Page 1

Operations Manual

for the T 1526

Vented Dryer

It is essential to read these

operating instructions before

installing or using the machine to avoid

the risk of accident, or damage

to the machine. M.-Nr. 05 017 940

]

Page 2

Contents

Contents

Guide to the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

IMPORTANT SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Your contribution to the environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Loading and unloading the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Notes on laundry care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Program selection

Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

To select a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

To change a program during drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Correct procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

After the program has finished. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Problem solving guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

After-sales service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

INSTALLATION INSTRUCTIONS

Grounding and Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installation - venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Consumption data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2

Page 3

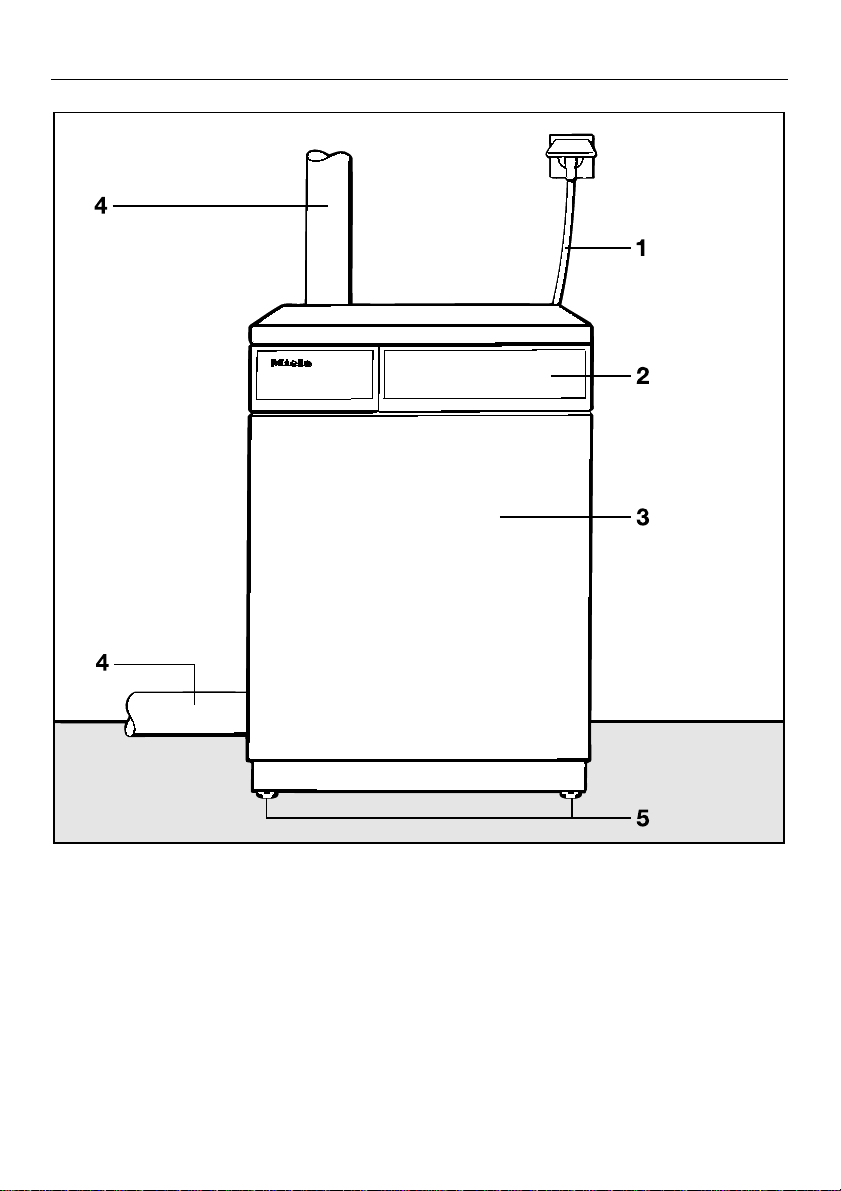

Guide to the machine

Guide to the machine

1 Supply cable with plug

2 Control panel

3 Drum door

4 Exhaust connection (left or rear)

5 Four height-adjustable legs

3

Page 4

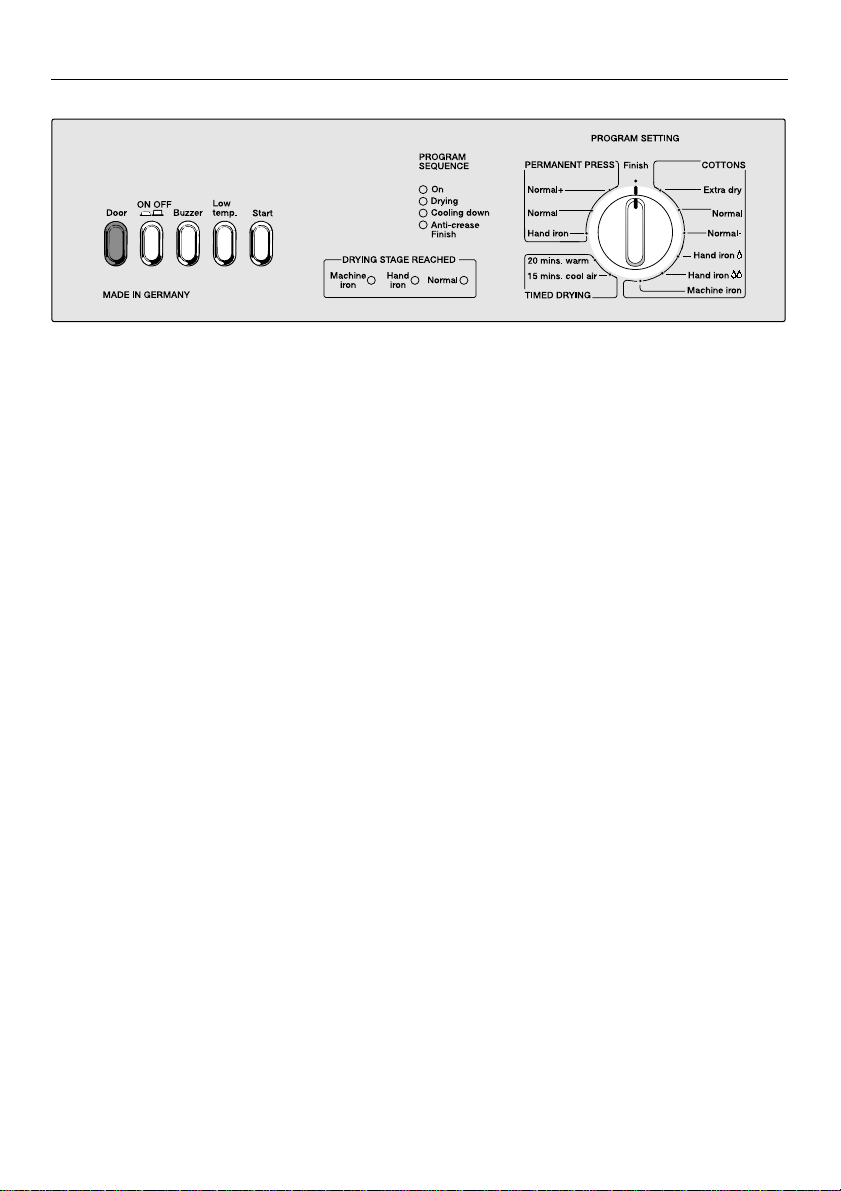

Guide to the machine

Pushbuttons

– Door

This button is used to open the door

(does not stay pushed in).

–j ON / k OFF

When the machine is turned on, the

“On” indicator will light up if the door is

closed. If the door is open, the drum

light will be on.

– Buzzer

Allows the buzzer to sound when the

drum rotates during the anti-crease

cycle.

– Low temp.

Lower drying temperatures for delicate fabrics, e.g. acrylics (symbol r).

– Start

Starts the selected program (does

not stay pushed in).

Indicator lamps

– PROGRAM SEQUENCE

The program sequence indicator

lamps show the current state of the

drying program.

– DRYING STAGE REACHED

These indicator lamps show which

drying stage the program has

reached. For program stages “Normal” and “Extra dry” the indicator

lamp remains at the “Normal” position.

PROGRAM SETTING-SELECTOR

Set the required program by turning the

knob either clockwise or counterclockwise.

– COTTONS

– PERMANENT PRESS

– TIMED DRYING

Items can be either dried for 20

minutes (incl. a cooling-down phase)

or cool air fluffed for 15 minutes.

4

Page 5

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

WARNING - To reduce the risk of fire,

electrical shock, or injury to persons

when using your appliance, follow

basic precautions, including the following:

1. Read these operating instructions before using your dryer for the first

time, as this is for your own safety

and for the protection of your machine.

2. Remember to remove the door when

disposing of an old machine to prevent children from accidently locking

themselves in the machine and endangering their lives.

3. Do not install or store this appliance

where it will be exposed to the

weather.

4. Do not install your dryer in rooms

where freezing temperatures may

occur. The reliability of the electronic

control system may be impaired.

5. This machine should only be used for

drying the following fabrics:

7. Clean the lint filter before and after

each load.

8. Do not dry articles that have been

previously cleaned in, washed in,

soaked in, or spotted with gasoline,

dry-cleaning solvents, other flammable or explosive substances as they

give off vapors that could ignite or

explode.

9. Do not allow children to play on or in

the appliance. Close supervision of

children is necessary when the appliance is used near the children.

10.To avoid back-pressure or accumulation of exhaust fumes, provide adequate room ventilation, by means of

permanent vents or an open window.

11.Always close the door after use to

prevent children from leaning on the

door and causing the dryer to tilt.

12.Keep area around the exhaust opening and adjacent surrounding areas

free from accumulation of lint, dust

and dirt.

– Items which can be machine dried

as specified by the laundry care

label.

– Items which have been washed in

water.

6. The following fabrics pose a fire hazard:

– Items which contain foam rubber,

rubber or rubberlike components.

– Items which have been treated with

inflammable cleaning agents, such

as gasoline or dry-cleaning solvents.

– Items containing hair lacquer, hair-

spray, nail polish remover or similar

substances.

5

Page 6

IMPORTANT SAFETY INSTRUCTIONS

13.The interior of the machine and exhaust duct should be cleaned periodically by qualified personnel.

14.Do not reach into the dryer if the

drum is moving.

15.Do not tamper with controls.

16.Do not repair or place any part of the

appliance or attempt any servicing

unless specifically recommended in

the user maintenance instruction or

in published user repair instructions

that you understand and have the

skills to carry out.

Repairs to electrical appliances

should only carried out by qualified

personnel.

Incorrectly repaired machines may

pose a considerable risk to the user.

17.Formation of lint.

Lint is principally the result of friction

when items are worn and washed.

Machine-drying hardly causes any

lint to form and, as has been established by reseach institutes, has no

effect on the lifetime of fabrics.

19.Do not place items exposed to cooking oils in your dryer. Items contaimed with cooking oils may contribute to a chemical reaction that could

cause a load to catch fire.

SAVE THESE INSTRUCTIONS

For grounding and electrical connection instructions, refer to the electrical connection section.

18.Warning - Do not use fabric softener/anti static dryer sheets.

Residues from these products blockup (clog) the lint filter causing premature failure of the dryer.

Miele dryers are designed to dry

laundry without static cling. However, should fabric softener be required, use liquid fabric softener in

the wash cycle.

Clean lint filter mesh monthly by washing/scrubbing with hot soap and

water.

6

Page 7

Your contribution to the environment

Your contribution to the environment

Disposal of the packing material.

The transport and protective packing is

mostly manufactured from the following

recycled or re-useable materials:

– corrugated paper/cardboard

– polystyrene - CFC-free

– polyethylene foil (transparent)

– untreated wood

– fiber board

Please check local environmental regu-

lations before disposing of packing materials and discarding the appliance.

Disposal of your old machine.

Old machines contain materials which

can be recycled. Please contact your

recycling center or scrap merchant

and render the machine inoperative as

per the “Important Safety Instructions”

before disposing of the appliance.

7

Page 8

Loading and unloading the machine

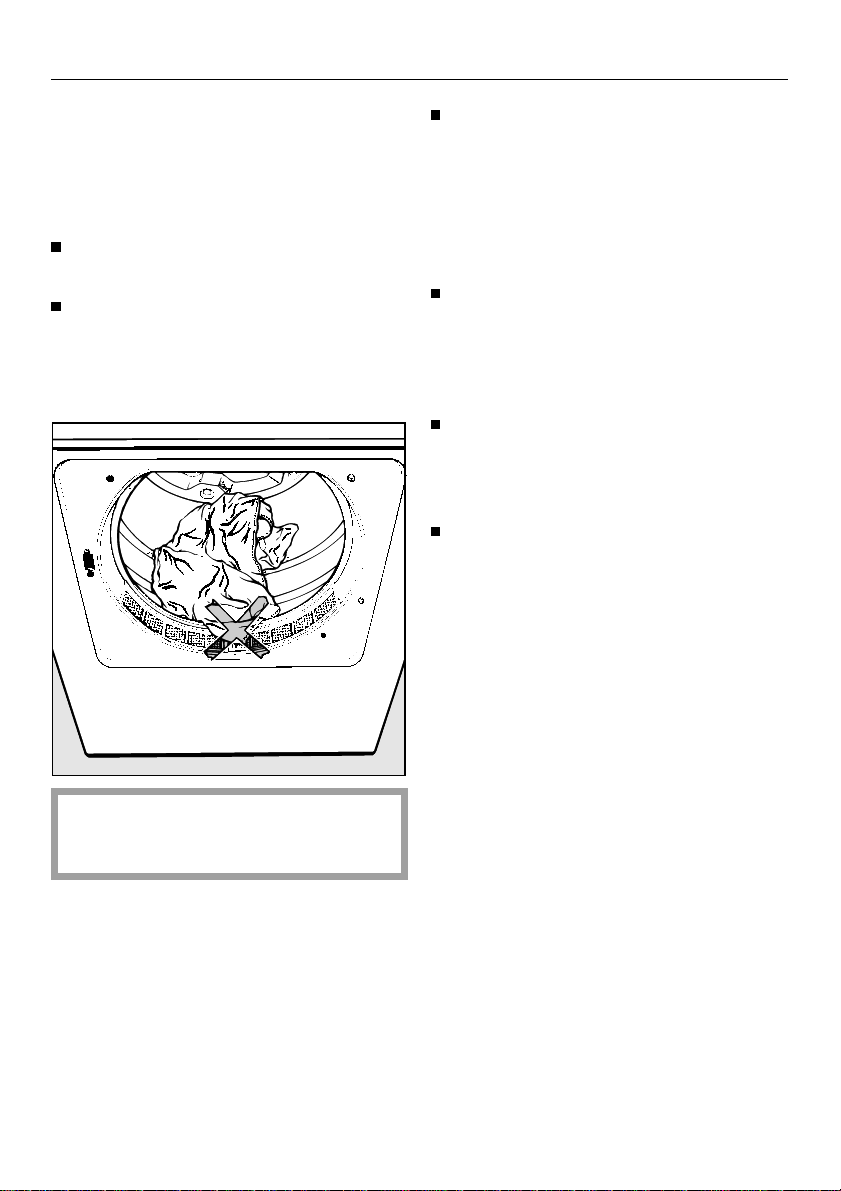

Loading and unloading the machine

WARNING - To reduce the risk of fire,

electric shock, or injury to persons,

read the IMPORTANT SAFETY INSTRUCTIONS before operating this appliance.

Load the laundry loosely into the

drum.

Duvet covers and pillowcases

should be fastened before drying in

order to prevent small items from rolling inside of them.

If the wash is not removed at the end

of the drying program, the machine

will automatically enter the anticrease cycle for 60 minutes. This entails the drum being rotated at short

intervals in order to reduce the formation of creases.

Once the laundry has been

removed, check that the drum is

empty. Any items left in the drum

could be damaged through overdrying during the next program.

Clean the lint filter after each drying

cycle to prevent excessive energy

consumption, longer program times

and the risk of fire.

The door should always be closed

after use.

Important: Check that laundry cannot be trapped by the door as this

may cause damage to the fabric.

8

Page 9

Notes on laundry care

Before drying, check the instructions

on the fabric care label.

The following fabrics should not be

dried in a tumble dryer:

– Woollens and wool blends

These fabrics tend to become matted

and shrink.

– Items filled with down

The fine fabric interior tends to shrink,

depending on the quality of the item

involved.

– Pure linen

These items should only be machinedried if specified as suitable by the

manufacturer on the textile care label.

The surface of the fabric may otherwise tend to become “rough”.

Miele dryers have been designed to

dry laundry free of static cling, without

the use of dryer softener sheets or similar products. The dryer continuously

monitors the moisture content of the

laundry, and automatically shuts off the

heat when the selected degree of dryness is reached. Through the use of a

cool down period, (where the machine

operates without heat), cool, static free

laundry is the end result. Dryer softener

sheets perform the same function by

depositing a chemical residue on both

the clothes and the interior of the dryer.

Over time, this coating may lead to performance reductions in the dryer.

Notes on laundry care

Notes:

Knitted fabrics and flannel sheets tend

to shrink when washed for the first time

and also when dried. They should not

be overdried (Extra dry)!

Starched laundry can also be dried in

the tumble dryer.

Permanent press items should be

briefly spun in the washing machine before drying. Items which are prone to

creasing should not be dried in the

“PERMANENT PRESS- Normal +” - Program.

Drip-dry shirts made of pure cotton

may tend to crease, depending on the

quality of their finish.

These items should be dried in a

“Hand iron”program.

Permanent press fabrics tend to crease

more as the size of the load increases.

This is particularly true of very delicate

fabrics. The load should be reduced to

2 kg or, if necessary, to 1.5 kg.

Do not dry new dark-colored fabrics

together with light-colored items as

they may discolor.

If fabric softening is desired, it is more

convenient, economical and beneficial to

the clothing if a liquid softener is automatically dispensed while the clothes are

in the washing machine. Please see the

washing machine operating instructions

for directions on how to automatically dispense a liquid softener.

9

Page 10

Program selection

Program selection

Functional description

An electronic sensor system monitors

the moisture content of the laundry.

Once the required degree of dryness is

reached, cold air enters the drum to

cool the laundry.

The drying program is then terminated.

Function of the pushbuttons

– Door

This button is used to open the door.

– ON/OFF

When the machine is turned on, the

“On” indicator lamp lights if the door is

closed. When the door is open, the

drum is illuminated.

– Low temp.

When selected the machines lower

drying temperatures for delicate fabrics, (e.g. acrylics, nylon).

– Start

Starts the selected program.

“PROGRAM SEQUENCE”

indicators

The program sequence indicator lamps

show the current status of the drying

program.

“DRYING STAGE REACHED”

indicators

This indicator shows which drying

stage the program has reached.

“PROGRAM SETTING” selector

There is a range of settings for both

"Cottons" and "Permanent Press".

In addition, items can be either dried

for 20 minutes (incl. a cooling-cycle

lasting 8 mins.) or fluffed in cool air for

15 minutes.

– Buzzer

When depressed, the buzzer will

sound as the drum rotates during the

anticrease cycle.

10

Page 11

Program selection

To select a program

Press the "On/Off" button.

Set the desired program by turning

the program selector either clockwise or counterclockwise.

Press the "Start" button.

The program status will be stored for

30 minutes in the event of a power

failure.

The program is canceled if:

– There is a power failure lasting more

than 30 minutes.

– The door is opened after the ma-

chine has entered the "Cooling

down" or "Anti-crease" stage.

To change a program during

drying

Set the program selector to the

desired program.

The new program will start from the beginning.

The tables on the following pages list

the range of applications for the different programs.

Correct procedure

1

Press the "On/Off" button.

2 Press the "Door" button.

3 Open the door and load the machine.

4 Close the door with a firm swing - do

not push it shut.

5 If drying delicate fabrics, press the

"Low temp." button.

6 Select the "Buzzer" if so desired.

7 Select a program.

8 Press the "Start" button.

After the program has finished

1

Set the program selector to "Finish".

2 Remove the laundry.

3 Clean the lint filter.

4 Turn off the machine.

11

Page 12

Programs

Programs

Drying stage T ype of laundry/fabric Max. load Special instructions

COTTONS

Extra dry

Normal

Normal-

Hand iron r

Hand iron rr

Machine iron

Multi-layer fabrics, mixed

loads of cotton fabrics,

e.g.jeans, towels,

sweatsuits.

Uniform loads of cotton

fabrics e.g. flannel items,

underwear, socks.

Knitted cotton fabrics

susceptible to shrinkage,

e.g. jersey wear or

lightweight cotton fabrics.

Cotton or linen fabrics, to

be left damp for easier

ironing.

Cotton or linen fabrics,

including starched laundry,

to be ironed on the rotary

iron, (B865E).

6 kg The “Extra dry” program

should not be selected for

jersey wear items or items

that may shrink.

6 kg If items are still damp,

select the “Extra dry”

program.

6 kg If items are still damp,

select the “Normal“

program.

6 kg Moisture can be increased

or decreased by using

“Hand iron rr” or “Hand

iron r” respectively.

6 kg The laundry can be loosely

rolled to prevent it from

drying out until it can be

ironed.

12

Page 13

Programs

Drying stage T ype of laundry/fabric Max. load Special instructions

PERMANENT PRESS

Normal +

Normal

Hand iron

TIMED DRYING

warm

cool air

Permanent press items

made of synthetic or

blended fabrics, e.g.

pullovers, dresses, pants,

etc., which are not dried

adequately in the “Normal”

program.

Permanent press shirts,

table cloths, bedding etc.

made of blended woven or

knitted fabrics, e.g.

cotton/synthetic.

Permanent press shirts,

table cloths, pillowcases

etc. cotton/synthetics,

which are to be pressed.

Individual items, e.g.

comforters, or very small

loads.

Items which you want to

"fluff".

3 kg With blended fabrics

consisting of wool and

synthetics, consult the

manufacturer’s instructions,

as the wool component

may cause the fabric to

matt and shrink.

3 kg

3 kg

- This cycle will run for the

full 20 minutes, even if the

clothes are dry sooner.

6 kg -

13

Page 14

Cleaning and care

Cleaning and care

Cleaning the lint filter

The lint is collected by the lint filter in

the door.

Clean the filter after every program.

Cleaning the dryer

Before cleaning the tumble dryer;

disconnect the machine from the

power supply.

Grip the filter by the recessed

handle and pull up to remove.

Any remaining lint in the hollow part

of the door can be removed through

the gap at the bottom.

The lint filter can be rinsed with water if

necessary.

Dry the lint filter before putting it

back in place.

The dryer can be cleaned using

soapy water or a mild detergent (not

scouring powder) and dried with a

soft cloth.

The drum may be cleaned using a

suitable stainless steel cleaner following the manufacturer’s instructions.

The machine must never be hosed

down. Do not use any abrasive substances or scouring pads to clean

the machine.

14

Page 15

Problem solving guide

Problem solving guide

Electrical appliances should only be repaired by qualified personnel. Incorrectly repaired machines may put the user at risk. There are, however, minor

problems which can be corrected without contacting the Service Department.

What to do if, . . . ? Cause . . . Remedy . . .

. . . the tumble dryer fails to

start when turned on?

. . . the laundry is not sufficiently dry?

. . . the drying times are too

long?

. . . the “anti-crease” indicator

lamp in the sequence indicator display starts flashing?

Check whether the “On”

indicator lights up. If so, failure

to start may be due to an

incorrect program selection

procedure.

If the “On” indicator lamp does

not illuminate, check that:

The load consists of dissimilar

items (size and fabrics).

Small loads or individual items

may cause the program to

terminate the cycle prematurely.

The lint filter is clogged. Clean the lint filter in the door.

The laundry was not spun in the

washer for a sufficient time.

Repeat the switch-on procedure

in the correct sequence, as

outlined in the “Program

Selection” chapter.

– The “ON/OFF” button is

depressed.

– The door is properly closed.

– The machine is plugged in

and the fuse or circuit breaker

has not tripped.

Select a longer drying program.

Small loads can be time-dried.

Make sure that the laundry is

thoroughly spun before drying.

– Turn the program selector

to “finish”.

– Turn the machine off and

then on again.

– Select a program.

– Press the “Start” button.

If the indicator lamp starts

flashing again, this indicates a

fault in the machine.

Please contact the Miele

Service Dept.

15

Page 16

Problem solving guide

What to do if, . . . ? Cause . . . Remedy . . .

. . . the drum door opens dur-

ing the drying cycle?

. . . the interior drum light fails

to function?

. . . you have to open the door

in the event of a power

failure?

The machine has overheated.

The temperature limiter opened

the drum door and caused the

machine to turn off

automatically.

Possible reasons for

overheating:

– The lint filter in the door is

clogged.

– The vent duct is blocked.

– The vent aperture (e.g.

louvred window vent, wall

vent) is blocked.

It only lights up when the

machine is switched on. The

bulb may be burnt out.

Before restarting the program,

proceed as follows:

– Release the ON/OFF button.

– Clean the affected part of the

machine.

– Turn on the machine again.

– Reselect the terminated

program.

– Press the “Start” button.

If the drum door opens again,

the Miele Service Dept. should

be contacted.

See next page.

See next page.

16

Page 17

Problem solving guide

The interior drum light fails to function: The bulb may be burnt out.

Replace it as follows:

Turn off the machine or disconnect

it from the power supply.

Open the door.

To open the door in the event of a

power failure

Pull forward on the un-hinged side of

the door.

Unscrew the plastic bulb cover located inside the drum and above the

door (see illustration).

The light bulb must not exceed the

maximum wattage quoted on the

data plate.

Replace the bulb and the plastic

cover.

The cover must be correctly installed

and tightened, otherwise moisture may

seep in and cause the socket to corrode.

This is a temperature-resistant bulb

and should only be ordered from your

Miele Service Dept.

17

Page 18

After-sales service

After-sales service

In the event of problems which cannot

be solved, please contact:

– Your Miele Dealer

– The nearest Miele Service Depart-

ment (see back cover for the adress).

When contacting the Service Department, please quote the Model and Serial numbers of your appliance, both of

which can be found on the right side

after the door is opened.

Specimen:

18

Page 19

INSTALLA TION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

Grounding and Electrical connection

Grounding instructions

This appliance must be grounded.

In the event of a malfunction, grounding will reduce the risk of electric shock

by providing a path of least resistance

for the electric current. This appliance

is equipped with a cord having an

equipment grounding conductor and a

grounding plug. The plug must be

plugged into an appropriate outlet that

is properly installed and grounded in

accordance with all local codes and ordinances.

Warning

Improper connection of the equipment-grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or

serviceman if you are in doubt as to

whether the appliance is properly

grounded.

Do not modify the plug provided

with the appliance; if it will not fit the

outlet, have a proper outlet installed

by a qualified electrician.

Electrical connection

This installation should be done by an

experienced and qualified person, in

most cases a licensed electrician, in accordance with local codes and regulations.

This dryer is supplied with a 1.5 m power

cord with a 3-pole, 4 wire grounding plug,

14-30P (regular Canadian dryer plug).

This plug has to be plugged into a 3-pole,

4 wire grounding receptacle, 14-30R

(regular Canadian dryer receptacle).

The receptacle has to be connected to

Line 1, Line 2, Neutral and Ground wires.

The voltage is 120/240 V AC or 120/208 V AC.

“EASY INST ALLA TION KIT”

If you do not have a designated line,

4 wire, 120/240 V – 15 or 30 Amps, for

this appliance, but you have the 4 wire,

120/(208)240 V – 30 Amp Canadian

dryer wall receptacle (14-30 R) you can

use the Miele Double Receptacle Box.

This consists of two standard receptacles 14-30 R, 4 fuses, box and plug

cord, which allows you to use that

single dryer wall receptacle to supply

power to a Miele washer and Miele

dryer. Both machines may operate at

the same time because each uses

maximum about 15 A current.

For more information on the electrical

connection on the Miele Double Receptacle Box please contact:

– your Miele dealer

– the nearest Miele Service Depart-

ment.

19

Page 20

INST ALLATION INSTRUCTIONS

Installation

The machine should be level to ensure

safe and proper operation. Minor discrepancies do not, however, have an

adverse effect on operation.

Turn the counternuts up and tighten

against the bottom.

A gap of 10 mm must be maintained between the bottom of machine and the floor. This gap must

not be blocked by deep pile carpet,

plinths etc., as this will prevent a sufficient intake of cold air.

Where to install the machine

The space required by the vent

duct should be taken into consideration when calculating the distance

between the machine and a wall or

other appliances.

The tumble dryer can also be placed

on top of a Miele washing machine (capacity 6 kg) for a stacked installation.

The machine can be leveled by turning the legs clockwise or counterclockwise as necessary.

20

An appropriate stacking kit is required

and can be obtained from your Miele

dealer, or the Miele Parts Dept.

Page 21

INSTALLA TION INSTRUCTIONS

Exhaust venting

The moist air from the dryer must be

vented to the outside.

The appliance should not be vented

into a chimney, a wall, a ceiling, or

any concealed spaces of the building.

When installing, try to avoid:

– very long venting systems

– too many bends or angles

– tight corners

otherwise . . .

. . . the drying results will be affected,

. . . drying will take longer and use more

energy.

Materials suitable for venting:

– rigid metal pipe

– flexible metal pipe

Install the venting in such a way that

the expelled air cannot be drawn

back into the machine.

Installing the connector on the left

side of the machine

Remove the cap covering the exhaust part as follows:

– Insert a thin screwdriver into the slot

by the retaining hook. Press the hook

gently upwards.

At the same time turn the cap

counterclockwise.

Do not vent the dryer into a flue

used by gas or fuel boilers or

heaters.

A vent connector is included with the

machine. It should be pressed into the

vent outlet and will simplify the connection of the exhaust pipe.

Before installation, disconnect the

tumble dryer from the electrical supply (unplug from the wall socket, or

turn off the circuit breaker.

Installation at the rear

The machine comes supplied with

the connector installed on the rear

exhaust port.

In the same way remove the vent

socket from the rear exhaust port.

Secure into the side port by pressing

it in and turning it clockwise.

Seal the rear exhaust port using the

cap.

21

Page 22

INST ALLATION INSTRUCTIONS

The shorter the exhaust ductwork, the

more efficient the dryer will be. Expelled air is slowed down in the ducts

due to friction against the inner walls,

therefore the shorter and smoother the

inner walls are, the less friction will

occur.

An elbow or bend creates more friction

than a straight duct. An additional duct

length factor must therefore be added

for each elbow or bend (see Table I).

This factor expresses the resistance of

the bend in terms of a straight length of

duct.

The additional length factor is then

added to the measured duct length to

give the effective duct length.

A larger duct diameter also helps to reduce friction. The duct diameter should

therefore be increased with increasing

duct length.

To calculate the effective duct length.

Measure the actual duct length.

Establish the number of elbows or

bends necessary, noting the type of

bend, angle and radius involved

(see Table I).

Add the additional length factor as

specified in Table I to the actual duct

length to give the effective duct

length.

The necessary duct diameter should

then be found in Table II.

Note:

Drying times and energy consumption

remain unaltered for 100 mm duct up to

a total length of 8 m.

Longer duct may lead to slight increases in drying times and energy

consumption but will not impair the

function of the machine as long as the

necessary duct diameter is used (see

Table II) .

Tabel I

T ype of bend Angle Radius in mm Additional duct

Flexible metal piping 90°

90°

45°

Plain piping 90° 100 0.35

Elbow 2.3

Concertina bend 90° 200 0.7

Wall vent kit with louvres, or window vent kit

Wall vent kit with flap, or window vent kit

Exhaust connection, left side 4,9

22

100-300

300-500

100-500

length in m

0.5

0.3

0.3

3.6

1.25

Page 23

INSTALLA TION INSTRUCTIONS

Table II

Effective duct

length (m)

0-8

8-12

12-17

17-23

23-31

31-41

Internal diameter or

edge length (mm)

100

110

120

130

140

150

Flexible ducting has been used for the

following example.

Example:

Exhaust connection, left . . . . . . . 4.9 m

Length (L) . . . . . . . . . . . . . . . . . . 1.2 m

Lower radius (R = 400 mm) . . . . 0.5 m

Height (H) . . . . . . . . . . . . . . . . . . 1.2 m

Upper radius (R) . . . . . . . . . . . . . 0.5 m

Wall pipe with louvred vent . . . . . 3.6 m

Effective duct length . . . . . . . . .

Result:

A duct diameter of 110 mm is adequate since the effective length is less

than 12 m as specified in Table II.

11.9 m

23

Page 24

INST ALLATION INSTRUCTIONS

Moist air can be ducted outside by a wall

vent or window vent, both of which are

available from most hardware stores.

Wall vent kit - example

1. Louvred wall vent frame

2. Wall vent duct

3. Adapter

4. Louvred wall vent

5. Flap

6. Screw

7. Wall anchor

Dryer-top view:

1. Wall pipe

2. Flexible foam-gasket

Window vent kit - example

1. Louvred window vent frame

4. Louvred window vent

5. Flap

8. Clips (4 pcs.)

9. Raised head screws (4 pcs.)

Dryer-side view:

1. Window vent kit

2. Adapter for vent duct

A flexible foam gasket must be used if the

tumble dryer is directly connected to the wall

vent.

24

The window vent kit is installed into in a plexiglass pane. If using an existing glass pane, cut a

hole with a diameter of 125 mm.

Page 25

INSTALLA TION INSTRUCTIONS

Fig. 1

Ducting (side view) with flexible vent hose to an

exhaust flue.

1. Wall vent duct A. Wire spiral-wound hose

2. Adapter B. Flexible ducting

3. Flue isulated against damp

Fig. 2

Ducting (side view) with plastic piping to a wall

vent kit.

Fig. 3

Connection of piping to the tumble dryer.

1. Drain pipe

2. Adapter for vent duct between tumble dryer

and plastic drain pipe

Fig.4

Height of vent outlet for washer dryer stack.

1. Wall vent kit

2. Adapter

3. Drain pipe (outer dia. 110 mm)

25

Page 26

Technical data

Technical data

Height. . . . . . . . . . . . . . . . . . . . . . . . . .

85 cm (adjustable +1/-0.5 cm)

Width . . . . . . . . . . . . . . . . . . . . . . . . . .

Depth (incl. distance from wall) . . . . . .

Weight . . . . . . . . . . . . . . . . . . . . . . . . .

Drum volume . . . . . . . . . . . . . . . . . . . .

Capacity. . . . . . . . . . . . . . . . . . . . . . . .

Rated load . . . . . . . . . . . . . . . . . . . . . .

Fuse rating . . . . . . . . . . . . . . . . . . . . . .

59.5 cm

70 cm

57 kg

126 l

6 kg dry laundry

See Data Plate

See Data Plate

26

Page 27

Consumption data

loadkgFinal spin speed in washer*

Cottons

rpm

Consumption data

Electrical

consumption

kwh

Drying time

incl.

cooling down

time

mins

Extra dry

Normal

Normal-

Hand iron rr

Machine iron

Permanent Press

Normal +

Normal

Hand iron

6 1200

1400

1600

6 1200

1400

1600

6 800 (70 % residual moisture)

1200

1400

1600

6 800 (70 % residual moisture)

1200

1400

1600

6 1200

1400

1600

3 1000 1.49 44

3 1000 (50 % residual moisture) 1.40 41

3 1000 1.20 37

3.65

3.50

3.20

3.15

3.00

2.70

3.85

3.00

2.85

2.55

3.10

2.25

2.10

1.80

1.80

1.65

1.35

92

89

81

82

79

71

98

79

75

68

82

63

59

52

52

48

41

The specified program running times and electrical consumption values were established under standard conditions (EN 61121/A11).

Different types of fabrics, load size and residual moisture after spinning may effect the specified

values.

*These values apply if the laundry is spun in a Miele washing machine before drying.

27

Page 28

All rights reserved/001 3498

This paper is made from 100% chlorine-free bleached cellulose and therefore protects the environment.

Loading...

Loading...