Page 1

VA113301

Quick Reference Guide

Matrx VMS®,, VMS® Plus,

and VMC™ Anesthesia Machines

Model Number:

Serial Number:

Dealer Information:

Purchase Date:

10578000 Rev DA1 3/20/18

This guide outlines basic operation and

maintenance of the Anesthesia Machine.

Additional information is available on

www.Midmark.com. If service is

required, contact your authorized Midmark

dealer.

Maintenance Kits

Calling for Service

If service is required, contact your Midmark dealer.

To contact Midmark directly:

8:00am until 5:00 PM Monday through Friday (EST)

Customer Service

1-800-Midmark (1-800-643-6275), Fax 1-877-725-6495

Technical Service

1-888-279-1260, Fax 1-716-662-8440

Registration

To register your product warranty, go to www.midmark.com

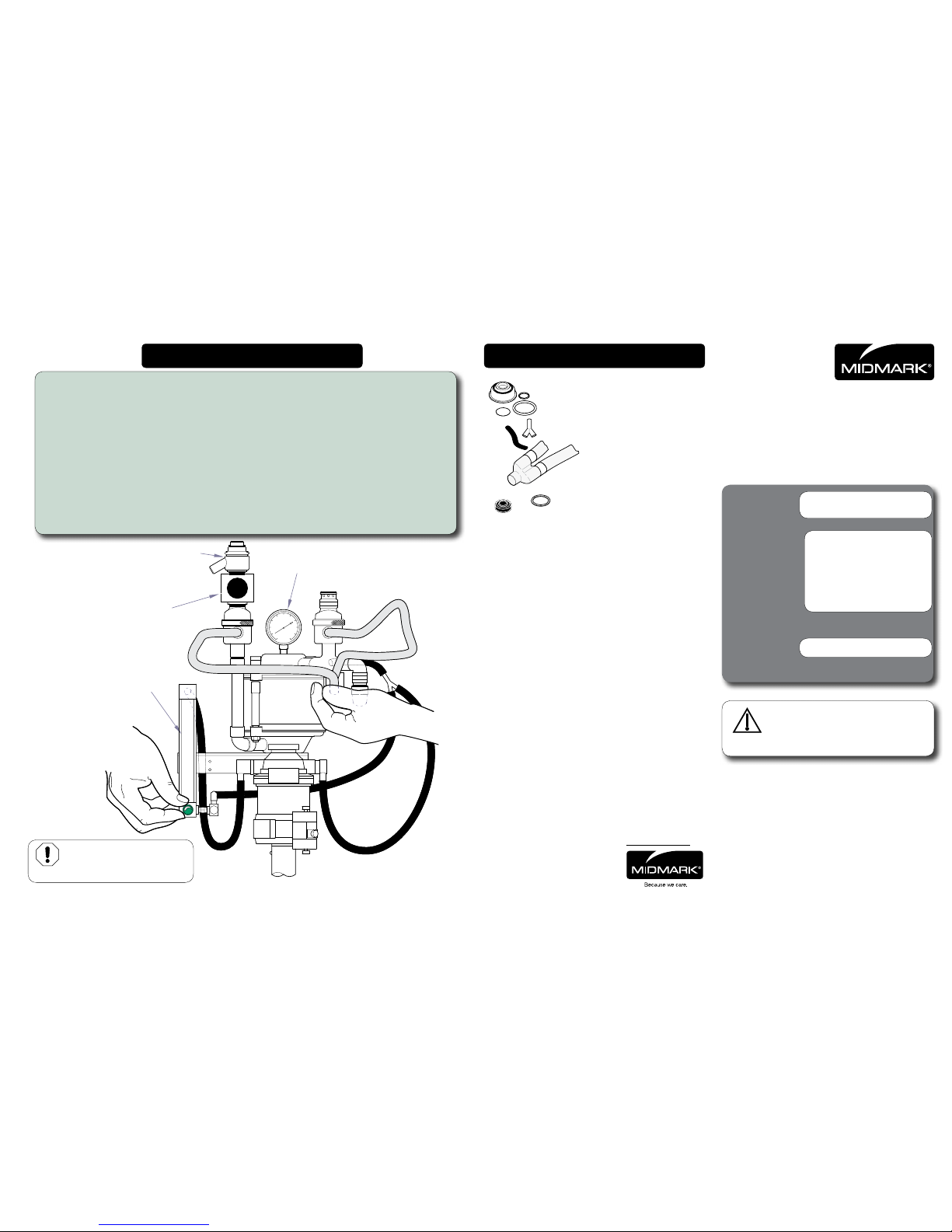

Leak Test Procedure

To perform leak test...

A) Close APL (Scavenging /Adjustable Pressure Limiting) valve by turning knob clockwise.

B) Place thumb over patient connection of breathing circuit Y.

C) Remove breathing bag and cover bag port opening. (Use palm of hand that is covering Y.)

D) With oxygen (50-55 PSI [3.4-3.8 Bar]) supplied to anesthesia machine, slowly open

flowmeter to register 30cm H20 on anesthesia machine pressure gauge.

E) Turn off flowmeter when pressure reaches 30cm H2O. (If pressure holds steady the system

is leak free but if pressure drops, proceed to step (F).)

F) Slowly open flowmeter until pressure stabilizes at 30cm. H2O setting. (This determines the

magnitude of the leak. If leak rate is greater than 300ml/min; proceed to step (G).)

G) Refer to page 2, “What if machine leaks?

H) Replace reservoir bag. Repeat step (B) and steps (D) through (F). This will determine the

integrity of breathing bag.

Flowmeter

APL Valve

(Scavenging /Adjustable

Pressure Limiting)

Pressure Gauge

VA113401

VMS® , VMS® Plus

and VMC™

Order #: 91303015

Includes:

•Disc(2)

•LargeO-ring(2)

•SmallO-ring(3)

•Dome(2)

•Tubing

•BreathingCircuit(1)

•UpperandLowerGaskets

•Diaphragm(VMS® only)

• Back Up Ring (VMS® only)

Equipment Alert

Do not activate the oxygen ush

during any part of this leak test.

1

Occlusion Valve

(VMS

®

only)

Sodasorb

®

Order #: 002-1761-00

Sodasorb® LF, Canister Pak, Case

Order #: 002-1762-00

Sodasorb® Standard, Canister Pak, Case

Order #: 002-1763-00

Sodasorb® LF, Pre-pak, Case

Order #: 002-1764-00

Sodasorb® Standard, Pre-pak, Case

Order #: 002-1765-00

Sodasorb® Standard, Bucket

© 2008 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

Caution

Federal law restricts this device to sale

by or on the order of a licensed

veterinarian.

Page 2

VA113501

Equipment Alert

Never invert or tilt the vaporizer when

it contains anesthetic liquid. Never overtighten the

flowmeter needle valves, damage to the needle and

seat will eventually result.

CAUTION

Insure gas supplies are adequate and turned on. Verify vaporizer is filled to eliminate the possibility of anesthetic depletion during surgery.

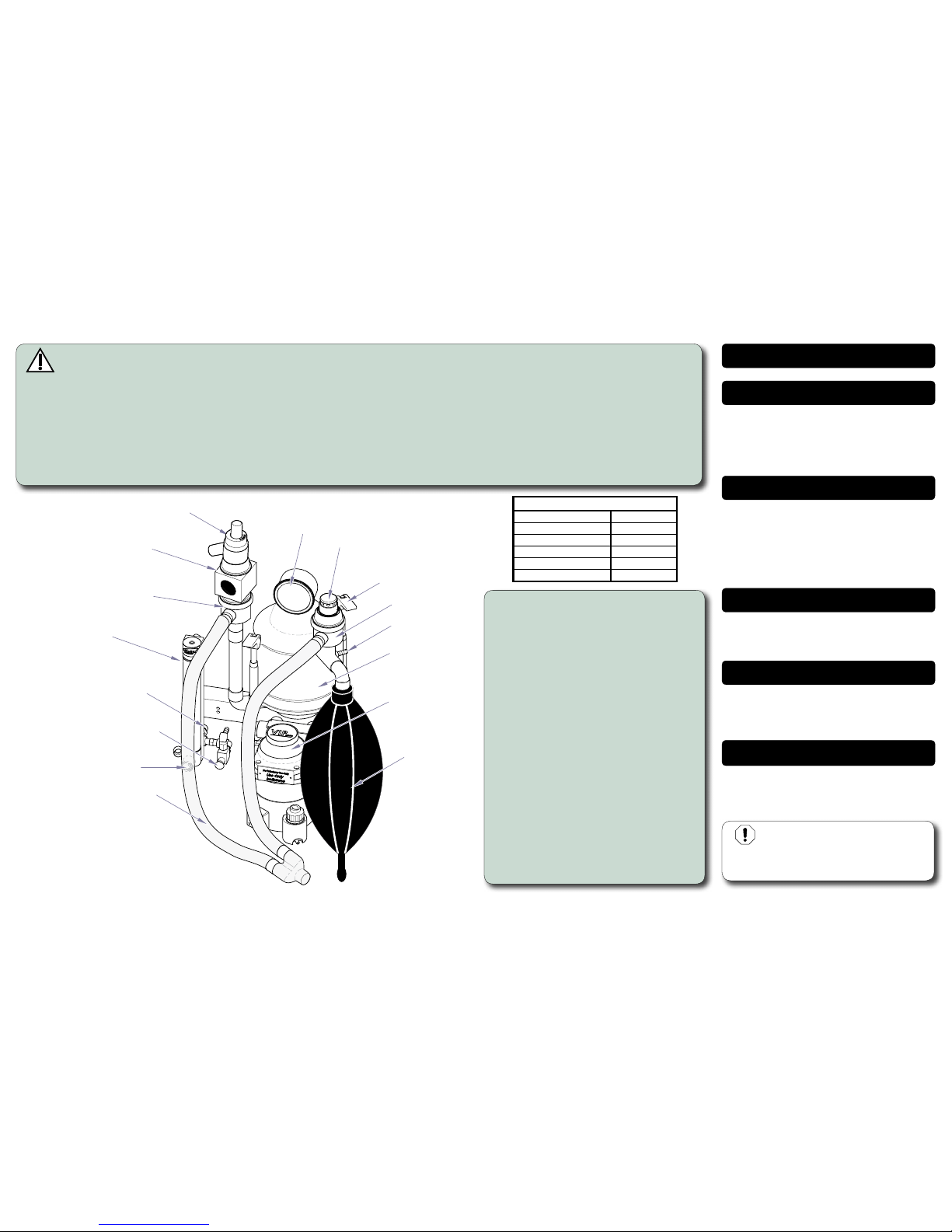

To Operate Anesthesia Machine...

A) Lift CO2 absorber canister lock levers. Slide clear canister free of absorber assembly. Fill canister with absorbent material, following directions on canister

label. Be sure canister and gasket mating surfaces are completely free of absorbent. Replace canister in absorber assembly. Simultaneously, close both

lock levers to secure canister.

B) Connect breathing bag and breathing circuit.

C) Connect a 50-55 PSI (3.4-3.8 Bar) oxygen supply line to the oxygen supply fitting on the back of the flowmeter.

D) Adjust flowmeter and vaporizer settings to meet physiologic needs of the patient.

E) During anesthesia, monitor the pressure gauge, inhalation and exhalation valves, and the breathing bag. Make necessary corrections in flow rate,

vaporizer setting, and Scavenging/Adjustable Pressure Limiting (APL) valve, to insure adequate depth of anesthesia and adequate ventilation of the patient.

Note: For guidelines on induction and anesthesia techniques, or particular species physiologic requirements, etc., please refer to a veterinary anesthesia textbook.

Maintenance Schedule

Flowmeter

Breathing Circuit

Flowmeter Adjustment Knob

Oxygen Supply Fitting

Inhalation Valve

Pressure Gauge

(Manometer)

Breathing Bag

Safety Valve

(Negative Pressure Relief)

Oxygen Flush

Fresh Gas

Connection

Absorber

Canister

Vaporizer

(Not Included)

Before Every Surgery

A. Inspect.

Check machine connections and rubber parts for

looseness, damage or wear. Replace as necessary.

B. Perform leak test.

What if Machine Leaks?

1) Breathing Bag - If leak occurs, replace.

2) Breathing Circuit - Install new breathing

circuit or obstruct inhalation / exhalation

openings to determine if leak originates from

breathing circuit.

3) Vaporizer Fittings - Verifyfittingsandtubing

are securely attached.

4) Canister Gaskets - Check for loose

absorbent grains between canister housing

gaskets.

5) Verify Canister is seated properly.

6) Safety Valves - Remove valve and obstruct

opening to determine if leak originates from

negative pressure relief valve. Check the o-ring

under valve for damage.

7) APL Valve - Remove valve and obstruct

opening to determine if leak originates from APL

valve. Check the o-ring under valve for damage.

8) Occlusion Valve - Remove valve and

obstruct opening to determine if leak originates

from the occlusion valve. Check the o-ring, diaphragm & back-up ring on valve for damage.

9) O-Rings under chrome retaining rings. Check

the o-rings for damage.

Daily

Weekly

Annually

A. Clean.

Remove breathing bag and breathing circuit. Wash

with warm water and mild soap, rinse well. Hang to

dry. Remove white disks from inhalation and

exhalation valves. Wipe with soft cloth, wipe out

valves and reassemble. Remove absorber canister,

wipe off gaskets, canister and absorber housings.

A. Service Vaporizer.

Service and calibrate vaporizer. Contact Dealer for

details.

A. Change Absorbent Material.

Follow manufacturer’s recommendations for proper

use of CO2 absorbents.

Every Two (2) Years

A. Replace Maintenance Components.

Replace components found in maintenance kit

91303015.

Patient Weight Bag Size

15 lbs or less (7kg) 500 ml

15-30 lbs (7-14 kg) 1 liter

30-60 lbs (14-27 kg) 2 liter

60-100 lbs (27-45 kg) 3 liter

100 + lbs (45 + kg) 5 liter

BREATHING BAG

Lock Levers (Typical)

APL Valve

(Scavenging /Adjustable

Pressure Limiting)

2

Exhalation Valve

Occlusion Valve

(VMS

TM

only)

© 2008 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

Loading...

Loading...