Page 1

Operating instructions

for condenser tumble dryer

T 4262 C

To avoid the risk of accidents or

damage to the machine it is

essential to read these instructions

before it is installed and used for the first time.

G

M.-Nr. 06 465 730

Page 2

Caring for the environment

Disposal of the packing

material

The transport and protective packing

has been selected from materials which

are environmentally friendly for disposal

and can normally be recycled.

Ensure that any plastic wrappings,

bags etc. are disposed of safely and

kept out of the reach of babies and

young children. Danger of suffocation!

Rather than just throwing these

materials away, please ensure they are

offered for recycling.

Disposal of your old appliance

Electrical and electronic appliances

often contain materials which, if

handled or disposed of incorrectly,

could be potentially hazardous to

human health and to the environment.

They are, however, essential for the

correct functioning of your appliance.

Please do not therefore dispose of your

appliance with your household waste.

Please dispose of it at your local

community waste collection / recycling

centre and ensure that it presents no

danger to children while being stored

for disposal.

It should be unplugged or disconnected

from the mains electricity supply by a

competent person. The plug must be

rendered useless and the cable cut off

directly behind it to prevent misuse.

See the "Warning and Safety" section of

this booklet for further details.

Energy saving tips

To avoid unnecessarily long drying

times and high consumption of energy:

Make sure that your laundry is

–

thoroughly spun before drying.

The higher the spin, the greater the

savings that can be made in energy

and time during drying.

– Load according to the optimum

amount of laundry recommended for

the programme being used (see

Programme chart).

Underloading is uneconomical.

Overloading gives a poorer quality of

drying and may cause unnecessary

creasing.

–

Make sure the room in which the

dryer is located is well ventilated.

–

Make sure the fluff filters are clean

before using the dryer.

–

Check the condenser unit from time

to time and clean it when necessary.

2

Page 3

Contents

Caring for the environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Disposal of the packing material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Disposal of your old appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Energy saving tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warning and Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Notes on laundry care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Care symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Tips on drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

How to dry correctly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Brief instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Low temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Changing the programme sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Programme chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Emptying the condensed

water container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cleaning the fluff filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cleaning them whilst dry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cleaning them with water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cleaning the tumble dryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cleaning the condenser unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Removing the condenser unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Checking the condenser unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cleaning the condenser unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Replacing the condenser unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Problem solving guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

General problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Check and fault indicator lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Changing the lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3

Page 4

Contents

After sales service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Repairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Appliance guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Front view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Transporting the machine to its installation site . . . . . . . . . . . . . . . . . . . . . . . . 30

Building under a continous worktop / in a row of kitchen units . . . . . . . . . . . . 30

Replacing the lid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Levelling the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Room in which the dryer is located . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Washer - dryer stack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Before moving the machine again (e.g. when moving house). . . . . . . . . . . . . 31

External condensed water outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Setting up the drain hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Connection to a sink drain outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

If you no longer wish to use an external condensed water outlet . . . . . . . . . . 33

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Electrical connection U.K. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Consumption data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Programmable functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Altering the residual moisture level in the Cottons programmes. . . . . . . . . . . . . . 38

Altering the residual moisture level in the Minimum iron programmes . . . . . . . . . 39

Activating and deactivating the buzzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Extending the cooling down time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Changing the standard drying level in the Minimum iron - Normal programme . . 42

Changing the standard drying level in the Automatic programme . . . . . . . . . . . . 43

4

Page 5

Warning and Safety instructions

To avoid the risk of accidents and

damage to the machine please read

these instructions carefully before

using it for the first time. They

contain important information on its

safety, installation, use and

maintenance.

Keep these instructions in a safe

place and ensure that new users are

familiar with the content. Pass them

on to any future owner of the

machine.

Technical safety

Before setting up the machine,

check it for any externally visible

damage.

Do not install or use a damaged

machine.

Before connecting the machine,

ensure that the connection data on

the data plate (voltage and connected

load) match the mains electricity

supply. If in any doubt, consult a

qualified electrician.

Correct use

The tumble dryer is only intended

for drying fabrics which have been

washed in a water solution, marked on

the manufacturer's care label as being

suitable for tumble drying.

"Dry cleaning kits" for freshening up

garments in a tumble dryer are

increasingly available on the market. If

using, do so at your own risk, and

follow the instructions provided on the

packaging.

Any other applications may be

dangerous. The manufacturer is not

liable for damage resulting from

improper use or operation.

The electrical safety of this

machine can only be guaranteed

when continuity is complete between it

and an effective earthing system which

complies with local and national

regulations. It is most important that this

basic safety requirement is present and

regularly tested, and where there is any

doubt the household wiring system

should be inspected by a qualified

electrician. The manufacturer cannot be

held liable for the consequences of an

inadequate earthing system (e.g.

electric shock).

Do not connect the appliance to

the mains electricity supply by an

extension lead. Extension leads do not

guarantee the required safety of the

appliance (e.g. danger of overheating).

5

Page 6

Warning and Safety instructions

The machine is built in accordance

with current safety requirements.

Unauthorised repairs could result in

unforeseen dangers for the user, for

which the manufacturer cannot accept

liability. Repairs should only be

undertaken by a Miele approved

technician.

Ensure current is not supplied to the

machine until after maintenance or

repair work has been carried out.

Faulty components must only be

replaced by genuine Miele original

spare parts. Only when these parts are

fitted can the safety standards of the

machine be guaranteed.

If the connection cable is faulty it

must only be replaced by a Miele

approved service technician to protect

the user from danger.

In countries where there are areas

which may be subject to infestation

by cockroaches or other vermin, pay

particular attention to keeping the

machine and its surroundings in a

clean condition at all times. Any

damage which may be caused by

cockroaches or other vermin will not be

covered by the machine guarantee.

6

Page 7

Warning and Safety instructions

In the event of a fault or for

cleaning purposes, the machine is

only completely isolated from the

electiricty supply when:

it is switched off at the wall socket

–

and the plug is withdrawn, or

it is switched off at the mains, or

–

the mains fuse is withdrawn.

–

Operation

This equipment may only be used

in mobile installations such as

ships, caravans, aircraft etc. if a risk

assessment of the installation has been

carried out by a suitably qualified

engineer.

The dryer must not be used without

the fluff filters in place or if the fluff

filters are damaged in any way.

The fluff filters must be thoroughly

dried after cleaning. If they are still

damp or wet when replaced there is a

risk of faults occurring when the

machine is used.

If the water is drained externally

through the drain hose instead of

being collected in the condensed water

container, make sure the drain hose is

securely attached if you hang it in a

sink or basin to avoid the hose slipping

and the water causing damage.

Condensed water is not drinking

water. It can cause health

problems in both people and animals.

Always keep the area around the

machine free of dust and fluff. Dust

drawn into the machine can, over time,

cause blockages in the condenser unit.

The dryer must not be used without

the condenser unit in place.

Do not install the machine in a

room where there is a risk of frost

occurring. At temperatures around

freezing point the machine may not be

able to operate properly.

There is a risk of damage if the

condensed water is allowed to freeze in

the pump, hoses and / or condensed

water container.

The ambient room temperature should

be between +2°C and +35°C.

7

Page 8

Warning and Safety instructions

To prevent the risk of fire the

following textiles must not be

dried in this machine:

fabrics which contain a large

–

proportion of rubber, foam rubber or

rubber like materials.

items which contain padding or

–

fillings (e.g. pillows, jackets).

items which have been treated with

–

inflammable cleaning agents.

items which have been splashed with

–

hair lacquer, hair spray, nail varnish

remover or similar substances.

– items which have been soiled with

oils or residues containing grease

(kitchen oils, cosmetics etc.).

– items soiled with wax or other

chemicals (e.g. mops and floor

cloths).

– items which have not been

thoroughly cleaned and which are

still soiled with grease or oil, e.g.

workwear. Such clothing may require

a heavy duty detergent to get them

clean. If necessary consult the

detergent manufacturer for advice.

Do not let anyone sit or lean on the

door, as this can cause the

machine to tip up.

Safety with children

This machine is not a toy. To avoid

the risk of injury keep children

away from the machine at all times and

supervise them whilst you are using it.

Do not allow children to play on or near

it or to play with its controls. Supervise

its use by the elderly or infirm.

Using accessories

Accessory parts may only be fitted

when expressly approved by Miele.

If non-Miele parts are used with this

machine, guarantee, performance and

product liability claims may be

invalidated.

Disposal of your old machine

Before discarding an old machine,

switch it off at the wall socket and

unplug it. Render the plug useless and

cut off the cable directly behind the

machine. This should be done by a

competent person.

The manufacturer cannot be held

liable for damage caused by

non-compliance with these Warning

and Safety instructions.

Always close the door after use.

This way you will avoid the danger

of:

–

children climbing onto or into the

dryer or hiding things in it.

–

pets or other small animals climbing

into it.

8

Page 9

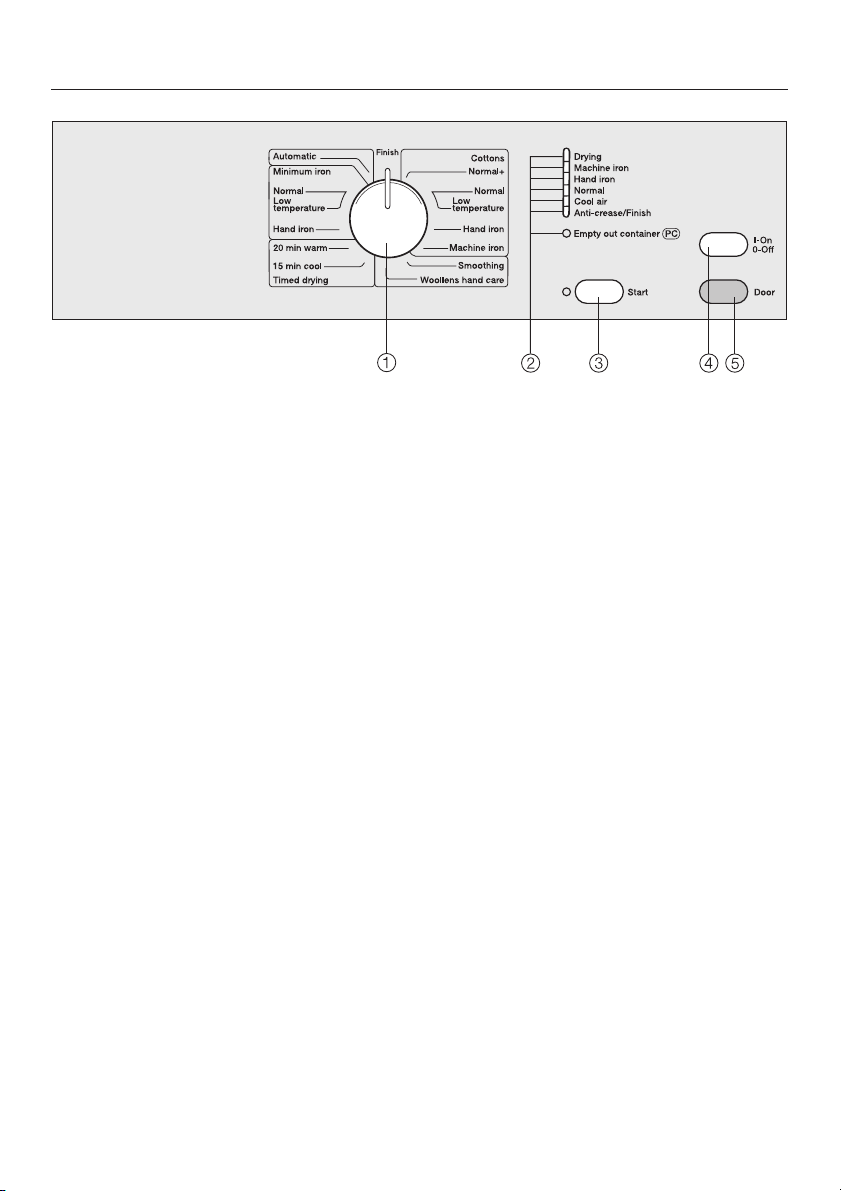

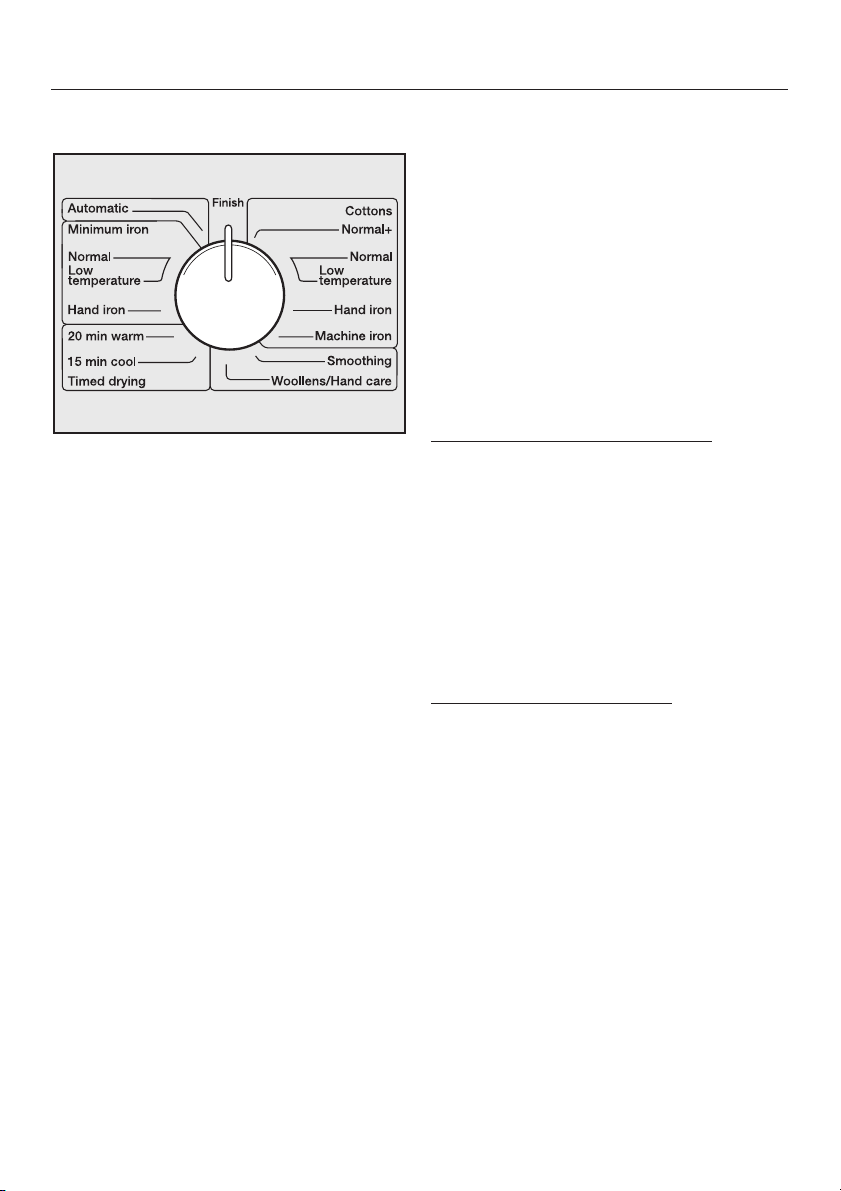

Control panel

a Programme selector

The programme selector can be

turned clockwise or anti-clockwise.

b Programme sequence and check

lamps

c Start button

Press the

programme.

The

soon as a programme can be

started. It lights up constantly once

the programme has started.

d I-On/0-Off button

To switch the machine on or off / to

interrupt a programme.

The Anti-crease/Finish lamp will light

up as confirmation that the machine

has been switched on.

Start

button to start a

Start

indicator lamp will flash as

e Door Button

To open the door / to cancel a

programme.

Pressing this button will open the

door even when the machine is

switched off at the mains.

If the machine is switched on at the

mains and the door is opened the

drum lighting will come on. It will go

out a few minutes later to save

energy.

PC indicator light

The indicator light marked PC is used

by Miele Service technicians as an

optical interface.

9

Page 10

Notes on laundry care

Care symbols

Before drying check the drying symbol

on the care label. If there are no

symbols, dry at your own risk!

q . . . . . . . . . Dry at normal temperature

r . . . . . . . . . . Dry at a low temperature

s . . . . . . . . . . . . . . . Do not tumble dry

For delicates and fabrics with the

–

following care label r select

temperature

.

Low

Tips on drying

– Always observe the maximum

recommended loads given in the

"Programme chart". Never overload

the drum.

Overloading can cause unnecessary

wear and tear to the laundry, give a

disappointing drying result and

cause more creasing.

– Do not put soaking wet items into the

tumble dryer. Spin them thoroughly

after washing using the appropriate

spin speed.

–

Use the

drying mixed loads of cottons and

minimum iron fabrics.

–

Open jackets

evenly.

–

Woollens and wool blends

become matted and shrink if dried in

a tumble dryer. They can, however,

be partially dried using the

hand care

Automatic

programme.

programme for

so that they can dry

tend to

Woollens

Down-filled garments

–

which have a tendency to shrink,

depending on the quality of the item.

They can be partially dried using the

Smoothing

Pure linen

–

dried if specified as suitable by the

manufacturer on the care label, as

the surface of the fabric may

otherwise become rough. They can

be partially dried using the

Smoothing

Loopknit garments

–

underwear) tend to shrink depending

on their quality. Do not over-dry these

textiles. When purchasing these

garments it is advisable to take their

shrinkage properties into account.

– Minimum iron fabrics

cotton shirts or blouses tend to

crease more, the greater the load.

This is especially true of very fine

weaves.

Reduce the load or use the

programme.

should only be machine

programme.

iron - Hand iron

–

Starched laundry

tumble dryer. To achieve the usual

finish, double the amount of starch

should be used.

–

New dark coloured garments

be washed and dried separately

from light coloured garments to avoid

the danger of colours running and

discolouring other garments or even

plastic components in the machine.

Dark coloured fibres can also settle

on light coloured garments and vice

versa.

have linings

(e.g. T-shirts and

and 100%

Minimum

programme.

can be dried in the

should

10

Page 11

How to dry correctly

Brief instructions

The headings numbered (A, B, C ...)

show the operating sequence and can

be used as a brief guide to using your

machine.

A Sort the laundry

To ensure an even drying result

separate out the washed laundry and

sort it according to: . .

. . . the drying level required

. . . the type of fibre or weave

. . size

. . the moisture content after spinning.

Make sure that objects e.g.

,

detergent dispensing balls have

been removed from the laundry.

They could melt, and cause damage

to the dryer or the laundry.

– Check seams and stitching to ensure

that padding and linings are intact.

– Fasten duvet covers and pillow

cases to prevent small items from

being trapped inside them.

C Load the tumble dryer

Door

Press the

^

door.

Load the laundry loosely into the

^

drum.

Do not overload the drum. See the

"Programme chart" for

recommended loads for each

programme.

Overloading can cause unnecessary

wear and tear to the laundry and

give a disappointing drying result.

^ Before closing the door make sure

the fluff filter is correctly positioned.

button to open the

–

Fasten hooks and eyes etc.

–

Tie fabric belts and apron strings.

–

Sew in or remove underwiring from

bras.

B Turn on the tumble dryer

^

Switch the dryer on by pressing the

I-On/0-Off

The tumble dryer may be switched on

after loading, saving energy as the light

will not come on.

button in.

Check the laundry is right inside the

drum so that it cannot get trapped or

damaged when the door is shut.

^

Shut the door either with a gentle

swing, or lean against it and push it

shut.

11

Page 12

How to dry correctly

D Select a programme

^ Turn the programme selector to the

required programme.

Low temperature

^ For drying particularly sensitive

fabrics (care symbol r) e.g. acrylics

turn the programme selector to the

Low temperature

Because the heater rating is reduced

for the

dry more slowly thus lengthening drying

times.

Low temperature

position.

setting clothes

E Start the programme

Press the

^

The indicator lamp for the

will then change from flashing to being

on constantly.

The drying cycle begins.

Depending on the programme

selected, the drying stage reached is

shown by the sequence indicator lamps

on the right hand side of the control

panel.

Before the end of a programme

The cooling down phase takes place

before the end of a programme so that

the garments are not too hot to handle

(the

Cool air

on). The programme is not finished until

the cooling down phase is complete.

The

Woollens handcare

programmes do not include a cooling

down phase.

At the end of a programme

The

Anti-crease/Finish

comes on.

Start

button.

Start

button

indicator lamp will come

and

Smoothing

indicator lamp

12

The drum will continue to rotate at

intervals to prevent laundry creasing, if

you do not wish to remove it immediate

ly. The anti-crease phase lasts for an

hour. There is no anti-crease phase on

the

Woollens handcare

During the anti-crease phase . . .

. . . (depending on the programme

selected) the indicator lamp for the

drying stage reached will also light up.

. . . the buzzer will sound at intervals.

programme.

-

Page 13

How to dry correctly

F Remove the laundry

Door

Press the

^

Open the door.

^

Remove the laundry.

^

Make sure that the drum is empty. If

items are left in the dryer, they could

be damaged by overdrying when

the dryer is next used.

Switch the dryer off by pressing the

^

l-On/0-Off

Clean the fluff filters.

^

^ Close the door.

^ Empty the condensed water

container (where there is no external

drainage of the water).

^ The condenser unit should be

checked and cleaned on a regular

basis.

button.

button.

Switch the dryer on with the

^

I-On/0-Off

The programme will continue (only with

the

Cottons, Minimum iron and Auto

matic

programmes).

Other programmes:

Press the

^

To cancel a programme

Turn the programme selector to

^

Finish

Adding or removing laundry after a

programme has started

^ Press the

^ Open the door.

button.

Start

button.

or open the door.

Door

button.

-

,Do not touch the back of the

drum when adding or removing

items. The drum could be very hot danger of burning.

Changing the programme

sequence

Changing a programme while it is

running

As long as the cooling down phase or

the anti-crease phase has not been

reached, it is possible to change a

programme after it has started by

turning the programme selector to a

different programme position.

To interrupt a programme

^

Switch the machine off with the

I-On/0-Off

To continue drying:

button.

^

Add or remove items.

^

Close the door.

^

Press the

Start

button.

13

Page 14

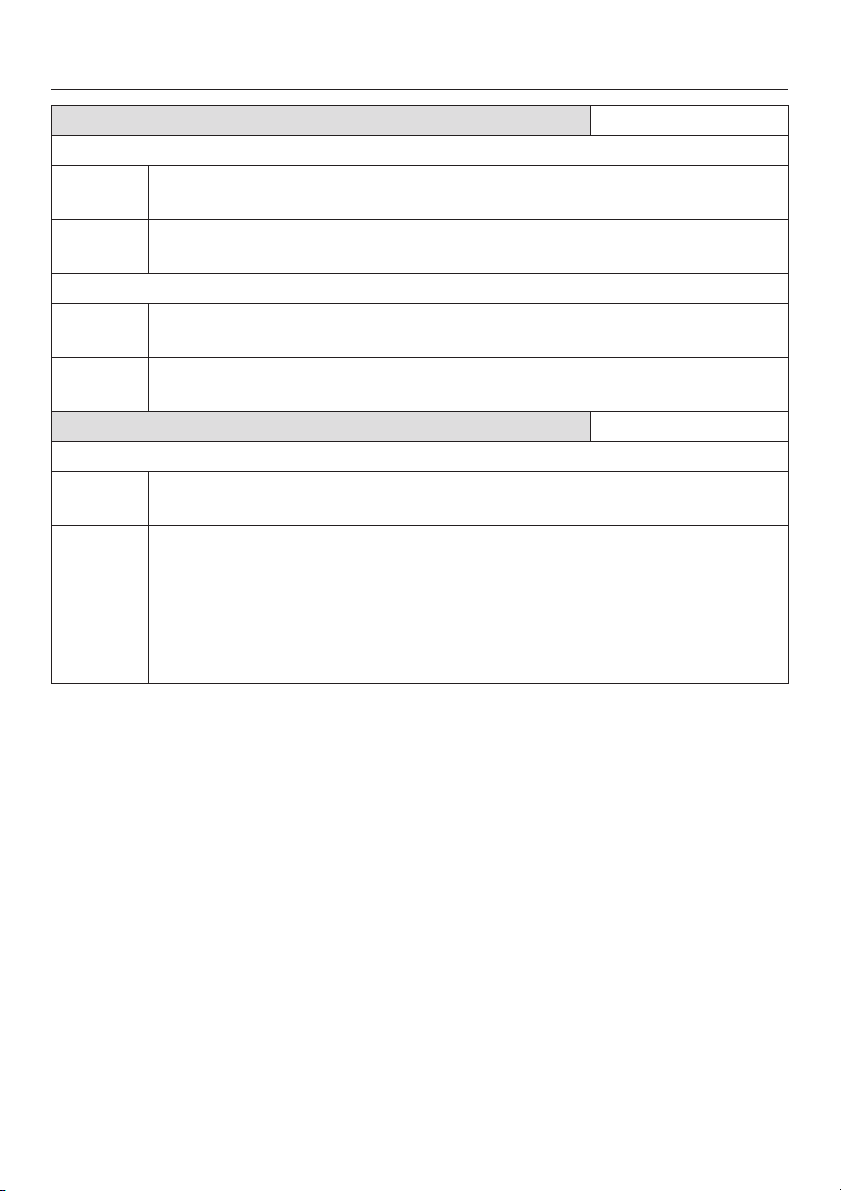

Programme chart

Cottons Max. load: 6 kg*

Normal+, Normal**, Low temperature

Fabric

type

Note

Hand iron**, Machine iron

Fabric

type

Note To prevent laundry from drying out it should be rolled up until you are

Minimum iron Max. load: 3 kg*

Normal**, Low temperature, Hand iron

Fabric

type

Notes – Select

* Weight of dry laundry

** Note for test institutes:

Programme setting for testing in accordance with EN 61121

Single and multi-layered cottons fabrics such as towelling, jerseywear,

underwear, flannelette bed linen.

Select

–

dried at a lower temperature.

Cottons and linen fabrics, e.g. table linen, bedlinen, starched laundry.

ready for ironing.

Minimum iron items made of cotton, synthetic or blended fabrics, e.g.

shirts, blouses, skirts and table cloths.

garments). Laundry is dried at a lower temperature.

– Select

more, reduce the load to 1.5 kg*.

– In the Miniumum iron

very little creasing, depending on fabric type and amount of load.

Low temperature

Low temperature

Hand iron

for delicate fabrics and to reduce creasing even

Hand iron

for fabrics with the r symbol. Laundry is

for fabrics with the r symbol (e.g. acrylic

programme, items are dried with

14

Page 15

Programme chart

Automatic Max. load: 3 kg*

Fabric

type

Timed drying Max. load: 6 kg*

Warm air

Fabric

type

Cool air

Fabric

type

Woollens handcare Max. load: 2 kg*

Fabric

type

Notes – To refresh and fluff up woollen garments quickly. Woollen fabrics

Smoothing Max. load: 3 kg*

Fabric

type

Notes

* Weight of dry laundry

Mixed load of cotton and minimum iron fabrics.

Multi-layered fabrics whose layers have different drying

–

characteristics, e.g. jackets, pillows.

For drying individual items, e.g. bath towels, bathing costumes,

–

tea-towels.

Any item which only needs airing.

Woollen fabrics

are not dried completely by this programme.

– Remove garments as soon as the programme has finished and

leave to finish drying at room temperature.

– Cottons and linen fabrics.

– Minimum iron items made of mixed fibres, cottons or synthetics e.g.

trousers, jackets, shirts.

–

Smooths out creasing caused during the spin cycle in the washing

machine.

–

Fabrics are not completely dried in this programme. Remove

garments as soon as the programme has finished and leave to

finish drying at room temperature.

15

Page 16

Cleaning and care

Emptying the condensed

water container

The condensed water will be collected

in the condensed water container

unless the machine has been fitted with

a drain hose (see installation).

The condensed water container

should be emptied after every

drying cycle or as soon as the

Empty out container

comes on.

indicator lamp

The drying programme will be

interrupted if the maximum level of the

condensed water container is reached.

The

Empty out container

comes on and the buzzer sounds.

^

Grip the container firmly with both

hands, as shown, and pull it out

slightly towards the right-hand side.

^

Hold the container with both hands

and carry it in a horizontal position.

indicator lamp

^ Open the shutter and empty out the

water.

^ To replace the container hold it at a

slight angle (as when removing it)

and push it in gently until you feel it

click into position.

^ Before starting a new programme,

first switch the machine off and then

on again. The

indicator lamp will go out.

Condensed water should not be

consumed. It could lead to health

problems for people and animals.

Condensed water can be put to

household use (e.g. used in a steam

iron or humidifier). To ensure that any

residual particles of fluff in the

condensed water are removed before

use, pass it through a fine sieve or

paper filter first.

Empty out container

16

Page 17

Cleaning and care

Cleaning the fluff filters

The fluff which is created by the drying

process is collected by the fluff filters in

the door and the door opening. Clean

the filters after each drying programme.

Cleaning them whilst dry

^ Open the door and pull the fluff filter

(1) out of the door as illustrated.

Remove any fluff from the hollow part

^

of the door holder. A cleaning brush

is available as an optional extra from

your Miele dealer or the Miele Spare

Parts Department.

Tip: You can also use a vacuum

cleaner.

Once clean, push the filter back into

^

the door holder until it clicks into

position. Ensure it is facing the

correct way.

Also clean the door seal (2) with a

^

damp cloth.

^

Use your fingers to remove the fluff

from the surface of the filter.

^

Use your fingers to remove the fluff

from the two fluff filters in the door

opening.

^

Close the door.

17

Page 18

Cleaning and care

Cleaning them with water

If there is a great deal of compacted

fluff on any of the filters, they can be

removed and cleaned under hot

running water.

To remove the fluff filter from the door

^

holder see previous page.

^ To remove the filters in the door

opening, grip the holder and push

upwards in the direction of the arrow

to remove it.

^

Rinse the filters under hot, running

water.

^

Then shake the filters until no more

water droplets are visible.

^

Dry the filters thoroughly with care.

,

Do not replace them if they are

damp or wet. Damp or wet filters

could cause operational faults.

Place the filters back in the door

^

opening (the left and right filters are

identical) with the finger holders

facing upwards. See illustration.

Cleaning the tumble dryer

Disconnect the machine from the

mains electricity supply.

Clean the housing and control panel

^

with a slightly damp cloth and a mild

detergent or soapy water.

The drum and other stainless steel

^

parts can be cleaned with a suitable

proprietary stainless steel cleaner

following the manufacturer's

instructions.

Do not use solvents, abrasive

cleaners, glass cleaners or

all-purpose cleaners. These could

damage plastic sufaces and other

parts. The machine must never be

hosed down.

^

Dry all parts with a soft cloth.

^

A microfibre E-Cloth is available from

the Miele UK Spare Parts Department

which is suitable for cleaning

surfaces such as stainless steel,

glass, plastic and chrome without the

use of chemicals. It can be washed

300 times.

^

Push the large filter back into the

door holder until it clicks into position.

Ensure it is facing the correct way.

18

Page 19

Cleaning the condenser unit

Detergent residue, hair and fine fluff

from the dryer can get through the fluff

filters and block the condenser unit.

Dust from the room in which the dryer is

installed can also get into the

condenser unit and cause a blockage.

Check the condenser unit at least

twice a year. If the dryer is used

frequently then clean the condenser

unit after approx. 100 drying cycles.

Removing the condenser unit

Cleaning and care

Turn the lever on the inner cover

^

downwards to the vertical position.

^ Pull the cover forwards

^ Then remove it by pulling it

diagonally upwards.

^

Open the service panel by pressing

the two lower corners at the same

time (see illustration).

The hooks at the side will prevent the

panel from falling off.

^

Now remove the panel by pulling it

diagonally upwards.

^

Then place it to one side.

^

Turn the lever on the condenser unit

to the vertical position.

19

Page 20

Cleaning and care

Pull the condenser unit out of its

^

housing by the handle.

Checking the condenser unit

If you cannot see any fluff:

Replace the condenser unit (see

^

following page).

If you can see some fluff:

Clean the condenser unit as

^

described below.

Cleaning the condenser unit

When rinsing the condenser unit,

^

make sure you position it as shown

in the next two illustrations.

^

Hold the condenser unit up to the

light as shown.

^

Check to see if there is any fluff

inside it.

The arrows in the illustration above

indicate where to look.

20

^

Use a shower head or similar to rinse

the unit out as shown.

Page 21

Then flush the unit through from the

^

front.

Cleaning and care

Replacing the condenser unit

With the handle facing upwards,

^

push the condenser unit back into

position in its housing.

Turn the lever down to the horizontal

^

position, making sure that the hook

on the lever clicks into the groove.

When replacing the cover after

cleaning, ensure that the rubber seal

fits correctly into the groove.

Replace the cover making sure the

^

hooks locate correctly. Hold it at an

angle and push it gently downwards.

^ Check the condenser unit again for

any visible fluff and if necessary flush

it through again until it has all gone.

^ Remove any soiling still visible inside

the housing unit by hand using a

damp cloth. Do not try and access

areas you cannot reach by hand!

^ Also make sure the rubber seals are

clean.

The rubber seals must not be

removed and must be free of kinks.

^ Then turn the lever upwards into the

horizontal position to lock the cover.

^ Replace the service panel and press

the upper edge until it clicks into

position.

,

It is important to ensure that both

the condenser unit and the cover are

correctly positioned and locked

otherwise water may leak from the

machine.

21

Page 22

Problem solving guide

With the help of the following notes minor faults in the performance of the

machine, some of which may result from incorrect operation, can be put right

without contacting the Service Department.

Repair work to electrical equipment should only be carried out by a suitably

,

qualified person in accordance with local and national safety regulations.

Repairs and other work by unqualified persons could be dangerous. The

manufacturer cannot be held liable for unauthorised work.

General problems

Problem Possible cause Remedy

The tumble dryer fails to

start when switched on.

Items made of synthetic

fibres are charged with

static electricity after

drying.

No obvious cause.

Synthetic fibres tend to

attract static charge.

Have you followed the

–

switch-on procedure

correctly (see “How to

dry correctly”)?

– Is the plug correctly

inserted in the socket

and switched on?

– Is the door closed

properly?

– Has the fuse or circuit

breaker tripped?

Static charge can be

reduced by adding a

fabric conditioner to the

final rinse in the washing

machine or a fabric

conditioner sheet to the

load in the dryer.

22

Page 23

Problem solving guide

Problem Possible cause Remedy

There is a build

up of fluff.

The laundry is

not sufficiently

dry.

The interior

drum lighting

does not come

on.

Fluff is principally the result of

friction when garments are

being worn and washed.

Machine drying hardly

causes any fluff to form and

has been established by

research institutes to have no

appreciable effect on the

lifetime of the garment.

The load consisted of

different fabrics.

The lighting switches off

automatically (to save

energy).

The lamp needs changing. Change the lamp as

Fluff is collected by the fluff

filters and can be easily

removed (see "Cleaning and

Care").

Finish drying using "Warm

–

air" (timed drying).

Select a more suitable

–

drying programme next

time (see "Programme

chart").

Switch the dryer off and then

on again.

described at the end of this

section.

23

Page 24

Problem solving guide

Problem Possible cause Remedy

The drying process

goes on too long or

even switches off.

Important: Before attempting to remedy one of the

following causes, switch the dryer off and switch on again

to start the programme again.

Ventilation to and from the

dryer may be insufficient

(e.g. because it is installed

in a small room). This has

caused the temperature in

the room to rise sharply.

The vents below the door

are blocked.

The fluff filters are clogged

up with fluff or were still wet

when they were replaced.

Detergent residues, hair and

fine fibres can block up the

condenser unit.

The laundry has not been

spun sufficiently.

The tumble dryer has been

overloaded.

Metallic components, e.g.

zips have prevented the

dryer from registering the

correct moisture level in the

laundry.

Open a door or window

while the machine is in

operation for increased air

flow.

Remove any objects that

–

are blocking the vents.

Remove any fluff.

–

– The fluff filters must be

completely dry.

Check the condenser unit

from time to time and clean

it if necessary (see

"Cleaning and Care").

Make sure that your laundry

is thoroughly spun at the

appropriate spin speed.

Do not exceed the maximum

load for the programme

selected.

–

Open zips next time.

If the problem occurs again,

dry garments with long zips

using "Warm air" (timed

drying).

24

Page 25

Problem solving guide

Problem Possible cause Remedy

The condenser unit

service panel will not

shut.

Water leaks from the

machine after the

condenser unit has

been cleaned.

Check and fault indicator lamps

Problem Possible cause Remedy

The Empty out

container indicator

lamp comes on.

The programme has

been interrupted, the

indicator lamp for

Hand iron or Machine

iron is flashing, and

the buzzer sounds.

The inner cover of the

condenser unit has not

been locked properly

and/or the condenser

unit has not been

positioned correctly.

Fluff has collected at

the bottom of the

condenser unit housing.

The condensed water

container is full or there

is kink in the drain hose.

There is no obvious

cause.

Ensure that the condenser

–

unit is positioned correctly

and lock the cover.

Check the rubber seals.

–

Use a cloth to remove any

–

fluff from the inside of the

condenser unit housing.

– Empty out the condensed

water container.

– Check the drain hose.

– Before starting a new

programme, first switch the

dryer off and then on again.

– Switch off the dryer.

– Then switch the dryer back

on and start the programme

again.

If the programme stops again

and an indicator lamp flashes,

there is a fault. Contact the

Miele Service Department.

25

Page 26

Problem solving guide

Problem Possible cause Remedy

The programme has

stopped, the

Anti-crease/Finish lamp

has come on in the

sequence display and

the buzzer is sounding.

This is not a fault.

The electronic unit has

recognised that there is

no laundry in the drum

and cancelled the

programme.

Drying individual

garments or items which

are already dry can also

cause the programme to

be stopped.

Use the "Timed drying Warm air" programme to

dry individual items.

Before changing a

programme: Open and

close the drum door.

26

Page 27

Changing the lamp

Disconnect the machine from the

mains electricity supply.

Problem solving guide

The lamp specification and

maximum wattage is stated on the

data plate and on the lamp cover.

Open the door.

^

You will find the interior lamp cover at

the top of the drum aperture.

^ Insert a suitable tool, such as a wide

bladed screwdriver, under the side

edge of the lamp cover as illustrated.

^

Apply a little pressure and whilst

doing so turn your wrist in the

direction of the arrow to open the

cover.

Replace the lamp.

^

To close the cover push it upwards

^

and press it on the left and right until

you hear it click into position.

Ensure that it is fitted into

,

position securely, as any moisture

could cause a short circuit.

The cover will open downwards.

The temperature resistant lamp should

only be ordered from your Miele dealer

or the Miele Spare Parts Department.

27

Page 28

After sales service

Repairs

In the event of any faults which you

cannot remedy yourself, or if the

machine is under guarantee, please

contact

your Miele dealer, or

–

the Miele Service Department

–

(see back cover for contact details).

When contacting your Dealer or the

Service Department, please quote the

model and serial number of your

machine, both of which are shown on

the data plate situated on the right

hand side below the drum aperture.

Appliance guarantee

Please see the guarantee card

supplied with your machine.

Optional accessories

Optional accessories for this dryer is

available from your Miele Dealer or from

the Miele Spare Parts Department.

Please note that telephone calls may

be monitored and recorded to

improve our service.

28

Page 29

Front view

Installation

a Mains connection cable

b Condensed water container

c Control panel

d Door

e Service panel for condenser unit

f Four height-adjustable screw feet

g External drainage options (e.g. via

wash basin, wash basin drain outlet,

or gully).

29

Page 30

Installation

Installation site

Make sure the dryer door can be

,

opened without hindrance after

installation.

Transporting the machine to its

installation site

When moving the machine you can

hold it by the lid where it protrudes to

the rear of the dryer.

To manoeuvre the dryer out of its

packing case to its installation site you

will also need to hold it by the front feet.

Building under a continous worktop /

in a row of kitchen units

The dryer should not be installed

next to a refrigerator or freezer. The

warm air expelled from the rear of

the dryer would increase the

temperature around the

refrigerator's/freezer's heat

exchanger causing the compressor

to run continuously.

If it is not possible to install the dryer

anywhere else, then the

refrigerator/freezer must be sealed

off from the dryer.

If you wish to push your machine under

a worktop and there is space to do this

without removing the lid, a building

under kit is not necessary. Otherwise

the building under kit is essential.

The building under kit* must be

,

fitted by a suitably qualified person.

The machine lid is replaced by a

coverplate. It is essential that the

coverplate is fitted to ensure

electrical safety.

The building under kit is supplied with

its own installation instructions.

N.B. When built under running times

may be longer.

– The electrical socket must be

located in an accessible position

near the machine.

With niche heights of:

– 840 mm, longer screw feet* are

required.

–

870/885 mm - 915/930 mm, one or

two height adjustment frames* are

required.

* Available as an optional accessory

from your Miele dealer or the Miele

Spare Parts Department.

30

Replacing the lid

If the lid has been removed in order to

fit a cover plate, ensure that, if the lid is

replaced, it fits securely into the rear

holders. Otherwise, it is not properly

secure for transport.

Page 31

Installation

Levelling the machine

The machine must be perfectly level to

ensure safe and proper operation.

Room in which the dryer is located

Air taken in for use in the drying

process will be warm when it is

expelled from the rear of the dryer. This

expelled air heats up the air in the

room. It is therefore very important to

ensure that the room is adequately

ventilated, particularly if the dryer is

located in a small room. Otherwise

running times and energy consumption

could be increased.

Washer - dryer stack

The tumble dryer can also be

combined with a Miele washing

machine in a washer-dryer stack. To do

this the appropriate stacking kit* (WTV)

to match your washing machine is

required.

* Available as an optional accessory

from your Miele dealer or the Miele

Spare Parts Department.

^

The screw feet can be adjusted to

compensate for any unevenness in

the floor.

,

The ventilation gaps in the plinth

must not be covered over as this

would prevent a sufficient intake of

air.

,

Stacking kits must be fitted by a

suitably qualified fitter.

Before moving the machine again

(e.g. when moving house)

After each use a small quantity of

condensed water will collect in the area

around the pump. This water can run

out if the machine is tipped up when it

is being moved. It is a good idea to run

the

Cool air

approximately 1 minute before moving

the machine. Any remaining

condensed water will then be fed into

the condensed water container or out

through the drain hose.

programme for

31

Page 32

Installation

External condensed water

outlet

When drying is in progress, condensed

water is pumped into the condensed

water container through the drain hose

at the back of the dryer. The

condensed water can also be drained

off directly if the machine is installed

near a sink, drain outlet etc. so that

the condensed water container does

not have to be emptied.

The drain hose (approx. 2 m long) is

stored in the dryer. It must be pulled

out of the dryer to its full extent if

condensed water is to be drained

externally. Maximum delivery head:

1 m.

If it is not long enough, an extension

hose is available as an optional

accessory through your dealer or from

the Miele Spare Parts Dept.

Setting up the drain hose

From the back of the dryer at the

bottom:

^ Unclip the drain hose from clip (3).

^ Then pull the drain hose completely

out of the dryer towards the left (4)

(See illustration). Important:

,

Do not let the drain hose

become kinked, as this could

damage it.

From the back of the dryer at the top:

^

Unclip the drain hose from clip (1).

^

Then pull it off holder (2).

32

,

If you want to drain the water off

into a sink you will need to secure

the hose carefully, e.g. by tying it to

a tap to make sure it cannot slip

during use. Otherwise there is a risk

of overflowing water which could

cause damage.

Use the bow-shaped guide to prevent

the drain hose from becoming kinked

(see "Front view" illustration).

Page 33

Installation

Connection to a sink drain outlet

The drain hose can be connected

directly to a sink drain outlet.

^ Remove the following from the back

of the dryer at the bottom:

Adapter 1 and hose clip 3 behind it.

If this nut has a flat disc in it you should

take the disc out first. Important: if this

nut has a washer or seal in it this must

not be removed!

Attach the end of the hose to

^

adapter 1.

Use a screwdriver to tighten hose

^

clip 3 up close to the nut.

If you no longer wish to use an

external condensed water outlet

Do not push the drain hose

,

back into the dryer. Doing this could

cause it to become kinked and

damaged in the dryer.

^ Loop the drain hose up.

^ Use a suitable cable tie to secure the

looped hose to the back of the dryer,

or simply lay the looped hose behind

the dryer.

^ Attach the open end of the drain

hose back onto the holder at the

back of the dryer at the top (see

holder 2 in "Pulling out the drain

hose").

^

Fit adapter 1 to the sink drain outlet

using nut 2.

33

Page 34

Electrical connection

Electrical connection U.K.

All electrical work should be carried out

by a suitably qualified and competent

person, in strict accordance with

national and local safety regulations.

Ensure power is not supplied to the

appliance until after installation work

has been carried out.

The appliance is supplied with a mains

cable with moulded plug ready for

connection to a 230-240V mains

supply. The voltage and connected

load are given on the data plate.

Please ensure these match the

household mains supply. The fuse

rating is quoted on the plug.

Connection should be made via a

suitable switched socket which is easily

accessible after installation.

For extra safety it is advisable to install

a residual current device (RCD), with a

trip current of 30 mA (in accordance

with DIN VDE 0664, VDE 0100 Section

739).

Non-rewireable plugs BS 1363

The fuse cover must be refitted when

changing the fuse, and if the fuse cover

is lost, the plug must not be used until a

suitable replacement is obtained. The

colour of the correct replacement cover

is that of the coloured insert in the base

of the plug, or the colour that is

embossed in words on the base of the

plug (as applicable to the design of

plug fitted).

Replacement fuses should be ASTA

approved to BS 1362 and have the

correct rating. Replacement fuses and

fuse covers may be purchased from

your local electrical supplier.

WARNING: THIS APPLIANCE

MUST BE EARTHED

Do not connect via an extension lead.

Extension leads do not guarantee the

required safety of the appliance (e.g.

danger of overheating).

34

Page 35

Consumption data

Programme Load Final spin speed

in a domestic washing machine

kg* rpm kWh Minutes

Cottons Normal 6.0 800 (70 % residual moisture)**

1200

1400

1600

1800

Cottons Hand iron 6.0 800 (70 % residual moisture)**

1200

1400

1600

1800

Minimum iron Normal 3.0 1000 (50 % residual moisture)** 1.50 54

Minimum iron Hand iron 3.0 1000 1.30 47

Automatic 3.0 900 1.95 109

Woollens handcare 2.0 900 0.15 4

Smoothing 3.0 - 0.30 8

* Weight of dry laundry

** EN 61121 test programme:

All data established in accordance with EN 61121.

Before testing in accordance with EN 61121, dry a 3 kg load of cotton laundry with 70% residual

moisture as per the above standard using the Cottons Normal programme.

Consumption data can vary from the nominal values given above depending on the size of the

load, types of textiles, residual moisture levels after spinning, fluctuations in the electricity

supply and any additional options selected.

Energy Time

4.05

3.20

3.05

2.95

2.65

3.25

2.40

2.25

2.15

1.85

119

95

91

88

80

95

72

68

65

58

35

Page 36

Technical data

Height 850 mm (adjustable +7 / -7 mm)

Height for building under 820 mm

Width 595 mm

Depth 580 mm

Depth with door open 1,060 mm

Weight 54 kg

Drum volume 100 litres

Maximum capacity 6 kg dry weight

Capacity of condensed

water container approx. 3.5 l

Hose length 2 m

Maximum delivery head 1 m

Maximum drain hose length 3 m

Length of connection cable 2 m

Voltage see data plate

Connected load see data plate

Fuse rating (UK) see plug

Lamp wattage see data plate

Energy consumption see "Consumption data" section

Test certificates awarded Radio / TV suppression, VDE

36

Page 37

Programmable functions

for changing

standard settings

37

Page 38

Programmable functions

Altering the residual moisture

level in the Cottons

programmes

The machine is designed to dry

effectively using as little energy as

possible.

However, if you require the laundry to

be drier, it is possible to reduce the

default residual moisture level in the

Cottons programmes.

Please note that programme

durations will be longer if this option

is activated.

Follow steps A to G to programme

and store in memory.

Before you begin, first ensure that:

– The tumble dryer is switched off.

– The door is closed.

– The programme selector is at

Finish

A Press the

pressed in whilst carrying out steps

B-C.

B Switch the dryer on with the

I-On/0-Off

C Wait until the

comes on . . .

D . . . and then release the

E Turn the programme selector to the

Cottons Normal

F Pressing the

between activating and deactivating

the drier setting.

– If the

flashing: the drier setting is

activated

– If the

flashing, the drier setting is not

activated and the residual moisture

level is on the standard default

.

setting.

Start

Drying

Drying

button and keep it

button.

Start

indicator lamp

Start

position.

Start

button switches

indicator lamp is

indicator lamp is not

button.

38

G Switch the machine off with the

I-On/0-Off

The setting you have selected is now

stored in memory. You can change it

again at any time.

To check:

^

Make sure the dryer is switched off,

the door is closed and the

programme selector is at Finish and

then carry out steps A to E.

The

Drying

if the drier setting has been selected.

^

Switch off the dryer.

The check is complete.

button.

indicator lamp will show you

Page 39

Programmable functions

Altering the residual moisture

level in the Minimum iron

programmes

The machine is designed to dry

effectively using as little energy as

possible.

However, if you require the laundry to

be drier, it is possible to reduce the

default residual moisture level in the

Minimum iron programmes.

Please note that programme

durations will be longer if this option

is activated.

Follow steps A to G to programme

and store in memory.

Before you begin, first ensure that:

– The tumble dryer is switched off.

– The door is closed.

– The programme selector is at

Finish

A Press the

pressed in whilst carrying out steps

B-C.

B Switch the dryer on with the

I-On/0-Off

C Wait until the

comes on . . .

D . . . and then release the

E Turn the programme selector to the

Start

button and keep it

button.

Start

indicator lamp

Start

Cottons Low temperature

F Pressing the

between activating and deactivating

the drier setting.

– If the

– If the

.

Drying

flashing, the drier setting is

activated

Drying

flashing, the drier setting is not

activated and the residual moisture

level is on the standard default

setting.

Start

button switches

indicator lamp is

indicator lamp is not

button.

position.

G Switch the machine off with the

I-On/0-Off

The setting you have selected is now

stored in memory. You can change it

again at any time.

To check:

^

Make sure the dryer is switched off,

the door is closed and the

programme selector is at Finish and

then carry out steps A to E.

The

Drying

if the drier setting has been selected.

^

Switch off the dryer.

The check is complete.

button.

indicator lamp will show you

39

Page 40

Programmable functions

Activating and deactivating the

buzzer

A buzzer sounds (at intervals for a

maximum of 1 hr) to let you know the

programme has finished.

The machine is delivered with the

buzzer activated but you can

deactivate it if wished.

The buzzer will still sound if there is a

fault, even if it has been deactivated.

Follow steps A to G to programme

and store in memory.

Before you begin, first ensure that:

– The tumble dryer is switched off.

– The door is closed.

– The programme selector is at

Finish

A Press the

pressed in whilst carrying out steps

B-C.

B Switch the dryer on with the

I-On/0-Off

C Wait until the

comes on . . .

D . . . and then release the

E Turn the programme selector to the

Cottons Hand iron

F Pressing the

between activating and deactivating

the buzzer.

– If the

flashing:

the buzzer is deactivated

– If the

flashing:

.

the buzzer is activated

G Switch the machine off with the

I-On/0-Off

Start

Drying

Drying

button and keep it

button.

Start

indicator lamp

Start

position.

Start

button switches

indicator lamp is not

indicator lamp is

button.

button.

40

The setting you have selected is now

stored in memory. You can change it

again at any time.

To check:

^

Make sure the dryer is switched off,

the door is closed and the

programme selector is at Finish and

then carry out steps A to E.

The

Drying

if the buzzer is activated.

^

Switch off the dryer.

The check is complete.

indicator lamp will show you

Page 41

Programmable functions

Extending the cooling down

time

The cooling down phase which takes

place before the end of a programme

can be lengthened if required. This

makes the garments easier to

handle.

The dryer is delivered with the

extended cooling down time option

deactivated. You can extend the

cooling down time by 5 minutes or 10

minutes.

The option of extending the cooling

down time is available with the

Minimum iron and Automatic

programmes.

Follow steps A to G to programme

and store in memory.

Before you begin, first ensure that:

– The tumble dryer is switched off.

–

The door is closed.

–

The programme selector is at

A Press the

pressed in whilst carrying out steps

B-C.

B Switch the dryer on with the

I-On/0-Off

Start

button and keep it

button.

Cottons,

Finish

If the

–

–

–

G Switch the machine off with the

Drying

once:

The cooling down time will be five

miinutes longer.

If the

Drying

twice:

The cooling down time will be ten

minutes longer.

If the

Drying

flashing:

The cooling down time is not

extended.

I-On/0-Off

The setting you have selected is now

stored in memory. You can change it

again at any time.

To check:

^ Make sure the dryer is switched off,

the door is closed and the

programme selector is at Finish and

then carry out steps A to E.

The

Drying

.

if the cooling down time has been

extended.

^

Switch off the dryer.

The check is complete.

indicator lamp flashes

indicator lamp flashes

indicator lamp is not

button.

indicator lamp will show you

C Wait until the

comes on . . .

D . . . and then release the

E Turn the programme selector to the

Cottons Machine iron

F Pressing the

cooling down time.

Start

indicator lamp

position.

Start

button alters the

Start

button.

41

Page 42

Programmable functions

Changing the standard drying

level in the Minimum iron Normal programme

The drying level for this programme

is set at a standard level.

You have the option of changing this

to an increased drying level.

The machine is delivered with the

drying level set at

You can change this to

than the standard drying level).

Important: the "Normal+" drying level

will work in addition to the "Altering the

residual moisture level in the

iron programmes

function, if you have already set this.

Follow steps A to G to programme

and store in memory.

Before you begin, first ensure that:

–

The tumble dryer is switched off.

–

The door is closed.

–

The programme selector is at

A Press the

pressed in whilst carrying out steps

B-C.

Normal

Normal+

" programmable

Start

button and keep it

(drier

Minimum

Finish

Start

F Pressing the

drying level.

Drying

If the

–

flashing:

the standard drying level is

Normal+

If the

–

G Switch the machine off with the

The setting you have selected is now

stored in memory. You can change it

again at any time.

To check:

^ Make sure the dryer is switched off,

The

if the Normal+ drying level has been

set.

.

^

The check is complete.

Drying

flashing, the increased drying level

is not activated and the drying level

will remain on the standard setting

(

I-On/0-Off

the door is closed and the

programme selector is at Finish and

then carry out steps A to E.

Switch off the dryer.

Drying

).

button.

indicator lamp will show you

button alters the

indicator lamp is

indicator lamp is not

B Switch the dryer on with the

I-On/0-Off

C Wait until the

comes on . . .

D . . . and then release the

E Turn the programme selector to

Minimum iron - Normal

42

button.

Start

indicator lamp

Start

.

button.

Page 43

Programmable functions

Changing the standard drying

level in the Automatic

programme

The drying level for this programme

is set at a standard level.

You have the option of changing this

to an increased drying level.

The machine is delivered with the

drying level set at

You can change this to

(damper) or

standard drying level).

Follow steps A to G to programme

and store in memory.

Before you begin, first ensure that:

– The tumble dryer is switched off.

– The door is closed.

– The programme selector is at

A Press the

pressed in whilst carrying out steps

B-C.

B Switch the dryer on with the

I-On/0-Off

C Wait until the

comes on . . .

D . . . and then release the

Normal

Hand iron

Normal+

Start

button.

(drier than the

button and keep it

Start

indicator lamp

Start

Finish

button.

Start

F Pressing the

drying level.

Drying

If the

–

twice:

the standard drying level is

Normal+

If the

–

–

G Switch the machine off with the

The setting you have selected is now

stored in memory. You can change it

again at any time.

To check:

.

^ Make sure the dryer is switched off,

The

if the drying level has been changed.

^

The check is complete.

Drying

flashing:

the standard drying level is Hand

iron

If the

Drying

once, the drying level has not been

changed and will remain on the stan

dard setting (

I-On/0-Off

the door is closed and the

programme selector is at Finish and

then carry out steps A to E.

Drying

Switch off the dryer.

button.

indicator lamp will show you

button alters the

indicator lamp flashes

indicator lamp is not

indicator lamp flashes

).

-

E Turn the programme selector to the

Automatic

position.

43

Page 44

Alteration rights reserved/0505

M.-Nr. 06 465 730 / 00

en-GB

Loading...

Loading...