Page 1

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99 Rev. WA1 (2/7/18)

Style P

User’s Guide

VetPro® 1000

Mobile Dental

Delivery System

For Models:

8000-001

8000-002

8000-003

8000-004

8000-005

8000-006

8000-006S

8000-007

8000-007S

8000-008

8000-008S

English

Español

Français

Page 2

© Midmark Corporation 2016

English - 2

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

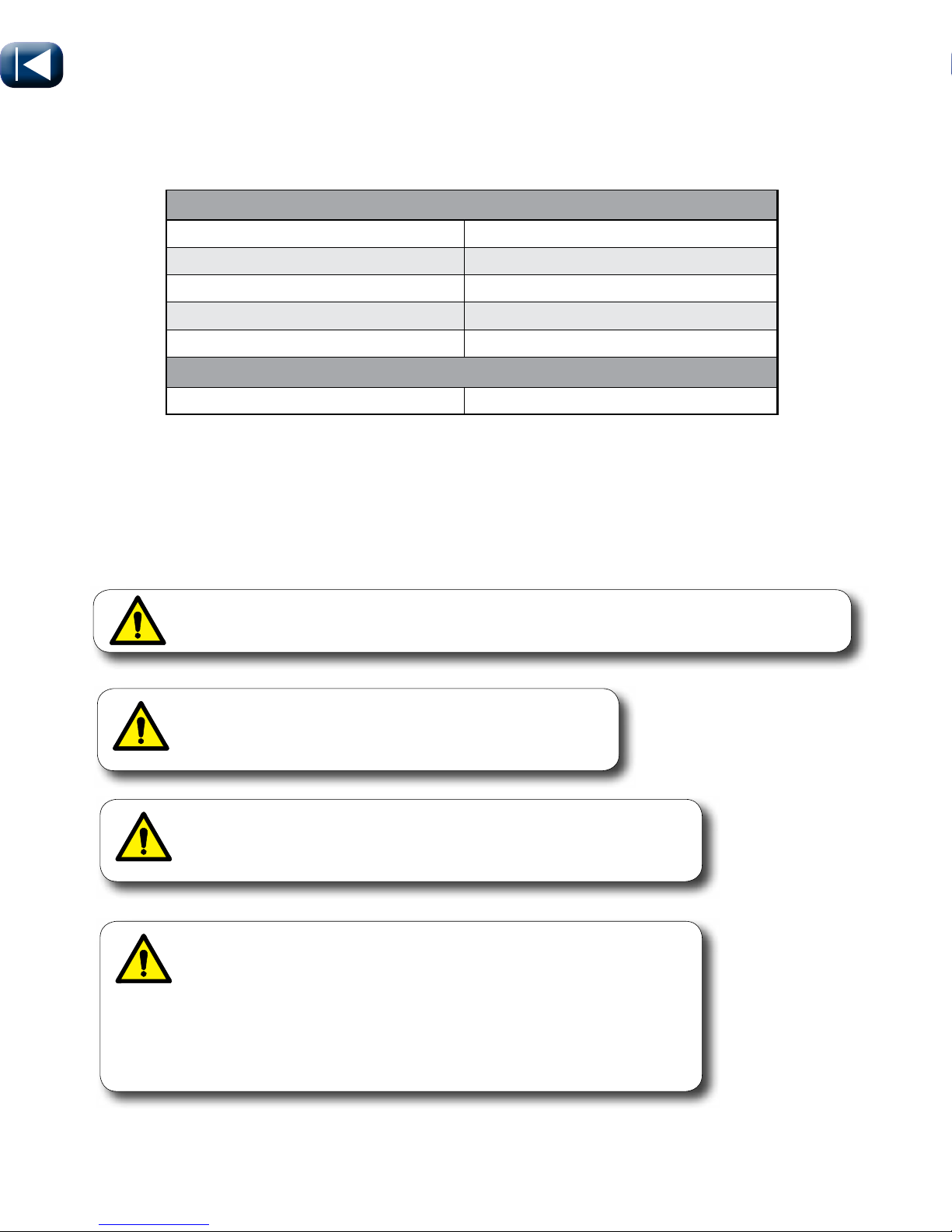

Product Information

(The information below is required when calling for service.)

Model / Serial Number:

Date of Purchase:

Midmark Authorized Service

Company:

Dealer :

Model / Serial Number Location

Page 3

© Midmark Corporation 2016

English - 3

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Table of Contents

Important Information

Safety Symbols....................................................................................................................4

Intended Use .......................................................................................................................5

Electromagnetic Interference...............................................................................................5

Disposal of Equipment.........................................................................................................5

Authorized EU Representative ............................................................................................ 5

Transportation / Storage / Operating Conditions .................................................................5

Transport

Transporting Dental System ................................................................................................6

Operation

Electrical System ................................................................................................................. 7

Water System ......................................................................................................................8

Air System ...........................................................................................................................9

Delivery System...................................................................................................................10

Handpiece Care...................................................................................................................11

Syringe Tip Replacement & Handpeice Installation.............................................................12

Drive Air Adjustment & Locking Casters .............................................................................. 13

Air Pressure Regulator & Water Flow Adjustment ............................................................... 14

Coolant Air Adjustment ........................................................................................................ 15

Cleaning / Maintenance

Cleaning ..............................................................................................................................16

Maintenance ........................................................................................................................ 18

Calling for Service ...............................................................................................................22

Specifications

Drawing ...............................................................................................................................23

Weights / Dimensions .......................................................................................................... 24

Electrical .............................................................................................................................. 25

Model Identification / Compliance Chart ..............................................................................26

Warranty

Warranty Information ...........................................................................................................27

For installation information go to:

Technical Library at Midmark.com

Page 4

© Midmark Corporation 2016

English - 4

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Type B, Applied Part

Temperature Limit

Handle With Care

Humidity Limit

Fuse Rating

Specifications

Pressure Limit

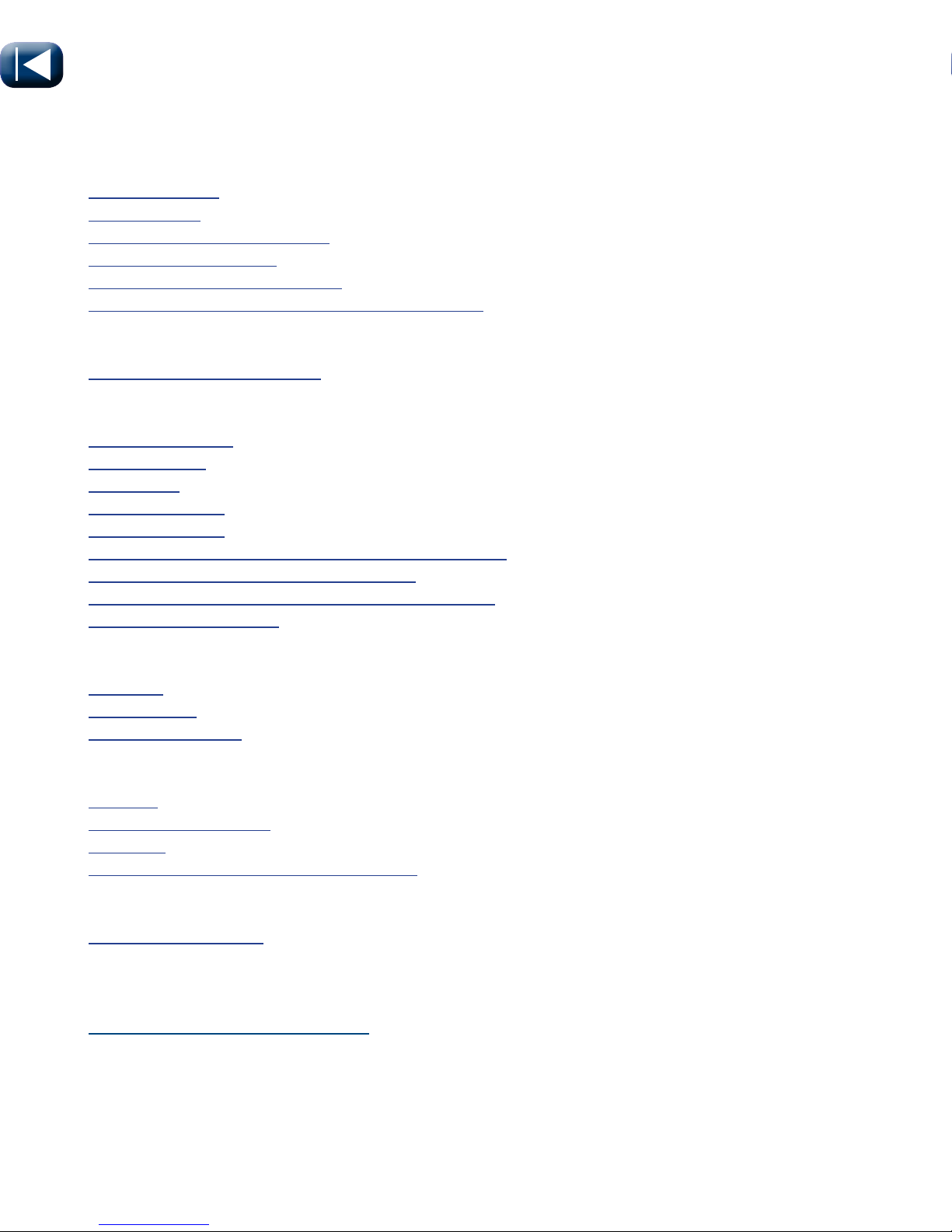

Safety Symbols

Important Information

Proper Shipping

Orientation

Maximum stacking

height

(Do not stack)

Fragile

Keep Dry

Refer to Instruction

Manual/Booklet

WARNING

Indicates a potentially hazardous situation which could result in serious injury.

Caution

Indicates a potentially hazardous situation which may result in minor or moderate injury. It may

also be used to alert against unsafe practices.

Equipment Alert

Indicates a potentially hazardous

situation which could result in equipment

damage if not avoided.

Note

Ampliesaprocedure,practice,orcondition.

Type BF, Applied Part

Protective Earth Ground

LED Scaler Handpiece

Duty Cycle

US

C

TUVRheinland

TUV - Domestic

Models Only

Do Not Tumble

100 F

38 C

23 F

-5 C

Page 5

© Midmark Corporation 2016

English - 5

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Disposal of Equipment

At the end of product life, the unit(s), accessories, and other consumable goods may be

contaminated from normal use. Consult local codes and ordinances for proper disposal of

equipment and other consumable goods.

Authorized CE Representative

Countries in the EEC should direct all questions, incidents, and complaints to Midmark’s Authorized CE

representative listed below:

Midmark EMEA Ltd

Beech House

First Floor, East Wing

Ancells Business Park

Fleet

Hampshire GU51 2UN

United Kingdom

Tel: + 44 (0) 1252 360 940

Fax: + 44 (0) 1252 360 941

Transportation / Storage / Operating Conditions

Transportation / Storage Temperature Range: .......................................23°F to 100°F (-5°C to 38°C)

Operating Temperature Range: .............................................................. 50°F to 104°F (+10°C to +40°C)

Transportation / Storage Relative Humidity: ........................................... 10% to 90% (non-condensing)

Operating Relative Humidity: .................................................................. 30% to 75% (non-condensing)

Transportation / Storage Atmospheric Pressure:....................................50 kPA (7.2 psi) to 106 kPA (15.3 psi)

Operating Atmospheric Pressure:...................................................700 hPA (20 in Hg) to 1060 hPA (31 in Hg)

Intended Use

The Midmark® VetPro® 1000 is a mobile dental delivery system intended to give qualified veterinarians

and/or technicians a self-contained, compact, portable unit for performing veterinary dental procedures.

Electromagnetic Interference

This product is designed and built to minimize electromagnetic interference with other devices.

However, if interference is noticed between another device and this cart:

•Removeinterferingdevicefromroom

•Plugcartintoanisolatedcircuit

•IncreaseseparationbetweenMidmarkproductandinterferingdevice

•ContactMidmarkifinterferencepersists

Page 6

© Midmark Corporation 2016

English - 6

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Transport

WARNING

Exercise care when transporting over thresholds and other low lying objects.

Failure to do so can lead to injury.

Threshold

When transporting over large thresholds or steps...

A) Pull cart up and over onto level surface.

Page 7

© Midmark Corporation 2016

English - 7

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

6

A

M

P

6

A

M

P

VA1227

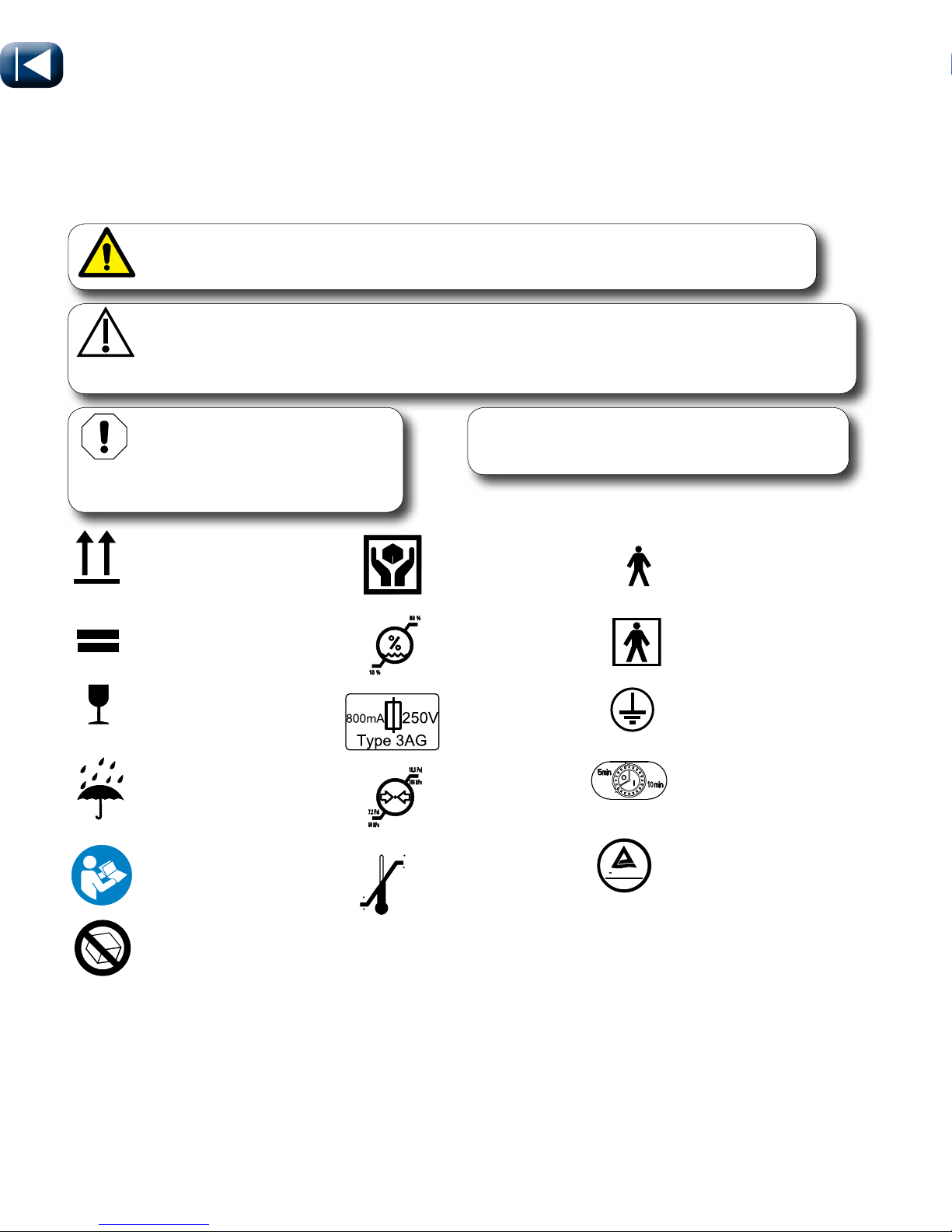

Operation

Electrical System

On/Off Switch

On/Off Switch is located on the back of the cart. It controls the main power source and must be ON to

operate the delivery system.

Circuit Breakers

There are two circuit breakers located on the lower back panel of the cart. If the unit’s maximum load is

exceeded, the circuit breakers interrupt power to the unit. Maximum load is 115 VAC, 6 amps (domestic)

230 VAC, 3 amps (export).

Mains Disconnect

Power can be terminated by unplugging the mains disconnect or turning switch off.

(O) Off Switch

( I ) On Switch

Circuit Breakers

Tripped

(No Power)

Mains

Disconnect

Reset

(Power)

Page 8

© Midmark Corporation 2016

English - 8

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

VA1229

Operation

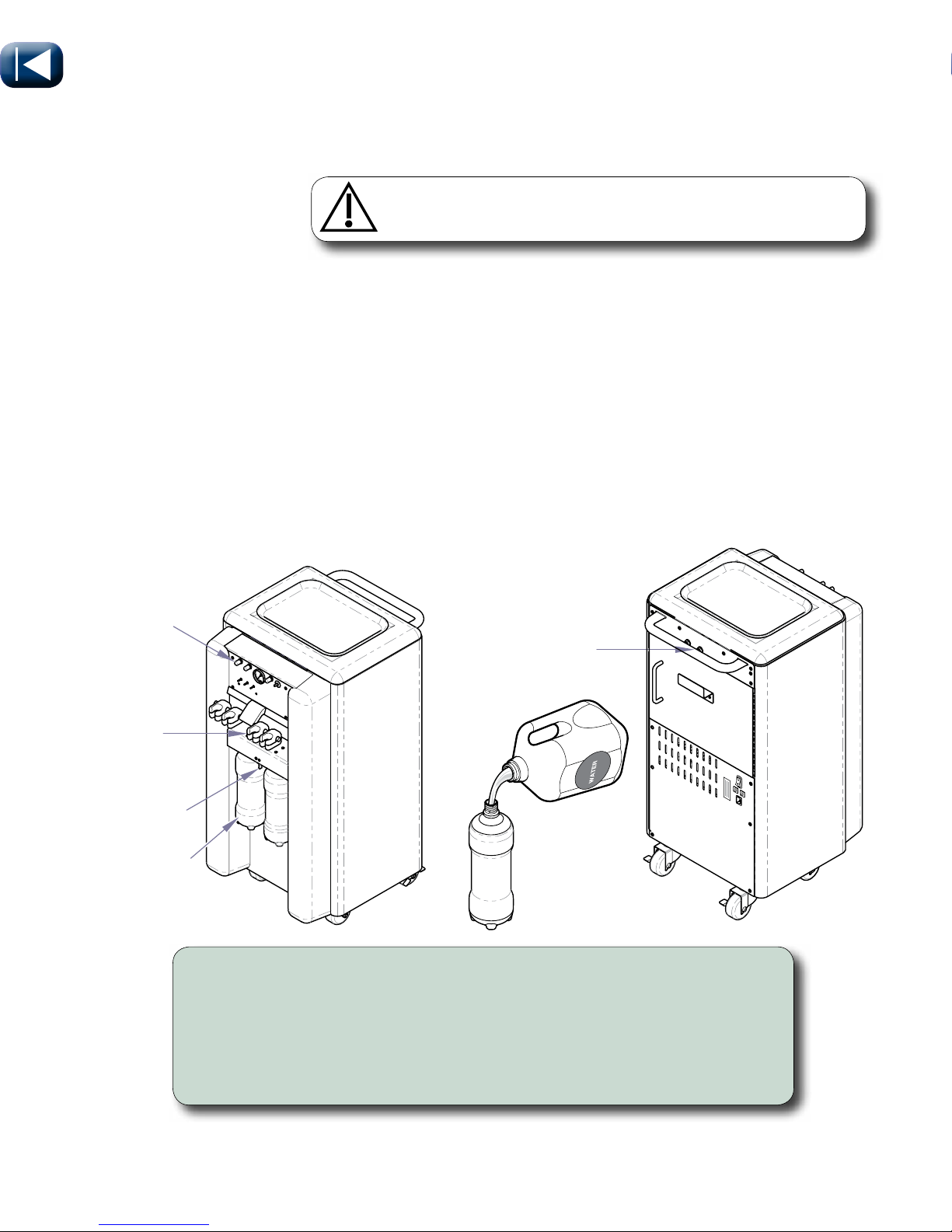

Water System

Water Bottles

The unit has two 1 liter bottles. The water bottles supply water to the handpieces, air/water syringe and a

quick disconnect on the back of the cart. Air flows through the water regulator and the toggle switch to the

water bottles. The water system is regulated to 40 PSI. Use the water needle valve to adjust water flow

for each instrument. The toggle switch between the water bottles that controls which bottle will supply the

water. When the toggle is in the center neither water bottle is pressurized. Move the toggle toward the

left to pressurize the left bottle and depressurize the right bottle. Toggle to the right to pressurize the right

bottle and depressurize the left bottle.

Toggle

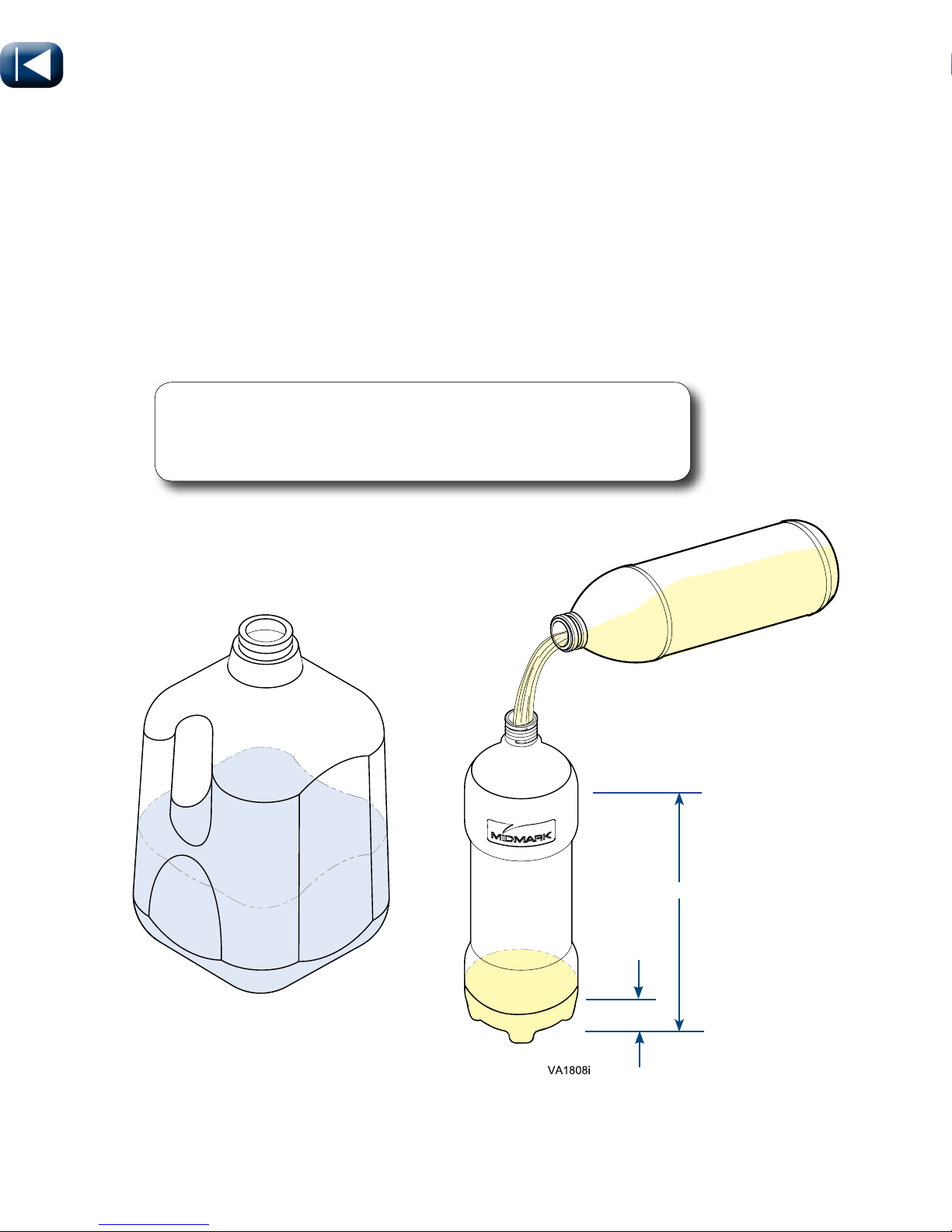

To fill water bottles...

A) Move toggle to center.

B) Remove water bottle and fill. (Distilled Water Is Recommended)

C) Replace water bottle and move toggle toward filled water bottle.

Note: Water bottles should be checked in between each patient and filled if necessary.

Water Quick Disconnect

The water quick disconnect has a blue ring. You can attach accessories to the cart that will utilize the

water from the cart. You may need to add a regulator if attaching equipment that can not handle 40 PSI.

Water

Needle

Valve

Water

Regulator

Water

Bottles

Water Quick

Disconnect

Caution

Failure to properly seal water bottles can lead to patient injury.

Page 9

© Midmark Corporation 2016

English - 9

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

VA1231

Operation

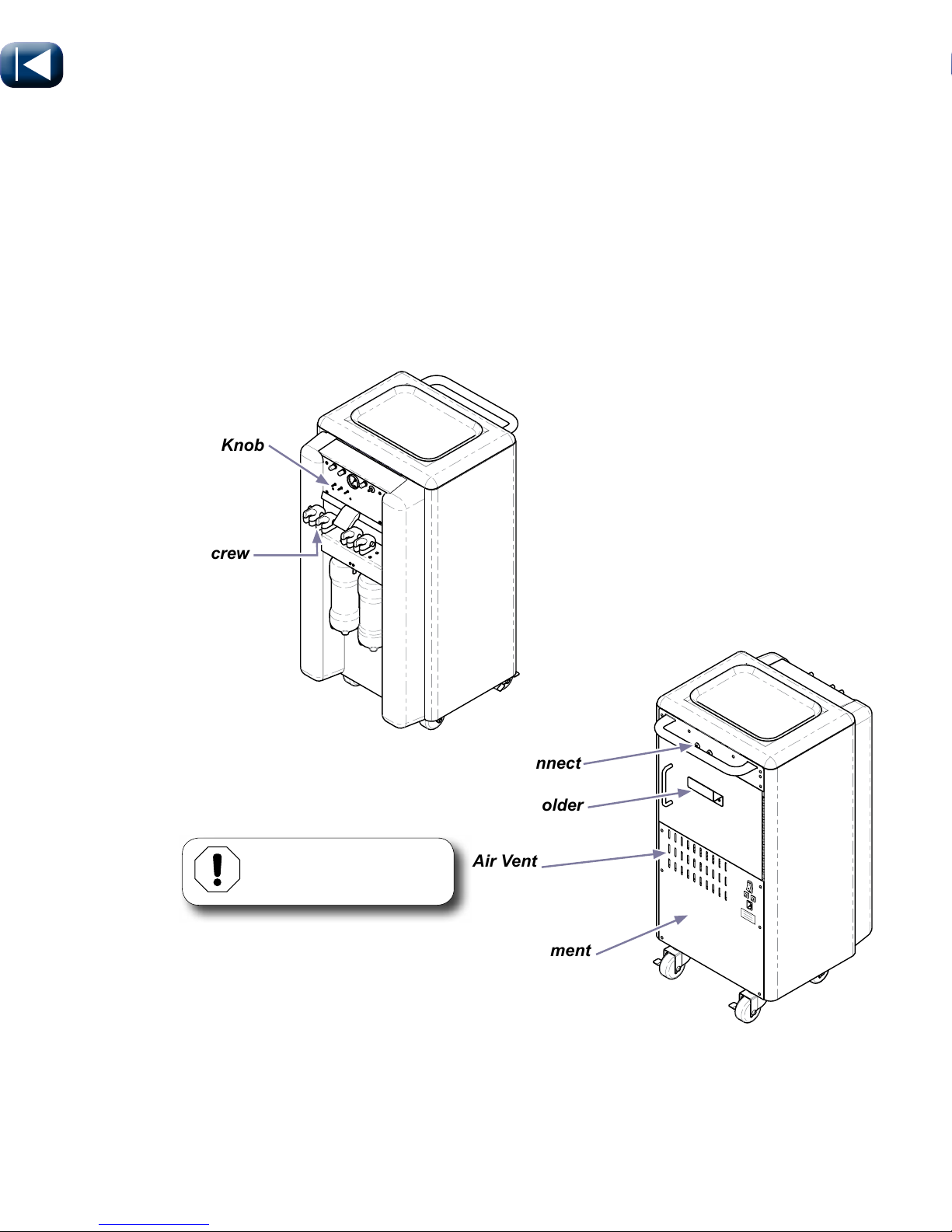

Air System

Compressor

The air system is a 1/3 HP compressor with a 2 liter air tank and regulator. It supplies air for the

handpieces, air/water syringe, and a quick disconnect on the back of the cart. The compressor will cycle

between 70 to 100 PSI. The regulator is factory set at 65 PSI.

Air Quick Disconnect

The air quick disconnect has a red ring. You can attach accessories to the cart that will utilize the air from

the cart. You may need to add a regulator if attaching equipment that can not handle 100 PSI.

Coolant Air

Adjustment Screw

Drive Air

Adjustment Knob

Air Quick Disconnect

Air Vent

Compressor Compartment

Foot Control Holder

Equipment Alert

Do not block air vent.

Page 10

© Midmark Corporation 2016

English - 10

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

VA1233

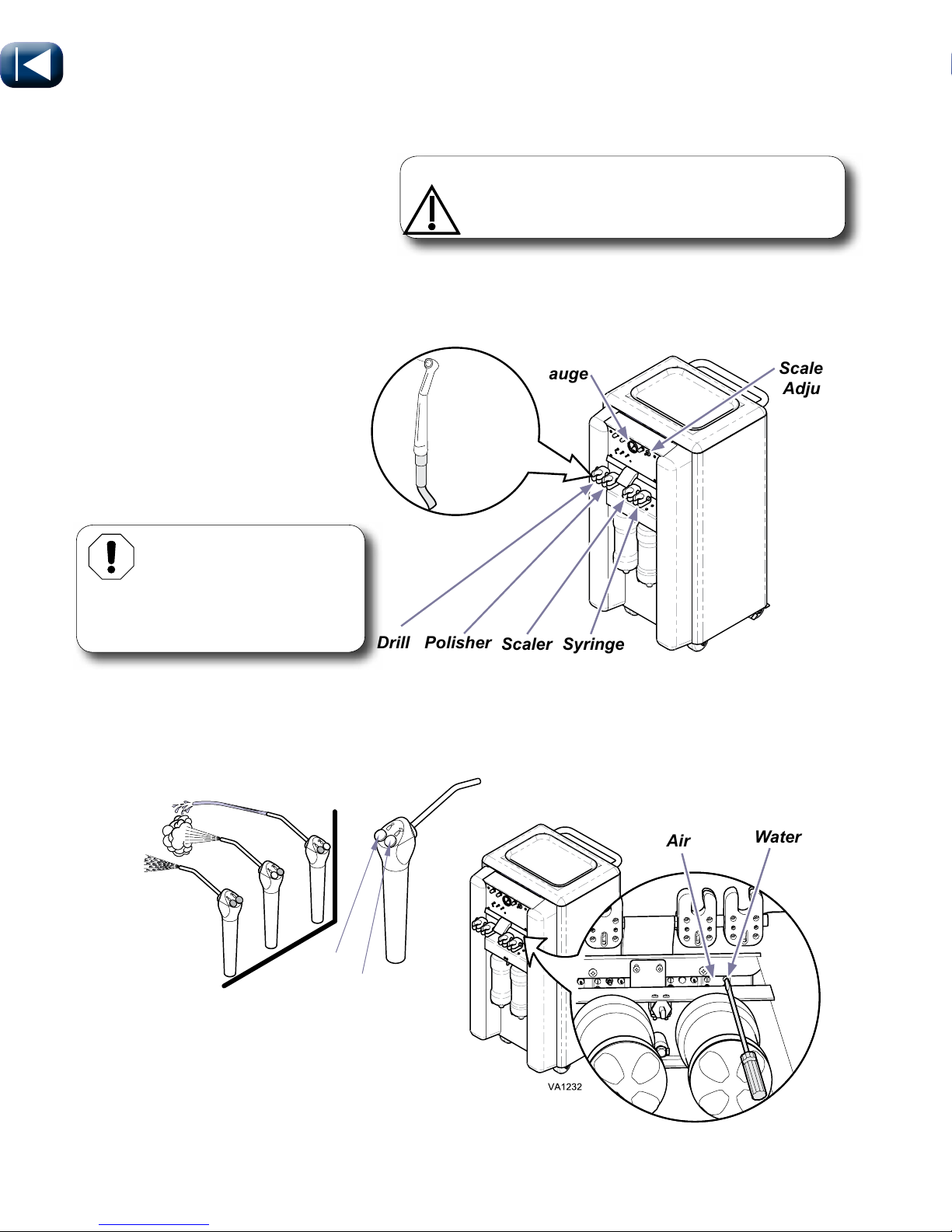

Handpieces

The delivery system controls up to four handpieces. The handpiece pressure is controlled by handpiece

drive air adjustment valves. The gauge on front of the delivery system indicates the handpiece pressure.

Handpiece pressure should not exceed 60 PSI under normal operation. The scaler tool (optional) has an

adjustment knob for the intensity level.

Operation

Delivery System

Air/Water Syringe

There are air and water buttons on top of the syringe. When both buttons are depressed you will get a

mist of both water and air. Air and water adjustments are located under the syringe holder. Insert flat head

screwdriver into adjustment screw(s). Counter-Clockwise to increase flow and Clockwise to decrease flow.

Turn screw until desired air/water flow is coming through the instrument.

Gauge

Air

Water

Equipment Alert

Refer to handpiece

manufacturer for suggested PSI

settings. Only check one handpiece

at a time.

Handpiece

Holders

Scaler

Adjustment

Air

Water

Caution

Handpieces and Syringe Tip should be changed

or disinfected between each patient.

Drill Polisher

Syringe

Scaler

Page 11

© Midmark Corporation 2016

English - 11

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

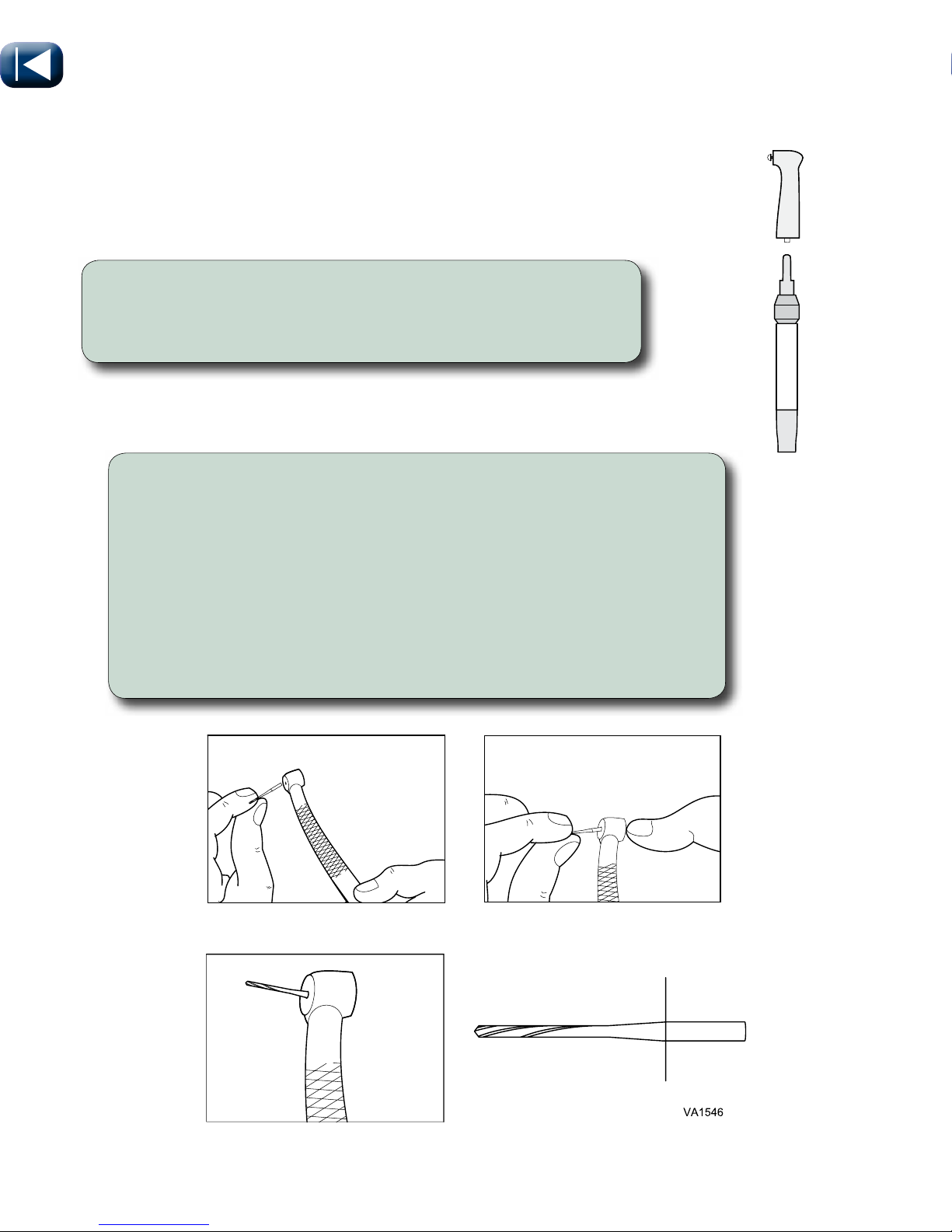

Operation

To Change Bur in High Speed Handpiece...

A) Push button on back of handpiece and pull the bur out.

B) Push bur into handpiece. (The shank will only go in half-way)

C) Then push button on back of handpiece and push the bur in until

shank is all the way in.

Note: Friction grip burs (FG Style) are designed so that the entire straight portion of

the shaft should be inside the chuck of the handpiece. You should only see the tapered

portion of the bur if installed properly. New bur recommended for each procedure.

Prophy

Angle

Prophy Angle Replacement

To Change Prophy Angle...

A) Rotate chuck to the right to unlock.

B) Install Prophy angle, turn chuck release ring left to tighten.

Push

Button

Push Bur Into Handpiece

Finish Sliding Bur Into

Handpiece

Shaft Inside Handpiece

This Portion of

the Bur Should

be Inside the

Handpiece

Burr Replacement

Page 12

© Midmark Corporation 2016

English - 12

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

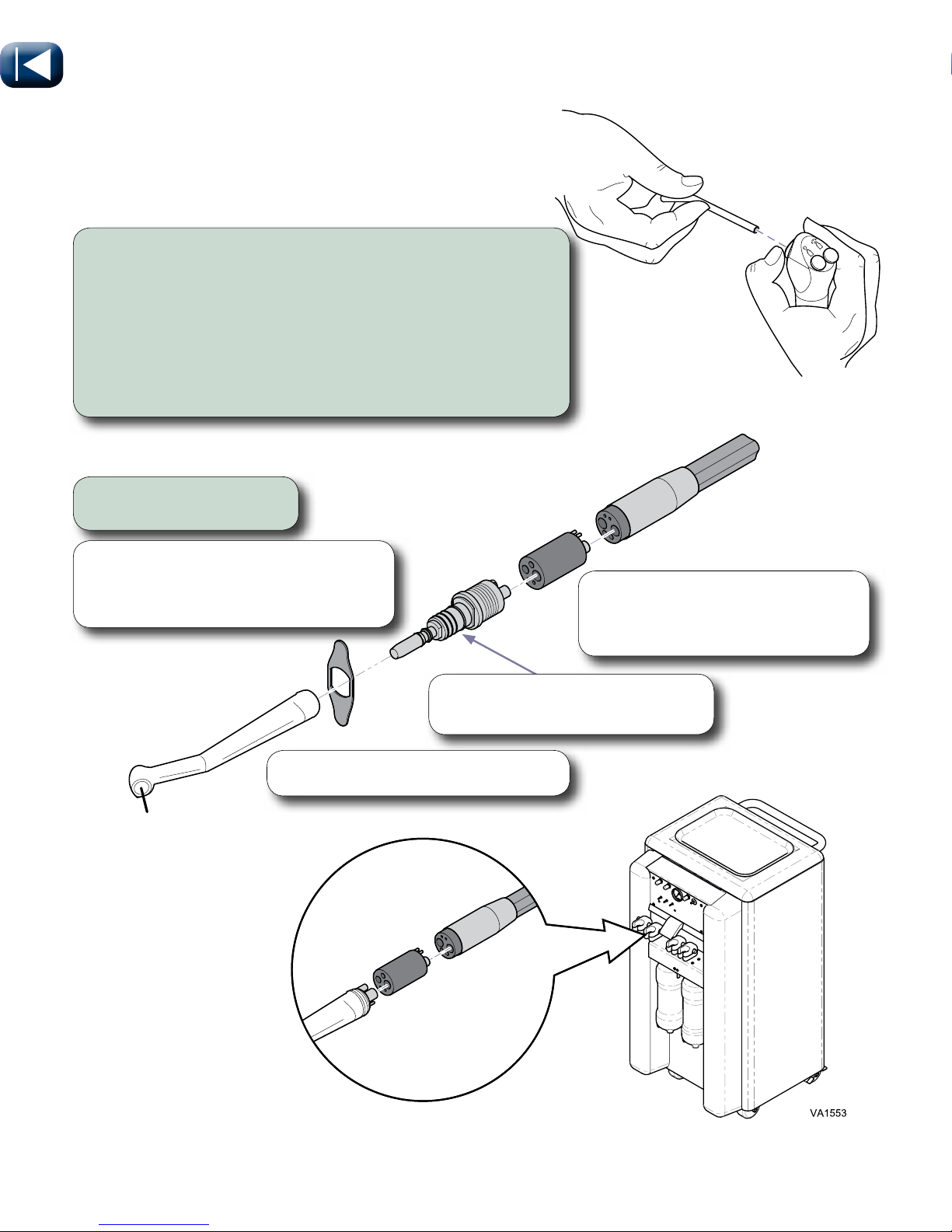

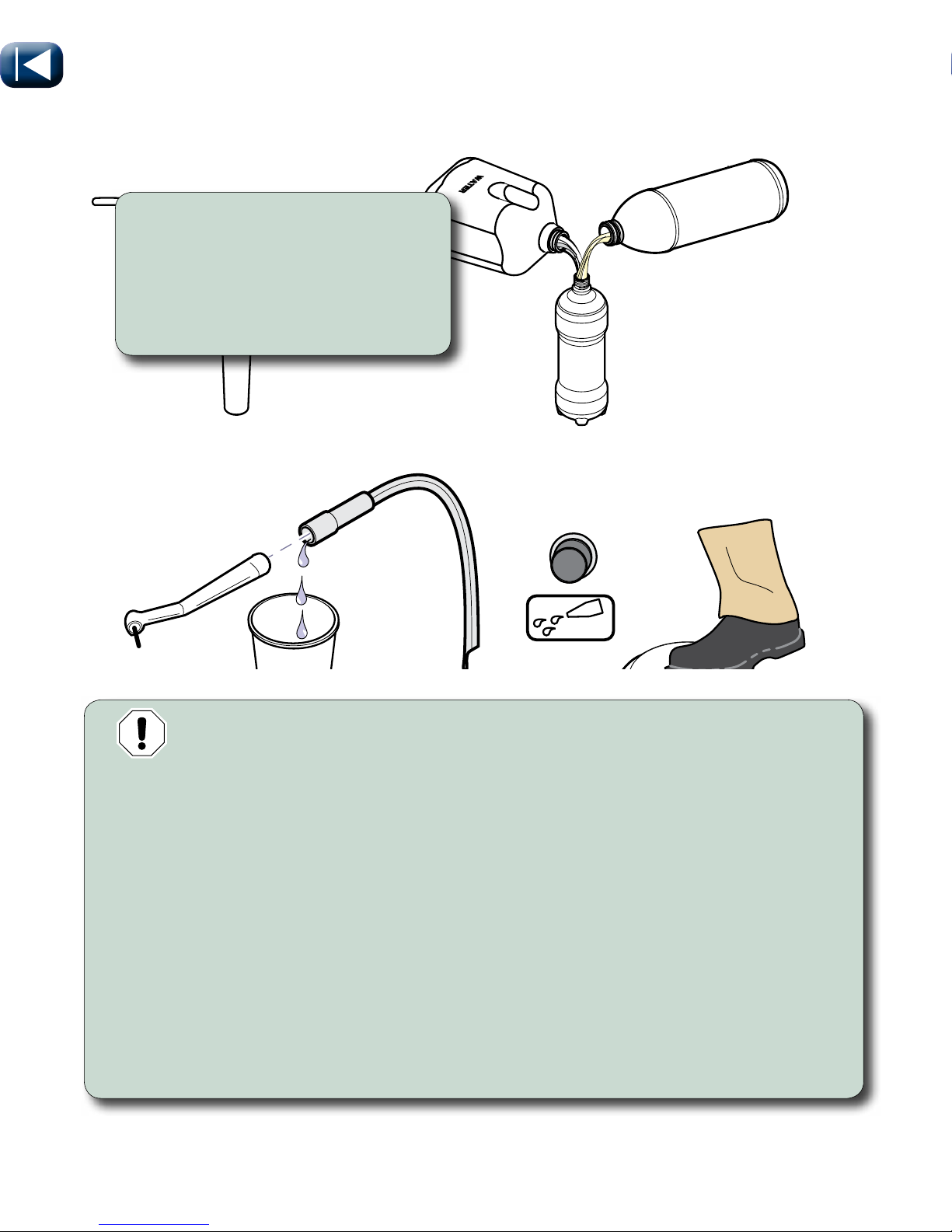

Handpiece Installation

VA1807i

To Change Syring Tip...

A) Press down on large collar.

B) When a soft “click is felt pull tip straight out.

C) Hold collar down and insert new tip. Be sure to

press it all the way in, then release collar.

D) Test the installation by giving a firm pull on tip, to

assure it is inserted all the way and locked in place.

Syringe Tip Replacement

Install handpieces.

Line up components properly to

prevent damage resulting in hand

piece failure.

Lightly spray the exposed o-rings

with one step conditioner.

Tighten coupler firmly with wrench.

Handpiece

Connection

Swivel Coupler

Connection

Note

Not all units will be equipped with lamp

module.

Page 13

© Midmark Corporation 2016

English - 13

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

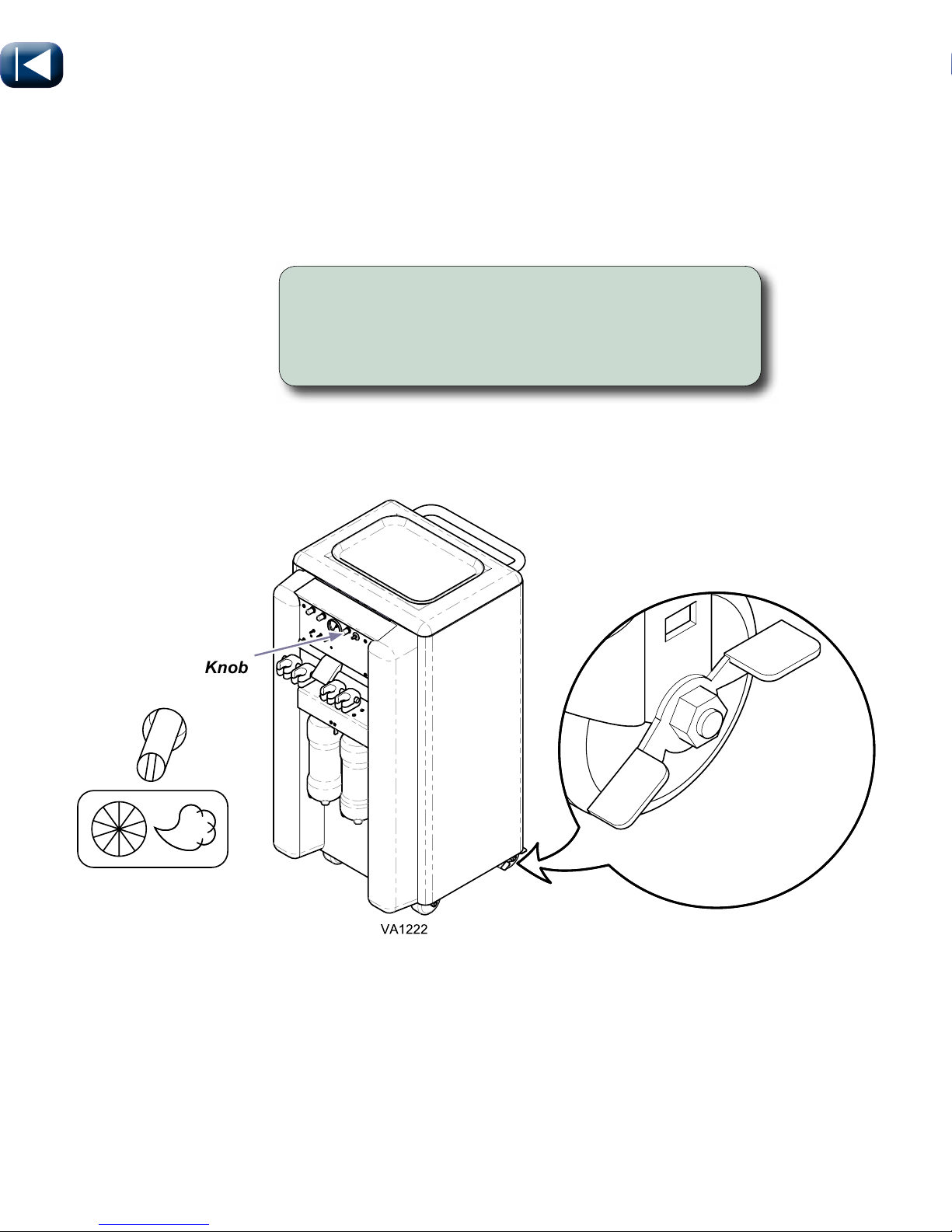

Drive Air Adjustment

& Locking Casters

Drive Air

Adjustment Knob

To adjust drive air...

Insert flat head screwdriver into knob for Drive Air

Adjustment (for desired handpiece). Turn knob until

proper air pressure displays on the pressure gauge.

OFF for Unlock

ON for Lock

Page 14

© Midmark Corporation 2016

English - 14

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

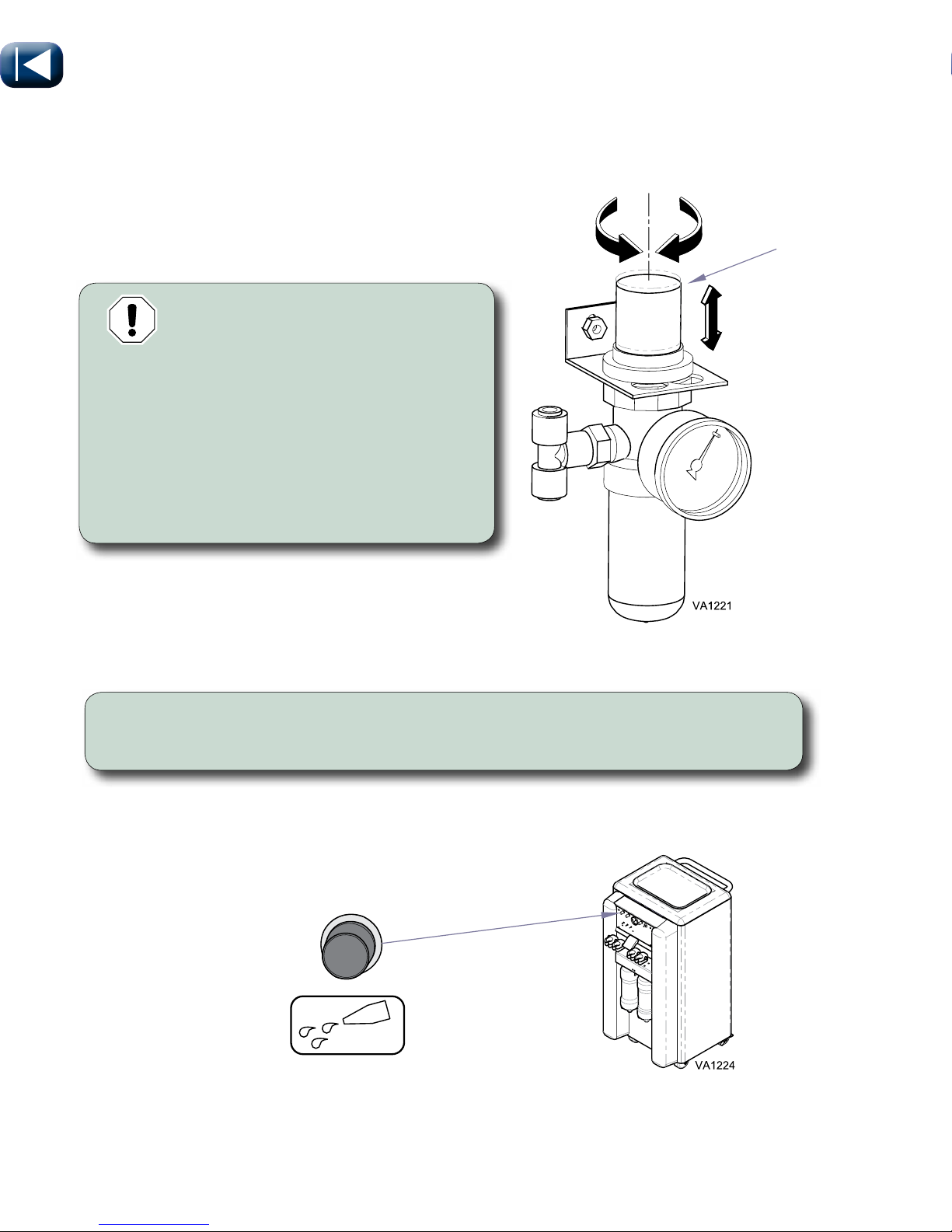

Operation

Decrease

Increase

Adjustment

Knob

Unlock

Lock

Air Pressure Regulator Adjustment

EQUIPMENT ALERT

Do not adjust regulator over

65 PSI.

To Adjust Regulator...

A) Pull adjustment knob upward to unlock.

B) Rotate adjustment knob clockwise to

increase pressure, counterclockwise to

decrease pressure.

C) Push adjustment knob downward to lock.

To adjust water flow...

Rotate Water Needle Valve (for desired handpiece) until desired flow is achieved.

Water Needle Valve

Water Flow Adjustment

Page 15

© Midmark Corporation 2016

English - 15

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

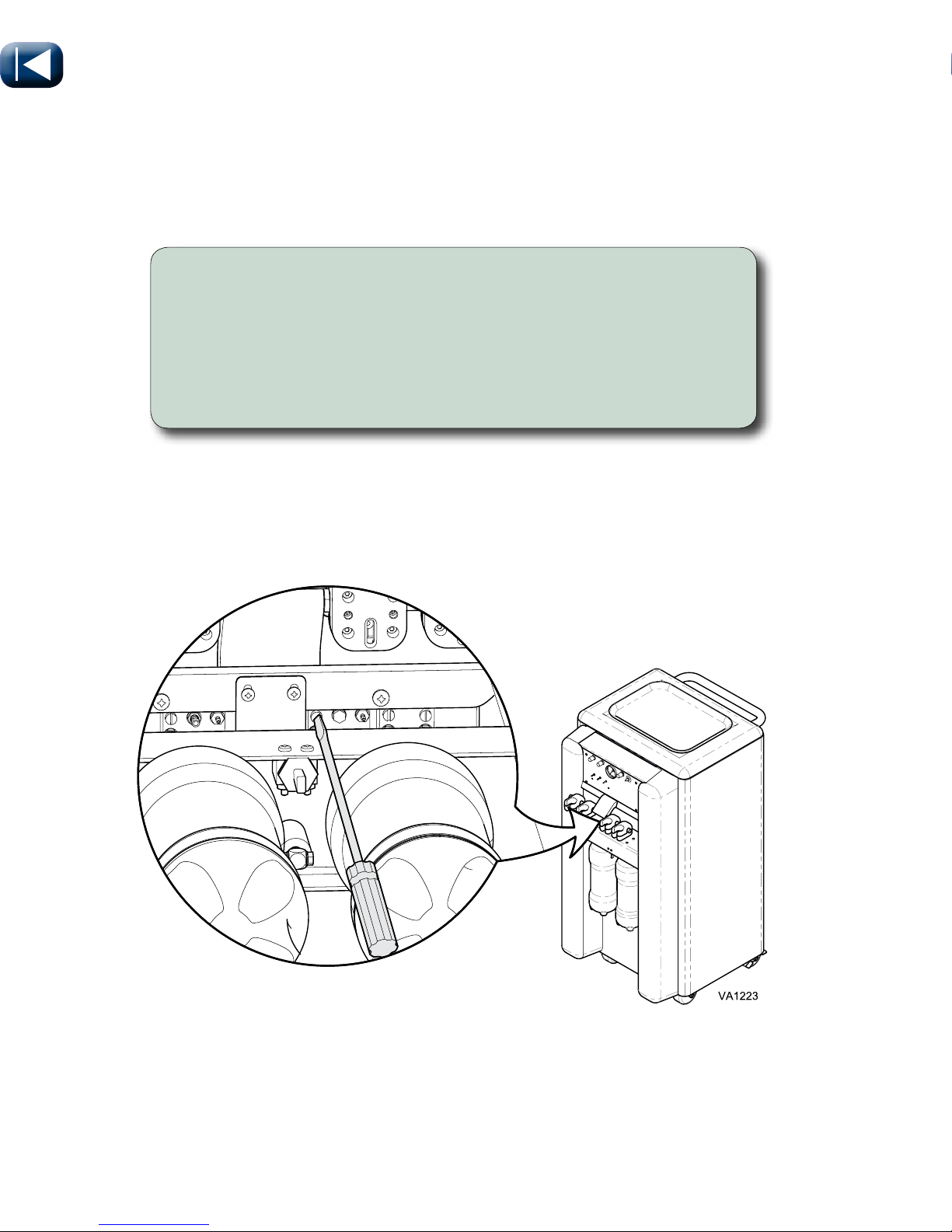

Operation

To adjust coolant air...

Insert flat head screwdriver into knob for Coolant Air Adjustment

(for desired handpiece). Counter-Clockwise to increase flow and

Clockwise to decrease flow. Turn screw until desired air pressure is

coming through the instrument.

Note: Drive air adjustment screws are located below tool holders for each instrument.

Coolant Air

Adjustment Screws

Coolant Air Adjustment

Page 16

© Midmark Corporation 2016

English - 16

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Note:

Use only 5.25% Bleach Solution. Do not use bleach with

scents, color guards, or other additives. Mix fresh every day.

~90%

~10%

Cleaning

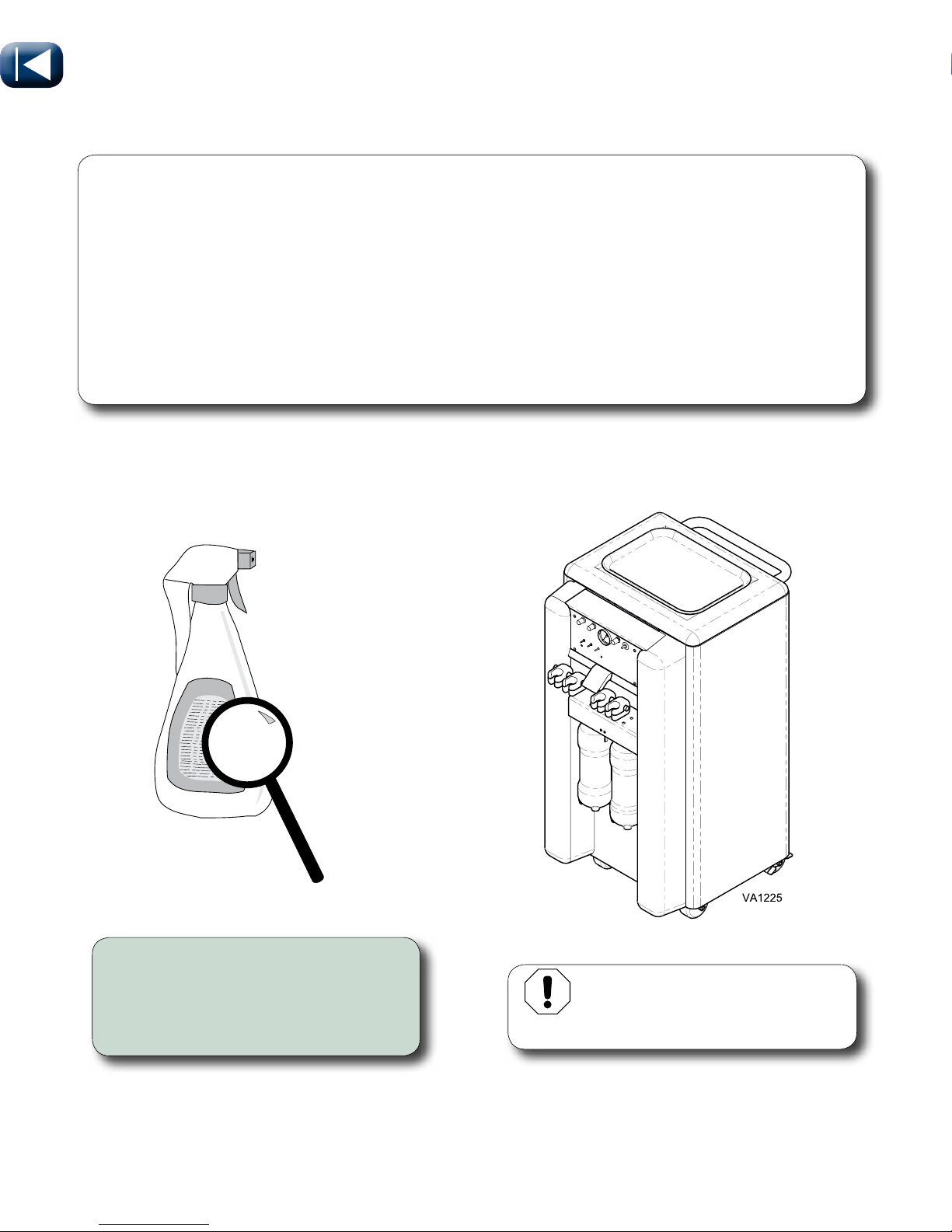

•Usecleanersthatareappropriateforthesituation,suchaswarmwaterandmilddetergents,

or a 10% solution of bleach with 90% water.

•Cleantheexteriorsurfaceswithaclean,lintfreecloth,dampenedwithdisinfectant.Donot

drip any liquid into open vents, plugs or connectors. Dry the surfaces with a clean cloth or

paper towel.

•Aftercleaning,visuallyinspecttheproductfordeteriorationofcovers.Donotusethedelivery

system if excessive discoloration, cracking, or other signs of wear are noticeable (See Calling

for Service instructions).

Page 17

© Midmark Corporation 2016

English - 17

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Note

Every veterinary practice setting is different and no one disinfectant is the best choice for every

facility. There are several organizations educated in disinfection procedures. Refer to web sites of

accredited sources that can assist veterinary personnel in choosing what is best for

their practice. Listed below are a few of the sites.

Organization for Safety & Asepsis Procedures

http://www.osap.org

Dept. of Health & Human Resources Centers for Disease Control & Prevention (CDC)

http://www.cdc.gov

When using disinfectants...

• Carefully read the product label

and directions for use.

• Do not exceed the dilution rate.

DA148100i

Read

carefully

Equipment Alert

Refer to handpiece manufacturer

for suggested cleaning procedures.

Cleaning continued...

Page 18

© Midmark Corporation 2016

English - 18

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Maintenance

At the beginning of each work day...

• Fill water bottles with fresh distilled water.

• Flush handpieces.

Between each patient...

• Remove disposable tips,

instruments, etc..

• Flush delivery system.

• Disinfect handpieces and scaler

per manufacturers instructions.

• Disinfect syringe tip.

• Fill water bottles.

To Flush Delivery System..

A) Remove all handpieces that use water.

B) Open water needle valve.

C) Hold end of tubing over a container and depress foot control.

D) Allow water to run 20 to 30 seconds.

E) Install newly disinfected handpieces and syringe tip.

F) Refill water bottle.

Water Needle Valve

Note

Distilled water is not mandatory.

However, water must meet

requirements for drinking.

Equipment Alert

AUTOCLAVABLE SYRINGE TIP STERILIZATION

The autoclavable syringe tips supplied with the delivery system

must be sterilized prior to use with each patient, including initial use. Be sure to

thoroughly rinse and clean syringe tips prior to sterilization, any debris may reduce

the effectiveness of the sterilization. Recommended sterilization process is steam

autoclave. Recommended parameters are 125°C (250°F) and 106 kPa (15 PSI) for 40

minutes at temperature and pressure.

Equipment Alert

HANDPIECE STERILIZATION

Between each procedure complete

manufacture’s instructions for “Infection Control /

Sterilization found in the documentation included

with the handpieces. Failure to do this will cause

premature failure of handpieces.

Page 19

© Midmark Corporation 2016

English - 19

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

BLEACH

Maintenance continued...

At the end of each day...

• Bleach flush delivery system and

empty water system.

• Drain air regulator.

• Drain condensation from air tank.

• Clean system.

EQUIPMENT ALERT

Do not use colored/scented bleach, or concentrations greater than

recommended. Do not leave bleach solution in delivery system longer than

30 minutes, it could damage the delivery system.

To Bleach Flush Delivery System..

A) Remove all handpieces that use water.

B) Remove water bottles and fill with 9 parts water and 1 part bleach.

C) Open water needle valve.

D) Hold end of tubing over a container and depress foot control.

E) Allow water to run 20 to 30 seconds.

F) Leave bleach solution in delivery system for 10 - 20 minutes, then

remove / empty / rinse water bottles.

G) Fill water bottles with fresh water and repeat steps C thru E until bleach odor is gone.

H) Install newly disinfected handpieces and syringe tip.

I) Empty water bottles.

Page 20

© Midmark Corporation 2016

English - 20

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

VA1238

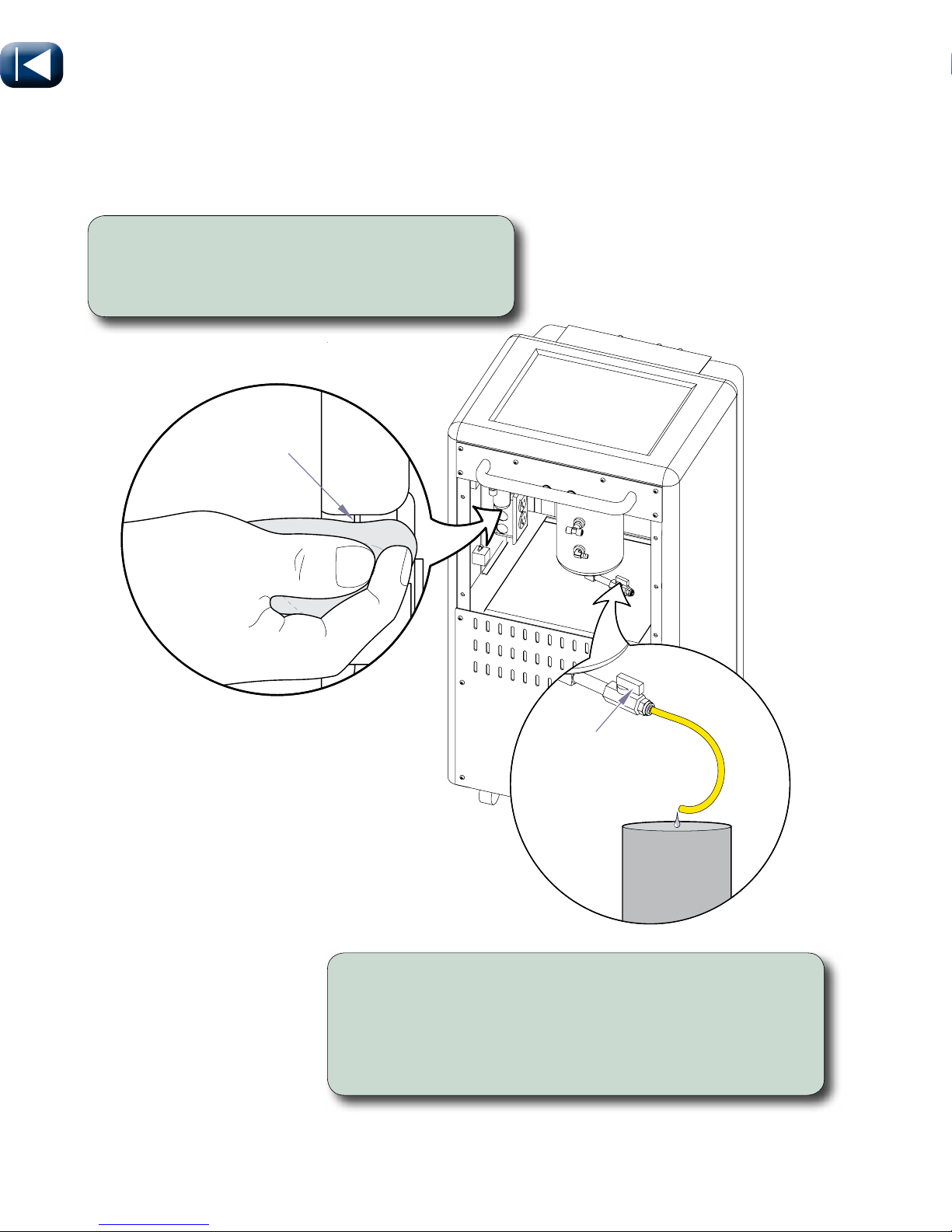

To Drain Condensation from Air Tank...

A) Turn power switch off.

B) Position end of red tube so it drains into a container.

C) Turn drain valve slowly to open.

D) When no water is coming out, slowly close valve.

To Drain Air Regulator...

Place a cloth under the regulator and depress

the button until there is no water coming out.

Valve

Opened

Maintenance continued...

Button

Page 21

© Midmark Corporation 2016

English - 21

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

VA1241

Maintenance continued...

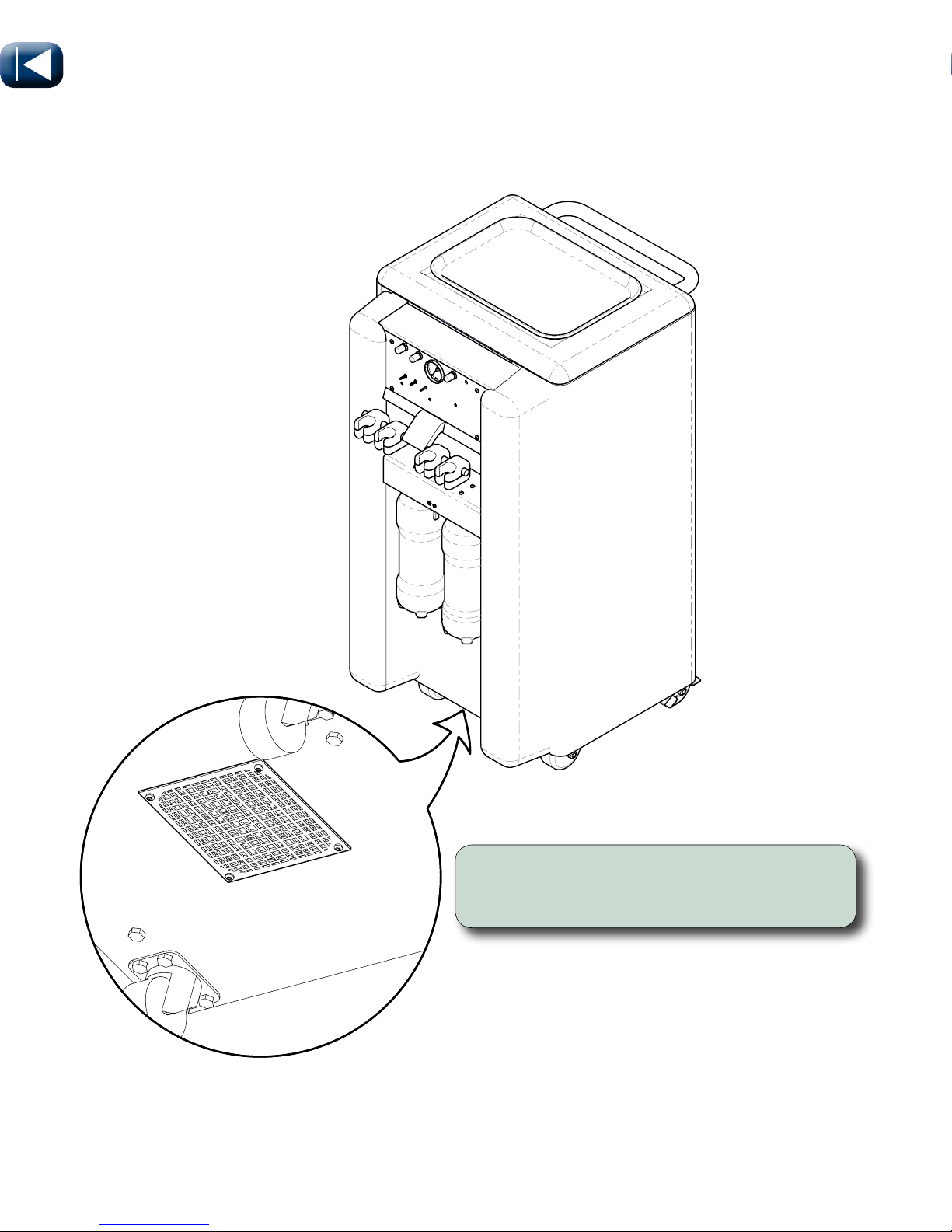

Each Month...

• Clean screen underneath cart with a rag.

Page 22

© Midmark Corporation 2016

English - 22

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Maintenance continued...

VA1676i

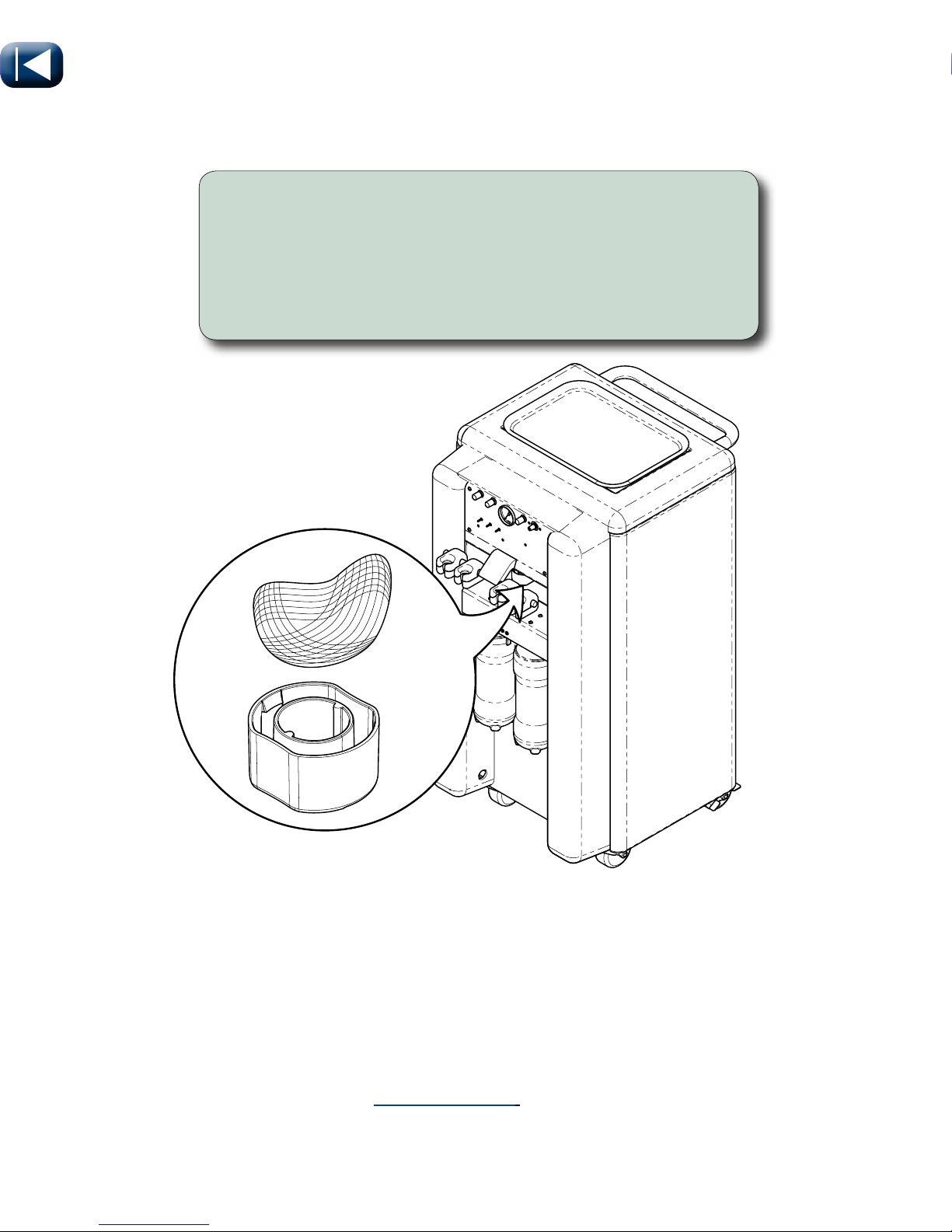

To clean the air/oil separator...

A) Turn master switch OFF.

B) Remove container by squeezing sides in while pulling out.

C) Remove fluid and saturated gauze.

D) Clean container and mounting cap.

E) Install clean gauze and reinstall the container.

Calling For Service

Direct all service inquiries to your authorized Midmark dealer. When

calling for service, you must provide the following information:

Model / serial number

Date of purchase

Symptom(s) of malfunction

Service and Parts Manual is available at www.midmark.com.

Page 23

© Midmark Corporation 2016

English - 23

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

VA1247

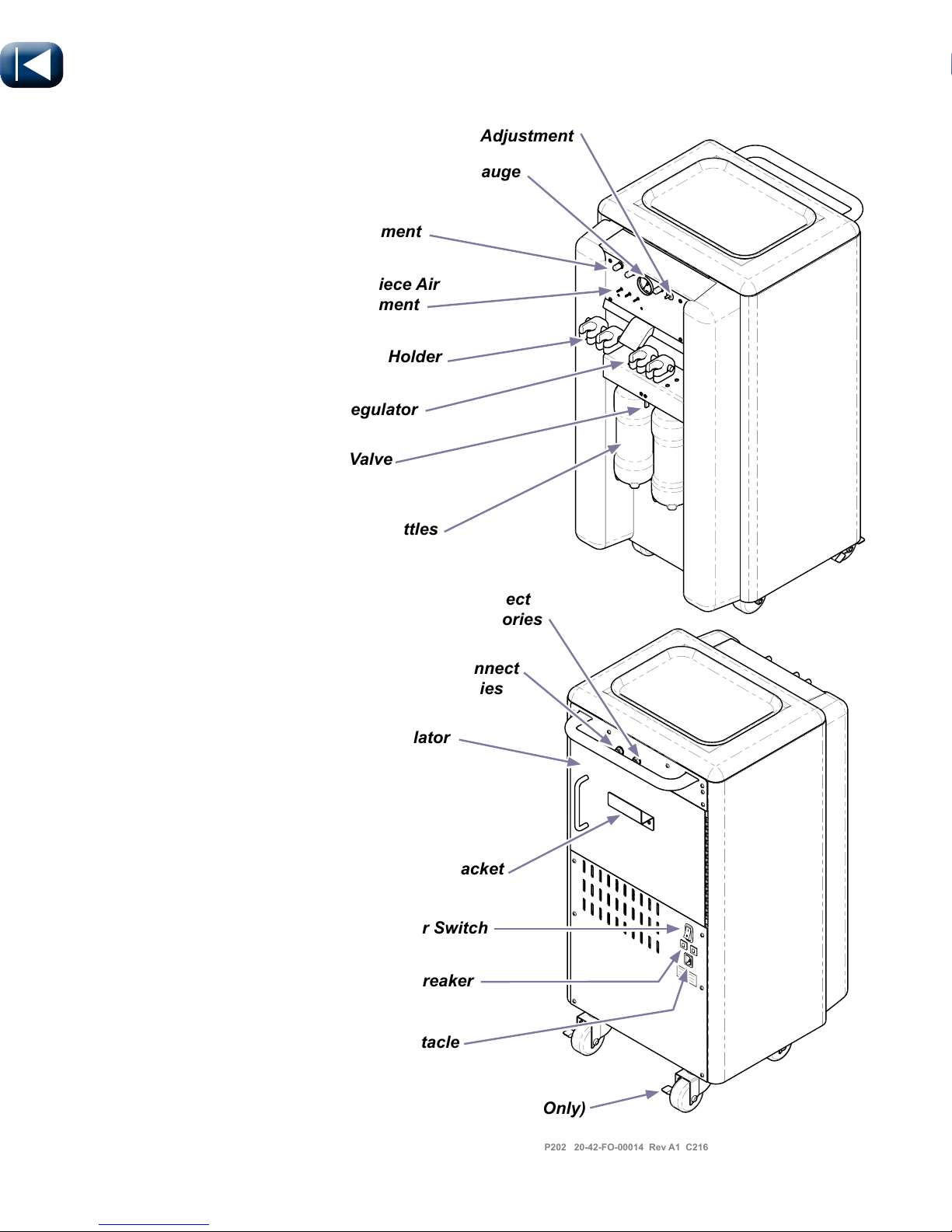

Scaler Adjustment

Water Adjustment

Handpiece Pressure Gauge

Handpiece Air

Adjustment

Handpiece Holder

Water Regulator

Water Toggle Valve

Quick Disconnect

Water Accessories

Air Pressure Regulator

Inside Back Door

Quick Disconnect

Air Accessories

On/Off Power Switch

Circuit Breaker

Power Cord Receptacle

Water Bottles

Foot Control Storage Bracket

Locking Casters (Rear Only)

VetPro® 1000

Page 24

© Midmark Corporation 2016

English - 24

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

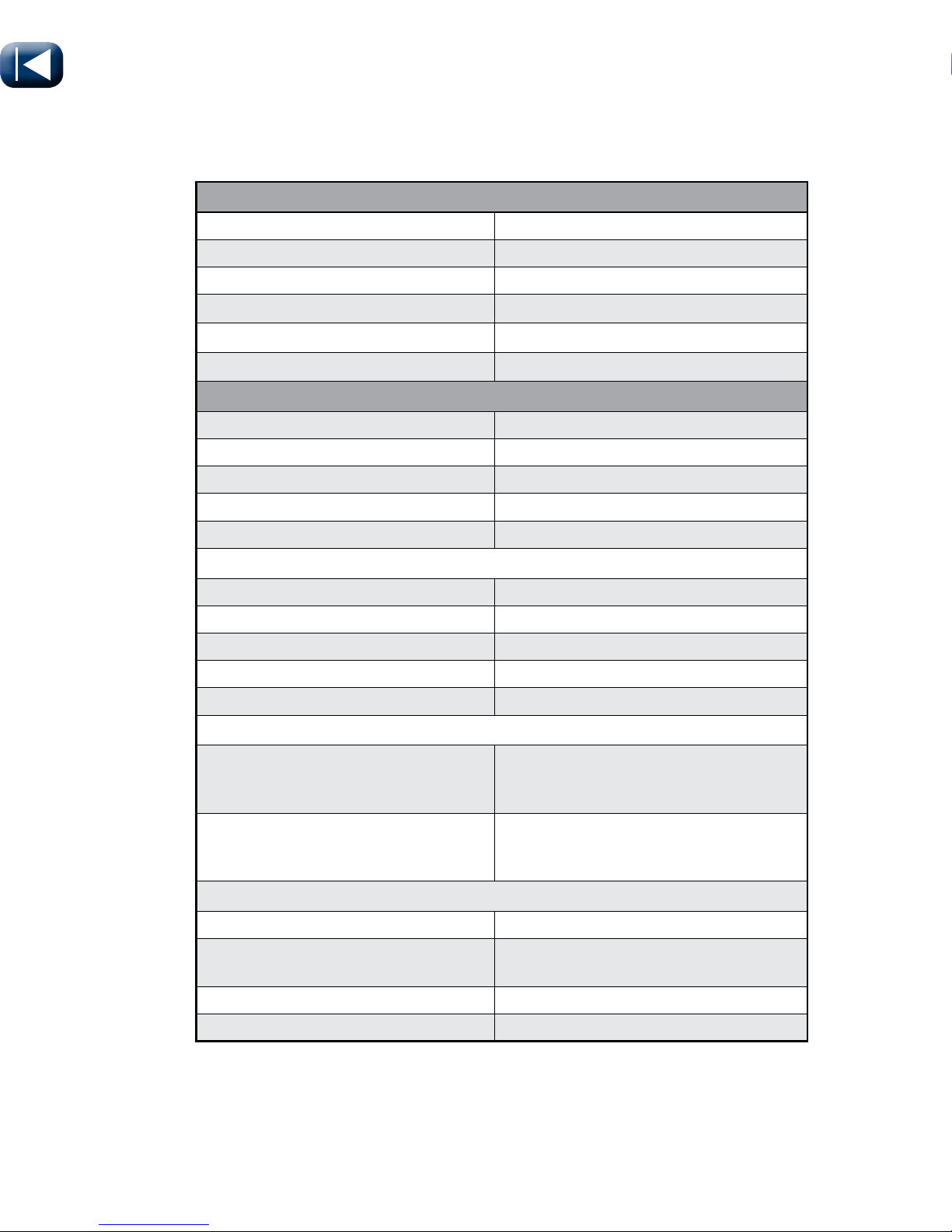

Specifications

Cart

Width 23 inches (58.42 cm)

Length 18 1/2 inches (46.99 cm)

Height 36 1/2 inches (92.71 cm)

Weight 130 lbs (58.97 kg)

Shipping Weight 150 lbs (68.04 kg)

Top of Cart Weight Restriction 25 lbs (11.33 kg)

Compressor

Motor Oil Free 1/3 HP

Working Pressure 70-100 PSI

Flow Rate 2.5 scfm @ 40 PSI

Sound Level (full load) 40 dB

Air Tank 1 Gallon

Water Module

Reservoirs Two - 1 Liter - Toggled

Pressurized System 30-40 PSI

Aseptic Non-Retracting HPC Coolant

Handpiece Flush System Manual

Air and Water Connections External Quick Connects

Other

Duty Cycle Continuous Operation

Note: Exception, Units with LED Scaler,

10 min. ON, 5 min. OFF

Classifications Class 1, Type B Applied Part, except as

noted for optional accessories,

Ordinary Equipment [IPXO]

Optional Accessories:

Acteon Satelec Scaler Type BF Applied Part

High Speed Handpiece with and

without out Fiber Optics

Type B Applied Part

Low Speed Handpiece Type B Applied Part

Air Water Syringe Type B Applied Part

Page 25

© Midmark Corporation 2016

English - 25

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

WARNING

Do not modify this equipment without authorization

of the manufacturer.

WARNING

Equipmentnotsuitableforuseinthepresenceofaammableanestheticmixture.

WARNING

To avoid the risk of electric shock, this equipment must ONLY

be connected to supply mains with protective earth.

Electrical(SeeRegulatoryComplianceChart-NextPage)

Fuse (Scaler Transformer) T0.8AL, 250V, 3AG

Circuit Breakers (2) 115VAC 6A 250V, Push to Reset

Circuit Breakers (2) 250VAC 3A 250V, Push to Reset

Power Cord (115VAC) 15A/125VAC x 10 ft. Hospital Grade

Power Cord (230VAC) 10A/250VAC x 2.5 meters

Handpiece

Connection Type Midwest 4-Hole Type Handpiece

Specifications continued...

WARNING

The Acteon Newtron® LED scaler complies with current

electromagnetic compatibility standards. However, it must not

be used by or on those with cardiac stimulators or other active implants

unless adequate electromagnetic interference shielding is present.

Check with a cardiologist to verify the EMI shielding capabilities of the

implant. See enclosed Newtron® LED manual for further advisories.

Page 26

© Midmark Corporation 2016

English - 26

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

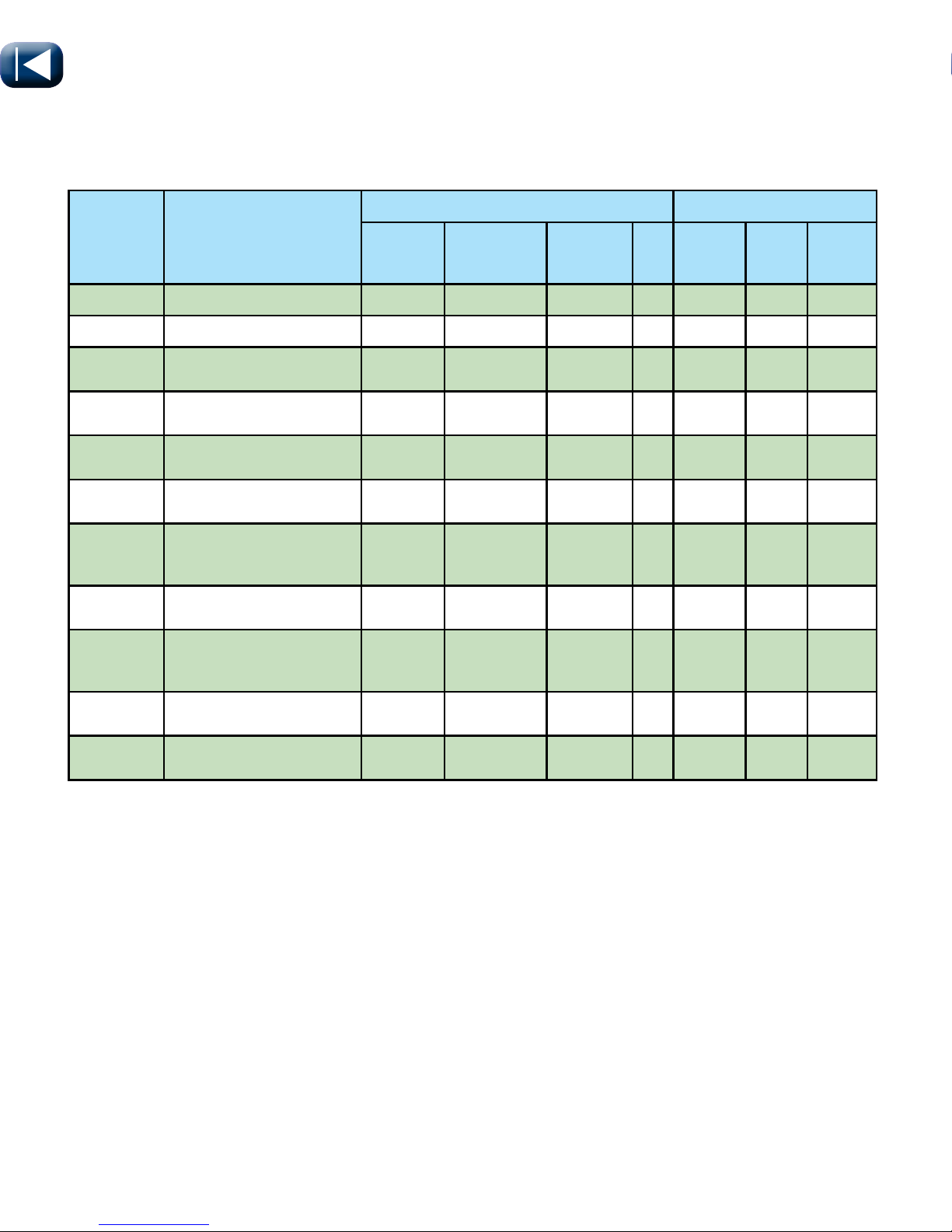

ModelIdentication/ComplianceChart

Model Description

Complies To: Electrical Ratings:

UL

60601-1,

Ed. 1

CAN / CSA

22.2,

#601.1-M90

IEC

60601-1,

Ed. 2

CE

VAC

+/- 10%

Amps

Cycles

(Hz)

8000-001 VetPro 1000 w/ Scaler

• • • •

115 6 60

8000-002 VetPro 1000 w/o Scaler

• • • •

115 6 60

8000-003 VetPro 1000 w/ Scaler and

Fiber Optics

• • • •

115 6 60

8000-004 VetPro 1000 w/o Scaler

and Fiber Optics

• • • •

115 6 60

8000-005 VetPro 1000 w/ Scaler,

Export

•

230 3 50

8000-006 VetPro 1000 w/ LED Scaler

and Fiber Optics. Export

•

230 3 50

8000-006S VetPro 1000 w/ LED Scaler

and Swivel Fiber Optics.

Export

•

230 3 50

8000-007 VetPro 1000 w/ LED Scaler

and 2 Position Fiber Optics

• • • •

115 6 60

8000-007S VetPro 1000 w/ LED Scaler

and 2 Position Swivel Fiber

Optics

• • • •

115 6 60

8000-008 VetPro 1000 w/ Scaler and

Fiber Optics

• • • •

115 6 60

8000-008S VetPro 1000 w/ Scaler and

Swivel Fiber Optics

• • • •

115 6 60

Page 27

© Midmark Corporation 2016

English - 27

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

SCOPE OF WARRANTY Midmark Corporation (“Midmark”) warrants to the original retail purchaser that it will repair or replace components of the animal health products manufactured by Midmark (except for products and components not warranted under “Exclusions”)

that are defective in material or workmanship under normal use and service. The sole remedy under this limited warranty is the repair

or replacement, at Midmark’s option, of the applicable products or components. This limited warranty shall only apply to defects that:

(i) are reported to Midmark within the applicable warranty period; and (ii) are determined to exist upon examination by Midmark. This

limited warranty extends only to the original retail purchaser of a product, and is not transferable or assignable.

APPLICABLE WARRANTY PERIOD The applicable warranty period, measured from the date of delivery to the original user, shall be

as follows: The VetPro® 1000 unit is warranted against defect in material and workmanship for a period of two years from the

time of delivery.

PRODUCTS are warranted against defect in material and workmanship for the period indicated below from the time of delivery:

a) 2 years for all products and components (except for the periods in b and c).

b) Accessories not manufactured by Midmark are excluded (i.e. Fiber optic systems, Scalers, Handpieces, etc.).

c) Replacement parts and accessories carry a 90 day warranty

OBTAINING WARRANTY SERVICE Warranty service must be obtained through either Midmark or an authorized dealer in the Midmark

product line for which warranty service is requested. Midmark may be contacted for warranty service inquiries or issues via email at

www.midmark.com, by mail to Midmark Corporation, 60 Vista Drive, Versailles, Ohio 45380, or by phone at: 1-800-MIDMARK.

It is the retail purchaser’s obligation to arrange for delivery of a product to Midmark or one of its authorized dealers for warranty service, which delivery shall be at retail purchaser’s expense. It is also the retail purchaser’s obligation to comply with the warranty service

instructions provided either by Midmark or its authorized dealer. The retail purchaser must provide Midmark with completed warranty

registration information within thirty (30) days after purchase in order to obtain the benefits of this limited warranty.

EXCLUSIONS This limited warranty does not cover and Midmark shall not be liable for the following:

(1) defects, damage or other conditions caused, in whole or in part, by misuse, abuse, negligence, alteration, accident (including animal acts of any kind), freight damage, tampering or failure to seek and obtain repair or replacement in a timely manner;

(2) matching of color, grain or texture except to commercially acceptable standards;

(3) changes in color caused by natural or artificial light;

(4) products which are not installed, used and properly cleaned and maintained as required in the installation and operation manuals

for the applicable product (imaging product must be installed by a certified Midmark installer);

(5) products considered to be of a consumable nature;

(6) accessories or parts not manufactured by Midmark;

(7) specially manufactured products;

(8) charges by anyone (including Midmark’s authorized dealers) for adjustments, repairs, replacement parts, installation or other work

performed upon or in connection with such products which are not expressly authorized in writing in advance by Midmark;

(9) costs and expenses of routine maintenance and cleaning;

(10) all sinks, faucets and plumbing accessories;

(11) representations and warranties made by any person or entity other than Midmark; and

(12) with respect to software that is a product or a component thereof, that the software will be error free, can be used without problems or interruptions, or will be free from vulnerability to intrusion or attack by viruses or other methods.

EXCLUSIVE REMEDY; CONSEQUENTIAL DAMAGES DISCLAIMER Midmark’s only obligation under this limited warranty is the

repair or replacement of defective parts. Midmark shall not be liable for and hereby disclaims any direct, special, indirect, incidental, exemplary or consequential damages or delays including, but not limited to, damages for loss of profits or income, loss of use, downtime,

cover, and employee or independent contractor wages, payments and benefits. This disclaimer shall survive any failure or asserted

failure of the essential purpose of this limited warranty or its remedies specified herein.

NO AUTHORIZATION No person or firm is authorized to create or approve for Midmark any other obligation or liability in connection

with Midmark products.

WARRANTY DISCLAIMER: THIS LIMITED WARRANTY IS MIDMARK’S ONLY WARRANTY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED. MIDMARK MAKES NO IMPLIED WARRANTIES OF ANY KIND INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

STATUTE OF LIMITATIONS No action may be brought against Midmark for breach of this limited warranty, an implied warranty, if any,

or for any other claim arising out of or relating to the products, more than ninety (90) days following expiration of the warranty period.

In the event multiple warranty periods exist with respect to a product, the ninety (90) day period provided for herein shall begin to run

from expiration of the warranty period for the component to which the claim relates.

SEVERABILITY In the event any provision of this limited warranty is determined to be invalid or otherwise unenforceable: (i) the provision shall be enforced in a manner that closest holds to its intent, while at the same time curing the invalidity or unenforceability, and

(ii) the balance of this limited warranty, being severable, shall not be affected in the event the provision that is invalid or unenforceable

cannot be enforced in any respect.

Warranty

Page 28

Midmark Corporation

60 Vista Drive

Versailles, OH 45380 USA

1-800-643-6275

1-937-526-3662

003-1879-99

TP202 20-42-FO-00014 Rev A1 C2169

Page 29

TP202 20-42-FO-00014 Rev A1 C2169

Guía del usuario

VetPro® 1000

Sistema Dental Móvil

Para modelos:

8000-001

8000-002

8000-003

8000-004

8000-005

8000-006

8000-006S

8000-007

8000-007S

8000-008

8000-008S

English

Español

Français

Page 30

© Midmark Corporation 2016

Español - 2

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Información del producto

(La siguiente información es necesaria al llamar para solicitar mantenimiento.)

Modelo / Número de serie:

Fecha de compra:

Empresa de mantenimiento

autorizada por Midmark:

Distribuidor:

Ubicación del modelo / número de serie

Page 31

© Midmark Corporation 2016

Español - 3

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Índice

Información importante

Símbolos de seguridad ........................................................................................................4

Uso indicado ........................................................................................................................ 5

Interferencias electromagnéticas.........................................................................................5

Eliminación de equipos........................................................................................................5

Representante autorizado en la CE ....................................................................................5

Condiciones de transporte, almacenamiento y funcionamiento .......................................... 5

Transporte

Transporte del sistema dental .............................................................................................6

Funcionamiento

Sistema eléctrico .................................................................................................................7

Sistema del agua .................................................................................................................8

Sistema del aire ................................................................................................................... 9

Sistema dental ..................................................................................................................... 10

Cuidado de las piezas de mano .......................................................................................... 11

Instalación y sustitución de las piezas de mano y la punta de jeringa ................................ 12

Ajuste del aire de accionamiento y las ruedas de bloqueo .................................................13

Ajuste del flujo de agua y del regulador de presión de aire ................................................14

Ajuste del aire frío................................................................................................................15

Limpieza y mantenimiento

Limpieza ..............................................................................................................................16

Mantenimiento ..................................................................................................................... 18

Servicio técnico ...................................................................................................................22

Especificaciones

Plano ...................................................................................................................................23

Peso / Dimensiones.............................................................................................................24

Especificaciones eléctricas..................................................................................................25

Identificación del modelo / Tablas de cumplimiento de las normativas ............................... 26

Garantía

Información de garantía.......................................................................................................27

Para información sobre instalación, visite:

“Technical Library” en Midmark.com

Page 32

© Midmark Corporation 2016

Español - 4

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Tipo B, pieza aplicada

Límite de temperatura

Manejar con cuidado

Límite de humedad

Clasificación

del fusible

Especificaciones

Límite de presión

Símbolos de seguridad

Información importante

Método de transporte

correcto Orientación

Altura máxima de apilado

(No apilar)

Frágil

Manténgase seco

Consulte el folleto o

manual de instrucciones

ADVERTENCIA

Indica una situación potencialmente peligrosa que podría ocasionar lesiones graves.

Precaución

Indica una situación potencialmente peligrosa que puede ocasionar lesiones leves o

moderadas. También puede usarse para alertar contra prácticas peligrosas.

Alerta del equipo

Indica una situación potencial-

mente peligrosa que, de no evitarse,

podría provocar daños al equipo.

Nota

Amplía la información sobre un procedimiento,

un método o un error de funcionamiento.

Tipo BF, pieza aplicada

Toma de tierra de

protección

Pieza de mano del

escarificador LED

Ciclo de utilización

US

C

TUVRheinland

TUV - Sólo

modelos domésticos

No volcar

100 F

38 C

23 F

-5 C

Page 33

© Midmark Corporation 2016

Español - 5

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Cómo deshacerse del equipo

Al final del ciclo de vida del producto, tanto la(s) unidad(es) como sus accesorios y otros productos fungibles podrían estar

contaminados por efecto de su uso habitual. Consulte las ordenanzas y códigos locales para ver la forma

adecuada de desechar

estos equipos y otros productos fungibles.

Representante autorizado para la EU

Los países pertenecientes a la EU deben dirigir todas las preguntas, incidentes y reclamaciones al representante autorizado de Midmark en la EU que se indica a continuación:

Midmark EMEA Ltd

Beech House

First Floor, East Wing

Ancells Business Park

Fleet

Hampshire GU51 2UN

United Kingdom

Tel: + 44 (0) 1252 360 940

Fax: + 44 (0) 1252 360 941

Condiciones de transporte, almacenamiento y funcionamiento

Rango de temperaturas de transporte y almacenamiento: ........... -5ºC a 38ºC (23°F a 100°F)

Rango de temperatura de funcionamiento: ................................... 10ºC a 40ºC (50ºF a 104ºF)

Humedad relativa durante transporte/almacenamiento:................ 10% a 90% (sin condensación)

Humedad relativa durante el funcionamiento: ............................... 30% a 75% (sin condensación)

Presión atmosférica durante transporte/almacenamiento: ............ 50 kPA (7.2 PSI) a 106 kPA (15.3 PSI)

Presión atmosférica durante el funcionamiento: ........................... 700 hPA (20 in Hg) a 1060 hPA (31 in Hg)

Uso indicado

El sistema Midmark® VetPro® 1000 es un sistema dental móvil diseñado para proporcionar a veterinarios

o técnicos cualificados una unidad autónoma, compacta y portátil para realizar procedimientos dentales

veterinarios.

Interferencias electromagnéticas

Este producto se ha diseñado y construido para reducir al mínimo las interferencias electromagnéticas

con otros dispositivos.

Sin embargo, si detecta interferencias entre otros dispositivo y este carro:

•Saqueeldispositivoquecauseinterferenciasfueradelasala

•Enchufeelcarroauncircuitoaislado

•AumentelaseparaciónentreelproductodeMidmarkyeldispositivoquecauselasinterferencias

•PóngaseencontactoconMidmarksipersistenlasinterferencias

Page 34

© Midmark Corporation 2016

Español - 6

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Transporte

ADVERTENCIA

Al trasladar el dispositivo, tenga cuidado al pasar por los umbrales de las

puertas y cerca de objetos a ras de suelo.

De lo contrario se pueden producir lesiones.

Umbral

Al transportar a través de escalones o umbrales

muy altos...

A) Empuje el carro hacia arriba y sobre una superficie nivelada.

Page 35

© Midmark Corporation 2016

Español - 7

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

6

A

M

P

6

A

M

P

VA1227

Funcionamiento

Sistema eléctrico

Interruptor de encendido/apagado

El interruptor de encendido/apagado está situado en la parte posterior del carro. Controla la fuente principal

de alimentación y siempre debe estar en posición ENCENDIDO (ON) para que el sistema dental funcione.

Cortacircuitos

Hay dos cortacircuitos situados en el panel posterior inferior del carro. Si se supera la carga máxima de la

unidad, los cortacircuitos interrumpirán la alimentación. La carga máxima es de 115 V CA, 6 A (doméstico)

o 230 V CA, 3 A (exportación).

Desconexión de la red eléctrica

Puede interrumpirse la alimentación desenchufando el cable o apagando el interruptor.

(O) Interruptor

apagado

( I ) Interruptor

encendido

Cortacircuitos

Desactivado

(Sin energía)

Desconexión

de la red

eléctrica

Reestablecer

(alimentación)

Page 36

© Midmark Corporation 2016

Español - 8

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

VA1229

Funcionamiento

Sistema de agua

Botellas de agua

La unidad tiene dos botellas de un litro. Las botellas de agua suministran agua a las piezas de mano,

a la jeringa de aire/agua y a una toma de desconexión rápida en la parte posterior del carro. El aire

fluye a través del regulador del agua y del conmutador hasta alcanzar las botellas de agua. El sistema

de agua está regulado a 40 PSI. Utilice la válvula de aguja del agua para ajustar el flujo de agua para

cada instrumento. El conmutador situado entre las botellas de agua controla qué botella suministra el

agua. Cuando el conmutador está en el centro ninguna de las botellas está presurizada. Desplace el

conmutador hacia la izquierda para presurizar la botella izquierda y despresurizar la botella derecha.

Desplácelo hacia la derecha para presurizar la botella derecha y despresurizar la izquierda.

Conmutador

Para llenar las botellas de agua...

A) Desplace el conmutador al centro.

B) Retire la botella de agua y llénela (se recomienda usar agua destilada).

C) Vuelva a colocar la botella de agua y desplace el conmutador hacia la botella de agua llena.

Nota: Las botellas de agua deben comprobarse entre un paciente y otro y llenarse si es necesario.

Toma de desconexión rápida de agua

La toma de desconexión rápida de agua tiene un anillo azul. Puede acoplar accesorios al carro que

usarán el agua del mismo. Es posible que tenga que añadir un regulador si el equipo conectado no

admite 40 PSI.

Válvula de

aguja del água

Regulador

del agua

Botellas de

agua

Toma de

desconexión

rápida

de agua

Precaución

Si no se cierran herméticamente las botellas de agua el

paciente puede sufrir lesiones.

Page 37

© Midmark Corporation 2016

Español - 9

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

VA1231

Funcionamiento

Sistema de aire

Compresor

El sistema neumático consta de un compresor de 1/3 HP con un depósito de aire de dos litros y un regulador. Suministra aire a las

piezas de mano, a la jeringa de aire/agua y a una toma de desconexión rápida en la parte posterior del

carro. El compresor funciona entre 70 PSI y 100 PSI. El regulador se ajusta en fábrica a 65 PSI.

Toma de desconexión rápida de aire

La toma de desconexión rápida de aire tiene un anillo rojo. Puede acoplar accesorios al carro que

usarán el aire del mismo. Es posible que tenga que añadir un regulador si el equipo conectado no admite

100 PSI.

Tornillo de ajuste del

aire de refrigeración

Mando de ajuste del aire

de accionamiento

Toma de desconexión rápida de aire

Respiradero

Compartimento del compresor

Soporte del pedal de control

Alerta del equipo

No obstruya el respiradero.

Page 38

© Midmark Corporation 2016

Español - 10

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

VA1233

Piezas de mano

El sistema dental controla hasta cuatro piezas de mano. La presión de las piezas de mano se controla

mediante las válvulas de ajuste del aire de accionamiento. El medidor de la parte delantera del sistema

dental indica la presión de la pieza de mano. La presión de la pieza de mano no debe superar los 60 PSI

durante el funcionamiento normal. El escarificador (opcional) tiene un mando de ajuste para regular el

nivel de intensidad.

Funcionamiento

Sistema dental

Jeringa de aire/agua

Hay botones de aire y agua en la parte superior de la jeringa. Cuando se pulsan ambos botones se obtiene

una nebulización de aire y agua Los ajustes de aire y agua están situados debajo del soporte de la jeringa.

Inserte un destornillador plano en los tornillos de ajuste. Gire en el sentido de las agujas del reloj para

reducir el flujo y en el sentido contrario para aumentarlo. Gire el tornillo hasta que el flujo de aire/agua

deseado salga a través del instrumento.

Medidor

Aire

Agua

Alerta del equipo

Consulte con el fabricante de

la pieza de mano los ajustes de PSI

recomendados. Compruebe únicamente

una pieza de mano cada vez.

Pieza de

mano las

piezas de

mano

Ajuste del

Mando de

Aire

Agua

Precaución

La punta de la jeringa y de las piezas de mano

han de cambiarse o desinfectarse entre un paciente y otro.

Taladro

Pulidora

Jeringa

Escalador

Page 39

© Midmark Corporation 2016

Español - 11

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Funcionamiento

Para cambiar la fresa de la pieza de mano de alta velocidad...

A) Pulse el botón de la parte posterior de la pieza de mano y tire de la fresa

hasta extraerla.

B) Introduzca la fresa en la pieza de mano. (El vástago sólo entrará hasta la

mitad).

C) A continuación pulse el botón de la parte posterior de la pieza de mano y

empuje la fresa hasta que el vástago entre por completo.

Nota: Las fresas de agarre de fricción (estilo FG) se han diseñado para que toda la parte recta del

vástago esté en el interior del portafresas de la pieza de mano. Si la fresa está instalada correctamente,

sólo se debe ver la parte cónica de la fresa. Se recomienda usar una fresa nueva para cada paciente.

Ángulo pro-

láctico

Sustitución del ángulo profiláctico

Para cambiar el ángulo profiláctico...

A) Gire el portafresas a la derecha para desbloquearlo.

Instale el ángulo profiláctico y gire el anillo de liberación

del portafresas a la izquierda para apretarlo.

Presione

Botón

Introduzca la fresa en la

pieza de mano

Termine de introducir la

fresa en la pieza de mano

Vástago dentro de la pieza

de mano

Esta parte de la

fresa debe estar

dentro de la pieza

de mano

Sustitución de la fresa

Page 40

© Midmark Corporation 2016

Español - 12

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Instalación de pieza de mano

Instale las piezas de mano.

VA1807i

Para cambiar la punta de la jeringa...

A) Presione hacia abajo el collarín grande.

B) Cuando sienta un “clic” suave, tire de la punta en

línea recta.

C) Mantenga presionado el collarín e introduzca la

nueva punta. Asegúrese de introducirlo hasta el

fondo completamente y luego suelte el collarín.

D) Compruebe la instalación tirando firmemente de la

punta para ver si se ha insertado hasta el fondo y

está bloqueada en su sitio.

Sustitución de la punta de la jeringa

Alinear correctamente los

componentes para prevenir que

la pieza de mano se dañe y en

consecuencia se estropee.

Pulverice ligeramente las juntas tóricas

expuestas con un lubrificante en un paso.

Apriete el acoplador con firmeza

con una llave inglesa.

Conexión de acoplador

giratorio

Nota

No todas las unidades estarán equipadas con un módulo de lámpara.

Soporte

de las

piezas de

mano

Page 41

© Midmark Corporation 2016

Español - 13

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Ajuste del aire de accionamiento y ruedas de bloqueo

Mando de ajuste del

aire de accionamiento

Para ajustar el aire de accionamiento...

Inserte un destornillador de cabeza plana en el mando

de ajuste del aire de accionamiento (de la pieza de mano

deseada). Gire el mando hasta que se muestre la presión

de aire adecuada en el medidor de presión.

OFF para

desbloquear

ON para bloquear

Page 42

© Midmark Corporation 2016

Español - 14

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Funcionamiento

Disminuir

Aumentar

Mando de

ajuste

Desbloquear

Bloquear

Ajuste del regulador de presión

del aire

ALERTA DEL EQUIPO

No ajuste el regulador por

encima de 65 PSI.

Para ajustar el regulador...

A) Tire hacia arriba del mando de ajuste

para desbloquearlo.

B) Gire el mando de ajuste en el sentido

de las agujas del reloj para aumentar

la presión y en el sentido contrario para

reducirla.

C) Empuje el mando de ajuste hacia abajo

para bloquearlo.

Para ajustar el flujo de agua...

Gire la válvula de aguja del agua (de la pieza de mano que desee) hasta

conseguir el flujo deseado.

Válvula de aguja del agua

Ajuste del flujo de agua

Page 43

© Midmark Corporation 2016

Español - 15

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Funcionamiento

Para ajustar el aire frío...

Inserte un destornillador de cabeza plana en el mando de ajuste

del aire frío (de la pieza de mano deseada). Gire en el sentido de

las agujas del reloj para reducir el flujo y en el sentido contrario

para aumentarlo. Gire el tornillo hasta que salga la presión de aire

deseada a través del instrumento.

Nota: Los tornillos de ajuste de aire de accionamiento están situados debajo de los

soportes de herramientas de cada instrumento.

Tornillos de ajuste del

aire de refrigeración

Ajuste de aire frío

Page 44

© Midmark Corporation 2016

Español - 16

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Nota:

Utilice solo una solución de lejía al 5,25%. No utilice

lejía aromatizada, con protector del color u otros aditivos.

Cambie la mezcla todos los días.

~90%

~10%

Limpieza

•Utilicelimpiadoresadecuadosparalasituación,comoaguatempladaydetergentessuaves

o una solución de agua y lejía al 10%.

•Limpielassuperficiesexterioresconunpañolimpiosinpelusahumedecidocon

desinfectante. No vierta ningún líquido en respiraderos abiertos, enchufes ni conectores.

Seque las superficies con un paño limpio o una toalla de papel.

•Despuésdelalimpieza,inspeccionevisualmenteelproductoenbuscadedeteriorode

cubiertas. No use el sistema dental si nota decoloración excesiva, grietas u otros signos de

desgaste (consulte las instrucciones dadas para Contactar con el servicio técnico).

Page 45

© Midmark Corporation 2016

Español - 17

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Nota

Cadaconsultorioveterinarioesdiferenteynohayningúndesinfectanteespecícoquesealamejor

opción para todas las instalaciones. Existen varias organizaciones que ofrecen información sobre

procedimientosdedesinfección.Consultelossitioswebdefuentesconablesquepuedenayudaral

personal veterinario a elegir lo mejor para sus consultorios. A continuación se indican algunos de estos

sitios.

Organización de Seguridad y Procedimientos de Asepsia

http://www.osap.org

Departamento de salud y recursos humanos de Centros para el Control y la Prevención de

Enfermedades (CDC)

http://www.cdc.gov

Cuando utilice desinfectantes...

• Lea cuidadosamente la etiqueta del

producto y las instrucciones de uso.

• No supere la tasa de disolución.

DA148100i

Read

carefully

Alerta del equipo

Consulte con el fabricante de las

piezas de mano para ver los procedimientos

de limpieza recomendados.

Limpieza continuación...

Lea

atentamente

Page 46

© Midmark Corporation 2016

Español - 18

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Mantenimiento

Al principio de cada jornada de trabajo...

• Llene las botellas de agua con agua

destilada limpia.

• Lave las piezas de mano.

Entre un paciente y otro...

• Retire las puntas, instrumentos, etc.,

desechables.

• Lave el sistema dental.

• Desinfecte las piezas de mano y el

escarificador según las instrucciones

del fabricante.

• Desinfecte la punta de la jeringa.

• Llene las botellas de agua.

Para lavar el sistema dental...

A) Extraiga todas las piezas de mano que utilizan agua.

B) Abra la válvula de aguja del agua.

C) Sostenga el extremo del tubo sobre un recipiente y pise el pedal de control.

D) Deje que corra el agua entre 20 y 30 segundos.

E) Instale las piezas de mano y la punta de la jeringa recién desinfectadas.

F) Rellene la botella de agua.

Válvula de aguja del agua

Nota

No es obligatorio el uso de agua

destilada. Sin embargo, el agua debe

ser potable.

Alerta del equipo

ESTERILIZACIÓN DE LA PUNTA DE LA JERINGA DESINFECTABLE AL AUTOCLAVE

Las puntas de jeringa desinfectables al autoclave que se adjuntan con el sistema dental

deben esterilizarse antes de su uso con cada paciente, incluido su primer uso. Asegúrese de

enjuagar y limpiar cuidadosamente las puntas de jeringa antes de esterilizarlas, ya que cualquier

suciedad puede reducir la eficacia de la esterilización. El proceso de esterilización recomendado

es el de autoclave de vapor. Los parámetros de temperatura y presión recomendados son 125°C

(250°F) y 106 kPa (15 PSI) durante 40 minutos.

Alerta del equipo

ESTERILIZACIÓN DE LAS PIEZAS

DE MANO

Entre cada procedimiento, lleve

a cabo las instrucciones del fabricante para

Control de infección/Esterilización que hallará

en la documentación incluida con las piezas de

mano. Si no lo hace así se puede producir un fallo

prematuro de las piezas de mano.

Page 47

© Midmark Corporation 2016

Español - 19

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

BLEACH

Mantenimiento continuación...

Al final de cada día...

• Lave con solución de lejía el

sistema dental y vacíe el sistema

de agua.

• Drene el regulador de aire.

• Elimine la condensación del

recipiente de aire.

• Limpie el sistema.

ALERTA DEL EQUIPO

No utilice lejía de color/perfumada ni concentraciones mayores de

las recomendadas. No mantenga la solución de lejía en el sistema dental

durante más de 30 minutos, ya que esto podría dañar el sistema.

Para lavar con solución de lejía el sistema dental...

A) Extraiga todas las piezas de mano que utilizan agua.

B) Retire las botellas de agua y llénelas con 9 partes de agua y 1 de lejía.

C) Abra la válvula de aguja del agua.

D) Sostenga el extremo del tubo sobre un recipiente y pise el pedal de control.

E) Deje que corra el agua durante 20 o 30 segundos.

F) Deje que la solución de lejía permanezca en el sistema dental durante 10-20 minutos,

y luego retire, vacíe y enjuague las botellas de agua.

G) Llene las botellas de agua con agua limpia y repita los pasos C a E hasta que

desaparezca el olor a lejía.

H) Instale las piezas de mano y la punta de la jeringa recién desinfectadas.

I) Vacíe las botellas de agua.

Lejía

Page 48

© Midmark Corporation 2016

Español - 20

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

VA1238

Para eliminar la condensación del depósito de aire...

A) Apague el interruptor de alimentación.

B) Coloque el extremo del tubo rojo de modo que se vacíe

en un contenedor.

C) Gire la válvula de drenaje lentamente para abrirla.

D) Cuando no salga agua, cierre la válvula lentamente.

Para drenar el regulador de aire...

Coloque un paño bajo el regulador y oprima

el botón hasta que deje de salir agua.

Válvula

abierta

Mantenimiento continuación...

Botón

Page 49

© Midmark Corporation 2016

Español - 21

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

VA1241

Mantenimiento continuación...

Cada mes...

• Limpie con un trapo la rejilla que está en

la parte inferior del carro.

Page 50

© Midmark Corporation 2016

Español - 22

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Mantenimiento continuación...

VA1676i

Para limpiar el separador de aire y aceite...

A) APAGUE el interruptor general.

B) Saque el recipiente apretando los lados hacia adentro al mismo

tiempo que tira hacia afuera.

C) Retire el fluido y la gasa saturada.

D) Limpie el recipiente y la tapa de montaje.

E) Instale una gasa limpia y vuelva a colocar el recipiente.

Servicio técnico

Todas las solicitudes de servicio técnico se deben dirigir a un distribuidor autorizado de Midmark. Al solicitar

servicio técnico, debe proporcionar la información siguiente:

Modelo / número de serie

Fecha de compra

Síntomas del fallo

Puede consultar el Manual de Servicio y Piezas en www.midmark.com.

Page 51

© Midmark Corporation 2016

Español - 23

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

VA1247

Ajuste del escaricador

Ajuste del agua

Manómetro de las piezas de mano

Ajuste del aire de

las piezas de mano

Soporte de las piezas de mano

Regulador del agua

Válvula de conmutación de agua

Toma de desconexión rápida

para accesorios de agua

Regulador de presión de aire

dentro de la puerta trasera

Toma de desconexión rápida

para accesorios neumáticos

Interruptor de encendido/apagado

Cortacircuitos

Toma de corriente del cable de alimentación

Botellas de agua

Soporte de almacenamiento del pedal de control

Ruedas de bloqueo (sólo traseras)

VetPro® 1000

Page 52

© Midmark Corporation 2016

Español - 24

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Especificaciones

Carro

Anchura 58,42 cm (23 inches)

Longitud 46,99 cm (18 1/2 inches)

Altura 92,71 cm (36 1/2 inches)

Peso 58,97 Kg. (130 lbs.)

Peso de transporte 68,04 Kg. (150 lbs.)

Restricción de peso de la parte

superior del carro

11,33 Kg. (25 lbs.)

Compresor

Motor 1/3 HP, no necesita aceite

Presión de trabajo 70-100 PSI

Caudal 2,5 scfm a 40 PSI

Nivel acústico (a plena carga) 40 dB

Depósito de aire 3,8 l (1 gallon)

Módulo de agua

Depósitos Dos - 1 litro - conmutados

Sistema presurizado 30-40 PSI

Asepsia Refrigerante HPC sin retracción

Sistema de lavado de las piezas de

mano

Manual

Conexiones del aire y del agua Tomas de conexión rápida externas

Otros

Ciclo de utilización Funcionamiento continuo

Nota: excepción, unidades con escarificador LED, 10 min. encendido, 5 min.

apagado

Clasificaciones Clase I, parte aplicada Tipo B, excepto

según se indica para accesorios opcionales, equipo ordinario [IPX0]

Accesorios opcionales:

Escarificador Acteon Satelec Tipo BF, pieza aplicada

Pieza de mano de alta velocidad

con y sin fibra óptica

Tipo B, pieza aplicada

Pieza de mano de baja velocidad Tipo B, pieza aplicada

Jeringa de aire/agua Tipo B, pieza aplicada

Page 53

© Midmark Corporation 2016

Español - 25

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

ADVERTENCIA

No modifique este equipo sin autorización del fabricante.

ADVERTENCIA

El equipo no se puede utilizar en presencia de mezclas anestésicas inamables.

ADVERTENCIA

Para evitar riesgo de descarga eléctrica, este equipo debe conectarse

ÚNICAMENTE a enchufes provistos de toma a tierra.

Especificaciones eléctricas (consulte la tabla de

cumplimiento de las normativas en la página siguiente)

Fusible (transformador del escarificador)

T0.8AL, 250 V, 3AG

Cortacircuitos (2) 115 V CA 6 A 250 V, Presionar para restablecer

Cortacircuitos (2) 250 V CA 3A 250 V, Presionar para restablecer

Cable de alimentación (115 V CA) 15 A/125 V CA x 3,3 m. (10 pies) cla-

sificación para hospitales

Cable de alimentación (230 V CA) 10 A/250 V CA x 2,5 m.

Pieza de mano

Tipo de conexión Pieza de mano tipo Midwest de cuatro

orificios

Especificaciones continuación...

ADVERTENCIA

El limpiador de sarro con tecnología LED Newtron® de Acteon cumple

las normas de compatibilidad electromagnética actuales. No obstante, las personas

que tengan estimuladores cardíacos u otros implantes activos no deben utilizarlo, ni se debe

utilizar en animales con estimuladores cardíacos u otros implantes activos, a menos que se

cuente con protección contra las interferencias electromagnéticas. Se deberá consultar con

un cardiólogo para conocer las capacidades de protección contra interferencias electromagnéticas del implante. Pueden encontrarse más avisos en el manual de la luz Newtron® LED

adjunto

Page 54

© Midmark Corporation 2016

Español - 26

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Identicación del modelo y tablas de cumplimiento de

las normativas

Modelo Descripción

Conformidad con: Clasificaciones eléctricas:

UL

60601-1,

Ed. 1

CAN / CSA

22.2,

#601.1-M90

IEC

60601-1,

Ed. 2

CE

V CA

+/- 10%

Am-

perios

Ciclos

(Hz)

8000-001 VetPro 1000 con escari-

ficador

• • • •

115 6 60

8000-002 VetPro 1000 sin escari-

ficador

• • • •

115 6 60

8000-003 VetPro 1000 con escari-

ficador y fibra óptica

• • • •

115 6 60

8000-004 VetPro 1000 sin escarifica-

dor ni fibra óptica

• • • •

115 6 60

8000-005 VetPro 1000 con escari-

ficador (para exportación)

•

230 3 50

8000-006 VetPro 1000 con escari-

ficador LED y fibra óptica

Exportación

•

230 3 50

8000-006S VETPro 1000 con escari-

ficador LED y fibra óptica

giratoria. Exportación

•

230 3 50

8000-007 VetPro 1000 con escari-

ficador LED y fibra óptica

de dos posiciones

• • • •

115 6 60

8000-007S VETPro 1000 con escari-

ficador LED y fibra óptica

giratoria de dos posiciones

• • • •

115 6 60

8000-008 VetPro 1000 con escari-

ficador y fibra óptica

• • • •

115 6 60

8000-008S VETPro 1000 con es-

carificador y fibra óptica

giratoria

• • • •

115 6 60

Page 55

© Midmark Corporation 2016

Español - 27

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

COBERTURA DE LA GARANTÍA, Midmark Corporation («Midmark») garantiza al comprador minorista original que reparará o reemplazará los

componentes de los productos de salud animal fabricados por Midmark (excepto los productos y componentes no garantizados en «Exclusiones»)

que contengan materiales defectuosos o fallos de mano de obra en condiciones normales de uso y servicio. La responsabilidad única en virtud de

esta garantía limitada es a la reparación o la sustitución, a discreción de Midmark, de los productos o componentes aplicables. La garantía limitada

solo se aplicará a los defectos que: (i) se notifiquen a Midmark dentro del período de garantía aplicable; y (ii) cuya existencia se llega a determinar

tras un examen efectuado por Midmark. Esta garantía limitada se expide únicamente al comprador minorista original de un producto y no es

transferible ni asignable.

PERÍODO DE GARANTÍA APLICABLE l período de validez de la garantía a partir de la fecha de entrega al usuario original será el siguiente:

La unidad VetPro

®

1000 está garantizada frente a defectos de material o fabricación durante un período de dos años a partir del momento de la

entrega.

LOS PRODUCTOS ODONTOLÓGICOS están bajo garantía frente a defectos de material y fabricación durante el período que se indica a

continuación a partir de la fecha de entrega:

a) Dos años para todos los productos y componentes (excepto los periodos que se indican en los apartados b y c).

b) Quedan excluidos los accesorios no fabricados por Midmark (es decir, sistemas de fibra óptica, escarificadores, piezas de mano, etc.).

c) Las piezas de recambio y los accesorios tienen una garantía de 90 días.

OBTENCIÓN DEL SERVICIO DE GARANTÍA El servicio de garantía debe obtenerse a través de un distribuidor de Midmark o un distribuidor

autorizado por Midmark en la línea de productos para la que se solicita el servicio de garantía. Puede contactar con Midmark para consultarle dudas

o problemas sobre el servicio de garantía por correo electrónico en www.midmark.com, por correo postal a Midmark Corporation, 60 Vista Drive,

Versailles, Ohio 45380, o por teléfono al: 1-800-MIDMARK.

Es obligación del comprador minorista organizar la entrega de un producto a Midmark o a uno de sus distribuidores autorizados para el servicio de

garantía, la cual correrá a cargo del comprador. También es obligación del comprador minorista cumplir las instrucciones de servicio de garantía

proporcionadas, ya sea por Midmark o por su distribuidor autorizado. El comprador minorista debe suministrar a Midmark la información de registro

de la garantía completada en un plazo de treinta (30) días después de la compra con el fin de obtener los beneficios de esta garantía limitada.

EXENCIONES Esta garantía limitada no cubre (y Midmark no es responsable de) lo siguiente:

(1) defectos, daños u otras condiciones causadas, en su totalidad o en parte, por el mal uso, abuso, negligencia, alteración, accidente (incluido

cualquier tipo de espectáculos con animales), daños durante el transporte, la manipulación o la incapacidad de solicitar y lograr la reparación o la

sustitución dentro del plazo estipulado;

(2) coincidencia de color, grano o textura, a excepción de las normas comercialmente aceptables;

(3) cambios en el color causados por la luz natural o artificial;

(4) productos que no se hayan instalado, utilizado o limpiado y mantenido adecuadamente tal como se indica en los manuales de instalación

y funcionamiento del producto aplicable (la instalación de productos para la impresión de imágenes debe ser realizada por un instalador con

certificación Midmark);

(5) productos considerados de naturaleza consumible;

(6) accesorios o piezas no fabricados por Midmark;

(7) productos fabricados específicamente;

(8) facturas de terceros (incluidos los distribuidores autorizados por Midmark) en concepto de ajustes, reparaciones, piezas de recambio,

instalaciones o cualquier otra modificación del producto, o relacionada con el mismo, que se hayan realizado sin la autorización previa por escrito de

Midmark;

(9) costes y gastos de mantenimiento y limpieza rutinarios;

(10) fregaderos, grifos y accesorios de fontanería;

(11) declaraciones y garantías hechas por cualquier persona o entidad que no sea Midmark; y

(12) software o componente del mismo que no tenga errores, pueda utilizarse sin problemas ni interrupciones o no sea vulnerable a la intrusión o al

ataque de virus u otros métodos.

RESPONSABILIDAD EXCLUSIVA; DAÑOS EMERGENTES La única responsabilidad de Midmark en virtud de la presente garantía limitada es la de

reparar o sustituir las piezas defectuosas. Midmark no se hace responsable, y por la presente, renuncia a cualesquiera daños directos, especiales,

indirectos, accidentales, ejemplares, consecuentes o demoras, incluidos, sin limitación, daños por pérdida de ganancias o ingresos, pérdida de uso,

tiempo muerto, cobertura y salarios de empleados o de contratistas independientes, pagos y beneficios. La presente exención de responsabilidad

será válida aun en caso de incumplimiento o incumplimiento alegado del objetivo principal de esta garantía limitada o de sus responsabilidades

especificadas en el presente documento.

NO AUTORIZACIÓN Midmark no autoriza a ninguna persona ni empresa a imponer ni aprobar ninguna otra obligación ni responsabilidad en relación

con los productos Midmark.

EXENCIÓN DE RESPONSABILIDAD DE GARANTÍA: ESTA ES LA GARANTÍA LIMITADA DE MIDMARK Y SUSTITUYE A CUALQUIER OTRA

GARANTÍA, EXPLÍCITA O IMPLÍCITA. MIDMARK NO OFRECE GARANTÍAS IMPLÍCITAS DE NINGÚN TIPO, INCLUIDAS LAS IMPLÍCITAS DE

COMERCIABILIDAD O IDONEIDAD PARA UN PROPÓSITO DETERMINADO.

ESTATUTO DE LIMITACIONES No podrá interponerse ninguna acción contra Midmark por incumplimiento de esta garantía limitada, de una garantía

implícita, si las hubiere, o por cualquier otra reclamación que surja de o en relación con los productos, después de más de noventa (90) días una vez

vencido el período de garantía. En el caso de que existan múltiples períodos de garantía con respecto a un producto, el período de noventa (90) días

previsto en el presente documento comenzará a transcurrir a partir del vencimiento del período de garantía para el componente al que se refiere la

reclamación.

SEPARABILIDAD Si cualquiera de las disposiciones de la presente garantía limitada se determinara no válida o inaplicable: (i) la disposición seguirá

aplicándose de la forma más fiel a su propósito, al mismo tiempo que se repara la invalidez e inaplicabilidad, y (ii) el contenido restante de esta

garantía limitada, considerada separadamente, no se verá afectado si la disposición no válida o inaplicable no pudiera aplicarse en modo alguno.

Información sobre la garantía

Page 56

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Midmark Corporation

60 Vista Drive

Versailles, OH 45380-0286 (Estados Unidos)

Teléfono: 937-526-3662

Fax: 937-526-5542

www.midmark.com

Page 57

TP202 20-42-FO-00014 Rev A1 C2169

Guide de l’utilisateur

VetPro® 1000

Système de distribution

dentaire mobile

Pour les modèles :

8000-001

8000-002

8000-003

8000-004

8000-005

8000-006

8000-006S

8000-007

8000-007S

8000-008

8000-008S

English

Español

Français

Page 58

© Midmark Corporation 2016

Français - 2

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Informations produit

(Les renseignements ci-dessous sont nécessaires lorsque vous contactez le

service après-vente.)

Numéro de modèle/de série :

Date d’acquisition :

Société de service après-

vente agréée Midmark :

Revendeur :

Emplacement du numéro de

modèle/de série

Page 59

© Midmark Corporation 2016

Français - 3

TP202 20-42-FO-00014 Rev A1 C2169

003-1879-99

Table des matières

Renseignements importants

Symboles de sécurité .......................................................................................................... 4

Utilisation prévue ................................................................................................................. 5

Interférence électromagnétique ...........................................................................................5

Mise au rebut de l’équipement ............................................................................................5

Représentant CE autorisé ................................................................................................... 5

Conditions de transport, de stockage et d’utilisation ........................................................... 5

Transport

Transport du système dentaire ............................................................................................ 6

Fonctionnement

Système électrique .............................................................................................................. 7

Système hydraulique ........................................................................................................... 8

Système pneumatique .........................................................................................................9

Système de distribution ....................................................................................................... 10

Entretien des pièces à main ................................................................................................ 11

Remplacement de l’embout de seringue et installation des pièces à main ......................... 12

Réglage de l’air d’entraînement et blocage des roulettes ...................................................13

Réglage du régulateur de pression pneumatique et réglage du débit d’eau ....................... 14

Réglage de l’air de refroidissement ..................................................................................... 15

Nettoyage/Maintenance

Nettoyage ............................................................................................................................16

Maintenance ........................................................................................................................ 18

Service après-vente.............................................................................................................22

Caractéristiques

Schéma ...............................................................................................................................23

Poids/Dimensions ................................................................................................................ 24

Spécifications électriques .................................................................................................... 25

Identification du modèle/Tableau de conformité .................................................................. 26

Garantie