E 902/3 mobile unit for modules

Please read the Warning and Safety instructions in the operating Instructions for your G 7827/28 or PG 8527/28 Washer-disinfector carefully. You should only

,

process instruments/medical devices in this mobile unit if they have been declared as suitable for machine processing by the manufacturer. Please also observe the

manufacturer's care instructions. The programme selected must be suitable for the materials from which the medical devices to be processed are made. Where

possible the programme should include thermal disinfection. The final rinse should, if possible, always be carried out with fully demineralised water.

If using automatic mobile unit recognition, please make sure that the coding is correctly set.

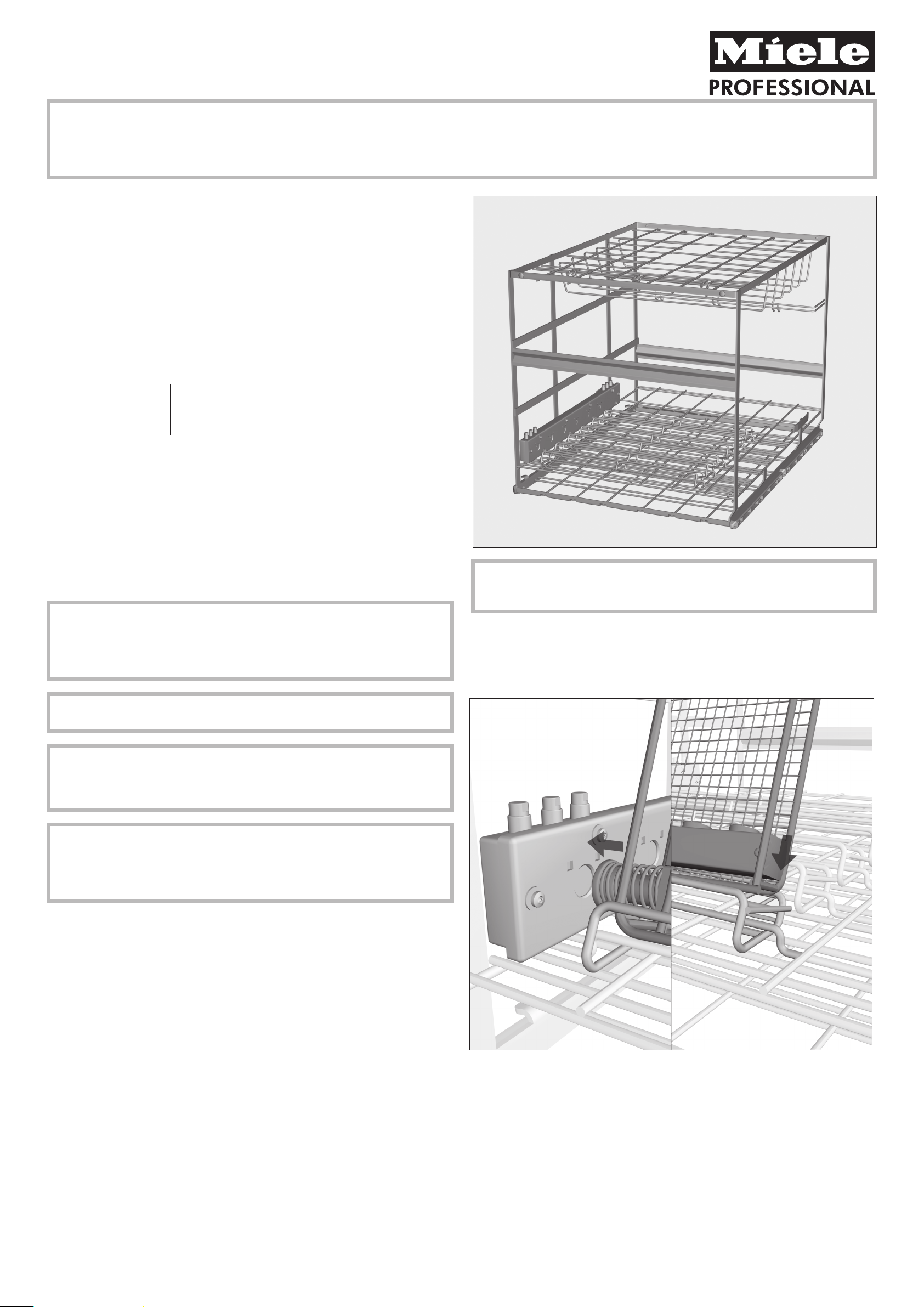

Mobile unit E 902/3, H 620, W 640, D 790 mm,

fitted with a magnet strip for automatic mobile unit recognition

Areas of application:

Up to six modules for MIS instruments or dental modules can be placed in the

mobile unit at any one time. Fibre optic cables and suction tubes can be

processed using up to six E 444 inserts. The holders for these are located at the

front and the back of the mobile unit. There are six connectors for internal cleaning

of suction tubes and long instruments.

In addition to this, special inserts for cleaning optical instruments and mesh trays

can be placed in the upper level. Mesh trays can be placed in the lower level.

Loading dimensions

Upper level

Lower level

Before loading the machine and before starting a programme, please check

that:

the water intake valves on each of the modules are working correctly,

–

the modules are correctly connected to the water intake for the mobile unit,

–

the mobile unit is correctly connected with the water intake in the washer-

–

disinfector.

To ensure a suitable standardised spray pressure for all connections, all

,

screw connectors must be fitted with jets, adapters, sleeves or blanking screws.

Damaged jets, adapters or sleeves etc. must not be used.

Empty jets, etc. do not have to be replaced with blanking screws.

For validation purposes please make sure that you follow the loading

instructions given on the template.

E 902/3 [HxWxDinmm]

65 x 593 x 780

53 x 593 x 780

Make sure that items in either level are not covered by other items, and do

,

not place items inside other items, as this will prevent instruments being

cleaned properly.

,

All MIS instruments must be dismantled for processing in accordance with

the manufacturer's instructions.

Long, narrow lumen instruments which cannot be taken apart must be pre-was

hed in accordance with the manufacturer's instructions.

,

Before connecting a hollow instrument please make sure that all hollow

sections are free of blockages. Otherwise the cleaning solution will not be able

to access all areas properly.

Instruments should not be able to come into contact with one another during the

cleaning and disinfecting process.

-

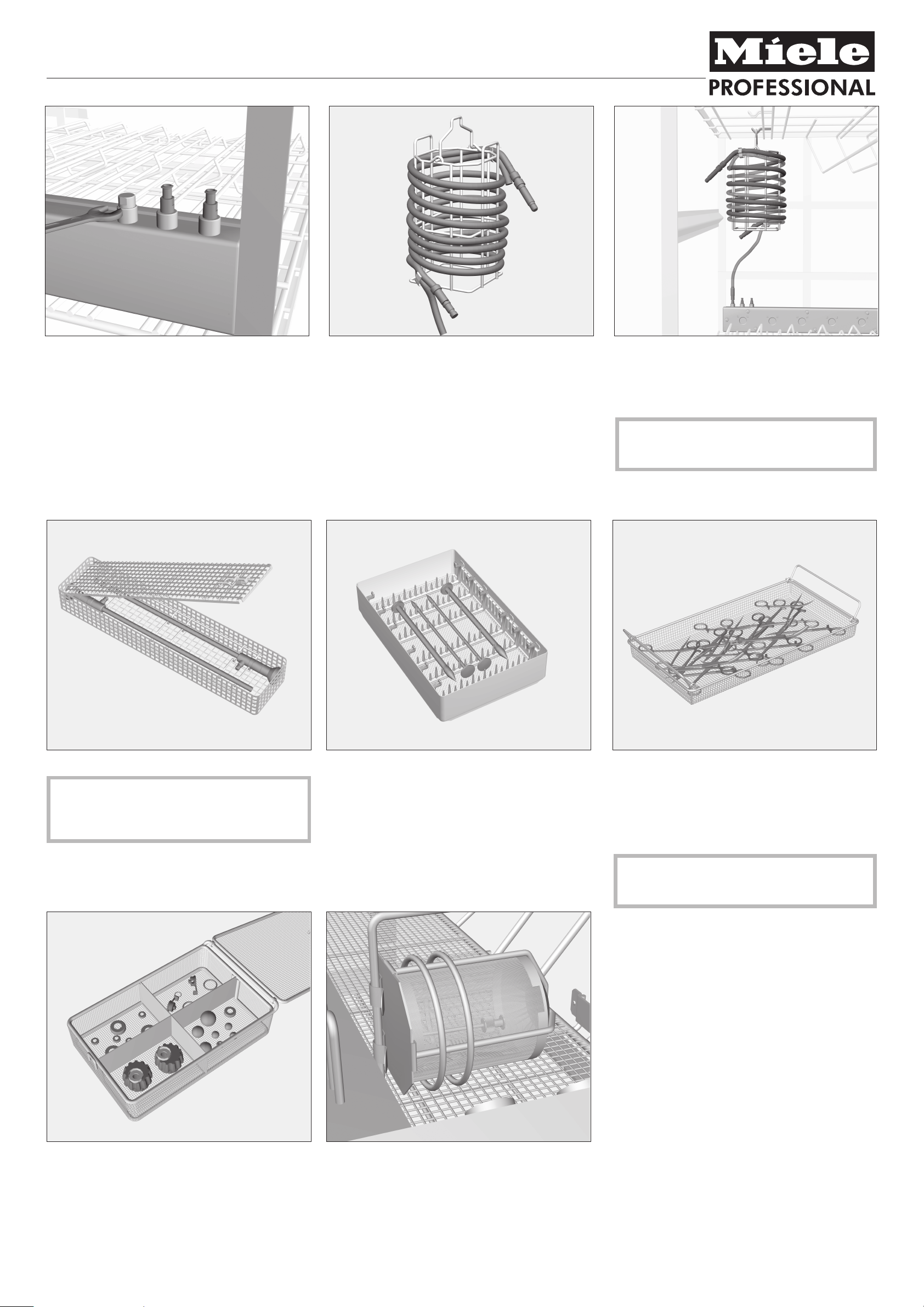

Placing modules into the mobile unit

^

Push the module into the mobile unit, connecting the water intake on the module

to that on the mobile unit. The valve will open automatically.

^

Fit the module behind the holding bracket on the frame.

Miele Company Ltd., Fairacres, Marcham Road, Abingdon, Oxon, OX14 1TW, Tel 0330 160 6600,

Internet: http://www.miele.co.uk / ! 0297 Alteration rights reserved / Publication date 2015-11-01

M.-Nr. 10 336 060 / 00 en

E 902/3 mobile unit for modules

Fitting the injector jets and Luer lock adapters

On either side of the mobile unit there are three

connectors for injector jets, tube adapters and

suction tubes (available as optional accessories).

Unscrew the blanking screws from the connectors

^

using an SW 9 spanner.

Screw the Luer lock adapters or the injector jets

^

into the connectors and tighten them with a

spanner.

Fibre optic cables and suction tubes

Fibre optic cables and suction tubes can be

processed in insert E 444 (available as an optional

accessory).

The insert comes with its own instructions.

Hang insert E 444 from the hook in the mobile unit,

^

as shown.

Fit the end of the suction tube to one of the

^

adapters at the side of the mobile unit so that clea

ning solution flushes upwards through the tube.

Make sure that the ends of the cables and suction

tubes cannot get caught in the mobile unit or in

the door of the washer-disinfector.

-

Optical instruments

,

In order to protect them from damage, optical

instruments must only be processed in the optic

manufacturer's inserts, or in Miele special insert

E 460 (available as an optional accessory).

^

Place inserts containing optical instruments on the

upper level of the mobile unit.

Trocars without lumen

Trocars (without lumen) and micro-instruments can

be processed in insert E 441/1 (available as an

optional accessory).

^

Place the trocars in the notches.

^

Place the insert in the upper or lower level of the

mobile unit.

Mesh trays

Hinged instruments must be opened up before being

placed in mesh trays to minimise the risk of surfaces

not being accessed during processing.

^

Place mesh trays (available as an optional

accessory) on the upper level of the mobile unit.

Do not overload the mesh trays as this would

prevent the surfaces of the items from being

cleaned properly.

Small instruments

Place small items such as seals and valves in lidded

mesh tray E 451 (available as an optional accessory).

^

Close the lid, and place in the lower level of the

mobile unit.

Place very small items (which could be washed

through the mesh trays or through the gap between

the mesh tray and the lid) in insert E 473/1 (available

as an optional accessory).

^

Secure insert E 473/1 to one of the struts in the mo

bile unit.

-

Loading...

Loading...