Page 1

TAMPINGRAMMER

MTX-60ER

MTX-70ER

MTX-80ER

Original

INSTRUCTIONMANUAL

EN

302-05401

Page 2

Page 3

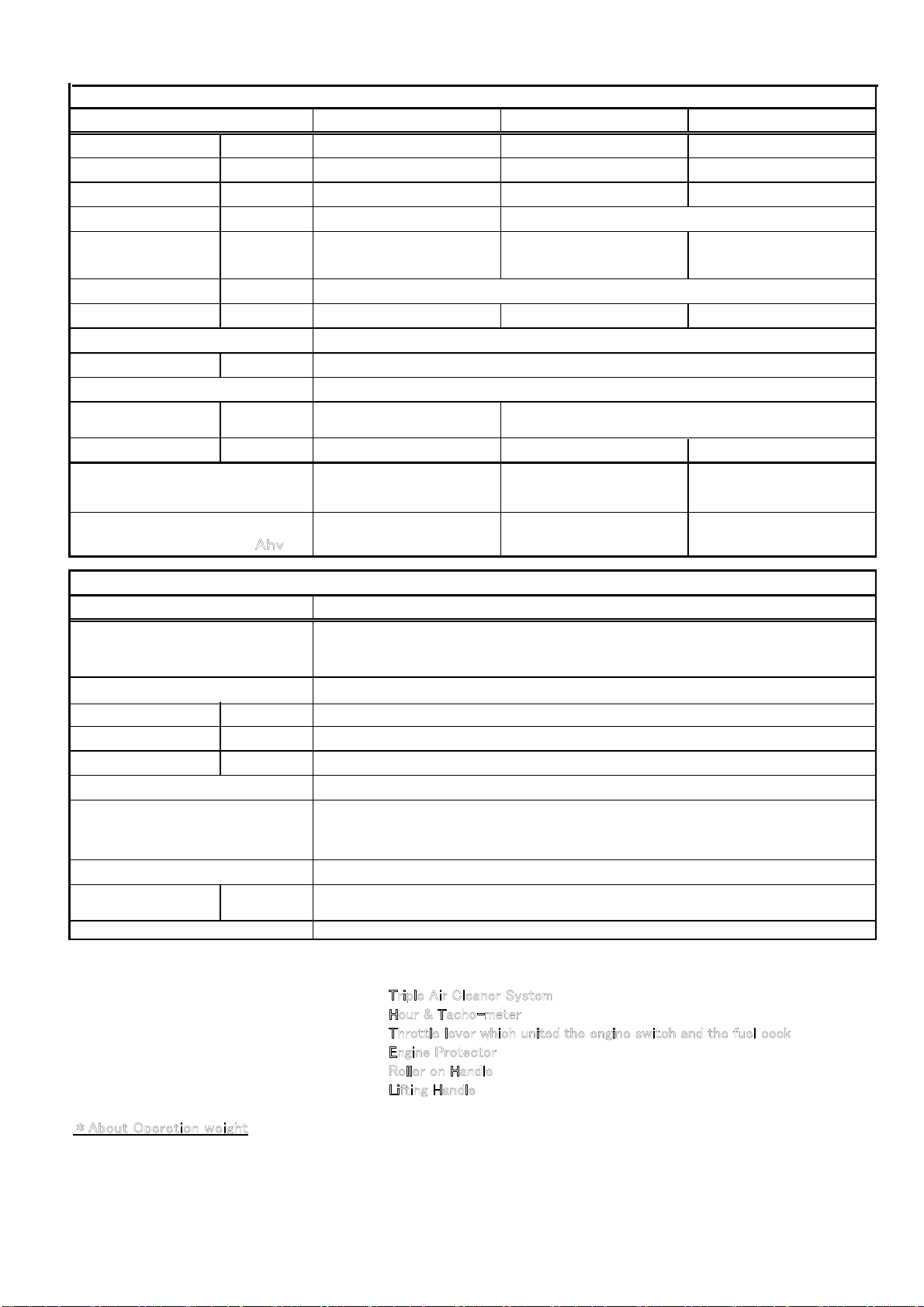

Specifications for MTX-series

t

y

t

2012-05-01

Rammer Specifications

Model MTX-60ER MTX-70ER MTX-80ER

Overall height mm 1,025 1,027 1,027

Overall width mm 350 350 365

Overall length mm 713 788 788

Shoe Size W x L mm 265 x 340

Number of Blow

Jumping stroke mm

Hz 10.7 ~ 11.6 10.7 ~ 11.6 10.7 ~ 11.3

(min

-1

)

(644 ~ 695) (644 ~ 695) (642 ~ 679)

50 ~ 80

Impact Force kN (kgf) 13.6 (1,390) 14.9 (1,520) 15.6 (1,590)

Clutch

Fuel Tank Capacity liters

Lubricant for Body

Capacity of Lubrican

for Bod

liters 0.65

Automobile Oil SAE 10W-30; Class SE or higher

Automatic Centrifugal

2.5 liters

0.82

Operating weight kg 64 kg 75 kg 83 kg

285 x 340

Guaranteed Sound Power Level

(in comply with 2000/14/EC)

Hand Arm Vibration (m/sec

comply with 2002/44/EC) A

2

) (in

hv

Engine Specifications

Model

Type

Caburetor System

Piston Displacement cc

Max. Output kw / rpm

Setting speed rpm

Starting System

Spark plug

Only use the anti-EMI

(electromagnetic interference) type

Lubricant for Engine

Capacity of Lubrican

for Engine

Fuel

liters

107 dB 107 dB 107 dB

5.2 5.6 5.6

Robin ER120D45000

Air-Cooled 4 Stroke, OHV,

Single cylinder gasoline engine.

Diaphragm type

121

2.6 / 3,600

3,800 - 4,100

Recoil starter

NGK : CR5HSB

Automobile Oil ; Class SE or higher

0.35

Unleaded gasoline

Features are subject to change

Standard Equipment:

T

riple Air Cleaner System

Hour & Tacho-meter

Throttle lever which united the engine switch and the fuel cock

Engine Protector

oller on Handle

R

Lifting Handle

*About Operetion weight

1) Fuel tank is filled up with one half of the fuel of regulation tank capacity.

2) Oil measure of the body and engine is included the stated capacity

Page 4

MTX TAMPING RAMMER INSTRUCTION MANUAL

Table of contents

Preface

Application

Warning about incorrect applications and techniques

Structure

Power transmission

Warning labels

Precautions for safety

General precautions

Precautions when adding fuel

Precautions about where to use the machine

Precautions before starting work

Precautions while lifting

Transportation and storage precautions

Maintenance precautions

Places where decals are attached

Dimensions

Components

Inspection before operation

Operation

Starting

Operation

Stopping the machine

Maintenance and storage

Periodic checks and adjustments

Troubleshooting

............................................................................ 1

........................................................................ 1

........................................................................... 1

.......................................................... 1

.................................................................. 2

....................................................... 2

.................................................... 2

..................................... 3

............. 3

.............................. 3-4

............................................... 4

...................... 5

............................................ 5

................................... 6

....................................................................... 8

................................................................... 9

........................................... 10

........................................................................ 11

...................................................................... 11

.................................................................. 12

.................................................... 13

............................................... 14

.............................. 14-16

.............................................................. 17

..... 1

Page 5

Preface

This instruction manual describes the proper methods for using the tamping rammer, as well as

simple checks and maintenance. Be sure to read this instruction manual before using the

rammer, in order to get full use of the excellent performance of this machine, to improve your

operation and to perform engineering work effectively.

After reading this manual, store it in a handy location for easy reference.

For details about the engine in this machine, see the separate instruction manual for the

engine.

For inquiries about repair parts, parts lists, service manuals, and repair of the machine, please

contact the shop where you purchased it, our sales office, or the Mikasa Parts Service Center.

In addition, parts lists are available on the MIKASA website at:

http://www.mikasas.com/english/

The illustrations and the figures in this manual may be different from the machine

you actually purchased due to design changes and other reasons for improvement.

Application

Though compact and lightweight, this rammer creates a strong impact and you may expect a

large tamping effect on the ground.

It will compact nearly all types of soil, except soft soil that contains too much moisture.

Use this rammer to tamp the ground for creating roads, embankments, and to prepare the

surface to support buildings. It can also be used when burying gas or water lines, and electric

cables.

Warning about incorrect applications and techniques

Do not use this machine on ground that is harder than the machine can handle, or for driving

pilings or tamping rock beds. Furthermore, use of the machine on sloping ground such as the

side of an embankment, may be make the machine unstable and can cause an accident. It can

also result in premature machine wear due to uneven loads on the machine.

Use the machine with confidence for tamping earth and sand, soil, sand, gravel, and asphalt.

Do not use the machine for other type of jobs.

Structure

The upper section of the machine functions as a weight and consists of an engine section

guide, a gear reducer section, and reciprocating section. It also accommodates the handle and

the fuel tank sections, which are connected by rubber dampers.

The lower section of the machine which hits the ground, consists of a spring case to engage

sliding motion, a sloping section to allow the machine to tilt toward the front, bellows to cover

the foot, a sliding section, and a protective sleeve.

Power transmission

Power is provided by an air-cooled, 4-cycle, single-cylinder gasoline engine. The output end of

the engine crankshaft is equipped with a centrifugal clutch.

As the engine speed increases, the centrifugal clutch expands and a pinion gear that is a part

of the clutch drum engages a gear in the crank shaft on the main frame. The engine speed is

decreased in order to produce the required force for tamping.

The rotating motion of the main frame crankshaft is converted to a reciprocating motion through

a connecting rod. This reciprocating motion causes the foot to go up and down through a strong

coil spring. The weight of the main body and the strong force from the engine compress the

spring and the foot moves up and down, striking the ground forcefully.

1

Page 6

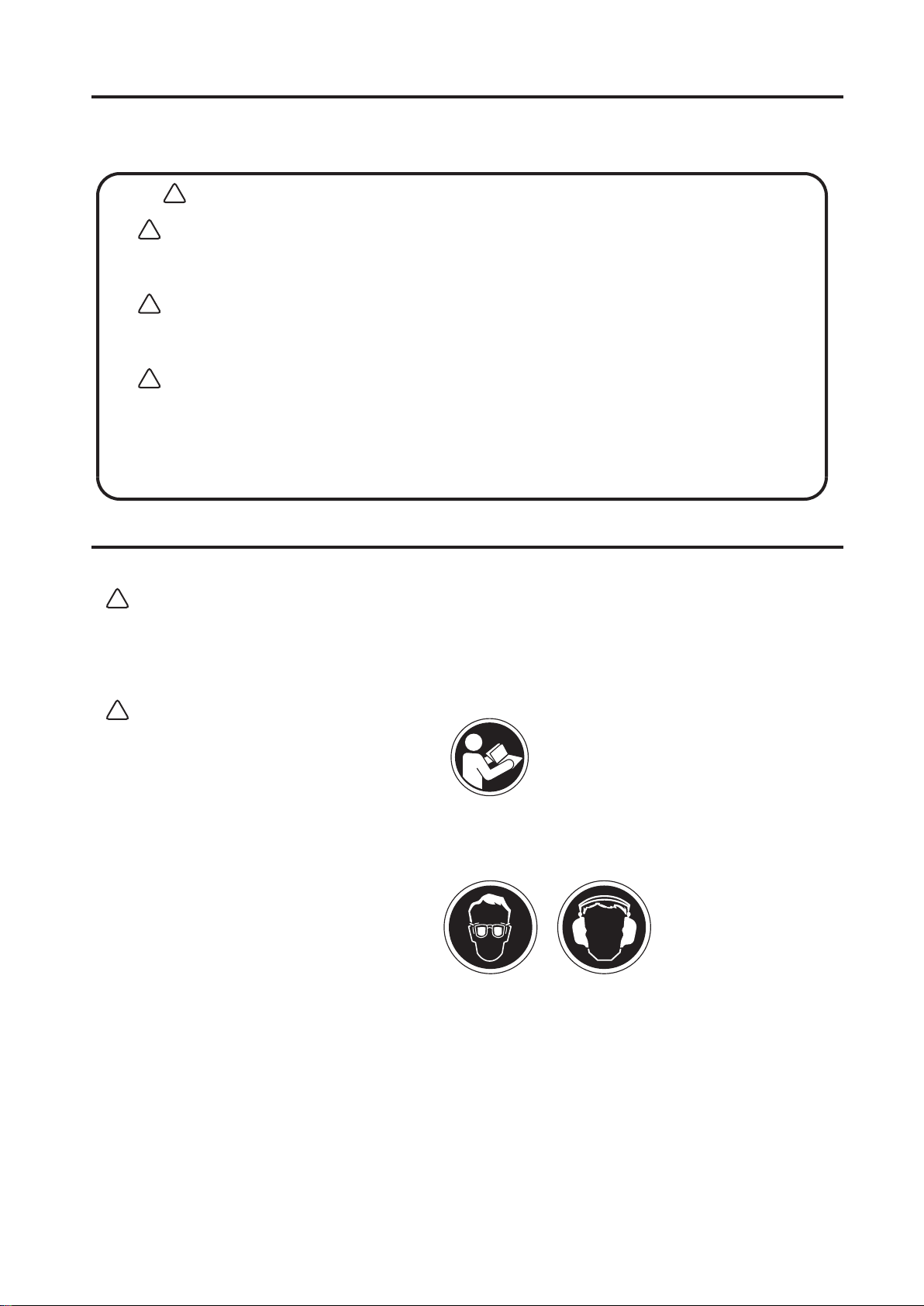

Warning labels

The triangle shaped marks used in this manual and on the decals stuck on the

main body indicate common hazards. Be sure to read and observe the cautions

described.

Warning labels indicating hazards to humans and to equipment.

!!

!!

DANGER:

Denotes an extreme hazard. It calls attention to a procedure,

practice, condition or the like, which, if not correctly performed

or adhered to, is likely to result in serious injury or death.

!!

WARNING:

Denotes a hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or

adhered to, could result in serious injury or death.

!!

CAUTION:

Denotes a hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or

adhered to, could result in injury to people and may damage or

destroy the product.

Precautions (without a triangular mark):

Failure to follow the instructions may

result in damage to property.

Precautions for safety

General precautions

!!

WARNING

■

DO NOT work in the following conditions.

- If you do not feel well due to overwork or illness.

- If you are taking any medicine.

- If you are under the influence of alcohol.

!!

CAUTION

■

Read this instruction manual carefully

and handle the machine as described

so that you can work safely.

■

For details about the engine, refer the separate instruction manual for the engine.

Make sure you thoroughly understand the construction and operation of the machine.

■

T o w o r k s a f e ly , a l w a y s w e a r

protective clothing (helmet, safety

glasses, safety shoes, ear plugs etc.)

and appropriate work clothes.

Always check the machine to make

sure that it is normal before starting

operation.

■

The decals on the machine body (operating methods, warning decals, etc.) are very

important to ensure safety. Keep the machine body clean so that they can be read at all

times. If any decal cannot be read, replace it with a new one.

■

It is very dangerous if children come into contact with the machine. Take the utmost care

about how and where the machine is stored.

■

Before performing any maintenance, be sure to turn the engine off.

■

Mikasa does not accept any liability for accidents or problems caused as a result of not

using genuine Mikasa parts (foot assembly, etc.), or if the machine has been modified.

2

Page 7

Precautions when adding fuel

!

DANGER

■

When adding fuel.

-

Be sure to work in a well ventilated location.

-

Be sure to turn the engine off and wait until it has cooled down.

-

Take the machine to a clear flat location without any combustibles nearby. Be careful not

any over fuel. If you do spill some gasoline, wipe it all up.

-

Do not allow any open flames nearby

while adding fuel. (In particular,

smoking while adding fuel is strictly

prohibited.)

■

Adding fuel until it comes too close to the top of the inlet may cause the fuel to overflow.

That is dangerous. Follow the instructions in the engine manual about the specified fuel

level.

■

When through adding fuel, tighten the tank cap securely.

Precautions about where to use the machine

!

DANGER

■

DO NOT run the engine in an

unventilated location, such as indoors

or in a tunnel. The exhaust gas from

the engine is carbon monoxide and is

deadly.

■

DO NOT operate the machine near

open fires.

Precautions before starting work

CAUTION

!

■

If you use the machine for a long time, be careful to watch for signs of vibration syndrome.

Since this machine vibrates, operation for a long time may have a negative effect on your

body. Take sufficient breaks while working.

■

Before starting to operate the machine, check for other people or obstacles that are too

close for safe operation.

■

When starting the engine, the rammer may jump suddenly. Hold the handle firmly with one

hand and pull the recoil starter with the other hand.

■

Always be careful around scaffolding. Operate the rammer in a stable manner so that it will

not become unbalanced.

■

During operation, don't let the foot of the machine come too close to your foot. The plate

may smash your foot.

■

The main parts of the engine, the

muffler, and muffler cover will be very

hot during operation. Be careful not to

touch them during operation or soon

after operation.

■

If you encounter any problems or abnormality with the machine during operation, while

moving it or stopping operation, stop work immediately.

■

Before leaving the machine, be sure to turn the engine off. Also, make sure to turn the

engine off if you want to move the machine. When the throttle lever is in the stop position,

the fuel cock is closed. Do not move the lever away from the stop position.

■

When lifting the machine by the handle, be careful not to pinch your fingers between the

handle and main body.

3

Page 8

Precautions before starting work(Continued)

!

DANGER

■

Take the utmost care not to allow the

machine to fall during work, or when

stopped or stored. Secure the

machine with a rope or similar tie

when stored or left idle so that it

cannot fall. If the rammer falls over

when children are around, a serious

accident may occur. If the machine

foot is worn, the machine will be

especially unstable. If the machine

foot is worn badly, replace it with a

new one.

■

If the machine falls over while working, the machine will move forward due to the kicking

motion of the foot while it is lying on its side. If the ground is solid, it will move quickly and is

very dangerous. To ensure that the operator and anyone nearby are safe, turn the throttle

lever to the engine stop position and make sure the machine stops. You must be extremely

careful when working on a road because a serious accident can easily occur.

Precautions while lifting

!

DANGER

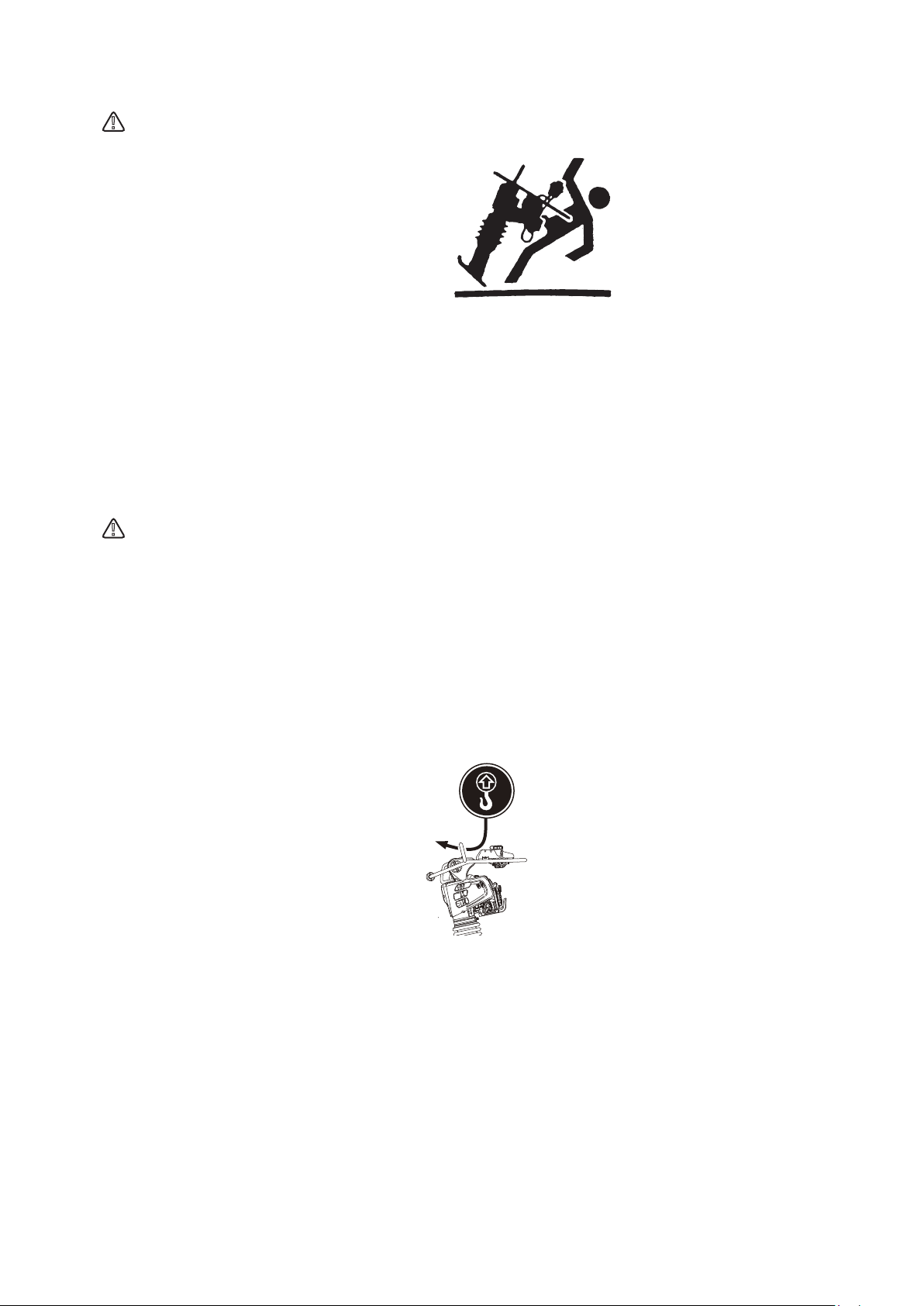

■

Before lifting the machine, make sure that there is no damage to any of the components on

the machine (look especially for damage to the rubber mounts and the hook). There must

not be any loose or missing screws and the machine must generally be in a safe condition.

■

Turn the engine off before lifting the machine.

■

Use wire cables with enough strength to support the machine.

■

DO NOT lift it higher than necessary, for safety.

■

DO NOTuse a damaged wire cable.

■

Only use the single hook to lift the

machine. DO NOT support it from any

other points (such as the handle).

■

Never lift or lower the machine rapidly when using a hydraulic shovel or a crane.

■

When lifting the machine, do not allow any people or animals to pass under or near the

machine.

■

When using any type of equipment to lift the machine, be careful that the lifting equipment

does not cause an accident. Make sure you check the lifting equipment carefully, to ensure

that there are no problems or damage.

4

Page 9

Transportation and storage precautions

!

DANGER

When transporting

■

Before transporting the machine, stop the engine.

■

DO NOT try to move it before the engine and machine body have cooled down enough.

■

Drain any fuel before transporting the machine.

■

Transport the rammer in a manner that keeps it level. If you must lay the machine down to

transport it, drain any fuel from the fuel tank and carburetor. Then close the fuel tank cap

and oil fill plug securely. Next, position the machine so that the carburetor will be facing up.

■

Secure the machine body so that the machine cannot move or fall during transportation.

■

When you want to lift the machine by gripping the handle, be careful not to pinch your

fingers or hands between the handle and the main body.

■

Since this machine is quite heavy, use a truck specifically designed to transport heavy

objects.

When storing the machine

■

After the engine and machine body have cooled down enough, store the rammer so that it is

level. Fasten the machine as needed so that the machine cannot fall down. If you must lay

the machine down, close the fuel tank cap and oil fill plug securely. Arrange the machine

position so that the carburetor will be facing up. After it lays down, make sure there are no

oil or fuel leaks. (If fuel is leaking, drain it all from the fuel tank.)

Maintenance precautions

!

WARNING

■

Appropriate maintenance of the machine is required to ensure safety and keep the machine

performing well. Always be aware of the machine's condition and keep it in good condition.

!

CAUTION

■

Be sure to turn the engine off before

checking or adjusting the machine.

■

The muffler and muffler guard

become very hot. Do not touch them

until they will have cooled down.

■

The lubrication oil and engine oil are

very hot and can burn you. Do not

start any maintenance on the

machine while the oil remains hot.

■

After performing any maintenance, check the condition of the safety components and the

general safety of the machine. In particular, check the nuts and bolts thoroughly.

■

If you have to disassemble any components on the machine, be sure to refer the

maintenance standard sheets and always work safely.

5

Page 10

Places where decals are attached

1

<

Gasoline Only (

E10)

=

Essence Uniquement

Bitte nur Benzin elnfullen

Usare solo Benzina

Solo para Gasoline

4

NPA-0000

2

3

5

STOP

NPA-0000

8(QUICK MANUAL)

series

quick manual

Engine Oil

Use SAE 10W/30,SE or higher grade motor oil

RAMMING CYLINDER OIL

Use SAE 10W/30,SF or higher grade moter oil

Fuel

Use normal quality gasoline

11

MODEL/MACHINE TYPE/

MODELL/MODELLO/MODELO

SERIAL NO./N DE SERIE/

FABRI.NR./N.MATRICOLA/

N.MATRICULA

WEIGHT/POIDS TOTAL/

BETREIBSGEWICHT/

PESO.MAX./PESO OPERATIRO

OUTPUT/PUISS.MAXI./

LEISTNG/POTENZA MASSIMA/

POTENCIA MAX

1-4-3,Sarugaku-cho,Chiyoda-ku,Tokyo,Japan

6

MIKASA SANGYO CO.,LTD

7

Made in Japan

NPA-0000

NPAJ1284

-

kg

kw

6

Page 11

No.

1

2

3

4

5

6

7

8

11

11

11

Part No.

9202-15440

9202-12460

9202-12470

9202-12490

9202-12480

9202-10310

9202-12840

9202-12540

9202-16870

9202-16860

9202-16850

Part Name

DECAL,OPERATION

DECAL,AIR CLERNER

DECAL,LEVER OPERATION

DECAL,MAX SPEED 4100

DECAL,MACHINE STOP

DECAL,EC NOISE REQ.LWA107

DECAL,CHOKE OPERATION

QUICK MANUAL

PLATE,SERIAL NO./MTX-60

PLATE,SERIAL NO./MTX-70

PLATE,SERIAL NO./MTX-80

Descriptions of the symbols on the warning decals

A.

A

E

F

B

G

H

DC

I

J

K

M

L

<

Gasoline Only (

E10)

N

7

6

=

Essence Uniquement

Bitte nur Benzin elnfullen

Usare solo Benzina

Solo para Gasoline

Read the instruction manual carefully

B.

Don't fill the fuel tank while the engine is running or hot.

C.

Don't operate the machine in a poorly ventilated area.

D.

Fire hazard

E.

Danger: poisonous exhaust gas

F.

Be careful not to get burned

G.

Don't let your foot slip under the machine foot.

H.

Lay the machine down carefully

I.

Wear protective clothing, such as safety glasses.

J.

Wear protective clothing, such as ear protectors.

K.

Lift point.

L.

Lifting with a forklift is prohibited

M.

Lifting the machine by the engine guard is prohibited

N.

Fuel specification (gasoline)

Remarks

MTX-60ER

MTX-70ER

MTX-80ER

MODEL/MACHINE TYPE/

MODELL/MODELLO/MODELO

SERIAL NO./N DE SERIE/

FABRI.NR./N.MATRICOLA/

N.MATRICULA

WEIGHT/POIDS TOTAL/

BETREIBSGEWICHT/

PESO.MAX./PESO OPERATIRO

OUTPUT/PUISS.MAXI./

LEISTNG/POTENZA MASSIMA/

POTENCIA MAX

MIKASA SANGYO CO.,LTD

1-4-3,Sarugaku-cho,Chiyoda-ku,Tokyo,Japan

Made in Japan

Starting and running

1)

Slide the throttle lever to the idle position.

2)

Turn the choke lever to the "Closed" position.

3)

Pull the recoil starter handle.

4)

Turn the choke lever to the "Open" position.

5)

Slide the throttle lever to the operating position.

Stopping

6)

After work, slide the throttle lever to the idle position.

7)

After the machine has cooled down a little, slide the

throttle lever to the stop position.

Product number name plate

Product name, machine serial number, weight,

engine output, and CE mark

kg

kw

7

Page 12

Dimensions

350(MTX-60ER,70ER)

365(MTX-80ER)

713(MTX-60ER)

788(MTX-70ER,80ER)

1025(MTX-60ER)

1027(MTX-70ER,80ER)

265(MTX-60ER)

285(MTX-70ER,80ER)

8

340

Page 13

Components

AIR CLERNER COVER

(UPPER)

ROLLER ASSY

HOOK

COMBINATION LEVER ASSY

HANDLE ASSY

FOOT ASSY

FUEL TANK CAP ASSY

BELLOWS

FUEL TANK ASSY

MUFFLER

ASSY

ENGINE ASSY

HOUR AND TACHO METER

RECOIL STARTER

OIL GAUGE

DRAIN PLUG

9

Page 14

Inspection before operation

!

WARNING

■

Only check the machine while the engine is stopped. Otherwise, you may be caught by the

rotating components and be seriously injured.

■

Check the machine body only after it

has cooled down. The muffler is very

hot and you may be badly burned.

Inspection points

Appearance

Air cleaner

Bolts, nuts

Handle

Rubber damper

Engine oil

Main body lubrication oil

Fuel tank

Fuel system

Clean each component thoroughly so that

1

Inspection items

Flaws, deformity, stains

Stains, flaws, deformation

Loose or missing parts

Flaws, deformity, cracks, breaks

Flaws, deformity, cracks, breaks

Leaks,oil level,dirt

Leaks,oil level,dirt

Leaks, fuel level, presence of dirt

Leaks, wear, loose parts

there is no mud or dirt on it.

In particular, remove any mud on the machine

foot, and clean the area a round the reco il

starter and carburetor.

2

Ma ke sure that all of the screws are tight.

Loose screws may cause an accident due to

the vibration.

3

To check the engine oil, place the machine

body on a level surface and then tilt it forward.

(Fig.1)

For details about the engine, see the separate

instruction manual for the engine.

4

Place the machine body on a level surface and

look at the oil gauge on the protective sleeve,

from the right side. See if the o il is at the

specified level. (Fig.2)

Use 10W-30 engine oil rated SE

or SF o

better for the engine.

Oil level gauge

Fig.1

Oil gauge assy

Drain plug

r

Add regular gasoline (Unleaded) to the fuel

5

tank and check the engine oil. Add oil before it

gets too low. Too little engine oil may cause

the engine to wear prematurely. (Fig.3)

Use 10W -30 engine oil rated SE or SF or

better for the engine.

!

DANGER:

!

CAUTION:

Fire hazard while refueling.

If any fuel spills, wipe it all up.

10

Fig.2

Fig.3

Page 15

Operation

Starting

Slide the throttle lever from the stop to the idle

1

position( ). That opens the fuel cock and the

e ngin e e l e c t r i c a l c i r c u i t i s t urne d o n

automatically. (Fig.4-1)

Diaphragm carburetor with Primer system

Push the bulb at Primer Pump several times, which

delivers fuel to the carburetor forcibly. (Fig.4-2)

Note

The one possible problem with Primer System is

the fuel flooding in the carburetor because the

bulb is pressed in excessive times.

Fig.4-1

Push the choke lever on the carburetor to the

2

cl osed pos ition. When it is cold, close the

choke all the way. When it is hot, such as in

the summer, or when the engine is already hot,

open the choke a little or leave it fully open.

If the engine cannot be st arted , open the

choke a little so as not to flood the carburetor.

(Fig.5-1, 5-2)

Primerpump

Diaphragm carburetor

Float carburetor

Fig.4-2

Fig.5-1

Fig.5-2

11

Page 16

Hold the recoil starter handle and pull it a little.

3

You will feel resistance. Then, pull it hard to

turn the engine. Allow the starter rope to return

slowly into the case before letting go of the

handle. (Fig.6)

After the engine has started, open the choke

4

lever gradually until it is wide open. Pay

attention to the sound of the engine to guide

you in the amount to open the choke. After the

engine has started, be sure to warm up the

engine at low speed for 3 to 5 minutes. During

this time, check the machine for leaking fuel,

abnormal sounds, or abnormal exhaust color

or odor.

Fig.6

CAUTION:

If the engine cannot be started after pulling the

5

starter handle several times, remove the spark

plug and see if it has a spark. If the plug is wet

from fuel (due to flooding from the carburetor),

or if it is stained, replace the plug or clean it

thoroughly. While the plug is removed, pull the

starter handle 2 to 3 times to discharge any

fuel from the cylinder.

When warming up, if in the semiclutch in order not to be,pay

attention to engine speed.

Operation

Shift the throttle lever from idle( ) to the

1

operating position( ) (Fig. 7) and the tamping

rammer will start up and down motions.

Shifting the lever slowly will cause irregular

operation and damage the clutch, springs, and

foot.

CAUTION:

If you start it’s operating too quickly

the engine may stop due to the

operation of the carburetor.

2

After operation is started, adjust the throttle

lever a little until the rammer tamps the soil

correctly. When the engine is running within

the specified rpm range, the rammer will be the

most effective. If the engine runs too fast, the

tamping force will not be increased. Instead,

the spring resonance will decrease the

tamping force and damage the machine.

WARNING:

If the rammer is used on sloping

ground, check the safety of the

surroundings and be careful not to

allow the machine to fall over.

12

Fig.7

Page 17

In the cold season, the oil in the machine will be

3

thicker, and the resistance of the components

will be much larger, which may cause irregular

motion . Shift the thr ottle lev er fr o m the

operation to the idle position several times and

allow it to warm up sufficiently before starting

actual work.

4

The surface of the foot in contact with the

ground is a metal sheet that has excellent wear

resistance. However if you need to tamp ground

that contains large stones (about the size of a

fist), first put some fill soil over them so that the

foot will tamp the ground evenly.

5

The machine body will advance as it jumps. If

you want to move forward faster, push the

handle a little forward to make the machine

body lean a little forward.

6

To halt work, quickly slide the throttle lever from

the operation position( ) to the idle position

( ). Do not slide the throttle lever slowly

(Fig.8).

Stopping the machine

1

Slide the throttle lever from the operation

position( ) to the idle position( ). Run the

engine at low speed for 3 to 5 minutes to cool it

down. Then slide the throttle lever from the idle

position to the stop position. The engine will

stop and the fuel cock is closed automat

(Fig.9)

If

the engine does not stop due to a problem

2

with the switch or something similar, take the

machine to a safe location and hold the throttle

lever in the stop position. Let the machine run in

idle and the engine will stop after a few

minutes.

Fig.8

ically.

fig.9

13

Page 18

Maintenance and storage

Wash off any dirt or mud on each part of the

1

machine using fresh water.

After the engine and main body have cooled

2

down, store the rammer on a level location.

Secure the machine body so that it can not fall

down. If you have to lay the machine down,

close the fuel tank cap securely and tighten

engine oil drain plug. After the engine and

machine body hav e c ooled down, lay the

machine so that the carburetor is facing up.

4

For prolonged storage

- Slide the throttle lever to the stop position.

- Drain any fuel and replace the lubrication oil.

Apply grease to the lubrication points.

Be sure to remove any fuel in the fuel hose,

too.

- Cover the air intake on the air cleaner and

the exhaust outlet on the muffler.

- Store the machine indoor. Do not leave it

outside.

Once the machine has been laid down, make

sure that there is no fuel or lubrication oil leaks.

(If the fuel leaks, drain the fuel from the fuel

tank.)

3

Put a cover on the machine body to prevent

dirt landing on it. Store the machine in a

location that is not exposed to direct sunlight

and which has low humidity.

Periodic checks and adjustments

Table of scheduled checks

How often? Place to check Item to check Others

Daily

(before starting operation)

After first 20 hours

Every 50 hours Spark plug

Every 80 to 100 hours Cleaning

Every 200 hours

Every 2 years Fuel hose

Appearance

Air cleaner

Bolts, nuts

Handle

Rubber damper

Engine oil

Main body lubrication oil

Fuel tank

Fuel system

Engine oil

Engine oil

Primary element

Secondary elementEvery 100 to 150 hours Cleaning Neutral detergent

Lubrication oil in

the main body

Pipe, Intake

Flaws, deformity, stains

Dirt, flaws, deformation

Loose or missing parts

Flaws, deformity, cracks, breaks

Flaws, deformity, cracks, breaks

Leaks,oil level,dirt

Leaks,oil level,dirt

Leaks, fuel level,presence of dirt

Leaks, wear, loose parts

Replace once, after the first 20 hours

Clean, adjust gap

Replace

Replace Engine oil

Replace

Replace

Engine oil

Engine oil

Gasoline

Engine oil

Engine oil

Lamp kerosene

Engine oil(25-30cc)

(water washing and

dry)

14

Page 19

Periodic checks and adjustments(Continued)

Daily maintenance

1

Carefully wipe off any mud, dirt or oil from

each component.

If oil leaks, retighten the joints and check

again.

Maintenance after every 50 hours of operation

2

Remove the fuel filter cup and clean the inside

thoroughly. (Fig.10) Remove the spark plug and

clean it. Then adjust the gap to 0.6 to 0.7 mm.

Replacing the lubrication oil

3

Remove the drain plug on the lower part of the

machine body and drain the oil inside. Then

add the specified amount of new oil.

(Fig.11)

Model

MTX-60ER MTX-70ER MTX-80ER

Oil gauge

Drain plug

Fuel filter

fig.10

Capacity

(liters)

Cleaning the air cleaner

4

Remove the upper air cleaner cover on the

main body. Loosen and remove the 2 Phillips

screws that hold the cover on the air cleaner

assembly.

a.

Primary element (clean every 80 to 100 hours)

If the primary element is dirty, wash it with

gasoline or lamp kerosene. Then, dip it in

engine oil SAE10W-30 and wring it out. (Wring

the element so that 25 to 30 cc of engine oil

remains in the element.) (Fig.12)

0.65 0.82 0.82

fig.11

Primary element

fig.12

15

Page 20

b.

Secondary element (clean every 100 to 150

hours)

When the secondary element (under the

primary element) becomes dirty, wash it with

neutral detergent solution and dry it well. Then

reuse it. (Fig.13, 14)

Secondary element

fig.13

5

Be sure to check the fuel line for damaged

or looseness.

Replace the fuel line every 2 years, even if it

does not show any abnormality.

6

Cleaning the machine body

If you want to clean the machine body using

high-pressure steam, do not spray water

directly into the air cleaner, carburetor, muffler,

or top of the fuel tank. Otherwi se engine

problems may occur.

fig.14

16

Page 21

Troubleshooting

Engine

1.Won't start

Fuel is present

but the spark plug

is not sparking.

Fuel and spark

are both present.

Fuel is not being

supplied to the

carburetor.

Electricity is being

su p pl i ed to th e

h i g h v o l t a g e

cable.

Electri city is not

being supplied to

the high vol tage

cable

Compressi o n i s

good

Compressi o n i s

low

No fuel in the fuel tank.

Faulty fuel cock operation.

The fuel filter is clogged.

The air hole in the cap on the fuel tank is clogged.

Air is trapped in the fuel line.

The gap in the spark plug tip is clogged.

Carbon is stuck on the spark plug

The spark plug has a short circuit due to faulty

insulation.

The gap in the spark plug is the wrong size.

The stop button switch has a short circuit.

The ignition coil is broken.

The muffler is clogged with carbon.

The wrong fuel was used.

The air cleaner is clogged.

The fuel is contaminated with water or dirt.

The cylinder head gasket is blown or the head is not

correctly tightened.

The piston rings don't fit well.

The cylinder is worn.

The spark plug is not seated tightly.

The valve seat is damaged.

2.Faulty operation

Too little

power

Engine

overheats

Smoke

comes from

the muffler

(In the winter, the machine may emit white smoke for a while when first started in the morning.

This is not abnormal.)

Good compression

and no misfiring

Low compression (See ”Compression in low” above

Good compression

but misfires

Excessive accumulation of carbon in the combustion chamber.

Clog exhaust port or muffler.

Faulty spark plug.

Black smoke

Blue

smoke

White smoke

Good

compression

Compression

is low

Dirt in the air cleaner.

Air trapped in the fuel line.

Carbon has accumulated in the cylinder.

Faulty ignition coil.

Dirt on the spark plug.

Ignition coil shorts sometimes.

Choke lever wasn't returned to the open position.

Blended oil (for 2-cycle engines) was used.

Too much oil.

Engine oil leaked into the air cleaner when the

machine was laid down on the wrong side.

Worn piston rings.

The piston rings don't fit well.

Moisture in the gasoline.

The air cleaner is wet.

Engine speed fluctuates

Faulty governor adjustment.

Faulty governor spring.

Faulty fuel flow.

Air being sucked into the fuel line.

17

Page 22

Note

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Page 23

Page 24

Loading...

Loading...