Page 1

Installationsplan / Installation plan

Installatietekening

Plan d`installation

Piano di installazione

Plano de instalación

Plano de instalação

Σχέδιο εγκατάστασης

Asennusohje

Installasjonsplan

Installationsplan

G

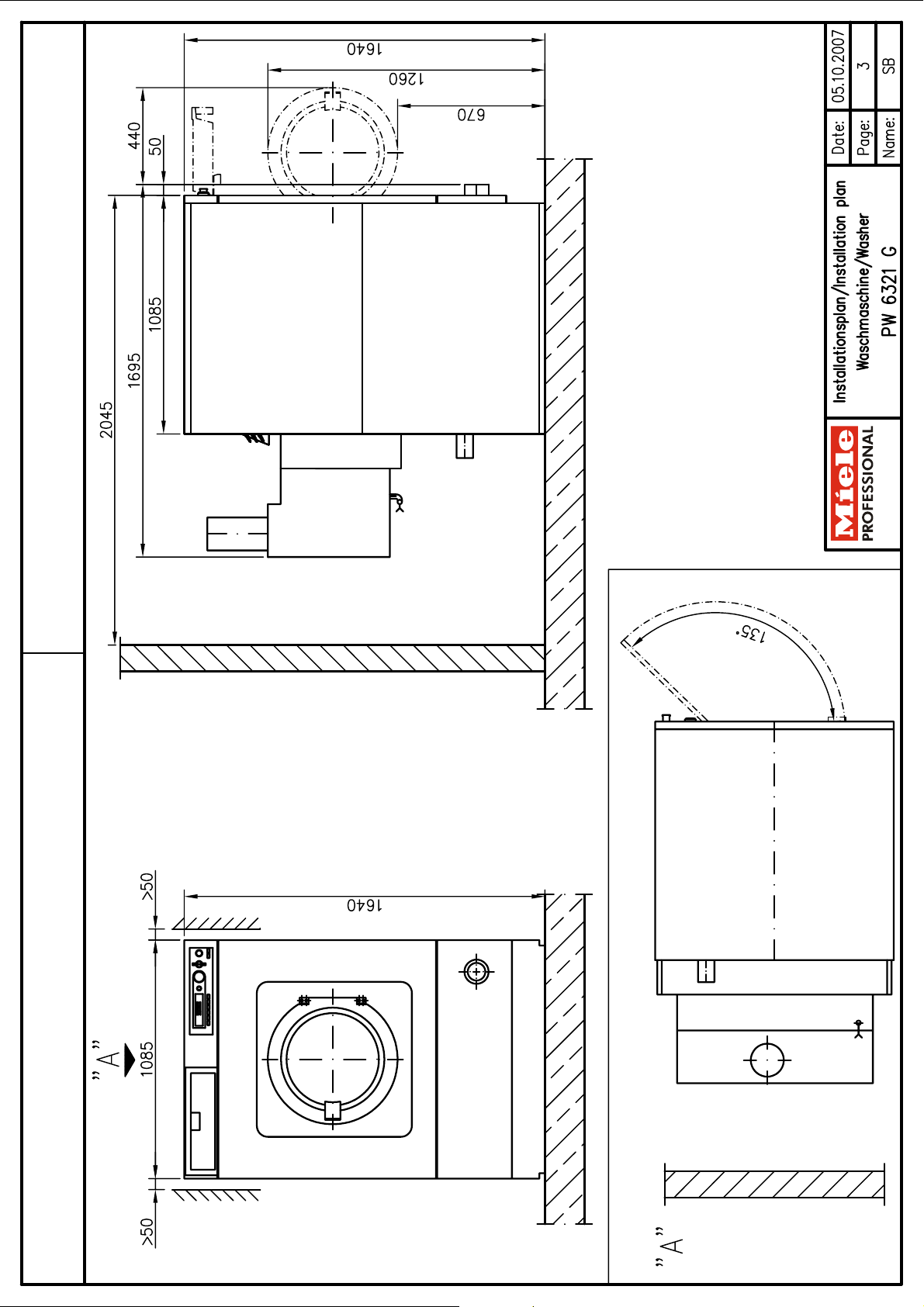

PW 6321 G

Materialnummer / Mat. no.: 06 564 750

Änderungsstand / Version: 01

Datum Zeichnung / Drawing date: 05.10.2007

Datum Legende / Legend date: 05.10.2007

Page 2

Page 3

Page 4

Page 5

Page 6

Technical Datasheet

Washer-extractor:

Heating:

PW 6321

Gas (G)

Legend:

Circled, bold-type abbreviations:

Connection required

G

Machine connections:

Electrical

connection

Connection cable, min. cross-section mm² 5 × 1.5

With threaded cable grommet M 20 x 1.5

Frequency Hz 50

Rated load kW 4.7

Fuse rating A 3 × 16

Abbreviations surrounded by broken circle:

Connection optional or required, depending on model

1. Standard voltage (as supplied) V 3N AC 380 - 415

Plug and socket connection in accordance with IEC 60309

Gas connection Natural gas

Length of connection hose (supplied) mm 350

Liquid gas

On-site connection (Ermeto quick-release connector) DN 12

Min. connection pressure (may vary depending on

Length of connection hose (supplied) mm 350

Gas regulating valve is provided by Miele. A gas stopcock

See also installation instructions on gas-heated washer-

Connection thread (on site) Inch ½" internal thread

Nominal heat load kW 34

Min. connection pressure (may vary depending on

recommended to facilitate electrical safety tests.

Install mains isolator according to IEC 60947 on hard-wired

connection.

Wall socket or mains isolator must be accessible after

installation.

The use of an earth leakage circuit breaker (ELCB) is strongly

recommended. If an ELCB is fitted, it must be a Type B RCD

able to cope with rectified three-phase supplies.

If necessary, equipotential bonding with good galvanic contact

must be provided in accordance with all appropriate national

and local regulations.

country)

country)

must be provided on site.

extractors.

Local gas and plumbing regulations must be observed!

Pa 1700

Pa 2800 - 5750

Installationsplan / Installation plan: PW 6321 G

Datum / Date: 05.10.2007 Seite / Page: 6

Page 7

Cold water

(soft water)

On-site connection thread according to DIN 44 991 Inch 1" external thread

Length of connection hose (parts supplied: 1 connection

Water requirements (average for 60°C programme)

Standard connection (with hot water connection) l/h Approx. 174

Min. flow pressure kPa 100

Max. pressure kPa 1000

Max. throughput (if hot water supply is not available) l/min 35.5 (80)

hose)

mm 1500

Increase alternative water type accordingly if one of water

Hot water

(soft water)

Max. throughput l/min 30

On-site connection thread according to DIN 44 991 Inch 1" external thread

Length of connection hose (parts supplied: 1 connection

Water requirements (average for 60°C programme)

Standard connection (with hot water connection) l/h Approx. 228

Cold water

(Hard water)

On-site connection thread according to DIN 44 991 Inch 1" external thread

Length of connection hose (parts supplied: 1 connection

Water requirements (average for 60°C programme)

Standard connection (with hot water connection) l/h Approx. 300

Waste gas Natural gas

Waste gas volume flow at nominal heat load g/s 32.1

Waste gas temperature at nominal heat load °C 110

CO2 concentration at nominal heat load % Approx. 4.0

Feed pressure at nominal heat load hPa -0.02

Liquid gas

Nominal heat load kW 34

Waste gas connection (Int. dia. × wall thickness × l) mm 150 x 1 x 275

Waste gas volume flow at nominal heat load g/s 35.3

Waste gas temperature at nominal heat load °C 100

CO2 concentration at nominal heat load % Approx. 4.0

Feed pressure at nominal heat load hPa -0.06

Atmospheric burner with integrated non-return device Type:

Nominal heat load kW 34

Waste gas connection (Int. dia. × wall thickness × l) mm 150 x 1 x 275

types is not available.

Max. temperature °C 70

Min. flow pressure kPa 100

Max. pressure kPa 1000

hose)

If no hot water supply, connect hose to cold water!

Min. flow pressure kPa 100

Max. pressure kPa 1000

Max. throughput l/min 40

hose)

If no raw water supply, connect hose to cold water!

B

11BS

See also installation instructions on gas-heated washerextractors.

Local gas and plumbing regulations must be observed!

mm 1500

mm 1500

Combustible and non-heat resistant materials should be kept

Drainage via

dump valve

Installationsplan / Installation plan: PW 6321 G

Datum / Date: 05.10.2007 Seite / Page: 7

at a safe distance from the gas supply line.

Max. temperature °C 95

Machine drain connection (d

On-site drain connection (d

Max. transient throughput l/min 200

Vented drainage required. If ventilation is insufficient, fit Miele

kit, Mat. no. 05238090.

Drain manifolds serving several machines must be of

sufficient cross-section.

× s × l) [DN 70] mm 75 × 1.9 × 110

ext

) [DN 70 sleeve] mm 75

int

Page 8

Foam

compensation

Machine must be bolted to the floor!

Fixing materials for floating screed floor to be provided on site

Machine data Width mm 1085

Depth mm 1695

Height mm 1640

Min. access width to installation site mm 1090

Minimum rear wall gap (measured to front of machine) mm 2045

Net weight kg 734

Dynamic floor load, max. N 9819

Static floor load, max. N Not yet available

Dynamic load, max. N Not yet available

Drum frequency, max. Hz 16.7

Average heat dissipation

Installation should only be carried out by authorised fitters in accordance with valid regulations!

Observe installation instructions when installing machine! All rights reserved! Dimensions in mm

4 × rawl plugs (Ø × length) mm 16 × 80

Excessive foaming may result in foam discharge through air

vent. In order to dispose of this foam, a drain with U tube can

be installed on site using conventional plumbing supplies. A

branch with an end cap should be provided for this purpose.

Without plinth Fittings (supplied)

4 × screws DIN 571 (Ø × length) mm 12 × 90

(dependent on ambient room temperature and programme

selected)

W Not yet available

Installationsplan / Installation plan: PW 6321 G

Datum / Date: 05.10.2007 Seite / Page: 8

Loading...

Loading...