Page 1

TAMPINGRAMMER

MT-76D

MT-76DL

INSTRUCTIONMANUAL

en

http://www.mikasas.com

WethankyouforselectingMikasaTampingRammer.

Foryoursafeandproperoperation,pleasereadthismanualand

bealwayssuretokeepitreadyforreference.

Contentsof“DeclarationofConformity”

PleaserefertheECDECLARATIONOFCONFORMITY

inthismanualaswell.

302-00912

*302-00912*

Page 2

Page 3

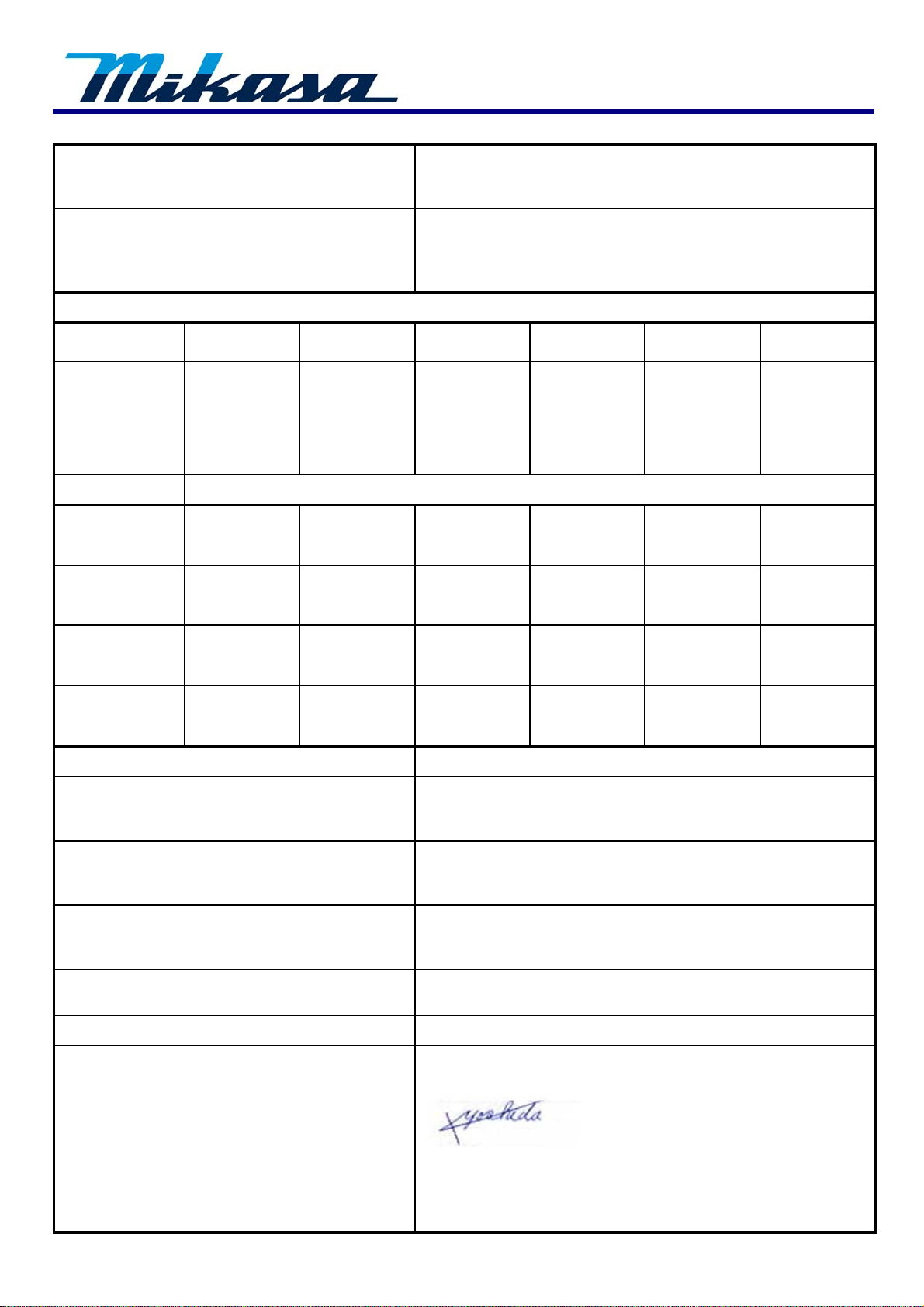

1) DECLARATION OF CO NF O RMITY

2) Manufacturer’s name and address.

3) Name and address of the person who keeps the

technical documentation.

4) Type: Vibratory Rammers

5) model

6) Equipment

item number

7) Serial number

8) power source

cont. output

<max.output>

9) Measured

sound power

level(dB)

10) Guaranteed

sound power

level(dB)

11) Operator's

sound pressure

level(dB)

MT-76D MT-76DL CE

251555, 251556,

251557, 251558,

251559, 251560

Yanmer L48N

3.1kW

<3.5kW>

251561

Yanmer L48N

3.1kW

<3.5kW>

107 105

108 107

96 97

For serial number, please refer it on front page.

12) Conformity assessment according to A nnex:

Mikas a Sangyo Co., Lt d.

4-3, Sarugaku-cho 1 chome, Chiyoda-ku, Tokyo101-0064, Japan

Takahiro Kis hino, engineer

R. & D. Division, Mikasa Sangyo Co., Ltd.

Shiraoka-city, Saitama, Japan

VIII (Full Quality Assurance procedure)

13) Name and address of the Notifi ed Body

14) Related Directive

15) Declaration

16) Other related Community Directives

17) EC Conformity Certificate No:

18) Place and date of the declaration

Société Nationale de Certification et d’ Homologation (S NCH)

11, route de Luxembourg

L-5230 Sandweiler LUXEMBOURG

Directive 2000/14/EC and, to be followed by Directive 2005/88/EC,

relating to the noise emission in the environment by equipment for

use outdoors.

The equipment referred in this document, fulfills with all the

requirements of Directive 2000/14/EC

2006/42/EC, 2005/ 88/ E C, 2004/108/EC, 2002/88/ E C(2004/ 26/EC)

EN500-1, EN500-4

e13*2000/14*2005/14*0472*01

Tokyo, Japan May, 2016

Signed by:

Keiichi YOSHIDA

Director, P roduct Control Division

Mikas a Sangyo Co., Lt d.

Page 4

Italian

Garanzia di Qualità totale )

1. DICHIARAZIONE “CE” DI CONFORMITÁ

2. Nome e indirizzo Fabbricante

3. Nome e indirizzo della persona che conserva la

documentazione tecnica

4. Tipo: Piastre vibranti

5. Modello

6. Codice macchina

7. Numeridi matricola

8. Potenza installata netta <resa massima>

9. Livello di potenza sonora misurato (dB)

10. Livello di potenza sonora garantito

11. Livello massimo di pressione sonora

12. Valutazione di conformità in accordo all'annesso VIII

( procedura Garanzia di Qualità totale

13. Nome dell'organismo notificato

14. Rappresentante Autorizzato in Europa

15. Direttiva di riferimento

13. Nom et adresse de l'organisme notifié

14. Mandataire dans la Communaute Europeenne

15. Directive concernee

Est egalement conforme aux dispositions de la directive

<<emission sonores des equipements utilises a l'exterieur

des batiments>> 2000/14/CE et aux legislations nationales

la transposant.

16. Declaration

L'équipement de référence satisfait aux exigences de la

Directive 2000/14/EC

17. Autres directives communautaires concernees

18. Certificate deConformite CE numero:

19. Lieu et date de la declaratio

Spanish

1. DECLARACIÓN “CE” DE CONFORMIDAD

2. Nombre y dirección del fabricante

Direttiva 2000/14/CE su l'emissione acustica ambientale

delle macchine ed attrezzature destinate a funzionare

all'aperto

16. Dichiarazione

Le attrezzature riportate nel documento soddisfano i requisiti

della Direttiva 2000/14/CE

17. Altre Direttive Comunitarie di riferimento

18. Certificato di Conformità CE No:

19. Luogo e data della dichiarazione

French

1. DECLARATION « CE » DE CONFORMITE

2. Non et adresse du Fabricant

3. Nom et adresse de la personne qui défient les documents

techniques

4. Type du materiel: Plaques vibrantes

5. Modello

3. Nombre y dirección de la persona que guarda la

documentación técnica.

4. Tipo: Bandejas vibrantes

5. Modelo

6. Número de referencia del equipo

7. Numeros de serie

8. Potencia neta instlada <rendimineto maximo>

9. Nivel sonoro medido del motor ( dB )

10. Nivel sonoro garantizado del motor ( dB )

11. Máximo nivel sonoro de presión ( dB )

12. Evaluación de la Conformidad de acuerdo al Anexo VIII

( Prcedimiento de total garantía asegurada )

13. Nombre y dirección de la Entidad Notificada

14. Representante autorizado

15. Directiva relacionada

Directiva 2000/14/CE en relación a la emisión sonora en el

ambiente por equipos que trabajan en espacios abiertos

6. Numero equipement

7. Numéro de série

8. Puissance reseau <rendement maximal>

9. Niveau sonore mesure(dB)

10. Niveau sonore garanti(dB)

11. Niveau sonore maximum

12. Certification de conformite selon l'annexe VIII ( procedura

16. Declaración

El equipo referido en este documento , cumple con todos los

requerimientos de la Directiva 2000/14/EC

17. Otras Directivas Comunitarias relacionadas

18. Certificado de Conformidad CE Nº

19. Lugar y fecha de la declaración

Page 5

Preface

This instruction manual describes the proper methods for using the tamping rammer, as well as

simple checks and maintenance. Be sure to read this instruction manual before using the

rammer, in order to get full use of the excellent performance of this machine, to improve your

operation and to perform engineering work effectively.

After reading this manual, store it in a handy location for easy reference.

For details about the engine in this machine, see the separate instruction manual for the

engine.

For inquiries about repair parts, parts lists, service manuals, and repair of the machine, please

contact the shop where you purchased it, our sales office, or the Mikasa Parts Service Center.

In addition, parts lists are available on the MIKASA website at:

http://www.mikasas.com/english/

The illustrations and Figures in this manual may be different from the machine you

actually purchased due to design changes and other reasons for improvement.

Application

Though compact and lightweight, this rammer creates a strong impact and you may expect a

large tamping effect on the ground.

It will compact nearly all types of soil, except soft soil that contains too much moisture.

Use this rammer to tamp the ground for creating roads, embankments, and to prepare the

surface to support buildings. It can also be used when burying gas or water lines, and electric

cables.

Warning about incorrect applications and techniques

Do not use this machine on ground that is harder than the machine can handle, or for driving

pilings or tamping rock beds. Furthermore, use of the machine on sloping ground such as the

side of an embankment, may be make the machine unstable and can cause an accident. It can

also result in premature machine wear due to uneven loads on the machine.

Use the machine with confidence for tamping earth and sand, soil, sand, gravel, and asphalt.

Do not use the machine for other type of jobs.

Structure

The upper section of the machine functions as a weight and consists of an engine section

guide, a gear reducer section, and reciprocating section. It also accommodates the handle and

the fuel tank sections, which are connected by rubber dampers.

The lower section of the machine which hits the ground, consists of a spring case to engage

sliding motion, a sloping section to allow the machine to tilt toward the front, bellows to cover

the foot, a sliding section, and a protective sleeve.

Power transmission

Power is provided by an air-cooled, 4-cycle, single-cylinder diesel engine. The output end of the

engine crankshaft is equipped with a centrifugal clutch.

As the engine speed increases, the centrifugal clutch expands and a pinion gear that is a part

of the clutch drum engages a gear in the crank shaft on the main frame. The engine speed is

decreased in order to produce the required force for tamping.

The rotating motion of the main frame crankshaft is converted to a reciprocating motion through

a connecting rod. This reciprocating motion causes the foot to go up and down through a strong

coil spring. The weight of the main body and the strong force from the engine compress the

spring and the foot moves up and down, striking the ground forcefully.

1

Page 6

Warning labels

The triangle shaped marks used in this manual and on the decals stuck on the

main body indicate common hazards. Be sure to read and observe the cautions

described.

Warning labels indicating hazards to humans and to equipment.

!

!

DANGER:

Denotes an extreme hazard. It calls attention to a procedure,

practice, condition or the like, which, if not correctly performed

or adhered to, is likely to result in serious injury or death.

!

WARNING:

Denotes a hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or

adhered to, could result in serious injury or death.

!

CAUTION:

Denotes a hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or

adhered to, could result in injury to people and may damage or

destroy the product.

Precautions (without a triangular mark):

Failure to follow the instructions may

result in damage to property.

Precautions for safety

General precautions

!

WARNING

■

DO NOT work in the following conditions.

- If you do not feel well due to overwork or illness.

- If you are taking any medicine.

- If you are under the influence of alcohol.

!

CAUTION

■

Read this instruction manual carefully

and handle the machine as described

so that you can work safely.

■

For details about the engine, refer the separate instruction manual for the engine.

Make sure you thoroughly understand the construction and operation of the machine.

■

T o work s afe l y, always wear

protective clothing (helmet, safety

glasses, safety shoes, ear plugs etc.)

and appropriate work clothes.

Always check the machine to make

sure that it is normal before starting

operation.

■

The decals on the machine body (operating methods, warning decals, etc.) are very

important to ensure safety. Keep the machine body clean so that they can be read at all

times. If any decal cannot be read, replace it with a new one.

■

It is very dangerous if children come into contact with the machine. Take the utmost care

about how and where the machine is stored.

■

Before performing any maintenance, be sure to turn the engine off.

2

■

Mikasa does not accept any liability for accidents or problems caused as a result of not

using genuine Mikasa parts (foot assembly, etc.), or if the machine has been modified.

Page 7

Precautions when adding fuel

!

DANGER

■

When adding fuel.

-

Be sure to work in a well ventilated location.

-

Be sure to turn the engine off and wait until it has cooled down.

-

Take the machine to a clear flat location without any combustibles nearby. Be careful not

any fuel. If you do spill some fuel of diesel, wipe it all up.

-

Do not allow any open flames nearby

while adding fuel. (I n par

smoking while adding fuel is strictly

prohibited.)

■

Adding fuel until it comes too close to the top of the inlet may cause the fuel to overflow.

That is dangerous. Follow the instructions in the engine manual about the specified fuel

level.

■

When through adding fuel, tighten the tank cap securely.

tic ular,

Precautions about where to use the machine

!

DANGER

■

D O NO T run the engine in an

unventilated location, such as indoors

or in a tunnel. The exhaust gas from

the engine is carbon monoxide and is

deadly.

■

DO NOT operate the machine near

open fires.

Precautions before starting work

CAUTION

!

■

If you use the machine for a long time, be careful to watch for signs of vibration syndrome.

Since this machine vibrates, operation for a long time may have a negative effect on your

body. Take sufficient breaks while working.

■

Before starting to operate the machine, check for other people or obstacles that are too

close for safe operation.

■

When starting the engine, the rammer may jump suddenly. Hold the handle firmly with one

hand and pull the recoil starter with the other hand.

■

Always be careful around scaffolding. Operate the rammer in a stable manner so that it will

not become unbalanced.

■

During operation, don't let the foot of the machine come too close to your foot. The plate

may smash your foot.

■

The main part s of the engine, the

muffler, and muffler cover will be very

hot during operation. Be careful not to

touch them during operation or soon

after operation.

■

If you encounter any problems or abnormality with the machine during operation, while

moving it, or stopping operation, stop work immediately.

■

Before leaving the machine, be sure to turn the engine off. Also, make sure to turn the

engine off if you want to move the machine. When the throttle lever is in the stop position,

the fuel cock is closed. Do not move the lever away from the stop position.

■

When lifting the machine by the handle, be careful not to pinch your fingers between the

handle and main body.

3

Page 8

Precautions before starting work(Continued)

!

DANGER

■

Take the utmost care not to allow the

machine to fall during work, or when

s t opped or stored. Secure the

machine with a rope or similar tie

when stored or left i d l e so that it

cannot fall. If the rammer falls over

when children are around, a serious

accident may occur. If the machine

foot is worn, the mac hine will be

especially unstable. If the machine

foot is worn badly, replace it with a

new one.

■

If the machine falls over while working, the machine will move forward due to the kicking

motion of the foot while it is lying on its side. If the ground is solid, it will move quickly and is

very dangerous. To ensure that the operator and anyone nearby are safe, turn the throttle

lever to the engine stop position and make sure the machine stops. You must be extremely

careful when working on a road because a serious accident can easily occur.

Precautions while lifting

!

DANGER

■

Before lifting the machine, make sure that there is no damage to any of the components on

the machine (look especially for damage to the rubber dampers and the hook). There must

not be any loose or missing screws and the machine must generally be in a safe condition.

■

Turn the engine off before lifting the machine.

■

Use wire cables with enough strength to support the machine.

■

DO NOT lift it higher than necessary, for safety.

■

DO NOTuse a damaged wire cable.

■

Only use the single hook to lift the

machine. DO NOT support it from any

other points (such as the handle).

■

Never lift or lower the machine rapidly when using a hydraulic shovel or a crane.

■

When lifting the machine, do not allow any people or animals to pass under or near the

machine.

■

When using any type of equipment to lift the machine, be careful that the lifting equipment

does not cause an accident. Make sure you check the lifting equipment carefully, to ensure

that there are no problems or damage.

4

Page 9

Transportation and storage precautions

!

DANGER

When transporting

■

Before transporting the machine, stop the engine.

■

DO NOT try to move it before the engine and machine body have cooled down enough.

■

Drain any fuel before transporting the machine.

■

Transport the rammer in a manner that keeps it level. If you must lay the machine down to

transport it, drain any fuel from the fuel tank. Then close the fuel tank cap and oil fill plug

securely. Next, position the machine so that the muffler will be facing down.

■

Secure the machine body so that the machine cannot move or fall during transportation.

■

When you want to lift the machine by gripping the handle, be careful not to pinch your

fingers or hands between the handle and the main body.

■

Since this machine is quite heavy, use a truck specifically designed to transport heavy

objects.

When storing the machine

■

After the engine and machine body have cooled down enough, store the rammer so that it is

level. Fasten the machine as needed so that the machine cannot fall down. If it you must lay

the machine down, close the fuel tank cap and oil fill plug securely. Arrange the machine

position so that the muffler will be facing down. After it is lying down, make sure there are

no oil or fuel leaks. (If fuel is leaking, drain it all from the fuel tank.)

Maintenance precautions

!

WARNING

■

Appropriate maintenance of the machine is required to ensure safety and keep the machine

performing well. Always be aware of the machine's condition and keep it in good condition.

!

CAUTION

■

Be sure to turn the engine off before

checking or adjusting the machine.

■

T he muffler and muffler guard

become very hot. Do not touch them

until they will have cooled down.

■

The lubrication oil and engine oil are

very hot and can burn you. Do not

start any maintenance on the

machine while the oil remains hot.

■

After performing any maintenance, check the condition of the safety components and the

general safety of the machine. In particular, check the nuts and bolts thoroughly.

■

If you have to disassemble any components on the machine, be sure to ref er t he

maintenance standard sheets and always work safely.

5

Page 10

Specifications

Model MT-76D/76DL

Overall height

Overall width 410 mm

Overall length

Impact shoe width 285 mm

Jumping stroke

Impact number

Impact force (max.)

Clutch Automatic centrifugal clutch

Total weight 82 kg

10.8~11.7Hz

1,010 mm

740 mm

50~80 mm

(650~700blows/min.)

15.7kN (1,600kgf)

Specifications for engine

Model Yanmar L48N6-SMK

Type Air-cooled 4-stroke diesel engine

Piston displacement 219cc

Max.Output

Cooling system

Lubricant

Fuel

Starting system Recoil starter with Auto-return decompression device

3.5 kw (4.7 PS) / 3600 rpm

Air-cooled by fan

Diesel engine lubricating oil

API classification "CC" or "CD" grade

Automotive Diesel Fuel

Hand-Arm Vibration Level

Model

MT-76D

MT-76DL

Vibration Level is in comply with EU Directive2002/44/EC and the value is shown as 3 axix

min. vibration level.

Test course ( Crushed gravel ) is in comply with EN500-4.

The above values are subject to change in case that the machine is modified or/and the

required regulations change.

Specifications are general and subject to change without notice.

※

If exact measurements are required, equipment should be weighed and measured.

! !

Ahv

(m/sec

18.5

16.8

WARNING:

2

)

The engine exhaust from this product con-

6

tains chemicals known to the State of California to cause cancer,birth defects or other reproductive harm.

Page 11

Fuel tank

Air Cleaner

Handle

Bellows

Protect sleeve

Foot

1.Definition of Tamping Rammer

The Mikasa MT-76D diesel rammer is a powerful

compacting tool capable of applying tremendous

force in consecutive impacts to a soil surface.

The impact force of the MT-76D levels and

uniformly compacts voids between soil particles to

increase dry density. Its applications include soil

compacting for road, embankment and reservoirs as

well as backfilling for gas pipelines, water pipelines

and cable installation work.

2. Construction of Tamping Rammer

The rammer is equipped with an air-cooled,

four-stroke diesel engine. Transmission of the

power takes place by increasing engine speed to

engage a centrifugal clutch.

Circular motion is converted into vertical motion to

create impact force.

3. Prior to Operation

3-1 Identification of Controls:

1. Throttle

2. Engine Lubrication Oil

3. Oil Fill Plug

4. Oil Level Sight Glass

5. Recoil Starter Handle

Throttle lever

Fuel filter

Recoil stater

Oil level gauge (engine)

Oil filter (engine)

Oil level sight glass

Drain plug

Preoperation Inspection:

3-2

Rammer Gearbox and Spring Cylinder This unit

uses an oil bath lubrication system. Check oil level

through oil level sight glass at rear of tamper foot. If

oil is not visible, add #10W-30 motor oil. Oil bath

contains approx. 1.7 pt. (800 cc) for MT-76D.

Engine :

3-3

Use only automobile diesel fuel. Check the engine

oil before starting operation and fill the oil

regularly. For check the oil level, move the engine

at vertical position and check that the oil is filled

with at the oil inlet level.(about 700 cc)

Check all nuts, bolts and fasteners for tightness.

3-4

Retighten as necessary.

Clean dirt from the recoil starter and foot. Wipe

3-5

entire unit clean before operating

Replace any missing or damaged Safety/Operation

3-6

decals.

Fuel tank ( Diesel )

Oil inlet plug

(Check the oil level!!)

Blocking

(Move the engine at vertical position!)

Fig.2

Fig. 1

7

Page 12

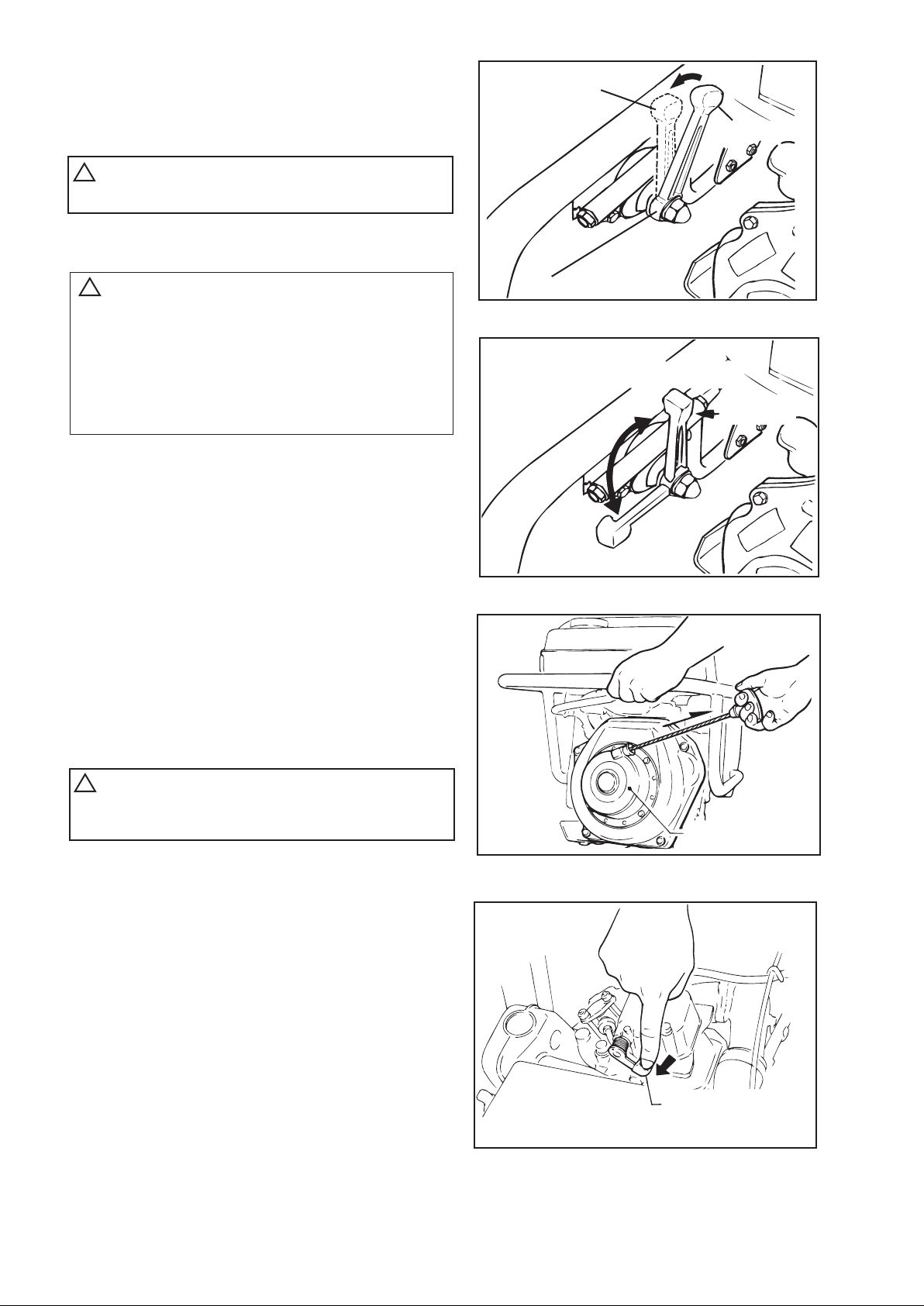

4.Starting

In cold weather, the engine should be

started at ope rating position or between

the idle and operation position of the

throttle lever.

Use caution as higher engine RPM. may

engage clutch, when engine starts.

Return throttle lever from starting position

to idle position when engine starts.

4 - 2 Grip the recoil starter handle and pull it

until you feel a slight resistance. (Fig.4)

4 - 3 Press the decompression lever to release

decompression.

The decompression lev er will return

automatically when the recoil starter is

pulled. (Fig.5)

4 - 4 Return the recoil starter, and pull the

handle sharply and quickly.

Warm up the engine by running at low

speed for three to five minutes, while

checking for fuel leakage or abno rmal

sounds.

Do no pull the s tarter rope all the way to the

end and do not let the starter rope snap back

as damage may result.

4 - 1 Move the throttle lever to IDLE position.

(Fig.3-1,3-2)

!

Throttle lever is used only at three (STOP,

IDLE & OPERATION) positions.

!

Idling position

Stop position

Throttle lever

Fig. 3-1

IDLE

Throttle

lever

OPERATION

Fig. 3-2

!

Recoil starter

Fig. 4

8

Decompression lever

(Decompressed posittion)

Fig. 5

Page 13

5 Operation

5-1 Move the throttle lever quickly from the IDLE to

OPERATION position to start tamping action. DO

NOT move the throttle lever slowly as this may

cause damage to the clutch or spring.

5-2 The tamping rammer is designed to tamp the

ground 650 to 700 times per minute for MT-76D at

an engine speed of 3,100 rpm.

Increasing the engine speed above the

recommended rpm will not increase the rammer

effectiveness.

Impact will actually decrease because a resonance

is created rather than a tamping effect, and

damage to the unit can result.

5-3 The rammer can be warmed by quickly moving the

throttle lever from the OPERATION to the IDLE

position several times until the rammer operates

smoothly.

5 -4 The tamping rammer is designed to travel forward

while tamping.

To increase travel speed, pull back slightly to the

handle so that the rear of the foot contacts soil

first.

5-5 To stop tamping, quickly move the throttle lever

from the OPERATION to IDLE position.

Do not move the lever slowly as irregular action

and damage may result.

6. Stopping the Engine

6-1 Move throttle lever quickly from idle to STOP while

pressing the throttle lever button.

Run the engine for three minutes at idle speed to

allow for proper cool down.

Following above procedure will prevent improper

cylinder lubrication caused by overheated

engine.(Fig.6)

Idling position

Stop position

Move the lever from Idling

to Stop position.

Throttle lever

Fig.6

9

Page 14

TEMPERATURE

CLASSIFICATION OF OIL

20 °C (+68 °F)or over

SAE 30

10 °C(+14 °F) - 20 °C(+68 °F)

SAE 20

B elow1 0 °C(+14 °F)

CC class or high er grade

SAE 10W - 30

!

7.Service

CAUTION:

Flammable Liquid. When refueling, stop engine and

allow it to cool. Do not smoke or allow work to be

performed in the immediate area. Fire or explosion

could result from flames or sparks, or if fuel is spilled

on a hot engine.

Moving Parts. Shut down the engine before performing

service or maintenance functions.

Contact with moving parts can cause serious injury.

High Temperatures. Allow machine and engine to cool

before performing service or maintenance functions.

Contact with hot components can cause serious

burns.

7 - 1 DAILY

* Thoroughly remove dirt and oil from the engine

and control area.

* Clean or replace air cleaner as necessary.

* Check and retighten all fasteners as necessary.

* Check spring box and bellows for oil leaks.

Repair as needed.

* Remove element from pre - cleaner at the top of

crankcase(body side) and clean it by air.

7 - 2 WEEKLY(every 50 hours)

* Remove the fuel filter cap and inspect clean fuel

tank.(Fig.7)

7 - 3 Replacement of Lubricant(BODY)

* Remove the drain plug at the rea r of tamper foot

and drain dirty oil. Refill with clean oil to the

middle of the sight glass. Oil bath contains

approx. 1.7 pt. (800 cc) for MT - 76D.

INITIAL OIL CHANGE:

After 50 hours of operation

SECOND OIL CHANGE AND/OR LATER:

Every 200 hours of operation

7 - 4 Replacement of Lubricant(ENGlNE)

7 - 4 - 1 While the engine is still warm, remove the

drain plug. For quick discharging, it is

advisable to take off the oil gauge.

Replace drain plug and refill engine

crankcase.(Fig.8)

7 - 4 - 2 Refer t he following chart, for oil types.

!

!

10

Fuel tank

Fuel filter

Fig.7

Drain plug

Fig.8

Page 15

The fuel filter is installed at the bottom of fuel

tank, should rammer be laid down dirt from

fuel filter may invade into injection nozzle and

fuel pump causing damage.

7-9 Storage

* When storing the rammer for long periods of

time, thoroughly drain all fuel from fuel line.

* Clean exterior of rammer with an oil-moistened

cloth. Cover and store in a clean, dry place.

7-4-3 The interval of oil replacement

INITIAL OIL CHANGE:

After 20 hours of operation

SECOND OIL CHANGE ANDIOR LATER:

Every 100 hours of operation

7-5 Cleaning the Air Cleaner

Cleaning the Air Cleaner (every 200- 300

hours) (Fig. 9)

* Remove element from pre-cleaner at the top

of crankcase(body side).

* Wash the element (outside) in detergent

solution.

* Shake out excess moisture and dry the

element.

* Clean inside element with air from the inside

of element.

7-6 Cleaning the Oil Filter

Drain oil filter every 100 hours of operation.

Replace the oil filter every 1,000 hours of

operation. (Fig.10)

7-7 Fuel Pipe & Oil Pipe

* Check fuel line regularly for damage, paying

attention to clamps to assure a tight fit.

* Replace fuel line every two years to maintain

original performance.

7-8 Transportation

Maintain upright position of rammer at all

times.

Transport rammer in upright position.

If machine must be laid down for

transportation, drain the diesel fuel first and

lay machine with muffler side down. (Fig.11)

Oil filter

Outer element

Inner element

Fig.9

Fig.10

Lay machine with

muffler side down

after draining the

diesel fuel.

Fig.11

11

Page 16

8. TROUBLE SHOOTING

1. Diesel Engine

(1) Starting Problem

(A) In case of compression problems

■

No compression at all

Intake/exhaust valve upthrust

Decompressor adjustment problems

■

Almost no compression

Contact with seat not close enough.

Piston ring wear

Cylinder wear

Cylinder, cylinder head mating surface problems

Nozzle seat looseness

(B) In case of inappropriate fuel injection inside the combustion chamber

■

Fuel flow low or no flow

Clogging of the tank cap air hole.

Clogging of the fuel filter

Fuel cock not open

Air inside the fuel pipe

■

Fuel not injected inside the combustion chamber

Injection pump barrel, plunger stuck

Nozzle hole clogging

Nozzle needle stuck

■

No fuel in the fuel tank

■

Mixing of water or foreign materials

(C) Fuel and compression pressure appropriate, but the engine does not start.

■

Does not reach the starting revolution.

Inappropriate starting operations

Engine oil viscosity high, engine oil is very dirty.

Air trapped inside the fuel pipe.

(2) Insufficient Output and Operation Problems

■

Insufficient compression

See the comment for insufficient compression.

■

Engine overheating with black smoke

Dirt and breakage of cooling fin

Mixing of water inside the fuel filter

Carbon accumulated in the combustion chamber or exhaust hole.

Smoke set inappropriate

Overload

Inappropriate injecting timing

Nozzle clogging

■

Revolution fluctuation

Governor fork and sleeve mating surface problems

Governor spring problems

Fly plate and sliding part wear and operation problems

12

■

Engine revolution does not increase.

Valve open/close timing inappropriate

Clogged exhaust hole, muffler

Overload

Page 17

■

Firing problem with white smoke (when unloaded)

Piston, cylinder ring wear

Nozzle hole clogging

Piston ring stuck

Wrong assembly (upside down) of piston ring

Inappropriate injection timing

Inappropriate valve open/close timing

Looseness of injection pump joint

■

Fuel consumption too high (black smoke)

Leakage from fuel passage

Clogging of the air cleaner element

Inappropriate fuel due to mixing of impurities

Overload

■

Extensive wear on sliding parts or stuck piston rings

Use of wrong oil

Failure to change oil

Breakage of the air cleaner element or failure to clean the air cleaner

■

Stopped suddenly with abnormal noise

Searing or damage of the piston, rod, etc.

■

Lubrication oil diluted and increased.

Wear on the injection pump barrel or plunger

■

Engine does not stop even though the fuel supply is cut (or over-running)

2. Rammer itself

Engine rotates but amplitude not uniform, or does not strike.

■

Too much oil

Wrong assembly of the governor system

Detached injection pump rack

Operating speed of throttle lever too slow.

Oil in excess.

Clutch slips.

Spring failure.

Set speed of engine improper.

13

Page 18

Note

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Page 19

Page 20

MIKASASANGYOCO.,LTD.

1-4-3,Sarugakucho,Chiyoda-ku,Tokyo,101-0064,Japan

PRINTEDINJAPAN

Loading...

Loading...