Page 1

CONCRETECUTTER

MCD-L14H

INSTRUCTIONMANUAL

en

http://www.mikasas.com

CODE

Contentsof“DeclarationofConformity”

PleaserefertheECDECLARATIONOFCONFORMITY

inthismanualaswell.

602-01507

*602-01507*

Page 2

S

㻤㻚㻞

㻡㻚㻟

㻤㻚㻟

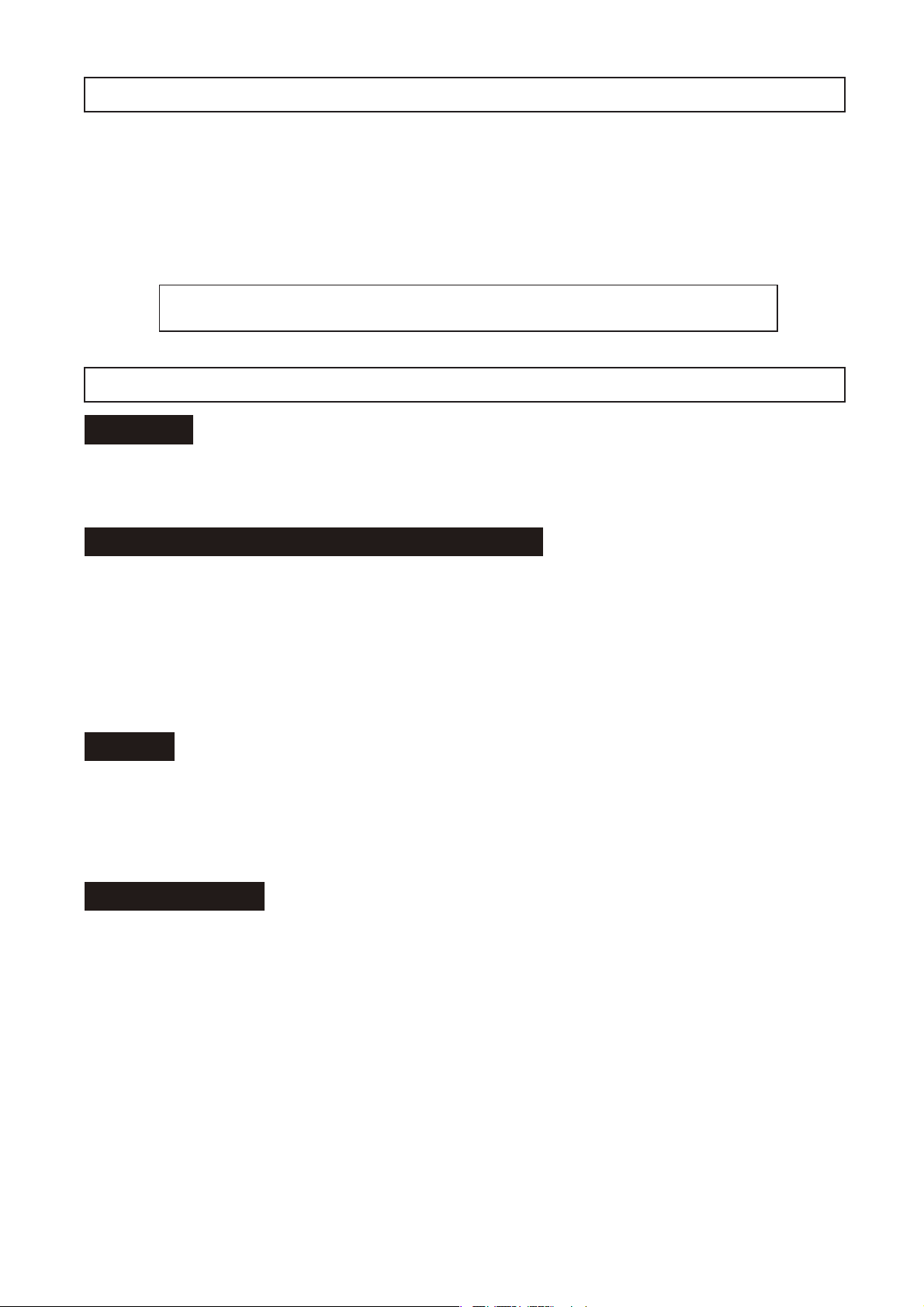

'(&/$5$7,212)&21)250,7<

2) Manufacturer’s name and address.

3) Name and address of the person who keeps the

technical documentation.

7\SH9LEUDWRU\5DPPHUV

PRGHO

(TXLSPHQW

LWHPQXPEHU

6HULDOQXPEHU

SRZHUVRXUFH

FRQWRXWSXW

PD[RXW

0HDVXUHG

VRXQGSRZHU

OHYHOG%

*XDUDQWHHG

VRXQGSRZHU

OHYHOG%

2SHUDWRUV

VRXQGSUHVVXUH

OHYHOG%

XW!

MCD-1UBLH MCD-L14H MCD-218CEH

654118

Honda GX-200

3.7kW <4.1kW>

654179, 654180,

654181

For serial number, please refer it on front page.

Honda GX-200

3.7kW <4.1kW>

107 107 115

108 108 116

87 88 93

Mikasa Sangyo Co., Ltd.

4-3, Sarugaku-cho 1 chome, Chiyoda-ku, Tokyo101-0064, Japan

Takahiro Kishino, engineer

R&D Division, Mikasa Sangyo Co., Ltd.

Shiraoka-city, Saitama, Japan

654280, 654290,

654297, 654298,

654299

Honda GX390UT

6.6kW <8.2kW>

12) Conformity assessment according to Annex:

13) Name and address of the Notified Body

14) Related Directive

15) Declaration

16) Other related Community Directives

17) EC Conformity Certificate No:

18) Place and date of the declaration

+DQG$UP9LEUDWLRQ/HYHO

02'(/ $KYPVHF

MCD-1UBLH

MCD-L14H

MCD-218CEH

Vibration Level is in comply with EU Directive2002/44/EC and the value is

shown as 3 axix min. vibration level.

Test course ( Crushed gravel ) is in comply with EN500-4.

VIII (Full Quality Assurance procedure)

Société Nationale de Certification et d’Homologation (SNCH)

11, route de Luxembourg

L-5230 Sandweiler 䚷LUXEMBOURG

Directive(& and, to be followed by Directive (&,

relating to the noise emission in the environment by equipment for

use outdoors.

The equipment referred in this document, fulfills with all the

requirements of Directive 2000/14/EC

(&(&(&(&(&

EN500-1, EN500-4

SNCH*2000/14*2005/88*0472*04

Tokyo, Japan June, 2016

Signed by:

Keiichi YOSHIDA

Director, R&D Division

Mikasa Sangyo Co., Ltd.

5HPDUNV

The above values are subject to change in case that the machine is modified

or/and the required regulations change.

Page 3

Italian

Garanzia di Qualità totale )

1. DICHIARAZIONE “CE” DI CONFORMITÁ

2. Nome e indirizzo Fabbricante

3. Nome e indirizzo della persona che conserva la

documentazione tecnica

4. Tipo: Piastre vibranti

5. Modello

6. Codice macchina

7. Numeridi matricola

8. Potenza installata netta <resa massima>

9. Livello di potenza sonora misurato (dB)

10. Livello di potenza sonora garantito

11. Livello massimo di pressione sonora

12. Valutazione di conformità in accordo all'annesso VIII

( procedura Garanzia di Qualità totale

13. Nome dell'organismo notificato

14. Rappresentante Autorizzato in Europa

15. Direttiva di riferimento

13. Nom et adresse de l'organisme notifié

14. Mandataire dans la Communaute Europeenne

15. Directive concernee

Est egalement conforme aux dispositions de la directive

<<emission sonores des equipements utilises a l'exterieur

des batiments>> 2000/14/CE et aux legislations nationales

la transposant.

16. Declaration

L'équipement de référence satisfait aux exigences de la

Directive 2000/14/EC

17. Autres directives communautaires concernees

18. Certificate deConformite CE numero:

19. Lieu et date de la declaratio

Spanish

1. DECLARACIÓN “CE” DE CONFORMIDAD

2. Nombre y dirección del fabricante

Direttiva 2000/14/CE su l'emissione acustica ambientale

delle macchine ed attrezzature destinate a funzionare

all'aperto

16. Dichiarazione

Le attrezzature riportate nel documento soddisfano i requisiti

della Direttiva 2000/14/CE

17. Altre Direttive Comunitarie di riferimento

18. Certificato di Conformità CE No:

19. Luogo e data della dichiarazione

French

1. DECLARATION « CE » DE CONFORMITE

2. Non et adresse du Fabricant

3. Nom et adresse de la personne qui défient les documents

techniques

4. Type du materiel: Plaques vibrantes

5. Modello

3. Nombre y dirección de la persona que guarda la

documentación técnica.

4. Tipo: Bandejas vibrantes

5. Modelo

6. Número de referencia del equipo

7. Numeros de serie

8. Potencia neta instlada <rendimineto maximo>

9. Nivel sonoro medido del motor ( dB )

10. Nivel sonoro garantizado del motor ( dB )

11. Máximo nivel sonoro de presión ( dB )

12. Evaluación de la Conformidad de acuerdo al Anexo VIII

( Prcedimiento de total garantía asegurada )

13. Nombre y dirección de la Entidad Notificada

14. Representante autorizado

15. Directiva relacionada

Directiva 2000/14/CE en relación a la emisión sonora en el

ambiente por equipos que trabajan en espacios abiertos

6. Numero equipement

7. Numéro de série

8. Puissance reseau <rendement maximal>

9. Niveau sonore mesure(dB)

10. Niveau sonore garanti(dB)

11. Niveau sonore maximum

12. Certification de conformite selon l'annexe VIII ( procedura

16. Declaración

El equipo referido en este documento , cumple con todos los

requerimientos de la Directiva 2000/14/EC

17. Otras Directivas Comunitarias relacionadas

18. Certificado de Conformidad CE Nº

19. Lugar y fecha de la declaración

Page 4

TABLE OF CONTENTS

INTRODUCTION ......................................................................................

1.

MACHINERY OVERVIEW ........................................................................

2.

WARNING SIGNS ....................................................................................

3.

CAUTIONS FOR SAFETY........................................................................

4.

General Cautions

4.1

Refueling Precautions

4.2

Location And Ventilation Precautions

4.3

Precautions Before Starting

4.4

Precautions During Work

4.5

Lifting Precautions

4.6

Precautions In Transportation / Safekeeping

4.7

Precautions In Maintenance

4.8

Installed Place Of Every Decal

4.9

4.10

APPEARANCE.........................................................................................

5.

SPECIFICATION......................................................................................

6.

BEFORE STARTING YOUR OPERATION...............................................

7.

OPERATION ............................................................................................

8.

STOPPING...............................................................................................

9.

TRANSPORTAION...................................................................................

10.

10.1

10.2

STORAGE.................................................................................................

11.

PERIODIC CHECK AND COORDINATION..............................................

12.

TROUBLESHOOTING .............................................................................

13.

13.1

13.2

Warning Labels And Information

Dimensions

5.1

Parts And Compornent

5.2

Main Body

6.1

Engine

6.2

Starting Up

8.1

Working

8.2

Loading And Unloading

Precautions In Transportation

Gasoline Engine

Machine

1

1

2

2

2

3

3

3

4

4

5

5

5

6

7

7

8

9

9

9

10

13

13

14

14

15

15

15

16

17

18

18

19

Page 5

1䠊INTRODUCTION

TThis instruction manual describes the proper methods for using Mikasa CONCRETE CUTTER, as well as simple

䖃

checks and maintenances. Be sure to read this instruction manual before operation, in order to get full use of the excellent performance of this machine, as well as to improve your operation and to perform engineering work effectively.

After reading this manual, store it in a handy location for easy reference.

䖃

For details about the engine of this machine, see the separate instruction manual.

䖃

For inquiries about repair parts, parts lists, service manuals, and repairs, please contact the store where you purchased

䖃

the product, our sales office, or the Mikasa Parts Service Center. For parts lists, please visit our homepage at:

http://www.mikasas.com/ where you can access Mikasa WEB parts lists.

The illustrations in this manual might slightly differ in part from the machine you actually

purchased due to design changes.

2䠊MACHINERY OVERVIEW

Application

Mikasa Concrete Cutter is used to cut the concrete or asphalt road surface by Diamond Blade that is attached on its Blade

shaft. Please choose machine type by cutting depth, and then choose appropriate blade to match the spot situation, such as

material age, presence or absence of reinforcement in the concrete.

Warning About Incorrect Applications And Techniques

Please use this machine to cut plain concrete, reinforced concrete and asphalt only.

Do not cut sediment, for that it flies into pieces and injuries man around the machine.

This cutter can be equipped with diamond blade only. Do not attach resinoid blade on this machine. Please pour water to

blade at cutting except using dry-type blade, for that conglutination of the blade or Blade chip flies into pieces.

Do not use this machine in the state that you turned more than the number of turn in accord with the blade, for that conglutination of the blade or Blade chip flies into pieces.

Do not use this machine in instability, or in a rough ground, for that conglutination of the blade or Blade chip flies into pieces.

Do not use this machine to cut a secondary product concrete.

Structure

Engine of Concrete Cutter is fixed on a main body base, and conveys power to Blade shaft with the V belt. The way of adjustment of V-belt tension is making Engine slide.

Belt cover, Handle guide, Handle for elevating the blade, and Blade cover which can be put on and off easily is attached on

Engine Base. Cutting depth is adjusted by rotating Handle for elevating the blade through Blade Arm that is equipped with

Front wheel The way to travel the machine is pushing the machine directly.

Power Transmission

Air-cooled petrol engine is amounted on Mikasa Concrete Cutter as power source.

V-pulley is attached on Engine shaft for driving Blade shaft, and Diamond Blade is attached on Blade shaft. The cutting depth

can be adjusted to change the Front wheel position by Handle.

The way of driving the machine while cutting is pushing the handle.

1

Page 6

3䠊WARNING SIGNS

The triangle shaped marks used in this manual and on the decals stuck on the main body

indicate common hazards. Be sure to read and observe the cautions described.

Warning labels indicating hazards to humans and to equipment.

䟿

Denotes an extreme hazard. It calls attention to a procedure, practice,

䟿

DANGER

䟿

WARNING

䟿

CAUTION

condition or the like, which, if not correctly performed or adhered to, is

likely to result in serious injury or death.

Denotes a hazard. It calls attention to a procedure, practice, condition

or the like, which, if not correctly performed or adhered to, could

result in serious injury or death.

Denotes a hazard. It calls attention to a procedure, practice, condition

or the like, which, if not correctly performed or adhered to, could

result in injury to people and may damage or destroy the product.

CAUTION

(without at )

Failure to follow the instructions may result in damage to property.

䟿

4䠊CAUTIONS FOR SAFETY

4.1 General Cautions

䟿

WARNING

Do not work with this machine, when

䖃

䟿

Read this instruction manual carefully and handle the machine as described so that you

䖃

can work safely.

For details about the engine, refer the separate instruction manual for the engine.

䖃

Make sure you thoroughly understand the construction and operation of the machine.

䖃

Please check each part before work, and execute the scheduled check and alignment

䖃

regularly.

To work safely, always wear protective clothing (helmet, safety glasses, safety shoes,

䖃

ear plugs etc.) and appropriate work clothes.

Please wear Hearing protector ( noise protective equipment of ear muff or ear stoppers)

䖃

by all means.

Always check the machine to make sure that it is normal before starting operation.

䖃

The decals on the machine body (operating methods, warning decals, etc.) are very im-

䖃

portant to ensure safety. Keep the machine body clean so that they can be read at all

times. If any decal cannot be read, replace it with a new one.

It is very dangerous if children come into contact with the machine. Take the utmost

䖃

care how and where the machine is stored.

Before performing any maintenance, be sure to turn the engine off.

䖃

Mikasa does not accept any liability for accidents or problems caused as a result of not

䖃

using genuine Mikasa parts or if the machine has been modified.

you are tired or sick and not feeling well,

䕿

you have taken medicine or drug, or

䕿

you have had a drink.

䕿

CAUTION

2

Page 7

4.2 Refueling Precautions

䟿

DANGER

Always refuel in a well ventilated area.

䖃

Make sure to stop the engine and wait until the engine cools down when refueling.

䖃

Select a flat surface area with no flammable material around for refueling. Be careful

䖃

not to spill the fuel. Wipe off well if there is any spill.

Never put fire near the machine during refueling. (Especially, be careful about

䖃

smoking.)

If you fill to the top of the fuel tank inlet, fuel might spill out from the tank, and it

䖃

becomes dangerous

After refueling, tighten the tank cap well.

4.3 Location And Ventilation Precautions

䟿

DANGER

Do not run the machine in an unventilated location, such as indoors or inside a tunnel.

䖃

The exhaust gas from the engine contains toxic gases such as carbon monoxide and

is very hazardous.

䖃

Do not operate the machine near open flames.

4.4 Precautions Before Starting

䟿

CAUTION

Check the clamping condition of each part. Cause the big failure that does not think

䖃

that a screw loosens by vibration. Tighten the screw well.

Confirm that the diamond blade does not have anomaly such as deficit of the blade

䖃

chip or the crack of the board.

If the machine were not run more than 3 months, be sure to start at low speed in a

䖃

few minutes to warm up thoroughly,

for the reason to avoid engine seizure by oil film shortage.

4.5 Precautions During Work

䟿

CAUTION

When starting and working with the machine, confirm that neighboring people and

䖃

obstruction are safe.

Always pay attention to foothold and work in easy position that allow to keep your

䖃

machine in good balance.

Be careful not to touch muffler and engine body as it becomes hot in operation or just

䖃

after operation.

Discontinue operation promptly whenever your machine goes deficient or you notice

䖃

any abnormality.

Be sure not to make the cutter with blade stand-by for work.

䖃

In the case to be without avoidance, be sure to run the engine at low speed possibly

in a short time.

(In case of running the engine at high speed at the above position for long time, it

might occur the engine seizure by oil film shortage.)

Be sure to stop engine before leaving the machine. Also shutdown engine for

䖃

transporting the machine, and close the fuel cock.

Mount blade cover by all means, and use it.

䖃

Because engine turns blade when start, be careful enough. Do not bring legs close

䖃

especially.

Be careful enough so that be not rolled up your hand or clothes in reel (inside of the

䖃

belt cover).

3

Page 8

4.5 Precautions During Work

䟿

DANGER

Precautions in inclined area

When you use machine on inclined area, various risk is accompanied. Adhere

rigidly to the following precautions to a minimum, and try for further safety

retention. When you cannot get safety, never use it.

Do not leave machine in the inclined area. There is danger to cause a serious

䖃

accident when machine begins to move by any chance.

In the inclined area, grasp a handle well, and never separate a hand from machine.

䖃

Machine begins to move in tare weight at the moment when you separated a hand,

and there is danger to cause a serious accident.

Because there is the danger that machine runs uncontrollably when a grip falls out

䖃

from the handle, warn you enough.

When you work in inclined area, be located in the upper part of the slope for machine

䖃

by all means, and let machine face straight it below for a slope, and work.

䖃

Stop the machine at flat space. When you stop machine in

inclined area out of necessity, lower straight machine after

having stopped the engine by all means, do ring stopper to the

front wheel for safe retention by all means. When be collided by

an automobile and be shaken in right and left, even if you put on

ring stopper down the front wheel, the machine climbs ring

stopper and begins to move, and be careful this risk is very likely.

Even if you put on ring stopper down the back wheel, there is not

effect. In addition, a parking brake of the rear wheel is not a thing

to guarantee certain fixation of the machine. Use ring stopper for

a front wheel on the occasion of a stop by all means.

When put ring stopper, never go in the front side of the machine. When machine has

䖃

begun to move by any chance. There is the danger of serious injury or decease, by

the physical truncation with blade and the conflict of machine.

If hand touches the blade when put ring stopper, there is danger injured seriously. Put

䖃

ring stopper from the non blade cover side of the machine by all means.

In case of stop, when water is in the water tank, the center of gravity rises and the

䖃

balance worsens . Even if you put ring stopper to the front wheel at the time, it is very

dangerous that the front wheel climbs over ring stopper and begins to move. In this

case pull water out of the water tank by all means.

When a road surface gets wet in inclined area, ring stopper in itself slips depending

䖃

on an angle, and effect is gone. Stop on the dry road surface by all means, when you

stop it in inclined area out of necessity.

Do not work on blade installation disassembly in inclined area, because it is

䖃

dangerous.

Do not work on to cross the slope. There is danger that tumble of the machine or the

䖃

damage of the blade cause a serious accident.

4.6 Lifting Precautions

䟿

DANGER

Be sure to work with sling by crane license holder.

䖃

Before work of lifting, check any damage of body parts (especially, Lifting hook, etc)

䖃

or looseness / omission of screws, and be sure safe.

Stop the engine at the time of the lifting, and close the fuel cock.

䖃

Use enough strength of wire rope.

䖃

The work of lifting uses only one-point lifting hook, and do not lift in other point

䖃

(handles).

Never put any person or animal under the lifted machine.

䖃

For safety, do not lift up the machine more than required height.

䖃

4

Page 9

4.7 Precautions In Transportation / Safekeeping

䟿

WARNING

Stop the engine at the time of transportation.

䖃

Carry it after engine and body got cold well.

䖃

By all means drain fuel before transporting the machine .

䖃

Fix the machine well not to move and fall down.

䖃

4.8 Precautions In Maintenance

䟿

CAUTION

Appropriate maintenance is always required for safety operation and to maintain

䖃

performance of the machine. Pay full attention in the condition of the machine, and

maintain good condition. Especially improper maintenance of lifting-related part

becomes cause of serious accident.

Do work after lower temperature of machine. Especially muffler becomes high

䖃

temperature, and there is danger that burn itself. In addition, be careful not to burn

itself enough, because engine or engine oil become hot.

Do the check alignment in situation that stopped engine by all means. There is badly

䖃

injured danger when you are rolled up in a reel.

After maintenance fulfillment, check the installation of safety protection parts and

safety of the machine. Especially, check bolts and nuts thoroughly.

When you do maintenance with dismantlement, refer to maintenance manual

regularly, and work safely.

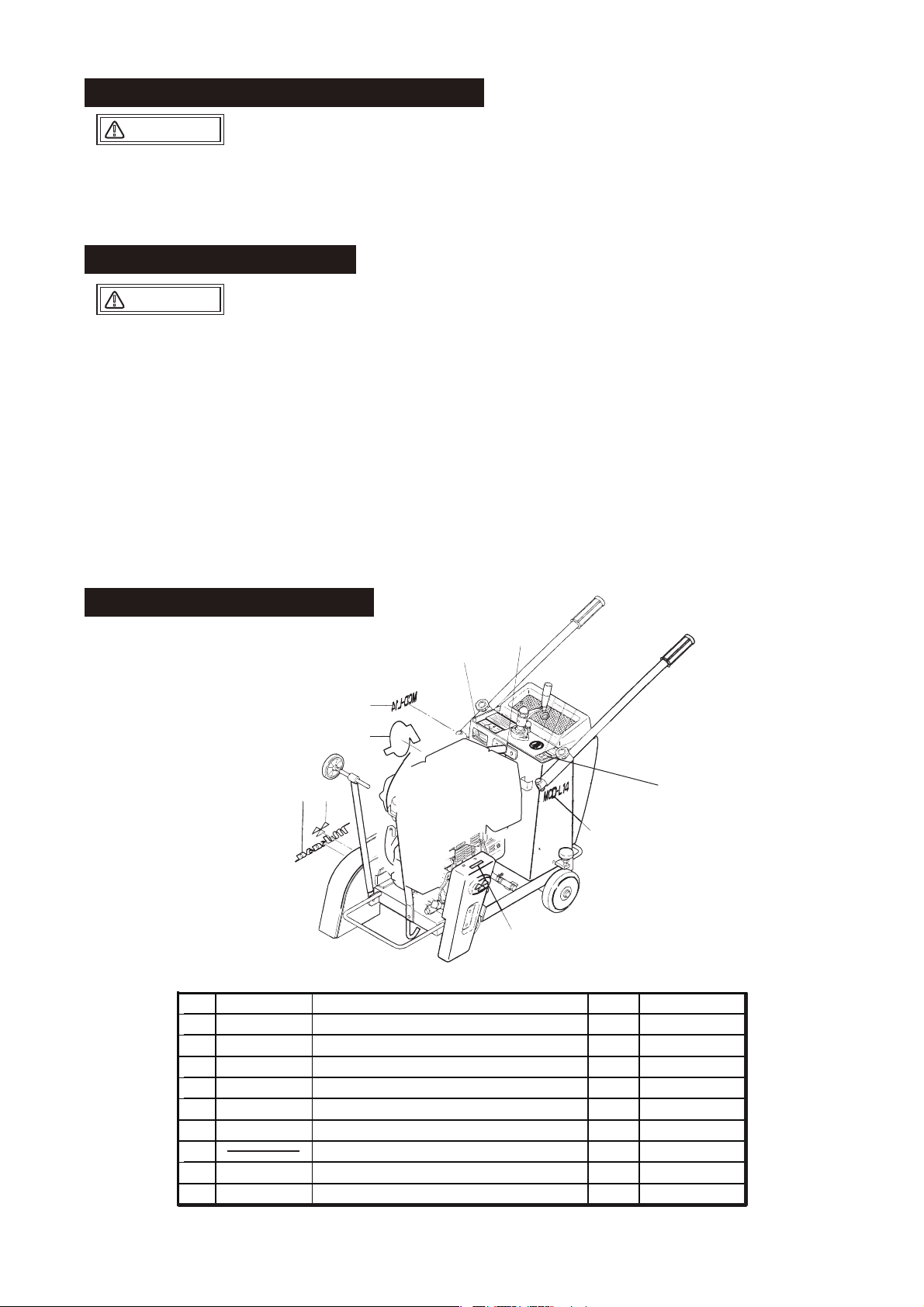

4.9 Installed Place Of Every Decal

12

11

㻺㻻㻚

㻼㻭㻾㼀㻛㻺㻻㻚

㻡

㻥㻞㻜㻝㻙㻜㻝㻞㻜㻜 㻰㻱㻯㻭㻸㻘㻌㻳㻾㻱㻭㻿㻱㻌㻛㻺㻼㻙㻝㻞㻜

㻥㻞㻜㻝㻙㻜㻥㻢㻥㻜

㻢

㻥㻞㻜㻝㻙㻝㻜㻜㻡㻜

㻝㻜

㻝㻝 㻥㻞㻜㻝㻙㻜㻜㻥㻞㻜

㻝㻞

㻥㻞㻜㻝㻙㻜㻝㻟㻥㻜

㻥㻞㻜㻞㻙㻜㻥㻤㻝㻜

㻝㻟

㻝㻠

㻥㻞㻜㻞㻙㻝㻜㻝㻞㻜

㻝㻡

㻞㻝

㻥㻞㻜㻞㻙㻝㻜㻢㻥㻜

㻰㻱㻯㻭㻸㻘㻌㻱㻹㻮㻸㻱㻹㻛㻯㼁㼀㼀㻱㻾

㻰㻱㻯㻭㻸㻘㻌㻹㻻㻰㻱㻸㻌㻹㻯㻰㻙㻸㻝㻠

㻰㻱㻯㻭㻸㻘㻌㻹㻙㻹㻭㻾㻷㻌㻔㻠㻜㼄㻤㻜㻕

㻰㻱㻯㻭㻸㻘㻌㻹㻵㻷㻭㻿㻭㻌㻔㻞㻡㻜㻕

㻰㻱㻯㻭㻸㻘㻌㼂㻙㻮㻱㻸㼀㻌㻟㼂㻙㻞㻢㻡

㻼㻸㻭㼀㻱㻘㻌㻿㻱㻾㻵㻭㻸㻌㻺㻻㻚

㻰㻱㻯㻭㻸㻘㻌㻵㻺㻰㻵㻯㻭㼀㻻㻾㻛㻹㻯㻰㻝㻞㻙㻞㻜㻜

㻰㻱㻯㻭㻸㻘㻌㻯㻭㼁㼀㻵㻻㻺㻔㻵㻯㻻㻺㻕㻛㻱㼄㻼

10

5

14

6

21

10

㻡

㻼㻭㻾㼀㻌㻺㻭㻹㻱

13

㻽㻓㼀㼅

㻝

㻞

㻞

㻝

㻝

㻝

㻝

㻝

㻝

㻾㻱㻹㻭㻾㻷㻿

5

Page 10

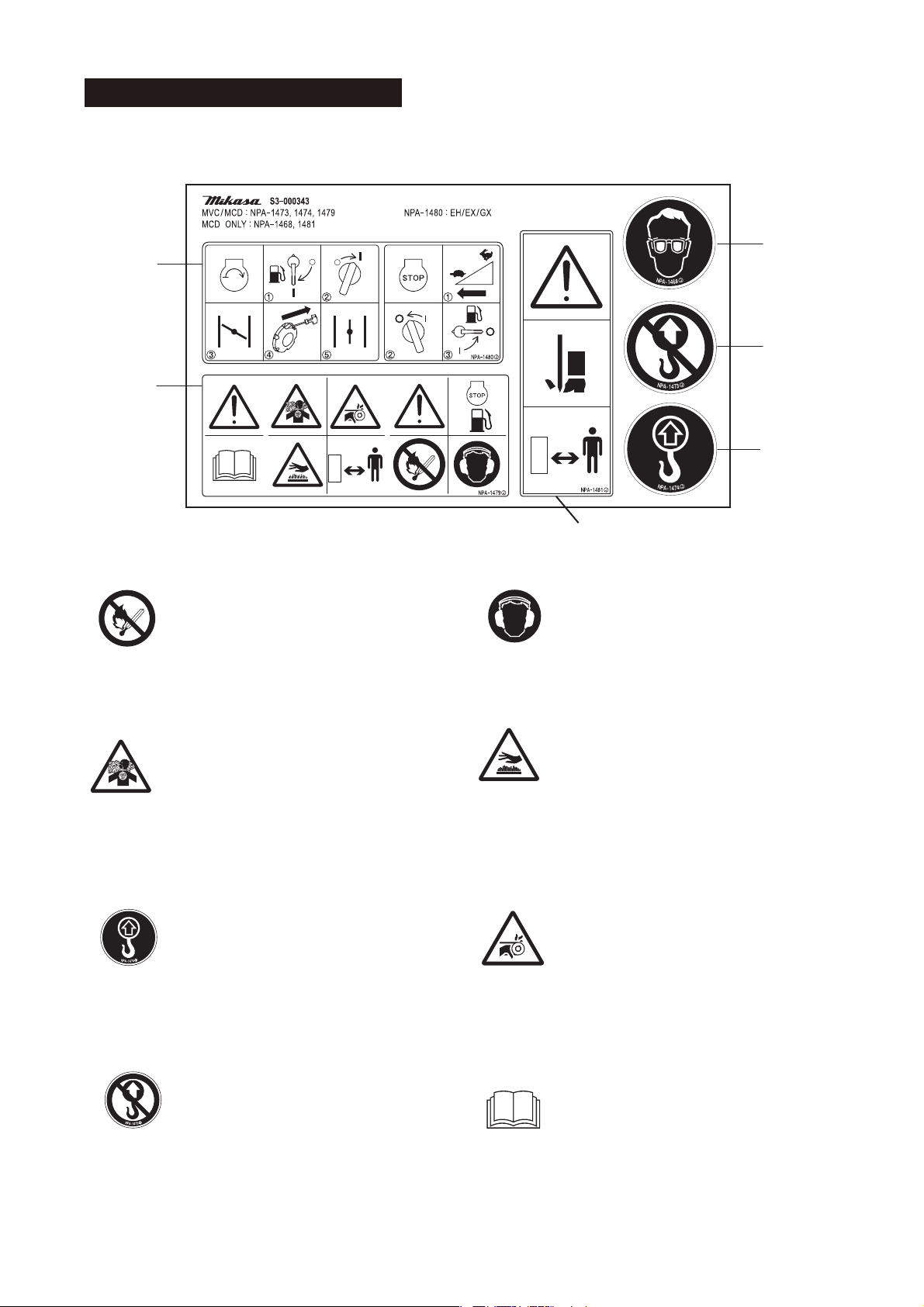

4.10 Warning Labels And Information

Decal for new European machine directives

NPA-1480

NPA-1479

䐟

3$5712

㻰㻱㻯㻭㻸㻘㻌㻿㻱㼀㻌㻛㻹㼂㻯㻘㻌㻹㻯㻰㻌㻛㻱㼄㻼㻘㻱㼁㻌

Fire hazard

Stop the engine when refueling. Fire

may occur if a flame is near the tank

fuel port.

䐣

NPA-1468

NPA-1473

NPA-1474

NPA-1481

Danger of hearing damage caused

by noise

Always use ear plugs while operating

the machine.

䐠

䐡

䐢

Danger: poisonous exhaust gas

Carbon monoxide poisoning may

occur if the exhaust gas is inhaled. Do

not operate the machine in a poorly

ventilated area.

Do not go under the lifted machine.

Do not let people or animals go under

the lifted machine.

Lifting by the handle is prohibited.

Due to a falling risk, do not lift the

machine by the handle.

䐤

䐥

䐦

Be careful not to get burned.

Accidental burn may occur if you touch

the hot parts (engine, muffler, etc.)

during operation or immediately after

the machine stops.

Be careful not to be caught in

rotating parts.

Make sure the engine is stopped when

removing the belt cover during a belt

change.

Read the manual carefully.

Always read the operation manual and

have good understanding of operation

before your work.

6

Page 11

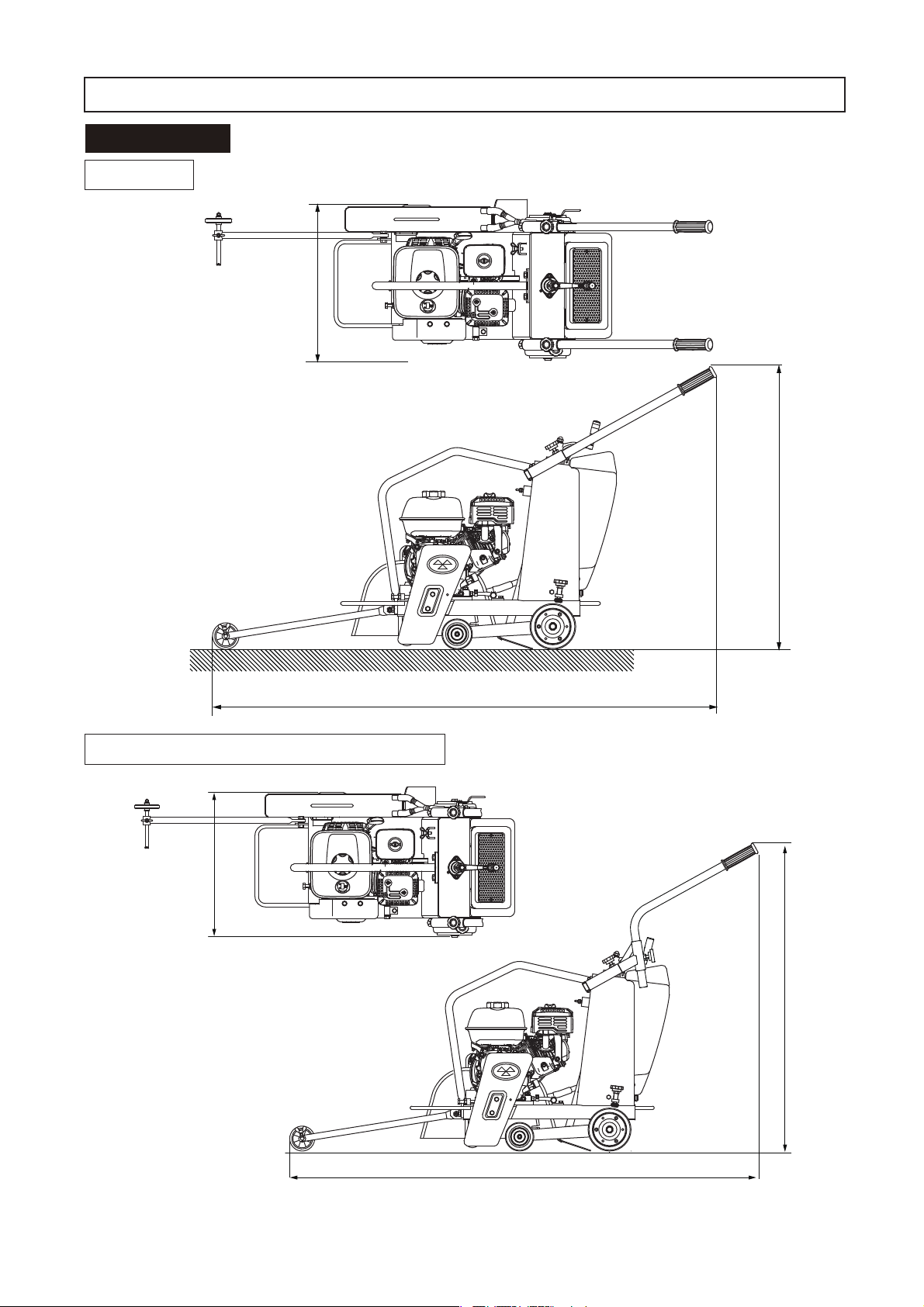

5䠊APPEARANCE

5.1 Dimensions

MCD-L14

(mm)

527

930

MCD-L14 ( with Special handlebar )

527

1650

1030

7

1630

Specifications are subject to change without notice.

※

Page 12

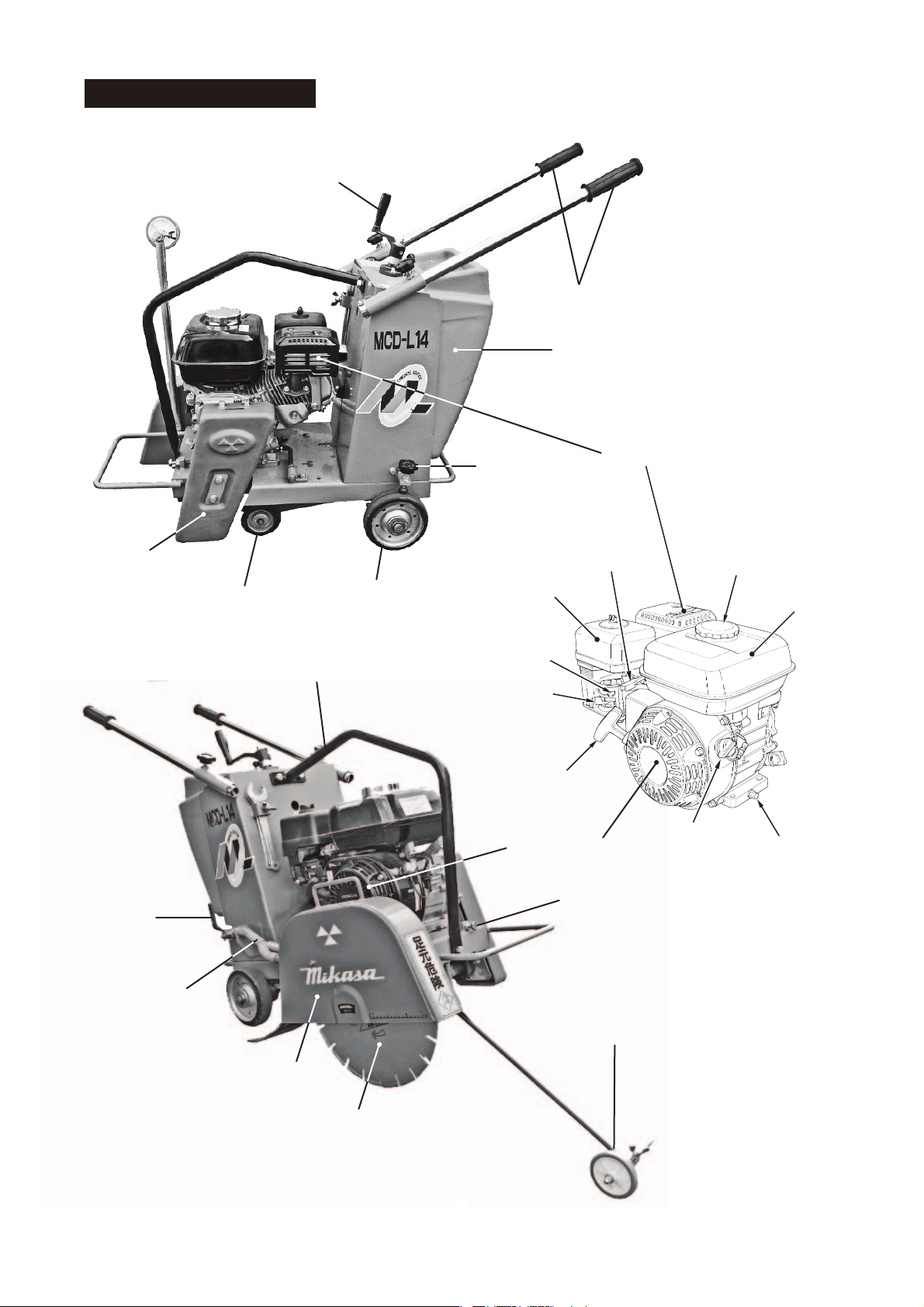

5.2 Parts And Compornent

Lifting handle

Handle

Water tank

Belt cover

Water cock

Front wheel

Hook

Rear wheel

Parking brake

Air cleaner

Choke lever

Fuel cock

Starter knob

Recoil starter

Muffler

Throttle lever

Switch

(ON-OFF)

Adjusting bolt & nut

of the belt tension

Fuel tank cap

Fuel tank

Drain plug

Sprinkling pipe

Line gauge

Blade cover

Diamond blade

8

Page 13

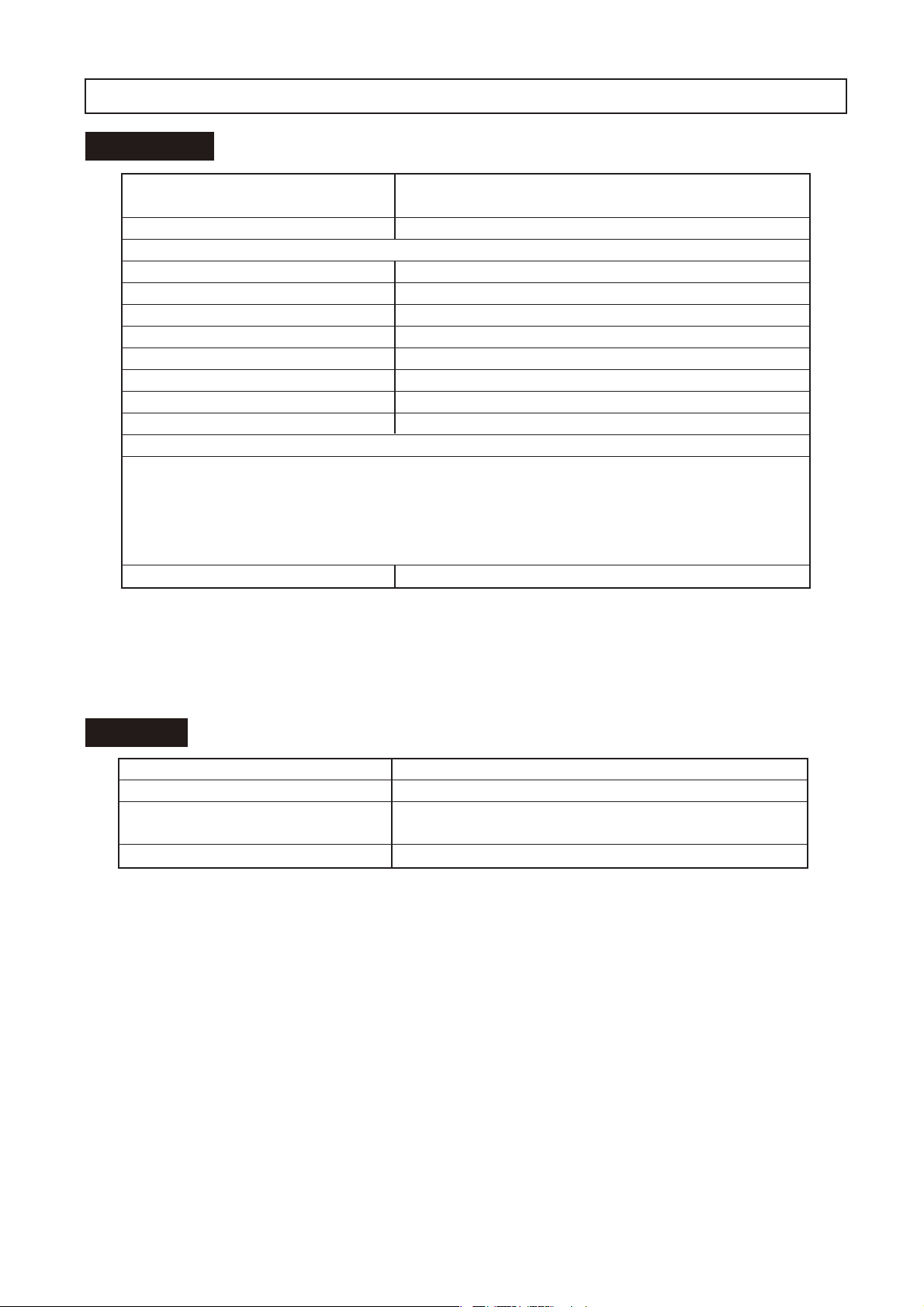

6䠊SPECIFICATION

6.1 Main Body

Model

Power source ( Engine model )

Dimensions

Overall Length ( on operating )

Overall Width

Overall Height

Operating Weight

Traveling system

Adjusting for cutting depth

Cooling System of blade

Water tank capacity

Blade size and maximum cutting depth ( Axis hole dimension of bladeφ27)

Blade size (Outer diameter)

(10in.) 254mm

(12in.) 305mm

(14in.) 356mm

Limitation of Blade size

Weight includes weigh of machine, lubricants, 50% of fuel and 50% of water in case with

※

water tank option.

Specifications are subject to change without notice.

※

[ with Special handlebar ]

Manual lifting screw system

Centrifugal injection type

Maximum cutting depth

MCD-L14H

GX200

1650mm [1630mm ]

527mm

930mm [1080mm ]

100kg

Hand push type

26L

70mm

95mm

120mm

Under 14in.

6.2 Engine

Manufacturer/

Type

Max. Output

Fuel tank capacity

Model

HONDA, GX200

Air-cooled 4-cycle petrol engine

4.1kW/3600min

(5.6PS/3600rpm)

3.6L

-1

9

Page 14

7䠊BEFORE STARTING YOUR OPERATION

DANGER:

Do the check alignment in situation that stopped engine

䚷㻌㻌㻌㻌

by all means. There is badly injured danger when you

are rolled up in a reel.

䚷㻌㻌㻌㻌㻸㼑㼢㼑㼘㻌㼠㼔㼑㻌㼙㼍㼏㼔㼕㼚㼑㻘㻌㼍㼚㼐㻌㼏㼔㼑㼏㼗㻌㼕㼠㻌㼍㼒㼠㼑㼞㻌㼠㼔㼑

㻌㻌㻌㻌㻌㻌㼙㼍㼏㼔㼕㼚㼑㻌㼏㼛㼚㼒㼕㼞㼙㼑㼐㻌㼠㼔㼍㼠㻌㼕㼠㻌㼐㼛㼑㼟㻌㼚㼛㼠㻌㼙㼛㼢㼑㻚

㻌㻌㻌㻌㻌㻌

ۻ

䚷㻌㻌㻌㻌㼀㼔㼑㻌㼏㼔㼑㼏㼗㻌㼜㼛㼕㼚㼠㻌㼎㼑㼒㼛㼞㼑㻌㼠㼔㼑㻌㼣㼛㼞㼗㻌㼟㼑㼑㻌㻎㼑㼍㼏㼔㻌㼜㼍㼞㼠

㻌㻌㻌㻌㻌㻌㼏㼔㼑㼏㼗㻌㼟㼏㼔㼑㼐㼡㼘㼑㻌㼘㼕㼟㼠㻎㻌㼙㼑㼚㼠㼕㼛㼚㼑㼐㻌㼕㼚㻌㻝㻣㻌㼜㼍㼓㼑㼟㻚

1

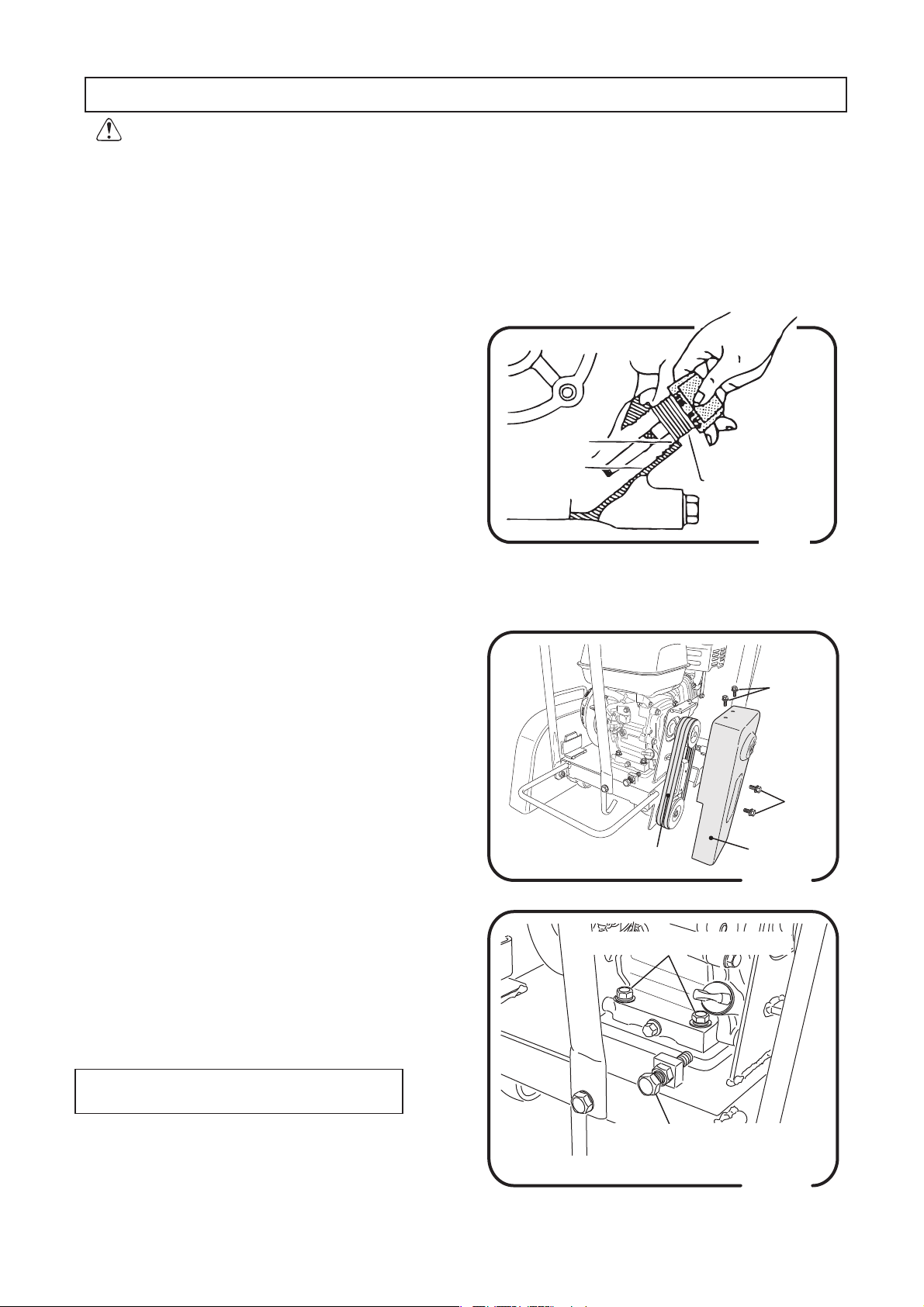

Engine oil (Fig.1)

With the engine positioned horizontally, check

oil-with oil gauge.

Replenish through filler port as necessary. Use

following oil

(10W-30 is in use when shipped).

SAE#30 (for normal temperature)

SAE#20 (for 10 or lower)

SAE#10W-30

This oil can be used throughout the year

regardless of ambient temperature (up to

ambient temperature -20 䉝㻌).

When it is used in normal temperature, its

consumption tends to increase. Pay additional

attention at the time of daily check. As for quality

of oil, be sure to use SE grade or better.

Degraded quality or decreased quantity may

induce damage by seizure.

Fuel

2

Use lead-free automobile gasoline. For

replenishment, be sure to shutdown engine and

use strainer provided at filler port. Wipe off any

spilled fuel clean.

V-belt

3

Check V-belt for any slack or damage. Tension is

proper if the belt bends about 10mm when

pressed with your finger at midway between two

shafts. Retighten as necessary but when

replacing, replace both of them simultaneously.

Place the usable one in stand-by parts. For

adjusting the tension, slide engine longitudinally.

㻹㼍㼤㻚㻌㻸㼑㼢㼑㼘

㻹㼕㼚㻚㻌㻸㼑㼢㼑㼘

㻌㻔㻾㼑㼜㼘㼑㼚㼕㼟㼔㻕

㻻㼕㼘㻌㻳㼍㼡㼓㼑

V-belt

Engine mounting bolts

Fig.1

Bolt

Bolt

Belt cover

Fig.2

Adjusting the belt

A With 4 bolts removed, take off belt cover.

(Fig.2)

B Loosen 4 engine mounting bolts.

Caution:

Bolts should be just loosened;

not removed.

C Rotating it clockwise increases the belt

tension. (Fig.3)

Adjusting bolt & nut

of belt tension

Fig.3

10

Page 15

Water tank

4

Use water tank filled with water.

Useful life of blade depends on volume of cooling

water.

Pay attention to the water level.

(Fig.4)

Sprinkling pipe

5

Open the cock to make sure that sprinkler pipe is not

clogged.

(Fig.4).

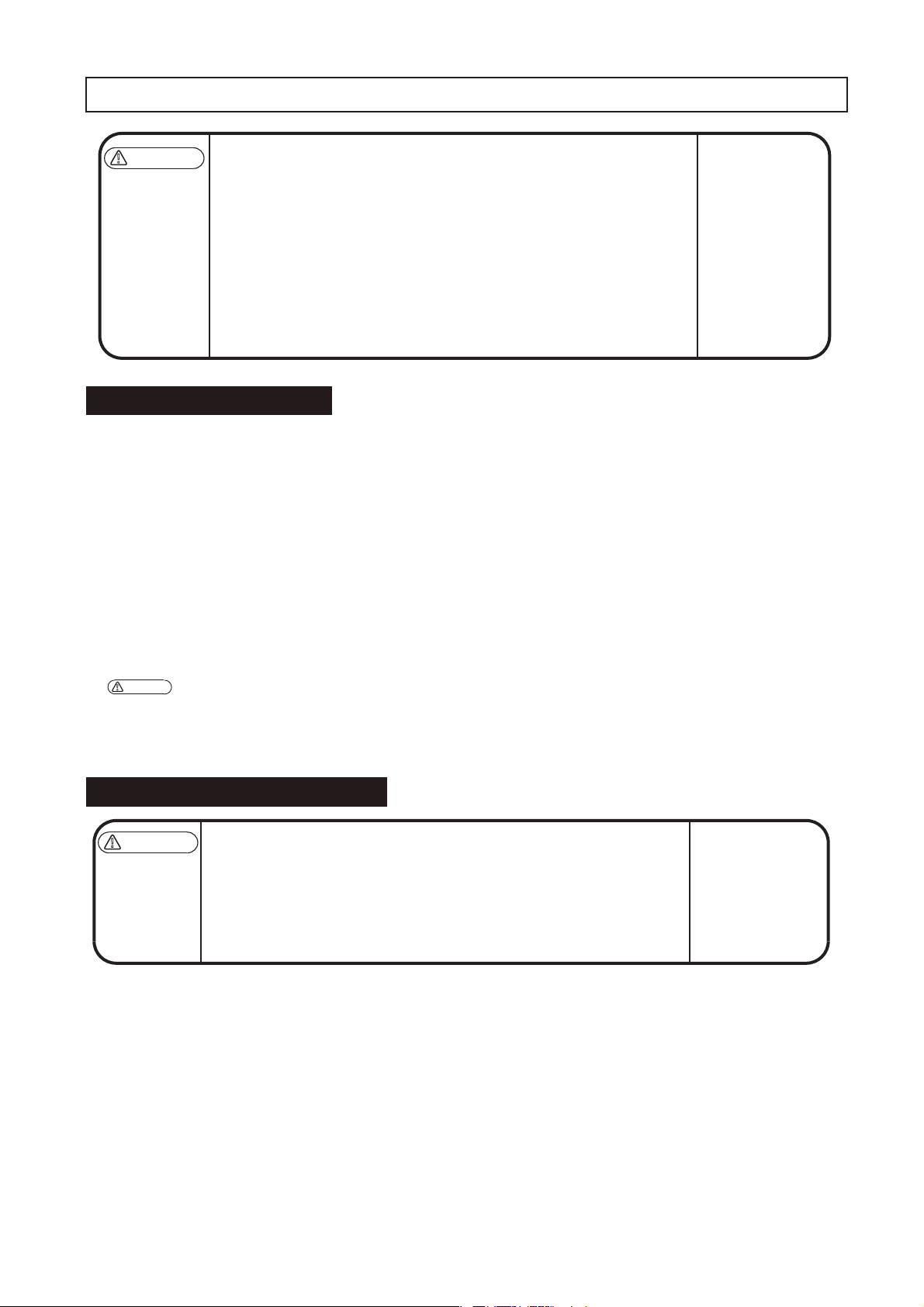

Installing the blade:

6

a.

Disconnect water pipe at the nipple of water tank side.

Remove the blade cover by lifting it upward.

b.

Place flange (IN), diamond blade and flange (OUT)

around the blade shaft in such order, and install

washer before tightening sufficiently with nut (left-hand

thread). (Fig.5, 6)

Water Tank

Water Cock

Flange

(OUT)

Blade cover

Fig.4

Flange(IN)

Caution:

With wrench engaged at designated location of the

blade shaft to lock it, rotate nut counterclockwise to

tighten. (Fig.6)

c.

After installing the blade, replace blade cover to base ,

before replacing water hose to nipple firmly. And

check the cooling water.

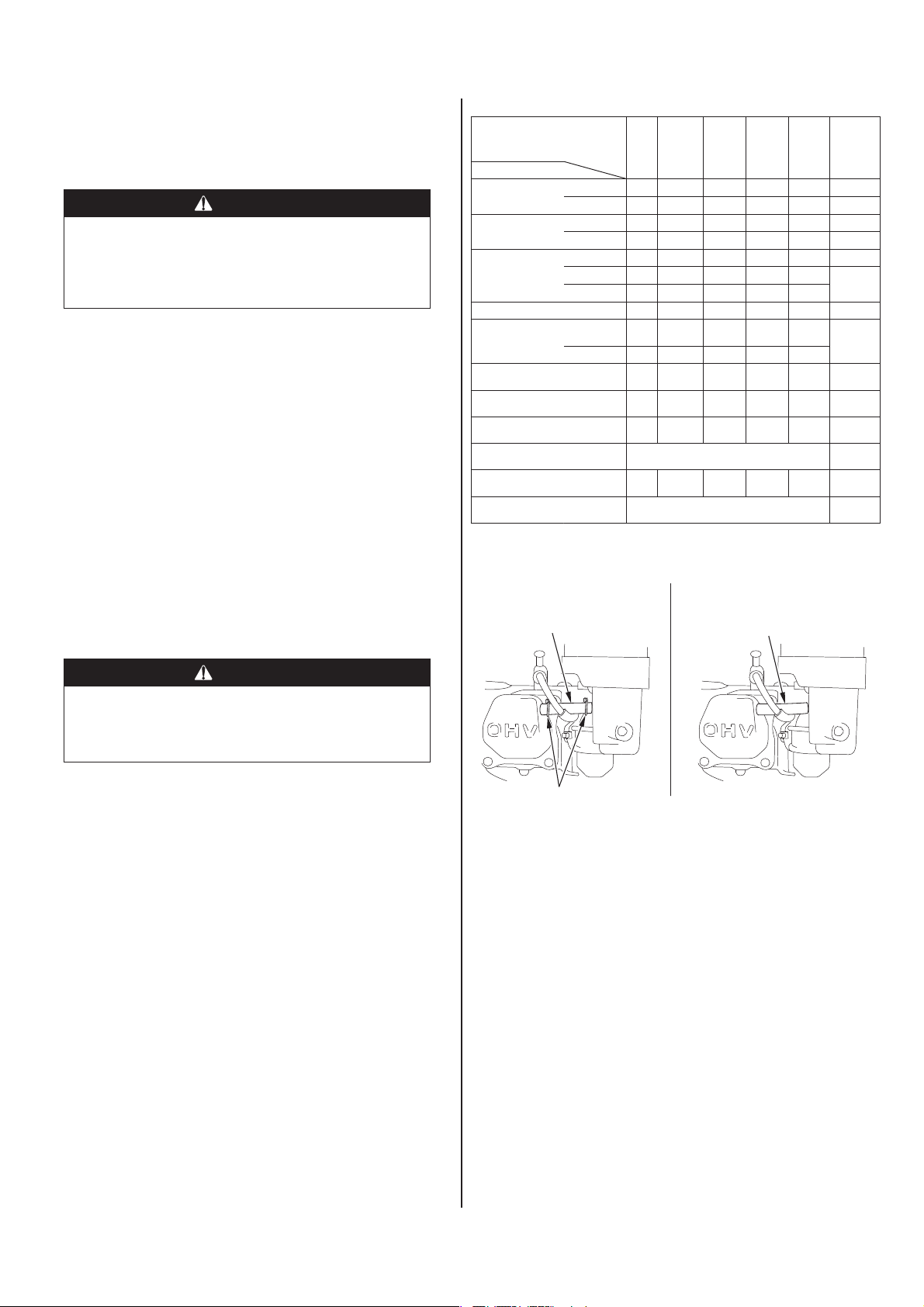

Cutting depth adjustment:

7

To unlock, set the knob to shallow groove.

This will enable you to exactly adjust the cutting depth

by turning the lifting handle.

To lower (feed motion) the machine body, rotate lifting

handle clockwise.

To raise the body, rotate the lifting handle counterclockwise.

When decided the cutting depth, set the knob at lock

position for lock the position of machine. (Fig.7)

Washer

Diamond blade

Nut

30mm(L14)

Tightening

Raise

Lower

(Feed motion)

To lock the lift or lower the machine, set

the knob to deep groove.

To unlock, set the knob to shallow groove.

Fig.5

27mm(L14)

Fig.6

㻯㼞㼍㼚㼗㻌㻴㼍㼚㼐㼘㼑

㻌㻌㻌㻌㻌㻔㻯㼡㼠㼠㼕㼚㼓㻌㼐㼑㼜㼠㼔㻌

㻌㻌㻌㻌㻌㻌㻌㻌㼍㼐㼖㼡㼟㼠㼙㼑㼚㼠㻕

Fig.7

11

Page 16

8.

Move each operation lever, and check on creak or

the wobble.

Check bolts and nuts for looseness or any other

9.

abnormality.

10.

Parking brake

There is a parking brake to left back wheel.

Turn a knob to right (a clock direction) and brake

it, and turn it to the left and remove brakes.

Remove brakes before the work. (Fig.8)

11.

Cut depth reading method

Cut depth is distance from the reading point of

Fig. 9 to blade tip.

There is blade tip in circumference of blade.

When you cut asphalt or concrete road with

diamond blade, the line trace (trace of line) of turn

happens on the side surface of blade.

Search the line trace of reading point, and read

distance from circumference to it with the scale of

blade cover. (Fig.9)

Parking brake

Reading point

Diamond Blade

Cut depth

Fig.8

Blade Cover

Scale

Trace of line

Circumference

Surface

of earth

Fig.9

12

Page 17

8䠊OPERATION

8.1 Starting Up

Move fuel cock lever with “ON” position.

㻝㻚

(Fig.10)

Fuel cock lever

DANGER:

㻞㻚

When cold or somehow starting is difficult, turn

The exhaust gas from the engine is carbon

monoxide and is deadly.

Do not run the engine in an unventilated

location, such as indoors or in a tunnel.

choke lever to START position. This is not necessary when engine is warm. (Fig.11)

㻟㻚

Move throttle control lever slightly to high speed

side. (Fig.11)

㻠㻚

Turn engine start switch to ON position.

(Fig.12)

㻡㻚

Hold recoil starter grip and pull it slightly until you

feel light resistance. Pull it strongly there. Be careful not to pull it too hard because it may come off.

Do not release the grip from the pulled position but

return it to starter case before releasing. (Fig.13)

䇾㻻㻲㻲䇿

Throttle control

lever

High speed

Choke lever

Choke close

(START)

ON/OFF Switch

IN (ON)

䇾㻻㻺䇿

Fig.10

Low ( Idling )

Choke open

OPERATION)

(

Fig.11

If engine has started, while listening to explosion

㻢㻚

sound, slowly return the choke lever to OPERATION position. (Fig. 11)

After started, be sure to run the engine at low

speed for a few minutes.

It must be done in cold weather particularly . Check

for abnormal noise or gas leak in the meantime.

DANGER:

CAUTION:

Because engine turns blade when start,

be careful enough.

Do not allow the starter grip to snap back

against the engine.

Return it gently to prevent damage to the

starter.

Fig.12

Starter grip

Fig.13

13

Page 18

8.2 Working

1.

Align the blade with cutting line. Aligning is easier if it is

done with the machine lifted.(Fig.14)

2.

With water cock opened, spray cooling water to the

blade. At least 5-6 liters per minute of cooling water

is required.

As the standard, if water mist is being sprayed to the

extent that water does not flow, the cooling will be

sufficient. Adjust the amount of water with cock.

(Spray on a little heavier side when there is sufficient

water.) (Fig.15)

Gauge

Blade

Cutting line

Fig.14

3.

Open throttle lever slowly to set engine revolution to

high speed. (Fig.11)

4.

To cut - in with the blade at the bottom, turn the Crank

handle to clockwise, and cut down while adjustment

the lowering speed so that engine speed is not

reduced excessively. After cutting down, set the knob

to the lock position which located beside of Crank

handle to lock the machine. (Fig.16)

5.

While listening to engine sound, push the machine

slowly for cutting operation.

Caution: Sudden feeding or cutting may

damage blade or decrease durability

of engine, V-belt, etc..

Water cock

Close

Open

Fig.15

Raise

㻯㼞㼍㼚㼗㻌㻴㼍㼚㼐㼘㼑

㻌㻌㻌㻌㻌㻔㻯㼡㼠㼠㼕㼚㼓㻌㼐㼑㼜㼠㼔㻌

㻌㻌㻌㻌㻌㻌㻌㻌㼍㼐㼖㼡㼟㼠㼙㼑㼚㼠㻕

Lower

(Feed motion)

To lock the lift or lower the machine, set

the knob to deep groove.

To unlock, set the knob to shallow groove.

Fig.16

9䠊STOPPING

When cutting is completed, turn the lift handle slowly

1.

counterclockwise to raise the machine body.

Close water cock to stop cooling water spray.

2.

Return throttle lever to lower engine speed.

3.

Idle the engine for a few minutes to cool down, then

turn the stop switch to the STOP (O) position.

Caution: Muffler gets hot during operation.

Be careful not to touch it when

operating throttle lever.

14

4.

Close(OFF) fuel cock lever.

Caution: Immediately after cutting

operation, machine is hot

on the whole. Be careful

not incur a burn.

Page 19

10䠊TRANSPORT

●

WARNING

䟿

10.1 Loading And Unloading

Be sure to work the license holder of crane

operation and slings.

10.1.1. Lifting work

Do loading and unloading by cranes.

10.1.2.

In loading and unloading select a leader,

and work by instructions of a leader by all

means.

10.1.3.

Lift the machine with the guard hook by all

means, to hook fittings. Never lift the

machine with handle, to hook fittings.

Before work of lifting, check any damage of body parts

(especially, Lifting hook, etc) or looseness / omission of

screws, and be sure safe.

●

Stop the engine at the time of the lifting, and close the fuel

cock.

●

The work of lifting uses only one-point lifting hook, and do

not the work of lifting in other point (handles).

●

Use enough wire rope of the strength.

●

Never put any person or animal under the lifted machine.

●

For safety, do not lift the machine up than required height.

䟿

CAUTION

Do not do loading and unloading

that use a gangboard, because it

is very dangerous.

10.2 Precautions In Transportation

●

WARNING

䟿

Stop the engine at the time of the transportation, and

close a fuel cock.

●

Remove a blade at the time of transportation by all

means.

●

By all means drain fuel before transporting the

machine .

●

Fix the machine well not to move and fall down.

15

Page 20

11䠊STORAGE

11.1.

Clean the machine by removing residual

mortar and water.

11.2.

Drain water of the water tank and the pipe.

11.3.

Supply grease to the pillow block and

grease nipple of each part .

Particularly, pillow block of the blade shaft

should be well greased a few times by

means of grease gun after work. (Fig.17)

Be sure to grease the thread portion of lifting

screw as well. (Fig.18)

11.4.

Put cover so that garbage and dust do not

appear.

Store it in the space which no hit rays of the

sun with a little moisture.

11.5. Proper storage:

For long term storage after work;

1.

Drain fuel from fuel tank, piping and

carburetor.

2.

With spark plug removed, drip a few

drops of engine oil into cylinder and

rotate engine manually to let the oil

reach everywhere inside the cylinder.

3.

Pull the recoil starter and leave it where

compression is felt.

4.

Store the machine away, covered and

in such place as it is free from direct

sun, moisture and dust.

Keep the machine indoors without

5.

leaving it outdoors.

Do not overthrew the machine

6.

sideways, and do not keep it.

Pillow block

of blade shaft

Blade shaft

Grease nipple

Supply grease to the grease nipple of each part .

㻲㼕㼓㻚㻝㻣

ࢢ࣮ࣜࢫ

㹅㹐㹃㸿㹑㹃

㻲㼕㼓㻚㻝㻤

About engine

For daily and periodical inspection or simple

maintenance services, see engine manual

separated provided.

16

Page 21

12䠊PERIODIC CHECK AND COORDINATION

1.ࠉEach part check schedule list

Check schedule

Daily

( before work )

20 hours

Every PRQWKV

or 100 hours.

Every year

or 200 hours

300 hours

Check point

Visual inspection

㻲㼡㼑㼘㻌㼠㼍㼚㼗

One-point lifting hook

Fuel system

Fuel filter

Engine oil

Air cleaner

Blade

Lifting device

Bolt, nuts

Engine oil

Engine oil

Lifting device (Fig.18)

Lifting screw

Pillow block (Fig.17)

Spark plug

Spark arrester (optional part )

Fuel tank & filter

V-belt

Air-cleaner element

Spark plug

Engine idle speed

Engine combustion chamber

Check item

Crack䚸Deformation

Leak䚸Quantity of Fuel䚸Dirt

Falling off䚸Breakage䚸Crack

Looseness & falling off of bolt & nuts

Leak

Dirt

Leak䚸Quantity of oil䚸䚷Dirt

'XVWRIVSRQJH

Crackࠊ'DPDJH

Function validationࠊ

Oils and fats

Looseness䚸Falling off

First time

Change

Crackࠊ&XUYHࠊGreasing

Greasing

Check-Clean

Clean

Clean

Crack䚸Tension

Replace

Replace

Check-Adjust

Check-AdjustEngine valve clearance

Clean

Type of oils and fats

Gasoline

Engine oil

Grease

Engine oil

Engine oil

Grease

Grease

Every 2 years

Irregular time

Fuel line

Air-cleaner element

Pillow block

Change

Change of necessary

WearAbnormal noise&UHDN

Wobble

࣭&KHFNVFKHGXOHWLPHWRFKHFNLVIRUQRUPDOFRQGLWLRQ,WGHSHQGVRQXVHFRQGLWLRQV

Refer the attached engine instruction manual for the details of check & maintenance for engine.

In order to avoid deficient reassembly, watch carefully normal status of installation before

removing or disassembling any part.

17

Page 22

13䠊TROUBLESHOOTING

13.1 Gasoline Engine

(1) Starting problem

Fuel is supplied, but

Spark Plug does

not ignite

Fuel supplied, and

Spark Plug

ignites

Fuel does not reach

to Carburetor

Electricity reaches

to High Voltage Cable

Electricity does not

reach to High Voltage

Cable

Compression is

good

Compression is

not good

No fuel in tank

Fuel Cock does not open properly

Clogging of Fuel Filter

Clogging of Tank Cap Air Hole

Air trapped in fuel pipe

Bridging Spark Plug

Carbon accumulated on Spark Plug

Short circuit due to insulation problems of

Spark Plug

Inappropriate gap of Spark Plug

Short circuit of Stop Switch

Ignition coil problems

Th

e wrong fuel is used

Mixing of water or dust contamination

Air Cleaner not working

Intake/Exhaust Valve is stuck or pushed up

Piston Ring, Cylinder wear enough

Cylinder head, Spark Plug tightening problem

Head gasket or Spark Plug Gasket breaks

(2) Operation problem

Compression is

good and no firing

problem

Lowered power

Engine overheating

Revolution fluctuation

Insufficient compression (see the item “compression is not good.” )

Compression is

good, but no firing

Carbon accumulated inside combustion chamber and exhaust hole.

Thermal value of Spark Plug is poor

Dirt and breakage of Cooling Fin

Governor adjustment inappropriate

Governor Spring problem

Fuel flows in proper

Air taken from Intake Pipe line

Clogging of Pilot Jet ( Idle speed fluctuates improper)

(3) Recoil Starter does not work well

㻌

D

irt of Air Cleaner

Carbon accumulated in Cylinder.

Fuel Level in Carburetor inproper

Water mixed in fuel

Dirt of Spark Plug

Ignition Coil problem

Clogging of dust from rotating part

Weakening of Spiral Spring

18

Page 23

13.2 Machine

(1) Blade system

At the time of cutting, a cut line bends.

Check of blade

Check the installation of the blade axle

Yes

Normal

Normal

Abnormal

Abnormal

Replace

Adjustment

Check the transformation of the blade axle

Normal

Check the installation of the lifting frame

Normal

Check the uneven rear of the rear wheel

Normal

Check the transformation of the frame

Normal

Normal

Belt is easy to cut

Yes

Check the tension of the belt

Normal

Check the pulley

Normal

Check the pillow block of the blade axle

Normal

Check transformation of the belt cover, contact with the belt

Normal

Normal

Abnormal

Abnormal

Abnormal

Abnormal

Abnormal

Abnormal

Abnormal

Replace

Adjustment

Replace

Replace

Adjustment

or replace

Replace

Replace

Repair

Abnormal

(䠎) Height Adjusting System

The lifting motion is not smooth

Transformation of the lifting screw part, running

out of grease

Check the transformation of the lifting frame

Check the pillow block

Normal

Yes

Normal

Normal

Normal

19

Abnormal

Abnormal

Abnormal

Replacement

or greasing

Repair or

replace

Replace

Page 24

MIKASASANGYOCO.,LTD.

1-4-3,Sarugakucho,Chiyoda-ku,Tokyo,101-0064,Japan

PRINTEDINJAPAN

Page 25

INLEDNING

Tack för att du köpt en motor från Honda. Vi vill hjälpa till så att du ska

få bästa möjliga nytta av din nya motor och att du ska kunna hantera

den på ett säkert sätt. Denna bruksanvisning innehåller information

om hur man gör det. Läs den noggrant innan du använder motorn. Om

ett problem skulle uppstå, eller om du har frågor om motorn, ska du

kontakta en auktoriserad Honda-serviceverkstad.

All information i denna publikation bygger på senast tillgänglig

information vid tryckningen. Honda Motor Co., Ltd. förbehåller sig rätten

att göra ändringar när som helst utan föregående meddelande och utan

någon form av krav. Inga delar av det här dokumentet får kopieras utan

skriftligt tillstånd.

Bruksanvisningen ska anses vara en permanent del av motorpaketet

och ska därför följa med motorn om motorn säljs vidare.

Läs också anvisningarna för den utrustning som motorn ska driva. Där

kan finnas ytterligare information om motorstart, avstängning, drift,

justeringar eller underhåll.

För USA, Puerto Rico och amerikanska Jungfruöarna:

Vi rekommenderar att du läser garantipolicyn för att få en tydlig bild av

vad den täcker och vilket ansvar du har som ägare. Garantipolicyn är ett

separat dokument som du ska ha fått av återförsäljaren.

BRUKSANVISNING

GX120 · GX160 · GX200

SVENSKA

SÄKERHETSINFORMATION

Din säkerhet och andras säkerhet är mycket viktig. I den

här bruksanvisningen, och på själva motorn, finns viktig

säkerhetsinformation. Läs dessa meddelanden noggrant.

Säkerhetsinformationen visar på risker som kan innebära personskador

för dig själv och andra. Varje säkerhetsmeddelande föregås av en

varningssymbol

FÖRSIKTIGHET.

Dessa signalord betyder:

VARNING

FÖRSIKTIGHET

Varje meddelande talar om för dig vilken fara det handlar om, vad som kan

hända och vad du kan göra för att för att undvika eller minska skadan.

MEDDELANDEN OM FÖREBYGGANDE AV SKADOR

Det finns också andra viktiga meddelanden som föregås av ordet OBS.

Detta betyder:

OBS!

Syftet med dessa meddelanden är att skydda din motor, annan

egendom eller omgivningen från skada.

© 2012 Honda Motor Co., Ltd. Alla rättigheter förbehållna

3SZ4M600

00X3S-Z4M-6001

SVENSKA 1

och något av de tre orden, FARA, VARNING eller

Du KOMMER att DÖ eller SKADAS

FARA

Om du inte följer instruktionerna kan din motor eller

annan egendom skadas.

ALLVARLIGT, om du inte följer

anvisningarna.

Du KAN DÖ eller SKADAS ALLVARLIGT,

om du inte följer anvisningarna.

Du KAN SKADAS om du inte följer

anvisningarna.

GX120UT2·GX160UT2·GX200UT2

GX120RT2·GX160RT2·GX200RT2

INNEHÅLL

INLEDNING ..................................1

SÄKERHETSINFORMATION .......1

SÄKERHETSINFORMATION .......2

SÄKERHETSETIKETTERNAS

PLACERING ..................................2

KOMPONENTERNAS &

REGLAGENS PLACERING .........3

FUNKTIONER ...............................3

KONTROLLER FÖRE

ANVÄNDNING ...............................4

KÖRNING .....................................4

FÖRBEREDELSER FÖR

SÄKER DRIFT ...........................4

STARTA MOTORN ...................... 4

STÄNGA A V MOTORN ...............6

STÄLLA IN MOTORVARVTAL ....6

MOTORSERVICE ........................7

VIKTEN AV UNDERHÅLL ...........7

UNDERHÅLLSSÄKERHET ........7

SÄKERHETSÅTGÄRDER ..........7

SERVICESCHEMA .....................7

BRÄNSLEPÅFYLLNING .............8

MOTOROLJA ..............................8

Rekommenderad olja ...............8

Kontroll av oljenivå ...................9

Oljebyte ....................................9

SLUTVÄXELOLJA ......................9

Rekommenderad olja ...............9

Kontroll av oljenivå ...................9

Oljebyte ..................................10

LUFTRENARE ..........................10

Kontroll ...................................10

Rengöring ............................... 11

VARNING:

Motoravgaserna från den här produkten

innehåller kemikalier som enligt Staten

Kalifornien orsakar cancer, födelseskador

eller andra skador på fortplantningsorganen.

SLAMUPPSAMLINGSSKÅL ....12

TÄNDSTIFT ..............................12

GNISTSLÄCKARE ....................13

TOMGÅNGSV ARVTAL .............13

TIPS OCH FÖRSLAG .................13

FÖRV ARING A V MOTORN ....... 13

TRANSPORT ............................14

HANTERING AV OVÄNT ADE

PROBLEM ...................................15

BYTE AV SÄKRING ..................15

TEKNISK INFORMATION ...........16

Serienumrets placering ..........16

Batterianslutningar

för elstart ................................16

Länksystem för fjärrkontroll ....16

Modifiering av förgasare för

körning på hög höjd ................ 17

Information om system

för utsläppskontroll .................17

Luftindex .................................18

Specifikationer ........................18

Motorinställningss-

pecifikationer ..........................19

Snabbreferens ........................19

Kopplingsscheman .................19

KONSUMENTUPPLYSNING ....20

Information om garanti,

distributör/återförsäljare ..........20

Information om kundservice ...20

Page 26

SÄKERHETSINFORMATION

• Förstå hur alla kontroller fungerar och hur man stoppar motorn snabbt

i en nödsituation. Se till att användaren har fått tillräcklig information

innan han/hon använder utrustningen.

• Låt inte barn köra motorn. Håll barn och husdjur borta från

driftsområdet.

• Motorns avgaser innehåller giftig kolmonoxid. Kör inte motorn utan

tillräcklig ventilation och kör den aldrig inomhus.

• Motorn och avgassystemet blir mycket heta under drift. Motorn ska

stå minst en (1) meter från byggnader och annan utrustning under

drift. Håll brännbara material på avstånd och lägg ingenting på motorn

medan den är igång.

SÄKERHETSETIKETTERNAS PLACERING

De här etiketterna varnar för risker som kan orsaka allvarliga

personskador. Läs dem noggrant.

Om etiketten faller av eller blir svårläst – kontakta Hondas återförsäljare

för en ny.

VARNINGSSKYLT FÖR LJUDDÄMPARE

VARNINGSSKYLT

VARNINGSSKYLT För EU Förutom EU

VARNINGSSKYLT FÖR

LJUDDÄMPARE

fäst på

produkten

medföljer

produkten

medföljer

produkten

För EU Förutom EU

ingår ej

medföljer

produkten

medföljer

produkten

medföljer

produkten

fäst på

produkten

medföljer

produkten

medföljer

produkten

fäst på

produkten

medföljer

produkten

2 SVENSKA

Bensin är mycket brandfarligt och explosivt.

Stäng av motorn och låt den svalna före

bränslepåfyllning.

Motorn släpper ut giftig koloxid. Kör inte motorn

i slutna utrymmen.

Läs bruksanvisningen före användning.

Man kan bränna sig på en varm ljuddämpare.

Håll dig borta från den om motorn varit på.

Page 27

KOMPONENTERNAS & REGLAGENS PLACERING FUNKTIONER

BRÄNSLETANK

OLJETÖMNINGSPLUGG

LJUDDÄMPARE

TÄNDSTIFT

TANKLOCK

ELSTART (vissa modeller)

OLJEPÅFYLLNINGSLOCK/

OLJESTICKA

LUFTRENARE

REPSTARTSANORDNING

OIL ALERT®-SYSTEM (vissa modeller)

’’Oil Alert är ett registrerat varumärke i USA’’

Oil Alert-system är utformat för att förhindra att motorn skadas på

grund av att det är för lite olja i vevhuset. Oil Alert-systemet stoppar

automatiskt motorn innan oljenivån i vevhuset går under säkerhetsnivån

(motorns omkopplare står kvar i läget ON (PÅ)).

Om motorn stannar och inte startar igen, ska du kontrollera oljenivån

(se sidan 9) innan du felsöker andra områden.

KRETSSÄKRING (vissa modeller)

Kretssäkringen skyddar batteriets

laddningskrets. En kortslutning eller

ett batteri som anslutits felaktigt

kommer att göra att kretssäkringen

löser ut.

Den gröna indikatorn inuti

kretssäkringen kommer att hoppa

ut, vilket visar att säkringen stängt

av. Lokalisera orsaken till problemet

och åtgärda detta innan du

återställer kretssäkringen.

Tryck in kretssäkringen för att

återställa systemet.

KRETSSKYDD

BRÄNSLEVENTILARM

GASREGLAGE

ON (PÅ)

OFF (AV)

STARTHANDTAG

MOTORSTYRNINGSTYPER

EJ ELSTARTMODELLER

CHOKEREGLAGE

MOTOROMKOPPLARE

MOTOROMKOPPLARE

ELSTARTMODELLER

CHOKEREGLAGE

(luftrenare av lågprofiltyp)

MOTOROMKOPPLARE

KRETSSKYDD

SVENSKA 3

Page 28

KONTROLLER FÖRE ANVÄNDNING

KÖRNING

ÄR MOTORN FÖRBEREDD OCH KLAR?

För din egen säkerhet, och för att maximera användningstiden för

din utrustning, är det mycket viktigt att du tar en liten stund för att

kontrollera motorns skick innan du startar den. Tillse att alla problem

åtgärdats, gärna av serviceverkstaden, innan du startar motorn.

VARNING

Felaktigt underhåll eller underlåtenhet att inte rätta till ett

problem före drift kan orsaka ett funktionsfel där du kan

skadas allvarligt eller dödas.

Utför alltid en kontroll före varje igångkörning och åtgärda alla

eventuella problem.

Innan några kontroller görs – tillse att motorn står plant och att motorns

omkopplare står i läge OFF (AV).

Kontrollera alltid följande innan du startar motorn:

Kontrollera motorns allmänna skick

1. Titta runt och under motorn för att se om det finns tecken på

oljeläckor eller bensinläckor.

2. Ta bort all smuts och allt skräp, särskilt runt ljuddämparen och

startrepsanordningen.

3. Se efter om det finns tecken på skador.

4. Kontrollera att alla skydd och höljen finns på plats och att alla

muttrar, skruvar och bultar är åtdragna.

Kontrollera motorn

1. Kontrollera bränslenivån (se sidan 8). Start med full tank hjälper till

att eliminera eller minska driftavbrott för bränslepåfyllning.

2. Kontrollera motoroljenivån (se sidan 9). Om motorn körs med låg

oljenivå kan motorskador uppstå.

Oil Alert-systemet (vissa modeller) stannar motorn automatiskt innan

oljenivån går under säkerhetsnivån. Men för att slippa besvär med en

plötslig avstängning, ska man alltid kontrollera motoroljenivån innan

man startar motorn.

3. Kontrollera oljenivån i slutväxeln på vissa modeller (se sidan 9). Olja

är nödvändig för slutväxelns funktion och för lång livslängd.

4. Kontrollera luftfilterelementet (se sidan 10). Ett smutsigt

luftfilterelement begränsar luftflödet till förgasaren och försämrar

motorns prestanda.

5. Kontrollera den utrustning som drivs av motorn.

Läs igenom instruktionerna som följde med den utrustning som drivs

av denna motor för eventuella försiktighetsåtgärder eller procedurer

som ska genomföras före start.

FÖRBEREDELSER FÖR SÄKER DRIFT

Innan du startar motorn första gången ber vi dig läsa avsnittet

SÄKERHETSINFORMATION på sidan 2 och KONTROLLER FÖRE

ANVÄNDNING på sidan 4.

För din säkerhets skull, ska du undvika att starta eller köra motorn i ett

slutet utrymme som till exempel ett garage. Motorns avgaser innehåller

giftig koloxid som kan samlas snabbt i ett slutet utrymme och orsaka

illamående eller dödsfall.

VARNING

Avgaser innehåller giftig koloxid som kan ansamlas till farliga

nivåer i slutna utrymmen. Inandning av koloxid kan orsaka

medvetslöshet eller dödsfall.

Kör aldrig motorn i ett slutet, eller delvis slutet utrymme, där

det kan finnas människor.

Granska också instruktionerna som följer med den utrustning som

motorn ska driva. Där kan finnas säkerhetsinformation som ska följas

vid start, stopp eller drift av motorn.

Kör inte motorn i backar som sluttar mer än 20° (36%).

STARTA MOTORN

1. Flytta bränslekranens spak till läget ON (PÅ).

BRÄNSLEVENTILARM

ON (PÅ)

ON

OFF (AV)

2. Vid start av en kall motor ska chokereglaget flyttas till stängt läge

CLOSED (STÄNGD).

CHOKEREGLAGE

CLOSED

(STÄNGD)

CLOSED

(STÄNGD)

ON

ON (PÅ)

OPEN

OPEN

(ÖPPEN)

När man ska starta om en varm motor ska chokereglaget stå i läget

Vissa motorsystem har en fjärrmanövrerad choke i stället för det

4 SVENSKA

OPEN (ÖPPEN).

motormonterade chokereglage som visas här. Se anvisningarna från

respektive tillverkare.

Page 29

3. Flytta gasreglaget bort från MIN-läget, och cirka 1/3 av vägen mot

MAX-läget.

GASREGLAGE

5. Dra igång motorn med startanordningen.

STARTANORDNING:

Ta tag i starthandtaget lätt tills du känner ett motstånd. Dra sedan

snabbt i pilens riktning som visas nedan. Släpp starthandtaget

försiktigt.

STARTHANDTAG

MIN.

MIN.

MAX.

1/3-LÄGET

MIN.

På vissa motortillämpningar är det bättre att använda fjärrkontrollen

för gasreglaget än det gasreglage som är monterat på motorn och

som visas här. Se anvisningarna från respektive tillverkare.

4. Vrid motoromkopplaren till läget ON (PÅ).

EJ ELSTARTMODELLER

MOTOROMKOPPLARE

ON (PÅ)

ON (PÅ)

ELSTARTMODELLER

ON (PÅ)

MOTOROMKOPPLARE

ON (PÅ)

ON (PÅ)

Dragriktning

OBS!

Låt inte starthandtaget smälla tillbaka mot motorn. Låt det gå tillbaka

lugnt för att undvika skador på startmotorn.

START

ELSTART (vissa modeller):

Vrid nyckeln till START och håll kvar den

där tills motorn startar.

Om motorn inte startar inom fem (5) sekunder

släpper du nyckeln. Vänta sedan minst

10 sekunder innan du försöker starta igen.

OBS!

START

Om man använder elstarten i mer än fem

sekunder i taget kommer startmotorn att

överhettas och då kan den bli förstörd.

Den här typen av överhettning omfattas

inte av garantin.

Släpp nyckeln när motorn startar så att den

kan gå tillbaka till läge ON (PÅ).

MOTOROMKOPPLARE

(vissa modeller)

6. Om chokereglaget flyttats till stängt läge CLOSED (STÄNGD) vid

motorstart – flytta det gradvis mot öppet läge OPEN (ÖPPEN) när

motorn värms upp.

CHOKEREGLAGE

ON (PÅ)

MOTOROMKOPPLARE

SVENSKA 5

OPEN (ÖPPEN)

CLOSED (STÄNGD)

OPEN

OPEN

(ÖPPEN)

Page 30

STÄNGA A V MOTORN

Vrid bara motorns stoppknapp till läget OFF (AV) om du behöver

stänga av motorn i en nödsituation. Gör på följande sätt vid normala

förhållanden. Se anvisningarna från respektive tillverkare.

1. Flytta gasreglaget till MIN-läget.

På vissa motortillämpningar är det bättre att använda fjärrkontrollen

för gasreglaget än det gasreglage som är monterat på motorn och

som visas här.

GASREGLAGE GASREGLAGE

STÄLLA IN MOTORVARVTAL

Ställ in gasspjällsarmen på önskat motorvarvtal.

På vissa motortillämpningar är det bättre att använda fjärrkontrollen för

gasreglaget än det gasreglage som är monterat på motorn och som

visas här. Se anvisningarna från respektive tillverkare.

Se de instruktioner som följde med den utrustning som drivs av denna

motor för rekommendationer när det gäller motorvarvtal.

2. Vrid motoromkopplaren till läge AV/OFF.

EJ ELSTARTMODELLER

MOTOROMKOPPLARE

OFF (AV)

OFF

OFF (AV)

ELSTARTMODELLER

OFF (AV)

OFF (AV)

OFF (AV)

OFF

MIN.

MAX.

MA

MIN.MAX.

MIN.MIN.

MOTOROMKOPPLARE

OFF (AV)

MOTOROMKOPPLARE

3. Flytta bränslekranens spak till läget FRÅN/OFF (AV).

BRÄNSLEVENTILARM

OFF (AV)

OFF (AV)

6 SVENSKA

ON

ON (PÅ)

Page 31

MOTORSERVICE

VIKTEN AV UNDERHÅLL

Väl utfört underhåll är avgörande för säker, ekonomisk och problemfri

drift. Det hjälper också till att minska utsläppen.

VARNING

Felaktigt utfört underhåll, eller underlåtenhet att åtgärda

problem före drift, kan orsaka fel som kan leda till allvarliga

personskador eller dödsfall.

Följ alltid de rekommendationer för kontroller och underhåll

som anges i bruksanvisningen.

För att du ska få hjälp med att underhålla din motor på rätt sätt,

finns det ett underhållsschema på de följande sidorna, procedurer

för rutinkontroller och enkla underhållsprocedurer med hjälp av

grundläggande handverktyg. Andra serviceuppgifter som är svårare

eller som kräver specialverktyg utförs bäst av proffs och sådan service

görs normalt av en Honda-tekniker eller annan kvalificerad mekaniker.

Underhållsschemat gäller vid normala användningsförhållanden.

Om motorn körs under svårare förhållanden, t.ex. med hög last

under lång tid eller vid hög temperatur, eller vid särskilt våta eller

dammiga förhållanden – kontakta återförsäljare/serviceverkstad

för rekommendationer som gäller avsedd användning.

Underhåll, byte eller reparation av avgaskontrollenheter- och

system, kan utföras av en bilverkstad eller en enskild person

med hjälp av delar som är EPA-certifierade.

UNDERHÅLLSSÄKERHET

Här följer några av de viktigaste säkerhetsföreskrifterna. Vi kan däremot

inte varna för varje tänkbar risk som kan uppstå vid underhållsarbeten.

Bara du själv kan avgöra om du ska utföra ett givet moment av

underhållet eller inte.

SERVICESCHEMA

SERVICEINTERVALL (3)

Utförs vid angiven månad eller efter

antal timmar, beroende på vilket som

inträffar först.

Motorolja

Slutväxelolja

(vissa modeller)

Luftfilter

Slamuppsamlare Rengör O 12

Tändstift

Gnistsläckare

(vissa modeller)

Tomgångsvarvtal

Ventilspel

Förbränningskammare Rengör Efter varje 500-timmarsperiod (2)

Bränsletank och filter Rengör O (2)

Bränsleslang Kontrollera

• Endast förgasare med intern ventil och dubbla element.

*

• Cyklontyp var 6:e månad eller var 150:e timme.

MED INTERN VENTIL

AVLUFTNINGSRÖR AVLUFTNINGSRÖR

Kontrollera nivå O 9

Byte O O 9

Kontrollera nivå O 9-10

Byte O O 10

Kontrollera O 10

Rengör O (1)

Byt ut

KontrolleraJustera

Byt ut O

Kontrollera O (4) 13

KontrolleraJustera

KontrolleraJustera

Varje

gång

Första

månaden

eller efter

20 timmar

Var tredje

månad

eller var

50:e

timme

Vartannat år

(Byte vid behov) (2)

STANDARDTYPMODELL MED FÖRGASARE

Var sjätte

månad

eller var

100:e

timme

(1)

O

*

O

Varje år

eller var

300:e

timme

O

* *

O (2) 13

O (2)

Se:

sidanDetalj

11-12

12

Verkst.

handbok

Verkst.

handbok

Verkst.

handbok

Verkst.

handbok

VARNING

Att inte följa instruktioner om underhåll kan orsaka att du blir

allvarligt skadad eller dödad.

Följ alltid anvisningar och säkerhetsföreskrifter enligt denna

bruksanvisning.

SÄKERHETSÅTGÄRDER

• Kontrollera att motorn är avstängd innan du påbörjar något

underhållsarbete eller några reparationer. Koppla från tändkabelskon

vid tändstiftet för att undvika oavsiktlig start. Du kan undvika många

potentiella risker så här:

— Koloxidförgiftning från avgaserna.

Använd bara motorn utomhus, på avstånd från fönster och dörrar.

— Brännskador av uppvärmda delar.

Låt motorn och avgassystemet svalna innan du rör vid dem.

— Skada från rörliga delar.

Kör inte motorn innan du fått anvisningar om att göra detta.

• Läs anvisningarna innan du börjar och se till att du har de verktyg och

färdigheter som krävs.

• Var försiktig när du arbetar i närheten av bensin för att minska risken

för brand eller explosion. Använda bara lösningsmedel som inte är

brandfarliga, inte bensin när du rengör delar. Cigarretter, gnistor och

eld måste hållas på behörigt avstånd från alla bränslerelaterade delar.

Kom ihåg att en auktoriserad Honda-återförsäljare kan din motor bäst

och har rätt utrustning för att serva och reparera den. För att vara

säker på bästa kvalitet och funktion bör du bara använda nya Honda

originalreservdelar eller motsvarande vid reparation och service.

SLANGKLÄMMA

• Byt endast papperselementtyp.

**

• Cyklontyp vartannat år eller var 600:e timme.

(1) Utför service oftare vid användning i dammiga miljöer.

(2) Service på dessa delar ska utföras av serviceverkstad såvida

du inte har rätt verktyg och själv har de mekaniska kunskaper

som krävs. Se Hondas verkstadshandbok för uppgifter om

serviceförfaranden.

(3) Vid kommersiell användning, ska du logga antalet driftstimmar för

att fastställa rätt underhållsintervall.

(4) I Europa och andra länder där maskindirektivet 2006/42/EC gäller,

ska den här rengöringen utföras av återförsäljaren.

Om underhållsschemat inte följs kan detta leda till fel som inte täcks

av garantin.

SVENSKA 7

Page 32

BRÄNSLEPÅFYLLNING

Rekommenderat bränsle

Blyfri bensin

USA Pumpbensin, oktantal på 86 eller högre

Utanför

USA

Bensin med oktantal på 91 eller högre

Pumpbensin, oktantal på 86 eller högre

Denna motor är godkänd för att köras på blyfri bensin med ett oktantal

på 86 eller högre (oktantal på 91 eller högre).

Fyll på bränsle i ett väl ventilerat utrymme med motorn avstängd. Låt

motorn svalna först om den varit igång. Fyll aldrig på bränsle inomhus

där bensinångorna kan komma i kontakt med flammor eller gnistor.

Man kan använda blyfri bensin som inte innehåller mer än 10

volymprocent etanol (E10) eller 5 volymprocent metanol. Dessutom

ska metanolen innehålla lösningsmedel och korrosionsskyddsmedel.

Användning av ett bränsle som innehåller mer etanol eller metanol än

vad som visas ovan kan leda till problem när det gäller start och/eller

prestanda. Det kan också skada delar i metall, gummi och plast som

ingår i bränslesystemet. Motorskador eller driftsproblem på grund av

att man använder bränsle med procentuellt större mängd etanol eller

metanol i än vad som visas här ovan, täcks inte av garantin.

Om utrustningen ska användas sällan eller oregelbundet bör du läsa

bränsleavsnittet i kapitlet FÖRVARING AV MOTORN (se sidan 13) för

ytterligare information om bränslenedbrytning.

Använd aldrig gammal eller förorenad bensin eller oljeblandad bensin.

Se till att smuts och vatten inte kan komma in i bränsletanken.

VARNING

Bensin är mycket brandfarligt och explosivt och kan

orsaka brännskador eller allvarliga personskador vid

bränslepåfyllning.

• Stanna motorn och undvik gnistor, värme och öppen låga.

• Fyll endast på bränsle utomhus.

• Torka upp spill omedelbart.

Fyll på försiktigt så att du inte spiller ut bränsle. Fyll inte tanken helt.

Det kan var nödvändigt att ha mindre bensin i tanken beroende på

driftsförhållandena. Efter tankning skruvar du på locket tills ett klick hörs.

Håll bensin på behörigt avstånd från tändsystem, grillar, elutrustning,

motordrivna verktyg etc.

Utspillt bränsle är inte bara brandfarligt utan även miljöfarligt. Torka upp

spill omedelbart.

MOTOROLJA

Oljan är en viktig komponent som påverkar prestanda och livslängd.

Använd fyrtaktsolja av biltyp.

Rekommenderad olja

Använd en fyrtaktsolja som uppfyller eller överskrider kraven för API,

servicekategori SJ eller senare (eller motsvarande). Kontrollera alltid

API-serviceskylten på oljebehållaren för att försäkra dig om att den har

bokstäverna SJ eller senars (eller motsvarande).

OMGIVNINGSTEMPERATUR

SAE 10W-30 rekommenderas för allmän användning. Andra viskositeter

i schemat kan användas när medeltemperaturen i ditt körområde är

inom angivna intervaller.

OBS!

Bränsle kan skada lacker och vissa typer av plast. Var försiktig så att

du inte spiller ut bränsle när du fyller på tanken. Skador som orakats

av utspillt bränsle täcks inte av Leverantörens begränsade garanti.

Flytta dig minst 1 meter från bränslekällan och platsen innan du

startar motorn.

1. Motorn ska vara stoppad och på ett jämns underlag när man tar

av tanklocket för att kontrollera bränslenivån. Fyll på tanken om

bränslenivån är låg.

2. Fyll på bränsle till precis under gränslinjen i bränsletanken. Fyll inte

på för mycket. Torka upp utspillt bränsle innan du startar motorn.

TANKLOCK

MAX.

BRÄNSLENIVÅ

8 SVENSKA

Page 33

Kontroll av oljenivå

Kontrollera motoroljenivån med motorn avstängd och på plant underlag.

1. Ta bort oljepåfyllningslocket/oljestickan och torka av.

2. Sätt in oljepåfyllningslocket/oljestickan så som figuren visar men

skruva inte in. Ta sedan ut oljestickan igen och kontrollera nivån.

3. Om oljenivån är nära eller under den nedre gränsmarkeringen på

oljestickan – fyll på med rekommenderad olja (se sidan 8) till det

övre gränsvärdet (nedre kanten på oljepåfyllningshålet). Fyll inte

på för mycket.

4. Sätt tillbaka oljepåfyllningslocket/oljestickan.

4. Montera oljepåfyllningslocket/oljestickan och dra åt ordentligt.

BRICKA

TÖMNINGSPLUGG

OLJEPÅFYLLNINGSLOCK/

OLJESTICKA

OLJENIVÅ

OLJEPÅFYLLNINGSLOCK/OLJESTICKA

OLJEPÅFYLLNINGSHÅL

(nedre kant)

ÖVRE GRÄNS

NEDRE GRÄNS

OBS!

Om motorn körs med låg oljenivå kan motorskador uppstå. Denna typ

av skada täcks inte av Leverantörens begränsade garanti.

Oil Alert-systemet (vissa modeller) stannar motorn automatiskt innan

oljenivån går under säkerhetsnivån. Men för att slippa besvär med en

plötslig avstängning, ska man alltid kontrollera motoroljenivån innan

man startar motorn.

Oljebyte

Töm ut den gamla oljan när motorn är varm. Varm olja rinner ut snabbt

och fullständigt.

1. Ställ en behållare under motorn för den gamla oljan. Ta sedan bort

oljepåfyllningslocket/oljestickan, oljepluggen och brickan.

2. Låt den gamla oljan rinna ut helt och hållet, och sätt sedan tillbaka

oljepluggen och en ny bricka. Dra åt oljepluggen ordentligt.

Ta hand om gammal motorolja på ett godkänt och miljövänligt

sätt. Ta med den använda oljan i en stängd behållare till en

återvinningsstation eller verkstad för återvinning. Den får inte kastas

i soporna, hällas ut på marken eller hällas ut i avloppet.

3. Ställ motorn på plant underlag, fyll på med rekommenderad olja

(se sidan 8) upp till övre gränsvärdet på oljestickan (nedre kanten

på oljepåfyllningshålet).

OBS!

Om motorn körs med låg oljenivå kan motorskador uppstå. Denna

typ av skada täcks inte av Leverantörens begränsade garanti.

Oil Alert-systemet (vissa modeller) stannar motorn automatiskt innan

oljenivån går under säkerhetsnivån. Fyll på till övre gränsen och

kontrollera oljan regelbundet för att undvika oavsiktlig avstängning.

Tvätta händerna med tvål och vatten efter att du har handskats med

smutsig olja.

SLUTVÄXELOLJA (vissa modeller)

Rekommenderad olja

Använd samma olja som rekommenderas för motorn (se sidan 8).

Kontroll av oljenivå

Kontrollera slutväxelns oljenivå med motorn avstängd och på plant underlag.

2 : 1 Slutväxel med centrifugalkoppling

1. Ta bort oljepåfyllningslocket/oljestickan och torka av.

2. Sätt in och ta ut oljepåfyllningslocket/oljestickan utan att skruva

in i påfyllningshålet. Kontrollera oljenivån på oljepåfyllningslocket/

oljestickan.

3. Fyll på olja till det övre gränsvärdet på oljestickan. Använd

rekommenderad olja.

4. Skruva in oljepåfyllningslocket/oljestickan och dra åt ordentligt.

PÅFYLLNINGSLOCK/

ÖVRE

GRÄNS

NEDRE GRÄNS

OLJESTICKA

SVENSKA 9

Page 34

6 : 1 Slutväxelhus

1. Ta bort oljenivåskruven och

OLJENIVÅ

PÅFYLLNINGSBULT

brickan, och se om oljan når upp till

skruvhålets kant.

2. Om oljenivån är under skruvhålets

nivå – ta bort påfyllningsskruven och

brickan. Fyll på olja tills oljan börjar

rinna ut genom kontrollskruvhålet.

Använd rekommenderad olja

(se sidan 9).

3. Sätt tillbaka oljekontrollskruv,

påfyllningsskruv och brickor. Dra åt

dem säkert.

Oljebyte

SKRUV FÖR KONTROLL AV OLJENIVÅ

2 : 1 Slutväxel med centrifugalkoppling

Töm ut den gamla oljan när motorn är varm. Varm olja rinner ut snabbt

och fullständigt.

1. Ställ en behållare under slutväxelhuset för den gamla oljan. Ta sedan

bort oljepåfyllningslocket/oljestickan, tömningspluggen och brickan.

2. Låt den gamla oljan rinna ut helt och hållet, och sätt sedan tillbaka

oljepluggen och en ny bricka. Dra åt oljepluggen ordentligt.

Ta hand om gammal motorolja på ett godkänt och miljövänligt

sätt. Ta med den använda oljan i en stängd behållare till en

återvinningsstation eller verkstad för återvinning. Den får inte kastas i

soporna, hällas ut på marken eller hällas ut i avloppet.

3. Ställ motorn på plant underlag, fyll på upp till övre gränsvärdet på

oljestickan. Använd rekommenderad olja (se sidan 9). Kontrollera

oljenivån genom att sätta in och ta ut oljestickan utan att skruva in den.

Oljekapacitet i slutväxelhuset: 0,5 liter

OBS!

Om motorn körs med för lite olja i slutväxelhuset kan motorskador

uppstå.

4. Skruva in oljepåfyllningslocket/oljestickan säkert.

Tvätta händerna med tvål och vatten efter att du har handskats med

smutsig olja.

PÅFYLLNINGSLOCK/

OLJESTICKA

ÖVRE

GRÄNS

NEDRE GRÄNS

TÖMNINGSPLUGG

6 : 1 Slutväxelhus

Töm ut den gamla oljan när motorn är varm. Varm olja rinner ut snabbt

och fullständigt.

1. Ställ en behållare under slutväxelhuset för den gamla oljan. Ta sedan

bort påfyllningslocket/oljestickan, oljenivåskruven och brickorna.

2. Töm ut den gamla oljan helt och hållet i en behållare genom att tippa

motorn mot oljekontrollhålet.

Ta hand om gammal motorolja på ett godkänt och miljövänligt

sätt. Ta med den använda oljan i en stängd behållare till en

återvinningsstation eller verkstad för återvinning. Den får inte kastas

i soporna, hällas ut på marken eller hällas ut i avloppet.

3. Ställ motorn plant. Fyll på olja tills oljan börjar rinna ut genom

kontrollskruvens hål. Använd rekommenderad olja (se sidan 9).

OBS!

Om motorn körs med för lite olja i slutväxelhuset kan motorskador

uppstå.

4. Sätt tillbaka oljekontrollskruv, påfyllningsskruv och brickor. Dra åt

ordentligt.

PÅFYLLNINGSBULT

OLJENIVÅ

SKRUV FÖR KONTROLL AV OLJENIVÅ

Tvätta händerna med tvål och vatten efter att du har handskats med

smutsig olja.

LUFTRENARE

En smutsig luftrenare begränsar luftflödet till förgasaren och försämrar

motorns prestanda. Om motorn körs på mycket dammiga platser måste

luftfiltret rengöras oftare än vad som anges i underhållsschemat.

OBS!

Om man använder motorn utan luftfilter, eller med ett skadat luftfilter,

kan det komma in smuts i motorn, vilket snabbt ger skador på den.

Denna typ av skada täcks inte av Leverantörens begränsade garanti.

Kontroll

Ta bort luftrenarkåpan och kontrollera filterelementen. Rengör eller byt

ut smutsiga filterelement. Byt alltid ut skadade filterelement. Kontrollera

även oljenivån om utrustningen har luftrenare av oljetyp.

Se sidorna 11 – 12 för anvisningar som gäller luftrenare och filter för

aktuell motortyp.

10 SVENSKA

Page 35

Rengöring

Dubbelfilter

1. Ta bort vingmuttern från

luftrenarkåpan och ta bort

kåpan.

2. Ta bort vingmuttern från

luftfiltret och ta bort filtret.

3. Ta bort skumplastfiltret

från pappersfiltret.