Miele PW 811, PW 814, PW 818 Installation diagram

Installation plan

Commercial Washing Machine

PW 811

PW 814

PW 818

To avoid the risk of accidents or damage to the

machine, it is essential to read these instructions

before it is installed and used for the first time.

en-GB

M.-Nr. 10 682 100

Contents

Installation and planning notes..........................................................................................4

Installation requirements ....................................................................................................... 4

Storage / Transport................................................................................................................ 4

General operating conditions ................................................................................................ 4

Installation ............................................................................................................................. 5

Installation on concrete plinth .......................................................................................... 5

Levelling the machine............................................................................................................ 6

Securing the machine............................................................................................................ 6

Installation of steam-heated washing machines................................................................... 7

Steam connection valve ................................................................................................... 7

Condensate trap............................................................................................................... 7

Heater bank information................................................................................................... 8

Fitting information for steam and condensate hoses....................................................... 8

Machine connections ............................................................................................................ 9

Models with detergent dispensing compartment (WEK) ................................................. 9

Models without detergent dispensing compartment (WEK)........................................... 10

Electrical connection ........................................................................................................... 11

Plumbing ............................................................................................................................. 13

Cold water connection ................................................................................................... 13

Hot water connection..................................................................................................... 14

Dump valve..................................................................................................................... 15

Dispenser pump connections ............................................................................................. 16

Optional accessories........................................................................................................... 18

Payment system or peak-load management ................................................................. 18

XKM RS232 communication module ............................................................................. 18

Plinth .............................................................................................................................. 19

Weighing plinth............................................................................................................... 19

Vapour and foam venting kit (BWS) ............................................................................... 19

Technical drawings............................................................................................................20

PW 811................................................................................................................................ 20

Dimensions..................................................................................................................... 20

PW811 with Mieleplinth (UG/UO) / weighing plinth (WI) .............................................. 21

Installation ...................................................................................................................... 22

PW 814................................................................................................................................ 23

Dimensions..................................................................................................................... 23

PW814 with Mieleplinth (UG/UO) / weighing plinth (WI) .............................................. 24

Installation ...................................................................................................................... 25

PW 818................................................................................................................................ 26

Dimensions..................................................................................................................... 26

PW818 with Mieleplinth (UG/UO) / weighing plinth (WI) .............................................. 27

Installation ...................................................................................................................... 28

Anchoring the machine ....................................................................................................... 29

Fixing to floor / concrete plinth ...................................................................................... 29

Attaching to the floor / concrete plinth when installing in a run..................................... 29

Attaching to the floor with Miele plinth........................................................................... 30

Technical data....................................................................................................................31

Plumbing ............................................................................................................................. 31

Models with detergent dispensing compartment (WEK)................................................ 31

Models without detergent dispensing compartment (WEK)........................................... 31

Dump valve..................................................................................................................... 31

2

Contents

Optional steam valves for steam-heated models................................................................ 32

Electric steam valve (ELD01)......................................................................................... 32

Pneumatic steam valve (PND)........................................................................................ 32

Connection for equipotential bonding................................................................................. 32

Anchoring ............................................................................................................................ 32

Attaching to the floor...................................................................................................... 32

Attaching to the floor with Miele plinth........................................................................... 32

Attaching to a concrete plinth (provided on-site) ........................................................... 32

PW 811................................................................................................................................ 33

Voltage variants and electrical data ............................................................................... 33

Installation dimensions................................................................................................... 34

Transport data, weight and floor load ............................................................................ 35

Emissions data ............................................................................................................... 35

PW 814................................................................................................................................ 36

Voltage variants and electrical data ............................................................................... 36

Installation dimensions................................................................................................... 37

Transport data, weight and floor load ............................................................................ 38

Emissions data ............................................................................................................... 38

PW 818................................................................................................................................ 39

Voltage variants and electrical data ............................................................................... 39

Installation dimensions................................................................................................... 40

Transport data, weight and floor load ............................................................................ 41

Emissions data ............................................................................................................... 41

3

Installation and planning notes

Installation requirements

The washing machine must be installed and commissioned by a

MieleService technician or by an authorised dealer.

The washing machine must be installed in accordance with applic-

able regulations and standards. Local energy supplier and water authority regulations must also be observed.

This washing machine must only be operated in a room that has

sufficient ventilation and which is frost-free.

This machine should not be installed or operated in any area where

there is a risk of explosion!

Storage / Transport

The following conditions must be observed for transport and storage:

– Ambient temperature: 0 - 40 °C

– Humidity: non-condensing

General operating conditions

This washing machine is intended only for use in a commercial environment and must only be operated indoors.

– Ambient temperature of location: 0 - 40 °C

– Relative humidity: non-condensing

– Maximum height above sea level of location site: 2000 m

Depending on the nature of the installation site, sound emissions and

vibration may occur.

Tip: Have the installation site inspected and seek the advice of a professional in instances where increased noise may cause a nuisance.

4 PW 811 / PW 814 / PW 818

Installation and planning notes

Installation

Transport the washing machine to its installation site using a suitable

pallet truck and remove the transport packaging.

The washing machine must be set up on a level and firm surface with

the minimum stated load bearing capacity (see "Technical data").

The floor load created by the washing machine is concentrated and

transferred to the installation footprint via the machine feet.

Tip: A concrete floor is the most suitable installation surface, being

far less prone to vibration during the spin cycle than wooden floorboards or a carpeted surface.

The washing machine requires a gap of at least 50mm at each side

to allow for movement during operation. To ensure suitable access for

further maintenance and service work, please ensure a minimum distance of 400mm is maintained between the back of the machine and

the wall.

Installation on concrete plinth

The washing machine can be installed on a concrete plinth if desired.

The concrete materials and the durability of the concrete plinth must

be assessed in accordance with the floor load bearing capacity

given in "Technical data".

To guarantee the stability of the washing machine, make sure that

the concrete plinth is sufficiently stable on the floor and that it is

capable of withstanding any burden or force from the washing machine.

The washing machine must be secured to the concrete plinth using

the fixtures and fastenings supplied.

The washing machine must be secured to the plinth immediately after installation!

There is a risk of the washing machine falling off a raised plinth during a spin cycle if it is not secured.

PW 811 / PW 814 / PW 818 5

Installation and planning notes

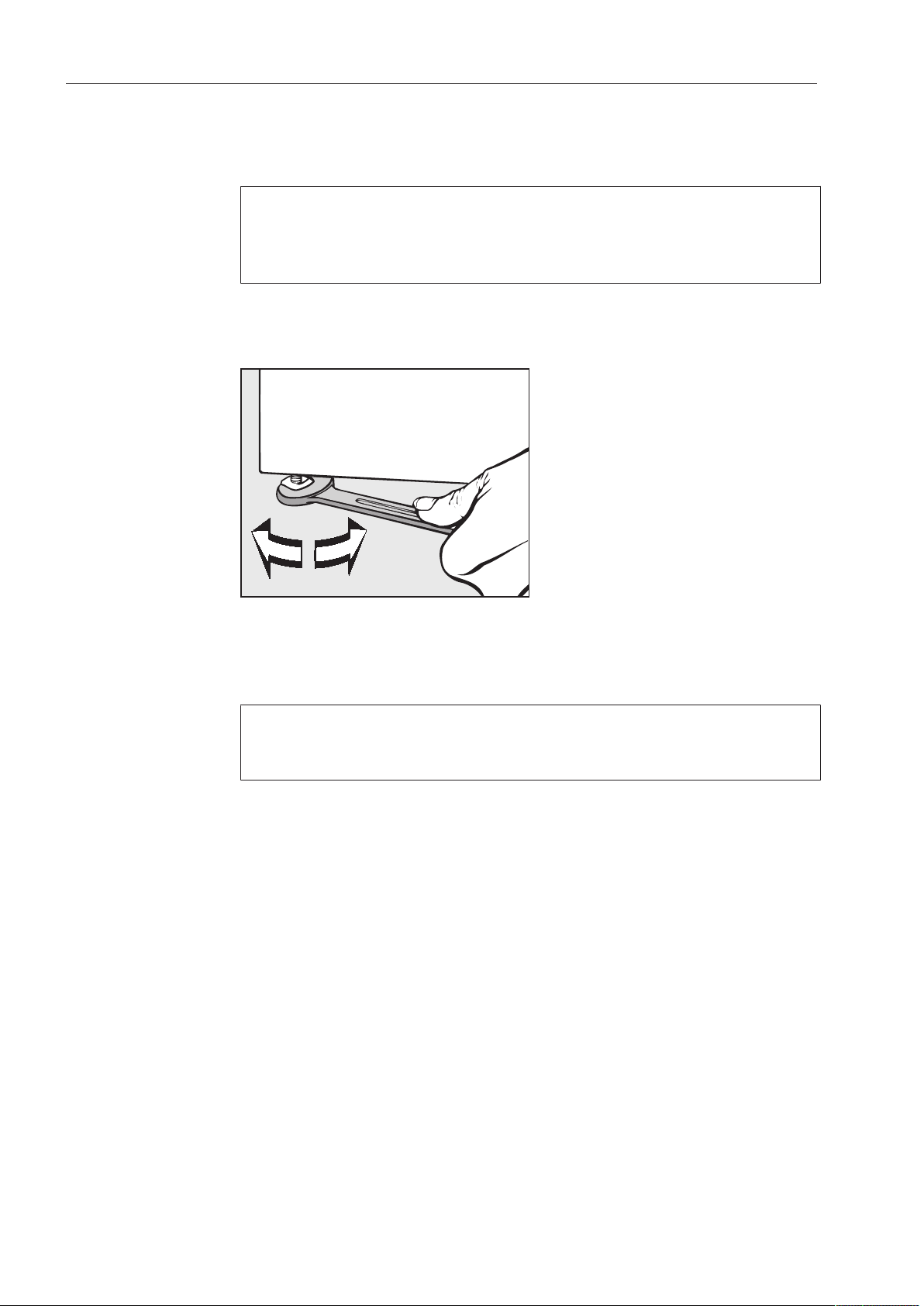

Levelling the machine

Align the washing machine vertically and horizontally using the ad-

justable feet and a spirit level.

The washing machine must stand evenly and horizontally on all four

feet to ensure trouble-free and energy-efficient operation. Otherwise

the water and energy consumption increases and the washing machine might move around.

After aligning the machine, tighten the lock nuts by turning them in

an counterclockwise direction with a wrench. This will prevent the

feet from adjusting themselves.

Securing the machine

The feet of the washing machine must be secured to the concrete

plinth using the fixtures and fastenings supplied.

Fittings supplied are for installation on a concrete floor. For other

types of flooring, please purchase suitable fastening materials separately.

6 PW 811 / PW 814 / PW 818

Installation and planning notes

Installation of steam-heated washing machines

The steam connection must only be carried out by a registered

installation technician. During connection please observe the installation instructions, the data plate on the washing machine, the

wiring diagram, the installation diagram and the documentation

supplied.

Steam-heated washing machines must in all cases be secured to

the floor!

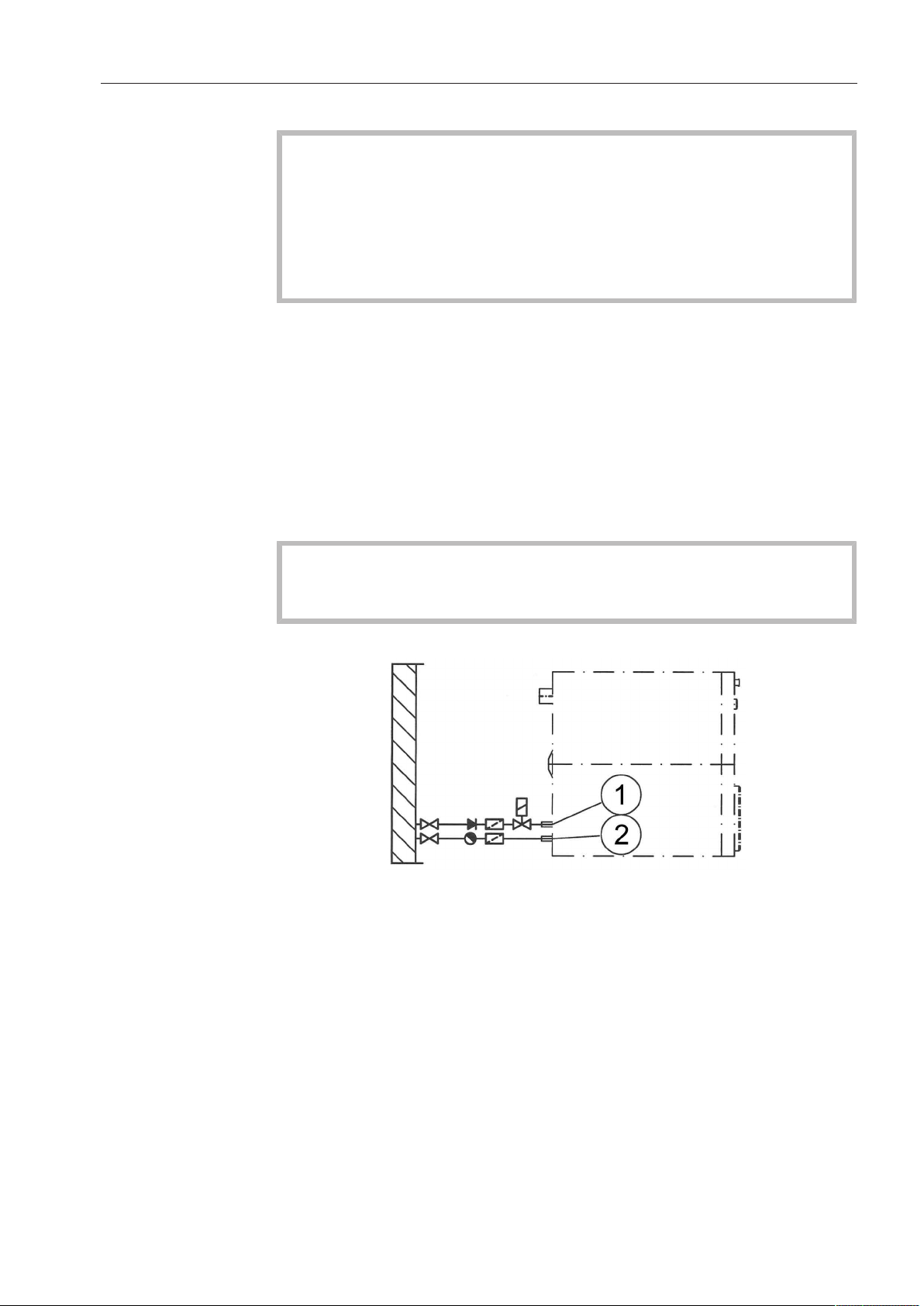

Steam connection valve

Condensate trap

Before connecting a steam-heated machine, ensure that the steam

inlet valve, the dirt filter and the steam shut-off valve have been correctly installed on site.

Steam valves are available from Miele specialist dealers or Miele

Spares Dept.

For steam-heated washing machines, a condensate trap for the condensate is required at the installation site. The condensate trap ensures that condensate is completely drained away from the washing

machine heater bank.

The condensate trap must be installed in such a way that condensate cannot get back into the heater bank when the machine is not

in operation.

Tip: Use a bell condensate trap for the condensate drain.

a

Steam valve

PW 811 / PW 814 / PW 818 7

b

Condensate trap

Installation and planning notes

Heater bank information

Fitting information for steam and

condensate hoses

To avoid damage to the heater bank, the following must be observed

during commissioning:

– In order to avoid unnecessary heat variations, ensure that heating is

even. Do not allow sudden bursts of steam.

– To prevent corrosion, treatment of the water supply is absolutely

essential. In particular, when the machine is not in operation, it

must be ensured that no air or CO2 can enter the system.

– Protect the heater bank from aggressive gases

– The entire heating system must guarantee that no operating pres-

sure or temperature can arise that is higher than the details given

on the data plate.

– All appropriate regulations, standards and legislation from respons-

ible authorities and accident prevention associations for heating

and ventilation systems (in particular for the operation of the heat

exchanger) must be observed.

Make sure that steam and condensate hoses are not twisted or compressed. Do not use the hoses to compensate for connection tube

misalignments!

8 PW 811 / PW 814 / PW 818

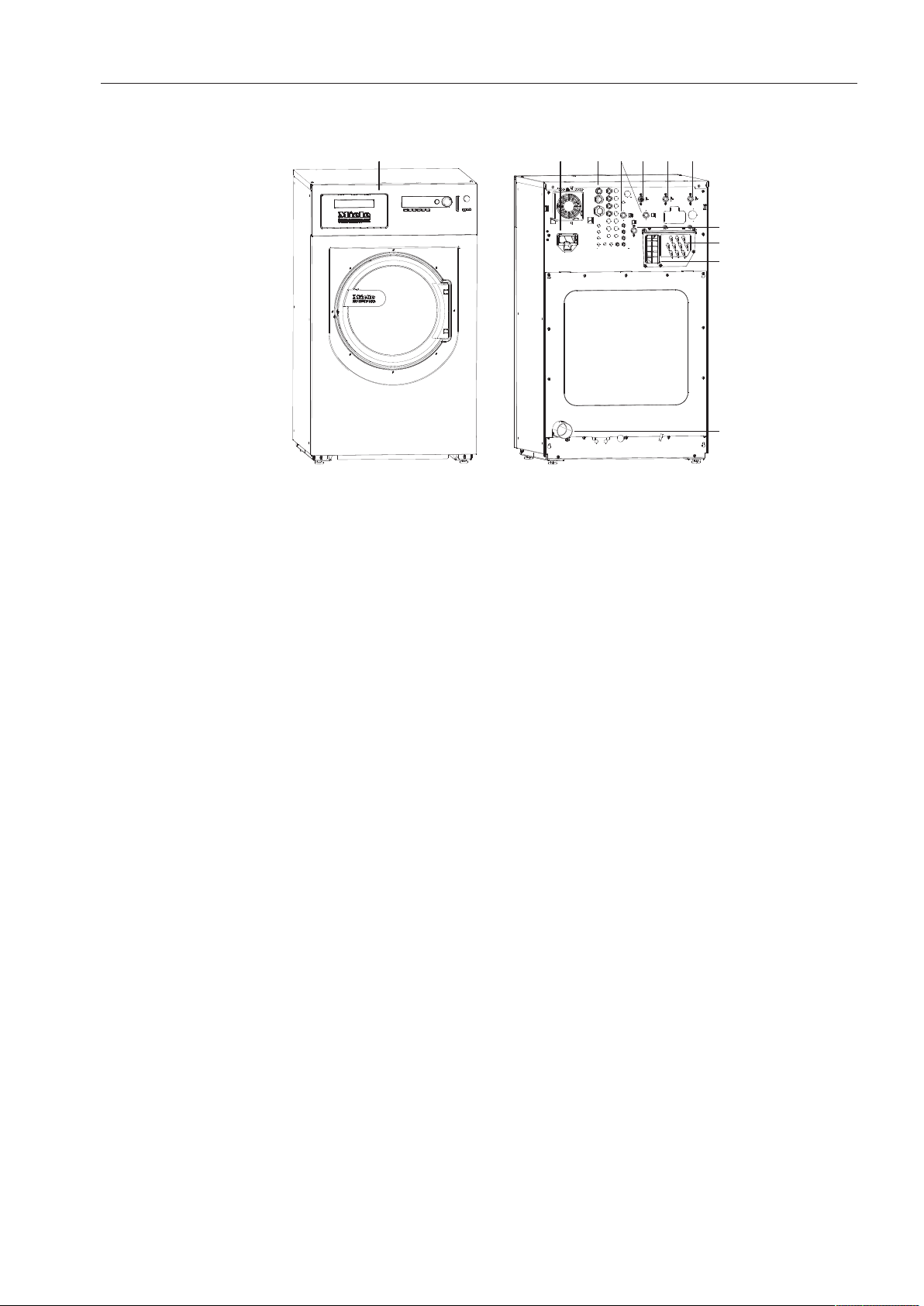

Models with de-

⑥

①

②

③

④

⑤

⑦

⑧

⑨

⑩

⑪

tergent dispensing compartment

(WEK)

Installation and planning notes

Machine connections

a

Detergent dispensing compartment (WEK)

b

Communication module slot

The XKMRS232 communication module is available as an optional

accessory.

c

Electrical connection

d

2x hard water connection

(Optional)

e

Cold water connection

f

Hot water connection

Water temperature to maximum 60°C.

g

Cold water connection

h

Cold water connection for liquid dispensing

(Optional)

i

Connections for external dispenser pumps

For up to 12 dispenser pumps

j

Vapour extraction / free outlet Type AB

k

Dump valve

Connection for plastic pipe HTDN 70.

PW 811 / PW 814 / PW 818 9

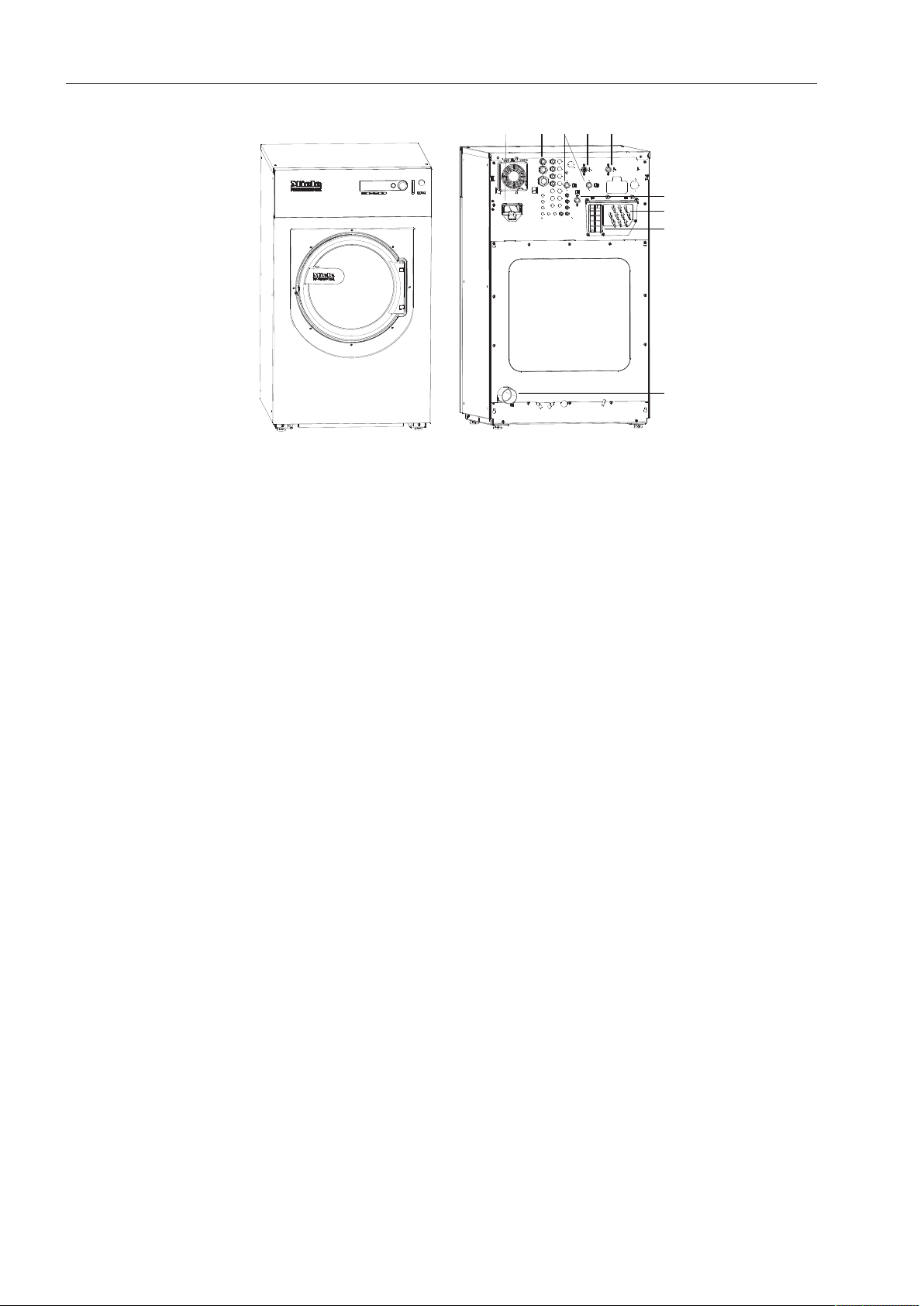

Installation and planning notes

⑥

①

② ③

④

⑤

⑦

⑧

⑨

Models without

detergent dispensing compartment (WEK)

a

Communication module slot

The XKMRS232 communication module is available as an optional

accessory.

b

Electrical connection

c

2x hard water connection

(Optional)

d

Cold water connection

e

Hot water connection

Water temperature to maximum 60°C.

f

Cold water connection for liquid dispensing

g

Connections for external dispenser pumps

For up to 12 dispenser pumps

h

Vapour extraction / free outlet Type AB

i

Dump valve

Connection for plastic pipe HTDN 70.

10 PW 811 / PW 814 / PW 818

Installation and planning notes

Electrical connection

The electrical connection must only be carried out by a qualified

electrician who must ensure that all electrical work is carried out in

accordance with applicable electrical regulations and standards

(BS 7671 in the UK).

This washing machine must be connected to an electrical mains

supply that complies with local and national regulations. Please also

observe your insurance and energy supplier's regulations as well as

any health and safety at work regulations.

The required voltage, connected load and fusing rating can be

found on the data plate on the washing machine. Before connecting

the machine to the power supply, please ensure that the mains supply voltage complies with the values given on the data plate.

Connection to a supply voltage other than the one quoted on the

data plate can lead to functional faults and damage the washing

machine!

If more than one voltage is quoted on the data plate, the washing

machine can be converted for connection to the voltages stated.

Conversion to a different voltage must only be carried out by a

Miele Service engineer or by an authorised Service Dealer. The wiring

instructions given on the wiring diagram must be followed.

Tip: We recommend connection to the power supply via a suitably

rated plug and socket which must be easily accessible for servicing

and maintenance work after the machine has been installed. An electrical safety test must be carried out after installation and after any

service work.

The machine can either be hard-wired or connected using a plugand-socket connection in accordance with IEC 60309-1. For a hardwired connection an all-pole isolation device must be installed on

site.

For hard-wired machines connection should be made via a suitable

mains switch with all-pole isolation which, when in the off position,

ensures a 3mm gap between all open contacts. These include circuit breakers, fuses and relays (IEC/EN60947).

If the mains supply cannot be permanently disconnected, the isolator

switch (including plug and socket) must be safeguarded against being switched on either unintentionally or without authorisation.

PW 811 / PW 814 / PW 818 11

Installation and planning notes

If it is necessary to install a residual current device (RCD) in ac-

cordance with local regulations, a residual current device typeB

(sensitive to universal current) must be used.

An existing typeA residual current device, (RCD) must be exchanged

for a typeB RCD.

If necessary, equipotential bonding with good galvanic contact

must be guaranteed in compliance with all applicable local and national installation specifications.

Equipotential bonding must have an earth current rating >10mA

Accessories for equipotential bonding are not supplied and need to

be ordered separately.

12 PW 811 / PW 814 / PW 818

Installation and planning notes

Plumbing

The washing machine complies with current local and national

safety regulations. In the UK it must be connected to the drinking

water supply using the non-return valve supplied.

The water flow pressure must be at least 1bar and should not exceed

10bar. If it exceeds 10bar a pressure reducing valve must be used.

The machine must be connected to the water supply using the inlet

hoses provided. Extension hoses are available from Miele as spare

parts.

The connection points are subject to water supply pressure.

Turn on the tap slowly and check for leaks.

Correct the position of the washer and union if appropriate.

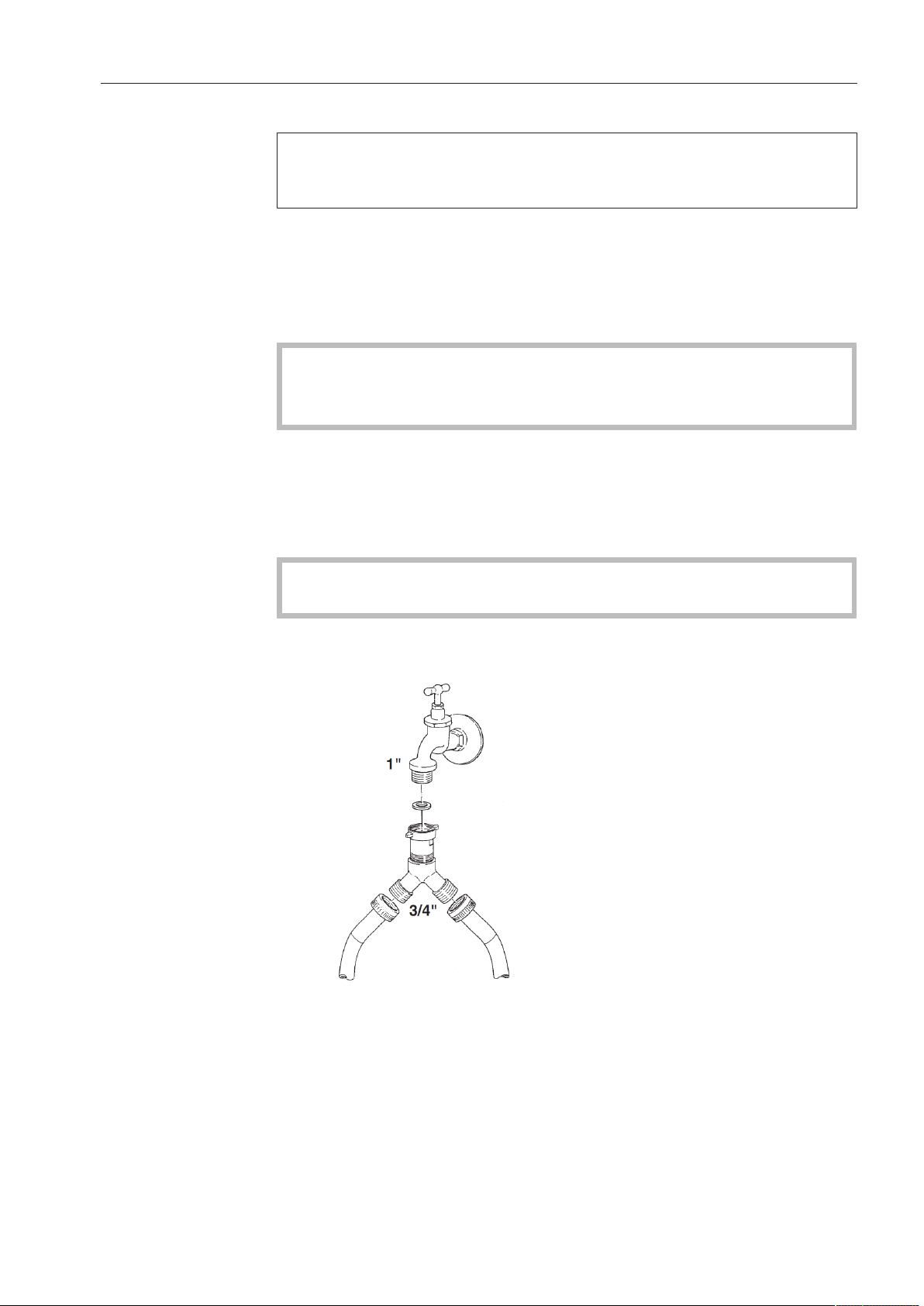

Cold water connection

Use the inlet hose supplied (cold - blue stripes) for the cold water

connection. For the cold water connection (single or double) one water tap each with a 3/4" external thread is required. If this is not available, only a qualified installer may connect the washing machine to

the mains water supply.

The inlet hose for cold water (blue stripes) is not intended to be

used for a hot water connection.

If the hot or hard water connection is missing, cold water consumption increases accordingly to account for the missing water intake.

A Y-piece for connecting two inlet hoses to a single cold water line is supplied.

PW 811 / PW 814 / PW 818 13

Loading...

Loading...