Page 1

1. KEEP CLEAR! Gate may move at any time.

2. Do not allow children to operate gate or play in gate area.

3. This gate is for vehicles only. Pedestrians must use separate entrance.

WARNING

!

MOVING GATE

Can Cause Injury or Death

UL325 SERIES

50

2

®

E-Z GATE OPENER

1-800-543-GATE (4283) • www.mightymule.com

1. KEEP CLEAR! Gate may move at any time.

2. Do not allow children to operate gate or play in gate area.

3. This gate is for vehicles only. Pedestrians must use separate entrance.

WARNING

!

MOVING GATE

Can Cause Injury or Death

UL325 SERIES

50

2

®

E-Z GATE OPENER

1-800-543-GATE (4283) • www.mightymule.com

UL325 SERIES

502

®

E-Z GATE OPENER

DUAL GATE SYSTEM

©

2002 GTO, Inc.

WARNING!

This equipment is similar to other gate or door equipment and meets or exceeds

Underwriters Laboratory Standard 325 (UL 325). However, gate equipment has

hazards associated with its use and therefore by installing this product the installer

and user accept full responsibility for following and noting the installation and

safety instructions. Failure to follow installation and safety instructions can result

in hazards developing due to improper assembly. You agree to properly install this

product and that if you fail to do so GTO, Inc. shall in no event be liable for direct,

indirect, incidental, special or consequential damages or loss of profi ts whether

based in contract tort or any other legal theory during the course of the warranty

or at any time thereafter. The installer and/or user agree to assume responsibility

for all liability and use of this product releasing GTO, Inc. from any and all

liability. If you are not in agreement with this disclaimer or do not feel capable

of properly following all installation and safety instructions you may return this

product for full replacement value.

READ ALL INSTRUCTIONS CAREFULLY AND COMPLETELY before

attempting to install and use this automatic gate opener. This gate opener

produces a high level of force. Stay clear of the unit while it is operating and

exercise caution at all times.

All automatic gate openers are intended for use on vehicular gates only.

This product meets and exceeds the requirements of UL 325, the standard which regulates gate opener safety,

as established and made effective March 1, 2000, by Underwriters Laboratories Inc.

3121 Hartsfi eld Road • Tallahassee, Florida, USA 32303

Telephone GTO Sales: 1-800-543-GATE (4283) or (850) 575-0176 • Fax (850) 575-8912

or GTO Technical Service: 1-800-543-1236 or (850) 575-4144 • Fax (850)575-8950

www.mightymule.com

L

I

S

T

E

D

US

Page 2

VEHICULAR GATE OPENER CLASS CATEGORIES

Residential Vehicular Gate Opener-Class I

hotel, garages, retail store, or other building servicing the general public.

use in an industrial location or building such as a factory or loading dock area or other locations not intended to

____________________

____________________

Remember to keep all receipts for

proof of purchase.

kilograms 2.2046 pounds lb. (or #)

pounds 0.4535 kilograms kg

Page 3

-------------------------------------------------------------

--------------------------------------------------

Disconnecting the Opener

-------------------------------------------------------------

page 1

Important Safety Instructions for the Consumer

page 2

Secondary Means of Protection Against Entrapment

------------------------------

page 5

Required Safety Precautions for Gates

-----------------------------------------------

page 6

Warning Signs and Labels

page 7

--------------------------------------------------------------------------

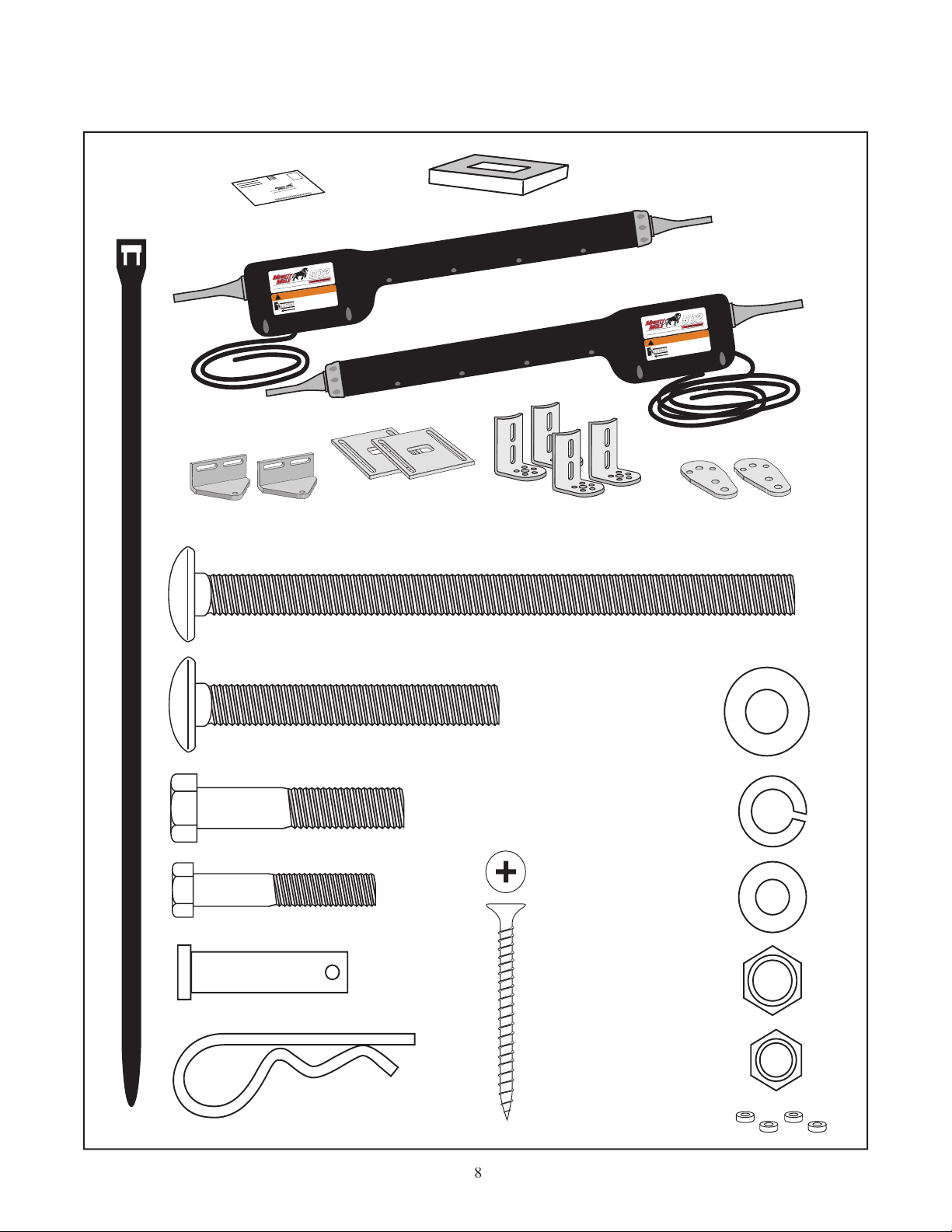

Parts List

---------------------------------------------------------------------------------

page 8

Technical Specifi cations

page 10

Installation of the Mounting Hardware

----------------------------------------------

page 12

Mounting the First Opener

page 16

Installing the Second Opener

----------------------------------------------------------

page 16

Installation of the Closed Position Stops

--------------------------------------------

page 17

Mounting the Control Box

page 19

Connecting the Opener Power Cables

-----------------------------------------------

page 20

--------------------------------------------------------------

Solar Chart

page 21

Connecting the Transformer

-----------------------------------------------------------

page 21

----------------------------------------------------------

Obstruction Sensitivity

-----------------------------------------------------------------

page 25

Main DIP Switches

page 26

Dual Mode DIP Switches

--------------------------------------------------------------

page 27

Setting Closed Position Limits

--------------------------------------------------------

page 28

-------------------------------------

----------------------------------------

----------------------------------------------------------

Setting Open Position Limits

----------------------------------------------------------

page 33

--------------------------------------

--------------------------------------------------

Accessory Catalog

----------------------------------------------------------------

Table of Contents

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE

Page 4

Mighty Mule® E-Z Gate® Opener

—GTO's "do-it-yourself" automatic gate opener!

When correctly installed and properly used, your

Mighty Mule® E-Z Gate® Opener

will give you many years

Mighty Mule® E-Z Gate® Opener

Mighty Mule® E-Z Gate® Opener

pull-to-open dual leaf gate

the property). By purchasing an

Mighty Mule® E-Z Gate® Opener

from the property). The gate must not exceed 18 feet in length and

on page 10). The

Mighty Mule® E-Z Gate® Opener

can be used on vinyl, aluminum, chain

high resistance to the wind. If the wind is strong enough, the opener will obstruct and stop.

Mighty Mule® E-Z Gate® Opener

accommodates extra transmitters, digital keypads, solar panels, push buttons,

Mighty Mule®

Accessory Catalog

Mighty Mule® E-Z Gate® Opener

features

adjustable obstruction sensing.

MIN

is the factory setting;

Mighty Mule® E-Z Gate® Opener

also has an

adjustable auto-close feature

button at any time after the gate opens fully will cause it to close immediately.

Swing gates longer than 18 feet or weighing more than 850 pounds;

Slide gates;

Heavy duty or commercial uses;

Professional installation;

please call GTO at

(850) 575-0176

for information about our

professional

dealer near you.

E-Z GATE OPENERS

®

®

carefully and completely

to become familiar with all parts and installation steps. The video tape is only designed as

Page 5

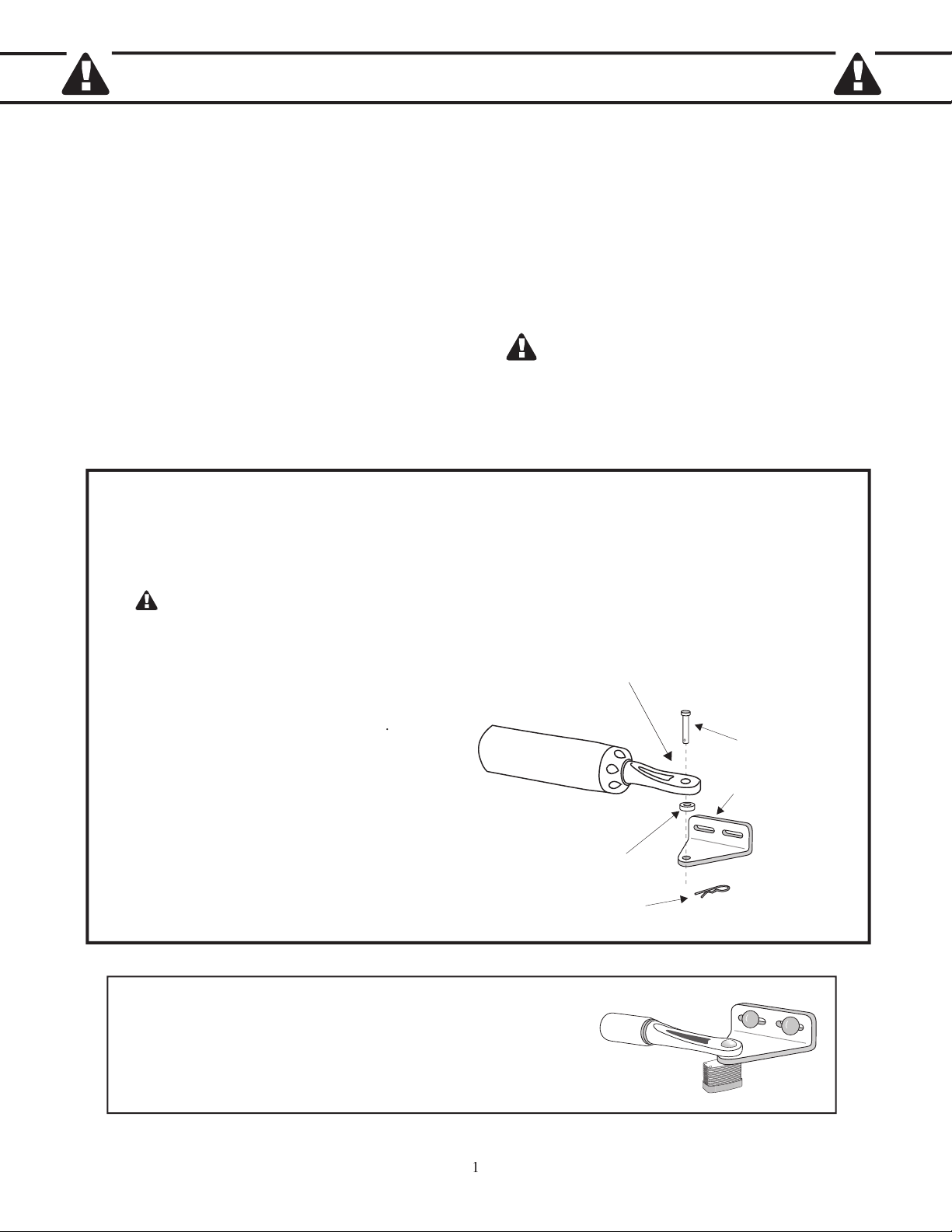

Keep in mind that the gate opener is just

one component of the total gate operating system

that can result in damage to the opener or its components, serious

only

part

of the total gate operating system, it is the responsibility of the

Substitute a

Pin Lock

for the clevis pin on the front

the opener from the gate (

Clevis Pin

Hairpin Clip

Gate Bracket

Front or Rear Mount

Bushing

Page 6

1.

Failure to meet the requirements set forth in the instruction

2. When designing a system that will be entered from a highway or main thoroughfare, make sure the system is placed

3. The gate must be installed in a location that provides adequate clearance between it and adjacent structures when

open into public access areas.

4. The gate and gate opener installation

1. Verify this dual opener is proper for the type and size of gate, its frequency of use and the proper class rating.

2. Make sure the dual gate has been properly installed and swings freely in both directions. Repair or replace all worn

3. Review the operation of the system to become familiar with its safety features. Understand how to disconnect the

4. This gate opener is intended for

use (

5. Always keep people and objects away from the gate and its area of travel.

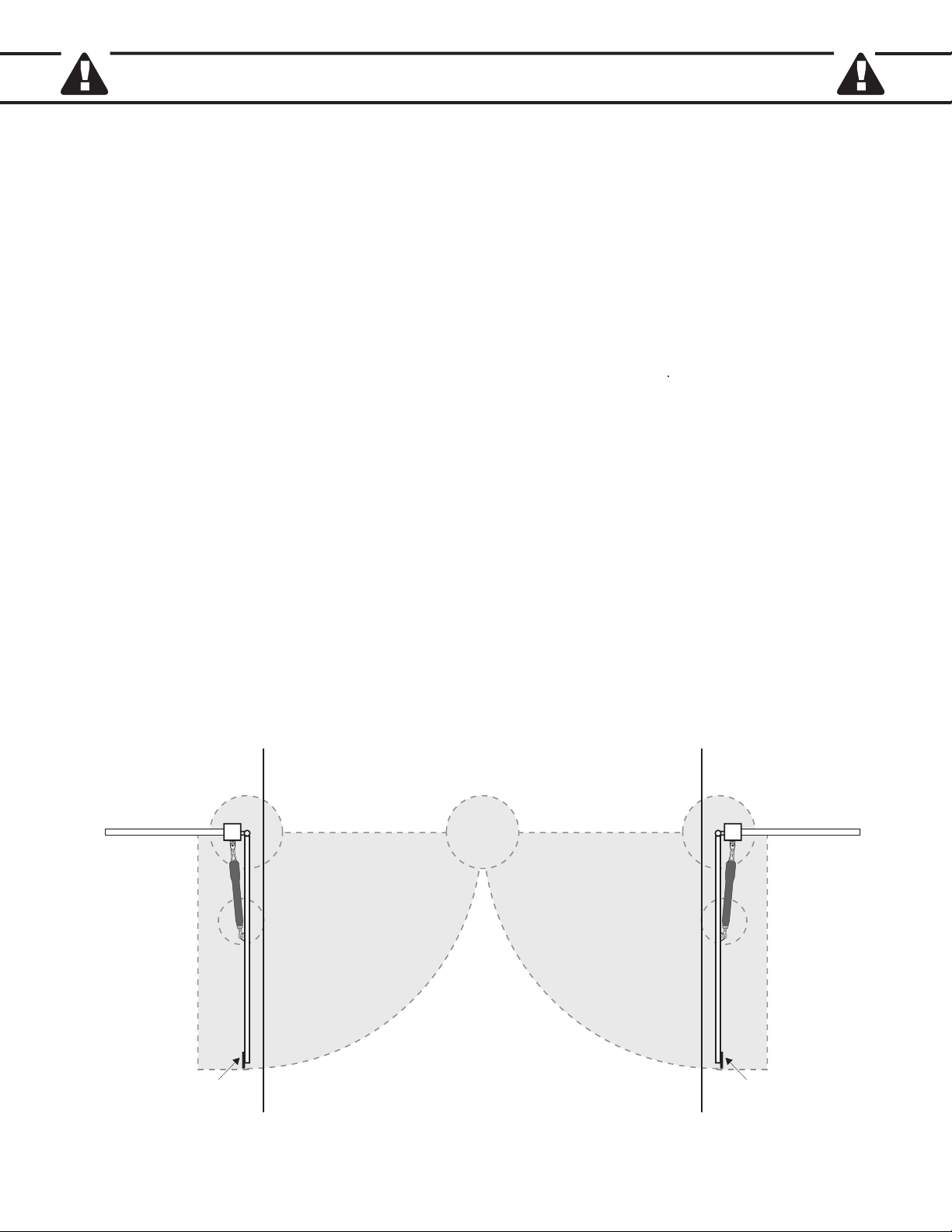

6. Pay close attention to the diagram below and be aware of these areas at all times.

Gate in the

Open Position

Gate in the

Open Position

ZONE 2

ZONE 3

ZONE

4

ZONE

5

Driveway

ZONE 1

ZONE 2

ZONE 4

ZONE 5

ZONE 3

Page 7

Entrapment Zones for a proper Pull-To-Open installation:

Zone 1 – leading edge of the gate and the fence post.

Zone 2 – between the gate and the gate post.

Zone 3 – the path of the gate.

Zone 4 – the space between the gate in the open position and any object such as a wall, fence, tree, etc.

Zone 5 – pinch points between the opener and gate or post.

1. Install the gate opener on the inside of the property and fence line.

DO NOT

install an opener on the outside of the

2. Be careful with moving parts and avoid close proximity to areas where fi ngers or hands could be pinched.

3. Devices such as contact sensors (safety edges) and non contact sensors (photo beams) provide additional protection

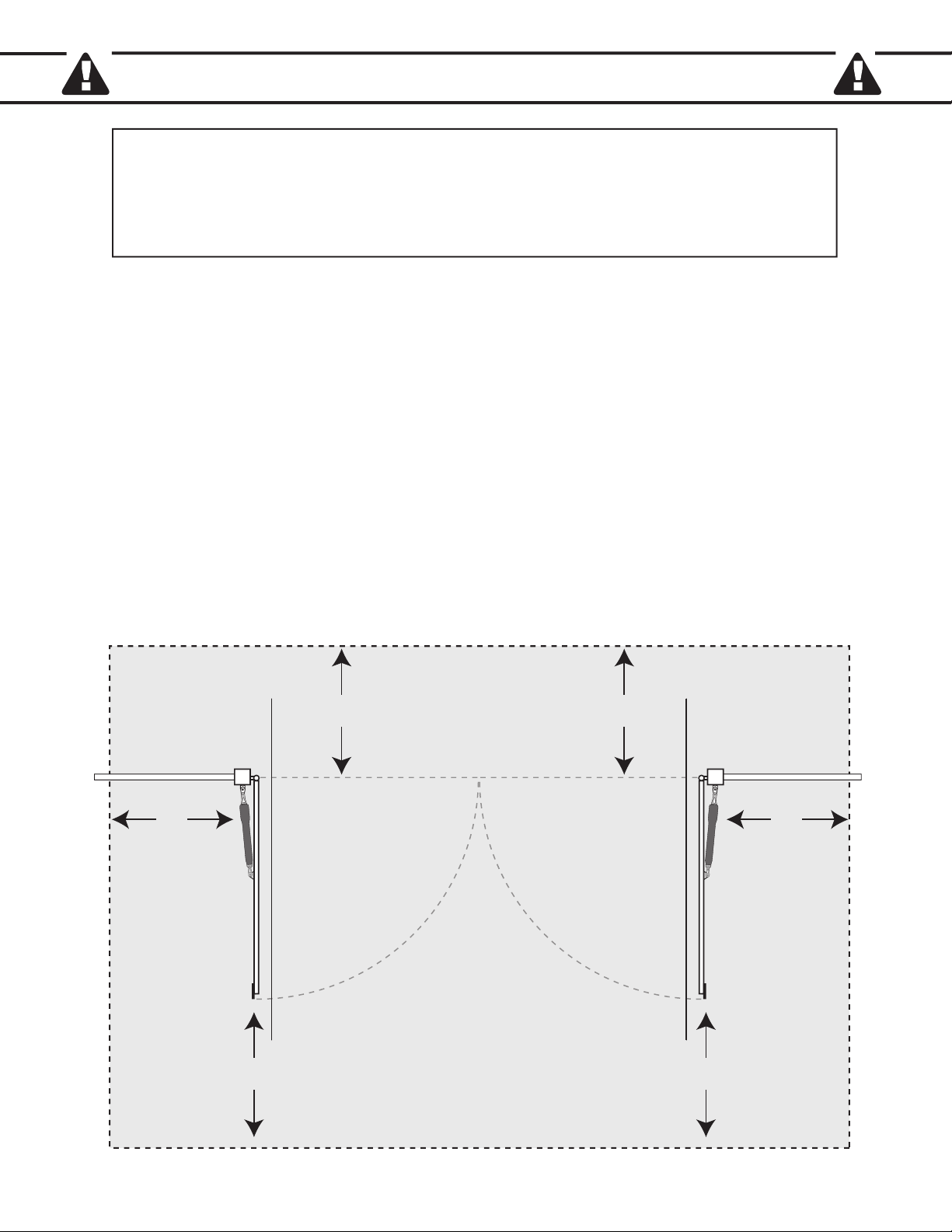

4. If push buttons or key switches are installed, they should be within sight of the gate, yet located at least 10 feet from

Never install any control device where a user will be tempted to

reach through the gate to activate the gate opener.

5. Do not activate your gate opener unless you can see it and can determine that its area of travel is clear of people,

pets, or other obstructions. Watch the gate through its entire movement.

6. Secure outdoor or easily accessed gate opener controls in order to prohibit unauthorized use of the gate.

Moving Gate

Area

Moving Gate

Area

Driveway

10'10'

10'10'

10'10'

NEVER INSTALL

any control device

within gray area

Page 8

1. Attach the

(

your responsibility

to post warning signs on both sides of your gate. If any of these signs or warning decals become

2. The gate is automatic and could move at any time, posing a serious risk of entrapment. No one should be in contact

3. Do not attempt to drive into the gate area while the gate is moving; wait until the gate comes to a complete stop.

4. Do not attempt to "beat the gate" while the gate is closing. This is extremely dangerous.

5. Do not allow children or pets near your gate.

Never let children operate or play with gate controls

remote controls away from children and unauthorized users; store controls where children and unauthorized users do

6.

7. Service the gate and gate opener regularly. Grease hinges, and replace the battery every 3-5 years.

8. To operate this equipment safely, YOU must know how to disconnect the opener for manual gate operation

(

9. Disconnect the opener

when the power is

and the gate is

moving.

10. Make arrangements with local fi re and law enforcement for emergency access.

11. Distribute and discuss copies of the

section of this manual with all

persons authorized to use your gate.

12.

Should you lose or misplace this manual, a copy can be obtained by

Page 9

Secondary Means of Protection Against

As specifi ed by Gate Operator Safety Standard, UL 325 (30A.1.1), automatic gate openers shall have an inherent entrapment

provisions for

primary

type of entrapment protection. Also, the Mighty Mule® has

provisions for

the connection of

protection to be used

secondary

type of entrapment protection, if desired.

A. One or more contact sensors shall be located at the leading edge, bottom edge, and post edge, both inside and

outside of a vehicular swing gate system.

B. A hard wired contact sensor shall be located and its wiring arranged so that the communication between the

sensor and the gate opener is not subjected to mechanical damage.

C. A wireless contact sensor such as one that transmits radio frequency (RF) signals to the gate opener for entrapment

protection functions shall be located where the transmission of the signals are not obstructed or impeded by building

structures, natural landscaping or similar obstruction. A wireless contact sensor shall function under the intended

end-use conditions.

twice

while opening or closing. This alarm will sound for a period of

keypads will not deactivate the alarm.

Bottom Edge Contact Sensor

on both sides of the gate

Leading Edge Contact Sensor

on both sides of the gate

Post Edge Contact Sensor

on both sides of the gate

Post Edge Contact Sensor

on both sides of the gate

Vehicular GateVehicular Gate

500

UL325 SERIES

®

E-Z GATE OPENER

1-800-543-GATE (4283)

www.mightymule.com

Page 10

may not be sensitive enough

to prevent bodily injury

in

some circumstances

reverse gate direction upon sensing an obstruction, are suggested for enhanced protection against entrapment.

Warning Signs

be installed on both sides of the

alert people of automatic gate operation and are

when installing the Mighty Mule® E-Z Gate®

recommend using the

(

1. KEEP CLEAR! Gate may move at any time.

2. Do not allow children to operate gate or

play in gate area.

3. This gate is for vehicles only. Pedestrians

must use a separate entrance.

Moving Gate Can Cause

Injury Or Death

WARNING

!

Warning SignWarning Sign

Contact Sensor

(

recommended, not included

)

Contact Sensor

(

recommended, not included

)

Pedestrian Gate

Bulldog

Pedestrian

Gate L

ock

(recommended, not included

)

Vehicular GateVehicular Gate

Contact Sensor

(

recommended, not included

)

Contact Sensor

(

recommended, not included

)

Page 11

!

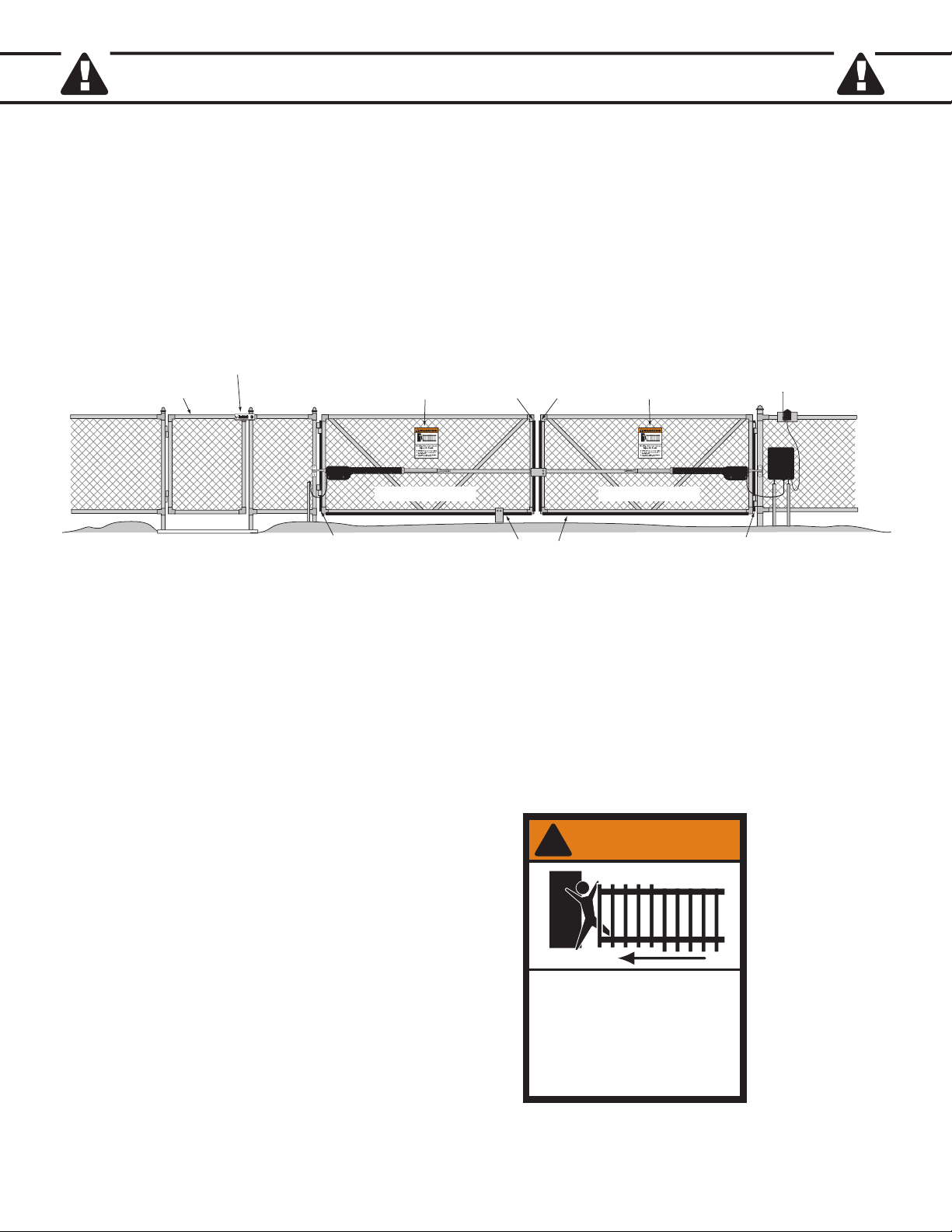

Warning signs (2 enclosed) to be installed on each side

of the gate (3—5 feet above the bottom of the gate)

Maximum Gate: 500 lb. (226.7 kg); 16 ft. (4.8 m)

Voltage: 12 Vdc; Frequency: 0 Hz; Power: 25

W

Class I, II, III and IV Vehicular Swing Gate Operator.

Serial Number: XXXXXXXXXX

#xxxxxxx

Conforms to UL 325 STANDARDS

TO MANUALLY OPEN AND CLOSE THE GATE:

1. Turn control box power switch OFF.

2. Disconnect front or rear mount from gate bracket

.

3. Pull opener away from front or rear mount.

DC SWING SERIES / 500

GTO, Inc. Tallahassee, Florida USA

Disconnect operator ONLY when the control box power

switch is OFF and the gate is NOT moving.

L

I

S

T

E

D

US

50

2

UL325 SERIES

®

®

E-Z GATE OPENER

Product identification and manual operation instruction

label (1) installed on control box cover

Logo and warning labels (2) installed on each side of

opener housing

C

Page 12

®

E-Z GATE OPENER

1. KEEP CLEAR

! Ga

t

e

may move at any

t

ime.

2. Do n

ot allow children

to operate gate

or play in gate ar

ea.

3. This gat

e is for vehicles on

ly. Pedestrians must

use separat

e entrance.

WARNING

!

MOVING GATE

Can Cause In

jury or Death

UL325 SERIES

502

®

E-Z GATE OPENER

1-800-543-GATE

(4283) • www.mightymule.com

1. KEEP CLEAR!

Gate may move at

any time.

2. Do n

ot allow children to o

perate gate or play i

n

gate

area.

3. This gate

is

for v

ehicles only

. Pedestrians mus

t

use s

eparate entrance.

WARNING

!

MOVING GATE

Can Cause Injur

y or Death

UL325 SERIES

502

®

E-Z GATE OP

ENER

1-800-5

43-GATE (4283) •

www

.mightymul

e.com

Page 13

///

/

/

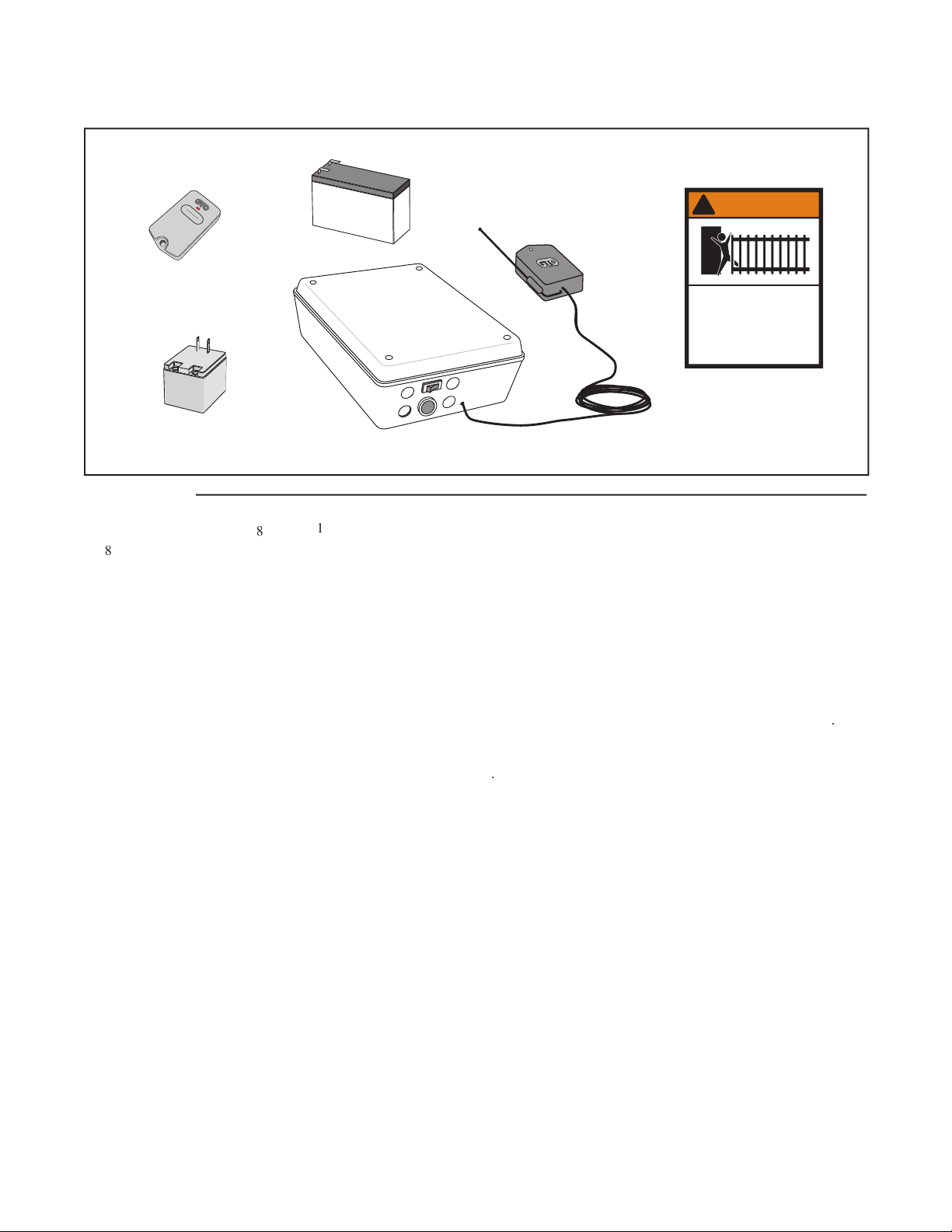

Transformer (1)

Battery (1)

Control Box (1)

Wa

rning Signs (4)

GT

O Transmitter(1)

1. KEEP CLEAR! Gate may move at any time.

2. Do not allow children to operate gate or

play in gate area.

3. This gate is for vehicles only. Pedestrians

must use a separate entrance.

Moving Gate Can Cause

Injury Or Death

WARNING

!

Receiver (1)

Accessory Catalog

page 39):

the transformer power supply and the control box. See

on page 21, and the

Accessory Catalog

power to trickle charge the battery. See the

Accessory Catalog

to mount the front of the

Page 14

DRIVE

NOTE: The transformer should not be

directly

with higher ampere rated fuses; doing so will void your warranty and may damage your control board.

/

/

GTO

microprocessor-based control board is set for single leaf, pull-to-open gate installations. DIP switches can be

/

4

tion of gate and installation.

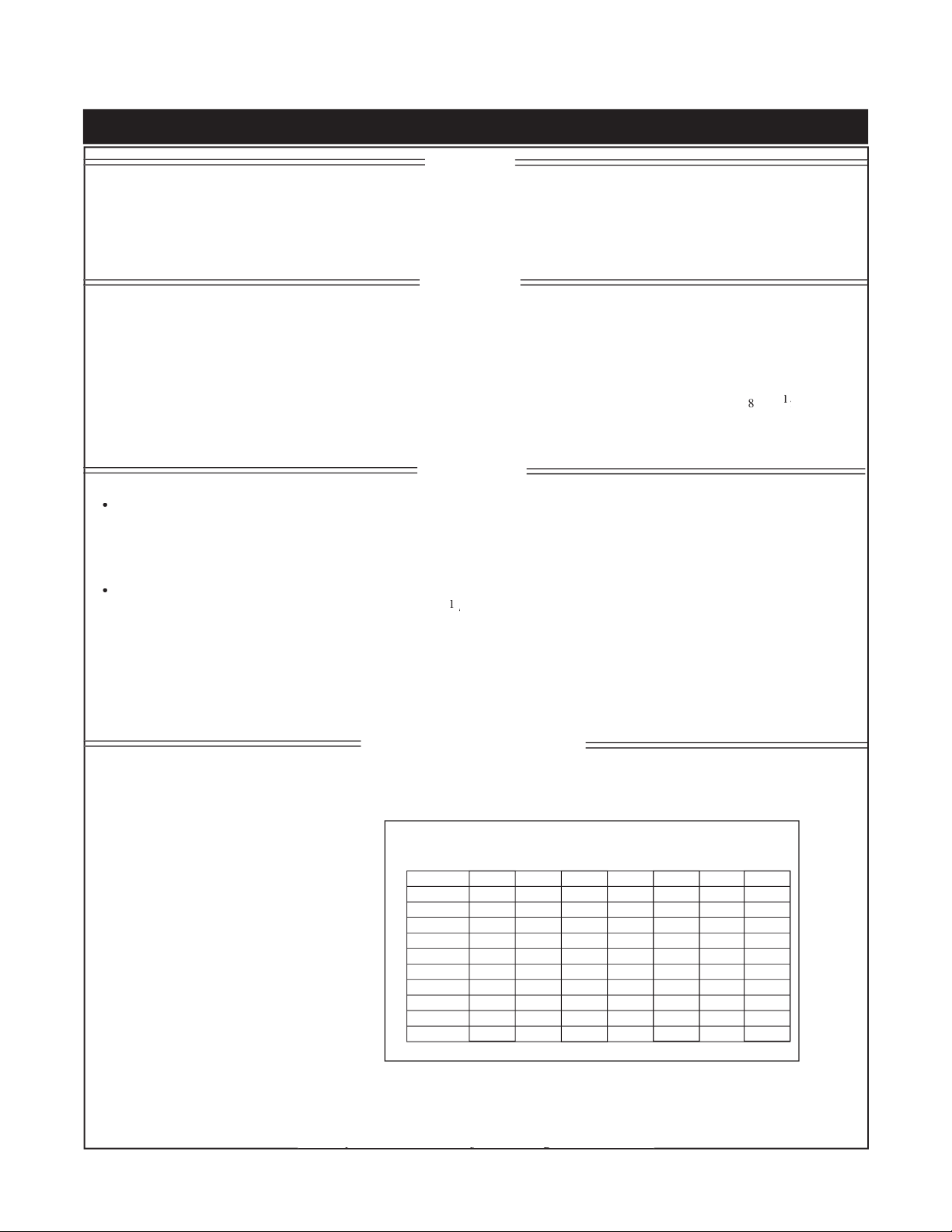

MIGHTY MULE® 502 E-Z GATE® OPENER

"NR" indicates this

Mighty Mule 502.

page 19

or call

(800) 543-1236

or

for more information.

Gate Weight

Gate Length

Number of Cycles Per Day

Mighty Mule 502 Gate Capacity /Cycle Chart

Estimated number of daily cycles, based on use with a transformer and one(1) 12 Volt battery.

850 lbs.

750 lbs.

650 lbs.

550 lbs.

450 lbs.

350 lbs.

250 lbs.

150 lbs.

100 lbs.

50 lbs.

68

73

78

83

88

93

98

103

108

113

5’ - 6’

63

68

73

78

83

88

93

98

103

108

8’

63

68

73

78

83

88

93

98

103

10’

63

68

73

78

83

88

93

98

12’

63

68

73

78

83

88

93

14’

63

68

73

78

83

88

16’

NR

NR

NR

NR

NR

63

68

73

78

83

18’

NR

NR

NR

NR

NR

NR

NR

NR

NR

NR

NR = NOT RECOMMENDED

Page 15

be plumb, level, and swing freely on

their hinges. Wheels must not be attached to the gates.

Note that gates

fi ttings.

of the gates to keep the gates

(if they are not already in

place) to provide a stable area for mounting the gate

brackets is also important.

if you intend

to mount the openers on columns. Furthermore, if you have push-to-open gates, you will need to purchase two (2)

(see

Accessory Catalog

before proceeding.

Horizontal Cross Member

Vertical Cross Member

Gate Swings Evenly and Freely

Hung Firmly and Plumb

Receiver

PVC conduit (not included)

to protect second opener

power cable and low voltage wire

from lawn mowers and weed eaters.

Post Bracket Assembly

Control Box with Battery

Gate Bracket

First Gate Opener

Concrete Poured

Around Gate Post

Run 1000' (max.) of low

voltage wire to control

box from transformer

(wire not included).

4 1/2' Power Cable

Closed Position Positive Stop Plates

120 Volt Indoor

Transformer

(surge protector

not supplied)

Second Gate Opener

5

0

0

U

L

3

2

5

S

E

R

I

E

S

®

E

-Z

G

A

T

E

O

P

E

N

E

R

L

I

S

T

E

D

U

S

5

0

0

U

L

3

2

5

S

E

R

I

E

S

®

E

-

Z

G

A

T

E

O

P

E

N

E

R

L

I

S

T

E

D

U

S

500

UL325 SERIES

®

E-Z GATE OPENER

1-800-543-GATE (4283)

www.mightymule.com

Page 16

not supplied

post to prevent the thrust of the opener from

pulling the bolts and washers out of the wood.

brackets are mounted by themselves.

Post

Bracket

Post

Pivot Bracket

Metal Plate

Wooden Post

Post

Bracket

Post

Pivot Bracket

Metal Plate

Wooden Post

Center of Gate Hinge

Pull-to-Open Installation

Larger than 6" diameter post

Thin Walled Tube Gate

Steel Pipe Cut in Half

Gate Bracket

Gate Bracket

Wood or Metal

Reinforcement

Gate Bracket

Panel Gate

1" x 6" Wood Reinforcement

(not supplied)

(not supplied)

We

using steel pipe, wood or metal to reinforce thin walled tube gates or wood to reinforce panel gates

Page 17

Level Opener

Fence Post

Gate In Open Position

LEVEL horizontal cross member

Post Bracket Assembly

Gate Bracket

Clevis Pin

Hairpin Clip

Post Bracket Assembly

Rear Mount

Opener

Bushing

Clevis Pin

Hairpin Clip

Bushing

Gate Bracket

Front Mount

With the gate in the open position (up to 110º from its closed position) and the gate opener fully retracted, adjust the post

bracket assembly and gate bracket until the opener is level. While holding the opener level, use C-clamps to

temporarily

keep the post bracket assembly and gate bracket in their respective positions on the fence post and gate.

/

the center hole of the post

brackets and post pivot bracket

/

/

/

the nut because the

post pivot bracket will have to be

hairpin clips.

3/8" x 2" Bolt

3/8" Nut

Post Pivot Bracket

Post Bracket

Post Bracket

3/8" Lock Washer

Post Bracket Assembly

3/8" Washer

gate

your

push-to-

(

two

Accessory

beginning on

page 32.

Page 18

Gate in the

CLOSED POSITION

Pinch Area

Gate in the

OPENED POSITION

Pinch Area

2" minimum

2" minimum

Be sure gate opener

and bracket don't bind.

When you feel that you have the best position for the post pivot bracket in the open position, insert the 5/16" x 1-3/4" bolt

through the aligned holes of the post bracket and post pivot bracket to hold it in place. Remove the clevis pin from the front

With the post pivot bracket in the optimum position for clearance and freedom of movement, reattach the opener to the gate

bracket in the open position and recheck the gate opener level and make sure the brackets are clamped securely.

While determining the mounting point for the post pivot bracket assembly, be sure that the position allows

Page 19

Mark reference points for bolt holes on the fence post through middle of bracket slots. Marking reference points in this

reference points, remove the

/

Fasten post bracket assembly to

the fence post using

/

provided

bolt length extending beyond

the tightened nuts with a

hacksaw or bolt cutters.

In cases where the

than 6",

not supplied

Mark reference points for bolt holes on

the gate cross member through middle of

/

the gate cross member as marked.

Mount gate bracket using (2)

/

provided

Gate In Open Position

LEVEL horizontal cross member

Mark cross member through middle of

gate bracket slots and drill 3/8" holes

Post Bracket

Assembly

Mark fence post through

middle of bracket slots

and drill 3/8" holes

Round Metal Post

Round Wood Post

Square Metal Pos

t

Square Wood Pos

t

Remove excess bolt length

with hacksaw or bolt cutters

SIDE VIEW

TOP VIEW

EXAMPLES

Round Tube & Chain Link Gate

Square Tube Gate

Mounting Plate

Created for

Decorative Gate

(required but not

supplied)

Remove excess bolt length

with hacksaw or bolt cutters

FRONT VIEW

SIDE VIE

W

FRONT VIEW

SIDE VIEW

Page 20

Mounting the First Opener

Accessory Catalog

Level Opener

Gate In Open Position

LEVEL horizontal cross member

Post Bracket Assembly

bolted to fence post

Clevis Pin, Bushing, and Hairpin Clip

Clevis Pin, Bushing, and Hairpin Clip

Gate Bracket bolted

to gate cross member

Fence Post

through

Page 21

Closed Position

Stop Plates

Gate Hinge

CONTROL BOX

Gate Hinge

The gate leaf can open

up to 110˚ (max.)

Optional Ground Stop

(beneath gate)

The gate leaf can open

up to 110˚ (max.)

MASTER GATE SLAVE GATE

Mighty Mule® Automatic Gate Lock

Accessory Catalog

MASTER

gate and

box will be referred to as the

gate and

Closed Position Stop Plate mounted

horizontally on metal post with U-bolts.

SLAVE Gate Frame

MASTER Gate Frame

TOP VIEW

FRONT VIEW

MASTER gate leaf.

Illustration A

tube or chain link; screw or bolts for wood or metal)

closed position stop plate

(

Do not

tighten

Illustration

position, tighten its hardware completely.

Illustration B

Page 22

At this stage of the installation, the openers should be installed on the

Post Bracket Assembly

Gate Bracket

MASTER Gate Opener

Closed Position

Positive Stop Plates

SLAVE Gate Opener

OPTIONAL Closed Position

Ground Stop Post

Using appropriate hardware for your type of gate attach the

closed position stop plate

to the SLAVE gate frame

Do not

tighten it completely at this time. You must slide the closed position stop plate toward the

ground stop

until

they touch (

Illustration C

For a push-to-open installation (gate opens

from the property) attach the closed position stop plate to the

not

provided

Illustration A

and may be made of metal

recommend setting it in concrete).

Closed Position Stop Plate mounted

on the gate leaf that CLOSES FIRST

Closed Position Stop Plate

Low Profile Ground Stop

in Near the Center of Driveway

FRONT VIEW

SIDE VIEW

Mount Vertically

Page 23

Make sure the control box power switch is in the

position. The ON/OFF Switch is located on the bottom of

the control box. Remove the control box cover and slide

the battery into position with its terminals to the

battery wire to the

(

battery

(

Pay close attention to

Mounting the Control Box

/16" of insulation from each

tightly (there are seven [7] wires inside the power cable

bottom of control box. Insert power cable into control

box through strain relief. Thread approximately 6"

Mount the control box using the screws (

provided

to protect it from rain splash,

RED wire to POSITIVE (+) terminal

BLACK wire to NEGATIVE (–) terminal

RED

BLACK

Operator Power Cable

Strain Relief

Battery wires

for optional

second battery

12 Volt Battery

(included)

Space for optional

second 12 Volt Battery

(see Accessory Catalog)

Sealing Nut

Hub

Lock Nut

Strain Relief

Use mounting

holes and screws

provided to mount

control box to a

secure surface.

The battery that came with your Mighty

Mule®,

MUST

be placed in the top (horizontal)

battery slot with the terminals on the

battery. An optional second battery can be used for

Page 24

Power Cable from the

Master Operatorr Arm

RECEIVER

SWITCH

MASTER INPUTS

GRN WHT BLUE BRN ORG RED BLK COM COM

CYCLE

CLOSE

SAFETY

EXIT/

OPEN

SHADOW

LOOP

CLOSE

EDGE

OPEN

EDGE

BLKGRN RED

STALL FORCE

M

I

N

M

A

X

terminals on the

MASTER

terminal, the

blue wire into

terminal.

Correct

Wrong Wrong

Wire

Terminal

Block

Terminal

Block

Terminal

Block

Wire Wire

MASTER Operator

/16" of insulation from each wire

tightly. Insert the second opener power cable upward

through the

(if necessary, loosen the

black sheath

place.

block. The green wire should be inserted into the

terminal, the blue wire into

terminal.

illustration on

page 11

before proceeding.

not provided

SLAVE Operator

SWITCH

RELAY OUT SLAVE INPUTS

GRN WHT BLUE BRN ORG RED BLKNC RLY-COM NO

MASTER INPUTS

GRN WHT BLUE BRN ORG RED BLK COM COM

Power Cable from the

Slave Operator Ar

m

Page 25

• The transformer is designed and intended for

use. If the transformer can be plugged only into

be used.

• All low voltage wire used with the Mighty Mule

Gate Opener must be 16 gauge dual conductor,

multi-stranded, direct burial wire (

and the

Accessory Catalog

Do not run more than

• If your gate is more than 1000 ft. from an ac power source, you will need to use at least one 5 watt

Accessory Catalog

Activity

Make sure the power switch is

before proceeding to the next step.

Measure the distance from this outlet to the control box following the

path where the wire will be laid. After you have measured how much

ON/OFF Switch

the maximum number of

using from 10 to 30 watts of

Accessory Catalog

the use of any accessory items.

Accessories

power from the battery.

Mighty Mule® Gate Opener. Consult

Panel

Installation Instructions for further

Winter Ratings Zone 1 Zone 2 Zone 3

Page 26

Lay the measured length of low voltage wire in a trench following a path from

the selected electrical outlet to the control box. Wires coming up from the

blades, weed eaters, and grazing animals. Be sure to bury the wire laid in the

trench.

Feed the low voltage wires upward through the strain relief opening on the

tighten the strain relief screw to secure the wires.

use telephone wire or solid core wire. Unlike multi-stranded wire, these types of wire are

/

terminals located on the

terminal block

terminal.

terminal. The transformer wires can be

18VAC

terminals regardless of color.

help prevent corrosion.

RED

BLACK

RED

BLACK

Low Voltage Wire

from AC Transformer

18VAC

SWITCH

SOLAR RELAY OUT SLAVE INPUTS

GRN WHT BLUE BRN ORG RED BLKNC RLY-COM NO

MASTER INPUTS

GRN WHT BLUE BRN ORG RED BLK

+–~~

Low Voltage Wire

from Transformer

Power Cable from

Opener Arm

PVC Pipe

BE PLUGGED INTO

AN OUTLET

DURING STEP 7

Page 27

recommended.)

Keep a few mothballs in the control box to

/

terminals.

A dab of household petroleum jelly on each terminal will

help prevent corrosion.

Make sure the exposed wires do not touch each other!

SURGE PROTECTOR

Transformer

Page 28

1ON2 3 4 5 6 7

ON

OFF

1 2 3 4 5 6 7

DIP#6 DIP#7 Delay Time for Auto-Close

ON ON 15 seconds

ON OFF 30 seconds

OFF ON 60 seconds

OFF* OFF* 120 seconds (factory preset)

DIP#5

ON

D1 mode, constant pressure to operate gate.

OFF*

B2 mode, momentary contact to operate gate.

DIP#4

ON Push-to-open operation.

OFF* Pull-to-open operation.

DIP#3

ON Auto-close enabled.

OFF* Auto-close disabled.

DIP#2

ON* Buzzer warning enabled.

OFF Buzzer warning disabled

DIP#1

ON* Soft start enabled.

OFF Soft start disabled.

* Factory preset.

DIP Switch #1 - Soft Start/Stop

The Soft Start/Stop feature slowly starts the gate as

the closed position. This saves wear and tear on the

DIP Switch #2 - Warning Buzzer

The Warning Buzzer alerts you when the gate

two times in one cycle. Switching this to OFF

DIP Switch #3 - Auto-Close

With the Auto-Close switch in the OFF position

the gate will remain open until it receives another

transmitter, keypad, or push button control. With

the Auto-Close switch in the ON position the gate

remain open is determined using DIP Switches #6

DIP Switch #4 - Push/Pull-to-Open

If your gate opens into the property the DIP Switch

the property the DIP Switch must be set to the ON

position. NOTE: if you have a Push-to-Open gate

DIP Switch #5 - B2/D1 Mode

This DIP Switch must remain in the OFF position

unless the gate opener is going to be used by a

DIP Switches #6 and #7

The combination of these two switches determines

the amount of time the gate will remain open when

Leave DIP Switch #3 in the OFF position untill installation is complete, to prevent gate from

IMPORTANT CONTROL BOARD SETTINGS:

CONTROL BOARD DIP SWITCH #1 is factory

preset in the ON position and MUST remain in the

ON position. Changing this setting can damage

your gate, gate opener and

possibly void your warranty!

Page 29

1

ON

2 3 4

DUAL

MODES

ON

OFF

1 2 3 4

1

ON

2 3

4

DUAL

MODES

ON

OFF

1 2 3 4

1

ON

2 3 4

DUAL

MODES

ON

OFF

1 2 3 4

1

ON

2 3 4

DUAL

MODES

ON

OFF

1 2 3 4

1

ON

2 3

4

DUAL

MODES

ON

OFF

1 2 3 4

1

ON

2 3 4

DUAL

MODE

S

ON

OFF

1 2 3 4

ON

6 7

SET

LIMIT

ON

OF

F

1 2 3 4 5 6 7

Set Limit Button

Dual Mode DIP Switches

Factory setting.

Single Arm (Master

Only) operation.

MASTER gate starts to open 2 seconds

before SLAVE gate / SLAVE gate starts to

close 4 seconds before MASTER gate.

MASTER gate starts to open 2 seconds

before SLAVE gate / SLAVE gate starts to

close 8 seconds before MASTER gate.

MASTER and SLAVE gates open

simultaneously / SLAVE gate starts to close 4

seconds before MASTER gate.

MASTER and SLAVE gates open

simultaneously / SLAVE gate starts to close 8

seconds before MASTER gate.

1

ON

2 3 4

DUAL

MODES

ON

OFF

1 2 3 4

1ON2 3 4

DUAL

MODES

ON

OFF

1 2 3 4

#1 OFF & #2 OFF

#1 ON , #2 OFF

and #3 OFF

#1 ON, #2 OFF

and #3 ON

#1 OFF, #2 ON

and #3 ON

#1 OFF, #2 ON

and #3 OFF

*

REQUIRED SETTING for use with an Automatic Gate Lock accessory.

*

#4 OFF to set or CLEAR

MASTER Position Limit

#4 ON to set or CLEAR

SLAVE Position Limit

DIP Switches #1 and #2 (Factory Set OFF/OFF)

DIP Switch #3 - Additional Delay (Factory Set OFF)

DIP Switch #4 - Used to set MASTER and SLAVE gate closed

#4 ON =

#4 OFF =

Page 30

Setting the Closed Position Limits

(Gate in the OPEN POSITION / FACTORY SET NOT ADJUSTABLE) The open limit setting is

the fully open position.

(Gate in the CLOSED POSITION) To achieve optimum closed position, you are required

to complete the following SEVEN STEPS:

positions toward their closing position. Prepare to STOP gate that reaches the desired closed position fi rst by pressing the

position has been achieved, proceed to step 3.

With the gate that closed fi rst in the desired closed position, program the closed limit setting by setting the number 4 DIP

positions toward their closing position. The fi rst gate will stop at the spot you just programmed and the second gate will

With the second gate in the desired closed position. Program the

then PRESS & HOLD the “SET LIMIT" button on the control

board for 5 seconds.

1

ON

2 3 4

DUAL

MODES

ON

OFF

1 2 3 4

ON

6 7

SET

LIMIT

ON

OFF

1 2 3 4 5 6 7

Set Limit Button

Dual Mode DIP Switches

Page 31

1

2

3 4 5

6 7 8

9

EC

E

A23S 12V

ALKALINE BA

TTER

Y

+

0

–

LE

D

Setting Your Personal Transmitter Code

All GTO transmitters are set to a standard code at the factory and are ready to operate your Mighty Mule® Gate Opener

For your safety and security, however, we

strongly recommend

that you replace the factory setting with your own personal

positions, then press and hold the "SET LIMIT" button for 10 seconds. This will clear the memory for the closed limit

positions. Follow Steps 1-7 again.

LEARN TRANSMITTER

button on

the control board for 5 seconds.

button.

is stored in control board memory.

1

ON

2 3 4 5 6 7

1

ON

2 3 4

RECEIVER

DUAL

MODES

SET

LIMIT

LEARN

TRANSMIT

TER

MODES

ON

OFF

ON

OFF

1 2 3 4 5 6 7

1 2 3

4

COM

CYCLE

CLOSE

SAFETY

EXIT/

OPEN

SHADOW

LOOP

CLOSE

EDGE

OPEN

EDGE

BLKGRN RED

Learn Transmitter Button

STALL FORCE

M

I

N

M

A

X

positions (

0

DO NOT

set all the switches in the same position, such as all

the two screws on the sides of the visor clip and separate the front cover from the

transmitter. With the front cover removed, the battery and the DIP switches will

be exposed. To set a new code, use a small screwdriver to move the switches.

+

0

ECE

1 2 3 4 5 6 7 8 9

Page 32

before permanently mounting it

external interference.

FCC Regulation

NOTE:

unauthorized modifi cations to this equipment. Such modifi cations could void the

user’s authority to operate the equipment.

ALWAYS KEEP

AT THE TOP OF YOUR LIST WHEN ADJUSTING OR

STALL FORCE

M

I

N

M

A

X

For safety reasons the obstruction setting or

on

(mini-

potentiometer on the control board operates like a volume

row in the center of the potentiometer. Adjust

Page 33

properly,

may not be sensitive enough

to prevent bodily injury in some circumstances

recommends

using some form of additional safety device.

When installed, contact sensors must be

Refer to the sensor manufacturer’s instructions for information about installing these devices on a vehicular gate.

Contact sensors are not

included with

the Mighty Mule® 502.

to the

terminal and the other to

the

terminal on the Mighty Mule® 502

to the

terminal and the other to the

terminal on the Mighty Mule® 502

Activation of a contact sensor while the gate is in motion

Although GTO strongly recommends the use of additional safety devices, we do not endorse any

Wire from Contact Sensor

(open safety edge)

Wire from Contact Sensor

(close safety edge)

RECEIVER

COM COM

CYCLE

CLOSE

SAFETY

EXIT/

OPEN

SHADOW

LOOP

CLOSE

EDGE

OPEN

EDGE

BLKGRN RED

STALL FORCE

M

I

N

M

A

X

Page 34

Refer to the sensor manufacturer’s instructions for information

about installing these devices on a vehicular gate.

the

terminal and the other to the

terminal on the Mighty Mule® 502 control board.

Non-contact sensors are not

included with

the Mighty Mule® 502.

Wire from Non-Contact

Sensor (photo beam)

RECEIVER

COM COM

CYCLE

CLOSE

SAFETY

EXIT/

OPEN

SHADOW

LOOP

CLOSE

EDGE

OPEN

EDGE

BLKGRN RED

STALL FORCE

M

I

N

M

A

X

Shadow Loop

Wire from Shadow Loop

RECEIVER

COM COM

CYCLE

CLOSE

SAFETY

EXIT/

OPEN

SHADOW

LOOP

CLOSE

EDGE

OPEN

EDGE

BLKGRN RED

STALL FORCE

M

I

N

M

A

X

Refer to the sensor manufacturer’s instructions for information

about installing these devices on a vehicular gate.

terminal and the other to the

terminal on the

Mighty Mule® 502 control board.

is a detector located with the moving path

the path.

Non-contact sensors are not

included with

the Mighty Mule® 502.

Page 35

Refer to the sensor manufacturer’s instructions for information about installing these devices on a vehicular gate.

Accessory Input Connection:

terminal and the other to the

terminal on the

Mighty Mule® 502 control board.

OPEN STOP CLOSE STOP

Wire from Accessory

(push button, key pad, etc.)

RECEIVER

COM COM

CYCLE

CLOSE

SAFETY

EXIT/

OPEN

SHADOW

LOOP

CLOSE

EDGE

OPEN

EDGE

BLKGRN RED

STALL FORCE

M

I

N

M

A

X

Page 36

Gate in the Closed Position

Pinch Area (gray)

Gate in the Open Position

Pinch Area (gray)

2" minimum

2" minimum

With the gates

bracket until the opener is level. While holding the opener level, use

bracket in their respective positions on the fence post and gate.

from the property.

A Push-to-Open Bracket is required for this type of installation

(

Accessory Catalog

the

property), return to page 13; step 3.

position.

3/8" x 2" Bolt

3/8" Nut

Push-To-Open Bracket

(optional accessory)

Post Bracket

Post Bracket

3/8" Lock Washer

Post Bracket Assembly

3/8" Washer

/

/

4

bolt through the aligned holes of the post bracket

/

If you loosened the clamp on

the post bracket to achieve the optimum position,

tighten it in its new position and recheck the gate

bracket with the gate in the open position (move the

While determining the mounting point for the post

pivot bracket assembly be sure that the position allows for maximum

positions, as shown in the diagrams below. This clearance will give the

Page 37

Operator

Fence Post

Gate Post and Gate Cross Member

(In Closed Position)

POST PIVOT BRACKET level with the

horizontal surface of the GATE BRACKET

LEVEL

LEVEL

LEVEL

With the gate in the

fully closed position

and the opener retracted, swing the opener to the gate. Mark reference points for

bolt holes on gate cross member through middle of gate bracket slots. The opener must be level. (Some vertical adjustment

/

Make sure the control box power switch is

DIP switch from the factory

power switch

push

the gate open.

Setting the Open Position Limit

toward their open position. Prepare to STOP gates by pressing the entry transmitter button again when the fi rst gate reaches

the desired open position. This step may be repeated until desired open position is achieved. Once the desired OPEN

position has been achieved, proceed to step 3.

page 25 for gate sequencing and other programming steps before

proceeding.

1ON2 3 4 5 6 7

ON

OFF

1 2 3 4 5 6 7

DIP#4

ON Push-to-open operation.

OFF Pull-to-open operation (factory setting).

Page 38

With the fi rst gate in the desired open position. Program the open limit setting by setting the number 4 DIP switch on the

LIMIT IS NOW PROGRAMMED.

button. Your gates should now be moving from the closed positions

toward their open positions. The fi rst gate will stop at the spot you

just programmed and the second gate will continue to open until

you press the transmitter button again. Press the transmitter button

With the second gate in the desired open position. Program the

then PRESS & HOLD the “SET LIMIT" button on the control

board for 5 seconds.

positions, then press and hold the "SET LIMIT" button for 10 seconds. This will clear the memory for the open limit

positions. Follow steps one (1) to seven (7) again.

1

ON

2 3 4

DUAL

MODES

ON

OFF

1 2 3 4

ON

6 7

SET

LIMIT

ON

OFF

1 2 3 4 5 6 7

Set Limit Button

Dual Mode DIP Switches

Page 39

Maintenance & Troubleshooting Guide

If the Opener Does Not Work

1. Test the transformer for voltage with a voltmeter. The acceptable range can be found in the

transformer 12 hours to charge the battery before using the gate opener.

2. If the transformer test shows voltage, check the

terminal block on the control board for voltage.

1. Check the battery in your transmitter and replace with a fresh one if needed..

2. Verify that the power cable is securely connected.

3. Replace the control board fuse if it is blown (

A HIGHER RATED

1. Make sure the

switch at the bottom of the control box is set to

2. Check all connections for looseness and corrosion.

On all gates weighing 250 lb. or more, routinely grease the ball bearing hinges at least 4 times a year; more

frequently if the gates are near a coastal area.

•

Keeping a few mothballs in the control box will discourage insects from entering it and damaging the control

board.

•

Clean the push-pull tube with a soft, dry cloth and apply silicone spray to it at least once per month.

While oxidation is a normal part of weathering of equipment that is exposed to the elements, we recommend

you apply silicone spray the front and rear mounts to minimize this effect.

Page 40

is open

– 5:30

(Eastern Time)

is open

is open

If the Opener is Working

___________________________

_______________________

measure voltage at panel and control box.

________________________________

_____________________________

measure voltage with battery connected

1. Check the position of the mounting brackets and readjust if necessary.

2. Check the gate for binding or hinge damage.

1. Check the position of the mounting brackets and readjust if necessary.

2. Check the gate for binding or hinge damage.

Page 41

Gate Opener is not operating properly, please follow the steps below:

Maintenance & Troubleshooting Guide

(

Refer to the serial number (located on the control box cover) and date of purchase when calling for assistance.

Authorization (RGA) number

to you for warranty repair.

4. Securely pack the component(s) authorized for return to the factory. Write the RGA number issued to you on the outside

of the package in

be accepted. Also, items returned to GTO freight

be accepted.

Page 42

MASONRY, BRICK, OR ROCK (etc.) COLUMNS:

PROCEEDING

back corner of the columns.

job is

for the inexperienced!

Column

Pivot Bracket

Gate

A

B

Column Mount Example

(A + B can not exceed 14 inches)

Example: If A is 2" then B can not exceed 12"

Hinge

Page 43

Not Compatible with Mighty Mule® 250

is a 5 watt solar powered battery charger for use with the

FM500 & FM502

gate opener systems.

comes with tubular steel support, mounting clips, wire

Mighty Mule®

has clearly labeled terminal connections for easy installation of the

Unlit doorbell button for remote entry or exit control. Wires directly to the control board and uses 16 gauge multi-

substitutes for the clevis pin at the front end of the Mighty Mule® gate openers. Helps prevent theft of

the opener from the gate, while allowing quick release of the opener.

Mighty Mule®

entry transmitter and has the same

Mighty Mule®

entry transmitter, with adjustable code settings, is standard equipment with all

Mighty Mule®

use up to 25 different personal identifi cation number (PIN) codes. Each code is face programmable with additional

burial wire (sold separately). Requires 3 AA batteries (not included).

Not Compatible with Mighty Mule® 250

Mule® automatic gate opener models (see Sensor Box for model compatibility). The Sensor is an electromagnetic

Automatic Gate Lock Pull-to-Open (FM143)

Not Compatible with Mighty Mule® 250

MUST for added security. Solenoid driven with a steel housing. Unlocks and locks automatically as gates open and

Mighty Mule®

system for maximum stability and security. Comes with a keyed manual release.

Wireless Entry Intercom / Keypad (FM136)

Allows owner to screen guest at the gate before allowing access to the property. Keypad also allows owner to give up to

be face mounted or mounted on top of the gate posts.

AUTOMATIC

G

ATE

L

OCK

®

ELECTRO

NIC SEC

URITY

L

OCK

Accessories are Available From Your Retail Store

E-Z GATE OPENERS

®

®

ACCESSORIES

POW

E

R

K

e

y

p

a

d

B

a

t

t Lo

w

Gran

t

Perm

i

ssio

n

An

s

w

er

D

V

9V

A

CC

ES

S CONTR

OL

S

YS

T

E

MS

1-

80

0

-5

4

3

-

4

2

8

3

1

2

ABC

3

DEF

4

GHI

5

JKL

6

MNO

7

PRS

8

TUV

9

WXY

0

Page 44

40

Not Compatible with Mighty Mule® 250

Mighty Mule® FM500 & FM502

gate opener

Mighty Mule® FM500 & FM502

Life expectancy is 3-5 years.

is for connecting the AC powered transformer, or

the

to the control board. Also used for the connection of accessories, such as locks, keypads, push buttons

Available in 1000' rolls or special lengths.

Not Compatible with Mighty Mule® 250

Mighty Mule®

500/502 gate opener(s) must push the gate open, such as on a sloping driveway or

Not Compatible with Mighty Mule® 250

For mounting the

Automatic Gate Lock

on brick columns, walls, or for other applications with limited space

between gate and post.

Mighty Mule®

Mighty Mule®

entry transmitter (see Dual and Triple

HEDDOLF

UNIVERSAL

RECEIVER

MODEL 294

Accessories are Available From Your Retail Store (con't)

The contents of all material available on this installation manual are copyrighted by GTO, Inc. (“GTO”), unless otherwise indicated. All rights are reserved by GTO, and content may not be reproduced, down-

loaded, disseminated, published, or transferred in any form or by any means, except with the prior, written permission of GTO. Any reprinting of GTO publications is by permission only. Copyright infringe-

ment is a violation of federal law.

Mighty Mule¨, E-Z Gate¨, GTO¨, are registered trademarks of GTO, Inc. America’s DIY Automatic Gate Openers is a trademark of GTO, Inc. and are the exclusive property of GTO, Inc. (“GTO”).

All rights are reserved by GTO, and these marks may not be used, in any for without the prior, written permission of GTO.

Loading...

Loading...