Mobile injector unit E 729 for opthalmic instruments

Please observe the Warning and Safety instructions in the Operating instructions for your G 7825/26 washer-disinfector carefully. You should only process

,

instruments/medical products in this mobile unit if they have been declared as suitable for machine processing by the manufacturer. Please also observe the

manufacturer's care instructions. The programme selected must be suitable for the materials from which the items to be processed are made. Where possible the

programme should include thermal disinfection. The final rinse should, if possible, always be carried out with fully de-mineralised water.

If using automatic mobile unit recognition please make sure that the coding is correctly set.

Items supplied:

Mobile unit E 729 equipped with: Supplied as separate items:

15 x Luer lock adapters \

–

15 x Luer lock adapters ]

–

16 x Luer lock adapters \, with hose connector

–

1 magnetic strip for automatic mobile unit recognition (without magnets)

–

Optional accessories

E 441/1 insert for micro instruments

–

E 142 DIN mesh tray

–

E 478/1 holder with microfilter for narrow lumen cannulae

–

E 448 silicone tubes, 300 mm, with Luer lock adapters \ for Luer locks ]

–

E 531 caps for Luer locks

–

E 362 Blanking screws

–

50 x E 476 holders for micro instruments, e.g. for E 142 DIN mesh trays

–

20 x E 477 connectors for micro instruments, e.g. for E 142 DIN mesh trays

–

8 x E 791 Luer lock connectors ] / Luer \

–

8 x E 790 Luer lock connectors ] / Luer lock ]

–

E 479 holders for micro instruments

–

E 476 holders for micro instruments

–

E 477 connectors for micro instruments

–

E 791 Luer lock connectors ] / Luer \

–

E 790 Luer lock connectors ] / Luer lock ]

–

E 792 Luer-Lock connector\ with silicone tube

–

5 magnets for automatic mobile unit recognition (ML)

–

Areas of application:

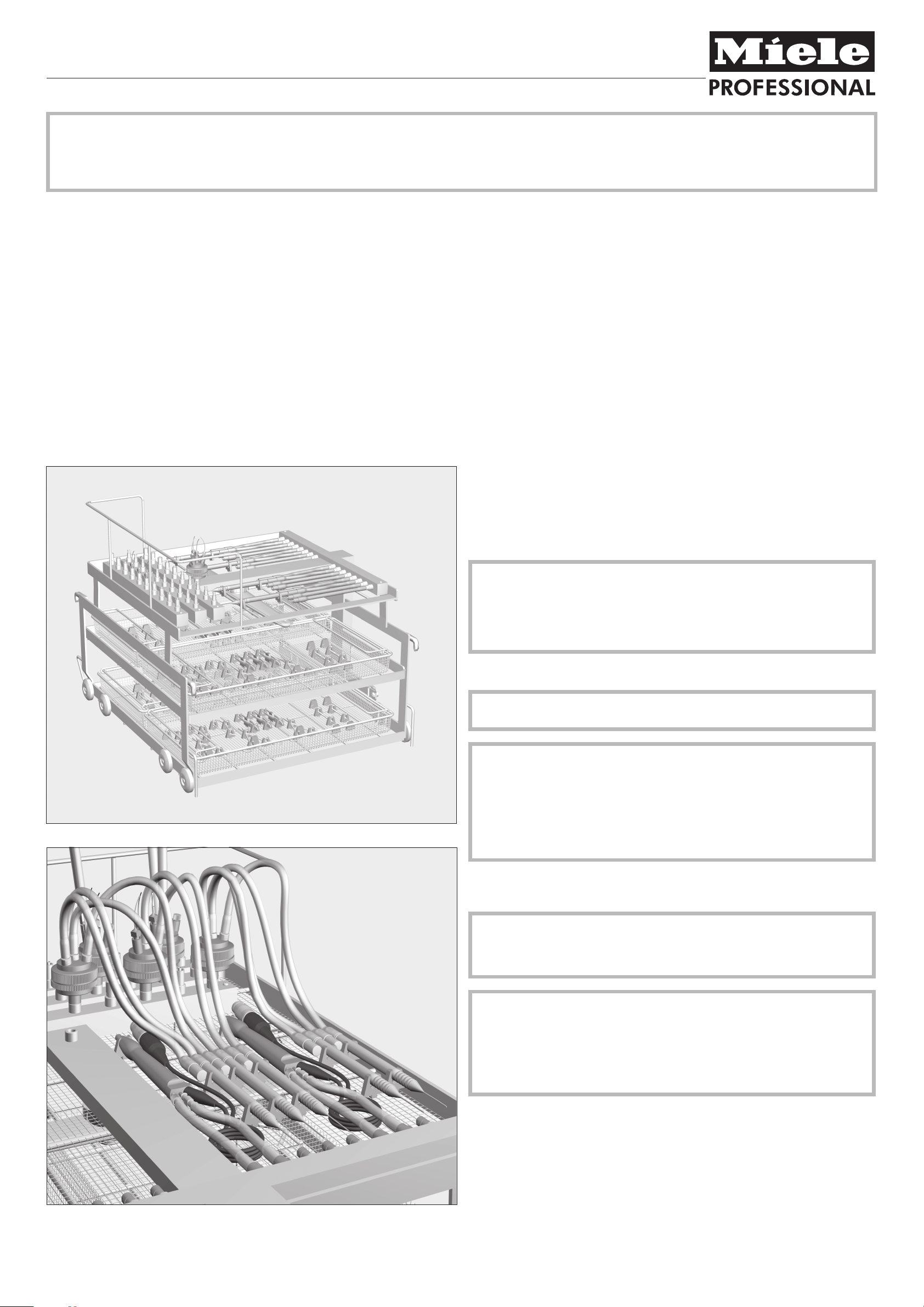

The E 729 mobile injector unit is solely designed for cleaning and disinfecting

opthalmic instruments.

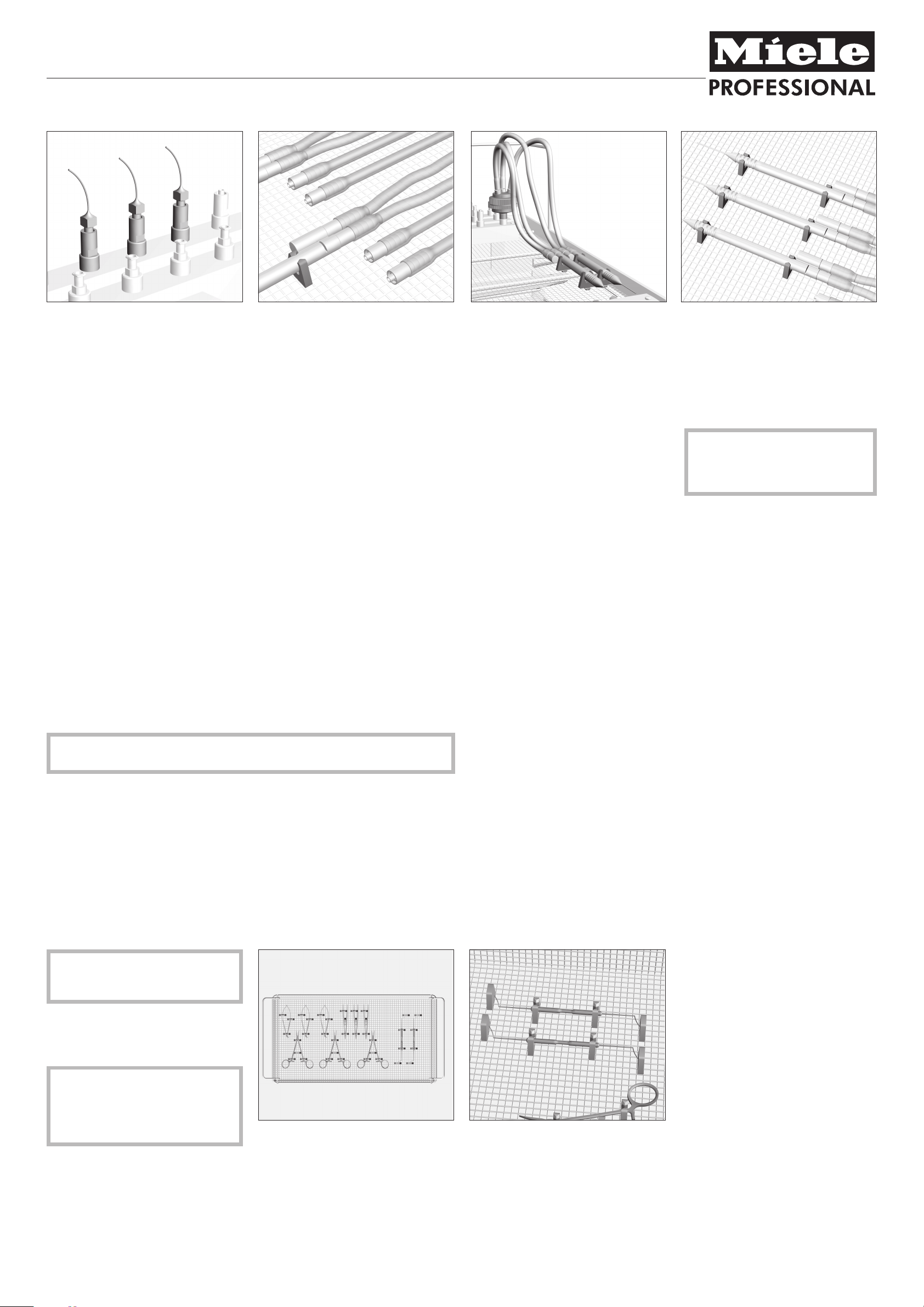

The top level is fitted with various connections for hollow instruments, e.g. rinsing

and suction tubes and cannulae.

A maximum of 16 x E 478/1 may also be connected for additional filtering.

Narrow lumen instruments, e.g. special cannulae (e.g. Sauter) and rinsing

,

and suction handles must be connected to the E 478/1 holder. The E 478/1 has

its own separate operating instructions.

Consult the instrument manufacturer for guidance on degree of sud filtration for

specific instruments.

The filter plate of the E 478/1 has a filtration level of 0 0.1 mm.

Instruments are secured to the hose connectors in the mobile injector unit using

the silicone holders and connectors in the rack.

For validation purposes please make sure that you follow the loading

instructions given on the template.

,

Individual instruments should not touch each other during cleaning and

disinfection.

Before connecting hollow instruments, ensure that lumens and canals are

accessible for suds.

Rinse cannulae and other hollow instruments as soon as possible after patient

use, preferably while still in the operating theatre, using a syringe and water.

This will help to prevent narrow cannulae becoming clogged by blood or other

residues, which would hinder the cleaning process.

The lower two levels of the mobile injector unit are designed to take E 441/1 inserts

or E 142 mesh trays for processing solid instruments. See over page for

instructions on loading an E 142 mesh tray.

,

Opthalmic instruments should only be processed in a machine designated

for their sole use. This way there is no risk of residues from other disciplines

getting into the narrow lumen of hollow instruments. Synthetic cover nets, e.g.

Miele A 2 and A3 cover nets may not be used in this washer-disinfector.

,

To ensure a suitable standardised spray pressure for all connections, all

screw connectors must be fitted with jets, adapters, silicone tubes with Luer

lock connectors, caps or blanking screws.

Damaged jets, adapters or silicone tubes with Luer lock connectors etc. must

not be used.

Empty jets, etc. do not have to be replaced with blanking screws.

Miele Company Ltd., Fairacres, Marcham Road, Abingdon, Oxon, OX14 1TW, Tel 0330 160 6600,

Internet: http://www.miele.co.uk / ! 0297 Alteration rights reserved / Publication date 2015-11-01

M.-Nr. 10 333 680 / 00 en

Mobile injector unit E 729 for opthalmic instruments

Arranging opthalmic instruments

Long hollow instruments should be

^

screwed to the flexible hose

connectors using Luer lock adapters

\.

Connect cannulae with Luer connectors

to the Luer lock adapter on the injector

unit using a connecting piece, e.g. Luer

lock ] / Luer \.

When processing hollow instruments

^

with several connectors, such as

rinsing or suction hand pieces, each

connector needs to be secured to a

hose.

Hollow instruments with a male

^

connector should be connected to

the hose using a Luer lock ] / Luer

lock ] connector.

Quality assurance testing

^ Expel residual water from hollow instruments using medical compressed air. This

also verifies lumen are clear.

^ At the same time, the pH value of displaced water can be checked using litmus

paper (ß 0.5 grade).

Connect narrow lumen instruments

^

with multiple connections to an

E 478/1 holder.

Link each connection of the

^

instrument, e.g. the rinsing and

suction handles, with an E 448.

Use a Luer-Lock ] / Luer-Lock ]

^

connector between instruments with

a male Luer lock connector and the

E 448.

Fit hollow instruments securely into

^

the silicone holders on the rack in

the injector unit.

Space the silicone holders in the

^

rack according to the size of the

instruments.

Unscrew hollow instruments after

^

cleaning.

Any hollow instruments that

,

have become disconnected from

the adapters during processing

must be reprocessed.

If the result is negative:

^ Remove the cause of any blockage manually and reprocess the instruments.

^

If the pH value is not neutral reprocess the instruments.

If the pH value continues not to be neutral, contact the Service Department to

arrange for further analysis of the problem.

E 142 mesh tray for opthalmic instruments

The instruments should not be able

to touch each other during the

cleaning and disinfecting process.

Light, delicate non-hollow instruments

can be secured in position in the E 142

mesh tray using silicone holders E 476

or E 479 and silicone connectors E 477.

If E 142 mesh trays are used in the

lowest level of the injector unit the

E 479 silicone holders have to be

used in order to hold the instruments

securely.

To ensure that all surfaces are cleaned

and rinsed thoroughly:

^

Hinged instruments, e.g. scissors,

clamps and forceps should be

opened up and then placed in the

tray.

^

Diamond knives must be opened up

and then placed on the tray.

^

Secure straight instruments in the

silicone holders so that they cannot

slip out during processing.

Loading...

Loading...