Miele E 429 Operating instructions

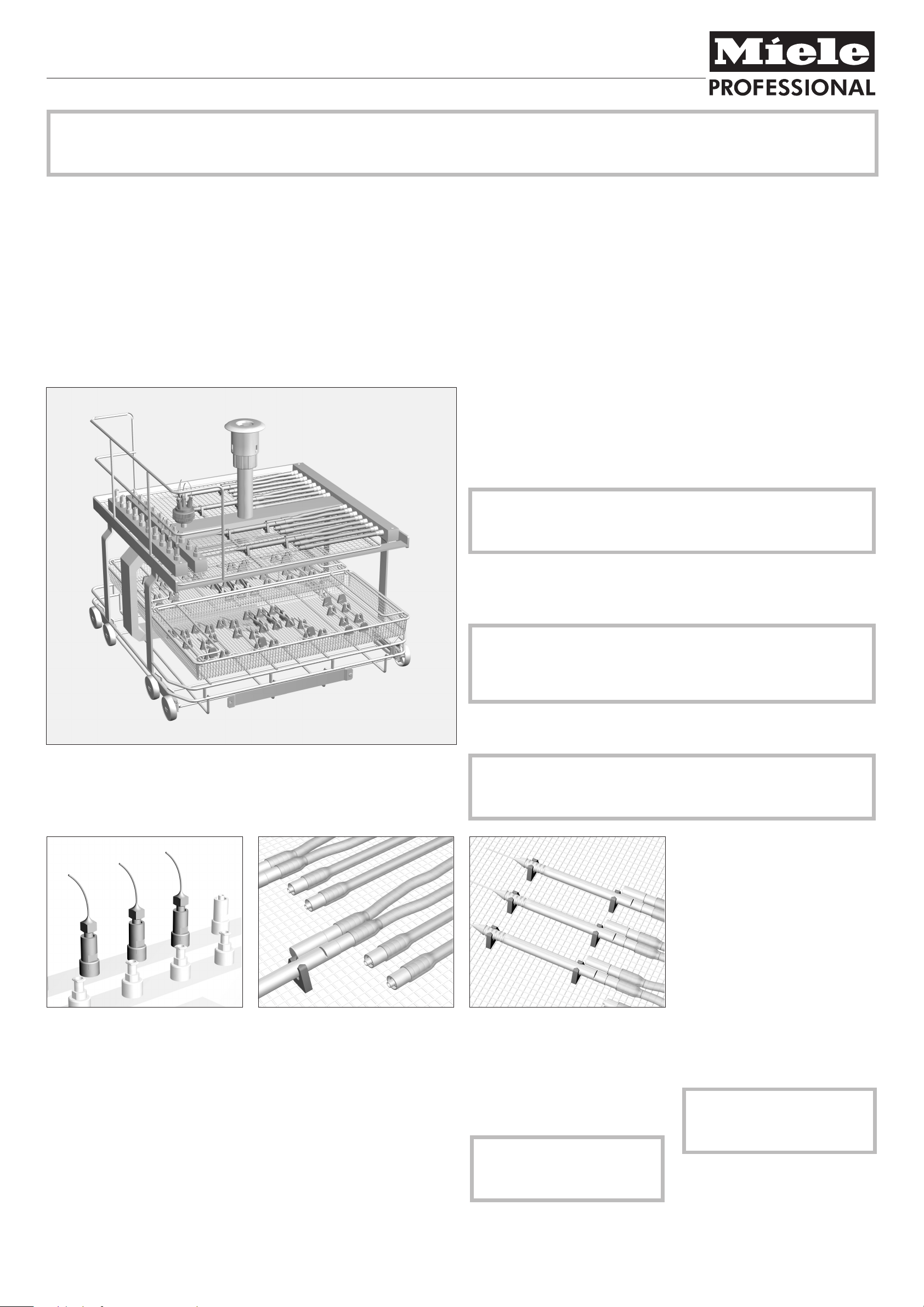

Mobile injector unit E 429 for opthalmic instruments

Please read the Warning and Safety instructions in the Operating Instructions for your washer-disinfector carefully. You should only process instruments/medical

,

products in this unit if they have been declared as suitable for machine processing by the manufacturer. Please also observe the manufacturer's care instructions. The

programme selected must be suitable for the materials from which the medical products to be processed are made. Where possible the programme should include

thermal disinfection. The final rinse should, if possible, always be carried out with fully de-mineralised water.

Items supplied:

Mobile unit E 429 equipped with:

10 x Luer lock adapters \

–

10 x Luer lock adapters ]

–

16 x Luer lock adapters \, with hose connector

–

Supplied as separate items:

An adapter for the water supply to the mobile injector unit

–

50 x E 476 holders for micro instruments, e.g. for E 142 DIN mesh trays

–

20 x E 477 connectors for micro instruments, e.g. for E 142 DIN mesh trays

–

8 x Luer lock ] / Luer \ connectors

–

8 x Luer lock ] / Luer lock ] connectors

–

Accessories available to order:

E 441 insert for micro instruments

–

E 142 DIN mesh tray

–

E 478 insert with micro filter for narrow lumen cannulae

–

Magnetic strip ML/2 for automatic mobile unit recognition

–

E 476 holders for micro instruments

–

E 477 connectors for micro instruments

–

Luer lock ] / Luer \ connectors

–

Luer lock ] / Luer lock ] connectors

–

Areas of application:

The E 429 mobile injector unit is designed for the cleaning and disinfecting of

ophthalmic instruments.

The bottom spray arm in the washer-disinfector has be to be replaced by a special

adapter in order to supply water to the mobile injector unit. See over for instruc

tions on how to fit this adapter.

In order to connect the E 429 mobile unit into a G 7835, G 7892, G 7882 or

,

G 7882 CD washer-disinfector, the dispensing pipes into the wash cabinet need

to be replaced by 3 mm C pipes, using a conversion kit if necessary. This work

should be carried out by a Miele authorised service technician.

-

The top level is fitted with various connections for hollow instruments, e.g. rinsing

and suction hand pieces, and cannulae.

Instruments are secured to the hose connectors in the mobile injector unit using

the silicone holders and connectors in the rack.

The instruments should not be able to come into contact with one another

,

during the cleaning and disinfecting process.

Before connecting a hollow instrument please make sure that all hollow sections

are free of blockages. Otherwise the cleaning solution will not be able to access

all areas properly.

The lower level of the mobile injector unit is designed to take E 441/1 inserts or

E 142 mesh trays for processing solid instruments. See over page for instructions

on loading an E 142 mesh tray.

,

Opthalmic instruments should only be processed in a machine designated

for their sole use. This way there is no risk of residues from other disciplines

getting into the narrow lumen of hollow instruments.

Under no circumstances must cover nets A2 or A3 be used in this mobile unit.

^

Any residual water left in hollow in

struments must be forced out using

pressurised filtered air.

This also makes sure that there are

no blockages in hollow sections after

processing.

^

At the same time, the pH value of

displaced water can be checked

using litmus paper (ß 0.5 grade)

-

^

Cannulae with Luer lock connectors

should be screwed into the appro

priate Luer lock adapters on the top

level of the injector unit.

^

Connect cannulae with Luer connec

tors to the Luer lock adapter on the

injector unit using a connecting

piece, e.g. Luer lock ] / Luer \.

Miele Company Ltd., Fairacres, Marcham Road, Abingdon, Oxon, OX14 1TW, Tel (01235) 554455,

Fax (01235) 554477, Internet: http://www.miele.co.uk / ! Alteration rights reserved / 1907

-

^

Long hollow instruments should be

screwed to the flexible hose connec

tors using Luer lock adapters \.

^

When processing hollow instruments

-

with several connectors, such as rin

sing or suction hand pieces, each

connector needs to be secured to a

hose.

^

Hollow instruments with a male con

nector should be connected to the

hose using a Luer lock ] / Luer lock ]

connector.

^

Fit hollow instruments securely into

-

-

-

the silicone holders on the rack in the

injector unit.

^

Space the silicone holders in the

rack according to the size of the

instruments.

^

Unscrew hollow instruments after

cleaning.

,

Any hollow instruments that have

become disconnected from the

adapters during processing must be

reprocessed.

If the result is negative:

^

Remove the cause of any blockage

manually.

After that, even if the pH value is not

neutral:

^

Re-process hollow instruments.

If the pH value continues not to be

neutral, contact the Service Depart

ment to arrange for further analysis

of the problem.

M.-Nr. 06 527 392 / 00

G

-

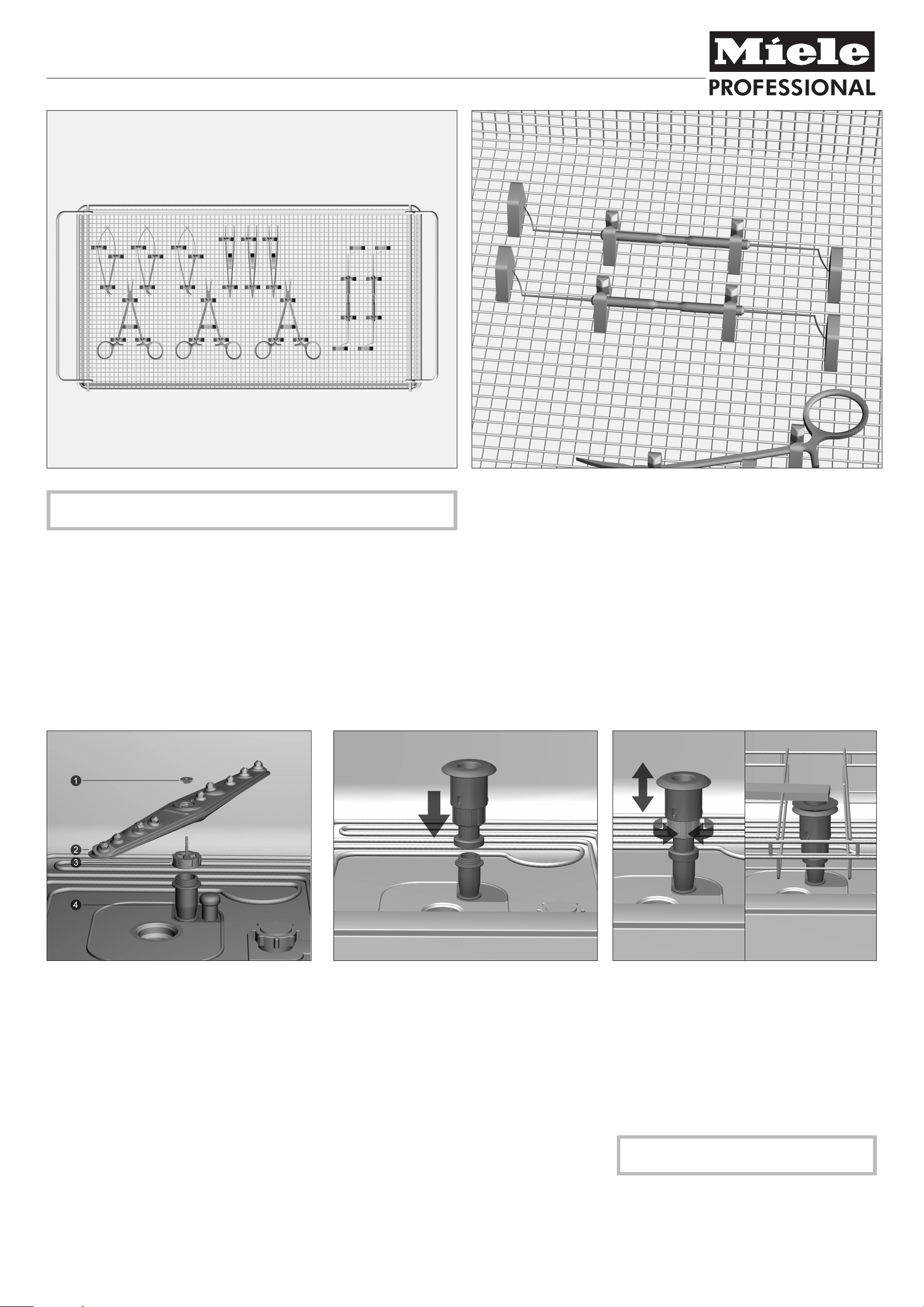

E 142 mesh tray for opthalmic instruments

The instruments should not be able to move around during the cleaning and

disinfecting process.

Light, delicate non-hollow instruments can be secured in position in the E 142

^

mesh tray using silicone holders and connectors.

To ensure that all surfaces are cleaned and rinsed thoroughly:

^ Hinged instruments, e.g. scissors, clamps and forceps should be opened up and

then placed in the tray.

^ Diamond knives must be opened up and then placed on the tray.

Fitting the adapter for the water feed:

Secure straight instruments in the silicone holders so that they cannot slip out

^

during processing.

The bottom spray arm in the washer-disinfector has

be to be replaced by a special adapter in order to

supply water to the mobile injector unit. To do this:

^

Loosen thumb nut A in the middle of the spray

arm.

^

Then take spray arm B off.

^

Unscrew spigot nut together with the spray arm

spindle C from feed pipe D.

^

Screw the adapter onto the feed pipe. The adapter is sprung and must connect correctly

with the water feed on the injector unit when it is pus

hed into the cabinet.

It needs to be set 4 to 5 mm higher than the water

feed on the mobile injector unit.

To align the height of the adapter:

^

Loosen the upper part of the adapter.

^

The push the adapter upwards or downwards to

set the height.

^

Then tighten up the upper part of the adapter.

,

The adapter should be checked on a regular

basis to make sure it is correctly set.

-

Loading...

Loading...