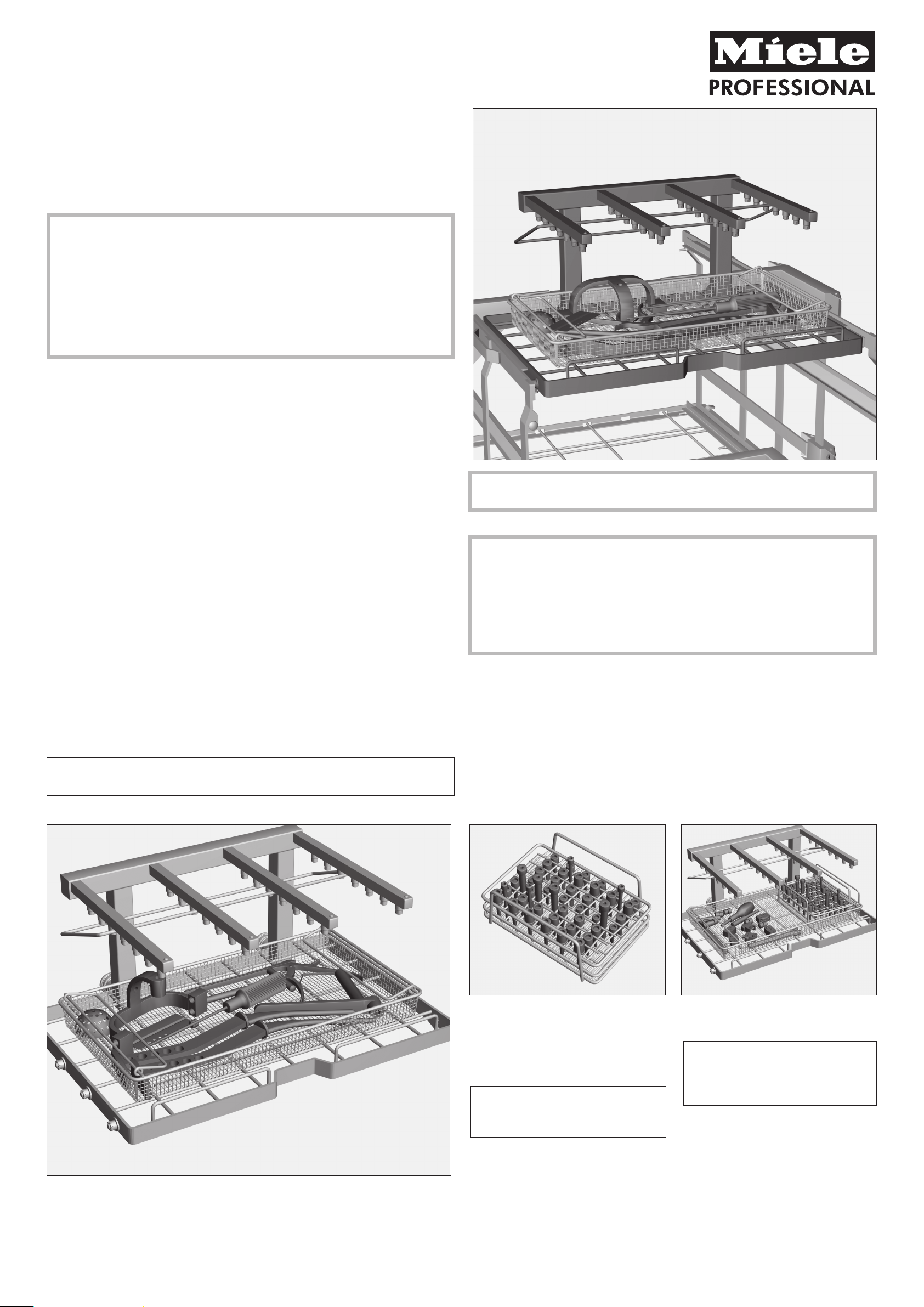

Module for orthopaedic surgical instruments E 948

Items supplied:

Module E 948 for one mesh tray, H 230, W 559, D 352 mm

Accessories available to order:

E 142 DIN mesh tray

–

A6 1/2 cover net, 215 x 460 mm

–

A16 lid for E 142

–

Please observe the Warning and Safety instructions in the Operating

,

Instructions for your G 7827/28 or PG 8527/28 Washer-disinfector carefully. You

should only process medical products in this module if they have been declared

as suitable for machine processing by the manufacturer. Please also observe

the manufacturer's care instructions. The programme selected must be suitable

for the materials from which the medical products to be processed are made.

Where possible, the programme should include thermal disinfection. The final

rinse should, if possible, always be carried out with fully de-mineralised water.

If using automatic mobile unit recognition please make sure that the coding is

correctly set.

Areas of application:

Module E 948 can be placed in both levels of the E 941 mobile unit. The E 941

mobile unit is supplied with its own operating instructions.

In the lower level, cleaning is particularly intensive because of the mechanical

wash effect of the machine spray arm from below and the spray of the module from

above. We recommend that the lower level is used for instruments which have

stringent cleaning requirements.

Module E 948 module can be used to machine process orthopaedic surgical

instruments, which have a surface structure which is difficult to clean or which are

taller than 6 cm. These include, for example, osteotomes, rasps, holders, frames,

muscle and tissue protectors, insertion and removal instruments, retractors and

large retractors.

The instruments should be placed in a DIN mesh tray underneath the jets of the

module. Load dimensions for mesh tray: H 125, W 520, D 290 mm.

Before loading the machine and before starting a programme, please check

that:

– the module is correcly connected to the water intake in the mobile unit.

For validation purposes please make sure that you follow the loading

instructions given on the template.

Before processing hollow intruments, they must be checked to ascertain

,

that the cleaning solution can pass through them.

Where the cleaning performance is insufficient when instruments with bone or

bone marrow deposits are being processed, depending on the chemical agent

used, additional pre-treatment, e.g. ultrasound should be carried out, if

necessary. It is particlarly important to validate the cleaning result of hollow

instruments (Test Kit).

Loading the mesh tray

^

Arrange the instruments in the mesh tray so that they do not cover each other.

To ensure that the jets can distribute the cleaning solution evenly, the load height

of 125 mm must not be exceeded.

Tray insert E 955

Hollow instruments with an internal diameter of more than 3 mm and up to 125 mm

long can be placed in the tray insert.

Such instruments include, Jacobs chucks, drill bushes, guide sleeves, handles

and adapters.

The compartments of the tray insert

have different diameters.

^

Place the instruments in a segment

which is appropriate to the external

diameter.

Instruments with ends which differ in

diameter should be placed with the

wider end facing upwards.

^

Place the loaded tray insert in

module E 948.

To make best use of the capacity of

the module, the tray insert can be

placed in a partially loaded mesh

dish.

^

Place the loaded tray underneath the jets of the module.

Miele Company Ltd., Fairacres, Marcham Road, Abingdon, Oxon, OX14 1TW, Tel 0330 160 6600,

Internet: http://www.miele.co.uk / ! 0297 Alteration rights reserved / Publication date 2015-11-01

M.-Nr. 10 335 580 / 00 en

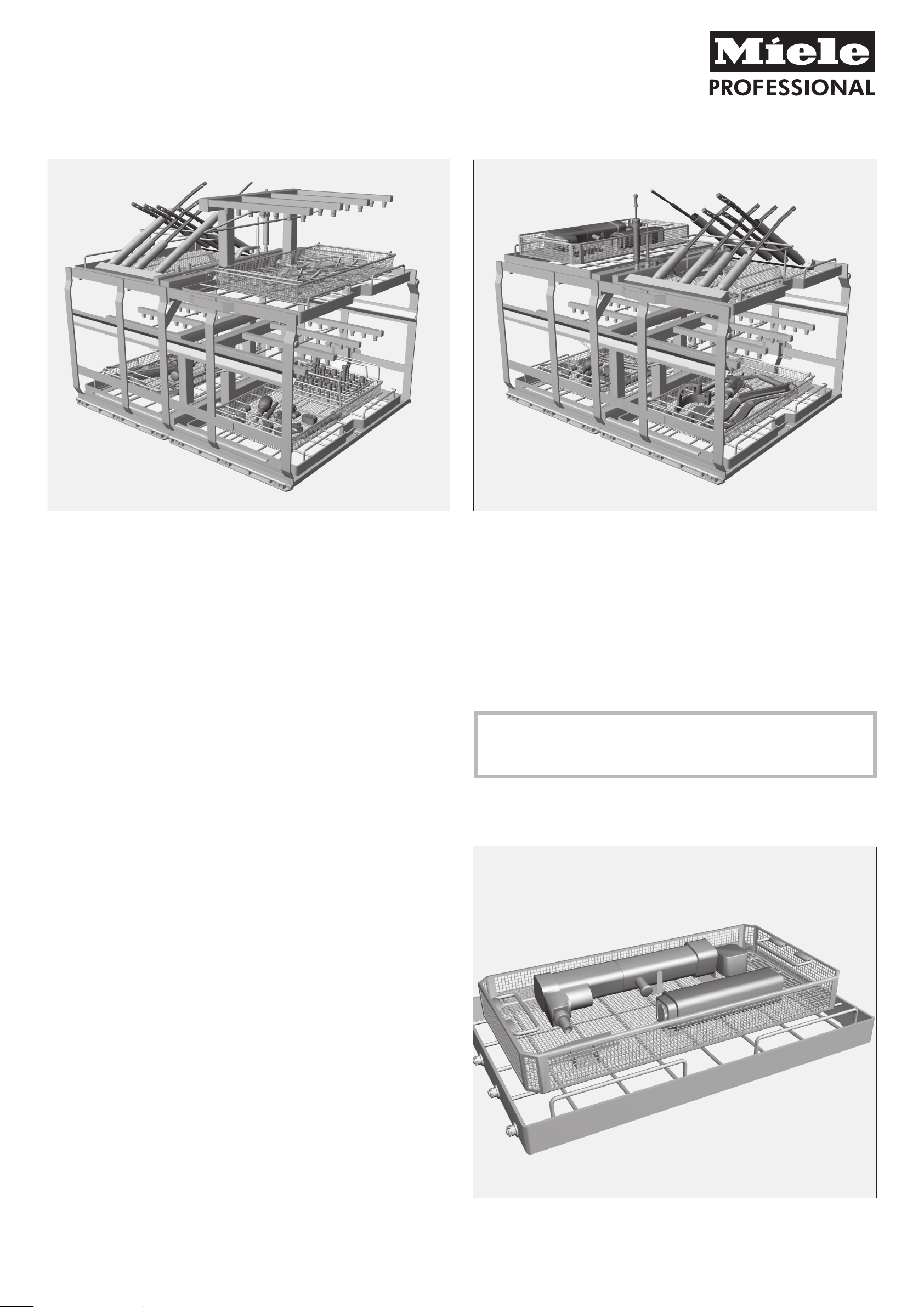

Module for orthopaedic surgical instruments E 948

Some suggested uses:

Mobile unit E 941 with three E 948 modules and one E 949 module

Mobile unit E 941 with two E 948 modules, one E 949 module and one E 945

frame

Frame E 945 is fitted with a mesh tray with special motor system manufacturers'

holders.

These holders have to be protected from spray and this is ensured by the

reduced mechanical action in the upper level of the mobile unit.

Motor systems

Motor systems which have been declared as suitable for machine processing by

the manufacturer can be placed in frame E 945 in the upper level of mobile unit

E 941.

If the washer-disinfector is being operated in conjunction with a conveyor belt,

it is essential to place frame E 945 in the upper level of mobile unit E 941.

Otherwise the mobile unit will not be able to be pulled out of the washerdisinfector.

Motor systems must be processed in mesh trays using the manufacturer's special

holders.

The holders prevent the cleaning solution from getting into the motor systems.

^

Place the mesh tray containing the motor systems on the frame.

Loading...

Loading...