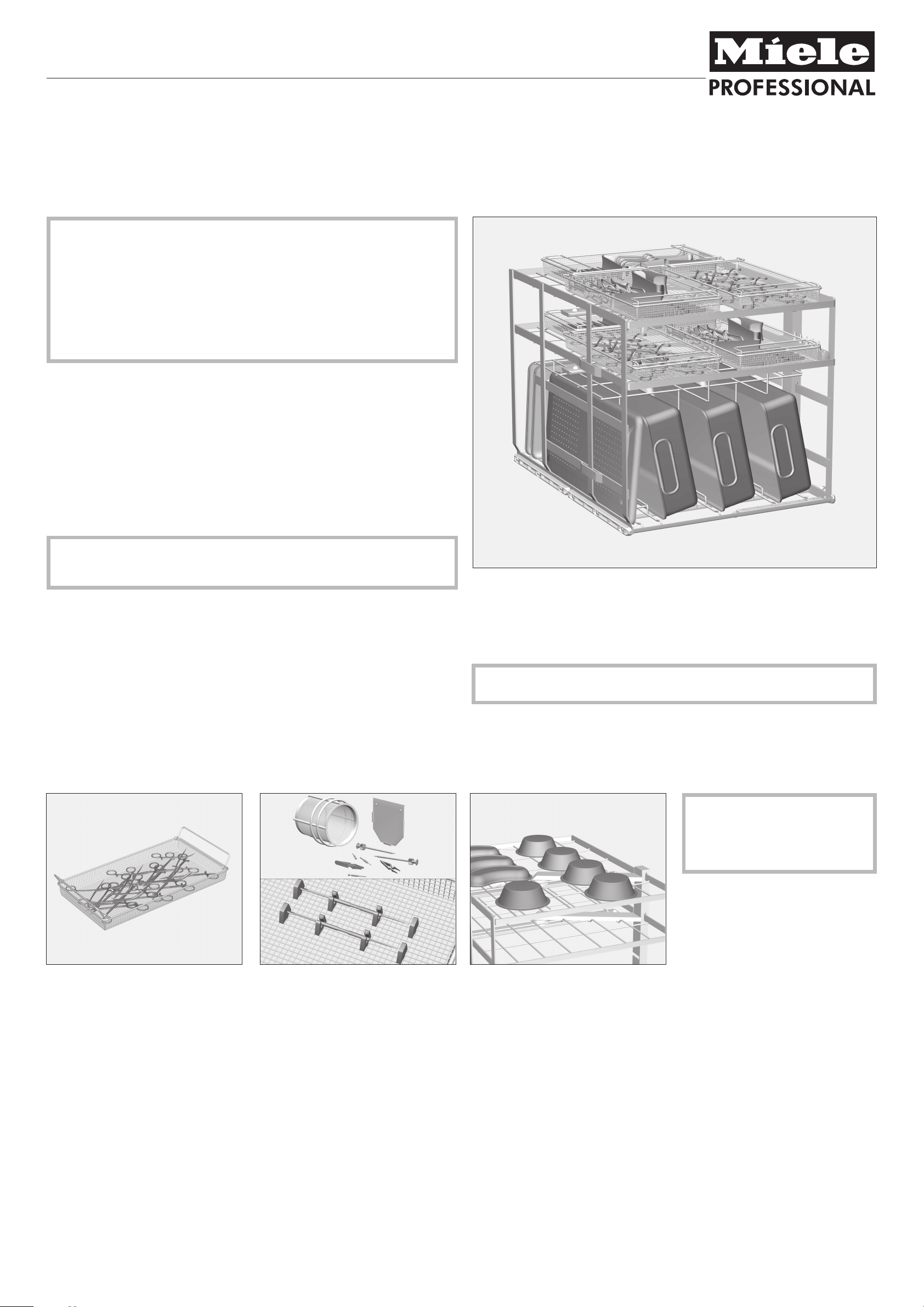

E 913/3 mobile unit for operating theatre instruments and containers

Items supplied:

Mobile unit E 913/3 with three levels, H 570, W 636, D 790 mm Optional accessories

E 142 DIN mesh tray

Connectors for hollow instruments on the second level:

2 x E 447 Luer lock adapters ] for Luer locks \

–

3xØ3mminjector jets, 24 mm long

–

1 magnetic strip for automatic mobile unit recognition

–

Spray arm magnets for spray arm monitoring (PG 8527/28 only)

–

Please read the Warning and Safety instructions in the Operating Instructions

,

for your G 7827/28 or PG 8527/28 Washer-disinfector carefully. You should only

process medical devices in this mobile unit if they have been declared as

suitable for machine processing by the manufacturer. Please also observe the

manufacturer's care instructions. The programme selected must be suitable for

the materials from which the items to be processed are made. Where possible,

the programme should include thermal disinfection. The final rinse should, if

possible, always be carried out with fully de-mineralised water.

If using automatic mobile unit recognition please make sure that the coding is

correctly set.

Areas of application:

–

A2 1/2 cover net, 216 x 456 mm

–

E 476 holders for micro instruments

–

Insert E 473/1 for small instruments

–

The lowest level of the E 913/3 mobile unit can be used to process three shallow

DIN containers and their lids (160 x 300 x 600 mm*).

The two upper levels of the mobile unit can each be used to accommodate three

DIN mesh trays of surgical instruments.

The second level of the mobile unit can take up to five hollow instruments using

injector jets and Luer lock adapters.

* Dimensions are given in mm for containers including their lids (height x width x

length), manufactured in accordance with DIN EN 868-8

Important:

A pH neutral cleaning agent must be used for anodised aluminium containers.

Coloured anodised aluminium containers must be cleaned, thermally disinfected

and rinsed using fully de-mineralised water.

– Add a suitable rinsing agent when processing plastic containers and lids for

quicker and better drying results.

– Remove any textile or paper filters from lids before processing.

– Teflon filters may be left in lids unless the manufacturer's instructions state

otherwise.

– Check that the valve is functioning correctly after processing disposal containers

with valves.

Note:

Please follow all relevant health and safety regulations on disinfection parameters

and personal safety to prevent the risk of injury.

Before loading the machine and before starting a programme, please check:

– that the spray arms rotate freely,

– that the spray arm jets are clean and free of any blockages,

– that the mobile unit is correctly fitted into the cabinet and that it has connected

correctly with the water intake.

For validation purposes please make sure that you follow the loading

instructions given on the template.

^

Hinged instruments must be opened

up before being placed in the mesh

trays to minimise the risk of surfaces

not being accessed during

processing.

^

To prevent the risk of lightweight

instruments such as bulldog clips

and other small items being moved

about during processing, silicone

holders e.g. E 476 and closable

inserts e.g. E 473 can be used to

keep them secure.

^

Containers e.g. beakers and kidney

dishes should be placed in the

mobile unit with the open side facing

downwards, ensuring that all

surfaces can be accessed easily

and that cleaning solution can flow

freely off them. They must also be

secure so that they cannot be flipped

over by the force of water during

processing.

,

If hollow containers are placed

such that cleaning solution can

collect in recesses etc., they will not

get properly clean and rinsing

results will be impaired.

Miele Company Ltd., Fairacres, Marcham Road, Abingdon, Oxon, OX14 1TW, Tel 0330 160 6600,

Internet: http://www.miele.co.uk / ! 0297 Alteration rights reserved / Publication date 2015-11-01

M.-Nr. 10 332 040 / 00 en

E 913/3 mobile unit for operating theatre instruments and containers

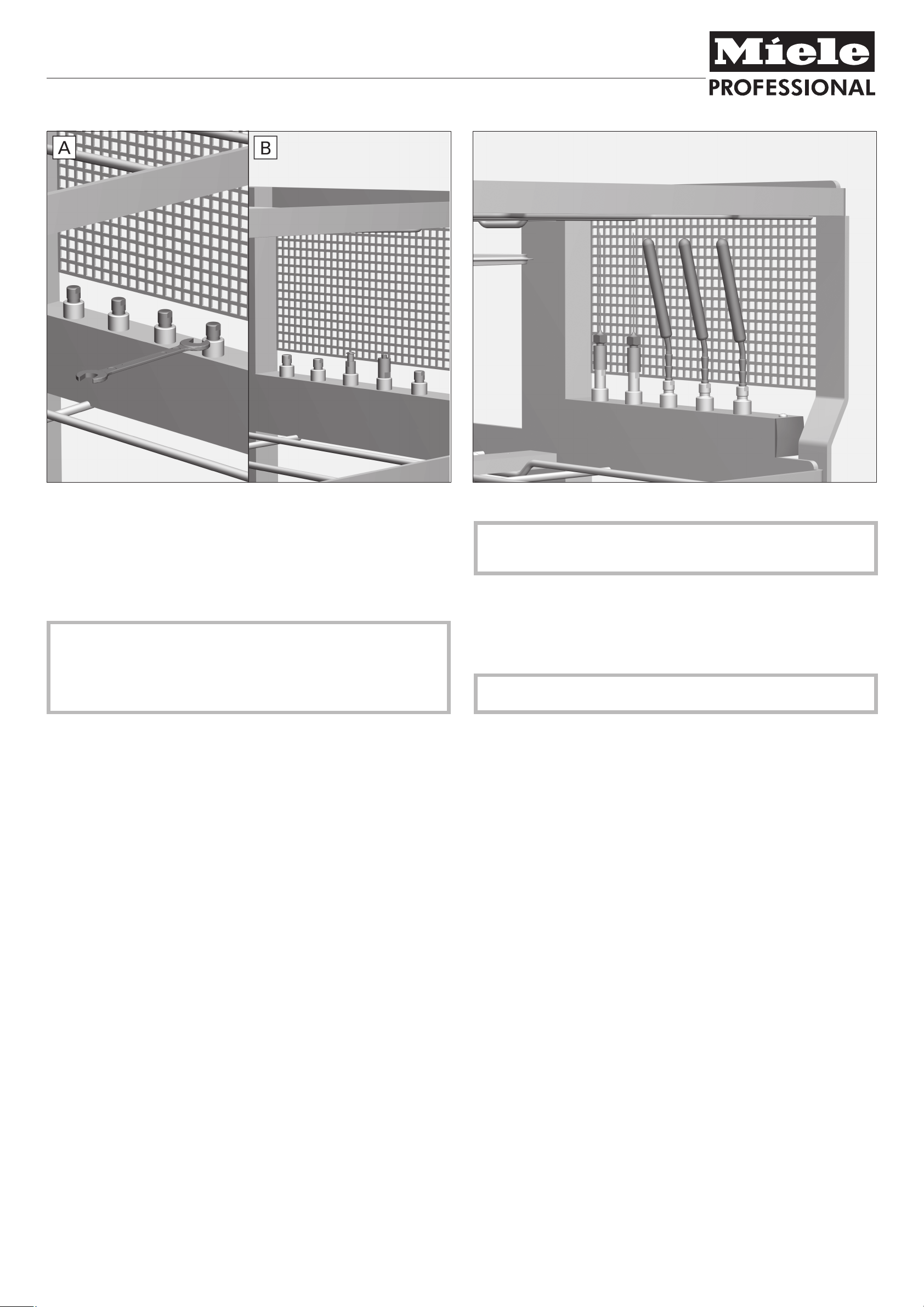

Connection for hollow instruments

Injector jets and Luer lock adapters

Up to five hollow instruments can be processed in the second level of the mobile

unit using the injector jets and Luer lock adapters supplied.

To do this:

^ Unscrew the locking caps from the connectors using an SW 7 spanner a.

^ Screw the Luer lock adapters or the injector jets into the connectors and tighten

them with the spanner b.

To ensure a suitable standardised spray pressure for all connections, all

,

screw connectors must be fitted with jets, adapters, sleeves or blanking

screws.

Damaged jets, adapters or sleeves etc. must not be used.

Empty jets, etc. do not have to be replaced with blanking screws.

To connect hollow instruments

Before connecting hollow instruments, please make sure that all hollow

,

sections are free of blockages. Otherwise the cleaning solution will not be able

to access all areas properly.

^ Cannulae with Luer lock connectors should be connected to the appropriate

Luer lock adapters in the mobile unit.

^ Cannulae with female connectors should be connected to the Luer lock adapter

in the mobile unit using a Luer lock \ / Luer lock \ connecting piece.

^ Surgical suction devices, e.g. Cooleys, should be connected to the jets.

,

Any hollow instruments that have become disconnected from the adapters

during processing must be reprocessed.

Loading...

Loading...