Page 1

Installation Instructions

KM2030 en-CA

IMPORTANT: SAVE FOR THE LOCAL ELECTRICAL INSPECTOR'S USE

To prevent accidents and machine damage read these instructions before installation or use.

Installation, repair and maintenance work should be performed by a

Miele authorized service technician in accordance with national and

local safety regulations and the provided installation instructions.

Page 2

SAFETY NOTICES FOR INSTALLATION

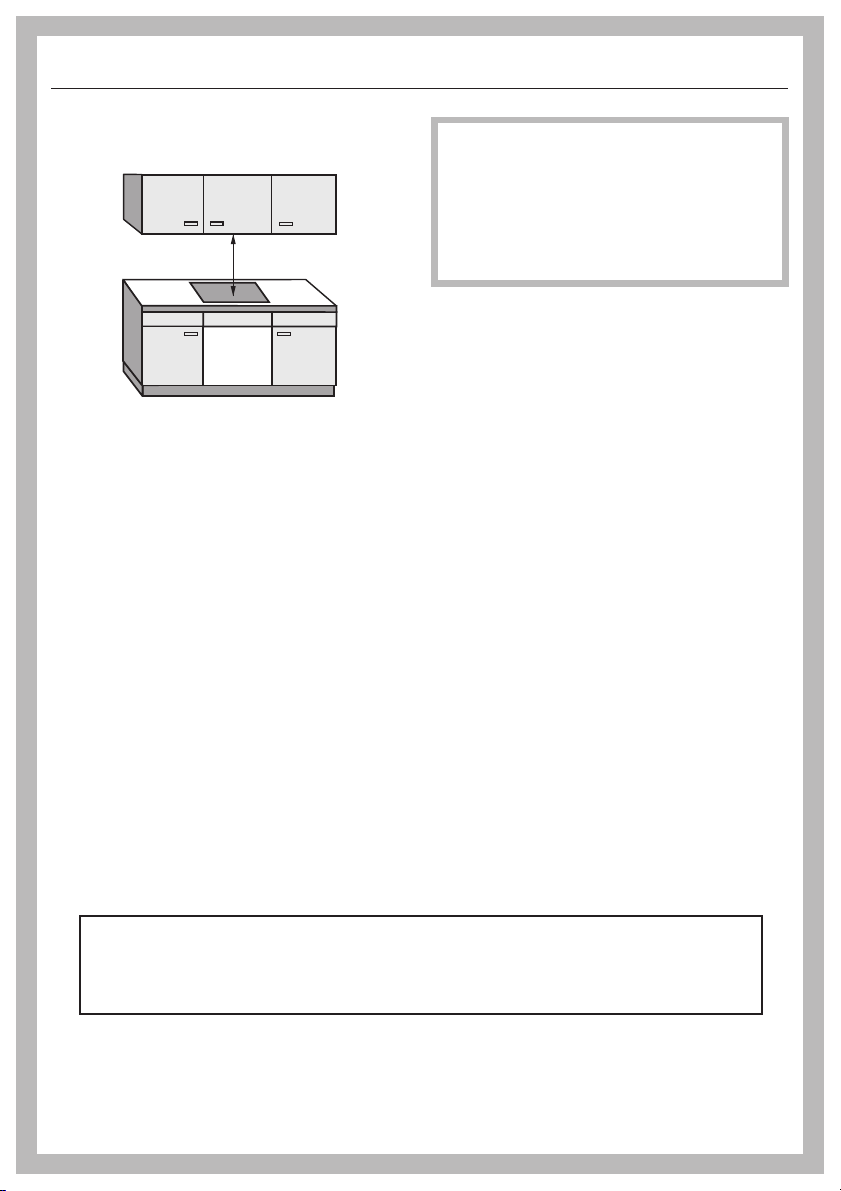

Storage cabinets above the cooktop

To avoid damage to the appliance, it

should not be installed until the

upper cabinet and exhaust hood

have already been mounted.

This appliance is not connected to

~

an exhaust vent. It must be installed

and connected to the power supply in

compliance with the applicable

installation requirements.

The room will need to be at least 20

~

3

m

in volume, with at least one door or

window opening to the outside.

The countertop veneers must be

~

affixed with heat-resistant glue

(100 °C), so that they do not become

deformed or detached.

The wall strips must be heat-resistant

as well.

Installation and assembly of this

~

appliance in non-stationary locations

(for example, aboard ships) should be

performed only by specialized

companies/technicians, to ensure that

the requirements for safe use are met.

Because there is the risk of

~

flameover, a gas cooktop should

NEVER be installed next to a

deep-fryer. A minimum distance of 12"

(300 mm) must be maintained between

these appliances. Other appliances

may be build in directly next to the gas

cooktop.

~

present a fire hazard.

This gas cooktop is not authorized

~

for installation atop

refigerators/freezers, dishwashers, or

washers/dryers.

Check to be sure that the gas line

~

and power cord will not come into

contact with any hot spots after

installation. Hot spots can cause heat

damage to the gas line and power

cord.

The power cord and a flexible gas

~

line must be arranged in such a way

that they will not come into contact with

moveable parts in the cabinetry (e.g., a

drawer) or be subject to any

mechanical strain.

Be sure to carefully observe the

~

clearance distances listed on the

following pages.

Never use caulking unless it is

~

explicitly called for in the instructions.

The sealing tape for the appliance

provides an adequate seal with the

countertop (see the section on "General

installation notices").

26

Page 3

SAFETY NOTICES FOR INSTALLATION

Upper clearance

For an exhaust hood above the

appliance, the safe clearance distance

indicated by the hood manufacturer

must be maintained.

If there are no specifications from the

hood manufacturer or if flammable

materials (e. g., a hanging cabinet) are

installed above the appliance, the

clearance distance must be at least 30"

(760 mm).

If there are various appliances with

different recommended clearance

distances beneath the exhaust

hood, e. g., a gas stovetop and an

electric cooktop, always choose the

greatest distance.

The maximum depth of cabinets

installed above the cooktop must be

13" (330 mm).

Miele appliances can be installed flush or proud. Discuss your installation

requirements with you architect, designer and installer.

27

Page 4

SAFETY NOTICES FOR INSTALLATION

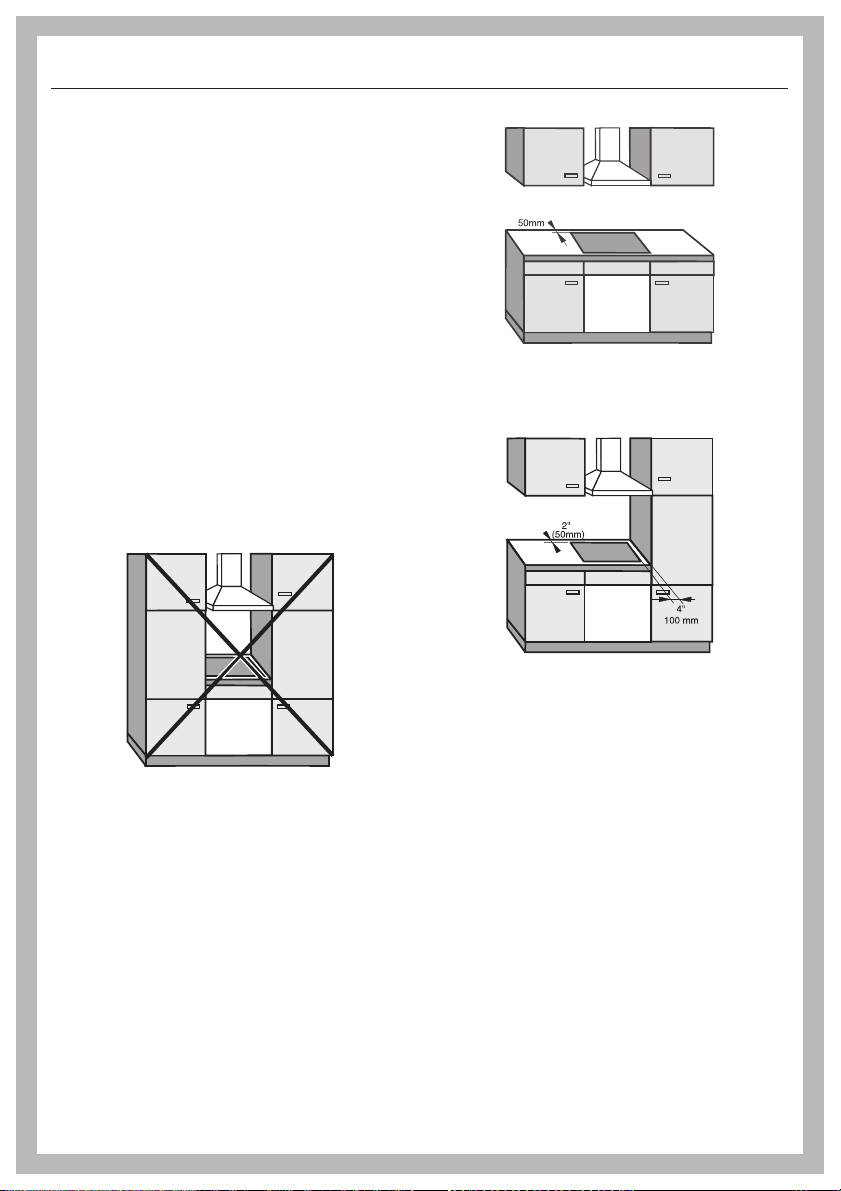

When installing a gas stovetop, the

cabinetry or walls to ONE side and to

the rear of the appliance can be as tall

as you wish. However, on the other side

there must not be any appliance or

furniture that is taller than the installed

gas stovetop (see illustrations).

You must ensure that the following

minimum safety clearances are kept:

4" (100 mm) to the right or left of the

–

countertop cut-out to the next closest

piece of furniture (e.g., tall

cupboard).

– 2" (50 mm) from the countertop

cut-out to the rear wall.

2 ”

Highly recommended

28

Not recommended

Not permitted

Page 5

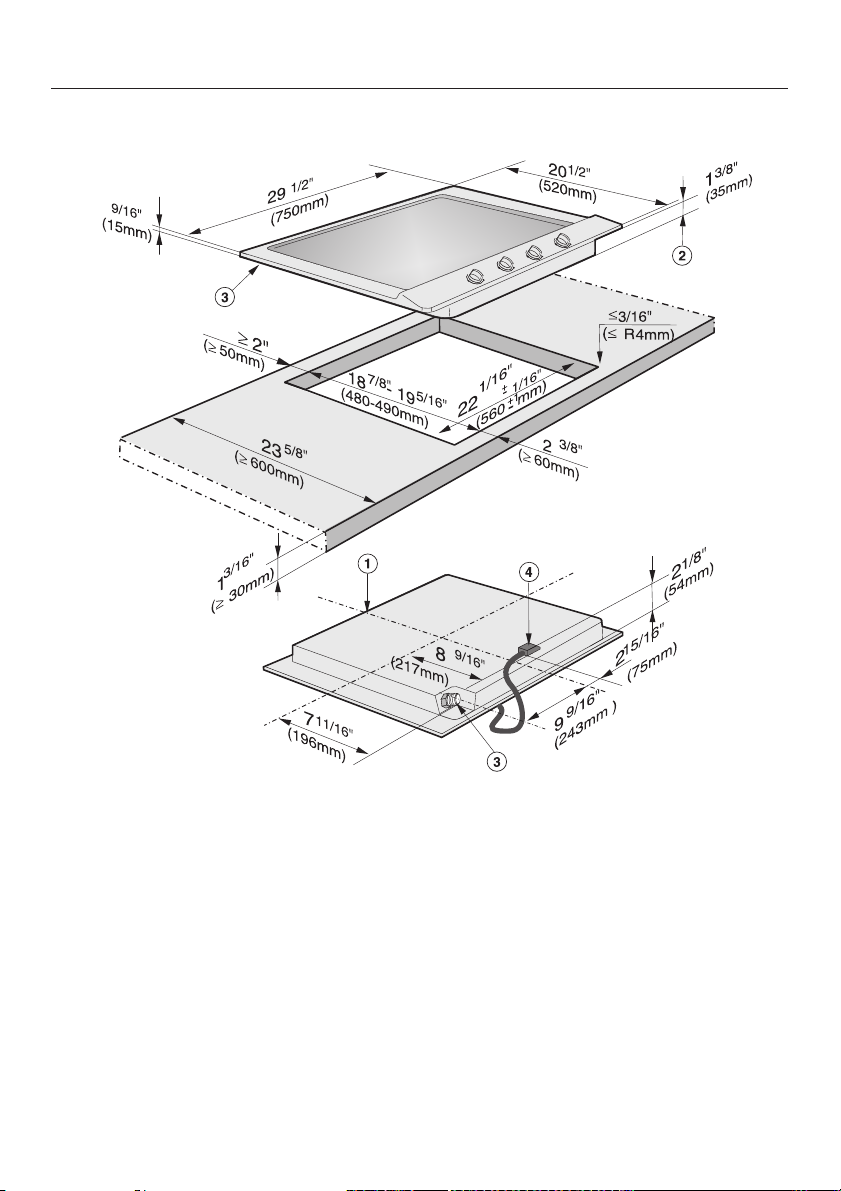

KM 2030

Appliance and installation dimensions

a front

b Installation height

c Gas connection R 1/2" ISO 7-1

d Junction box with power cable,L=78

3

/4" (2000 mm)

29

Page 6

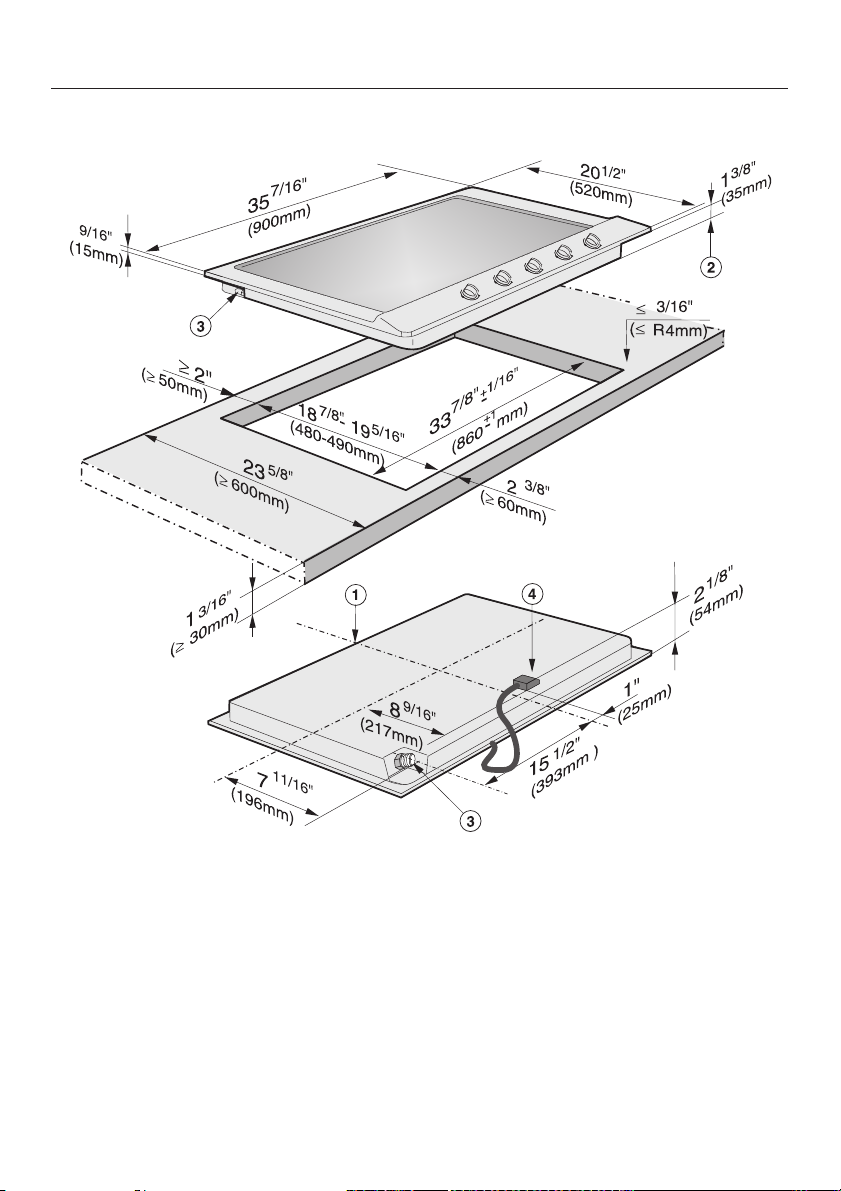

Appliance and installation dimensions

KM 2050

a front

b Installation height

c Gas connection R 1/2" ISO 7-1

d Junction box with power cable,L=78

30

3

/4" (2000 mm)

Page 7

Installation

How to make the countertop

cut-out

Use the template to make a

^

countertop cut-out.

Be sure to observe the minimum

distance from the rear wall and from

the left or right to a side wall.

See the section on "SAFETY

NOTICES FOR INSTALLATION".

Seal any wooden countertop

^

surfaces with a special varnish,

silicone rubber, or resin, to help

prevent swelling from moisture.

The materials used must be

temepature-stable.

If, during installation, you find that

the frame is not tightly sealed to the

countertop at the corners, then the

corner edges, ß R4, can be carefully

trimmed with a jigsaw.

How to install the gas stovetop

^ Feed the appliance power cord

downward through the countertop

cut-out.

^ Set the appliance loosely into place

in the cut-out.

^ Connect the appliance to the power

supply (see the section on "Electrical

connection").

^ Establish the gas connection (see the

section on "Gas connection").

^

Use the supplied brackets to hold the

appliance in place.

31

Page 8

General installation information

Sealing

NEVER use sealing unless it is explicitly

called for in the instructions. The

sealing strip under the edge of the

upper part of the appliance provides a

sufficient seal against the countertop.

NEVER use sealing between the

upper appliance frame and the

countertop!

It will hinder access to the appliance

during servicing, and the frame and

countertop can be damaged as a

result.

Tiled surfaces

The grouting a and shaded area under

the cooktop frame must be flat and

even, so that the frame will lie evenly

and the sealing strip under the edge of

the upper part of the appliance can

provide an adequate seal against the

countertop.

32

Page 9

Electrical connection

This appliance must be grounded

according to local or national codes.

All electrical work should be

performed by a qualified electrician

in accordance with local codes and

with the:

- National Electrical Code

ANSI / NFPA 70

for the USA

or

- Canadian Electrical Code Part I

for Canada

(CSA Standard C 22.1)

WARNING

,

Disconnect the appliance from the

main power supply before

installation or service. To reduce the

risk of electric shock, make sure that

the appliance is properly grounded

after installation.

Power supply

The automatic ignition requires that the

appliance be connected to a 120 VAC,

60 Hz power supply. The supply line

should be protected by a 15 A fuse.

This appliance is equipped with a

three-prong grounding plug to

prevent shock hazards. It should be

plugged directly into a properly

grounded outlet. Do not cut or

remove the grounding prong from

the plug. If the plug does not fit the

outlet, have the proper outlet

installed by a licensed electrician.

To guarantee the electrical safety of

this appliance, continuity must exist

between the appliance and an

effective grounding system. It is

imperative that this basic safety

requirement be met. If there is any

doubt, have the electrical system of

the house checked by a qualified

electrician.

The manufacturer cannot be held

responsible for damages caused by

the lack, or inadequacy, of an

effective grounding system.

Note to the installer

Please leave these instructions with the

consumer or the appliance.

Actual power consumption (during

ignition only) is 25 W.

This appliance is equipped with a

78 3/4" (2000 mm) long power cord that

is ready for connection to the

appropriate outlet.

Place the power outlet so that it is

accessible after the appliance has

been installed in the countertop.

33

Page 10

Gas connection

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

This appliance must be installed

with its own shut off valve and the

included gas pressure regulator.

Both the valve and the regulator

must be easily accessible to the

consumer to turn on or shut off the

gas supply after the appliance is

installed.

This appliance and its individual

shut off valve must be disconnected

from the gas supply during any

pressure testing performed in

excess of ½ psi (3.5 kPa), or

isolated from the gas line by closing

its individual manual shut off valve at

test pressures equal to or less than

½ psi (3.5 kPa).

Any pipe connections must be made

using a thread sealant approved for

gas connections. Failure to correctly

install these items could lead to a

gas leak and subsequent explosion.

The gas connection must be made

in accordance with local codes or, in

the absence of local codes, with

- the National Fuel Gas Code,

ANSI Z 223.1/NFPA 54

for the USA

or

- the current Can/CGA B 149.1

and .2 Installation Codes for gas

burning appliances for Canada.

Make sure that the maximum gas

supply pressure before the gas

pressure regulator is never more than

½ psi for both natural gas or LP gas.

The minimum supply pressure to get

the required gas input is

4" w.c. for natural gas:

10" w.c. for LP gas.

Leak testing of the appliance shall

be conducted according to the

manufacturer's instructions.

34

Page 11

Gas connection

Gas pressure regulator

A pressure regulator that is convertible

from natural to LP gas (Propane) or vice

versa is included with the appliance.

The included regulator corresponds

with the gas type of the appliance.

Verify before installing.

The adjusted pressure is:

natural gas - 4" w.c.

LP gas - 10" w.c.

a Appliance

b ½" NPT

c Regulator

For convenience, an AGA or CGA

approved flexible stainless steel gas

hose (accordion type) may be used

between the gas connection and the

regulator. This will allow the appliance

to be lifted out of the countertop for

cleaning or servicing. Make sure that

any drawers, cabinet doors, etc., do not

rub on this gas hose.

Do not use any regulator unless it

has been supplied by Miele. Doing

so may cause a gas leak.

If there is any doubt concerning

installation contact the Miele Technical

Service Department.

After connecting the appliance check

all fittings for gas leaks e.g. with

soapy water.

When installed properly, the flame will

be steady and quiet. It will also have a

sharp, blue inner core that will vary in

length proportional to the burner size.

Flame adjustment will not be

necessary.

As shown in the above diagram, the

included regulator must be used when

connecting the Miele appliance to your

gas supply. This item has been

customized by Miele to meet all

applicable safety requirements. Make

sure the regulator is easily accessible

for adjustment after the appliance has

been installed.

35

Page 12

Gas connection

The appliance should have been

ordered for connection to either natural

gas or LP gas (propane).

If the appliance is not configured for the

proper type of gas connection please

contact your Miele Dealer.

If the appliance is to be connected to a

type of gas other than it was originally

configured for, both the regulator and

burners must be converted. A

conversion kit is available as an

optional accessory from the Miele

Technical Service Department.

36

Page 13

Burner performance

Rated load at high setting

Burner Type of gas KM 2030 KM 2050

BTU/hr kW BTU/hr kW

Small burner Natural gas (NG)

Liquid gas (LP)

Regular burner Natural gas (NG)

Liquid gas (LP)

Power burner Natural gas (NG)

Liquid gas (LP)

Wok Natural gas (NG)

Liquid gas (LP)

Total Natural gas (NG)

Liquid gas (LP)

Rated load at low setting

Burner Type of gas KM 2030 / KM 2050

Small burner Natural gas (NG)

Liquid gas (LP)

Regular burner Natural gas (NG)

Liquid gas (LP)

Power burner Natural gas (NG)

Liquid gas (LP)

Wok Natural gas (NG)

Liquid gas (LP)

3500

3500

6200

5800

-

-

12000

11000

27900

26100

1,00

1,00

1,80

1,70

-

-

3,50

3,20

8,10

7,60

BTU/h kW

850

850

1200

1200

1700

2000

3700

3700

3500

3500

6200

5800

8900

8900

12000

11000

36800

35000

0,25

0,25

0,35

0,35

0,50

0,60

1,10

1,10

1,00

1,00

1,80

1,70

2,60

2,60

3,50

3,20

10,70

10,20

37

Page 14

How to switch to a different gas type

Switchover to a different gas type should only be performed by a duly

,

authorized gas company technician.

Save the nozzles removed from the appliance for future use.

Nozzle table

If you switch to a different type of gas, the large and small burner nozzles will

need to be changed.

Main nozzle Ø Low setting nozzle Ø

Natural gas (NG)

Small burner

Regular burner

Power burrner

Wok

Liquid gas (LP)

Small burner

Regular burner

Power burrner

Wok

The nozzle listings are for a 1/100mm bore diameter.

0,90

1,13

1,45

1,63

0,58

0,72

0,90

0,98

0,42

0,52

0,60

1,30 (1A)

0,27

0,32

0,40

0,60

38

Page 15

How to switch to a different gas type

How to change a nozzle

Unplug the appliance from the

electrical supply.

How to change the main nozzle

Remove the burner cover b, the

^

burner ring a (wok) and the burner

head c.

Use a socket wrench (M7) to

^

unscrew the main nozzle h.

^ Insert the proper nozzles (see Nozzle

table) and tighten them down.

Small, normal, and power burners

Wok burner

39

Page 16

How to switch to a different gas type

How to change the small nozzles

(all burners)

To change the small nozzles, you will

first need to remove the upper part of

the appliance.

Unscrew the mounting screws on the

^

burner.

Pull the control knob up and off.

^

Take off the upper part of the

^

appliance.

Remove the ignition switch a.

^

^ Use a small screwdriver to unscrew

the small nozzle b from the gas tap.

^ Use needle-nosed pliers to pull the

nozzle out.

^ Insert the proper nozzles (see Nozzle

table) and tighten them down.

a

b

40

Page 17

How to switch to a different gas type

After switching over

Use the reverse order to re-assemble

^

the burner parts.

Before putting the upper part of the

^

appliance back in place, light each

burner with matches to test the seal

on all the gas flow parts.

After testing, set aside the loose

^

burner parts.

Put the upper part of the appliance

^

back in place.

Screw down the lower part of the

^

burner, then put the loose burner

parts back into place, making sure to

follow the right order.

^ Put the control knob back on.

^ Finally, check the flame behaviour of

each burner.

The flame must not go out in the low

setting, even if the control knob is

quickly turned from "high" to "low".

At the high setting, the flame needs to

burn with a clearly visible core.

^

In the nozzle pack, find the

appropriate sticker for the new gas

type and stick it over top of the

previous sticker.

41

Page 18

Alteration rights reserved / 4908

For the most updated manual see the Miele web site.

M.-Nr. 07 520 080 / 00

Loading...

Loading...