Mikasa MVH-308, MVH-508, MVH-408 Service Manual

SERIES

MVH-308

MVH-408

MVH-508

SERVICE MANUAL

REVERSIBLECOMPACTOR

TABLE OF CONTENTS

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

5.1

5.2

8.1

8.2

8.3

8.4

8.5

9.1

9.2

9.3

9.4

9.5

9.6

9.7

9.8

9.9

10.1

10.2

10.3

1

2

2

2

2

2

3

3

3

5

5

9

9

10

11

18

21

21

22

22

23

23

24

24

25

28

29

30

...............................................................................................

............................................................................

........................................

...........................

..............................................................................

.................................................................................

...............................

........................................................

.....................................................................

.................................................................................

.....................................................................................

...................................................................

............................................................................................

..............

.................................................................................

...............................................................

.........................................................

..............................................................................

.......................................................................

.......................................................................

.......................................................................

..............................................

.......................................................

.....................................................

..................................................................................................

....................................................................................

........................................................................................

.............................................................................................

Work Site

Clothes And Protective

Cautions During Refuelinglothes And Protective

Prevention Of Burn And The Accident Of Getting Caught

Tools And Equipment

Handling Of Battery

Use Of Genuine Parts And Appropriate Oil And V-belt

Tightening Torque Of Bolts And Nuts

Disposal Of Waste Material

Appearance Check

Operation Check

How To Remove The Battery

Control Part

Main Body Part (Separation Of Engine Base And Vibrating Plate Assembly)

Vibrator Partontrol

Hand pump & Accumulator CP

Inspection and Maintenance Chart

Oil Application Table

Opening The Front Cover

Changing The Engine Oil

Cleaning The Air Cleaner

Checking/Changing The V-belt And Clutch

Checking/Changing The Vibrator Oil

Checking/Changing The Hydraulic Oil

Battery

Gasoline Engine

Diesel Engine

Main Body

1. INTRODUCTION

1

2. WARNING SIGNS

1

3. CAUTIONS FOR MAINTENANCE TO SECURE SAFETY

1

4. TOOLS

4

5. INSPECTION PROCEDURE

5

6. SPECIFICATION

6

7. CAUTIONS BEFORE MAINTENANCE WORK

8

8. DISASSEMBLY AND ASSEMBLY

9

9. REGULAR CHECK AND ADJUSTMENT

21

10. TROUBLESHOOTING

28

11. WIRING DIAGRAM

31

ࠉࠉ

1

1䠊INTRODUCTION

For correct operation, maintenance and service of Reversible Compactor, please read the separate operation manual

before your work for your safe work.

For the handling of engine, please read the separate engine operation manual and maintenance/service manual.

This service manual explains the maintenance standard and how to disassemble and assemble for Reversible Compac-

tor. Please read this service manual for a better understanding of the maintenance standard, the structure and function

of each part.

To improve the performance and quality of this machine, the change might be made in this machine without notice. If

you have any questions, please contact with our distributor. For parts list, Mikasa WEB parts list is available at our

homepage (http://www.mikasas.com/).

䖃

䖃

䖃

䖃

2䠊WARNING SIGNS

The triangle shaped marks used in this manual and on the decals stuck on the main body

indicate common hazards. Be sure to read and observe the cautions described.

Warning labels indicating hazards to humans and to equipment.

DANGER

䟿

WARNING

䟿

CAUTION

䟿

CAUTION

䟿

Denotes an extreme hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or adhered to, is

likely to result in serious injury or death.

Denotes a hazard. It calls attention to a procedure, practice, condition

or the like, which, if not correctly performed or adhered to, could

result in serious injury or death.

Denotes a hazard. It calls attention to a procedure, practice, condition

or the like, which, if not correctly performed or adhered to, could

result in injury to people and may damage or destroy the product.

Failure to follow the instructions may result in damage to property.

䟿

(without at )

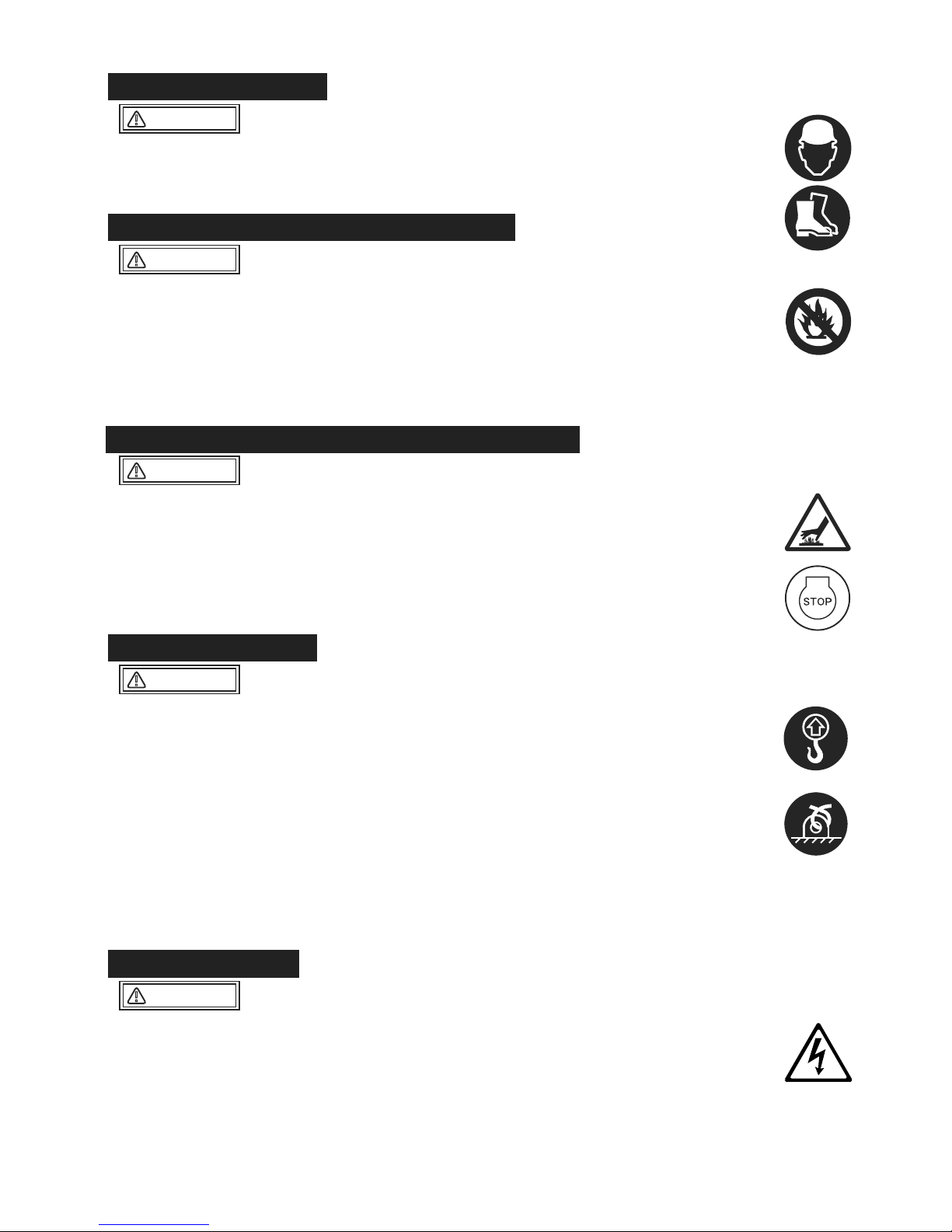

3䠊CAUTIONS FOR MAINTENANCE TO SECURE SAFETY

Do not work indoor or inside a tunnel where ventilation is poor. The emission from the

engine contains toxic gas such as carbon monoxide, and it is very dangerous if this

toxic gas and dust are inhaled. Also, to improve ventilation, please keep a proper

distance between this machine and a building when operating the machine.

Maintenance should be done in a place with a flat and hard surface to keep the

machine stable. Also, do maintenance at sufficient work space.

Before maintenance work, clean the floor. Oil on the floor, in particular, becomes the

cause of falling accident.

For maintenance work, have sufficient lighting in the work site. A portable lamp used to

illuminate the work area has to be protected by wire. In case if the lamp is broken, fuel

and oil might ignite.

To prepare for an accident, please have emergency medical supplies and fire

extinguisher ready at an easily accessible area.

3.1 Work Site

䖃

䖃

䖃

䖃

䖃

CAUTION

䟿

DANGER

䟿

2

To work safely, wear work clothes of appropriate size, and use suitable protective gear

such as helmet and safety shoes. The work clothes that do not fit the body size might

result in unpredicted injury because the clothes easily get caught by rotating part of the

machine.

When adding fuel

If fuel is filled to the top, it might overflow, and is dangerous.

After refueling, securely tighten the tank cap.

Start your work after the machine temperature drops. Especially, the muffler gets very

hot, and it will pose a danger of burn accident. Also, engine and engine oil as well as

vibrator become hot. Be careful not to get a burn.

If maintenance work is started with the engine running, injury might occur because you

might get caught by the rotating part such as pulley and V-belt. Always stop the engine

before maintenance.

Before maintenance work, remove the starter key of the engine.

Before starting maintenance, always remove the minus (-) terminal of the battery.

When lifting the machine body and the engine, always use a crane. When lifting the

machine and the engine, follow the cautions listed below. If the machine or the engine

is dropped, a serious accident might occur.

To operate a crane, a crane handling qualification is required. Have someone qualified

to handle and operate a crane do this work.

Before lifting, check the parts (especially, hook and anti-vibration rubber) of this

machine for damage and loosening/lack of bolts to secure safety.

Before lifting, stop the engine and shut the fuel cock.

Use sufficiently strong wire rope.

For lifting, use only the lifting hook. Do not use other part for lifting.

Never allow anyone or any animal come under the lifted machine.

For safety, do not lift to the height more than necessary.

Use an appropriate tool. If the tool that is not suitable for the part is used, not only the

damage on the part, but also unpredicted accident might occur.

Before starting maintenance, always remove the minus terminal of the battery. If short

circuit occurs, ignition might occur.

The battery gas might become a cause of explosion. Do not put fire nearby.

Especially, during charging, flammable gas is released. Do not put fire nearby.

The battery fluid is very toxic. Be careful when handling. If the battery fluid gets on your

skin, eye or on your clothes, wash it off with plenty of water, then see a doctor.

Always refuel in the well ventilated area.

Always refuel after the engine stopped and cooled sufficiently.

Select a flat surface location away from flammable material and Do not overfill

the tank. If spilled fuel, wipe it off well.

Never put fire near the refueling area. (Never refuel while smoking.)

3.2 Clothes And Protective

3.3 Cautions During Refuelinglothes And Protective

3.4 Prevention Of Burn And The Accident Of Getting Caught

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

WARNING

䟿

3.5 Tools And Equipment

WARNING

䟿

3.6 Handling Of Battery

WARNING

䟿

CAUTION

䟿

CAUTION

䟿

䕿

䕿

䕿

䕿

3

Always use genuine parts.

If inappropriate parts are used, not only it will shorten the machine life, but it might lead

to unpredicted accident.

Tighten bolts and nuts with the tightening torque specified in this maintenance manual.

Over tightening torque and lack of tightening torque not only affect the machine life, but

also might occur unexpected accident.

Unnecessary engine oil, hydraulic oil and fuel should be kept in a container. Never

dump it on the ground or pour into the sewage system such as side ditch.

For disposal of unnecessary engine oil, hydraulic oil and fuel, follow the law and other

regulations.

3.7 Use Of Genuine Parts And Appropriate Oil And V-belt

䖃

䖃

䖃

䖃

WARNING

䟿

CAUTION

䟿

3.9 Disposal Of Waste Material

CAUTION

䟿

3.8 Tightening Torque Of Bolts And Nuts

䠇

䞊

4

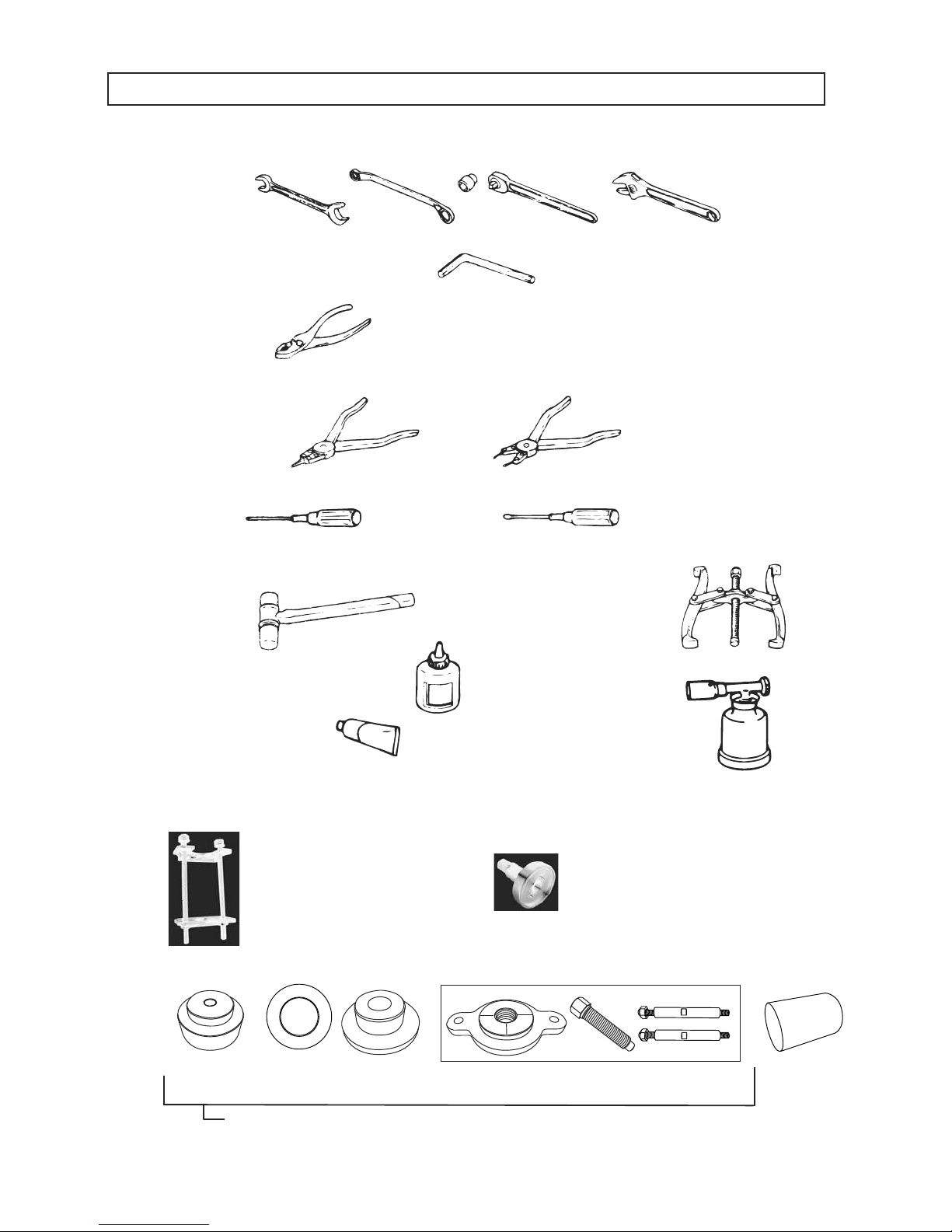

1. Wrench 10mm 12mm 13mm 14mm 17mm 19mm 22mm 24mm 27mm

Offset wrench/Socket wrench/Adjustable wrench

2. Hexagonal wrench 3/16inch

5mm 8mm 10mm 14mm

3. Plier

4. External snap ring plier/Internal snap ring plier(bent type can be also used)

6. Metal and plastic hammers 7. Pulley puller

9. Torch burner

8. Screw lock agent

(Locktite 242, 271 and 638)

10. Liquid gasket

11. Pressing machine

12. Special jig for hand pump disassembly and assembly

13. Special jig for vibrator disassembly and assembly

4䠊TOOLS

5. Screwdriver, flat and cross

9840-10060

Spring compression tool

9840-10040

Disassembling tool

9840-10070

9849-10011

Bearing insertion jig (driven shaft and drive one) set

Bearing

nsertion

cup

Bearing

insertion

ring

Bearing

insertion

holder

Bearing insertion puller

Bearing

remover

㻌

5

5.INSPECTION PROCEDURE

Assembly condition of each component (bolt loosening, defective parts, etc.)

Damage on machine body

Oil check (oil level, dirtiness)

V-belt check (tension, scratch, crack, deterioration, etc.)

Anti-vibration rubber check (scratch, crack, setting, deterioration, etc.)

Engine

Engine speed check (Operating speed, idling speed)

Travel

Check for abnormal noise during operation

Engine oil (when shipped, SAE10W30) (For oil level, please see the table below.)

Vibrator oil

Hydraulic oil (forward/backward travel)

Forward/backward travel switch check

Forward/backward travel speed check

5.1 Appearance Check

5.2 Operation Check

㻔㻝㻕

㻔㻞㻕

㻔㻟㻕

㻔㻠㻕

㻔㻡㻕

㻔㻝㻕

㻔㻞㻕

㻔㻟㻕

㼍㻚

㼎㻚

㼏㻚

㼍㻚

㼎㻚

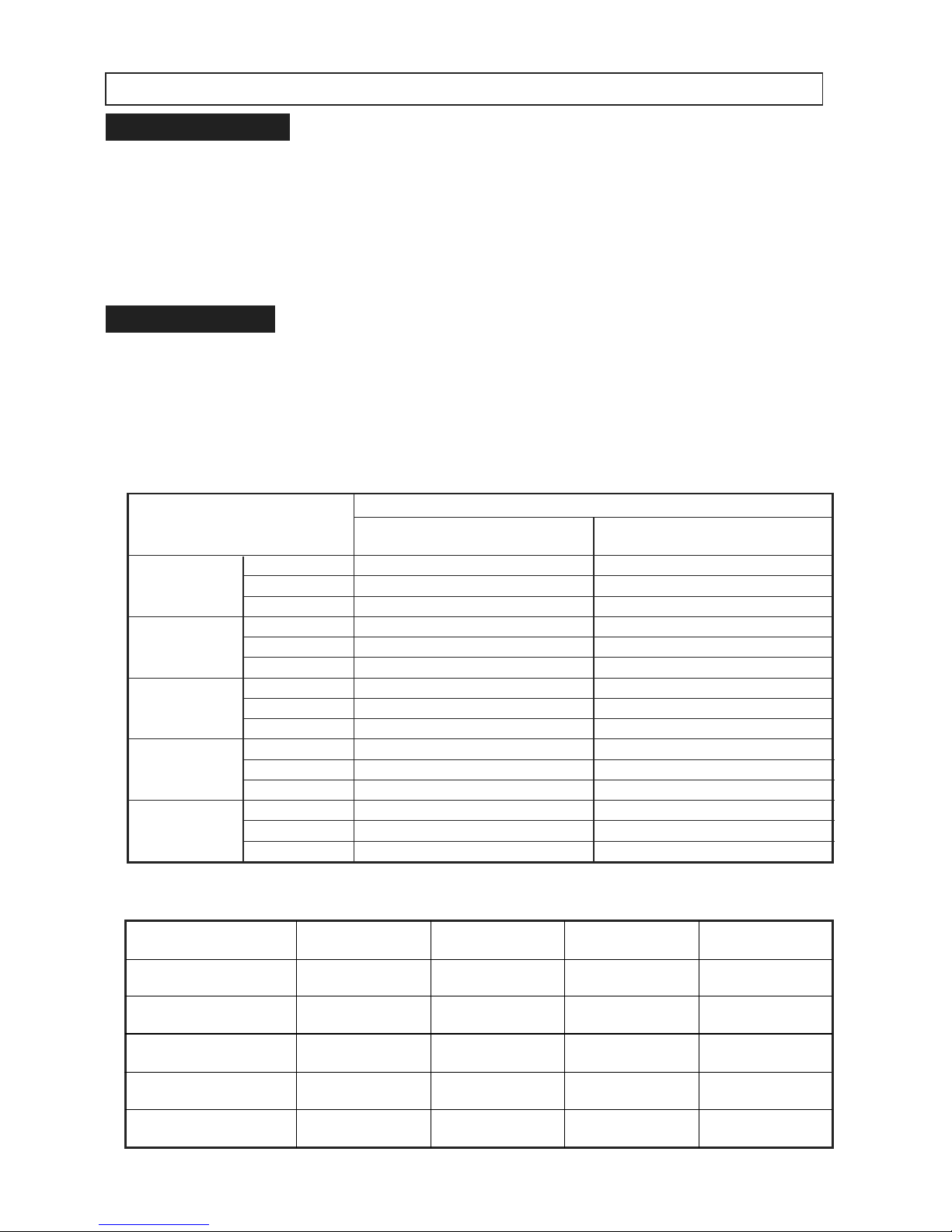

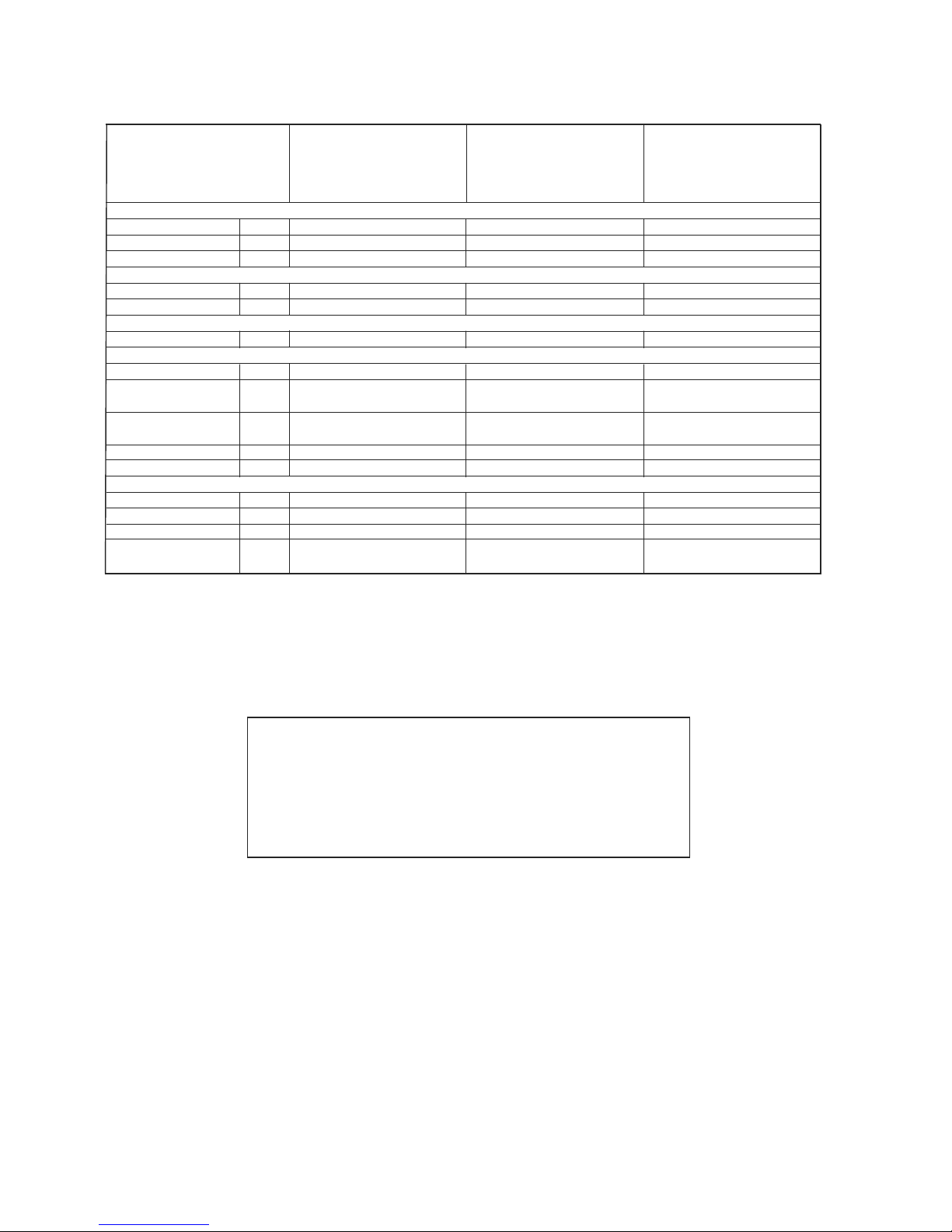

Screw diameter

M6

M8

M10

M12

M14

The collar screws materials

SS,FCD

Aluminum

Aluminum type+Helisert

N.m

Kgf

.

cm

ft

.

lbf

N

.

m

Kgf

.

cm

ft

.

lbf

N

.

m

Kgf

.

cm

ft

.

lbf

N

.

m

Kgf

.

cm

ft

.

lbf

N

.

m

Kgf

.

cm

ft

.

lbf

11.8 - 14.7

120 - 150

8.7 - 10.8

24.5 - 29.4

250 - 300

18.1 - 21.7

58.8 - 68.6

600 - 700

43.4 - 50.6

98.1 - 107.9

1000 - 1100

72.3 - 79.6

117.7 - 127.5

1200 - 1300

86.8 - 94.4

14.7 - 17.7

150 - 180

10.8 - 13.0

32.4 - 35.3

330 - 360

23.9 - 26.0

73.5 - 78.5

750 - 800

54.2 - 57.9

112.8 - 122.6

1150 - 1250

83.2 - 90.4

166.7 - 176.5

1700 - 1800

123.0 - 130.2

Table 1

Standard torque table

MVH-308DSC

MVH-308DSC-PAS

MVH-308DSZ

MVH-308DSZ-PAS

MVH-308GE MVH-308GH MVH-408GH

MVH-408DSC

MVH-408DSC-PAS

MVH-408DSZ

MVH-408DSZ-PAS

MVH-508DSC

MVH-508DSC-PAS

L70V

L70N

YANMAR YANMAR

L100V

L100N

HATZ 1B30

HATZ 1D81

ROBIN EX27

HONDA GX270 HONDA GX390

HATZ 1B50

1,050cc

1,050cc 1,050cc

1,600cc 1,100cc

1,100cc

1,500cc

2,000cc

Capacity of Lubricant

for Engine

Model

Engine type

Capacity of Lubricant

for Engine

Model

Engine type

Engine oil level table Table 2

6

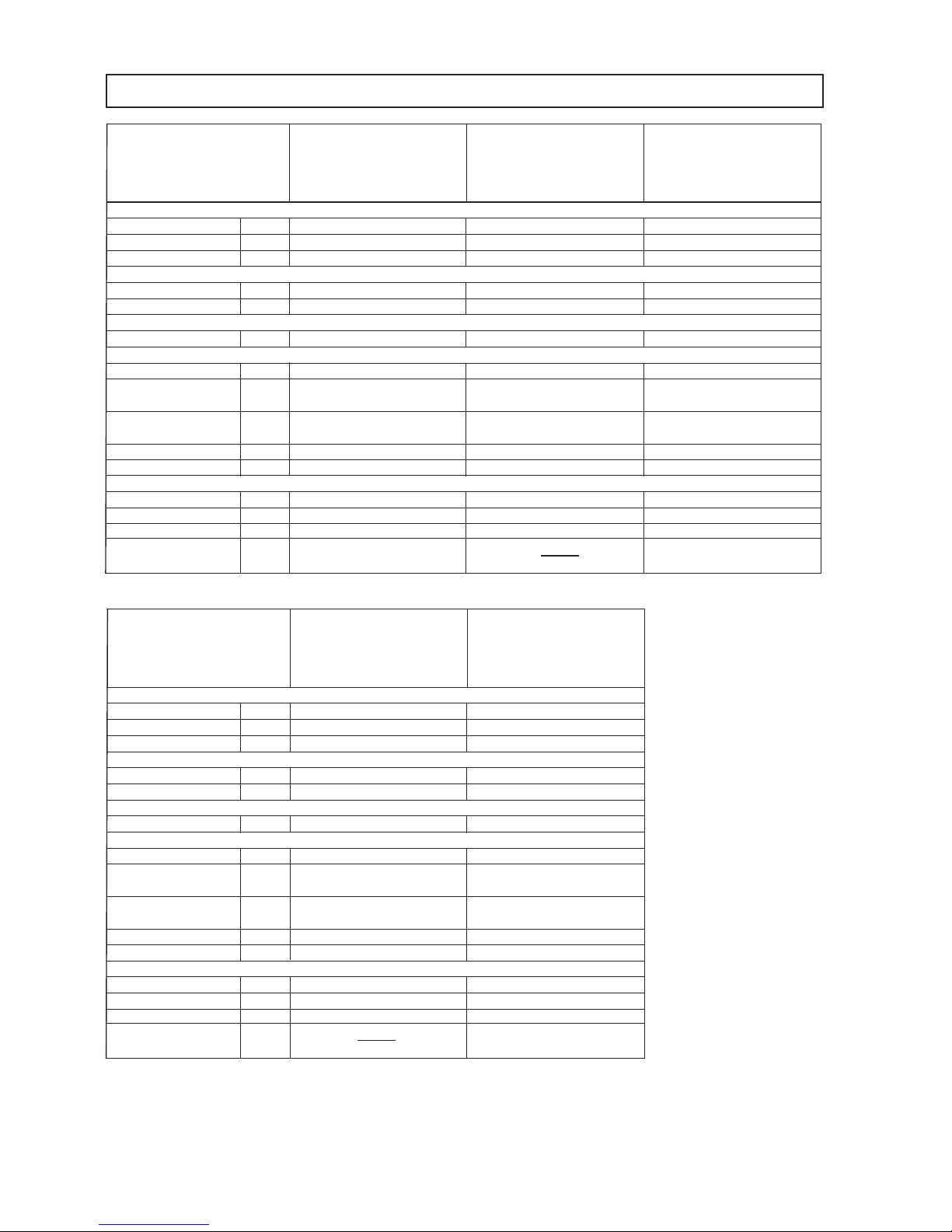

6䠊SPECIFICATION

Main Dimensions

Compacting Board

Weight

Engine

Parformance

1540

1030

445(595,745)

445(595,745)

860

345(360,375)

HATZ,1B30

Air-cooled 4-cycle

diesel engine

4.9/3300

6.7/3300

3350

○

73/4400

45/4600

0䡚27

6.1

1540

1030

445(595,745)

445(595,745)

860

341(356,371)

YANMAR,L70N6

Air-cooled 4-cycle

diesel engine

4.9/3600

6.7/3600

3600

○

73/4400

45/4600

0䡚27

Overall Length

Overall Height (Handle)

Overall Width

Width

Length

Operating Weight

Manufacturer/Type

Type Of Engine

Maximum Power

Set Engine Revolution

Electric Start

Vibrating Frequency

Centrifugal Force

Max. Traveling Speed

Hand Arm Vibration

(Ahv)

mm

mm

mm

mm

mm

kg

kw/min

-1

PS/min

-1

r.p.m

Hz/VPM

kN/kgf

m/min

m/sec

2

mm

mm

mm

mm

mm

kg

kw/min

-1

PS/min

-1

r.p.m

Hz/VPM

kN/kgf

m/min

m/sec

2

㻹㻻㻰㻱㻸

㻹㼂㻴㻙㻟㻜㻤㻰㻿㼅

㻹㼂㻴㻙㻟㻜㻤㻰㻿㼅㻙㻼㻭㻿

㻹㼂㻴㻙㻟㻜㻤㻰㻿㼆

㻹㼂㻴㻙㻟㻜㻤㻰㻿㼆㻙㻼㻭㻿

㻹㼂㻴㻙㻠㻜㻤㻰㻿㼅

㻹㼂㻴㻙㻠㻜㻤㻰㻿㼅㻙㻼㻭㻿

㻹㼂㻴㻙㻠㻜㻤㻰㻿㼆

㻹㼂㻴㻙㻠㻜㻤㻰㻿㼆㻙㻼㻭㻿

㻹㼂㻴㻙㻡㻜㻤㻰㻿㼆

㻹㼂㻴㻙㻡㻜㻤㻰㻿㼆㻙㻼㻭㻿

1570

1030

500(650,800)

500(650,800)

900

408(423,438)

HATZ,1B50

Air-cooled 4-cycle

diesel engine

6.7/2500

9.1/2500

2350

○

73/4400

55/5600

0䡚28

4.7

1570

1030

500(650,800)

500(650,800)

900

407(422,437)

YANMAR,L100N2

Air-cooled 4-cycle

diesel engine

7.0/3200

9.5/3200

3200

○

73/4400

50/5100

0䡚27

1600

1070

650(800)

650(800)

900

525(540)

HATZ,1D81

Air-cooled 4-cycle

diesel engine

8.9/2500

12.1/2500

2350

○

69/4150

65/6600

0㹼29

5.5

※

The number in parentheses is the dimension of the „extension plate(option)‰ with.

„( )‰ : MVH-308,408: (standard type, wide type)

MVH-508: (wide type)

Main Dimensions

Compacting Board

Weight

Engine

Parformance

Overall Length

Overall Height (Handle)

Overall Width

Width

Length

Operating Weight

Manufacturer/Type

Type Of Engine

Maximum Power

Set Engine Revolution

Electric Start

Vibrating Frequency

Centrifugal Force

Max. Traveling Speed

Hand Arm Vibration

(Ahv)

㻹㻻㻰㻱㻸

7

※

The number in parentheses is the dimension of the „extension plate(option)‰ with.

„( )‰ : MVH-308,408: (standard type, wide type)

MVH-508: (wide type)

Main Dimensions

Compacting Board

Weight

Engine

Parformance

Overall Length

Overall Height (Handle)

Overall Width

Width

Length

Operating Weight

Manufacturer/Type

Type Of Engine

Maximum Power

Set Engine Revolution

Electric Start

Vibrating Frequency

Centrifugal Force

Max. Traveling Speed

Hand Arm Vibration

(Ahv)

mm

mm

mm

mm

mm

kg

kw/min

-1

PS/min

-1

r.p.m

Hz/VPM

kN/kgf

m/min

m/sec

2

㻹㻻㻰㻱㻸

㻹㼂㻴㻙㻟㻜㻤㻳㻱

1540

1030

445(595,745)

445(595,745)

860

310(325,340)

HONDA,GX270

Air-cooled 4-cycle

petrol engine

6.3/3600

8.6/3600

3600

×

73/4400

45/4600

0㹼27

2.8

1570

1030

500(650,800)

500(650,800)

900

364(379,394)

HONDA,GX390

Air-cooled 4-cycle

petrol engine

8.7/3600

11.9/3600

3200

×

73/4400

55/5600

0㹼28

3.7

1540

1030

445(595,745)

445(595,745)

860

307(322,337)

ROBIN,EX27

Air-cooled 4-cycle

petrol engine

6.6/4000

9.0/4000

3600

×

73/4400

45/4600

0㹼27

3.8

㻹㼂㻴㻙㻟㻜㻤㻳㻴 㻹㼂㻴㻙㻠㻜㻤㻳㻴

Remarks:

Vibration Level is in comply with EU Directive 2002/44/EC and the

value is shown as 3 axix min vibration level.

Test course (Crushed gravel) is in comply with EN500-4.

The above values are sublect to change in case that the machine

is modified or/and the required regulations change.

8

Disassembly and assembly of this machine, with inspection and change of vibrator oil

included, should be done on a horizontal surface area. Before disassembly and

assembly, understand well the normal assembly condition so that you will not make

assembly error.

If oil seal, gasket, packing, O-ring or lock washer is disassembled, replace it with a new

one each time.

The contact surface between vibrator case and vibrator top cover should be sealed with

O-ring. (Clean the contact surface and be careful about O-ring position when

assembling.)

When tightening bolts and nuts, tighten them according to the specified standard torque

and applying the screw lock agent (Loctite, etc.). For bolts and nuts with no

specification, refer to the “Tightening torque list”. (When applying screw lock agent,

degrease and clean the screw part with the brake cleaner, etc.)

Note) The bolts used on this machine are all of the right hand thread.

When disassembling and assembling, work in the maintenance shop without dirt and

dust.

When the bolts applied the screw lock agent (Loctite, etc.) are difficult to loosen, they

loosen easily by heating them with a torch burner. Then, replace the heated bolt with a

new one. It should be a specified high tension bolt (genuine parts).

Use correct tools correctly.

First of all, the machine with battery remove the minus terminal before starting

disassembly. After assembly is done completely, install the minus terminal.

1.

2.

3.

4.

5.

6.

7.

8.

7䠊CAUTIONS BEFORE MAINTENANCE WORK

Tightening torque list

To change the unit to kgf・cm, convert with 1 N・m = 10.197 kgf・cm.

㻔㼡㼚㼕㼠㻦㻌㼗㼓㼒㻙㼏㼙㻘㻌㻝㼗㼓㼒㻙㼏㼙㻩㻥㻚㻤㻜㻢㻢㻡㻺㻙㼏㼙㻕

㻢㼙㼙

㻤㼙㼙 㻝㻜㼙㼙

㻝㻞㼙㼙 㻝㻠㼙㼙

㻝㻢㼙㼙 㻝㻤㼙㼙 㻞㻜㼙㼙

㻠㼀㻔㻿㻿㻠㻝㻕

㻣㻜

㻝㻡㻜

㻟㻜㻜

㻡㻜㻜 㻣㻡㻜

㻝㻘㻝㻜㻜

㻝㻘㻠㻜㻜

㻞㻘㻜㻜㻜

㻢㻙㻤㼀㻔㻿㻠㻡㻯㻕

㻝㻜㻜

㻞㻡㻜

㻡㻜㻜

㻤㻜㻜 㻝㻘㻟㻜㻜

㻞㻘㻜㻜㻜

㻞㻘㻣㻜㻜

㻟㻘㻤㻜㻜

㻝㻝㼀㻔㻿㻯㻹㻟㻕

㻝㻡㻜

㻠㻜㻜

㻤㻜㻜

㻝㻘㻞㻜㻜

㻞㻘㻜㻜㻜

㻞㻘㻥㻜㻜 㻠㻘㻞㻜㻜

㻡㻘㻢㻜㻜

When the mating material is aluminum.

㻝㻜㻜

㻟㻜㻜䡚㻟㻡㻜 㻢㻡㻜䡚㻣㻜㻜

㼀㼔㼞㼑㼍㼐㻌㼐㼕㼍㼙㼑㼠㼑㼞

Material

(Bolts used on the machine are all right-hand thread.)

9

1

3

4

5

7

12

8

9

10

11

13

2

3

4

5

7

8

11

14

15

10

9

29

27

34

35

25

26

28

16

36

38

39

37

40

59

44

46

47

48

45

43

61

60

62

18

21

20

19

77

78

63

64

68

75-1

75-2

75-2

67

69

71

51

85

53

80

84

81

76

70

82

83

49

55

56

50

57

58

52

57

58

22

23

MVH-308

CONTROL

13

72

74-1

73-1

74-2

73-2

YANMAR:

L70V / L70N

93

92

Fig.4

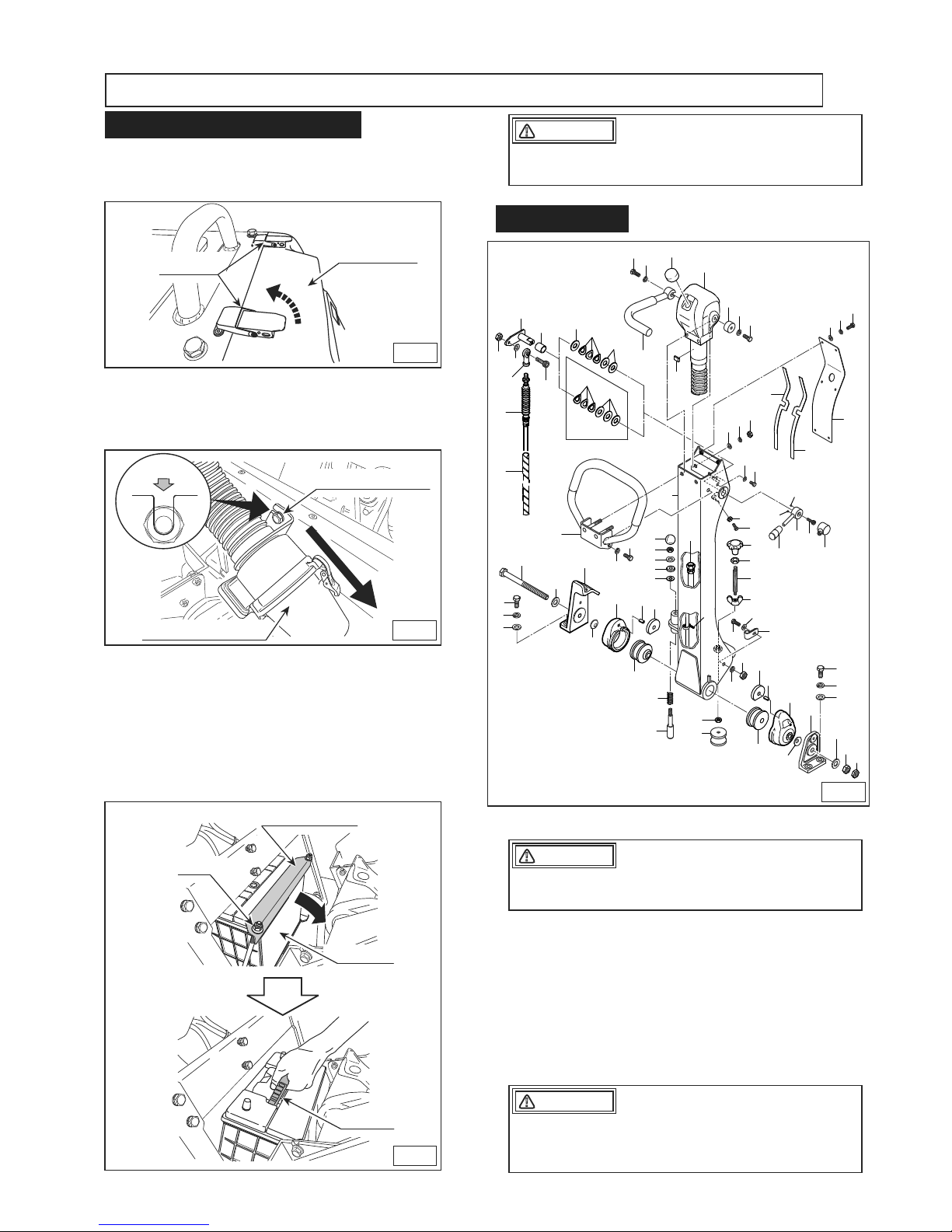

Fig.3

Nut

Battery holder

Battery

Handle

Fig.1

Rear cover

Stopper

Fig.2

M8 bolts (2 bolts)

㻯㼁㼀

Cyclone cleaner

1.

2.

3.

4.

Remove the stopper at the two locations

on the top portion of the rear cover to

open the rear cover.(Fig.1)

Loosen, but not remove, the M8 bolts (2

bolts) used for cyclone cleaner attachment. Take out the cyclone cleaner downward.(Fig.2)

Take off the nuts and remove the battery

holder. After tilting the battery backward,

disconnect the battery terminal. When

doing so, always disconnect the black terminal on the minus side first.

By holding the top surface handle, pull

upward to remove the battery from the

machine.(Fig.3)

Pay sufficient attention so that the battery terminal will not touch the frame.

CAUTION

䟿

Start your work after the temperature of hydraulic oil gets sufficiently lowered.

CAUTION

䟿

After the hydraulic hose is removed, tighten

the caps on both ends to prevent entry of

dust.

CAUTION

䟿

8䠊DISASSEMBLY AND ASSEMBLY

8.1 How To Remove The Battery

8.2 Control Part

(1)

a.

b.

c.

d.

Disassembly

Remove 6 bolts (46), then remove the

handle cover (43).

Remove a bolt (57), then remove the

travel lever (55).

Remove 2 bolts (63) and 2 nuts (62), then

remove the handle grip (59).

Remove the hydraulic hose (51) from

hand pump (50), then remove the hand

pump (50) from the handle (16). (Fig. 4)

Loading...

Loading...