Installation Plan

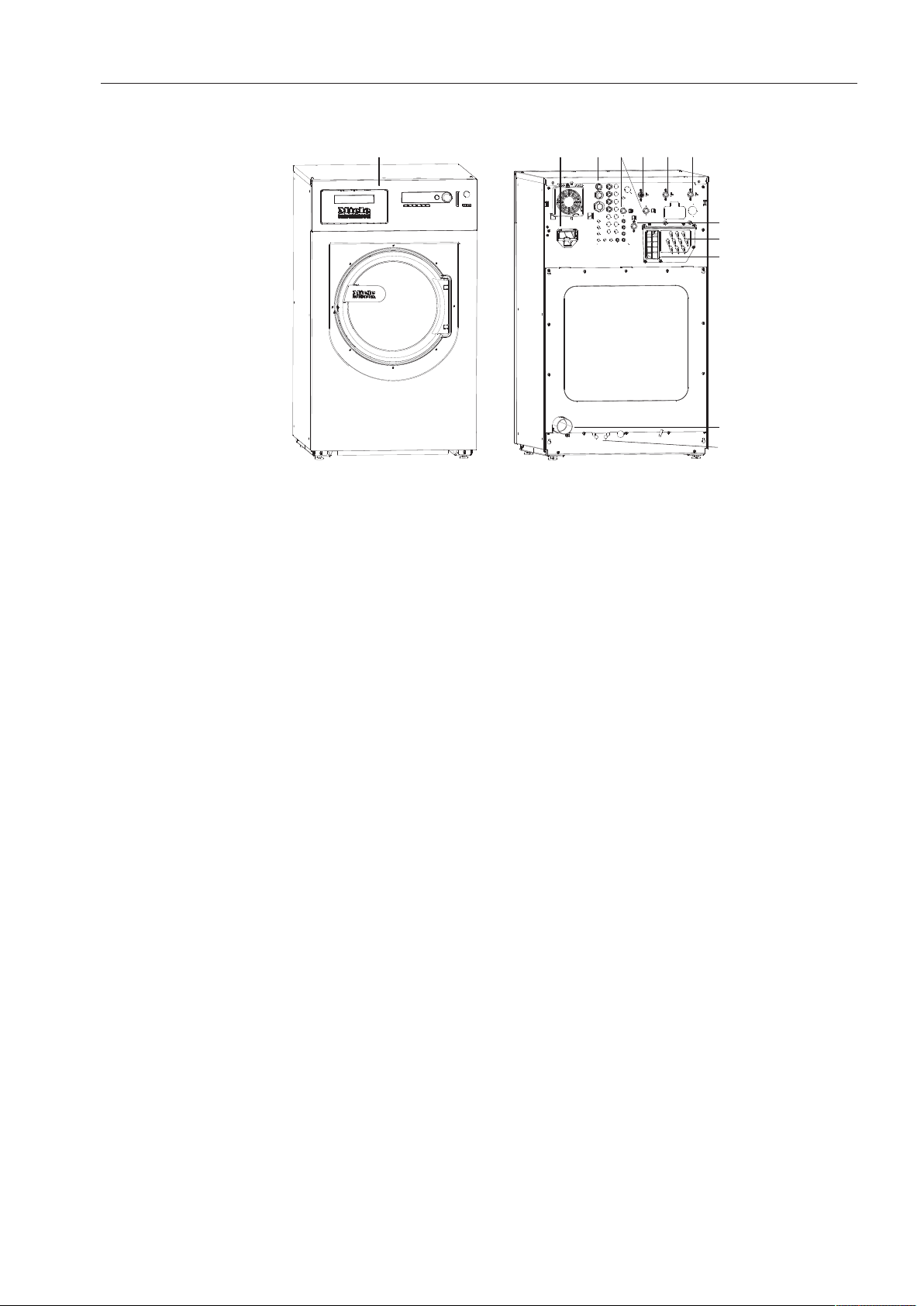

Washing Machine

PW 811

PW 814

PW 818

To prevent accidents and machine damage, read

these instructions before installation or use.

en-US

M.-Nr. 10 668 670

Contents

Installation and planning notes..........................................................................................4

Installation requirements ....................................................................................................... 4

Storage/Transportation.......................................................................................................... 4

General operating conditions ................................................................................................ 4

Installation ............................................................................................................................. 5

Installation on concrete base ........................................................................................... 5

Leveling the machine............................................................................................................. 6

Securing the machine............................................................................................................ 6

Installation of steam-heated washing machines ................................................................... 7

Steam connection valve ................................................................................................... 7

Condensate trap............................................................................................................... 7

Heater bank information................................................................................................... 8

Fitting information for steam and condensate hoses....................................................... 8

Machine connections ............................................................................................................ 9

Electrical connection ........................................................................................................... 10

Water connection ................................................................................................................ 12

Cold water connection ................................................................................................... 12

Hot water connection ..................................................................................................... 12

Drain valve...................................................................................................................... 12

Dispenser pump connections ............................................................................................. 14

Optional accessories........................................................................................................... 15

XKM RS232 communication module ............................................................................. 15

Base ............................................................................................................................... 15

Weighing base................................................................................................................ 15

Suds drain and vapor vent (BWS) .................................................................................. 15

Technical drawings - dimensions in inches ....................................................................16

PW811................................................................................................................................ 16

Dimensions..................................................................................................................... 16

Dimensions with Mielebase (UG/UO)/weighting base (WI) ........................................... 17

Installation ...................................................................................................................... 18

PW814................................................................................................................................ 19

Dimensions..................................................................................................................... 19

Dimensions with Mielebase (UG/UO)/weighting base (WI) ........................................... 20

Installation ...................................................................................................................... 21

PW818................................................................................................................................ 22

Dimensions..................................................................................................................... 22

Dimensions with Mielebase (UG/UO)/weighting base (WI) ........................................... 23

Installation ...................................................................................................................... 24

Anchoring PW811/814/818 ................................................................................................ 25

Attaching to the floor/concrete base.............................................................................. 25

Attaching to the floor/concrete base when installing in a run........................................ 25

Attaching to the floor with Mielebase............................................................................ 26

Technical drawings - dimension in millimeters ..............................................................27

PW811................................................................................................................................ 27

Dimensions..................................................................................................................... 27

Dimensions with Mielebase (UG/UO)/weighting base (WI) ........................................... 28

Installation ...................................................................................................................... 29

2

Contents

PW814................................................................................................................................ 30

Dimensions..................................................................................................................... 30

Dimensions with Mielebase (UG/UO)/weighting base (WI) ........................................... 31

Installation ...................................................................................................................... 32

PW818................................................................................................................................ 33

Dimensions..................................................................................................................... 33

Dimensions with Mielebase (UG/UO)/weighting base (WI) ........................................... 34

Installation ...................................................................................................................... 35

Anchoring PW811/814/818 ................................................................................................ 36

Attaching to the floor/concrete base.............................................................................. 36

Attaching to the floor/concrete base when installing in a run........................................ 36

Attaching to the floor with Miele base............................................................................ 37

Technical data....................................................................................................................38

Water connection ................................................................................................................ 38

Models with detergent dispenser drawer (WEK)............................................................ 38

Drain valve...................................................................................................................... 38

Optional steam valves for steam-heated models................................................................ 38

Electric steam valve (ELD01)......................................................................................... 38

Pneumatic steam valve (PND) ........................................................................................ 38

Connection for equipotential bonding................................................................................. 38

Anchoring ............................................................................................................................ 39

Attaching to the floor...................................................................................................... 39

Attaching to the floor with Miele base............................................................................ 39

Attaching to a concrete base (provided on-site) ............................................................ 39

PW811................................................................................................................................ 40

Electrical version and electrical data.............................................................................. 40

Installation dimensions................................................................................................... 40

Transport data, weight and floor load ............................................................................ 41

Emissions data ............................................................................................................... 41

PW814................................................................................................................................ 42

Electrical version and electrical data.............................................................................. 42

Installation dimensions................................................................................................... 43

Transport data, weight and floor load ............................................................................ 43

Emissions data ............................................................................................................... 43

PW818................................................................................................................................ 44

Electrical version and electrical data.............................................................................. 44

Installation dimensions................................................................................................... 45

Transport data, weight and floor load ............................................................................ 45

Emissions data ............................................................................................................... 45

3

Installation and planning notes

Installation requirements

The washing machine must be installed by Miele Service or by

properly trained staff of an authorized dealer.

This washing machine must be installed in accordance with all rel-

evant regulations and standards. Local energy supplier regulations

must also be observed.

This washing machine must only be operated in a room that has

sufficient ventilation and which is frost-free.

The washing machine should not be installed or operated in any

area where there is a risk of explosion.

Storage/Transportation

The following conditions must be observed for transport and storage

of the machine:

– Ambient temperature: 32-105°F (0-40°C)

– Humidity: non-condensing

General operating conditions

This washing machine is intended only for use in an industrial environment and must only be operated indoors.

– Ambient temperature of location: 32-105°F (0-40°C)

– Relative humidity: non-condensing

– Maximum height above sea level of location site: 6500 ft (2000 m)

Depending on the nature of the installation site, sound emissions and

vibration may occur.

Tip: Have the installation site inspected and seek the advice of a professional in instances where increased noise may cause a nuisance.

4 PW 811 / PW 814 / PW 818

Installation and planning notes

Installation

This washing machine must be transported to its installation site using a suitable pallet jack. Remove the transport packaging.

The washing machine must be set up on a level and firm surface with

the minimum stated load bearing capacity (see "Technical data").

The floor load created by the washing machine is concentrated and

transferred to the installation footprint via the machine feet.

Tip: A concrete floor is the most suitable installation surface for this

machine, being far less prone to vibration during the spin cycle than

wooden floorboards or a carpeted surface.

The washing machine requires a gap of at least 2" (50mm) on each

side to allow for movement during operation. To ensure suitable access for further maintenance and service work, please ensure a minimum distance of 16" (400mm) is maintained between the back of the

machine and the wall.

Installation on concrete base

The washing machine can be installed on a concrete base if desired.

The concrete materials and the durability of the concrete base must

be assessed in accordance with the floor load bearing capacity

given in "Technical data".

To guarantee the stability of the washing machine, make sure that

the concrete base is sufficiently stable on the floor and that it is capable of withstanding any burden or force from the washing machine.

The washing machine must be secured to the concrete base using

the fixtures and fastenings supplied.

The washing machine must be secured to the base immediately

after installation!

There is a risk of the washing machine falling off a raised base during a spin cycle if it is not secured.

PW 811 / PW 814 / PW 818 5

Installation and planning notes

Leveling the machine

Align the washing machine vertically and horizontally using the ad-

justable feet and a spirit level.

The washing machine must stand perfectly level on all four feet to

ensure safe and proper operation. Otherwise water and energy consumption will be increased and the machine could move.

After aligning the machine tighten the lock nuts by turning them in a

counterclockwise direction with a wrench. This will prevent the feet

from moving.

Securing the machine

The feet of the washing machine must be secured to the concrete

base using the fixtures and fastenings supplied.

Fittings supplied are for installation on a concrete floor. For other

types of flooring please purchase suitable fitting materials separately.

6 PW 811 / PW 814 / PW 818

Installation and planning notes

Installation of steam-heated washing machines

The steam connection must only be carried out by a registered

installer. During connection please observe the installation instructions, the data plate on the washing machine, the wiring diagram,

the installation diagram and the documentation supplied.

Steam-heated washing machines must in all cases be secured to

the floor!

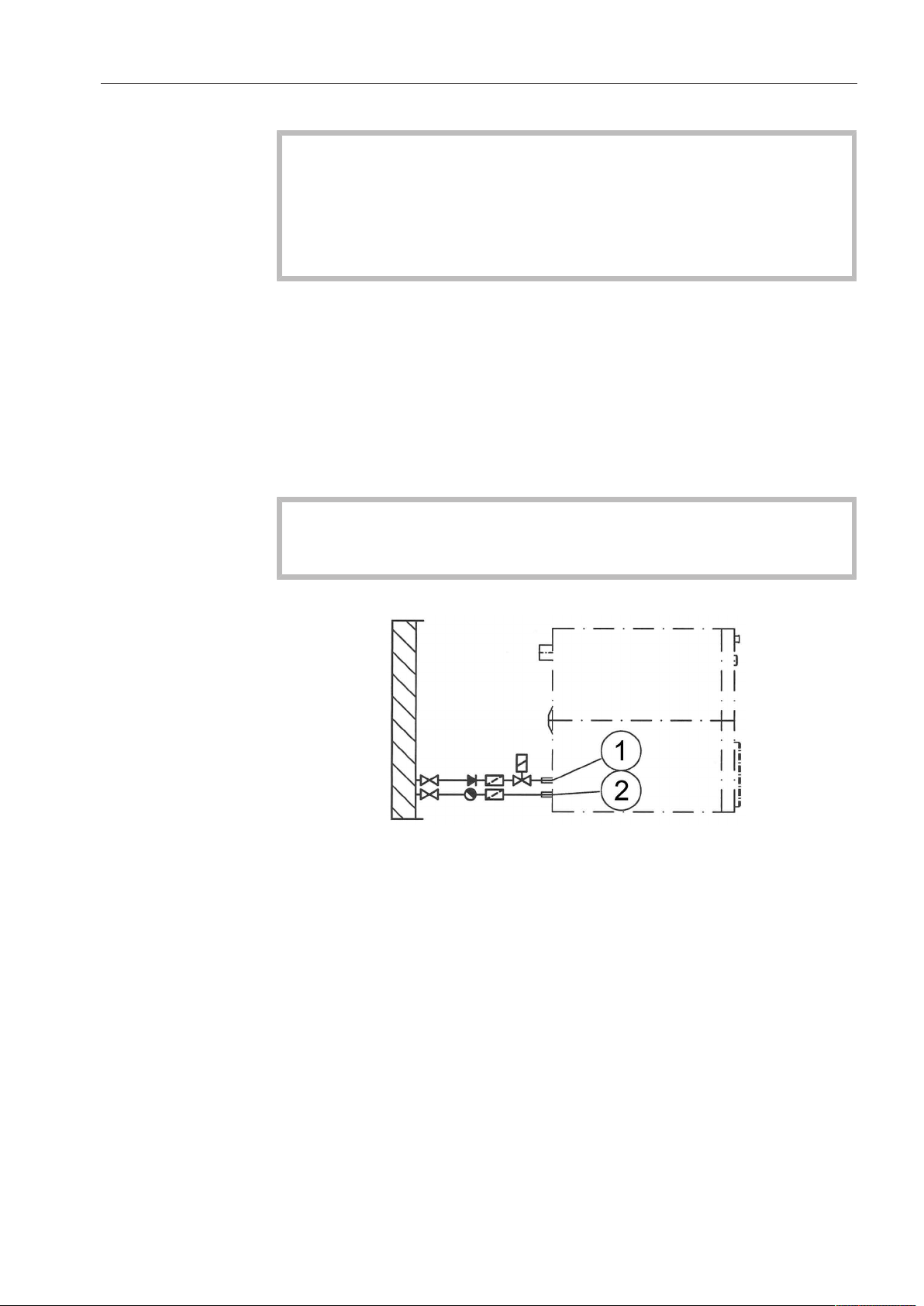

Steam connection valve

Condensate trap

Before connecting a steam-heated machine, ensure that the steam

inlet valve, the dirt filter and the steam shut-off valve have been correctly installed on site.

Steam valves are available from Miele service.

With steam-heated washing machines a condensate trap is required

for the condensate drain. The condensate trap ensures that condensate is completely drained away from the washing machine heater

bank.

The condensate trap must be installed in such a way that condensate cannot get back into the heater bank when the machine is not

in operation.

Tip: Use a bell condensate trap for the condensate drain.

a

Steam valve

PW 811 / PW 814 / PW 818 7

b

Condensate trap

Installation and planning notes

Heater bank information

Fitting information for steam and

condensate hoses

To avoid damage to the heater bank the following must be observed

during commissioning:

– In order to avoid unnecessary heat variations, ensure that heating is

even. Do not allow sudden bursts of steam.

– To prevent corrosion, preparation of the water supply is absolutely

essential. In particular, when the machine is not in operation, it

must be ensured that no air or CO2 can enter the steam system.

– Protect the heater bank from aggressive gases.

– The entire heating system must guarantee that no operating pres-

sure or temperature can arise that is higher than the details given

on the data plate.

– All appropriate regulations, standards and legislation from responsi-

ble authorities and accident prevention associations for heating and

ventilation systems (in particular for the operation of the heat exchanger) must be observed.

Make sure that steam and condensate hoses are not twisted or compressed. Do not use the hoses to compensate for connection tube

misalignments!

8 PW 811 / PW 814 / PW 818

⑥

①

②

③

④

⑤

⑦

⑧

⑨

⑩

⑪

⑫

Installation and planning notes

Machine connections

a

Detergent dispenser (WEK)

b

Communication module slot

The XKMRS232 communication module is available as an optional

accessory.

c

Electrical connection

d

2x hard water connection

(Optional)

e

Cold water connection

f

Hot water connection

Water temperature to maximum 158°F (70°C)

g

Cold water connection

h

Cold water connection for liquid dispensing

(Optional)

i

Connections for external dispenser pumps

For up to 12 dispenser pumps.

j

Vapor extraction/free outlet TypeAB

k

Drain pipe

Connection for plastic pipe NPS2 ¾" (HTDN70).

l

Connection option for direct/indirect steam

(Depending on model)

PW 811 / PW 814 / PW 818 9

Installation and planning notes

Electrical connection

The electrical connection must only be carried out by a qualified

electrician who must ensure that all electrical work is carried out in

accordance with applicable electrical regulations and standards.

The washing machine must be connected to an electrical supply

that complies with local and national regulations. Please also observe

your insurance and energy supplier's regulations as well as any health

and safety at work regulations.

The required voltage, power consumption and specifications for

external fusing are quoted on the data plate on the washing machine.

Ensure that the supply voltage complies with the voltage quoted on

the data plate before connecting the washing machine to the power

supply.

Connection to a supply voltage other than the one quoted on the

data plate can lead to functional faults and damage the washing

machine.

If more than one voltage is quoted on the data plate, the washing

machine can be converted for connection to the voltages stated.

Conversion to a different voltage must only be carried out by a

Miele Service engineer or by an authorized Service Dealer. The wiring

instructions given on the wiring diagram must be followed.

The washing machine can either be hard-wired or connected via a

plug and socket that complies with national codes and regulations.

For a hard-wired connection an all-pole isolation device must be installed on site.

For hard-wired machines connection should be made via a suitable

switch with all-pole isolation which, when in the off position, ensures

a 1/8" (3 mm) gap between all open contacts. These include circuit

breakers, fuses and relays.

If the power supply cannot be permanently disconnected, the isolator

switch (including plug and socket) must be safeguarded against being switched on either unintentionally or without authorization.

Tip: We recommend connection to the power supply via a suitable

plug and socket which must be easily accessible for servicing and

maintenance work after the machine has been installed.

10 PW 811 / PW 814 / PW 818

Installation and planning notes

If it is necessary to install a residual current device (RCD) in accor-

dance with local regulations, a residual current device typeB (sensitive to universal current) must be used.

An existing typeA residual current device, (RCD) must be exchanged

for a typeB RCD.

If necessary, equipotential bonding with good galvanic contact

must be guaranteed in compliance with all applicable local and national installation specifications.

Equipotential bonding must have an earth current rating >10mA.

Accessories for equipotential bonding are not supplied and need to

be ordered separately.

PW 811 / PW 814 / PW 818 11

Installation and planning notes

Water connection

The washing machine complies with current local and national

safety regulations protecting the drinking water supply and can

therefore be connected to the drinking water supply without a nonreturn valve.

The machine is designed to operate with a supply pressure of between 14.5psi (1bar) and must not exceed 145psi (10bar). If it is

highter than 145psi (10bar) a pressure reducing valve must be used.

The machine must be connected to the water supply using the inlet

hoses provided.

The connection points are subject to water supply pressure.

Turn on the faucet slowly and check for leaks.

Correct the position of the seal and union if necessary.

Cold water connection

Hot water connection

A supply faucet with ¾" threaded union is required for each connection to the water supply (single or double). If this is not present, the

washing machine should be connected to the water supply by a qualified plumber.

The inlet hose for cold water (blue stripes) is not intended to be

used with a hot water supply line.

To minimize energy consumption during operation with hot water,

the washing machine should be connected to a hot water ring circuit.

So-called "transmission lines" (single lines to hot water generators)

can result in cooling down of the water remaining in the pipes if not

in constant use. More energy would then be consumed to heat the

water up again.

Use the inlet hose supplied (red stripes) for the hot water connection.

The temperature of the water intake must not exceed 158°F (70°C).

If there is no hot water supply at the installation location for the washing machine, the connection hose must nevertheless be connected to

the cold water supply. A Y-piece is required in this case. The cold water consumption increases accordingly to account for the missing hot

water intake.

For functional and technical reasons it is not possible to operate

the machine exclusively with a hot water connection (without a

separate cold water intake).

Even if a hot water connection is present, the washing machine

must be connected to a cold water intake.

12 PW 811 / PW 814 / PW 818

Installation and planning notes

Drain valve

A motorized dump valve is used to drain the machine. A 2¾" angle

connector can be used for draining the machine directly into the

waste water system (without a siphon) or into an on-site gully (with

odor trap). The dump valve can also be operated manually to allow

the suds container to be emptied in the event of a power outage.

A vented drainage system is vital for unimpeded drainage.

If several machines are connected to a single drain pipe, it should

be large enough to allow all machines to drain simultaneously.

The appropriate Mieleinstallation set M.-No.:05238090 is avail-

able from Miele for venting a 2¾"(DN70) pipe.

If the slope for drainage is extremely steep, the piping must be

vented so prevent formation of a vacuum in the machine's drain

system.

Slow or obstructed drainage or a backup of water in the drum as a result of undersized pipework can result in faults occurring during programs, which will result in error messages appearing in the display.

Outflowing suds can be as hot as 203°F (95°C). Danger of injury

by burning!

Avoid direct contact.

PW 811 / PW 814 / PW 818 13

Installation and planning notes

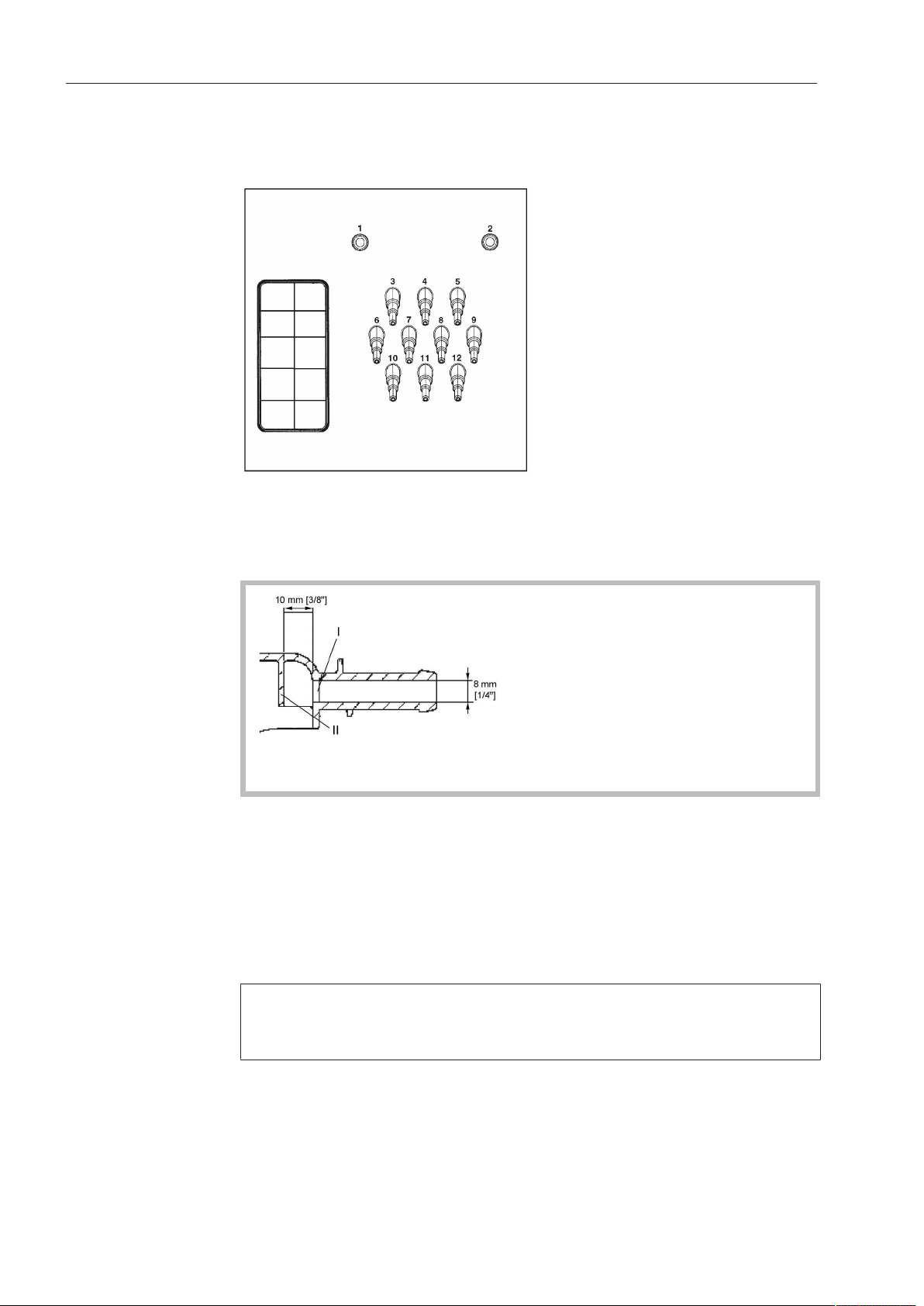

Dispenser pump connections

Up to 12dispenser pumps can be connected to the washing machine.

Dispenser pump connections on the back of the machine

Connections1 and 2 are for viscous agents. These connectors are

sealed and need to be drilled out before connection with a

5/16" (8mm) drill bit.

Make sure that you only drill through the first panel(I) as there is a

deflecting panel(II) 3/8"(10mm) behind it.

Connections 3 to12 are for liquid dispensing. These connections are

sealed and must be cut to the diameter of the hose with a small saw.

If opened connections are no longer required, they must be resealed

using a suitable sealant (e.g. silicone).

Connection terminals for five time-controlled dispenser pumps, which

can be operated without a multifunction module, are located behind

the cover adjacent to the electrical connection.

Calibration of the dispenser pumps and regulation of dispensing

quantities is carried out automatically for washing machines fitted

with a multifunction module.

A flowmeter or throughput sensors can be connected for precise

monitoring of the dispensing quantity.

Connections for level monitoring are available for every agent dispensed.

14 PW 811 / PW 814 / PW 818

Installation and planning notes

Optional accessories

Only use genuine Miele spare parts and accessories with this machine.

Using spare parts or accessories from other manufacturers will

void the warranty, and Miele cannot accept liability.

XKM RS232 communication module

Base

The serial interface RS-232 can be retrofitted to the washing machine

via an XKMRS232 (optional accessory available from Miele). This

communication module must only be used with MieleProfessionalmachines that are fitted with an appropriate slot for the module.

The data interface provided via communication module

XKMRS232 complies with SELV (Safety Extra Low Voltage) in accordance with EN60950.

Machines connected to this interface must also be SELV compliant.

Communication module XKMRS232 is supplied with a connection

cable and a D-sub-connector.

The machine can be installed on a machine base (open or box base,

available as an optional Miele accessory).

Elevating the washing machine gives a better ergonomic working

position when loading or unloading. It also simplifies the installation

of a waste water connection.

When installed on a raised base, the machine must be secured

to the base and the base must be secured to the floor.

There is a risk of the washing machine falling off a raised base during a spin cycle if it is not secured.

Weighing base

Suds drain and vapor vent (BWS)

The washing machine is optionally available with a weighing base. In

this version, the actual weight of the laundry load is displayed during

loading along with the maximum laundry load weight for the unit.

Make sure that the washing machine is not in contact with objects

or people located nearby or leaning against it. They could be

weighed as well and falsify the load weight shown on the display.

If excessive suds form, suds may escape from the vapor vent. To

drain the suds, an optional vapor vent kit (BWS) can be installed.

PW 811 / PW 814 / PW 818 15

Technical drawings - dimensions in inches

16.3"

20.9"

29.1"

53.2"

53.2"

31.5"

31.4"

37"

1"

31.5"

31.4"

3.4"

31.4"

6.5"

32.6"

3.5"

32.6"

19.4"

53.2"

18.6"

21"

0.9"

PW811

Dimensions

Dimensions in inches

16 PW 811 / PW 814 / PW 818

Technical drawings - dimensions in inches

31.5"

32.3"

16.3"

31.4"

32.6"

19.4"

32.6"

3.5"

37"

1"

31.5"

31.4"

21"

30"

64.6"

64.6"

64.7"

40.5"

Dimensions with Mielebase (UG/UO)/weighting base (WI)

Dimensions in inches

PW 811 / PW 814 / PW 818 17

Technical drawings - dimensions in inches

≥ 50.4"

23"

33.3"

5.9"

≥ 50.4"

27.4"

3.6"

27.4"

13.7"

≥ 15.8"

≥ 15.8"

Installation

Dimensions in inches

18 PW 811 / PW 814 / PW 818

PW814

16.3"

36.4"

22.3"

36.3"

30.4"

57.1"

57.2"

57.1"

29.8"

29.8"

2.7"

19.4"

21"

20"

0.9"

33.5"

1"

4.4"

7.1"

36.4"

36.3"

Dimensions

Technical drawings - dimensions in inches

Dimensions in inches

PW 811 / PW 814 / PW 818 19

Technical drawings - dimensions in inches

36.4"

32.3"

16.3"

36.3"

40.5"

67.2"

67.3"

29.8"

29.8"

2.7"

19.4"

67.2"

30

21"

36.3"

36.4"

33.5"

1"

Dimensions with Mielebase (UG/UO)/weighting base (WI)

Dimensions in inches

20 PW 811 / PW 814 / PW 818

Installation

38.2"

16.2"

32.4"

24.7"

≥ 45.7"

≥ 45.7"

20.2"

5.8"

3.3"

≥ 15.8"

≥ 15.8"

Technical drawings - dimensions in inches

Dimensions in inches

PW 811 / PW 814 / PW 818 21

Technical drawings - dimensions in inches

36.4"

36.3"

33.8" 19.4"

33.8"2.6"

37.4"

1"

16.3"

22.3"

30.4"

57.1"

57.2"

57.1"

21"

20"

0.9"

36.3"

36.4"

PW818

Dimensions

Dimensions in inches

22 PW 811 / PW 814 / PW 818

Technical drawings - dimensions in inches

36.4"

36.3"

32.3"

16.3"

40.5"

67.2"

67.3"

67.2"

30"

21"

33.8"

19.4"

33.8"

2.6"

37.4"

1"

36.3"

36.4"

Dimensions with Mielebase (UG/UO)/weighting base (WI)

Dimensions in inches

PW 811 / PW 814 / PW 818 23

Technical drawings - dimensions in inches

38.2"

16.2"

32.3"

28.6"

≥ 49.6"

≥ 49.6"

24.1"

5.8"

3.2"

≥ 15.7"

≥ 15.7"

Installation

Dimensions in inches

24 PW 811 / PW 814 / PW 818

Technical drawings - dimensions in inches

~ 3 1/2"

Ø 1/2"

~ 3 1/2"

Ø 1/2"

Anchoring PW811/814/818

Attaching to the floor/concrete base

Dimensions in inches

Attaching to the floor/concrete base when installing in a run

Dimensions in inches

PW 811 / PW 814 / PW 818 25

Technical drawings - dimensions in inches

~ 3 1/2"

Ø 1/2"

Attaching to the floor with Mielebase

Dimensions in inches

26 PW 811 / PW 814 / PW 818

PW811

415

529

737

1350

1352

799

795

940

25

799

795

86

795

164

828

87

827

492

1350

472

531

22

Dimensions

Technical drawings - dimension in millimeters

Dimensions in millimeters

PW 811 / PW 814 / PW 818 27

Technical drawings - dimension in millimeters

799

820

415

795

827

492

828

87

940

25

799

795

531

762

1640

1640

1642

1027

Dimensions with Mielebase (UG/UO)/weighting base (WI)

Dimensions in millimeters

28 PW 811 / PW 814 / PW 818

Installation

≥ 1280

583

845

148

≥ 1280

697

91

696

348

≥ 400

≥ 400

Technical drawings - dimension in millimeters

Dimensions in millimeters

PW 811 / PW 814 / PW 818 29

Technical drawings - dimension in millimeters

415

924

564

921

772

1450

1452

1450

757

757

67

492

531

507

22

850

25

112

179

924

920

PW814

Dimensions

Dimensions in millimeters

30 PW 811 / PW 814 / PW 818

Technical drawings - dimension in millimeters

924

819

415

920

1027

1705

1707

758

757

67

492

1705

762

531

920

924

850

25

Dimensions with Mielebase (UG/UO)/weighting base (WI)

Dimensions in millimeters

PW 811 / PW 814 / PW 818 31

Technical drawings - dimension in millimeters

970

411

821

627

≥ 1160

≥ 1160

513

148

82

≥ 400

≥ 400

Installation

32 PW 811 / PW 814 / PW 818

PW818

924

920

857 492

85866

950

25

415

564

772

1450

1452

1450

531

507

22

920

924

Dimensions

Technical drawings - dimension in millimeters

Dimensions quoted in millimeters

PW 811 / PW 814 / PW 818 33

Technical drawings - dimension in millimeters

924

920

819

415

1027

1705

1707

1705

762

531

857

492

858

66

950

25

920

924

Dimensions with Mielebase (UG/UO)/weighting base (WI)

Dimensions quoted in millimeters

34 PW 811 / PW 814 / PW 818

Installation

970

411

821

727

≥ 1260

≥ 1260

613

148

82

≥ 400

≥ 400

Technical drawings - dimension in millimeters

PW 811 / PW 814 / PW 818 35

Technical drawings - dimension in millimeters

~ 90

Ø 12

~ 90

Ø 12

Anchoring PW811/814/818

Attaching to the floor/concrete base

Dimensions in millimeters

Attaching to the floor/concrete base when installing in a run

Dimensions in millimeters

36 PW 811 / PW 814 / PW 818

Technical drawings - dimension in millimeters

~ 90

Ø 12

Attaching to the floor with Miele base

Dimensions in millimeters

PW 811 / PW 814 / PW 818 37

Technical data

Water connection

Models with detergent dispenser drawer (WEK)

Permitted supply pressure 14.5-145 psi (1-10 bar)

Maximum intake rate 21 gal/min (79.5 l/min)

Cold water connection

(to be provided on site, external thread according to DIN 44991, flat seal)

Optional cold-hard water connection

(to be provided on site, external thread according to DIN 44991, flat seal)

Hot water connection≤158°F(70°C)

(to be provided on site, external thread according to DIN 44991, flat seal)

Intake hose length 59" (1500 mm)

1 x ¾" (25 x 19 mm)

Drain valve

Maximum drain water temperature 203°F (95°C)

Waste water connection (on machine) NPS 2 ¾" (DN 70) plastic pipe

Drain (on-site) 2 ¾" connection

Maximum drainage rate 53 gal/min (200 l/min)

2 x ¾"

2 x ¾"

Optional steam valves for steam-heated models

Electric steam valve (ELD01)

Regulatable steam pressure 29 - 145 psi (200 - 1000 kPa)

Connection size 1/2" (12 mm)

Connection voltage 1N AC 230V

Frequency 50-60Hz

Pneumatic steam valve (PND)

Regulatable steam pressure 0 - 145 psi (0 - 1000 kPa)

Connection size 1/2" (12 mm)

Connection for equipotential bonding

Connection with male thread (machine) 3/8" x 1 3/8" (10 x 35 mm)

Washers and nuts M10

38 PW 811 / PW 814 / PW 818

Technical data

Anchoring

Attaching to the floor

Required anchor points 2

Wood screw (diameterxlength) 1/2" x 31/2" (12mm x 90mm)

Wall anchors (diameter x length) 5/8" x 31/8" (16mm x 80 mm)

Attaching to the floor with Miele base

Required anchor points 4

Wood screw (diameterxlength) 1/2" x 31/2" (12mm x 90mm)

Wall anchors (diameter x length) 5/8" x 31/8" (16mm x 80 mm)

Attaching to a concrete base (provided on-site)

Required anchor points 2

Wood screw (diameterxlength) 1/2" x 31/2" (12mm x 90mm)

Wall anchors (diameter x length) 5/8" x 31/8" (16mm x 80 mm)

PW 811 / PW 814 / PW 818 39

Technical data

PW811

Electrical version and electrical data

Electrically heated

Standard

Connection voltage 3 AC 220-240 V

Frequency 60 Hz

Fuse rating (on site) 3 x 25 A

Power rating 10.2-11.8 kW

Rated current 3 x 23.2 A

Power cord, min. cross-section 4 x AWG 12

Cord connector M 32

Convertible to:

Connection voltage 3 AC 200-208 V

Frequency 60 Hz

Fuse rating (on site) 3 x 25 A

Power rating 8.8-9.4 kW

Rated current 3 x 21.2 A

Power cord, min. cross-section 4 x AWG 12

Cord connector M 32

Installation dimensions

Standard

Casing width (without add-on components) 31.4" (795 mm)

Casing height (without add-on components) 53.2" (1350 mm)

Casing depth (without add-on components) 32.6" (827 mm)

Overall machine width 31.5" (799 mm)

Overall machine height 53.3" (1352 mm)

Overall machine depth 37" (940 mm)

Minimum width of transport opening 31.7" (805 mm)

Minimum distance between wall and front of appliance 50.4" (1280 mm)

Minimum distance between wall and rear of appliance 15.8" (400 mm)

With Mielebase (UG/UO)

Casing width (without add-on components) 31.4" (795 mm)

Casing height (without add-on components) 64.6" (1640 mm)

Casing depth (without add-on components) 32.6" (827 mm)

Overall machine width 31.5" (799 mm)

Overall machine height 64.7" (1642 mm)

Overall machine depth 37" (940 mm)

Minimum width of transport opening 31.7" (805 mm)

Minimum distance between wall and front of appliance 50.4" (1280 mm)

Minimum distance between wall and rear of appliance 15.8" (400 mm)

40 PW 811 / PW 814 / PW 818

Technical data

Transport data, weight and floor load

Packaging width 44.5" (1130 mm)

Packaging height 57.8" (1468 mm)

Packaging depth 43" (1090 mm)

Gross volume 63.9 cu. ft. (1808 l)

Gross weight 701 lb (318 kg)

Net weight 642 lb (291 kg)

Maximum floor load during operation 4479 N

Emissions data

Workplace related sound pressure level, washing 51 dB (A)

Sound power level, washing 59.7 dB (A)

Workplace related sound pressure level, spinning 65 dB (A)

Sound power level, spinning 76.8 dB (A)

Average heat dissipation rate to installation site 3754 BTU (3.96 MJ/h)

PW 811 / PW 814 / PW 818 41

Technical data

PW814

Electrical version and electrical data

Electrically heated

Standard:

Connection voltage 3 AC 220-240 V

Frequency 60 Hz

Fuse rating (on site) 3 x 40 A

Power rating 14.8-17.1 kW

Rated current 3 x 37.2 A

Power cord, min. cross-section 4 x AWG 8

Cord connector M 40

Convertible to:

Connection voltage 3 AC 200-208 V

Frequency 60 Hz

Fuse rating (on site) 3 x 40 A

Power rating 12.5 - 13.4 kW

Rated current 3 x 32.4 A

Power cord, min. cross-section 4 x AWG 8

Cord connector M 40

Steam-heated

Standard:

Connection voltage 3AC 220-240 V

Frequency 60 Hz

Fuse rating (on site) 3 x 16 A

Power rating 2.3 kW

Rated current 3 x 4.0 A

Power cord, min. cross-section 4 x AWG 14

Cord connector M 25

Convertible to:

Connection voltage 3AC 200-208 V

Frequency 60 Hz

Fuse rating (on site) 3 x 16 A

Power rating 2.3 kW

Rated current 3 x 4.0 A

Power cord, min. cross-section 4 x AWG 14

Cord connector M 25

42 PW 811 / PW 814 / PW 818

Technical data

Installation dimensions

Standard

Casing width (without add-on components) 36.3" (920 mm)

Casing height (without add-on components) 57.1" (1450 mm)

Casing depth (without add-on components) 29.8" (757 mm)

Overall machine width 36.4" (924 mm)

Overall machine height 57.2" (1452 mm)

Overall machine depth 33.5" (849,5 mm)

Minimum width of transport opening 36.7" (930 mm)

Minimum distance between wall and front of appliance 45.7" (1160 mm)

Minimum distance between wall and rear of appliance 15.8" (400 mm)

With Mielebase (UG/UO)

Casing width (without add-on components) 36.3" (920 mm)

Casing height (without add-on components) 67.2" (1705 mm)

Casing depth (without add-on components) 29.8" (757 mm)

Overall machine width 36.4" (924 mm)

Overall machine height 67.3" (1707 mm)

Overall machine depth 33.5" (849.5 mm)

Minimum width of transport opening 36.7" (930 mm)

Minimum distance between wall and front of appliance 45.7" (1160 mm)

Minimum distance between wall and rear of appliance 15.8" (400 mm)

Transport data, weight and floor load

Packaging width 44.5" (1130 mm)

Packaging height 61.8" (1568 mm)

Packaging depth 43" (1090 mm)

Gross volume 68.2 cu. ft. (1931 l)

Gross weight 884 lb (401 kg)

Net weight 825 lb (374 kg)

Maximum floor load during operation 5400 N

Emissions data

Workplace related sound pressure level, washing 51 dB (A)

Sound power level, washing 59.6 dB (A)

Workplace related sound pressure level, spinning 65 dB (A)

Sound power level, spinning 76.2 dB (A)

Average heat dissipation rate to installation site Electrically heated versions: 5460 BTU (5.76 MJ/h)

Steam-heated versions: 787 BTU (0.83 MJ/h)

PW 811 / PW 814 / PW 818 43

Technical data

PW818

Electrical version and electrical data

Electrically heated

Standard:

Connection voltage 3 AC 220-240 V

Frequency 60 Hz

Fuse rating (on site) 3 x 50 A

Power rating 19.4-22.6 kW

Rated current 3 x 48 A

Power cord, min. cross-section 4 x AWG 8

Cord connector M 40

Convertible to:

Connection voltage 3 AC 200-208 V

Frequency 60 Hz

Fuse rating (on site) 3 x 50 A

Power rating 16.6-17.7 kW

Rated current 3 x 41.8 A

Power cord, min. cross-section 4 x AWG 8

Cord connector M 40

Steam-heated

Standard:

Connection voltage 3 AC 220-240 V

Frequency 60 Hz

Fuse rating (on site) 3 x 16 A

Power rating 3 kW

Rated current 3 x 4 A

Power cord, min. cross-section 4 x AWG 14

Cord connector M 25

Convertible to:

Connection voltage 3 AC 200-208 V

Frequency 60 Hz

Fuse rating (on site) 3 x 16 A

Power rating 3 kW

Rated current 3 x 4 A

Power cord, min. cross-section 4 x AWG 14

Cord connector M 25

44 PW 811 / PW 814 / PW 818

Technical data

Installation dimensions

Standard

Casing width (without add-on components) 36.3" (920 mm)

Casing height (without add-on components) 57.1" (1450 mm)

Casing depth (without add-on components) 33.8" (857 mm)

Overall machine width 36.4" (924 mm)

Overall machine height 57.2" (1452 mm)

Overall machine depth 37.4" (950 mm)

Minimum width of transport opening 36.7" (930 mm)

Minimum distance between wall and front of appliance 49.7" (1260 mm)

Minimum distance between wall and rear of appliance 15.8" (400 mm)

With Mielebase (UG/UO)

Casing width (without add-on components) 36.3" (920 mm)

Casing height (without add-on components) 67.2" (1705 mm)

Casing depth (without add-on components) 33.8" (857 mm)

Overall machine width 36.4" (924 mm)

Overall machine height 67.2" (1707 mm)

Overall machine depth 37.4" (950 mm)

Minimum width of transport opening 36.7" (930 mm)

Minimum distance between wall and front of appliance 49.7" (1260 mm)

Minimum distance between wall and rear of appliance 15.8" (400 mm)

Transport data, weight and floor load

Packaging width 44.5" (1130 mm)

Packaging height 61.8" (1568 mm)

Packaging depth 46.9" (1190 mm)

Gross volume 74.5 cu. ft. (1931 l)

Gross weight 997 (452 kg)

Net weight 937 lb (425 kg)

Maximum floor load during operation 6037 N

Emissions data

Workplace related sound pressure level, washing 54 dB (A)

Sound power level, washing 62.0 dB (A)

Workplace related sound pressure level, spinning 67 dB (A)

Sound power level, spinning 79.0 dB (A)

Average heat dissipation rate to installation site Electrically heated versions: 7110 BTU (7.56 MJ/h)

Steam-heated versions: 1024 BTU (1.08 MJ/h)

PW 811 / PW 814 / PW 818 45

Please have the model and serial number

of your machine available when

contacting Technical Service.

U.S.A.

Miele, Inc.

National Headquarters

9 Independence Way

Princeton, NJ 08540

Phone:

Fax:

www.miele-pro.com

proinfo@mieleusa.com

Technical Service & Support

800-991-9380

800-220-1348

Phone:

Fax:

proservice@mieleusa.com

800-991-9380

609-419-4241

Alteration rights reserved / Publication date: 0917 M.-Nr. 10 668 670 / 00

PW 811

PW 814

PW 818

Loading...

Loading...