Page 1

PLATE COMPACTOR

INSTRUCTION MANUAL

402-04808

MVC

MVC

-

40G

-

50GB

We thank you for selecting

Mikasa Plate Compactor. For

your safe and proper operation,

please read this manual and be

always sure to keep it ready for

reference.

Contentsof“DeclarationofConformity”

Pleasereferthe

ECDECLARATIONOFCONFORMITY

inthismanualaswell.

Original

Page 2

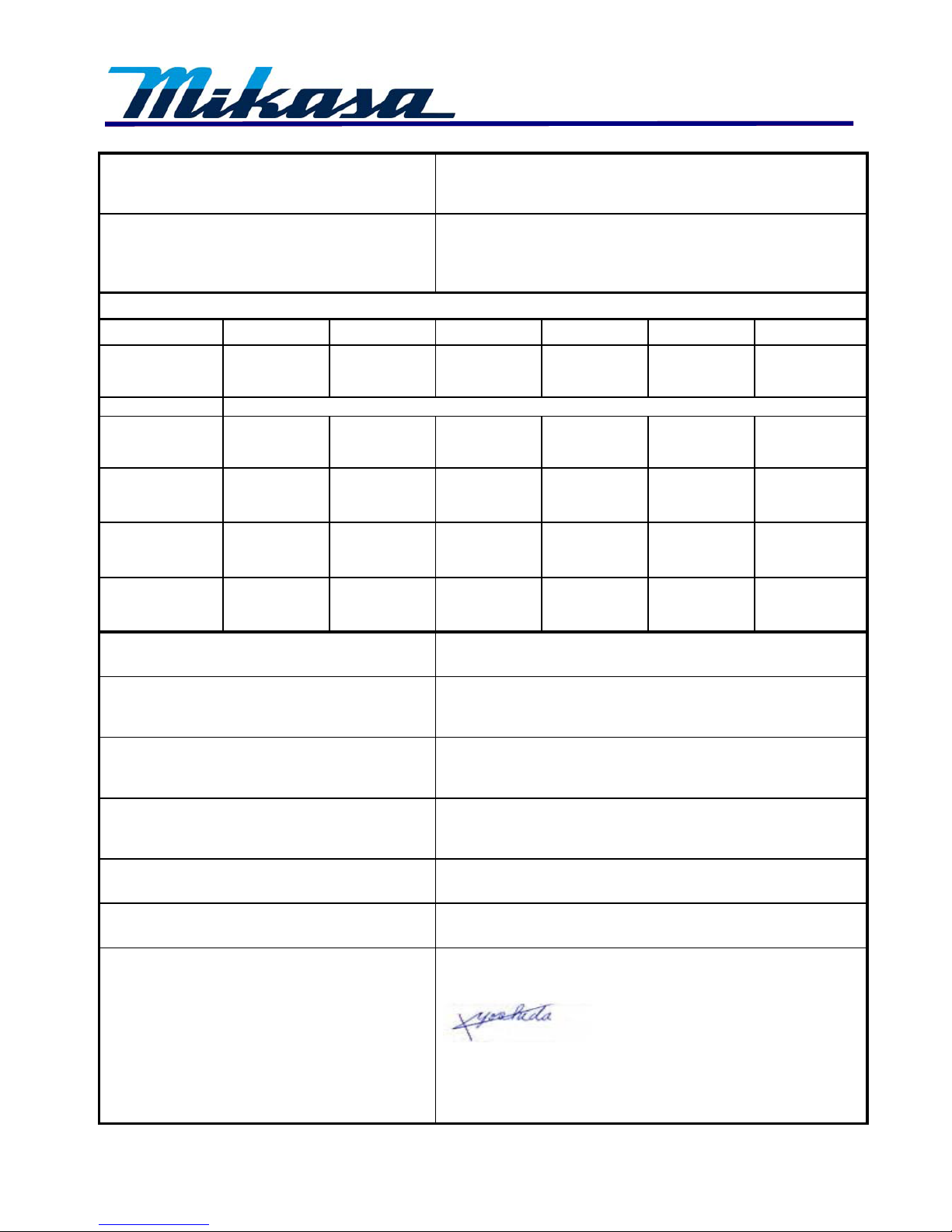

5) model

MVC-40G MVC-50GB

6) Equipment

item number

352062 352067

352068 352069

352070 352073

352050

7) Serial number

8) power source

cont. output

<m

ax.output

>

Robin EH09

1.5kW

<2.1kW>

Robin EX-13

2.2kW

<

3

.2kW>

9) Measured

sound power

level(dB)

97 101

10) Guaranteed

sound power

level(dB)

105 105

11) Max. Sound

pressure

level(dB)

84 91

For serial number, please refer it on front page.

Director, Product Control Division

Mikasa Sangyo Co., Ltd.

18) Place and date of the declaration

Keiichi YOSHIDA

Tokyo, Japan Feb, 2010

Signed by:

16) Other related Community Directives

2006/42/EC, 2005/88/EC, 2004/108/EC, 2002/88/EC(2004/26/EC)

EN500-1, EN500-4

e13*2000/14*2005/14*0472*01

4) Type: Vibratory Plates

Société Nationale de Certification et d’Homologation (SNCH)

11, route de Luxembourg

L-5230 Sandweiler LUXEMBOURG

15) Declaration

The equipment referred in this document, fulfills with all the

requirements of Directive 2000/14/EC

17) EC Conformity Certificate No:

1) DECLARATION OF CONFORMITY

14) Related Directive

Directive 2000/14/EC and, to be followed by Directive 2005/88/EC,

relating to the noise emission in the environment by equipment for

use outdoors.

2) Manufacturer’s name and address.

3) Name and address of the person who keeps the

technical documentation.

Mikasa Sangyo Co., Ltd.

4-3, Sarugaku-cho 1 chome, Chiyoda-ku, Tokyo101-0064, Japan

Yoshiharu Nishimaki, engineer

R. & D. Division, Mikasa Sangyo Co., Ltd.

Shiraoka-machi, Saitama, Japan

12) Conformity assessment according to Annex: VIII (Full Quality Assurance procedure)

13) Name and address of the Notified Body

Page 3

TABLE of CONTENTS

1. Preface

2. Applications, Warnings, Structure and Power Transmission

3. Warning Symbols

4. Safety Precautions

4.1 General precautions

4.2 Refueling precautions

4.3 Location and ventilation precautions

4.4 Precautions before starting

4.5 Precautions during work

4.6 Lifting precautions

4.7 Transportation and Storage precautions

4.8 Maintenance precautions

4.9 Labeling Position

4.10 Description of symbols used warning labels

5. Specifications

5.1 Machine specifications

5.2 Engine specifications

6. Appearance

6.1 Overall Dimensions

6.2 Control Unit Positions and Names

7. Inspection Before Operation

8. Operation

8.1 Starting

8.2 Operation

9. Stopping the machine

10. Transportation

10.1 Loading and Unloading

10.2 Transportation precautions

11. Storage

12. Regular Check and Adjustments

12.1 Inspection and maintenance schedule table

12.2 Changing the engine oil

12.3 Cleaning the air cleaner

12.4 Checking/Changing V-belt and Clutch

12.5 Inspection and Change of vibrator oil

13. Troubleshooting

1

1

2

2

7

8

10

11

13

13

13

14

16

2

2

3

3

3

3

3

4

5

6

7

7

8

9

11

12

13

13

14

15

15

15

15

Page 4

1

1. Preface

This operation manual describes the proper operation, basic inspection and maintenance procedures of the plate

compactor. Please read this operation manual before use in order to maximize the excellent performance of this

machine and make your work more efficient and effective.

After reading the manual, please keep it in a handy location for easy reference.

For the handling the engine, please refer to the separate engine operation manual.

For inquiries about repair parts, parts lists, service manuals, and repairs, please contact the store where you purchased

the product, our sales office, or the Mikasa Parts Service Center. For parts lists, please visit our homepage at:

http://www.mikasas.com/ where you can access Mikasa WEB parts lists.

●

●

●

●

The illustrations in this manual might slightly differ in part from the machine you actually

purchased due to design changes.

2. Applications, Warnings,

Structure and Power Transmission

Applications

Plate compactor is the machine that compacts the ground and it intends to make the surface smooth, by transmitting vibration through vibrating plate, which power generated from single rotor in vibrator case.

This machine is suitable for making the ground surface smooth, such as leveling the soil and beaching, finishing

the asphalt paving.

Warning about incorrect applications and techniques

This machine is hard to move forward on a soil with much water (especially clay soil). It is not suitable for such

application. This machine is difficult to level a ground include big stones due to insufficient compacting force. Plate

compactor is mainly applied for compacting surface smooth and it is not effective for jobs that requires heavy

compaction. In case of compacting ground deeply into lower layer, it is recommended to use Tamping Rammer,

Vibro Compactor or Vibration Roller of which compacting force is rather effective. Please use this compactor for

compacting surface on soil, sediment, beaching and asphalt. It is not recommended for use this machine for the

other applications.

Structure

The upper part is made up of Power source, Handle, Belt Cover, Water Tank for sprinkling and Guard Hook which

are fixed by Engine Base. The Engine base is fixed on Vibrating Plate by Shock Absorbing Rubber. The lower part

is made up of Vibrating Plate and Vibrator Unit that has an Eccentric rotary shaft built in. The power source is

transmitted from the centrifugal clutch on engine output shaft to the Eccentric rotary shaft through V-belt.

Power transmission

Air-cooled Single Cylinder Engine is amounted as power source and Centrifugal Clutch is fixed on engine output

shaft.

Centrifugal Clutch engages by running up the engine and engine R.P.M. is reduced to suitable number for

compacting. The rotation of engine is transmitted from V-pulley integrated with Clutch Drum to Vibrator Pulley

through V-belt.

Vibrator Pulley rotates Eccentric Rotor Shaft that is contained in Vibrator Case. The generated vibration created

from Eccentric Rotor is transmitted to Vibrating Plate.

Vibration of Vibrating Plate carries the machine forward; the vibration with the weight of the machine makes the

compaction of the ground possible.

Page 5

2

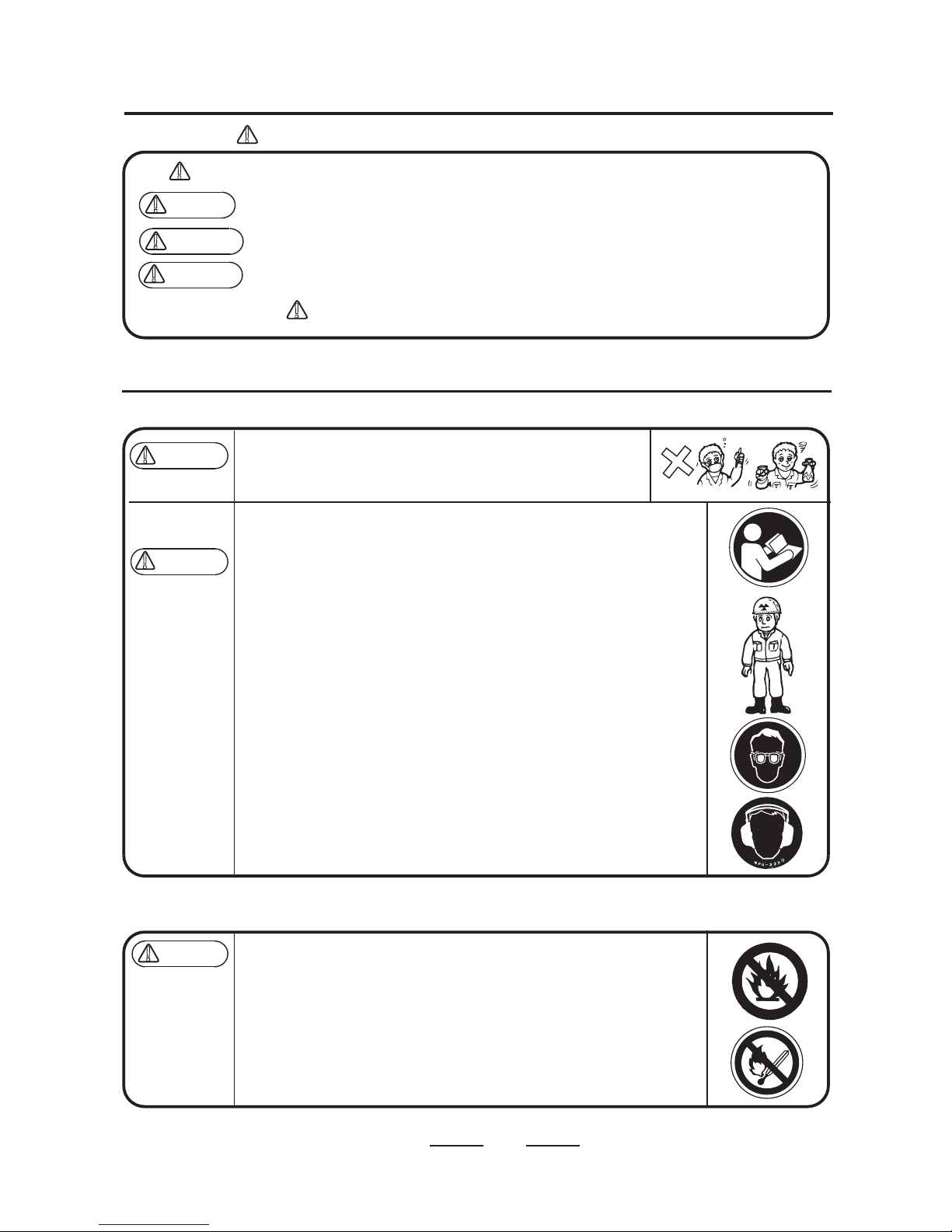

The triangle marks ( ) used in this manual and on the decals on the machine are warning symbols. Please follow these precautions.

Warning symbols indicating personnel hazards

Extremely hazardous. If the warning is not followed, it is likely to result in serious injury or death.

Hazardous. If the warning is not followed, it is likely to result in serious injury or death.

Potential hazard. If the warning is not followed, it may result in injury.

If the warning is not followed, it may result in property damage.

4.1 General precautions

4.2 Refueling precautions

!

Precautions (without mark)

!

!

3. Warning Symbols

4. Safety Precautions

○

○

○

Do not operate the machine,

Read this manual carefully and handle the machine as described to ensure safe

work.

For details about the engine, refer to the separate manual for the engine.

Make sure you understand the structure of the machine well.

For safe work, always wear protective gear (helmets, safety shoes, ear plugs,

etc.) and work in appropriate clothes.

Always check the machine before your work to make sure it is in normal

condition.

Decals on the machine (operation method labels, warning labels, etc.) are very

important for your safety. Keep the machine clean so that the decals can be read

all the time. Replace a decal if it becomes illegible.

Before performing maintenance work, be sure to turn the engine off.

It is very dangerous if children come into close contact with the machine. Have

the utmost concern about how and where to store the machine. In particular, for

an engine with a cell, always remove the starter key and keep it in a designated

place.

Before inspection and maintenance work, stop the engine, and do your work on

a flat surface area. If a cell is attached, remove the battery wiring before your

work.

Mikasa does not accept any responsibility for accidents caused by remodeling or

rework done on the machine.

When adding fuel,

Do not fill to the rim due to potential spillage.

After adding the fuel, tightly close the tank cap.

○ Make sure you work in a well ventilated location.

○ Make sure the engine is stopped and wait until it cools down.

○ Take the machine to a clear flat location without any combustibles nearby.

Be careful not to spill the fuel. Wipe well if any spill occurs.

●

●

●

●

●

●

●

●

●

●

●

●

●

●

DANGER

!

WARNING

!

CAUTION

!

WARNING

!

CAUTION

!

If you do not feel well due to overwork or illness.

If you are taking any medicine.

If you are under the influence of alcohol.

DANGER

!

Page 6

3

4.3 Location and Ventilation precautions

4.4 Precautions before starting

4.5 Precautions during work

4.6 Lifting precautions

For unloading using a crane, a licensed crane operator is needed. An operator should be qualified for crane and hooking work.

4.7 Transportation and Storage precautions

Do not run the machine in an unventilated location, such as indoors or inside a

tunnel. The exhaust gas from the engine contains toxic gases such as carbon

monoxide and is very hazardous.

Do not operate the machine near open flames.

Check each part to see if it is tightened properly. Vibration causes loosening of

bolts, which results in unexpected serious malfunctions of the machine. Tighten

the bolts securely.

Before starting the machine, make sure it is safe to start by checking your

surroundings for people and objects.

Always pay attention to your footing. Work in an area where you can maintain a

good balance of the machine and a safe comfortable posture.

The engine and muffler become very hot. Do not touch immediately after the

machine stops because they are still very hot.

If you notice deterioration of machine operation during your work, stop your work

immediately.

Before moving away from the machine, be sure to turn the engine off. Also when

the machine is transported, stop the engine and close the fuel cock.

Before lifting, check the machine parts (especially the hook and anti-vibration

rubber) for any damage and loosened or missing bolts.

Stop the engine and shut the fuel cock while lifting.

Use a wire rope with sufficient strength.

For lifting, use only one point hoisting hook, and do not lift at any other part.

When the machine is hoisted, never let people or animals come underneath.

For safety reasons, do not lift to a height that is higher than necessary.

Stop the engine during transportation.

Transport after the engine and the machine are cooled down.

Always drain the fuel before transporting.

Securely fix the machine to prevent it from moving or falling during

transportation.

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

DANGER

!

WARNING

!

CAUTION

!

CAUTION

!

Muffler

Burn warning

DANGER

!

Page 7

4

4.8 Maintenance precautions

Appropriate maintenance is required to ensure safe and efficient operation of the

machine. Always pay attention to the machine’s condition and keep it in good

condition. Pay special attention to the parts used for lifting, if they are not

maintained properly, it might result in a serious accident.

Start maintenance work after the machine has cooled down completely. The

muffler, in particular, becomes very hot, and there is a danger of burn. The

engine, engine oil and vibrator also become very hot. Be careful not to get

burned.

Always stop the engine before inspection and adjustment. If you are caught in a

rotating part, serious injury might occur.

After maintenance work, check the security parts to see if they are securely

installed. Special attention should be paid when checking bolts and nuts.

If disassembly is involved in maintenance, refer to the maintenance instruction

manual to make your work safe.

●

●

●

●

●

CAUTION

!

WARNING

!

Muffler

Burn warning

Page 8

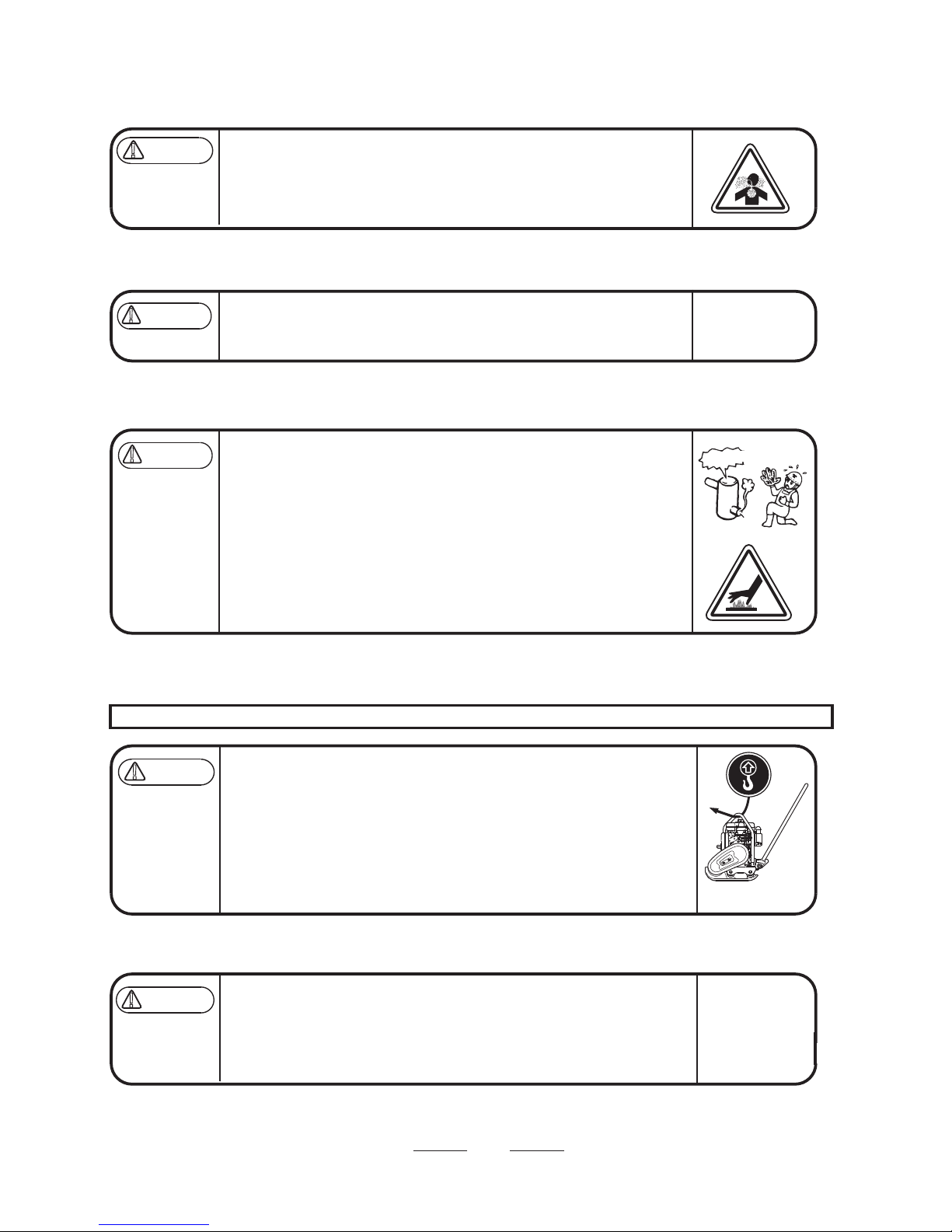

4.9 Labeling Position

5

MVC-50GB

1

9

10

7

7

2

5

5

8

6

6

3

4

4

MVC-40G

3

2

1

ENGINE BASE

RIGHT SIDE

ENGINE BASE

RIGHT SIDE

9202-10330

9209-00090

9209-00090

9209-00090

9209-00090

9202-00870

9201-09530

9201-00920

9201-05070

REF

No.

LABEL

No.

PART No. PART NAME Q’ TY REMARK

PLATE, SERIAL NO. / EU

DECAL,EC NOISE REQ.LWA105

DECAL,DO NOT LIFTING

DEAL,LIFTING POSITION

DEAL,CAUTION ICONS

DECAL,ENGINE HANDLING /GS

DECAL, WITHOUT ENGINE OIL

DECAL,MIKASA(125MM)YELLOW

DECAL, MIKASAMARK

DECAL,MIKASA MARK 125MM

Warnig labels

Starting, and stopping

40G

50GB/ WATER TANK

50GB/ WATER TANK

NPA-1033

NPA-1473

NPA-1474

NPA-1479

NPA-1480

NPA-87

NP-953

NP-92

NP-507

1

1

1

1

1

1

1

1

1

1

1

2

3

4

5

6

7

8

9

10

Page 9

6

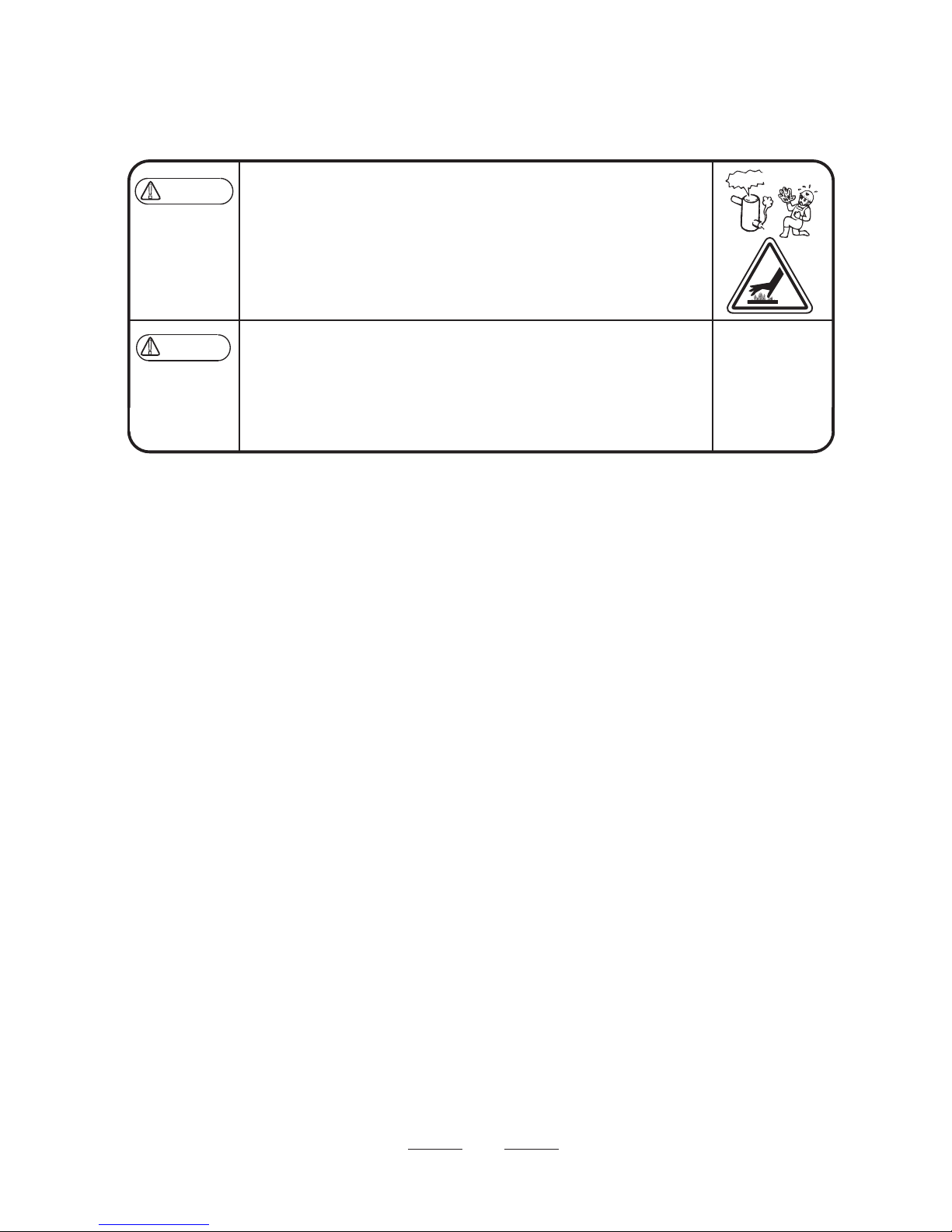

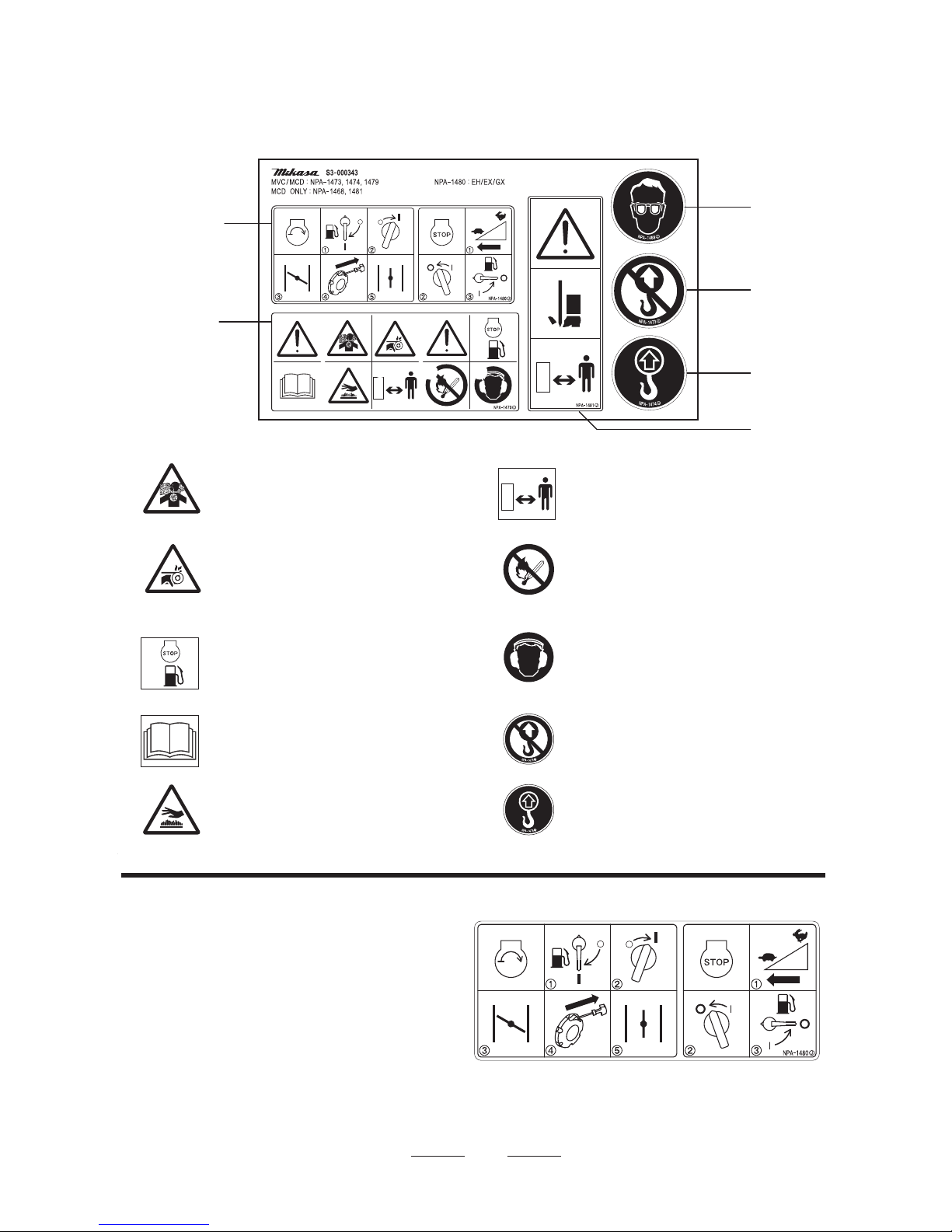

4-10. Descriptions of symbols used on warning labels

START

①Open Fuel Cock to start

②Turn Stop Switch to “I”(ON) position

③Close Choke Lever

④Pull Recoil Starter to start

⑤Return Choke Lever to open

STOP

①Return Throttle Lever fully until “O”(OFF) position to stop work

②After cooling down enough, stop the engine to move Stop Switch to “O”(OFF) position

③Close Fuel Cock at the end

Starting, and stopping

P/N 9209-00090

DECAL, SET /MVC, MCD /EXP, EU

①

Danger: poisonous exhaust gas

Carbon monoxide poisoning may occur if

the exhaust gas is inhaled. Do not operate

the machine in a poorly ventilated area.

⑤

Be careful not to get burned.

Accidental burn may occur if you touch the

hot parts (engine, muffler, etc.) during operation or immediately after the machine stops.

Fire hazard

Stop the engine when refueling. Fire may

occur if a flame is near the tank fuel port.

⑦②

Be careful not to get caught in the

rotating parts.

During operation, be careful not to have your

fingers, body, clothes, etc. come in contact with

the rotating parts such as the V-belt and clutch.

P/N 9209-00090

DECAL, SET /MVC, MCD /EXP,EU

NPA-1479

NPA-1480

Do not use.

(For cutters)

Do not use.

(For cutters)

NPA-1473

NPA-1474

Lifting position.

For lifting, use only one point hoisting hook,

and do not lift at any other part.

⑩

⑥

Be careful not to approach danger

source.

During operation, Be careful not to approach hot

parts and rotating parts.

Lifting by the handle is prohibited.

Due to a falling risk, do not lift the

machine by the handle.

⑨

③

Refueling Hazard.

Don't fill the fuel tank while the engine is

running or hot.

Danger of hearing damage caused

by noise

Always use ear plugs while operating the

machine.

⑧

④

Read the manual carefully.

Always read the operation manual and have good

understanding of operation before your work.

① ②

④

③

⑤ ⑥

⑦

⑩

⑨

⑧

Page 10

7

5.Specifications

(The specifications may be changed without notice)

5.1 Machine specifications

5.2 Engine specifications

Manufacturer

Model

Max. Output

Fuel Tank Capacity

liters

Lubricant capacity

cc

Starting system

Set R.P.M rpm

Robin

EX13 (petrol)

3.2kW(4.3PS)

/4000min

-1

2.7

600

Recoil starting

3600

Robin

EH09-2F (petrol)

2.1kW(2.8PS)

/4200min

1.5

300

Recoil starting

4000

-1

MVC-40G

Folding Handle

MVC-50GB

Robin

EH09-2F

Overall Length

mm

855

Overall Width mm

290

Overall Height

mm

920

Plate Size (W X L) mm

290 x 420

Operating Weight

kg

46

47

Travelling Speed

m/min

25

Vibrating Frequency

Hz [ vpm ]

103 [ 6200 ]

Centrifugal Force

kN [ kgf ]

7.2 [ 730 ]

Vibrating unit

SAE 10W-30

Lubrication oil in

vibration case

cc

300

V-Belt Size

RPF3270

Model

Engine model

Robin

EX13

865

345

920

345 x 460

59

25

97 [ 5800 ]

9.8 [ 1000 ]

SAE 10W-30

300

RPF3270

STD

With Water Tank

STD

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

66

Water tank capacity

8.5L

cc

MVC-50GB

Robin

EX13

880

345

850

345 x 460

60

25

97 [ 5800 ]

9.8 [ 1000 ]

SAE 10W-30

300

RPF3270

With Water Tank

STD

←

←

←

←

←

←

←

←

←

←

67

Overall Length

mm

Overall Width mm

Overall Height

mm

Plate Size (W X L) mm

Operating Weight

kg

Travelling Speed

m/min

Vibrating Frequency

Hz [ vpm ]

Centrifugal Force

kN [ kgf ]

Vibrating unit

Lubrication oil in

vibration case

V-Belt Size

Model

Engine model

Water tank capacity

8.5L

cc

(Folding Handle )

940

925

865

865

Page 11

6.1 Overall Dimensions

8

.

6. Appearance

Dimensions may change without notice.

6.1.1 MVC-40G

6.1.2 MVC-50GB

290

590

855 ( Folding Handle: 865)

420

920 ( Folding Handle: 865 )

545

460

345

60

865 ( Folding Handle: 880)

920 ( Folding Handle: 850 )

Page 12

MVC-50GB

MVC-40G

4

3

1

5

2

6

7

8

9

6.2 Control Unit Positions and Names

1. Starter Grip

2. Engine ON/OFF Switch

3. Choke Lever

4. Speed Control Lever

5. Fuel Cock

6. Handle Bar

7. Folding Handle

8. Lifting Hook

9. Vibrating Plate

10. Vibration Case

11. Water Shut-Off Valve

9

9

7

2

8

10

11

4

1

3

5

Page 13

10

7. Inspection Before Operation

Clean each part of the machine well to maintain dirt and

dust-free condition. Pay special attention to the soil

adhered to the bottom of the vibrating plate, engine

cooling air inlet, and the carburetor and air cleaner area

to keep those parts clean.

Check each part for any looseness of bolts. Vibration

causes bolts & nuts to loosen, which might result in

unexpected accident or malfunction.

Inspect the guard hook, belt cover and anti-vibration

rubber, as well as to check the function of speed adjustment wire and speed adjusting lever.

Check V-belt tension. The belt should have about 10 –

15mm of flexibility when pushed strongly with a finger

at the mid-point between the axes. If V-belt is loosened,

power is not transmitted connectively, which reduces

compacting force and shortens the life of V-belt. In

addition, the generated compaction force will lead to

irregular vibrations when the engine revolutions are

increased, and may result in a machine failure.

Set the engine on a level surface to check the oil level.

If the oil level is low, add oil. Use the following engine

oil.

Quality: Gasoline engine oil, Grade SE or above

Viscosity: SAE No. 30 at 20°C and above (summer)

SAE10W-30

1

2

3

4

5

Upper level

Lower level

(Refill line)

Oil Gauge

Fig.1

DANGER

!

Conduct inspection while the engine is stopped.

If you get caught in the rotating parts, you may

suffer serious damage. Conduct inspection after

making this machine level and checking that the

body does not move.

Refer to "Regular Check and Adjustments" on

page 14 for the inspection points before starting

operation.

★

Temperature

Morethan25℃

10〜25℃

10〜0℃

Lessthan0℃

Useoil

SAE#30

SAE#30,#20

SAE#20

SAE#10

Page 14

11

Set the machine on a level surface, then remove the oil

gauge of the vibrator. Check the oil gauge to see if the

oil is at the specified level. Use engine oil SAE10W-30

as lubrication oil.

Recommended oil quantity for MVC-40G/50G is 300cc.

Remove the oil plug in Vibrator Assembly and check

the oil level. Make sure the oil quantity is set at level of

plug hole for checking. Every month or every 200 hours

of operation, replace the oil.

A regular grade gasoline should be used in the engine.

When filling the fuel tank, make sure the fuel filter is

used.

Never refuel this machine while leaving the engine

running. There is danger of fire.

Never smoke, or put other flames close to this

machine while refueling. Serious hazards such as

burns and fire may result.

Choose a place free from flammable substances

for refueling. Be careful not to spill fuel. In case fuel

should be spilled, wipe off the spilled fuel

completely.

6

7

DANGER

!

DANGER

!

DANGER

!

DANGER

FUEL

Fire risk

Fig. 2

Gasoline engine

8.1 Starting

8.Operation

Turn the lever of the fuel cock downward and feed

fuel. (Figs.3-1 , 3-2)

1

DANGER

!

The engine exhaust gas contains carbon dioxide

and is very dangerous.

Do not use this machine where ventilation is poor.

MVC-40G

( ROBIN EH09-2F )

Choke Lever

High Speed

Fig.3-1

Open

Fuel Cock

Close

Speed control lever

MVC-50GB

(ROBIN EX13)

High Speed

Speed control lever

Choke Lever

Fuel Cock

Open

Close

Fig.3-2

Page 15

12

Turn the stop switch to “ON (I)” position. (Fig.4)

Open the speed control lever half. (Fig.3-1, 3-2)

When it is cold or the engine does not start easily,

close the choke lever. (Figs. 3-1 , 3-2)

2

3

Engine Switch

ON

“ON”

(RUN)

Fig.4

Grip the starting knob of the recoil starter. When you

pull the rope a little, you will feel some resistance.

Then pull it at a stroke. Be careful not to pull the rope

too strongly, or the rope may break or come off.

(Fig.5)

When the engine has started, return the speed control

lever to the low speed position immediately. Listening

to the sound of the explosion, return the choke lever

gradually to the fully open condition. (Fig.3-1 , 3-2)

After the start, be sure to conduct the warm-up

operation at low speed for 2-5 minutes. This is

particularly important when it is cold. During this time,

check for any abnormalities such as gas leakage.

Note: If you leave the speed control lever

half-open, the centrifugal clutch turns into a

slipped state. This may cause a failure of the

centrifugal clutch, and also cause abnormal

vibration of this machine, which is very

dangerous. So, as soon as the engine has

started, return the speed control lever to the

low-speed position.

4

5

Fig.5

8.2 Operation

If you open the speed control lever at a stroke, this

machine starts vibration and moves forward. If you

open it slowly, the clutch may slip, so open the speed

control lever at a stroke without hesitation. (Figs. 3-1 ,

3-2)

When this machine is used on cohesive soils, the

vibrating plate does not move over the ground easily

and the travel speed becomes slow. Check that clay is

not adhering to the bottom of the cvibration plate. The

compaction force of this machine does not act

effectively on cohesive soils or soils of a high moisture

ratio. In this case, use other machine such as a

rammer, or dry the soils and decrease the moisture

ratio.

When you stop the operation, return the speed control

lever at a stroke.

1

2

3

Page 16

13

11 Storage

Conduct fueling and replenishment/change of oil

without omission. Remove the spark plug, put a few

drops of engine oil into the cylinder, and rotate the

engine manually for spreading the oil inside sufficiently.

Securely cover the air cleaner and muffler air inlets and

exhaust port.

Do not leave the machine outdoors. Keep it indoors.

Don not store this machine by laying it on its side (or

backward).

4

5

6

7

CAUTION

!

9. Stopping the machine

When you finish the work and stop the engine, return

the speed control lever to the low speed position, and

keep the engine running at low speed for 3-5minutes.

When the temperature of the engine has decreased,

stop the engine.

If you stop the engine while it is still hot, this

machine will be affected adversely, causing, for

example, burning of the oil film on the inner wall

of the cylinder, which may accelerate wear of the

inner wall of the cylinder. This may result in a

shorter life of this machine, or cause unexpected

failure.

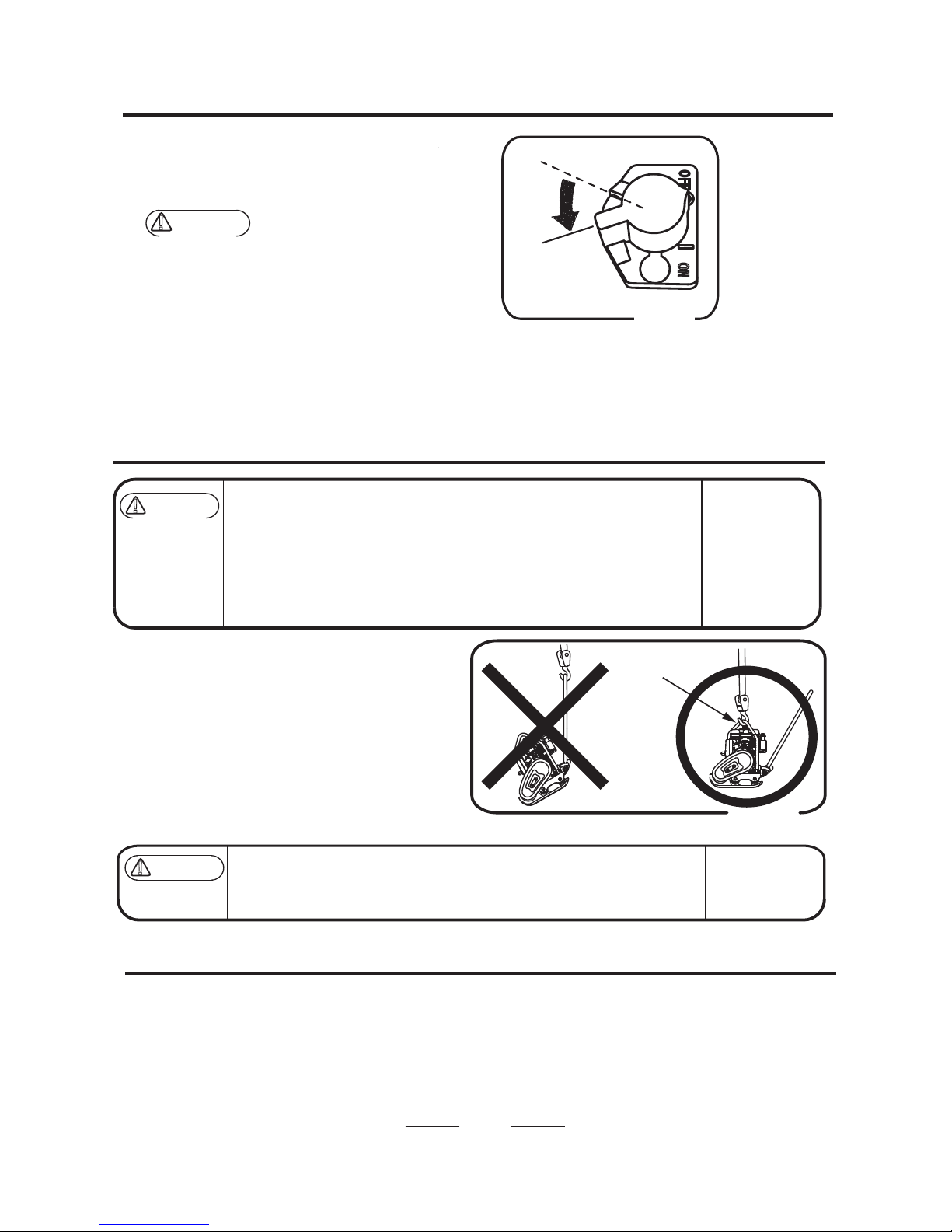

Turn the engine switch to the OFF position, then the

engine stops. (Fig. 6)

Close the lever of the fuel cock. (Fig. 3-1, 3-2)

1

2

Fig. 6

ON

“OFF”

(Stop)

Engine switch

Wash with water to remove any dust and dirt from all

parts of the machine.

Store in a dry area away from direct sunlight after

putting the cover over the machine to prevent dust and

dirt buildup.

1

2

(When storing this machine for an extended period of time)

Drain the fuel from the fuel tank, fuel pipe, and

carburetor completely.

3

10.1 Loading and Unloading

10.2 Transportation precautions

For loading and unloading using a crane, an

operator qualified for cranes and hooking works is

needed.

Use a crane for loading and unloading the machine.

Designate a person to guide the loading and unloading,

and always work under the instruction of that person.

When lifting, always use a special hook on the guard

frame. (Fig. 7)

Never lift by hooking the handle.

1

2

3

10 Transportation

Make sure there is no breakage of guard frame and anti-vibration rubber

nor loosened or missing bolts.

Always stop the engine when lifting.

Use an intact wire rope without any deformation with sufficient strength.

Slowly lift upward without applying any impact. Never let people or animals

go under the lifted machine.

For safety reasons, do not lift to a height that is higher than necessary.

●

●

●

●

●

WARNING

!

WARNING

!

Stop the engine when the machine is transported.

Always drain the fuel before transportation.

Fix the machine securely to prevent the machine from moving or falling.

●

●

●

Special hook

on the guard frame

Fig.7

Page 17

14

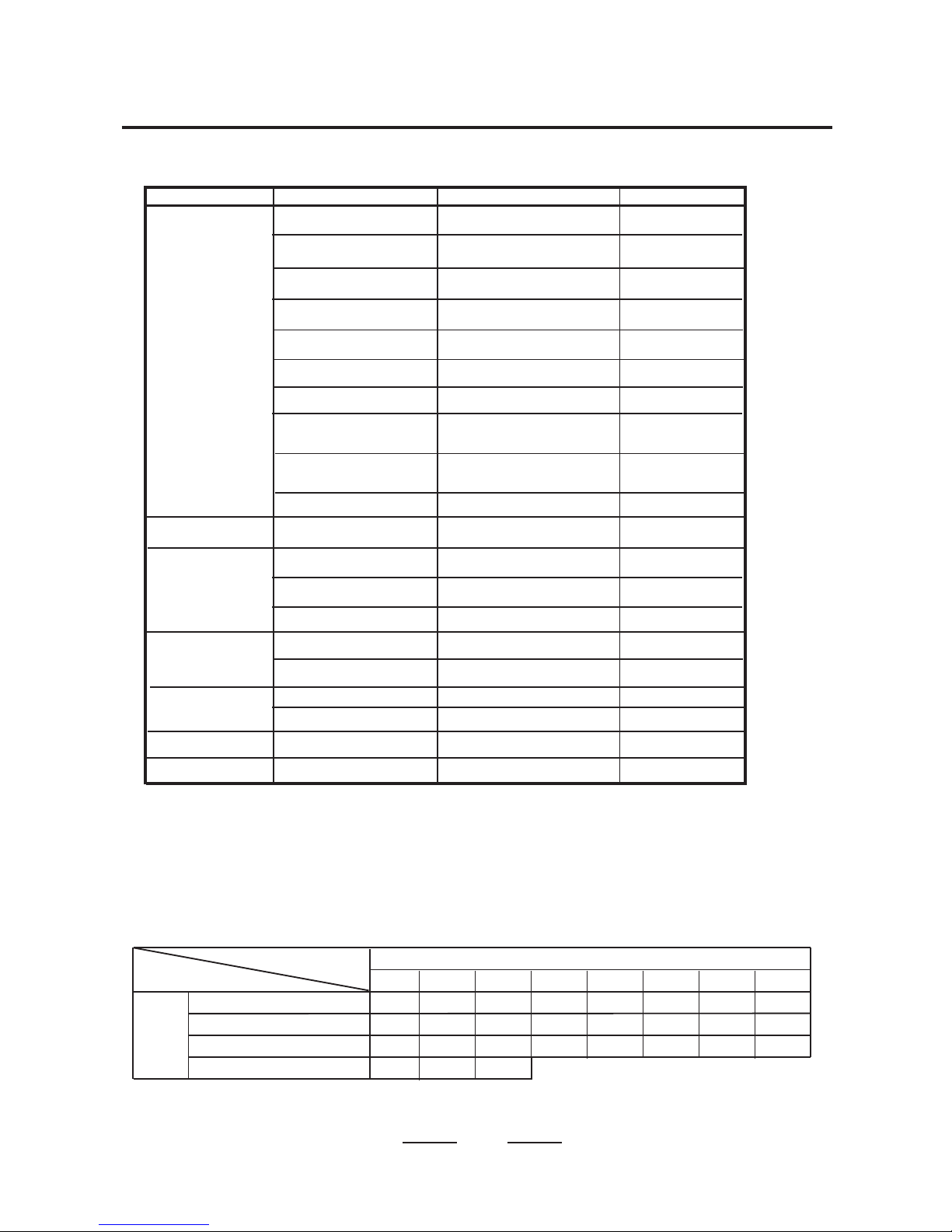

12.1 Inspection and maintenance schedule table

For details about the check and maintenance of the engine, please refer to the attached engine operation manual.

Caution:

The above table shows the check frequency for standard condition.

The check frequency may vary depending on the condition in which the machine is used.

For check of bolt and nut looseness and tightening, please see the following tightening torque list.

Tightening torque list (unit: kgf-cm, 1kgf-cm=9.80665N-cm)

6mm

8mm 10mm

12mm 14mm

16mm 18mm 20mm

4T(SS41)

70

150

300

500 750

1,100

1,400

2,000

6-8T(S45C)

100

250

500

800 1,300

2,000

2,700

3,800

11T(SCM3)

150

400

800

1,200

2,000

2,900 4,200

5,600

When the mating material is aluminum.

100

300~350 650~700

Thread diameter

Material

(Bolts used on the machine are all right-hand thread.)

12. Regular Check and Adjustments

Check frequency Check parts Check items Oils

Appearance

Flaw, deformation

Fuel tank

Leakage

Fuel system

Leakage

Engine oil

Leakage, oil level, dirt

Engine oil

Shock absorber Crack, damage, wear

Vibrator oil

Leakage

Engine oil

Air cleaner

Dust on sponge

Guard frame

Breakage, flaw, loosened

or missing bolts and nuts

Back and forth motion

lever operation

Operation check, play

Bolts and nuts

Looseness, missing

Engine oil

Replac

e only after

the first 20 hours

Every 2 years

Fuel pipes

Change

Air cleaner element ChangeIrregular

Daily

(before starting)

Every 20 hours

Engine oil

Change

Engine oil

Engine oil filter

Washing

Vibrator oil

Leakage, oil level, dirt

Engine oil

V-belt for vibrator Flaw, tension

Clutch

Dirt, flaw, wear

Vibrator oil

Change

Engine oil

Fuel filter

Change

Every 300 hours

Every 100 hours

Every 200 hours

Engine oil

Page 18

15

Fig.8

Changing the engine oil

Perform the first engine oil change after 20 hours of

operation, then change at every 100 hours.

Cleaning the air cleaner

When the air cleaner element becomes dirty, the

engine does not start smoothly, and sufficient output

can not be obtained. Machine operation will be

affected and the engine life will be shortened greatly.

Do not forget to clean the element. (For details, please

see the separate engine operation manual.) If the

element can not be cleaned, replace it with a new one.

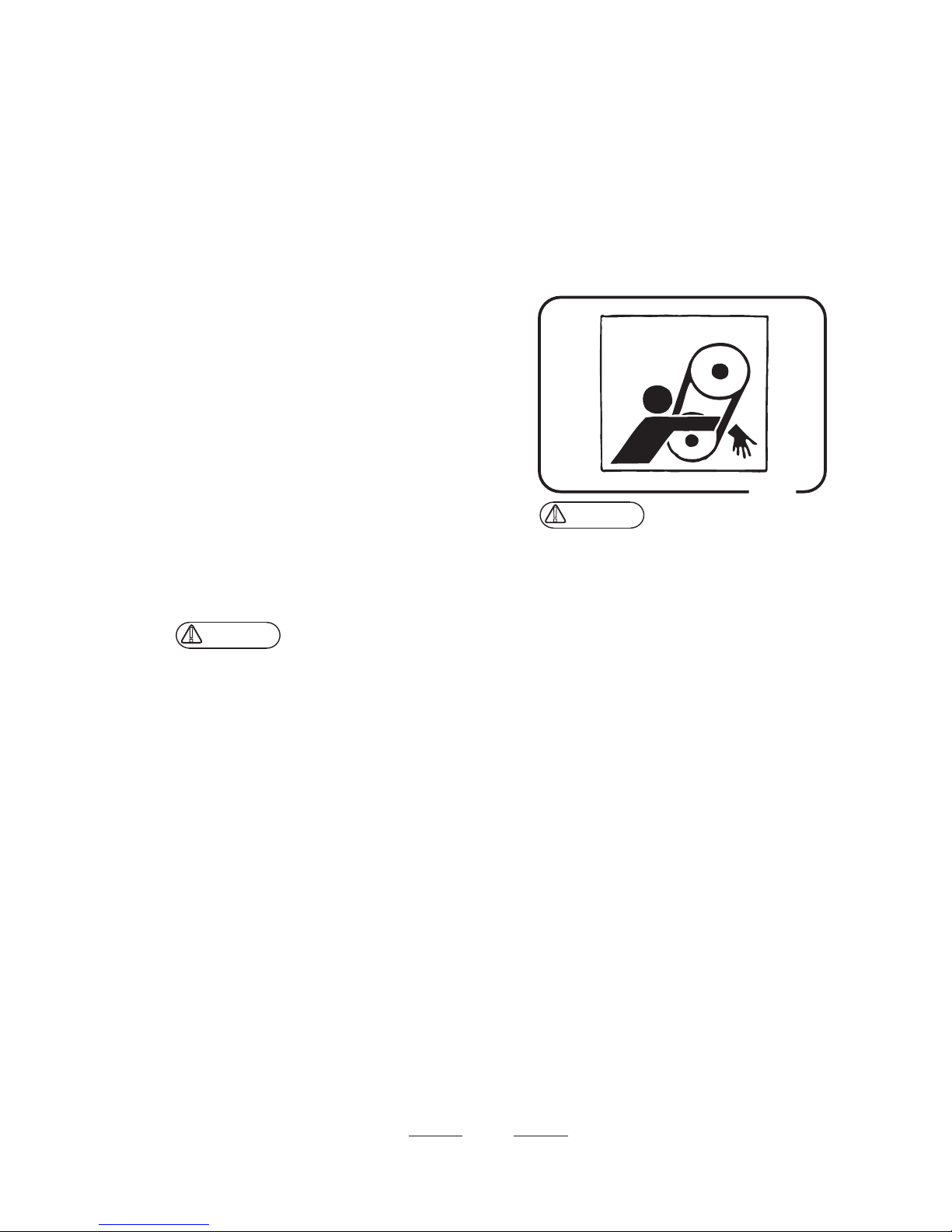

Checking/Changing V-belt and Clutch

Checking V-belt

Remove the belt cover and check that V-belt is

properly stretched every 200 hours. Press on the

portion midway between the two shafts with your

fingers strongly. The belt is properly stretched if that

portion bows by about 10-15 mm.

Checking the clutch

Inspect the clutch concurrently with the inspection of

V-belt. Check visually for burning of each clutch-shoe.

Check for wear the lining shoe or the like in the

operation check. If the shoe wears, power

transmission is not performed properly and the clutch

slips. Check wear of and damage to the V-groove. If

the V-groove is stained, clean it thoroughly.

When the vibration weakens during operation, or this

machine does not vibrate at all though the engine

rotates normally, conduct the inspection or change of

the V-belt and clutch without regard to the regular

inspection of every 200 hours.

Inspection and Change of vibrator oil

Make this machine level, and remove the oil level plug

off the vibrator. Check that vibrator oil is provided up

to the mouth level. The oil level plug is on the right

side of the vibrator case (opposite to the belt side).

(Refer to Fig.1 on page 10.)

Use the engine oil #10W-30 for vibrator oil. Refer to

page 7 for the amount. Drain the vibrator oil

completely by removing the plug and tilting the body

once a month or every 200 hours’ operation. Replace

with new oil.

12.2

12.3

12.4

1

2

12.5

CAUTION

!

Always stop the engine before inspection and

adjustment. If you are caught in a rotating part,

serious injury might occur.

CAUTION

!

Page 19

1. Gasoline engine

(1) Starting problem

Fuel is supplied, but

Spark Plug does

not ignite

Electricity reaches

to High Voltage Cable

Electricity does not

reach to High Voltage

Cable

Bridging Spark Plug

Carbon accumulated on Spark Plug

Short circuit due to insulation problems of

Spark Plug

Inappropriate gap of Spark Plug

Short circuit of Stop Switch

Ignition coil problems

Oil Sensor problem

Th

e wrong fuel is used

Mixing of water or dust contamination

Air Cleaner not working

Intake/Exhaust Valve is stuck or pushed up

Piston Ring, Cylinder wear enough

Cylinder head, Spark Plug tightening problem

Head gasket or Spark Plug Gasket breaks

Compression is

good

No fuel in tank

Fuel Cock does not open properly

Clogging of Fuel Filter

Clogging of Tank Cap Air Hole

Air trapped in fuel pipe

Fuel supplied, and

Spark Plug

ignites

Fuel does not reach

to Carburetor

(2) Operation problem

Compression is

good and no firing

problem

Insufficient compression (see the item “compression is not good.” )

Compression is

good, but no firing

Water mixed in fuel

Dirt of Spark Plug

Ignition Coil problem

Lowered power

Engine overheating

Carbon accumulated inside combustion chamber and exhaust hole.

Thermal value of Spark Plug is poor

Dirt and breakage of Cooling Fin

Revolution fluctuation

Governor adjustment inappropriate

Governor Spring problem

Fuel flows in proper

Air taken from Intake Pipe line

Clogging of Pilot Jet ( Idle speed fluctuates improper)

(3) Recoil Starter does not work well

Clogging of dust from rotating part

Weakening of Spiral Spring

16

13. Troubleshooting

nsufficient engine output and inappropriate high speed set revolution

Slipping of Clutch

Slipping of V-belt

Too much vibrator oil

Failure inside Vibrator Unit

Wear / damage of Shock Absorber

2. Main body

Low travel speed and

vibration weak

D

irt of Air Cleaner

Carbon accumulated in Cylinder.

Fuel Level in Carburetor inproper

Compression is

not good

Page 20

(402-04801)08-07-00(BSC)

Loading...

Loading...