clockwise to install.

Stop the engine when inspecting or changing the V belt.

Be careful not to have your hand or clothes

get caught between the V belt and the

clutch. Always wear work gloves.

At every 100 hours of operation, set the

machine on a level surface and remove the

oil gauge of the vibrator. Check the oil level

to see if it is within the allowable range.

(Fig.46)

Change the vibrator oil at every 300 hour

operation. Drain the oil from the drain plug.

For draining, put a beam under the compacting board at the other side of the drain

plug to tilt the machine.

Use engine oil SAE 10W-30 as lubrication oil.The quantity used is 600cc.

Appropriate maintenance is required to

ensure safe and efficient operation of the

machine. Pay special attention to the parts

used for lifting, if they are not maintained

properly, it might result in a serious accident.

When checking the vibrator oil, clean the

oil port beforehand to prevent dust and

other foreign materials from falling into the

oil. Whenever there is an oil leakage from

the vibrator, check the oil level.

In case that oil is drained from Drain Plug,

some oil still remains in Oil Pan. So be

sure to check oil level correctly by Oil

Gauge after filling oil.

Do not fill oil with excessive volume

(600cc). It may cause the terrible fuel consumption and lower machine performance

as the result of engine overload.

Check the hydraulic oil

Check the hydraulic oil at every 100 hours’

operation. By making the handle bar vertical (done at the time of storage), remove

the breather plug at the top of the hydraulic hand pump to see if the hydraulic oil is

at the specified level (OIL LEVEL).

(Fig. 47)

Changing the hydraulic oil

Remove the plug cap of the hand pump.

Then remove the breather plug (with

24mm wrench) before removing the hydraulic hose connected to the cylinder on

the vibrator side. Set the run lever to

reverse, then drain the hydraulic oil from

the pump.(Fig.47, 48)

After the oil is drained, attach the hydraulic

hose again to the cylinder on the vibrator

side. With the direction control lever at the

forward-most position, fix to the hook with

a rope to immobilize.

(Fig.48, 49)

CAUTION

!

CAUTION

!

Fig.46

600cc

Effective

Oil gauge

(19mm wrench)

Drain plug

(14mm wrench)

Fig.48

Air releasing plug

Cylinder

Hydraulic hose

Fig.49

Direction

control lever

Hook

Forward-most position

Fig.47

Breather

plug

Plug cap

OIL LEVEL

Hand pump

Page 29

3

4

5

6

●

●

●

1

2

3

4

24

11.8 Battery

How to remove the battery

Remove the stopper at the two locations

on the top portion of the rear cover to

open the rear cover.(Fig.51)

Loosen, but not remove, the M8 bolts (2

bolts) used for cyclone cleaner attachment. Take out the cyclone cleaner downward.(Fig.52)

Take off the nuts and remove the battery

holder. After tilting the battery backward,

disconnect the battery terminal. When

doing so, always disconnect the black terminal on the minus side first.

By holding the top surface handle, pull

upward to remove the battery from the

machine.(Fig.53)

If an old battery is used, even when the battery checker is not lighted (indicating charging

level low), the cell starter might not operate

because of low charging level. If that happens, change the battery with the new one.

Pay sufficient attention so that the battery terminal will not touch the frame.

Pour hydraulic oil(550cc) from the hand

pump breather plug attachment hole.

(Fig.47)

Remove the air releasing plug of vibrator

cylinder. Then oil will come out from the

air releasing plug. After air bubbles stop

coming out, attach the plug. Tighten securely. (Fig.48)

Then release the direction control lever

and move the lever forward and reverse

several dozen times (until air bubble not

be found). Stay the lever at the forward

position for 10 seconds every time.

(Because the check valve is opened at the

maximum forward position and air bubble

will come out from the oil tank of the hand

pump).(Fig.49)

In case the air bleeding is insufficient,

repeat the procedure of above “4” and “5”.

Attach the hand pump breather plug, put

on the plug cap. After making sure the hydraulic oil in the pump is at OIL LEVEL,

attach the breather plug.

Hydraulic oil:

Shell Terrace Oil #32 or equivalent

Checking the battery

The standard battery installed is a maintenance free battery. It is not necessary to

supply battery fluid. In case of a sudden

voltage drop, the battery cannot be

charged quickly, so it has to be replaced

with a new one.

Check of battery capacity by battery

checker

When the battery charging level gets low,

the battery checker of the hour tachometer

lights up in red.(Fig.50)

The level of the hydraulic oil in the hand pump

should always be at OIL LEVEL. If the level is

higher, the oil bursts out from the breather plug.

CAUTION

!

CAUTION

!

CAUTION

!

Fig.51

Rear cover

Stopper

Fig.50

DIESEL

ENGINE TACH

&HOUR

METER

Battery checker

HOUR TACHOMETER

Fig.52

M8 bolts (2 bolts)

CUT

Cyclone cleaner

Page 30

5

25

For assembly, take the reverse steps described above, but when attaching the battery terminal, start with the red terminal of

the plus side. Also, attach securely so that

it will not get loosened by vibration.

When charging the battery, always

remove it from the machine.

CAUTION

!

Nut

Battery holder

Battery

Handle

Fig.53

MVH-308

L W H SIZE

MVH-408

MVH-508

129

175

175

129

175

129

175

175

175

175

175

175

175

175

203

175

190

203

190

203

203

175

190

203

203

175

190

203

55B24L(JIS) No.51R(BCI)

DIN 55Ah or equivalent

55B24L (JIS) No.51R(BCI)

※

75D23L(JIS) No.35(BCI)

DIN 55Ah or equivalent

75D23L(JIS) No.35(BCI)

DIN 75Ah or equivalent

JIS/BCI TYPE Maximum capacity

DIN TYPE Maximum capacity

Maximum capacity

Maximum capacity

STD

Replacement

STD

Replacement

STD

Replacement

238

245

245

245

245

238

232

245

245

245

232

245

245

245

6 Mountable battery size table

Page 31

12.TROUBLESHOOTING

12.1 Gasoline Engine

(1) Starting problems

(2) Operation problems

(3) Recoil starter problems

26

Fuel is supplied, but

the igniter plug does

not ignite.

Electricity reaches

the high voltage cable.

Electricity does not

reach the high

voltage cable.

Bridging the igniter plug.

Carbon accumulated on the igniter plug.

Short circuit due to insulation problems of

the igniter plug.

Inappropriate spark gap

Short circuit of the ON-OFF switch

Ignition coil problems

Dirt of the point or inappropriate gap.

Breakage of ignition coil or short circuit

The wrong fuel is used.

Mixing of water or foreign materials

The air cleaner not working

Intake/exhaust valve is stuck or pushed up

Piston ring, cylinder wear

Cylinder head, igniter plug tightening problem

Head gasket, igniter plug gasket breakage

Dirt of air cleaner.

Carbon accumulated in the cylinder.

Carburetor oil level inappropriate.

Compression is

good,

No fuel in the fuel tank.

Fuel cock does not open properly.

Clogging of fuel filter.

Clogging of tank cap air hole

Air trapped in the fuel pipe.

Compression is

not good,

Fuel supplied, and

the igniter plug

ignites.

Fuel does not reach

the carburetor.

Compression is

good and no firing

problem.

Insufficient compression (see the item “compression is not good.” )

Compression is

good, but no firing.

Water mixed in fuel

Dirt of the igniter plug.

Ignition coil problem

Occasional short circuit of the ignition coil

Lowered power.

Engine overheating

Carbon accumulated inside combustion chamber and exhaust hole.

Spark plug thermal value inappropriate

Dirt and breakage of the cooling fin.

Revolution fluctuation

Governor adjustment inappropriate

Governor spring problems

Fuel does not flow properly.

Air taken from intake pipe system

Recoil starter operation not good

Clogging of foreign materials at the rotating part.

Weakening of the spiral spring

Page 32

12.2 Diesel Engine

(1) Starting problems

(2) Insufficient output and operation problems

27

(A) In case of compression problems

(B) In case of inappropriate fuel injection inside the combustion chamber

(C) Fuel and compression pressure appropriate, but the engine does not start.

Intake/exhaust valve upthrust

Decompressor adjustment problems

Contact with seat not close enough.

Piston ring wear

Cylinder wear

Cylinder, cylinder head mating surface problems

Nozzle seat looseness

Clogging of the tank cap air hole.

Clogging of the fuel filter

Fuel cock not open

Air inside the fuel pipe

Injection pump barrel, plunger stuck

Nozzle hole clogging

Nozzle needle stuck

No compression at all

Almost no compression

Fuel flow low or no flow

Fuel not injected inside

the combustion chamber

No fuel in the fuel tank

Mixing of water or foreign materials

Does not reach

the starting revolution.

Insufficient compression

Engine overheating

with black smoke

Revolution fluctuation

Inappropriate starting operations

Engine oil viscosity high, engine oil is very dirty.

Air trapped inside the fuel pipe.

See the comment for insufficient compression.

Dirt and breakage of cooling fin

Mixing of water inside the fuel filter

Carbon accumulated in the combustion chamber or exhaust hole.

Smoke set inappropriate

Overload

Inappropriate injecting timing

Nozzle clogging

Governor fork and sleeve mating surface problems

Governor spring problems

Fly plate and sliding part wear and operation problems

Page 33

12.3 Main Body

28

Valve open/close timing inappropriate

Clogged exhaust hole, muffler

Overload

Piston, cylinder ring wear

Nozzle hole clogging

Piston ring stuck

Wrong assembly (upside down) of piston ring

Inappropriate injection timing

Inappropriate valve open/close timing

Looseness of injection pump joint

Leakage from fuel passage

Clogging of the air cleaner element

Inappropriate fuel due to mixing of impurities

Overload

Use of wrong oil

Failure to change oil

Breakage of the air cleaner element or failure to clean the air cleaner

Too much oil

Wrong assembly of the governor system

Detached injection pump rack

Insufficient engine output and inappropriate high speed set revolution

Slipping of clutch

Slipping of V-belt

Too much vibrator oil

Failure inside vibrator

Hand pump problems

Inappropriately installed forward/backward motion lever

Breakage of the oil hose

Mixing of air in the hydraulic oil

Clogging of foreign materials in the check valve inside the hand pump

Breakage of the piston bearing in cylinder

V-belt coming off, slipping and breakage

Slipping of the clutch

Locking of the vibrator

Breakage of the piston bearing in cylinder

Piston inside the hand pump not moving smoothly

Vibrator cylinder piston does not move smoothly

Firing problem with

white smoke

(when unloaded)

Fuel consumption too

high (black smoke)

Stopped suddenly with abnormal noise

Searing or damage of the piston, rod, etc.

Lubrication oil diluted and increased

.

Wear on the injection pump barrel or plunger

Engine does not stop

even though the fuel

supply is cut

(or over-running)

Low travel speed and

vibration weak

Move forward or

backwards, but unable

to switch between back

and forth motion

No forward,

backward motion

Movement of l

ever heavy

Engine revolution

does not increase.

Extensive wear on

sliding parts or

stuck piston rings

Page 34

G

114399-78260

55B24L

+

-

CB104

CA104

CB104

CA104

IG

ST

BAT

M8

JASO

D601

20T

DC12V 0.8kW

AV20

AV20

7122-2046

7123-2249

121252-39450

6040-2111

6030-2981

Compaction

sensor panel

Compaction sensor

G

Dynamo

Dynamo

114399-78260

White

White

White

White

White

Black

White

White

Red

Red

Red

Red

Red

Green

Green

Green

Starter

Starter

55B24L

Regulator

+

-

CB104

CA104

IG

ST

BAT

Starter switch

Starter switch

Battery

Battery

M8

BOLT

BOLT

AV1.25

AV1.25

AV1.25

White

Black

Black

Red

AV1.25

AV1.25

AV1.25

JASO

D601

20T

DC12V 0.8kW

AV20

AV20

YAZAKI

YAZAKI

YAZAKI

YAZAKI

7122-2046

7123-2249

Oil pressure switch

Oil pressure

switch

121252-39450

AV0.5(

Sky-blue

)

AV0.5(

Orange

)

AV0.5(

Sky-blue

)

AV0.5(

Orange

)

SUMITOMO

SUMITOMO

SUMITOMO

SUMITOMO

6040-2111

6030-2981

(Green/

White)

CB104 CB104

CA104

CA104

CB104

(Green/

White)

(Green/

White)

(Green/

White)

Palus

DC12V

(Black/

Green)

Hour/tacho meter

DC12V

CA104

CB104

CA104

CB104

Palus

(Black/Green)

(White)

CA104

(White)

Hour/tacho meter

Regulator

(Green/

White)

CB104 CB104

CA104

CA104

CA104

CB104

(Green/

White)