Page 1

Dental

Go To Table Of Contents

Place Order

To purchase a printed copy of this manual,

click on the "Place Order" button below.

Style B

Chair

Service and

Midmark UltraComfort

®

& UltraTrim® Dental Chair

Serial Number Prefixes:

NT, NZ & V

(UltraComfort shown)

Parts Manual

Dental

Chair

FOR USE BY MIDMARK

TRAINED TECHNICIANS ONLY

SF-1620 Part No. 004-0287-00 (7/14/15)

Page 2

Go To Table Of Contents

Page 3

TABLE OF CONTENTS

TABLE OF CONTENTS

Section/Paragraph................................................Page Section/Paragraph ............................................... Page

IMPORTANT INSTRUCTIONS

General Safety Instructions ..........................................iii

Safety Alert Symbols ....................................................iii

Warranty Instructions ................................................. iii

SECTION I GENERAL INFORMATION

1.1 Scope of Manual .......................................... 1-1

1.2 How to Use Manual ...................................... 1-1

1.3 Description Of Midmark Dental Chair........... 1-1

1.4 Standard Torque Specifications.................... 1-7

1.5 Specifications ............................................... 1-7

1.6 Parts Replacement Ordering........................ 1-9

1.7 Special Tools ................................................ 1-9

SECTION II TESTING AND TROUBLESHOOTING

2.1 Operational Test .......................................... 2-1

2.2 Testing Positioning Potentiometer ................ 2-4

2.3 Troubleshooting Procedures......................... 2-6

SECTION III SCHEDULED MAINTENANCE

3.1 Scheduled Maintenance ............................. 3-1

SECTION IV MAINTENANCE/SERVICE

INSTRUCTIONS

4.1 Introduction................................................... 4-1

4.2 Upholstery

Removal .................................................... 4-1

Installation ................................................. 4-1

4.3 Covers

Removal .................................................... 4-2

Installation ................................................. 4-2

4.4 Headrest

Adjustment ................................................ 4-3

4.5 Rotational Brake

Removal .................................................... 4-4

Installation ................................................. 4-4

4.6 Membrane Touchpad

Removal .................................................... 4-5

Installation ................................................. 4-5

4.7 Hydraulic Back Cylinder

Removal .................................................... 4-5

Installation ................................................. 4-6

4.8 Hydraulic Base Cylinder

Removal .................................................... 4-7

Installation ................................................. 4-9

4.9 Hydraulic Pump

Removal .................................................. 4-10

Installation ............................................... 4-12

4.10 Capacitor, Motor Pump

Removal .................................................. 4-12

Installation ............................................... 4-13

4.11 Hydraulic Reservoir

Removal.................................................. 4-13

Installation............................................... 4-14

4.12 Hydraulic Fluid Level

Checking / Adding................................... 4-14

4.13 Hydraulic Solenoid Valve Assembly

Removal.................................................. 4-15

Installation............................................... 4-18

Adjustments ............................................ 4-18

4.14 Printed Circuit (P.C.) Board

Removal.................................................. 4-19

Installation............................................... 4-19

4.15 Fuses (P.C. Board)

Replacement .......................................... 4-19

4.16 Base Potentiometer

Removal.................................................. 4-20

Installation............................................... 4-21

Adjustment.............................................. 4-21

4.17 Back Potentiometer

(SN NZ1000 - NZ1019)

(SN NT1000 - NT1598)

Removal.................................................. 4-22

Installation............................................... 4-23

Adjustment.............................................. 4-24

4.18 Back Potentiometer

(SN NZ1019 to Present)

(SN NT1599 to Present)

Removal.................................................. 4-25

Installation / Adjustment.......................... 4-26

4.19 Safety Bail Limit Switch

Removal.................................................. 4-26

Installation............................................... 4-26

4.20 Hydroglide Assembly

Removal.................................................. 4-27

Installation............................................... 4-28

4.21 Foot Switch Control

Removal.................................................. 4-28

Installation............................................... 4-28

4.22 Using Manual Override Function

Operation ................................................... 4-30

SECTION V SCHEMATICS / DIAGRAMS

5.1 Electrical / Hydraulic Diagrams

P.C. Board / Related Circuitry (115 VAC). 5-1

P.C. Board / Related Circuitry (230 VAC).. 5-4

SW1 Switch Settings ................................ 5-7

J1 thru J5 Pendants .................................. 5-8

J-Box Wiring Diagram ............................... 5-9

Console / Accessory Wiring Diagram ..... 5-10

Base Up Hydraulic Function ................... 5-11

Base Down Hydraulic Function............... 5-12

Back Up Hydraulic Function.................... 5-13

Back Down Hydraulic Function ............... 5-14

(*) Indicates that there has been a serial number break for the illustration

and that there are additional point page(s) following the original page.

© Midmark Corporation 2000 SF-1620 Page i Printed in U.S.A.

Rev. 10/12

Page 4

TABLE OF CONTENTS

Go To Table Of Contents

SECTION VI PARTS LIST

6.1 Introduction ................................................. 6-1

6.2 Description Of Columns ............................... 6-1

6.3 Torque Specifications And Important

Assembly Notes ........................................... 6-1

Pictorial Index (UltraComfort ®) .................. 6-2

Pictorial Index (UltraTrim) ............................ 6-3

Silhouette Upholstery (UltraComfort ®) ...... 6-4

Ultraleather Upholstery (UltraComfort ®).... 6-5

Silhouette Upholstery (UltraTrim)................. 6-6

Ultraleather Upholstery (UltraTri m) .............. 6-7

Double Articulating Headrest ......................6-8*

Magnetic Headrest ....................................... 6-9

Covers .......................................................6-10*

Base Components ..................................... 6-11

Seat Components ..................................... 6-12*

Brake Components .................................... 6-13

Back Components (UltraComfort ®) ......... 6-14

Back Components (UltraTrim) ................... 6-15

Hydraulic Components.............................. 6-16*

Hoses and Fittings ..................................... 6-17

Electrical Components..............................6-18*

Foot Control ............................................... 6-19

L/R and Console Components.................. 6-20*

Remote Mounted Chair Control ................ 6-21*

COMMENTS ............................................................. 7-1

FAX ORDER FORM.................................................. 7-2

(*) Indicates that there has been a serial number break for the illustration

and that there are additional point page(s) following the original page.

© Midmark Corporation 2000 SF-1620 Page ii Printed in U.S.A.

Rev. 10/12

Page 5

TABLE OF CONTENTS

Go To Table Of Contents

General Safety Instructions

Safety First: The primary concern of Midmark Corporation is that this chair is maintained with the safety

of the patient and staff in mind. To assure that services

and repairs are completed safely and correctly, proceed

as follows:

(1) Read this entire manual before performing any

services or repairs on this chair.

(2) Be sure you understand instructions contained

in this manual before attempting to service or

repair chair.

Safety Alert Symbols

Throughout this manual are safety alert symbols that

call attention to particular procedures. These items are

used as follows:

DANGER

A DANGER is used for an imminently

hazardous operating procedure, practice, or condition which, if not correctly followed,

will result in loss of life or serious personal

injury.

NOTE

A NOTE is used to amplify an operating procedure,

practice or condition.

Warranty Instructions

Refer to Midmark “Limited Warranty” printed in the

Installation and Operation Manual for warranty information. Failure to follow guidelines listed below will void

the warranty and/or render the Dental Chair unsafe for

operation.

• In event of a malfunction, do not attempt to use

dental chair until necessary repairs have been

made.

• Do not attempt to disassemble chair, replace malfunctioning or damaged components, or perform

adjustments unless you are one of Midmark’s

authorized service technicians.

• Do not substitute parts of another manufacturer

when replacing inoperative or damaged components. Use only Midmark replacement parts.

WARNING

A WARNING is used for a potentially

hazardous operating procedure, practice, or condition which, if not correctly followed,

could result in loss of life or serious personal

injury.

CAUTION

A CAUTION is used for a potentially haz-

ardous operating procedure, practice, or

condition which, if not correctly followed, could result

in minor or moderate injury. It may also be used to

alert against unsafe practices.

EQUIPMENT ALERT

An EQUIPMENT ALERT is used for an

imminently or potentially hazardous operating procedure, practice, or condition which, if not

correctly followed, will or could result in serious, moderate, or minor damage to unit.

© Midmark Corporation 2000 SF-1620 Page iii Printed in U.S.A.

Page 6

Go To Table Of Contents

Page 7

SECTION I

Go To Table Of Contents

GENERAL INFORMATION

SECTION I

GENERAL INFORMATION

1.1 Scope of Manual

This manual contains detailed troubleshooting, scheduled maintenance, maintenance, and service instructions for the Midmark Dental Chair. This manual is

intended to be used by Midmark’s authorized service

technicians.

1.2 How to Use Manual

A. Manual Use When Performing Scheduled Mainte-

nance.

(1) Perform inspections and services listed in

Scheduled Maintenance Chart (Refer to

para 3.1).

(2) If a component is discovered to be faulty or out

of adjustment, replace or adjust component in

accordance with maintenance / service instructions (Refer to para 4.1).

B. Manual Use When Unit Is Malfunctioning And

Cause Is Unknown.

(1) Perform an operational test on chair (Refer to

para 2.1).

(2) Perform troubleshooting procedures listed in

Troubleshooting Guide (Refer to para 2.2).

(3) If a component is discovered to be faulty or out

of adjustment, replace or adjust component in

accordance with maintenance / service instructions (Refer to para 4.1).

C. Manual Use When Damaged Component Is Known.

(1) Replace or adjust component in accordance

with maintenance / service instructions (Refer

to para 4.1).

1.3 Description Of Midmark Dental Chair

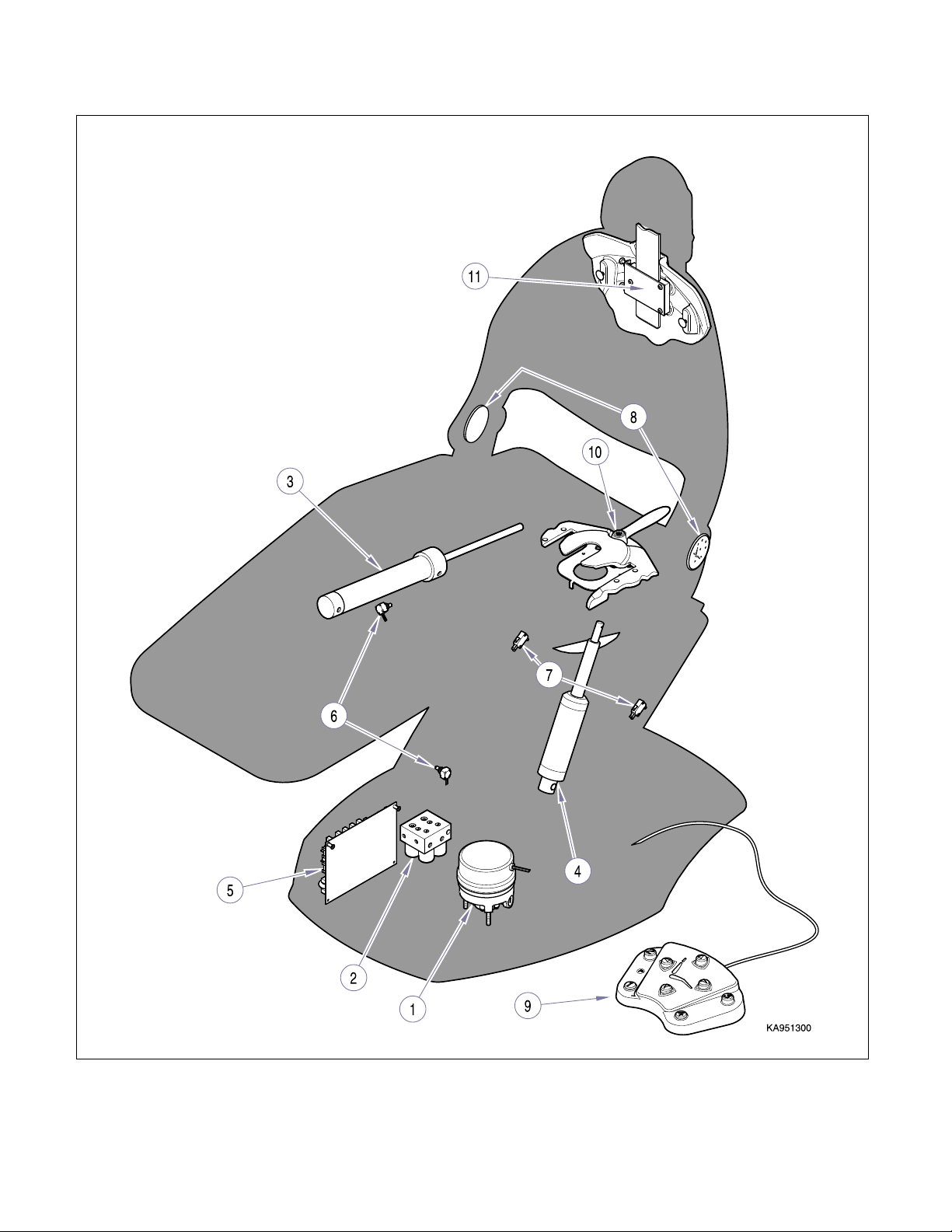

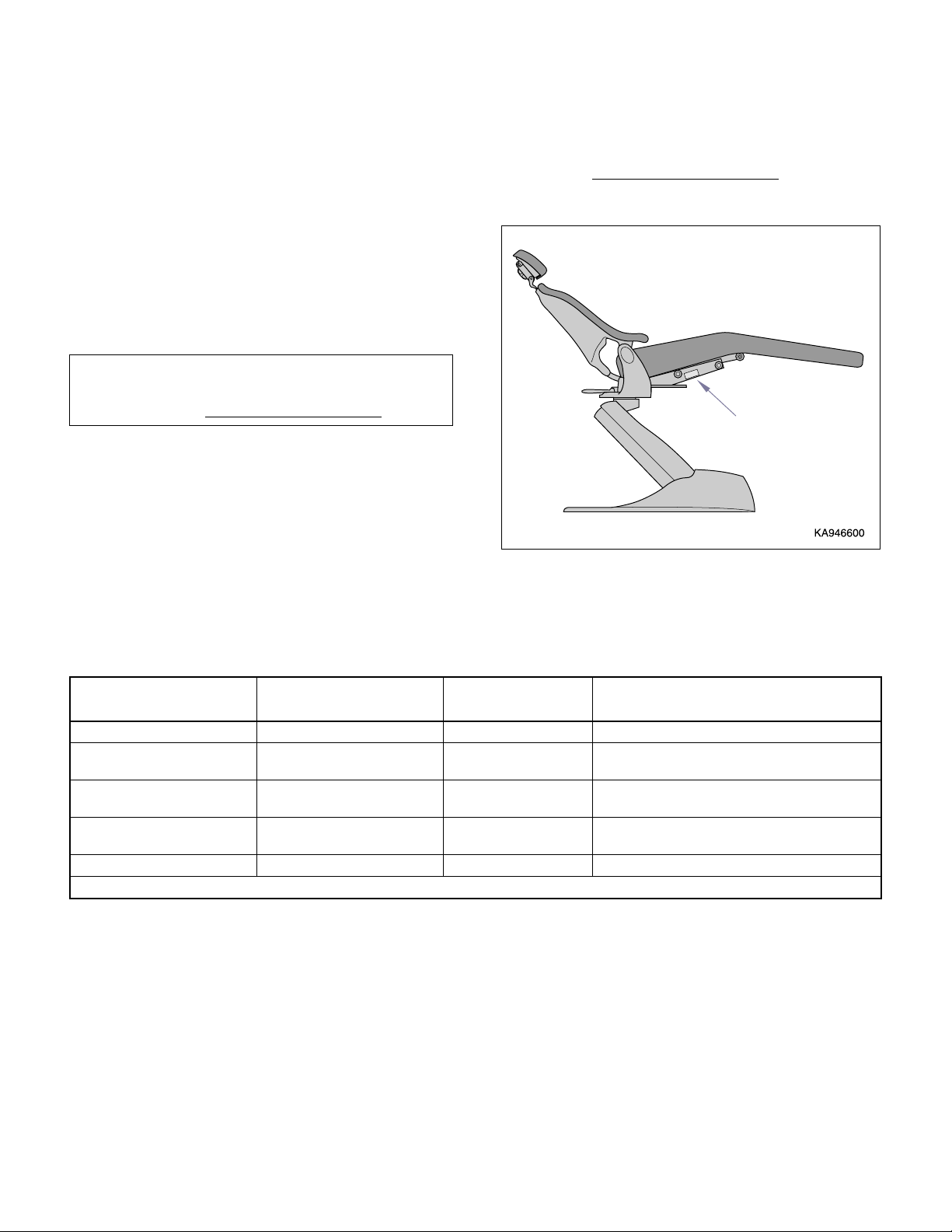

A. General Description (See Figure 1-1).

The Midmark Chair is a dental operating chair designed

for the general dentistry market. The chair is hydraulically positioned using a hydraulic pump, back, base cylinders and solenoid valve unit that are activated by

depressing either the desired membrane or foot switch.

B. Major Serviceable Components (See Figure 1-1).

Hydraulic Motor Pump (1, Figure 1-1)

Motor Pump provides hydraulic pressure to system and

works with the solenoid valves, check valves, and throttle valves to operate Back and Base cylinders.

A capacitor, mounted near the reservoir, provides start

and run power.

Motor is for intermittent

will cause motor to overheat, causing internal thermal

overload to open, removing power from motor. Normal

cool off period for thermal overload to reset is approximately 10 minutes.

Solenoid Valve Unit (2, Figure 1-1)

Solenoid Valve Unit consist of Back Up, Back Down,

Base Up, and Base Down Solenoid valves.

Four manually set Throttle Valves (TV1, TV2, TV3, and

TV4) control flow of hydraulic fluid during various functions.

Two Check Valves (CV1 and CV2) prevent fluid from

back flowing through Base Up and Back Up Solenoid

Val ves.

A Pressure Relief Valve protects the system should

higher then normal pressure occur during operation.

Back Hydraulic Cylinder (3, Figure 1-1)

Back Hydraulic Cylinder is a single-acting cylinder. During Back Up operation the Motor Pump is operating to

create hydraulic pressure required to raise the cylinder.

During Back Down function Motor is not

cylinder operates by pressure created by equipment

and patient weight to lower Back section.

Base Hydraulic Cylinder (4, Figure 1-1)

Base Hydraulic Cylinder is a single-acting cylinder. During Base Up operation the Motor Pump is operating to

create hydraulic pressure required to raise the cylinder.

During Base Down function Motor is not

cylinder operates by pressure due to equipment and

patient weight to lower Base section.

operation. Continuous operation

running and the

running and

© Midmark Corporation 2000 SF-1620 Page 1-1 Printed in U.S.A.

Page 8

SECTION I

Figure 1-1. Component Location

Go To Table Of Contents

GENERAL INFORMATION

© Midmark Corporation 2000 SF-1620 Page 1-2 Printed in U.S.A.

Page 9

SECTION I

Go To Table Of Contents

GENERAL INFORMATION

P.C. Board w/ Fuses (5, Figure 1-1)

Printed Circuit Board contains 115 VAC or 230 VAC line

voltage, 12 VDC, and 5 VDC plug connectors, 12 VDC

supply transformer for control circuitry, Pump, Base and

Back control relays, two 6.5 amp (115 VAC) or 3.15 amp

(230 VAC) line input fuses, one 100 mA fuse for 115

VAC Input to P.C. Board Transformer,

RV1 Surge Protector for over-voltage spikes, Program

switch (SW1), Calibration Button (SW2), and main

Microprocessor (U6).

Back and Base Positioning

Potentiometers (6, Figure 1-1)

Positioning Potentiometers provide P.C. board with

information, thru voltage change, on the positions of

Base and Back sections during operation.

P.C. board, during calibration mode, uses the potentiometers to determine where end of travel points are for

Base and Back. It stores this information and, while

monitoring voltage output of potentiometers, prevents

chair from reaching extreme ends of travel.

Output voltage from potentiometers allows P.C. board,

thru use of program and positioning buttons, to store

desired chair positions in P.C. board memory.

After a position has been programmed, depressing that

programmed button (1 thru 4) will automatically move

the chair to the position.

Safety Bail Limit Switches (7, Figure 1-1)

Two Safety Bail Limit Switches are normally closed

(N.C.) switches located on patient’s

parallel arms.

During chair’s descent, if bottom lift arm cover contacts

an obstruction, cover will depress switch actuator(s) of

Safety Bail Limit Switch(es). The normally closed contacts open, removing power from Base Down and Back

Down solenoid coils at plug connectors J17 (4 & 5) and

J18 (4 & 5) on PC board. Base Up and Back Up will

continue to work.

When the obstruction is removed, the switch(es) return

to the N.C. position. To continue a function, depressing

that function button allows chair to continue its operation.

right and left side

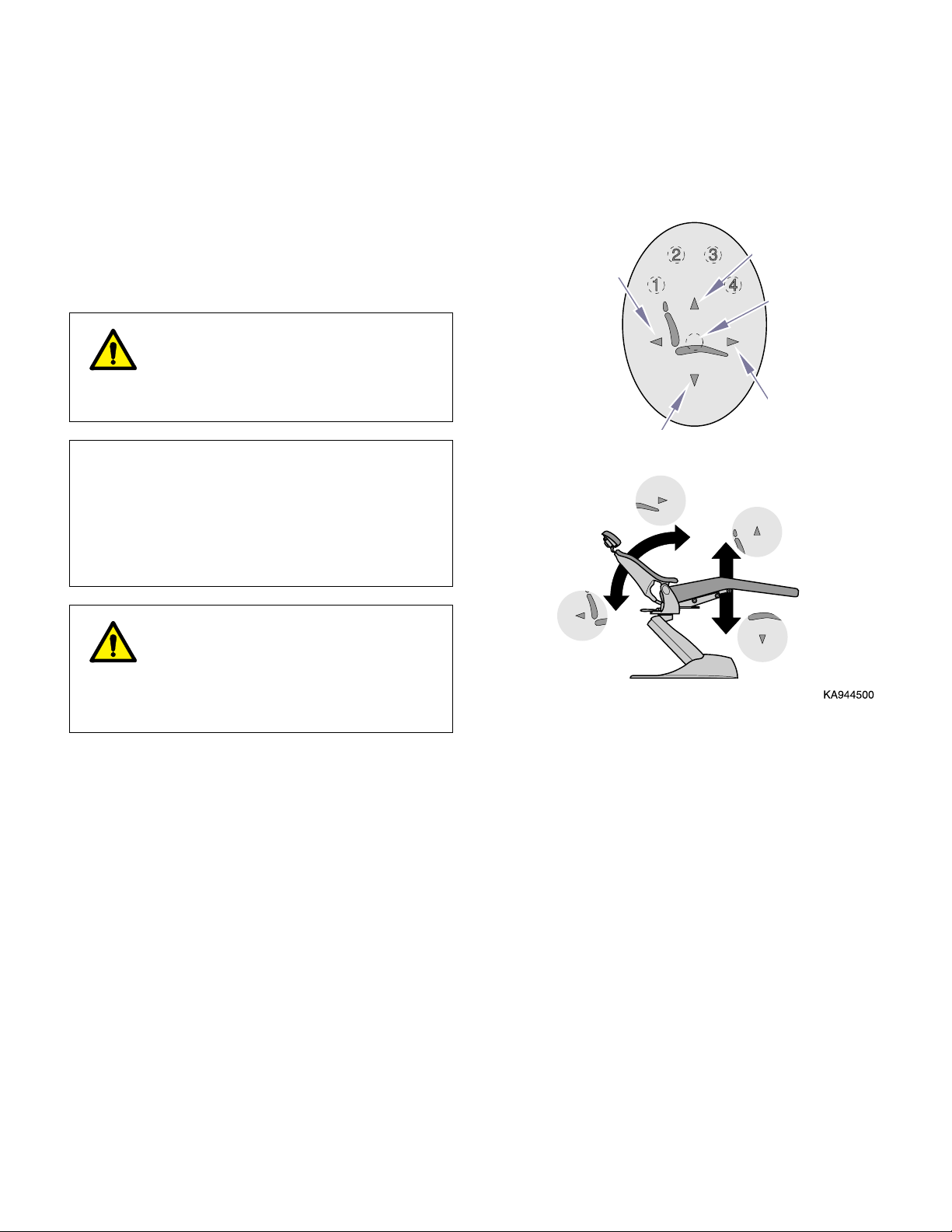

Membrane Touch Pads (8, Figure 1-1)

Membrane touch pads are located on both sides of the

chair or on consoles of the delivery systems. Operate

the chair by depressing one of four directional arrow

buttons that corresponds to back or seat graphic.

Depressing one of the four program buttons (1 thru 4)

allows for chair movement to a predetermined setting.

The functions can be stopped by momentarily depressing any switch on the touch pads or foot control.

A hidden switch, located in the center of the directional

arrows on the pad, is for setting programmed positions.

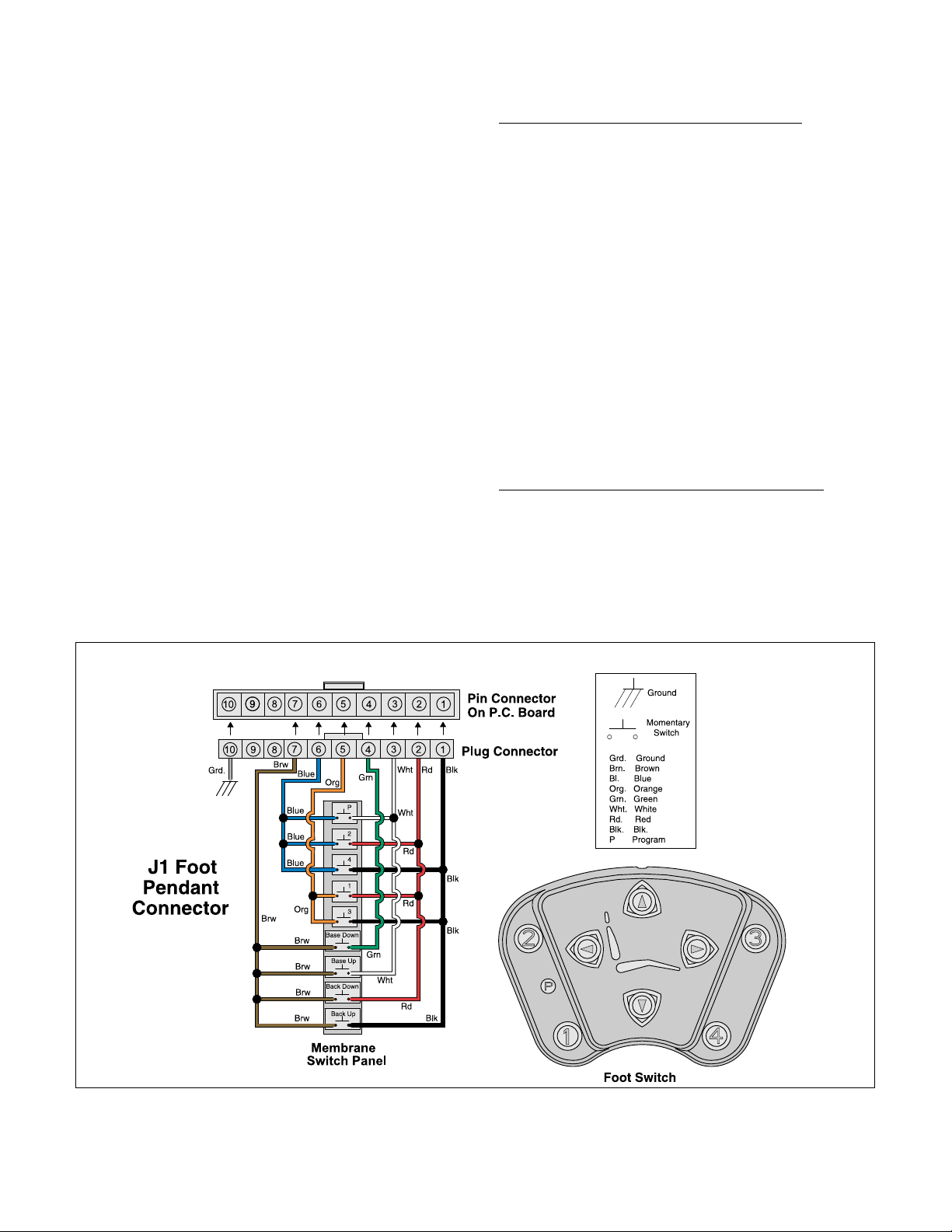

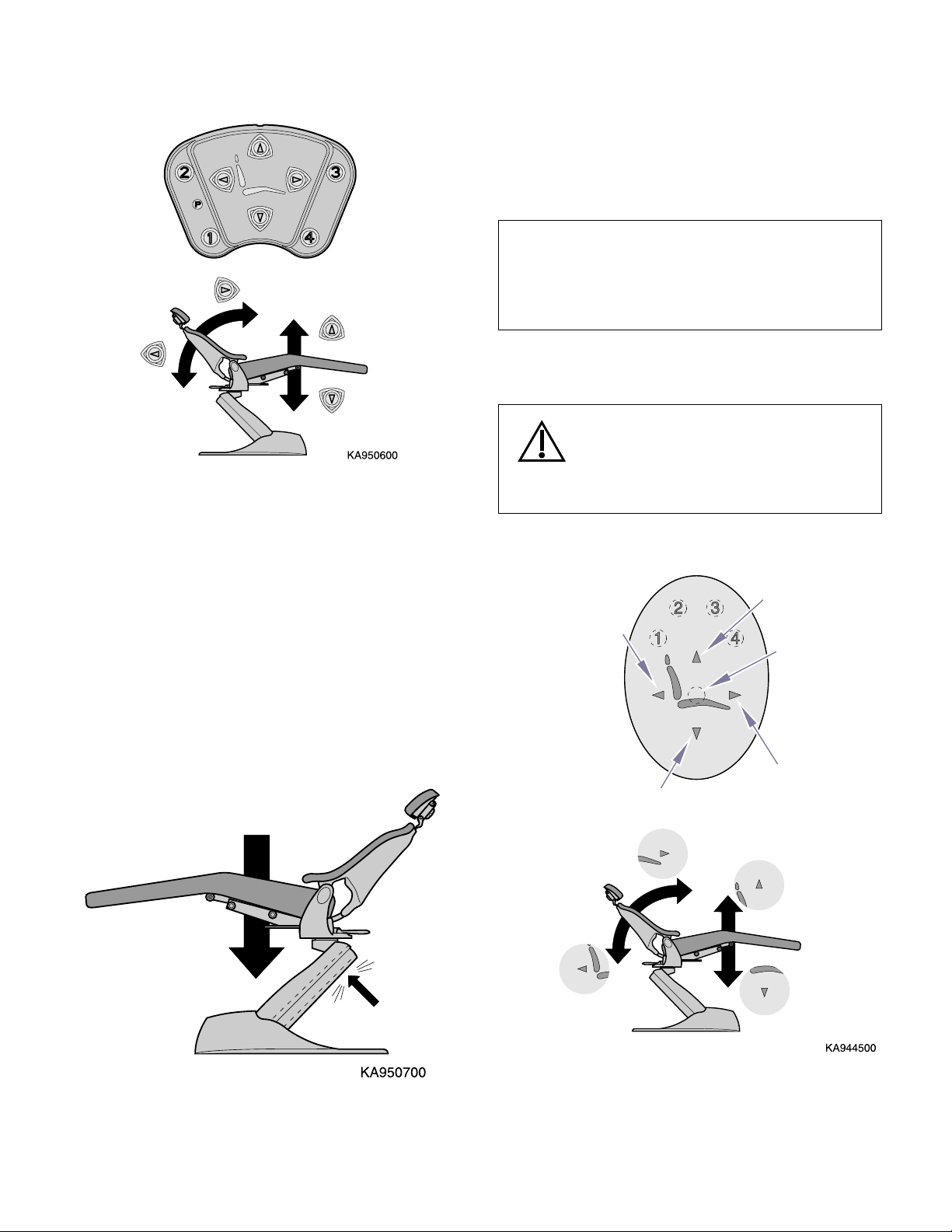

Foot Switch (9, Figure 1-1)

Foot Switch consist of four directional arrow buttons,

four numbered program position buttons and a button,

designated by the letter “P”, for programming.

Depressing one of the four directional arrow buttons

that corresponds to the back or seat graphic moves

chair in that direction.

Depressing one of the four program buttons (1 thru 4)

allows for chair movement to a predetermined setting.

Functions can be stopped by momentarily depressing

any switch on the touch pads or foot control.

The button, with the letter “P”, is for setting programmed

positions.

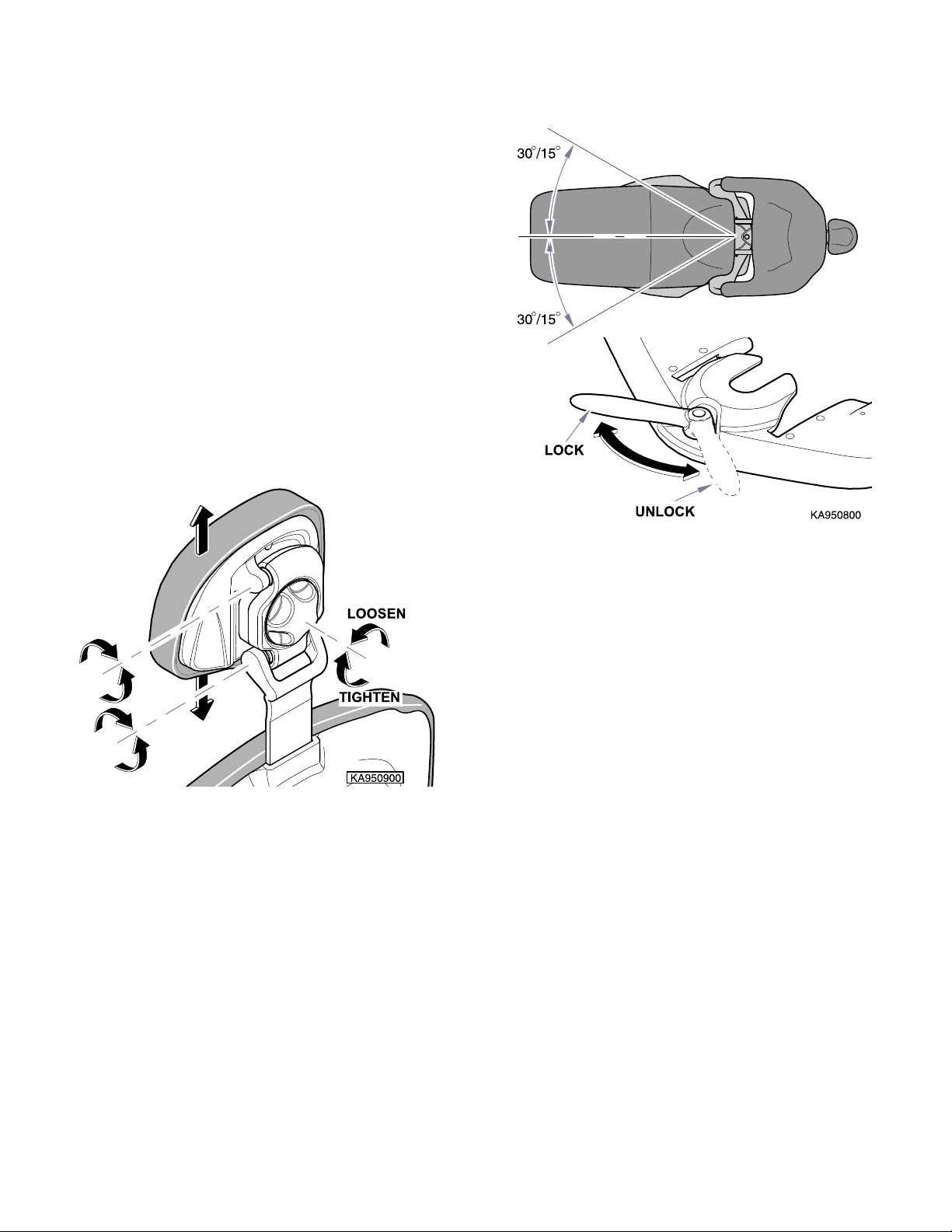

Rotational Seat Lock (10, Figure 1-1)

The chair seat will rotate 30° each way from center-line

for a stand-alone and console chair. For a L / R chair it

will rotate 15°. To release the rotational lock, rotate the

handle toward the patient’s right side.

To engage the rotational lock, rotate the handle toward

the patient’s left side.

Headrest Locking Assembly (11, Figure 1-1)

Headrest height can be changed by pulling out or pushing in on headrest. Tension of headrest locking assembly is pre-set at factory but can be adjusted if required.

© Midmark Corporation 2000 SF-1620 Page 1-3 Printed in U.S.A.

Page 10

SECTION I

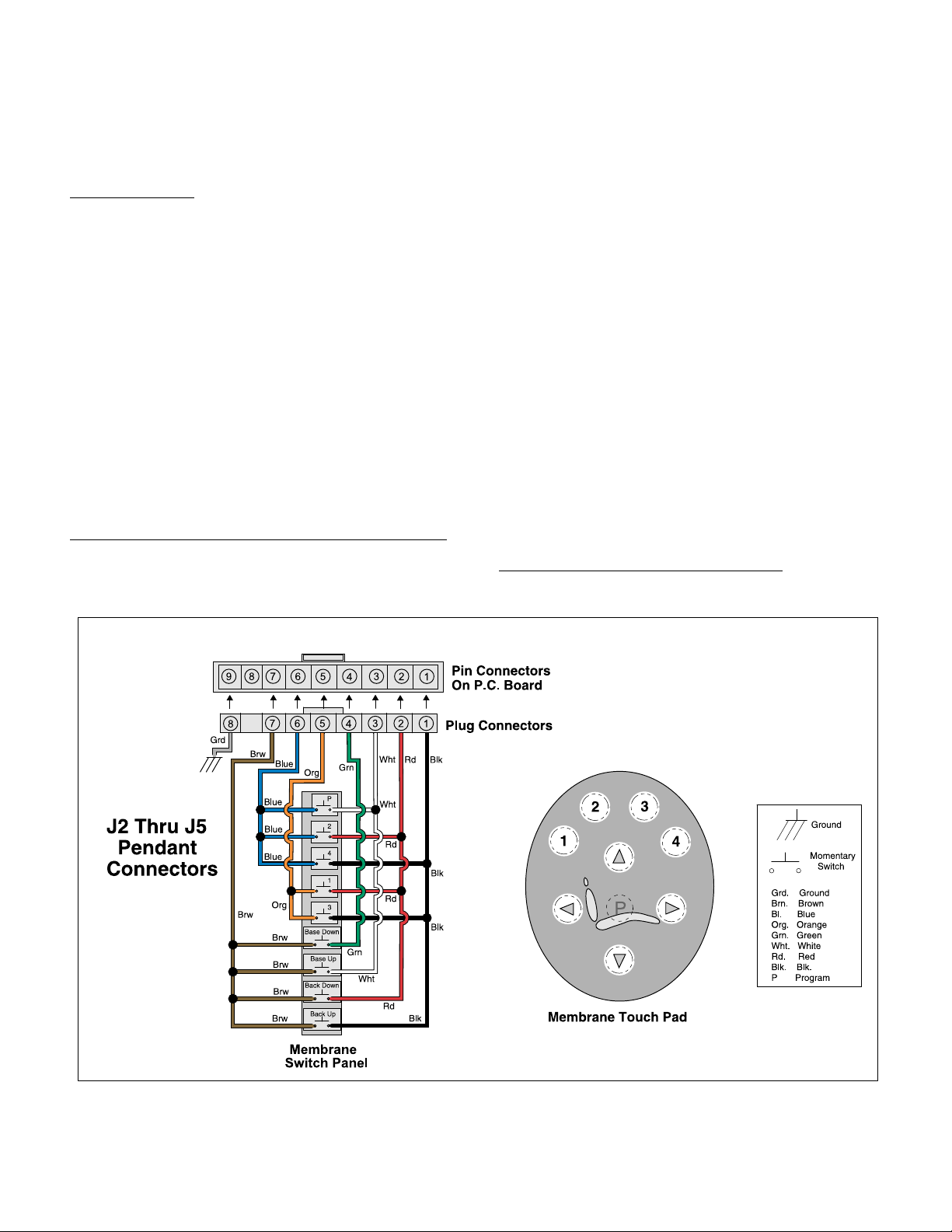

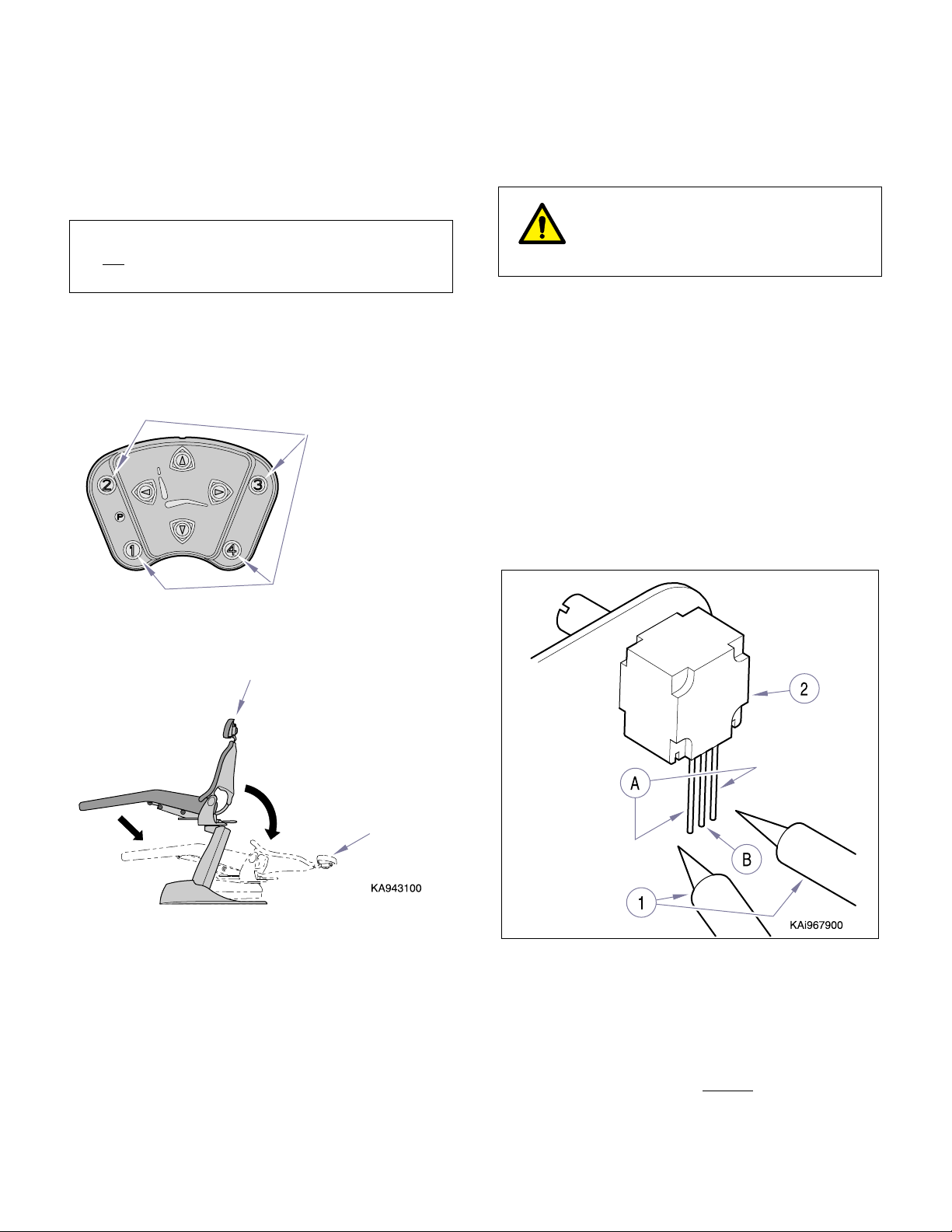

RH Touch Pad Shown.

Figure 1-2. Membrane Touch Pads.

Go To Table Of Contents

GENERAL INFORMATION

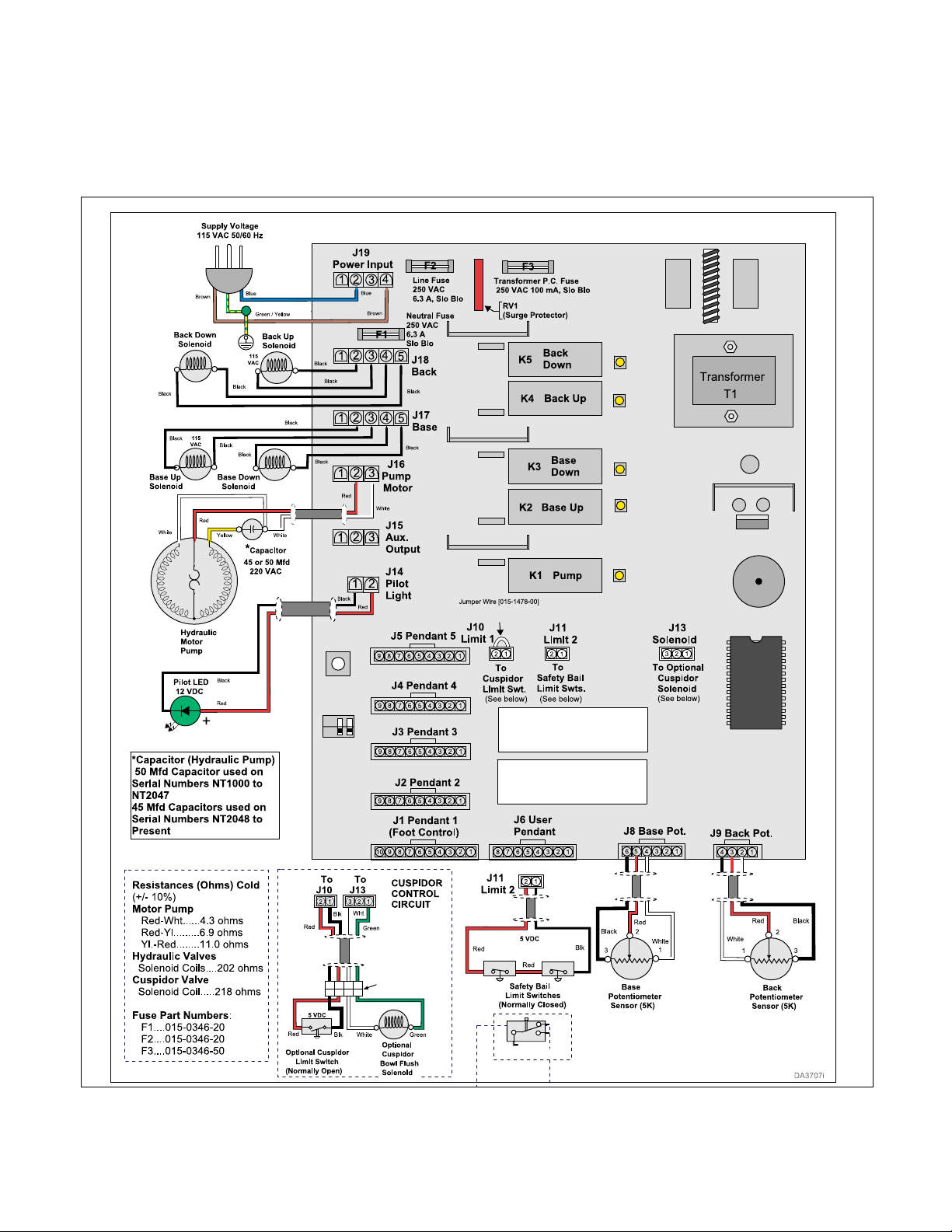

C. Theory of Operation (Refer to Figure 1-4 and

Section V for wiring diagram, electrical schematics and hydraulic layouts).

Electrical Power:

Line voltage is supplied to chair’s Main PC Board thru

power cord.

F1, F2, and F3 replaceable fuses, protect P.C. Board

from excessive current draw.

RV1 Surge Suppressor, protects P.C. board from voltage spikes by partially blocking electrical flow until supply voltage returns to a normal value.

A transformer along with voltage regulators on PC circuit board reduces line voltage to 12 and 5 VDC. This

provides power to operate the circuitry on PC circuit

board, limit switches, membrane switch panel, and foot

control.

Relays K1 thru K5 on P.C. board are for line voltage

operation of Solenoid Valves and Motor Pump.

LED’s, next to the specific relay, lights when that relay is

operated.

Operation of Membrane Switch Panels (Figure 1-2):

PC circuit board supplies 5 VDC to one side of each

normally open (N.O.) switches in membrane switch

panel. Pressing a membrane switch, closes contacts,

completing a circuit, allowing a signal to return to PC

circuit board, activating the function selected.

Functions available are Back Up and Down, Base Up

and Down, Programmed settings, 1 thru 4, and a Programming button “P”.

Program Function (Figure 1-2):

Using the Directional buttons, place chair in a desired

position. Press Program (P) button, unmarked button in

middle of Directional buttons. There is a short audible

beep after which you have three (3) seconds to depress

the desired Program Position button (1,2, 3, or 4). When

the Position button is depressed, three audible beeps

are sounded indicating the position has been stored.

Pressing the Position button will bring the chair to the

position that was programmed.

Manual Override Function (Figure 1-2):

Pressing and holding the Program (P) button while

pressing a Directional button by-passes the feedback

coming from the back and base potentiometers. This

allows for operation of the chair should a potentiometer

malfunction. This should only be used should a patient

be on the chair to allow for safe exit. Service should be

called to repair malfunction.

Operation of Foot Control (Figure 1-3):

PC circuit board supplies 5 VDC to one side of each of

© Midmark Corporation 2000 SF-1620 Page 1-4 Printed in U.S.A.

Page 11

SECTION I

Figure 1-3. Foot Control

Go To Table Of Contents

GENERAL INFORMATION

the normally open (N.O.) switches in foot switch. Pressing one of the switches, closes the contacts, completing

a circuit, allowing a signal to return to PC circuit board,

activating the function selected.

Functions available are Back Up and Down, Base Up

and Down, Programmed settings 1 thru 4, and a Programming button “P”. Should a malfunction occur the

Manual Override function can be used.

Program Function (Figure 1-3):

Using the Directional buttons, place chair in a desired

position. Press Program (P) button. There is a short

audible beep after which you have three (3) seconds to

depress the desired Program Position button (1,2, 3, or

4). When a Position button is depressed, three audible

beeps are sounded indicating the position has been

stored.

Pressing the Position button will bring the chair to the

position that was programmed.

Manual Override Function (Figure 1-3):

Pressing and holding the Program (P) button while

pressing a Directional button by-passes the feedback

coming from the back and base potentiometers. This

allows for operation of the chair should a potentiometer

malfunction. This should only be used should a patient

be on the chair to allow for safe exit. Service should be

called to repair malfunction.

Back Up Function Operation (Figure 1-4):

Depressing and holding one of the Back Up directional

button completes a circuit to the PC board.

On the PC board, K4 contacts close supplying line voltage to connector J18, pins 2 and 3, to the Back Up solenoid coil, energizing the coil, opening the hydraulic

valve.

At the same time, K1 contacts close supplying line voltage to connector J16, pins 2 and 3, to the hydraulic

motor pump, energizing the pump.

During the Back Up function, the Back Potentiometer,

connected to J9 connector, signals movement of the

Back section.

During normal operation, when the potentiometer

reaches the calibrated position, just before the extreme

end of travel, the signal it sends back to the PC board

tells the board to open K1 and K4 contacts removing

power from the Back Up solenoid valve and hydraulic

pump motor.

Back Down Function Operation (Figure 1-4):

Depressing and holding one of the Back Down directional button completes a circuit to the PC board.

On the PC board, K5 contacts close supplying line voltage to connector J18, pins 4 and 5, to the Back Up solenoid coil, energizing the coil, opening the hydraulic

valve.

© Midmark Corporation 2000 SF-1620 Page 1-5 Printed in U.S.A.

Page 12

SECTION I

LED

LED

LED

LED

LED

LS1

SW1

(Prog.)

Main P.C.

Board

SW2

(Calib.)

U6

ON

OFF

Dental Chair

115 VAC

NC

C

NC

C

Limit Switch Layout

C

NO

NC

1122443

3

NO

C

For Pendant (J1 thru J6)

Connectors Refer to

Pendant P.C. Schematics

NOTE:

For Harness Part Numbers

Refer to Section 5.

(Remove when

installing cuspidor)

Figure 1-4. Main P.C. Board and Related Components

Go To Table Of Contents

GENERAL INFORMATION

During the Back Down function, the Back Potentiometer, connected to J9 connector, signals movement of the

Back section. During normal operation, when the potentiometer reaches the calibrated position, just before the

extreme end of travel, the signal it sends back to the PC

board tells the board to open K5 contacts and remove

power to the Back Down solenoid valve.

© Midmark Corporation 2000 SF-1620 Page 1-6 Printed in U.S.A.

Rev. 1/14

Page 13

SECTION I

Go To Table Of Contents

GENERAL INFORMATION

Base Up Function Operation (Figure 1-4):

Depressing and holding one of the Base Up directional

button completes a circuit to the PC board.

On the PC board, K2 contacts close supplying line voltage to connector J17, pins 2 and 3, to the Base Up

solenoid coil, energizing the coil, opening the hydraulic

valve.

At the same time, K1 contacts close supplying line voltage to connector J16, pins 2 and 3, to the hydraulic

motor pump, energizing the pump.

During the Base Up function, the Base Potentiometer,

connected to J8 connector, signals movement of the

Base section. During normal operation, when the potentiometer reaches the calibrated position, just before the

extreme end of travel, the signal it sends back to the PC

board tells the board to open K1 and K2 removing

power to Base Up solenoid valve and hydraulic pump

motor.

Base Down Function Operation (Figure 1-4):

Depressing and holding one of the Base Down directional button completes a circuit to the PC board.

On the PC board, K3 contacts close supplying line voltage to connector J17, pins 4 and 5, to the Base Down

solenoid coil, energizing the coil, opening the valve.

During the Base Down function, the Base Potentiometer, connected to J8 connector, signals movement of the

Base section. During normal operation, when the potentiometer reaches the calibrated position, just before the

extreme end of travel, the signal it sends back to the PC

board tells the board to open K3 contacts and remove

power to the Base Down solenoid valve.

Safety Bail Limit Switches (Figure 1-4):

During Base or Back Down operations, as chair is

descending, should bottom lift arm cover contact an

obstruction, one or both normally closed (N.C.) Safety

Bail Limit Switches, located beneath cover, will open.

Power is removed from Base and Back solenoid valves,

closing the valves, stopping descent of both base and

back. Base Up and Back Up functions will continue to

work.

Removing the obstacle, returns switch contacts to

closed position.

Press the desired directional or program button to

resume operation.

1.4 Standard Torque Specifications

The following standard torque specifications in

Table 1-1 apply to the hardware used on the unit unless

otherwise listed elsewhere in the service procedures or

parts illustrations.

Table 1-1. Torque Specifications

Hardware Size* Torque Values

#6 .............................. 11 to 21 inch-lbs. (1.2 to 2.3 N•M)

#8 .............................. 20 to 30 inch-lbs. (2.2 to 3.3 N•M)

#10 ............................ 32 to 42 inch-lbs. (3.6 to 4.8 N•M)

1/4 inch ..................... 75 to 85 inch-lbs. (8.5 to 9.6 N•M)

5/16 inch ...................18 to 22 ft.-lbs. (24.4 to 29.8 N•M)

3/8 inch .....................31 to 35 ft.-lbs. (42.0 to 47.5 N•M)

1/2 inch .....................50 to 60 ft.-lbs. (67.8 to 81.4 N•M)

* All hardware should be grade 5 or above.

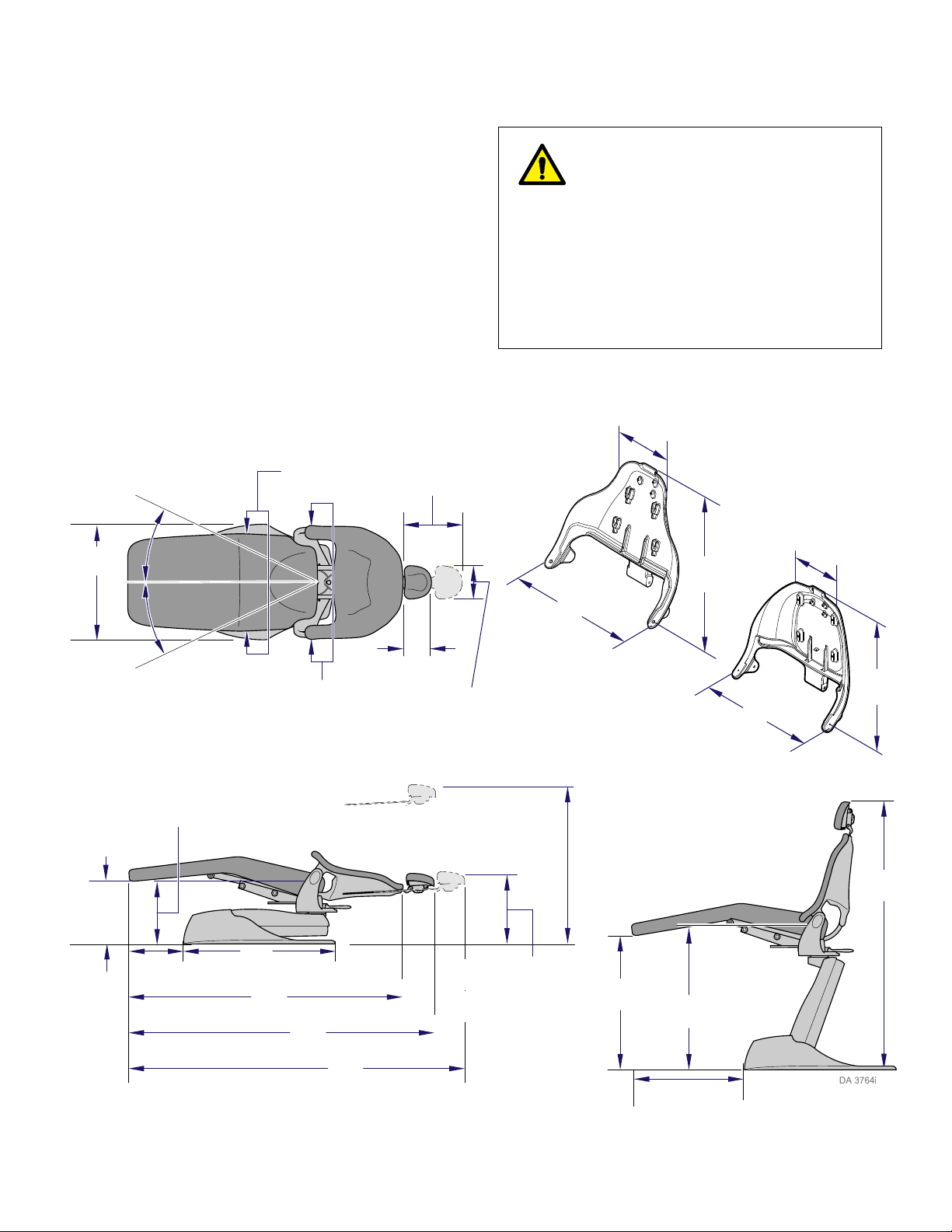

1.5 Specifications

Factual data for the Midmark Dental Chair is provided in

Table 1-2. Also, see Figure 1-5.

Table 1-2. Specifications

Description Data

Maximum Patient Weight.......................300 lbs (136 kg)

Weight of a Unit:

Without Shipping Carton

Chair Only ......................................290 lbs (132 kg)

Chair (L / R or Console) 310 lbs (141 kg)

With Shipping Carton

Chair Only ......................................350 lbs (159 kg)

Chair (L / R or Console)l.................370 lbs (168 kg)

Hydraulic Fluid Requirements

System Capacity ........................... 1 Quart (950 ml)

Type of Hydraulic Fluid ........................... ISO VG 32

Electrical Requirements:..................... 115 VAC +/-10%,

5A, 60 HZ,

single phase

or

230 VAC +/-10%,

2.5A, 50/60 HZ,

single phase

Fuse Rating*:

F1 Line Fuse, 115 VAC ................. T6.3 AL, 250 VAC

5 x 20mm, Type Slo-Blo

or

© Midmark Corporation 2000 SF-1620 Page 1-7 Printed in U.S.A.

Rev. 10/12

Page 14

SECTION I

29" max.

(73.7 cm)

27.5" max.

(69.9 cm)

58" max.

(147.3 cm)

22"

(55.9 cm)

25.8"

(65.6 cm)

11.2"

(28.4 cm)

20.7"

(52.5 cm)

25.9"

(65.8 cm)

10.3"

(26.1 cm)

20.5"

(52.7 cm)

8"

(20.3 cm)

20"

(50.8 cm)

8.75"

(22.2 cm)

27"

(68.6 cm)

27 .5"

(69.8 cm)

23"

(58.4 cm)

15o LR and Console

30

o

Chair Only

33" max. (83.8 cm)

w/ Back Level

30" max. (76.0 cm)

w/ Back Full Down

36"

(91.4 cm)

16.0" min.

(40.6 cm)

67"

(170.2 cm)

75"

(190.5 cm)

87"

(221.0 cm)

19.0" min. (48.2 cm)

w/ Back Level

16.25" min. (41.3 cm)

w/ Back Full Down

15"

(38.1 cm)

16.5"

(41.9 cm)

Ultra-Trim

Back

Ultra-Comfort

Back

Figure 1-5. Specifications

Go To Table Of Contents

GENERAL INFORMATION

F1 Line Fuse, 230 VAC.................T3.15 AL, 250 VAC

5 x 20mm, Type Slo-Blo

F2 Line Fuse, 115 VAC ..................T6.3 AL, 250 VAC

5 x 20mm, Type Slo- Blo

or

F2 Line Fuse, 230 VAC.................T3.15 AL, 250 VAC

5 x 20mm, Type Slo-Blo

F3 Transformer Fuse

115 VAC / 230 VAC ... T0.10 AL / T0.05 AL, 250 VAC

5 x 20mm, Type Slo-Blo

(*Fuses are located on P.C. Board.)

Duty Cycle ................................... Intermittent Operation

(30 seconds on / 5 minutes off,

motor run time)

WARNING

Should it be necessary to transport the

chair, its position is critical to ensure

safety. Before attempting to move / transport

chair, it must be lowered to its minimum height

and locked in place at 0° rotation (install shipping

bolt - refer to step 7 on page A-1 of the Installation Guide, Module A). NOTE: Midmark strongly

recommends disassembling any accessory arms

(unit, light, etc.) from chair before attempting to

move / transport an entire operatory.

© Midmark Corporation 2000 SF-1620 Page 1-8 Printed in U.S.A.

Rev. 11/8/12

Page 15

SECTION I

Figure 1-6. Model Number / Serial Number Location

Model / Serial

Number

Go To Table Of Contents

GENERAL INFORMATION

1.6 Parts Replacement Ordering

If replacement part(s) are required, order part(s) directly

from factory as follows:

(1) Refer to Figure 1-6 to determine location

of model number and serial number of chair

and record this data.

Refer to Parts List to determine item numbers

of parts, part numbers, descriptions, and quantities needed and record this data (Refer to

para 6.1).

NOTE

To assure expedient service and correct parts you

must have correct Model and Serial Number

of chair.

(2) Determine installation date of chair and record

this data. Call Midmark (1-800 643-6275) and

ask for Technical Service Department. Please

have Model and Serial Number

of chair.

Table 1-3. Special Tool List

Description of Special Tool

Multimeter * Commercially Available Any Type Used to perform continuity and voltage checks.

Scissor Jack (capable of lifting a

minimum of 1000 lbs. [454 kg])

Jack Stands (Qty. 2) (capable of

supporting 1000 lbs. [454 kg])

Jumper wire with insulated clips Made up by technician N/A For jumpering various test points during trouble-

Torque Wrench * Commercially Available Any Type Used to tighten nuts or screws to specified values.

Manufacturer’s

Name / Address / Phone

Commercially Available Any Type Used to elevate Back section when hydraulic Base

Commercially Available Any Type Used to support chair top when hydraulic base cyl-

* Tool should be calibrated annually to ensure proper specifications are met.

Manufacturer’s

Part Number

Purpose of Special Tool

cylinder or motor pump is malfunctioning.

inder or motor pump is being worked on.

shooting.

© Midmark Corporation 2000 SF-1620 Page 1-9 Printed in U.S.A.

Rev. 4/01

Page 16

SECTION I

Go To Table Of Contents

GENERAL INFORMATION

© Midmark Corporation 2000 SF-1620 Page 1-10 Printed in U.S.A.

Page 17

BACK

DOWN

PROGRAM

BUTTON

SEAT

UP

SEAT

DOWN

BACK

UP

RH Touch Pad Shown.

Figure 2-1. Operational Test

SECTION II

Go To Table Of Contents

TESTING AND TROUBLESHOOTING

2.1 Operational Test

In order to effectively diagnose a malfunction of chair, it

may be necessary to perform an operational test as fol-

lows:

WARNING

Refer to the Operator’s Manual for com-

plete instructions on operating the

chair. Failure to do so could result in personal

injury.

NOTE

The Operational Test, for the most part, only

describes what should happen when chair is operated. If the chair does something other than

described, a problem has been discovered. Refer to

Troubleshooting Guide to determine cause of problem and its correction.

SECTION II

TESTING AND TROUBLESHOOTING

WARNING

When performing various checks with

chair plugged in and covers off use

extreme care to prevent accidental electrical

shock. Failure to comply could cause severe

injury.

(1) Plug chair power cord into a grounded, non-iso-

lated, correctly polarized outlet, that has proper

voltage for chair.

(2) Depress Back Up, Back Down, Base Up, and

Base Down buttons on membrane switch panel

(Refer to Figure 2-1).

Observe. Chair should move in direction corresponding to button being depressed. Hydraulic

motor pump and cylinders should run quietly.

Movement should be smooth and match speed

and range of motions listed below:

Chair Speeds (±1 second w/ 180 lbs [82 kg]

load on chair)

Back Up to Back Down...................15 seconds

Back Down to Back Up...................15 seconds

Base Up to Base Down ..................15 seconds

Base Down to Base Up ..................15 seconds

See Figure 1-5 for max. and min. heights.

(3) Place a 300 lbs (136 kgs) weight on center of

seat section of chair.

Observe. Seat section should not drift downward under weight.

(4) Depress Base Up and Base Down buttons on

membrane switch panel.

Observe. Chair base should lift weight steadily

and without excessive noise.

(5) Remove weights from chair. Then, place a 100

lbs (45.4 kgs) weight on center of back section

of chair (with back section at approximately 45º

above horizontal).

© Midmark Corporation 2000 SF-1620 Page 2-1 Printed in U.S.A.

Rev. 8/01

Page 18

SECTION II

Figure 2-2. Headrest

Figure 2-3. Rotational Lock

Go To Table Of Contents

TESTING AND TROUBLESHOOTING

(6) Depress Back Up and Back Down buttons on

membrane switch panel.

Observe. Back should lift weight steadily and

without excessive noise.

(7) Remove weights from chair.

(8) Run Back Up function all the way up and Base

Down function all the way down.

(9) Slide headrest in and out stopping at different

positions. Push gently against headrest at

each position (Refer to Figure 2-2).

Observe. Headrest should not require excessive force to position. When in a position, headrest should not move when a slight pressure is

applied.

(10) If chair has Articulating Headrest, loosen knob,

move headrest to different positions.

Observe. Headrest should move smoothly

without requiring excessive force.

(11) Tighten knob.

Observe. Headrest should remain in position

when force is applied.

Observe. Chair top should rotate smoothly

and easily; not requiring excessive force. The

chair top should be able to be rotated from stop

to stop which is 60°

or 30° in each direction

from centerline of chair. L / R and console

chairs will rotate 30° and 15°.

(13) Tighten Rotation Lock lever to locked position.

Attempt to rotate chair top.

Observe. Chair top should not be able to be

rotated when Rotation Lock lever is engaged.

(14) Depress Back Up, Back Down, Base Up, Base

Down buttons on foot control (Refer to

Figure 2-4).

Observe. When each of the buttons on foot

control are depressed, appropriate function

should activate.

(12) Loosen Rotation Lock lever and rotate chair top

until it hits a stop. Then rotate chair top in

opposite direction until it hits a stop. (Refer to

Fig. 2-3).

© Midmark Corporation 2000 SF-1620 Page 2-2 Printed in U.S.A.

Rev. 10/12

Page 19

(15) Depress Base Down membrane or foot switch.

Figure 2-4. Foot Control

Figure 2-5. Safety Bail Limit Switches.

PROGRAM

BUTTON

BACK

DOWN

SEAT

UP

BACK

UP

SEAT

DOWN

RH Touch Pad Shown.

Figure 2-6. Manual Override

Go To Table Of Contents

As chair descends, push upward on bottom lift

arm cover until one or both of the Safety Bail

Limit switches operate (Refer to Figure 2-5).

SECTION II

TESTING AND TROUBLESHOOTING

(16) Check Manual Override using touchpad mem-

brane switch or foot control. Depress and hold

Program (P) button and then depress desired

Manual positioning button(s) (Refer to

Figure 2-6 ).

NOTE

The Program button on Membrane Touchpads is

located directly above Seat graphic. On Foot Control

it is located on left side and designated with the letter

“P”.

Observe. Chair should move to desired position as long as buttons are being depressed.

CAUTION

This procedure should be used by the

operator only in case of a chair malfunction

should a patient be on chair. This permits positioning

the chair to allow a patient to safely exit chair.

Observe. When bottom lift arm cover contacts

and operates Safety Bail Limit switch(es) chair

should immediately stop its descent.

Releasing bottom lift arm cover, returns Safety

Bail Limit switch(es) to normally closed position.

Operating Base Down membrane or foot switch

will cause chair to descend again.

© Midmark Corporation 2000 SF-1620 Page 2-3 Printed in U.S.A.

Rev. 8/01

Page 20

SECTION II

PROGRAM

POSITION

RECALL

BUTTONS

(EXAMPLE)

CURRENT CHAIR

POSITION

TO GO TO FAVORITE

PROGRAMMED POSI-

TION #1, DEPRESS

BUTTON “1”

Figure 2-7. Programmed Positions

Figure 2-8. Testing Potentiometer.

Go To Table Of Contents

TESTING AND TROUBLESHOOTING

(17) Check Programmed Positions using touchpads

or foot control. Depress one of the Programmed

recall buttons. The chair should advance to the

position programmed by the user (Refer to

Figure 2-7).

NOTE

Do not attempt to change a programmed position

unless requested by personnel at the Dental office.

(18) Press a Programmed Position again, while

chair is moving to position, press any button on

touchpad or foot control. Chair should stop all

movement.

2.2 Testing Positioning Potentionmeter

A. Check Continuity (Ohms)

WARNING

Unplug chair power cord before remov-

ing covers or working on chair. Failure

to comply could result in personal injury.

(1) Disconnect power to chair and remove uphol-

stery or covers whichever is applicable to

access potentiometer (refer to para 4.16

or 4.17).

(2) Set VOM on resistance (ohms) for a scale that

can read up to 6K ohms.

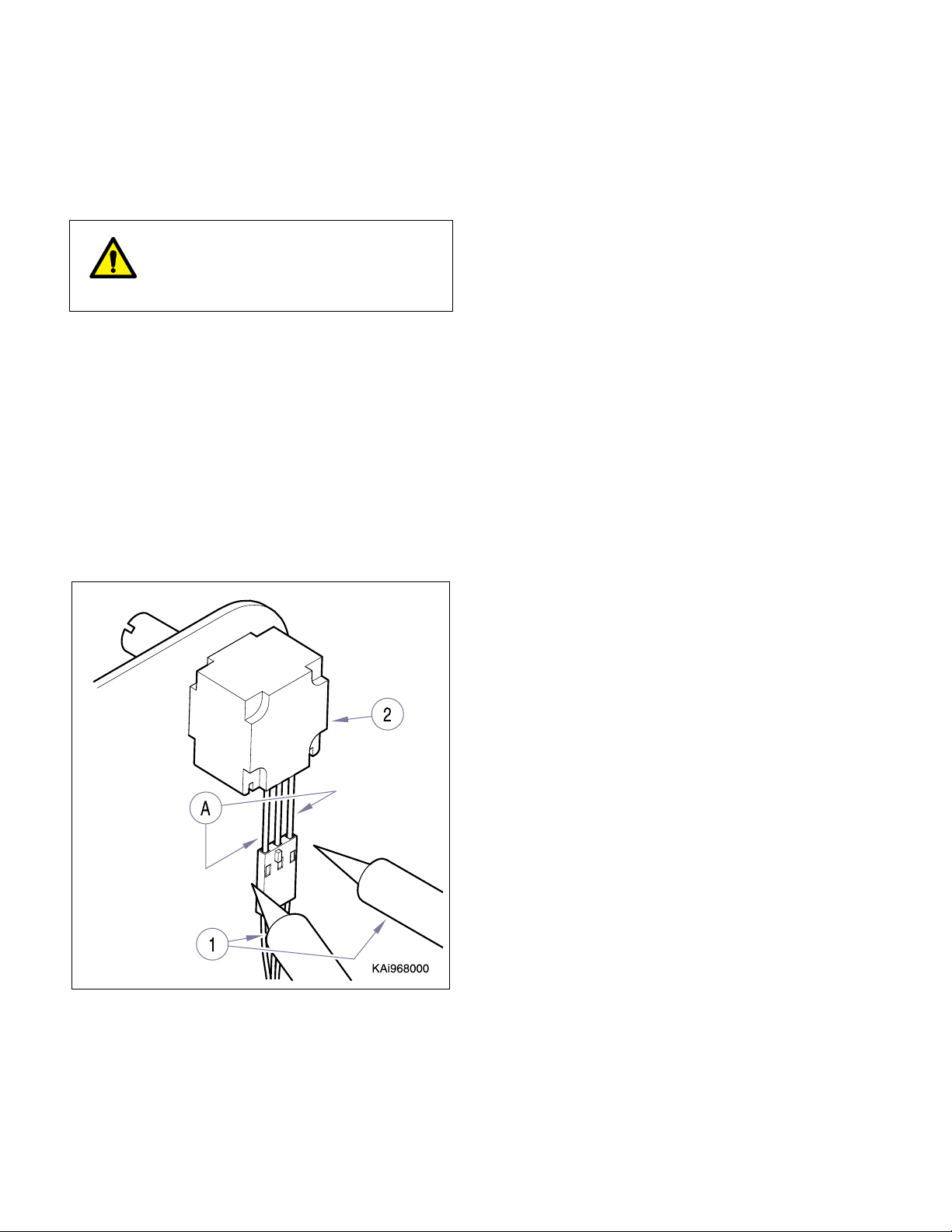

(3) After removing plug connector, place meter

probes (1, Fig. 2-8) on outside leads (A) of

potentiometer (2) for total resistance. Reading

should be 4K to 6K (ohms). Any reading outside this or if no continuity reading is present,

replace potentiometer.

© Midmark Corporation 2000 SF-1620 Page 2-4 Printed in U.S.A.

(4) Move one meter probe to middle lead (B) on

potentiometer.

(5) Slowly rotate potentiometer shaft fully one

direction and then back the other.

Meter should show a smooth

decrease in resistance. If reading becomes

erratic replace potentiometer (refer to para 4.16

or 4.17).

increase or

Page 21

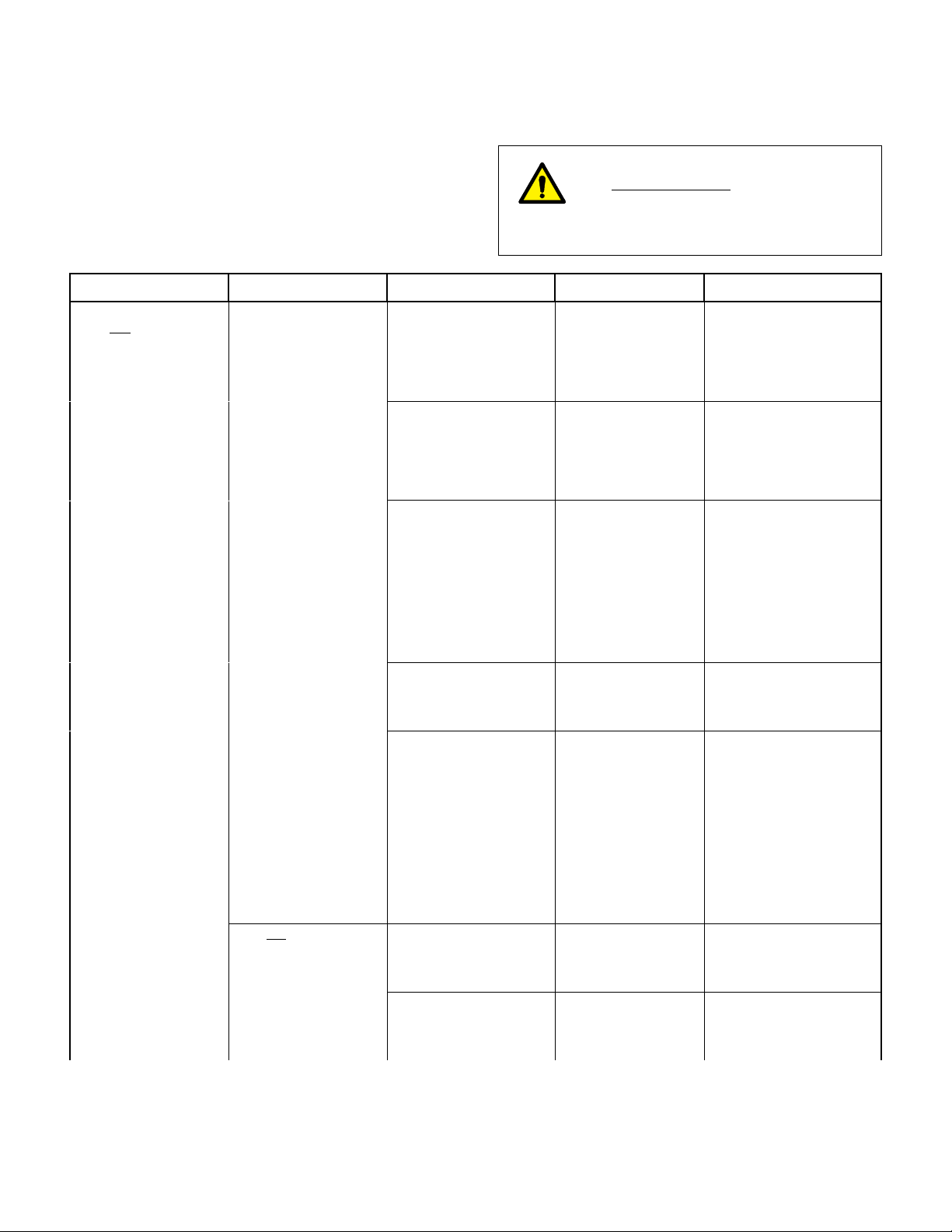

B. Check Voltage (VDC)

Figure 2-9. Testing Potentiometers

Go To Table Of Contents

(1) Remove seat upholstery or appropriate covers

to access back or base potentiometer (refer to

para 4.16 or 4.17).

WARNING

Use caution to prevent electrical shock

with chair plugged into outlet. Electrical

components and connections are exposed.

(2) Plug chair into outlet.

(3) Set meter to read voltage DC on scale appropri-

ate to read approximately 5 VDC.

(4) Place meter probes (1, Fig. 2-9) on two outside

leads (A) of potentiometer (2).

Reading should be approximately 5 VDC

(±1 VDC).

If voltage reading is zero (0), leads are broken

in wire harness between potentiometer and P.C.

board or P.C. is not working correctly (Refer to

Troubleshooting Guide, Table 2-1).

SECTION II

TESTING AND TROUBLESHOOTING

© Midmark Corporation 2000 SF-1620 Page 2-5 Printed in U.S.A.

Page 22

SECTION II

Go To Table Of Contents

TESTING AND TROUBLESHOOTING

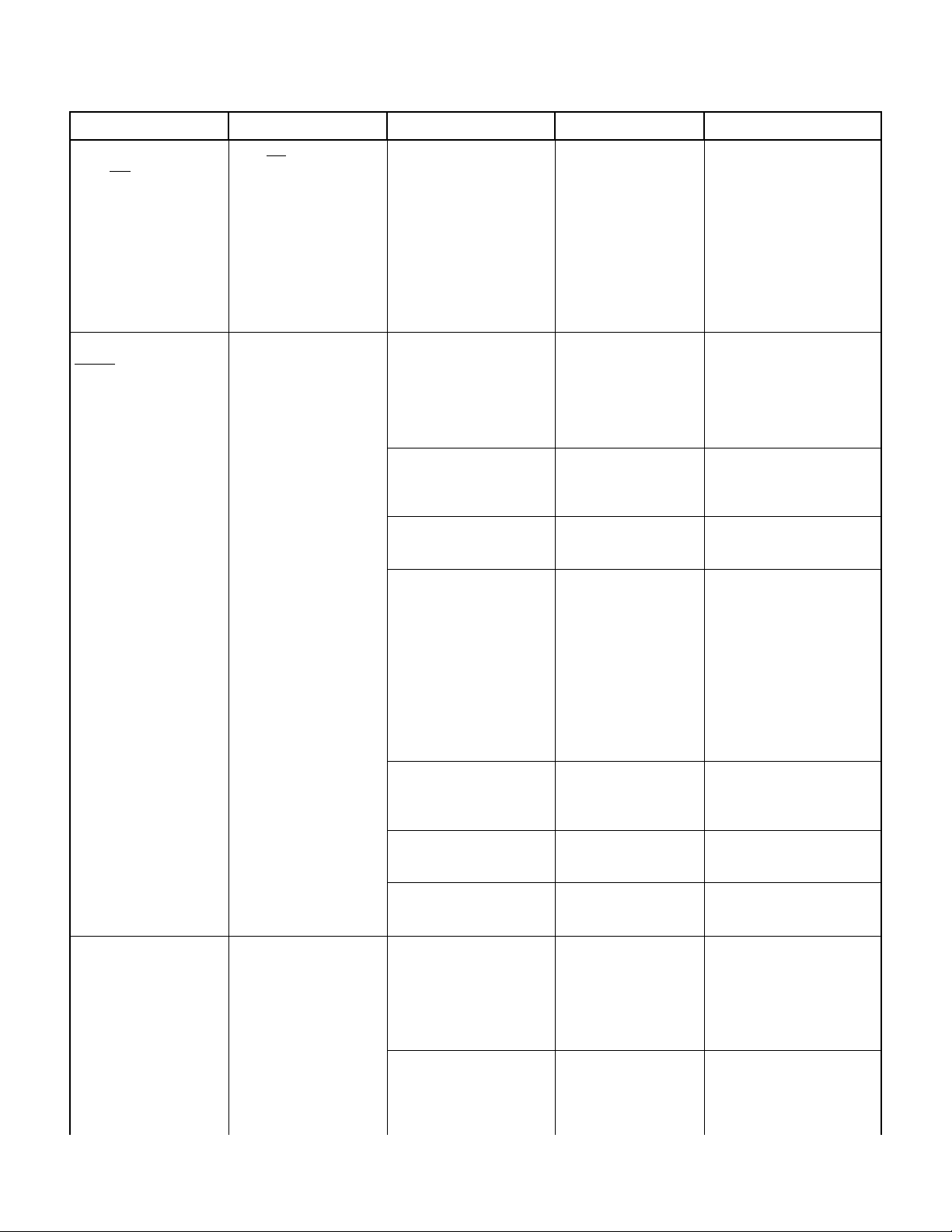

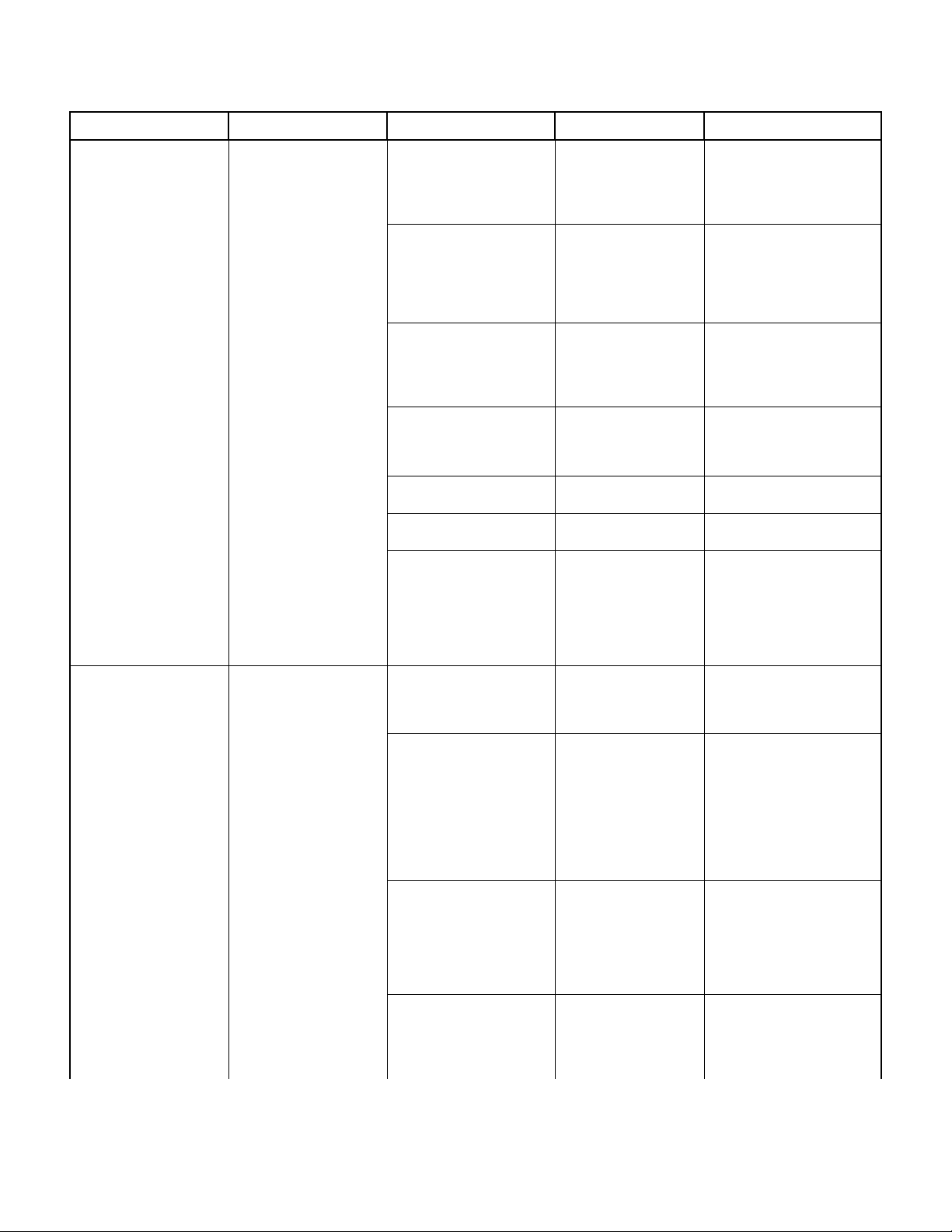

2.3 Troubleshooting Procedures

Table 2-1 is a Troubleshooting Guide which is used to

determine causes of malfunctions. Refer to diagrams in

Section V to assist in troubleshooting procedures.

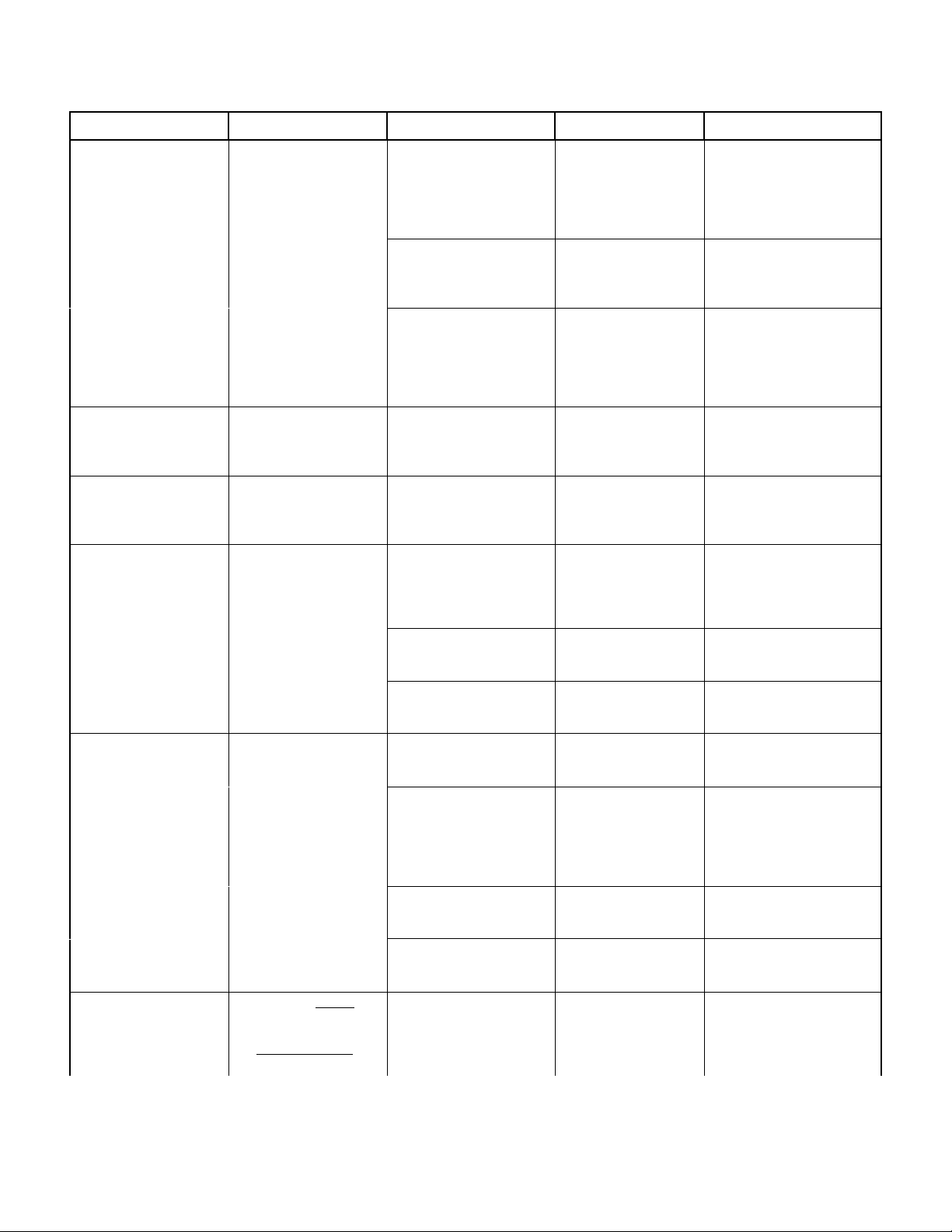

Problem Symptom Probable Cause Check Correction

Chair will not operate

when any

selected (from any of the

membrane switch panels or foot control

switches).

function is

When a membrane touchpad or foot control switch is

pressed, nothing happens

and relays cannot be heard

energizing).

Power cord is not plugged

into facility wall outlet.

Facility circuit breaker providing power to chair is

tripped.

Wire connections are loose. Check all wiring connec-

Fuse blown. Remove fuse, F1, F2,

PC circuit board is malfunctioning.

(Note: Incoming Line voltage is present at Power

Input, J19, pins 2 [Blue] & 4

[Brown].)

WARNING

Use extreme caution when testing com-

ponents with chair plugged into outlet.

Line voltage is present. Failure to comply could

result in personal injury.

Check to see if power

cord is plugged in.

Check to see if facility circuit breaker is tripped.

Plug a lamp into wall outlet that chair was plugged

into and see if it operates.

tions from power cord to

PC circuit board. Use a

multimeter to perform

continuity checks on

wires.

Check for line voltage at

plug J19 (line power

input) on pins 2 (blue) &

4 (brown).

and F3 from PC board

and check fuses for continuity.

Check for 12 VDC on

pins 1 & 2 of J14.

Check the LED’s next to

related relay when the

specific function is being

operated.

Plug power cord into facility

wall outlet.

If facility circuit breaker is

tripped, determine what

caused circuit breaker to trip,

correct problem, and then

reset / replace circuit breaker.

Clean any dirty connections.

Tighten any loose connections. Replace any damaged

connections. Refer to Section

V for Schematics.

Replace blown fuse with fuse

of same rating. Refer to Section V for Schematics.

If no 12 VDC is present on J14

replace board.

If LED’s do not light during

function, replace board.

Chair has

functions can be initiated

from membrane touchpad

and foot control.

© Midmark Corporation 2000 SF-1620 Page 2-6 Printed in U.S.A.

Rev. 8/01

power, but no

Plug connector(s) loose or

wire harnesses broken.

SW1 Switch on PC Board is

set in Calibration Mode (both

switches 1 & 2 are ON)

Check visually for damage components and

broken traces on PC

board.

Check all plug connectors and harnesses.

Check settings on SW1

Switch.

If damage is visible replace

board. Refer to para 4.14.

Repair or replace malfunctioning plug connector(s) or wire

harnesses. Refer to Section V

for Schematics.

Place SW1 switch settings in

proper position for user’s

application. Refer to Section V,

SW1 Switch Settings.

Page 23

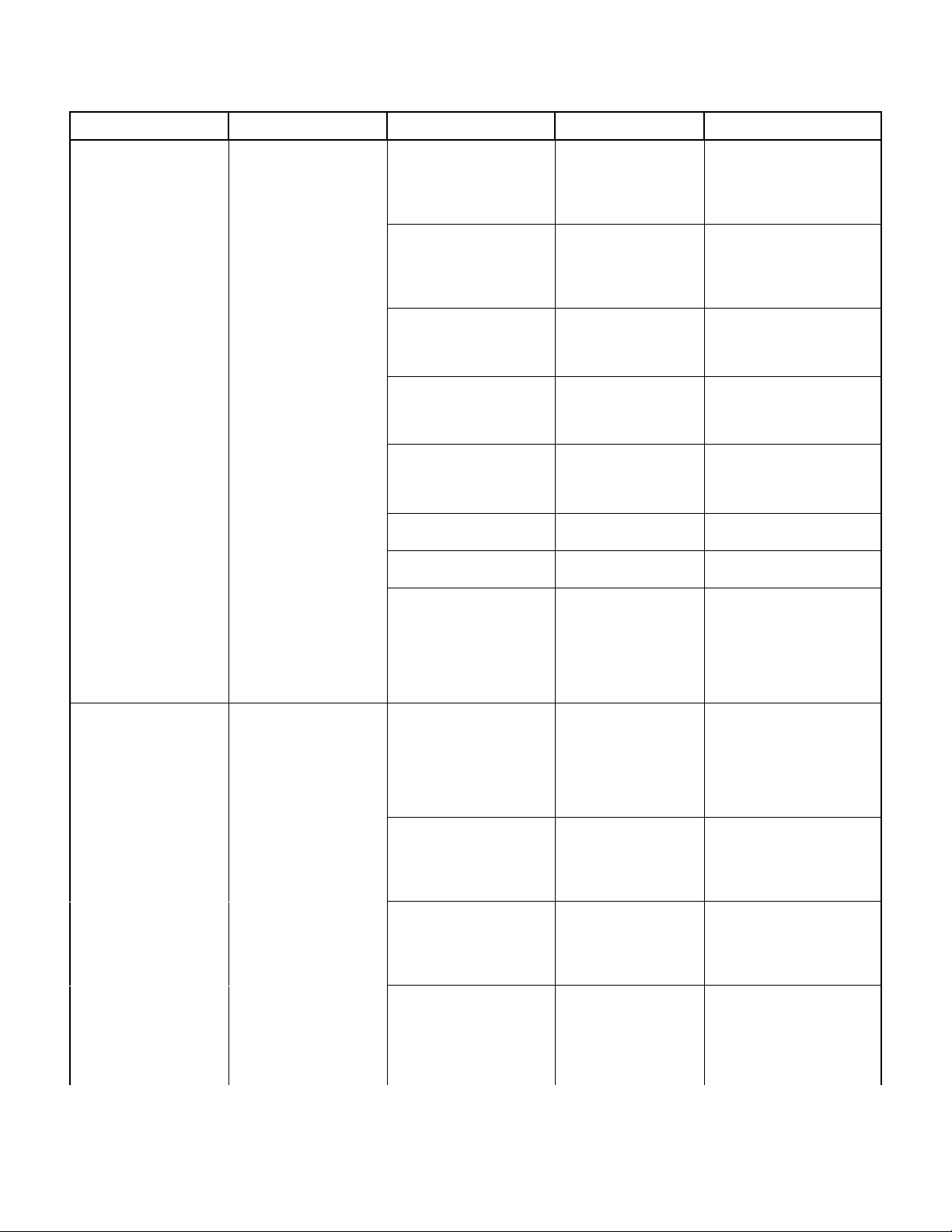

Problem Symptom Probable Cause Check Correction

Go To Table Of Contents

Chair will not operate

when any

selected (from any of the

membrane touchpads or

foot control switches).

(continued)

function is

Chair has

functions can be initiated

from membrane touchpad

and foot control. (continued)

power, but no

TESTING AND TROUBLESHOOTING

PC Board malfunctioning.

(Note: Incoming Line voltage is present at Power

Input, J19, pins 2 [Blue] & 4

[Brown].)

Check for 12 VDC on

pins 1 & 2 of J14.

Check the LED’s next to

related relay when the

specific function is being

operated.

SECTION II

If no 12 VDC is present on J14

replace board.

If LED’s do not light during

function, replace board.

One or more functions

be initiated from

cannot

membrane touchpad or

foot control.

BACK UP function does

not work.

Some functions can be initiated with membrane

touchpad or foot control,

but at least one cannot.

When any BACK UP button is depressed, chair will

not move (all other functions work).

Switch on Membrane Touchpad or Foot Control is malfunctioning.

Wires Broken or connections

loose .

Capacitor for hydraulic pump

motor weak or bad. (Up

functions would not work)

PC Board malfunctioning.

(Note: Incoming Line voltage is present at Power

Input, J19, pins 2 [Blue] & 4

[Brown].)

BACK or BASE potentiometer plug is loose from specific

potentiometer or wire leads

are broken.

BACK or BASE potentiometer is out of adjustment.

BACK and / or BASE

Potentiometer is damaged.

BACK UP solenoid coil has

an open winding, disconnected or broken lead.

BACK UP solenoid valve

stuck in closed position .

Check visually for damage components and

broken traces on PC

board.

Perform a continuity

check on each N.O. control switch in control

(when switch is pressed,

switch circuit should be

closed) Refer to Section

V for Schematics.

Check all wiring and

related connections

between control switches

and PC circuit board.

Replace capacitor with a

known good capacitor

and check operation.

Check for 12 VDC on

pins 1 & 2 of J14.

Check the LED’s next to

related relay when the

specific function is being

operated.

Check visually for damage components and

broken traces on PC

board.

Check conditions of plug

connectors and wire

leads to potentiometers.

Check adjustment of

BASE and/or BACK

potentiometer(s).

Check potentiometer(s).

Refer to para 2.2.

Check all wires to BACK

UP Solenoid and connections at P.C. Board, pins

2 & 3 on J18. Check

solenoid for an “open”

coil. Refer to Section V

for Schematics.

After checking solenoid

coil , connections, and

wires, assure coil is energized when depressing

BACK UP.

If damage is visible replace

board. Refer to para 4.14.

If control switch does not pass

continuity check, replace control. Refer to para 4.6 or 4.21.

Clean any dirty connections.

Tighten or repair any loose or

damaged connections. Refer

to Section V for schematics.

Replace capacitor. Refer to

para 4.10.

If no 12 VDC is present on J14

replace board.

If LED’s do not light during

function, replace board.

If damage is visible replace

board. Refer to para 4.14.

Connect plug to potentiometer or repair broken leads.

Refer to Section V for schematic.

Adjust potentiometer. Refer to

para(s) 4.16, 4.17 or 4.18.

Replace potentiometer(s).

Refer to para(s) 4.16, 4.17 or

4.18.

Repair wires and / or connections.

Replace Hydraulic Solenoid

Valve Assembly. Refer to para

1

3.

4.

Replace Hydraulic Solenoid

Valve Assembly. Refer to para

4.13.

© Midmark Corporation 2000 SF-1620 Page 2-7 Printed in U.S.A.

Rev. 08/01

Page 24

SECTION II

Go To Table Of Contents

TESTING AND TROUBLESHOOTING

Problem Symptom Probable Cause Check Correction

BACK UP function does

not work. (continued)

BACK DOWN function

does not work.

When any BACK UP button is depressed, chair will

not move (all other functions work). (continued)

When any BACK DOWN

button is depressed, chair

will not move (all other

functions work).

Throttle Valve (TV3) on

Hydraulic Solenoid Valve

Assembly turned in too far or

completely closed.

Hydraulic BACK cylinder

leaking.

Hydraulic Solenoid Valve

Assembly is clogged preventing fluid flow.

BACK potentiometer plug is

loose from potentiometer or

wire leads are broken.

BACK potentiometer is out of

adjustment.

BACK Potentiometer is damaged.

PC Board malfunctioning. When BACK UP is

Safety Bail Limit Switch(es)

harness not installed correctly (loose).

Safety Bail Limit Switch(es)

contacts open due to an

obstruction hitting cover or

Switch(es) malfunctioning,

stuck open

BACK DOWN solenoid coil

has an open winding, disconnected or broken lead.

BACK DOWN solenoid valve

stuck in closed position .

Check position of TV3

Throttle Valve. Refer to

para 4.13 and BACK UP

hydraulic schematic in

Sect. V.

Check for leakage

around hydraulic cylinder and fittings. Check for

excessive fluid returning

to reservoir from Vent

line.

Check for hydraulic fluid

flow to Back Cylinder during operation. Refer to

Section V for Schematics.

Check conditions of plug

connectors and wire

leads to potentiometer.

Check adjustment of

BACK potentiometer.

Check potentiometer.

Refer to para 2.2.

depressed, check LED

next to K4 contacts to

assure it is lit. Check for

line voltage at J18, terminals 2 & 3. Refer to Section V for Schematics.

Check both harness to

assure they are connected tightly.

Safety Bail cover

depressing safety bail

limit switch(es) actuator,

opening contacts on

switch.

Check continuity on

unoperated switch to

assure normally closed

(NC) contacts are closed.

Check all wires to BACK

DOWN Solenoid and

connections at P.C.

Board, pins 4 & 5 on J18.

Check solenoid for an

“open” coil. Refer to Section V for Schematics.

After checking solenoid

coil , connections, and

wires, assure coil is energizes when depressing

BACK DOWN.

Adjust Throttle Valve (TV3).

Refer to para 4.13.

Replace Hydraulic Back Cylinder. Refer to para 4.7.

Replace Hydraulic Solenoid

Valve Assembly. Refer to para

4.13.

Connect plug to potentiometer or repair broken leads.

Refer to Section V for schematic.

Adjust potentiometer. Refer to

para 4.17 or 4.18.

Replace potentiometer. Refer

to para 4.17 or 4.18.

If no voltage is present at J18,

terminals 2 & 3, when BACK

UP is depressed, replace PC

Board. Refer to para 4.14.

Connect harness correctly.

Remove obstruction that

causes cover to actuate limit

switch(es).

Replace Safety Bail Limit

Switch(es). Refer to para

4.19.

Repair wires and / or connec-

ns.

o

ti

Replace Hydraulic Solenoid

Valve Assembly. Refer to para

4.13.

Replace Hydraulic Solenoid

Valve Assembly. Refer to para

4.13.

© Midmark Corporation 2000 SF-1620 Page 2-8 Printed in U.S.A.

Rev. 08/01

Page 25

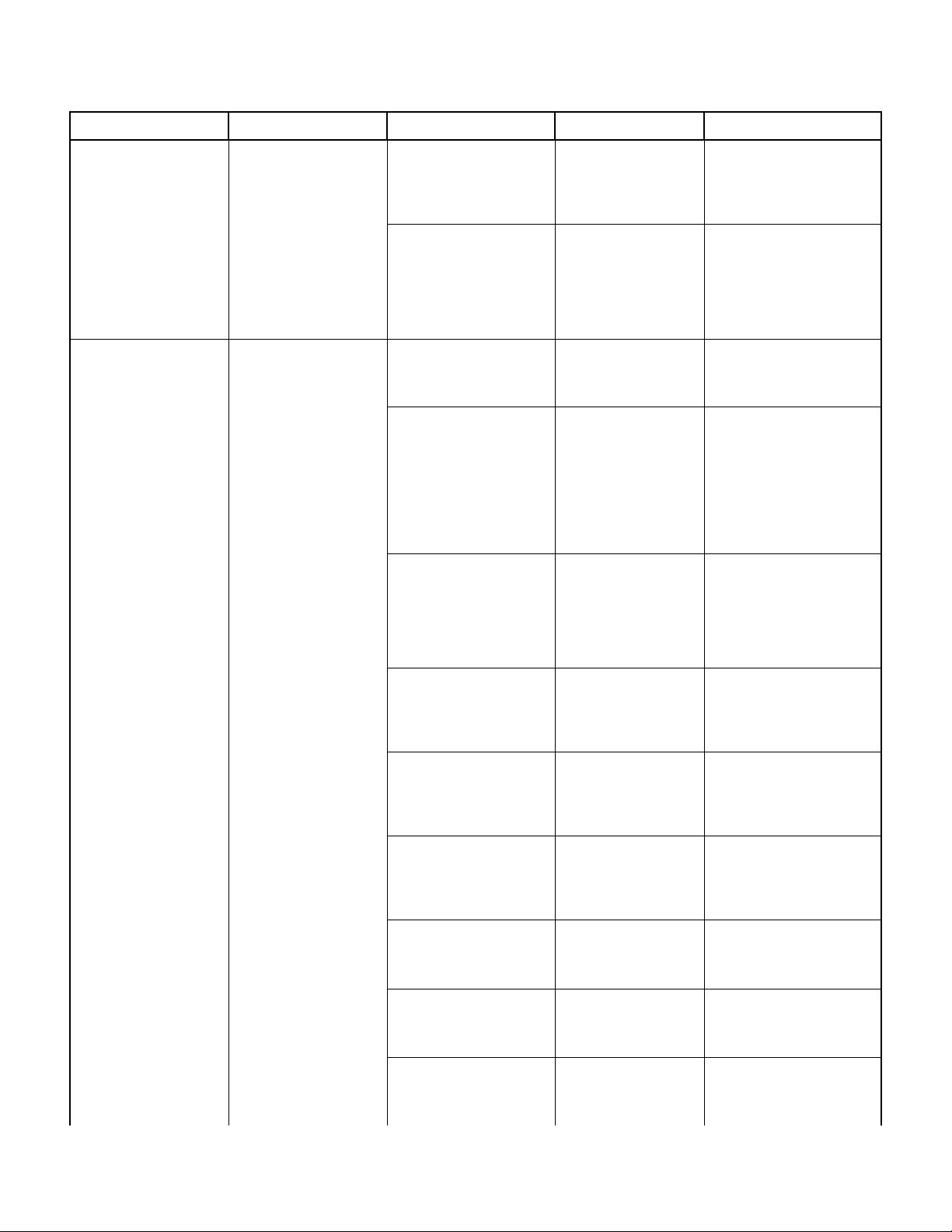

Problem Symptom Probable Cause Check Correction

Go To Table Of Contents

BACK DOWN function

does not work. (contin-

ued)

BASE UP function does

not work.

When any BACK DOWN

button is depressed, chair

will not move (all other

functions work). (continued)

When any BASE UP button is depressed, chair will

not move (all other functions work).

TESTING AND TROUBLESHOOTING

Throttle Valve (TV4) on

Hydraulic Solenoid Valve

Assembly turned in too far or

completely closed.

Hydraulic Solenoid Valve

Assembly is clogged preventing fluid flow.

Cuspidor Limit Switch contacts open due to cuspidor

hitting obstruction or malfunction.

Cuspidor not installed and

Jumper wire on J10 plug

connector missing.

BACK potentiometer plug is

loose from potentiometer or

wire leads are broken.

BACK potentiometer is out of

adjustment.

BACK Potentiometer is damaged.

PC Board malfunctioning. When BACK DOWN is

BASE UP solenoid coil has

an open winding, disconnected or broken lead.

BASE UP solenoid valve

stuck in closed position .

Throttle Valve (TV1) on

Hydraulic Solenoid Valve

Assembly turned in too far or

letely closed.

p

com

Hydraulic BASE cylinder

leaking.

Check position of TV4

Throttle Valve. Refer to

para 4.13 and BACK

DOWN hydraulic schematic in Sect. V.

Check for hydraulic fluid

flow from Cylinder to

Reservoir during operation. Refer to Section V

for Schematics.

Check if cuspidor is hitting obstruction and/or if

limit switch contacts

are open.

Check for a jumper wire

on P.C. Board plug connector J10.

Check conditions of plug

connectors and wire

leads to potentiometer.

Check adjustment of

BACK potentiometer.

Check potentiometer.

Refer to para 2.2.

depressed, check LED

next to K5 contacts to

assure it is lit. Check for

line voltage at J18, terminals 4 & 5. Refer to Section V for Schematics.

Check all wires to BASE

UP Solenoid and connections at P.C. Board, pins

2 & 3 on J17. Check

solenoid for an “open”

coil. Refer to Section V

for Schematics.

After checking solenoid

coil , connections, and

wires, assure coil is energized when depressing

BASE UP.

Check position of TV1

Throttle Valve. Refer to

para 4.13 and BASE UP

hydraulic schematic in

Section V.

Check for leakage

around hydraulic cylinder and fittings. Check for

excessive fluid returning

to reservoir from Vent

line.

SECTION II

Adjust Throttle Valve (TV4).

Refer to para 4.13.

Replace Hydraulic Solenoid

Valve Assembly. Refer to para

4.13.

Remove obstruction.

Replace Cuspidor limit switch.

Refer to ProCenter® Delivery

System Service & Parts.

Install a jumper wire on terminals 1 & 2, plug connector

J10. Refer to Section V for

Schematics.

Connect plug to potentiometer or repair broken leads.

Refer to Section V for schematic.

Adjust potentiometer. Refer to

para 4.17 or 4.18.

Replace potentiometer. Refer

to para 4.17 or 4.18..

If no voltage is present at J18,

terminals 4 & 5, when BACK

DOWN is depressed, replace

PC Board. Refer to para 4.1.

Repair wires and / or connections.

Replace Hydraulic Solenoid

Valve Assembly. Refer to para

4.13.

Replace Hydraulic Solenoid

Valve Assembly. Refer to para

4.13.

Adjust Throttle Valve (TV1).

Refer to para 4.13.

Replace Hydraulic Base Cylinder. Refer to para 4.7.

© Midmark Corporation 2000 SF-1620 Page 2-9 Printed in U.S.A.

Rev. 08/01

Page 26

SECTION II

Go To Table Of Contents

TESTING AND TROUBLESHOOTING

Problem Symptom Probable Cause Check Correction

BASE UP function does

not work. (continued)

BASE DOWN function

does not work.

When any BASE UP button is depressed, chair will

not move (all other functions work). (continued).

When any BASE DOWN

button is depressed, chair

will not move (all other

functions work).

Hydraulic Solenoid Valve

Assembly is clogged preventing fluid flow.

PC Board malfunctioning. When BASE UP is

Safety Bail Limit Switch(es)

harness not installed correctly (loose).

Safety Bail Limit Switch(es)

contacts open due to an

obstruction hitting cover or

Switch(es) malfunctioning,

stuck open

BASE DOWN solenoid coil

has an open winding, disconnected or broken lead.

BASE DOWN solenoid valve

stuck in closed position.

Throttle Valve (TV2) on

Hydraulic Solenoid Valve

Assembly turned in too far or

completely closed.

Hydraulic Solenoid Valve

Assembly is clogged preventing fluid flow.

Cuspidor Limit Switch contacts open due to cuspidor

hitting obstruction or malfunction.

Cuspidor not installed and

Jumper wire on J10 plug

connector missing.

BASE potentiometer plug is

loose from potentiometer or

wire leads are broken.

Check for hydraulic fluid

flow to Back Cylinder during operation. Refer to

Section V for Schematics.

depressed, check LED

next to K2 contacts to

assure it is lit. Check for

line voltage at J17, terminals 2 & 3. Refer to Section V for Schematics.

Check both harness to

assure they are connected tightly.

Safety Bail cover

depressing safety bail

limit switch(es) actuator,

opening contacts on

switch.

Check continuity on

unoperated switch to

assure normally closed

(NC) contacts are closed.

Check all wires to BASE

DOWN Solenoid and

connections at P.C.

Board, pins 4 & 5 on J17.

Check solenoid for an

“open” coil. Refer to Section V for Schematics.

After checking solenoid

coil , connections, and

wires, assure coil is energizes when depressing

BASE DOWN.

Check position of TV2

Throttle Valve. Refer to

para 4.13 and BASE

DOWN hydraulic schematic in Sect. V.

Check for hydraulic fluid

flow from Cylinder to

Reservoir during operation. Refer to Section V

for Schematics.

Check if cuspidor is hitting obstruction and/or if

limit switch contacts

are open.

Check for a jumper wire

on P.C. Board plug connector J10.

Check conditions of plug

connectors and wire

leads to potentiometer.

Replace Hydraulic Solenoid

Valve Assembly. Refer to para

4.13.

If no voltage is present at J17,

terminals 2 & 3, when BASE

UP is depressed, replace PC

Board. Refer to para 4.1.

Connect harness correctly.

Remove obstruction that

causes cover to actuate limit

switch(es).

Replace Safety Bail Limit

Switch(es). Refer to para

4.19.

Repair wires and / or connections.

Replace Hydraulic Solenoid

Valve Assembly. Refer to para

4.13.

Replace Hydraulic Solenoid

Valve Assembly. Refer to para

4.13.

Adjust Throttle Valve (TV2).

Refer to para 4.13.

Replace Hydraulic Solenoid

Valve Assembly. Refer to para

4.13.

Remove obstruction.

Replace Cuspidor limit switch.

er t

o ProCenter® Delivery

Ref

System Service & Parts.

Install a jumper wire on terminals 1 & 2, plug connector

J10. Refer to Section V for

schematic.

Connect plug to potentiometer or repair broken leads.

Refer to Section V for schematic.

© Midmark Corporation 2000 SF-1620 Page 2-10 Printed in U.S.A.

Rev. 08/01

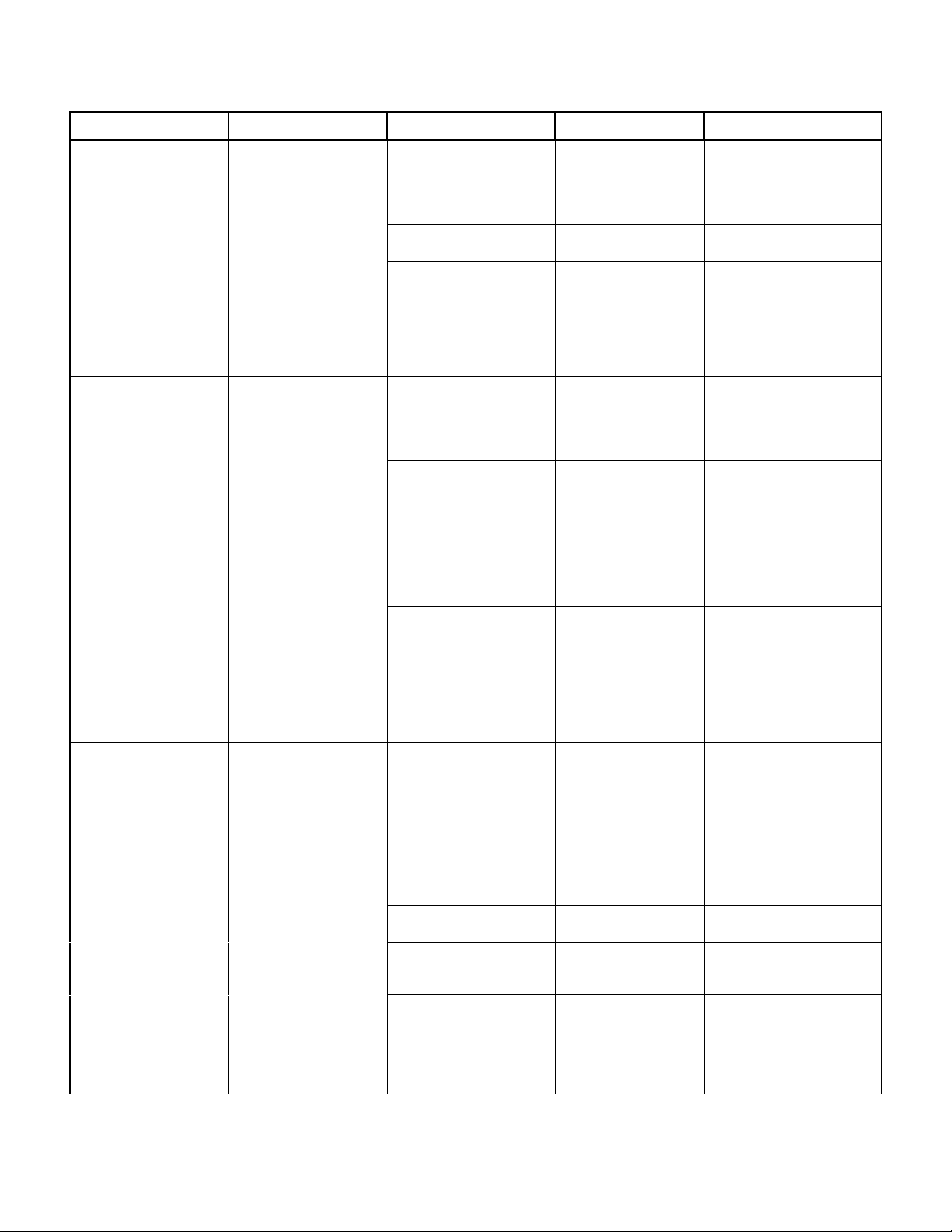

Page 27

Problem Symptom Probable Cause Check Correction

Go To Table Of Contents

BASE DOWN function

does not work. (contin-

ued)

BASE DOWN and BACK

DOWN functions do not

work.

BASE UP and BACK UP

functions do not work.

When any BASE DOWN

button is depressed, chair

will not move (all other

functions work). (continued)

When BASE DOWN and

BACK DOWN buttons are

pressed, chair will not

move. BASE UP and

BACK UP functions work.

When BASE UP and

BACK UP buttons are

depressed, chair will not

move. BASE DOWN and

BACK DOWN functions

work.

TESTING AND TROUBLESHOOTING

BASE potentiometer is out of

adjustment.

BASE Potentiometer is damaged.

PC Board malfunctioning. When BASE DOWN is

Safety Bail Limit Switch(es)

harness not installed correctly (loose).

Safety Bail Limit Switch(es)

contacts open due to an

obstruction hitting cover or

Switch(es) malfunctioning,

stuck open

Cuspidor Limit Switch contacts open due to cuspidor

hitting obstruction or malfunction.

Cuspidor not installed and

Jumper wire on J10 plug

connector missing.

Internal thermal overload on

hydraulic motor pump open

due to running continuously

or weak or malfunctioning

overload.

Hydraulic Fluid in reservoir

low.

Capacitor on motor pump

weak or inoperative.

Low voltage is being supplied to chair.

Check adjustment of

BASE potentiometer.

Check potentiometer.

Refer to para 2.2.

depressed, check LED

next to K3 contacts to

assure it is lit. Check for

line voltage at J17, terminals 4 & 5. Refer to Section V for schematic.

Check both harness to

assure they are connected tightly.

Safety Bail cover

depressing safety bail

limit switch(es) actuator,

opening contacts on

switch.

Check continuity on

unoperated switch to

assure normally closed

(NC) contacts are closed.

Check if cuspidor is hitting obstruction and/or if

limit switch contacts

are open.

Check for a jumper wire

on P.C. Board plug connector J10.

Check continuity

between white & red

motor leads and yellow

and red leads. Refer to

Section V schematics.

Check reservoir for

hydraulic fluid level.

Replace capacitor with

known good capacitor of

same rating.

Check voltage at wall

receptacle - should be

between 110.0 to 126.0

VAC on 115 VAC units or

220 to 252 VAC on 230

VAC units.

SECTION II

Adjust potentiometer. Refer to

para 4.16.

Replace potentiometer. Refer

to para 4.16.

If no voltage is present at J17,

terminals 4 & 5, when BASE

DOWN is depressed, replace

PC Board. Refer to para 4.1.

Connect harness correctly.

Remove obstruction that

causes cover to actuate limit

switch(es).

Replace Safety Bail Limit

Switch(es). Refer to para

4.19.

Remove obstruction.

Replace Cuspidor limit switch.

Refer to ProCenter® Delivery

System Service & Parts.

Install a jumper wire on terminals 1 & 2, plug connector

J10. Refer to Section V for

schematic.

Allow motor to cool for 10 minutes and recheck continuity. If

overload resets inform operator that motor is for intermittent

operation Running continuously for a 30 second period

will cause overload to open.

overload does not reset

f

I

replace hydraulic motor pump.

Refer to para 4.9.

Fill reservoir to correct level..

Refer to para 4.12.

Replace capacitor. Refer to

para 4.10.

Correct low voltage situation

at wall receptacle.

© Midmark Corporation 2000 SF-1620 Page 2-11 Printed in U.S.A.

Rev. 08/01

Page 28

SECTION II

Go To Table Of Contents

TESTING AND TROUBLESHOOTING

Problem Symptom Probable Cause Check Correction

BASE UP and BACK UP

functions do not work.

(continued)

BASE drifts down. BASE drifts down from ele-

BACK drifts down. BACK drifts down from ele-

Hydraulic Motor Pump

continues to run.

Chair doesn’t operate

correctly under heavier

loads.

BASE DOWN travel is too

slow.

When BASE UP and

BACK UP buttons are

depressed, chair will not

move. BASE DOWN and

BACK DOWN functions

work. (continued)

vated position.

vated position.

Depressing specific function button, hydraulic motor

pump continues to run

when chair reaches top or

bottom limitations.

Chair moves slowly or not

at all under heavier loads.

Chair exceeds normal

second descent time from

top position to bottom position w/ 180 lbs (82 kg)

on it.

15

load

Hydraulic motor pump electrical leads disconnected.

Hydraulic motor pump has

open winding(s).

Pressure relief valve open or

leaking

BASE Hydraulic cylinder

leaking past piston seals.

BACK Hydraulic cylinder

leaking past piston seals.

BACK or BASE potentiometer plug is loose from specific

potentiometer or wire leads

are broken.

BACK or BASE potentiometer is out of adjustment.

Potentiometer is damaged. Check potentiometer(s).

Capacitor for Hydraulic

Motor Pump is weak.

Low voltage is being supplied to chair.

Leakage past pressure relief

valve.

Hydraulic cylinder(s) leaking

past piston seals.

Throttle Valve (TV2) is

turned in too far restricting

hydraulic fluid flow back to

reservoir.

Check electrical connections on PC Board at J16,

terminals 2 & 3.

Check resistance values

of motor windings. Refer

to Section V for schematic.

Check if fluid is returning

to reservoir when BASE

UP and / or BACK UP

functions are activated

with no or normal load on

chair.

Check for excessive fluid

returning to reservoir thru

vent tubing of BASE cylinder.

Check for excessive fluid

returning to reservoir thru

vent tubing of BACK cylinder.

Check conditions of plug

connectors and wire

leads to potentiometers.

Check adjustment of

BASE and/or BACK

potentiometer(s).

Refer to para 2.2.

Replace capacitor with

known good capacitor of

same rating.

Check voltage at wall

receptacle - should be

between 110.0 to 126.0

VAC on 115 VAC units or

220 to 252 VAC on 230

VAC units.

Check for excessive fluid

flowing back to reservoir.

Check for excessive fluid

returning to reservoir thru

vent tubing of cylinder(s).

Check setting of Throttle

Valve (T V2 )

Reconnect electrical leads to

J16 on PC Board. Refer to

Section V Schematics.

Replace Hydraulic Motor

pump. Refer to para 4.9.

Replace Solenoid Valve

Assembly. Refer to para 4.13.

Replace BASE hydraulic cylinder. Refer to para 4.8.

Replace BACK hydraulic cylinder. Refer to para 4.7.

Connect plug to potentiometer or repair broken leads.

Refer to Section V for schematic.

Adjust potentiometer. Refer to

para(s) 4.16, 4.17 or 4.18.

Replace potentiometer(s).

Refer to para(s) 4.16, 4.17 or

4.18.

Replace capacitor. Refer to

para 4.10.

Correct low voltage situation

at wall receptacle.

olenoid

Replace Hydraulic

Valve Assembly. Refer to para

4.13.

Replace hydraulic cylinder(s). Refer to para 4.7 and /

or 4.8.

Adjust Throttle Valve (TV2).

Refer to para 4.13 (Adjustments).

S

© Midmark Corporation 2000 SF-1620 Page 2-12 Printed in U.S.A.

Rev. 08/01

Page 29

SECTION II

Go To Table Of Contents

TESTING AND TROUBLESHOOTING

Problem Symptom Probable Cause Check Correction

BASE DOWN travel is too

fast.

BACK DOWN travel is too

slow.

BACK DOWN travel is too

fast.

Hydraulic Pump is

exceedingly noisy.

Headrest difficult to

adjust or does not stay in

position.

Rotational Brake not

working.

Chair descends faster then

l 15 second descent

norma

time from top position to

bottom position w/ 180 lbs

(82 kg) load on it.

Chair exceeds normal

second descent time from

top position to bottom position w/ 180 lbs (82 kg)

on it.

Chair descends faster then

l 15 second descent

norma

time from top position to

bottom position w/ 180 lbs

(82 kg) load on it.

Noisy motor pump during

BACK UP or BASE UP.

Excessive force is required

to position the headrest.

Headrest does not lock into

a position or slides downward on own.

Brake is off, but chair top is

binding when rotated.

Brake lever is difficult to

engage.

Chair top rotates when

BRAKE lever is in locked

position.

15

load

Throttle Valve (TV2) is open

too far.

Throttle Valve (TV4) is

turned in too far restricting

hydraulic fluid flow back to

reservoir.

BACK lift spring(s) detached

or broken.

Throttle Valve (TV4) is open

too far.

Restriction in Suction line

from reservoir causing negative pressure.

Internal parts failure in motor

pump.

Headrest slide is too tight

and needs adjusted.

Headrest slide is too loose

and needs adjusted.

Brake is out of adjustment

(needs loosened).

Brake is out of adjustment

(needs loosened).

Brake is out of adjustment

(needs tightened).

Check setting of Throttle

Valve (TV2).

Check setting of Throttle

Valve (T V4 )

Check conditions of

BACK lift spring(s).

Check setting of Throttle

Valve (TV4).

Check for kinks in tubing

and / or restrictions in

suction line.

Check for noise or vibrations from motor pump

during operation.

Check adjustment of

headrest slide.

Check adjustment of

headrest slide.

Check adjustment of

brake.

Check adjustment of

brake.

Check adjustment of

brake.

Adjust Throttle Valve (TV2).

Refer to para 4.13 (Adjustments).

Adjust Throttle Valve (TV4).

Refer to para 4.13 (Adjustments)

Connect or replace BACK lift

spring(s).

Adjust Throttle Valve (TV4).

Refer to para 4.13 (Adjustments).

Repair or replace tubing.

Replace motor pump. Refer to

para 4.9.

Adjust the headrest slide

assembly. Refer to para 4.4.

Adjust the headrest slide

assembly. Refer to para 4.4.

Adjust brake. Refer to para

4.5.

Adjust brake. Refer to para

4.5.

Adjust brake. Refer to para

4.5.

© Midmark Corporation 2000 SF-1620 Page 2-13 Printed in U.S.A.

Rev. 03/10

Page 30

SECTION II

Go To Table Of Contents

TESTING AND TROUBLESHOOTING

© Midmark Corporation 2000 SF-1620 Page 2-14 Printed in U.S.A.

Page 31

SCHEDULED MAINTENANCE

Go To Table Of Contents

SECTION III

SCHEDULED MAINTENANCE

SECTION III

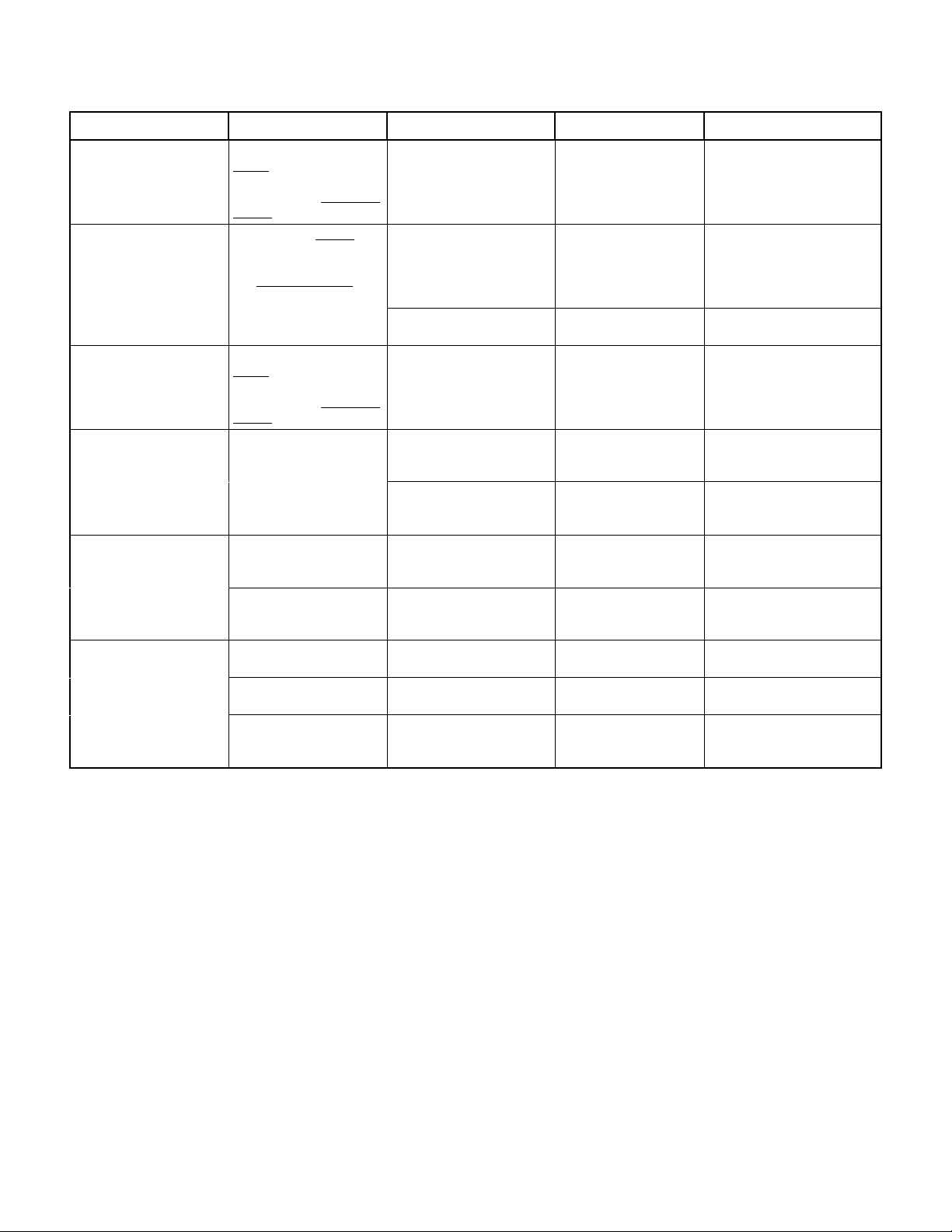

3.1 Scheduled Maintenance

inspections and services that should be performed periodically on the chair. These inspections and services

Table 3-1 is a Scheduled Maintenance Chart which lists

Interval

Semi-annually Obvious damage Visually check condition of chair for obvious damage such as: cracks in components,

Inspection or

Service

missing components, dents in components, frayed or damaged cords, or any other visible damage which would cause chair to be unsafe to operate or would compromise its

performance. Repair chair as necessary.

Fasteners / hardware Check chair for missing or loose fasteners / hardware. Replace any missing hardware

and tighten any loose hardware as necessary.

Warning and instructional decals

Pivot points / moving

parts / accessories

Membrane switch

panels

Foot control Check each switch on foot control for proper operation. Depress each foot control

Base and Back

Hydraulic Cylinders

Hydraulic Motor Pump

and Capacitor

Hydraulic Reservoir Check condition of reservoir, related fittings and fluid level. If necessary, correct any

Headrest Check headrest for proper operation by sliding headrest up and down. Headrest should

Rotation Check rotation for proper operation. Unlock brake and rotate chair top. Chair top

Safety Bail Limit

Switches

Upholstery Check all upholstery for rips, tears, or excessive wear.

Accessories Check that all accessories have all of their components and that they function properly.

Operational Test Perform an Operational Test to determine if the chair is operating within its specifications

Check for missing or illegible decals. Replace decals as necessary.

Lubricate all exposed pivot points, moving parts, and accessories with silicone based

lubricant.

Check each switch on each membrane switch panel for proper operation. Depress each

membrane switch to make sure selected function operates. If any switch does not work,

refer to Troubleshooting Guide in Section 2.

switch to make sure selected function operates when its button is depressed. If any

switch does not work, refer to Troubleshooting Guide in Section 2.

Check Base and Back hydraulic cylinders and related fittings . If cylinders or fittings will

not operate properly due to external or internal hydraulic fluid leakage, repair or replace

cylinder or fitting(s). Refer to para(s) 4.7 and / or 4.8.

Check hydraulic motor pump operation per instructions in Operational Test, para 2.1. If

motor does not lift properly refer to Troubleshooting, para 2.3 and repair or replace malfunctioning component(s).

problem and / or add fluid. Refer to para(s) 4.11 and 4.12.

not take excessive force to move but should require a slight force to begin movement. If

necessary, adjust headrest. Refer to para 4.4.

should rotate smoothly and easily 30° (15° for L / R Models) in each direction from centerline of chair. If binding occurs, adjust or repair brake. Refer to para 4.5.