Midmark Progeny Vantage Service Manual

Progeny Vantage Panoramic X-ray System

Product Generation 2.1

Technical Service Manual

00-02-1698

Revision B01

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Contents

2

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Contents

Contents

1 How to Use This Manual ........................................................................................................................ 5

Introduction .......................................................................................................................................... 5

Related Manuals ................................................................................................................................. 6

Warnings and Cautions ....................................................................................................................... 6

Symbols and Conventions ................................................................................................................. 11

Specifications .................................................................................................................................... 13

Obtaining Technical Support ............................................................................................................. 14

2 Theory of Operations ........................................................................................................................... 15

System Overview .............................................................................................................................. 15

About the Components...................................................................................................................... 16

Operational Systems ......................................................................................................................... 23

3 Troubleshooting Resources ................................................................................................................ 27

Obtaining Assistance through Remote Access ................................................................................. 27

Service Kit ......................................................................................................................................... 27

Message Center ................................................................................................................................ 28

Error Logs .......................................................................................................................................... 36

Wiring Diagrams ................................................................................................................................ 37

Printed Circuit Boards ....................................................................................................................... 38

Troubleshooting with Printed Circuit Boards ..................................................................................... 43

Network Communications ................................................................................................................. 56

4 Troubleshooting Procedures .............................................................................................................. 58

Communications Failure ................................................................................................................... 58

Operator Panel Failure ...................................................................................................................... 60

Movement Operations Failure ........................................................................................................... 60

X-ray Output Failure or Is Incorrect ...................................................................................................66

Sensor Failure ................................................................................................................................... 69

Indicators Failure ............................................................................................................................... 70

5 Troubleshooting Image Quality........................................................................................................... 71

Characteristics of a Quality Image .................................................................................................... 71

Typical Problems and Their Causes ................................................................................................. 72

Checking Image Quality .................................................................................................................... 73

6 Overview of Service Tasks .................................................................................................................. 76

Service Screen Overview .................................................................................................................. 76

Opening and Using the Service Screen ............................................................................................ 76

Cycle Test .......................................................................................................................................... 79

7 C-arm ..................................................................................................................................................... 80

C-arm Alignment ................................................................................................................................ 80

8 Overhead Arm ....................................................................................................................................... 81

Y-axis Alignment ................................................................................................................................ 81

3

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Contents

X-axis Alignment ................................................................................................................................ 82

9 Collimator and X-ray Source ............................................................................................................... 83

Collimator Calibration ........................................................................................................................ 83

Beam Alignment ................................................................................................................................ 84

10 Telescoping Column ............................................................................................................................ 85

Column Optical Limit Switch Function ............................................................................................... 85

11 Lasers ....................................................................................................................................................86

Align Lasers ....................................................................................................................................... 86

12 X-ray Sensors ....................................................................................................................................... 88

Align the X-ray Sensor ...................................................................................................................... 88

13 Patient Positioning Wands .................................................................................................................. 91

Set Wand Open Position ................................................................................................................... 91

14 Patient Positioning Table .....................................................................................................................92

Patient Positioning Table Alignment .................................................................................................. 92

15 Operational Readiness ........................................................................................................................93

System Function Checklist ................................................................................................................ 93

Appendix A. Operator Panel Non-Service Menus ..............................................................................95

Acquisition Setup Screen .................................................................................................................. 95

Options Screen .................................................................................................................................. 97

Recall Last Image .............................................................................................................................. 99

System Center ................................................................................................................................. 100

X-ray Voltage and Current Properties Screen .................................................................................. 101

Profile Properties Screen ................................................................................................................. 101

4

1 How to Use This Manual

For

Go

How the

system works

Chapter

Chapter

Error messages

Chapter

Boards and test points

Chapter

Chapter

IP addresses

Chapter

Troubleshooting

Chapter

Improving image quality

Chapter

Serv

Chapter

Maintenance procedures

Chapter

Readiness checklists

Chapter

Operator panel screens

Appendix A

In this Chapter

• Introduction

•

Related Manuals

•

Warnings and Cautions

•

Symbols and Conventions

Specifications

•

•

Obtaining Technical Support

Introduction

The Technical Service Manual is used for regular maintenance and service of the Progey Vantage®

panoramic X-ray system. The work should be performed by a technician familiar with this product.

Quick References

information on…

Progeny Vantage®

ice screen

to …

2, System Overview on page 15

2, About the Components on page 16

3, Message Center on page 28

3, Printed Circuit Boards on page 38

3, Troubleshooting with Printed Circuit Boards on page 43

3, Network Communications on page 56

4, Troubleshooting Procedures on page 58

5, Typical Problems and Their Causes on page 72

6, Service Screen Overview on page 76

7 through Chapter 14 starting from page 80

15, System Function Checklist on page 93

, Operator Panel on page 95

Progey Vantage® Panoramic X-ray System

Technical Service Manual

How to Use This Manual

Title Description

Progey Vantage

panoramic X

Installation Guide

The

explains

client computers

Vantage

Progey Vantage

panoramic X

User Guide

The

system and provides instructions o

patient, acquiring images, and resolv

WARNING

Ionizing Radiation

Related Manuals

The following manuals will be helpful when servicing the Progey Vantage® panoramic X-ray system.

Related Manuals

®

-ray system,

®

-ray system,

Installation Guide identifies requirements for installation;

®

device, how to install cables, and how to start up.

User Guide explains the components of the Progey Vantage®

setup; and describes how to install the Progey

n getting started, positioning a

ing image problems.

Warnings and Cautions

This X-ray unit may be dangerous to patient and operator unless

safe exposure factors, operating instructions, and maintenance

schedules are observed. Removing build-in protection devices

increases the risk of undesired X-ray irradiation.

Trained and authorized personnel only shall operate unit.

Read and understand all enclosed documents before installation,

use, maintenance, or repair.

RADIATION SAFETY INSTRUCTIONS

1. Operate by observing all laws and regulations concerning radiation protection.

2. Remain at a safe distance from the X-ray beam at all times for operator protection.

3. Use all radiation safety features on the equipment.

4. Do not operate without X-ray sensor and X-ray beam-limiting devices (collimator), primary and

secondary when equipped.

5. Do not open the X-ray tubehead. There are no serviceable parts inside.

6. Use all radiation protection devices, accessories, and procedures available to protect the

patient, operator, and the service personnel from X-ray radiation.

6

Progey Vantage® Panoramic X-ray System

Technical Service Manual

How to Use This Manual

WARNING

Dangerous Voltage Inside

Contact may cause electric shock or burn.

Under the covers, there are exposed parts carrying currents with

the line voltage, with 48 V, and with 24 V or lower voltages.

Do not allow water or any other liquid to leak inside the equipment

to protect against short-circuit and corrosion. This is an ordinary

medical device without protection against ingress of liquids.

Trained and authorized personnel only should install equipment and

remove covers.

Connect to supply mains with protective earth (ground).

Disconnect equipment from the electrical supply mains before

cleaning, disinfecting, maintenance, or servicing. Wait 30 s before

touching any internal parts.

Read and understand all enclosed documents before installation,

use, maintenance, or repair.

ELECTRICAL SAFETY INSTRUCTIONS

7

Progey Vantage® Panoramic X-ray System

Technical Service Manual

How to Use This Manual

CAUTION

Pinch Points Exists Inside

1. Do not change X-ray sensor when any part of the equipment or the operator touches the

patient.

1. Do not execute any maintenance or repair services that require removing of protective

covers when the patient is present.

2. Do not open the X-ray sensor or the X-ray tubehead. There are no serviceable parts

inside.

3. Do not touch the internal metal parts when energized.

4. Do not short two test points together or short a test point to any other part.

5. Install and use in areas that comply with all applicable laws and recommendations

concerning electrical safety in rooms used for medical purposes, e.g., U.S. National

Electrical code, local regulations, or IEC standards concerning provisions of an additional

protective earth (ground) terminal for power supply connection. Consult with a licensed

professional if needed.

This equipment contains closing motion of mechanical parts that

create pinch points when the covers are removed.

Disconnect equipment from the electrical supply mains before

cleaning, disinfecting, maintenance, or servicing.

Read and understand all enclosed documents before installation,

maintenance, or repair.

OPERATION SAFETY INSTRUCTIONS

1. Replace all enclosures before operating the equipment.

2. Keep all parts of the body away from the equipment when initiating motion.

8

Progey Vantage® Panoramic X-ray System

Technical Service Manual

How to Use This Manual

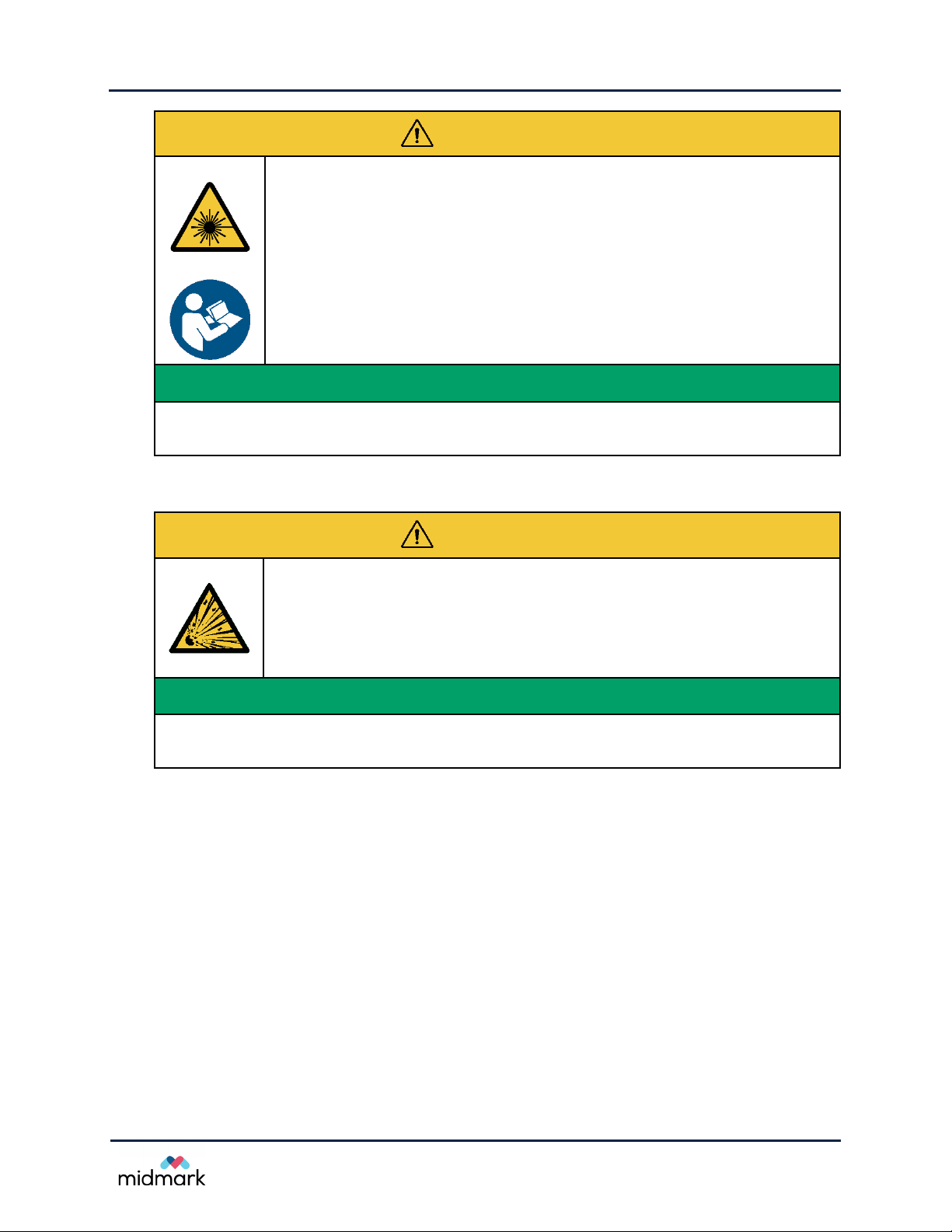

CAUTION

Laser Radiation

CAUTION

Risk of Explosion

This equipment contains CLASS 2 LASER PRODUCT, 650 nm,

3 mW with a 40° fan line beam and non-removable optical system.

Laser on time does not exceed 100 s per activation.

Read and understand all enclosed documents before installation,

use, maintenance, or repair.

LASER RADIATION SAFETY INSTRUCTIONS

3. Do not stare into the beam.

4. Do not place eyes closer than 100 mm.

Do not use in in the presence of flammable or potentially explosive

gases or vapors, which could ignite, causing personal injury and/or

damage to the equipment.

EXPLOSION SAFETY INSTRUCTIONS

1. Allow vapor to disperse before using the equipment after cleaning or disinfecting with

chemicals that create flammable or potentially explosive vapors.

9

Progey Vantage® Panoramic X-ray System

Technical Service Manual

How to Use This Manual

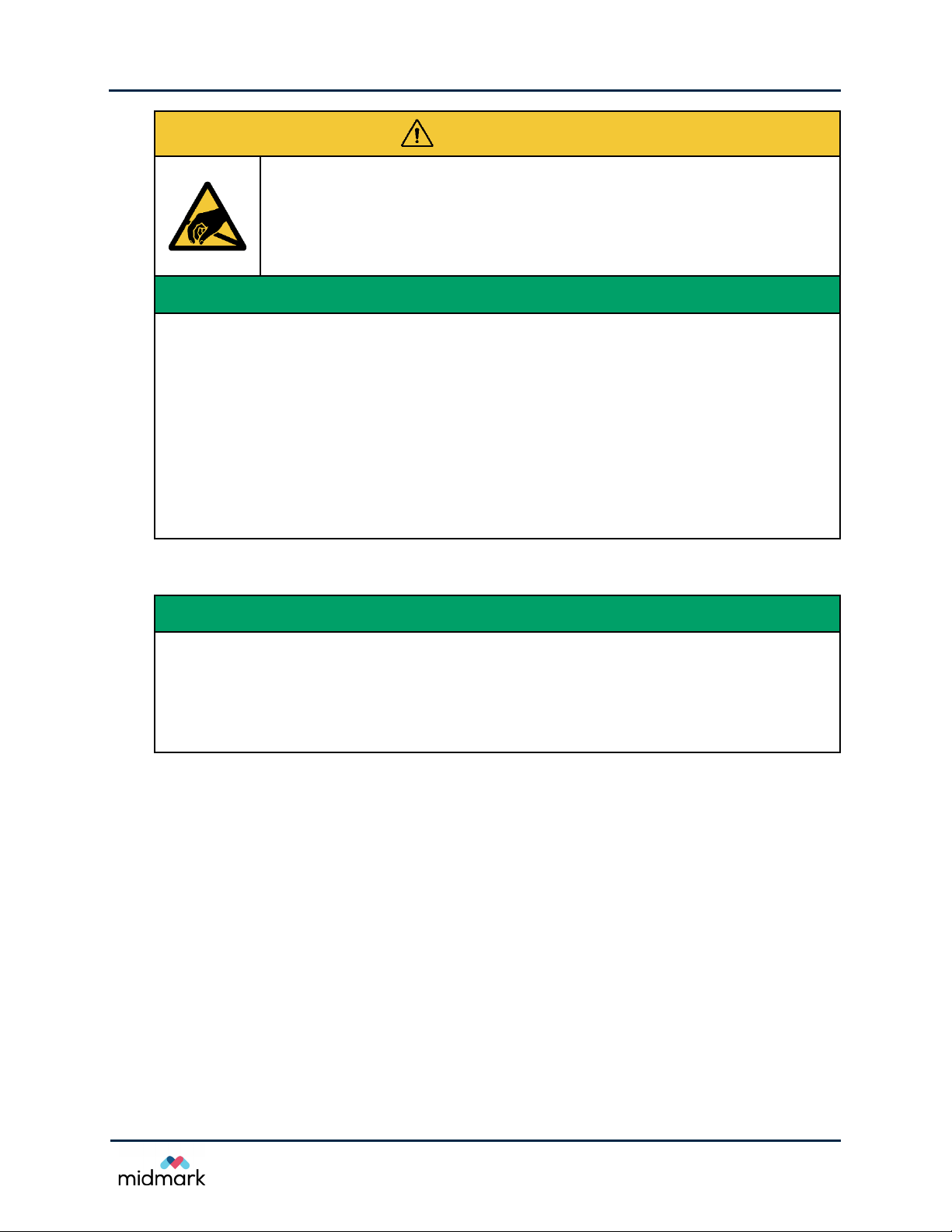

CAUTION

Electrostatic Sensitive Devices Inside

1.

⊕

⊕

This equipment contains electrical circuit that has not been tested

for immunity to electrostatic discharge and may be damaged when

improperly handled.

Do not touch or disconnect the electrical components and assemblies, i.e. boards, cables,

connectors, etc., unless this manual contains instructions to do so.

2. Do not remove electrical components and assemblies from the metal carrier or enclosure

unless instructed by this manual or by technical support.

3. Do not touch the conductive parts of the test leads when a measurement is taken.

4. Do not short two test points together or short a test point to any other part.

5. Keep the replacement components inside of the protective packaging until ready for

installation.

6. Place a removed component board-side-up on an antistatic surface or in a static-shielding

container.

ESD SAFETY INSTRUCTIONS

OTHER SAFETY INSTRUCTIONS

Trained and authorized personnel only should service equipment or remove covers.

Use the tools and the equipment specified in this manual for the performed task.

7. When finished servicing equipment, perform functional check and maintenance

procedures listed in this document and in the User Guide.

8. Use this document as a guidance. Contact technical support when help is needed

10

Progey Vantage® Panoramic X-ray System

Technical Service Manual

How to Use This Manual

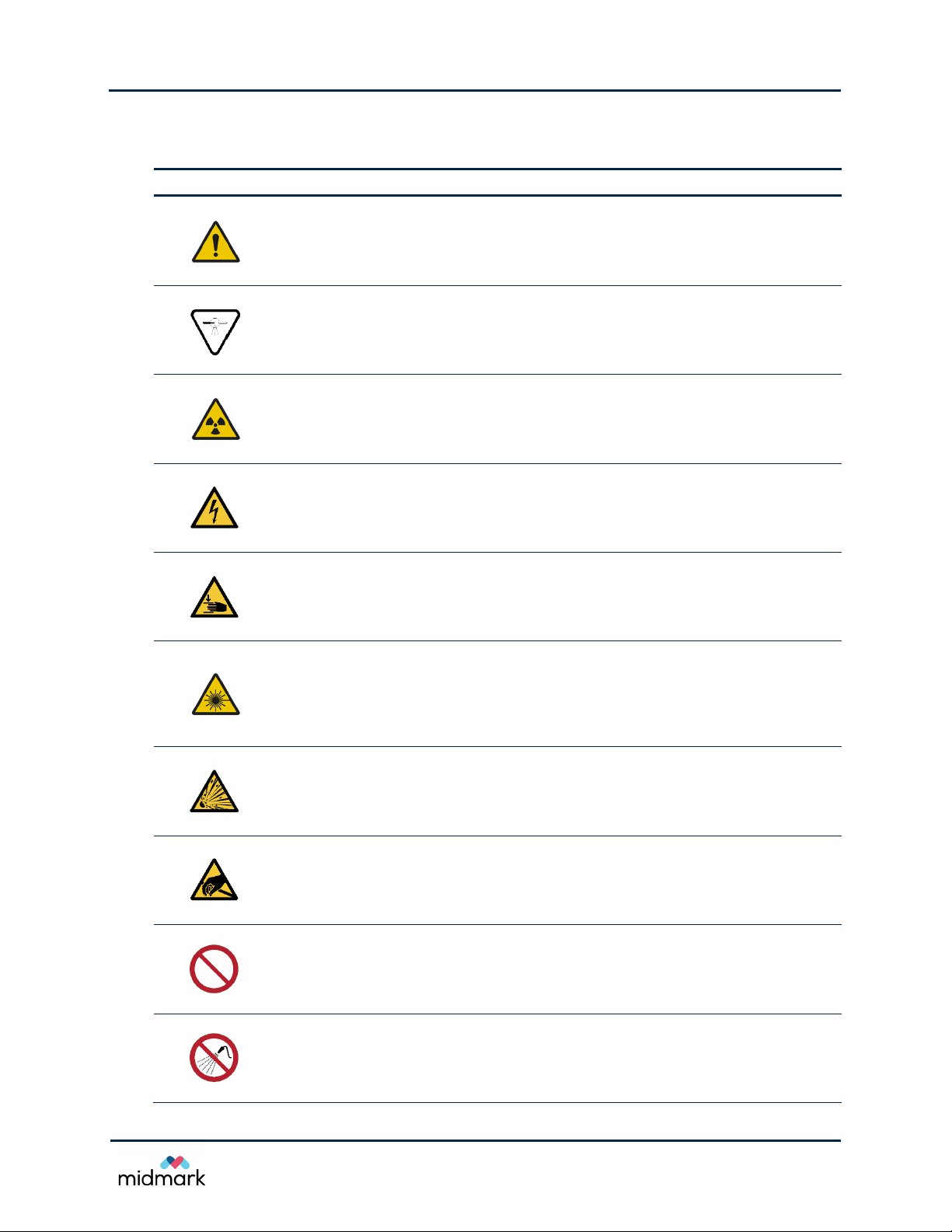

Symbol

Explanation

General warning sign

Advice

s with

the

if the hazardous situation is not explained next to the sign.

Caution

Advice

Attention

Conseils pour la présence de rayons X liées situation dangereuse

Warning

Advice

Warning, Electricity

Advice

Warning, Crushing of hands

Advice

Caution

Advice

sources

Warning

Advice

used

Caution, Electrostatic sensitive devices

Advice

devices.

General prohibition sign

Advice

an action specified by the supplementary sign.

Do not spray with water

Advice

spraying with water on

Symbols and Conventions

written instructions in the User Guide, Installation Manual, and Service Manual

for the presence of a hazardous situation. The operator must consult

X-ray

for the presence of X-ray related hazardous situation.

: Rayons-X

.

, Ionizing Radiation (X-ray)

for the presence of X-ray related hazardous situation.

for the presence of dangerous electricity.

for the presence of a dangerous closing motion of mechanical parts.

, Laser beam

for the presence of a dangerous laser beam. This device contains laser

that are:

, Explosive material

for the ability of this equipment to cause explosion when this equipment is

near or when handling explosive materials.

that the package or this equipment contains electrostatic-sensitive

for presence of a hazardous situation that will be prevented by not doing

for presence of a hazardous situation that will be prevented by not

this equipment.

Class 2 Laser Product

650 nm, 3 mW

11

Progey Vantage® Panoramic X-ray System

Technical Service Manual

How to Use This Manual

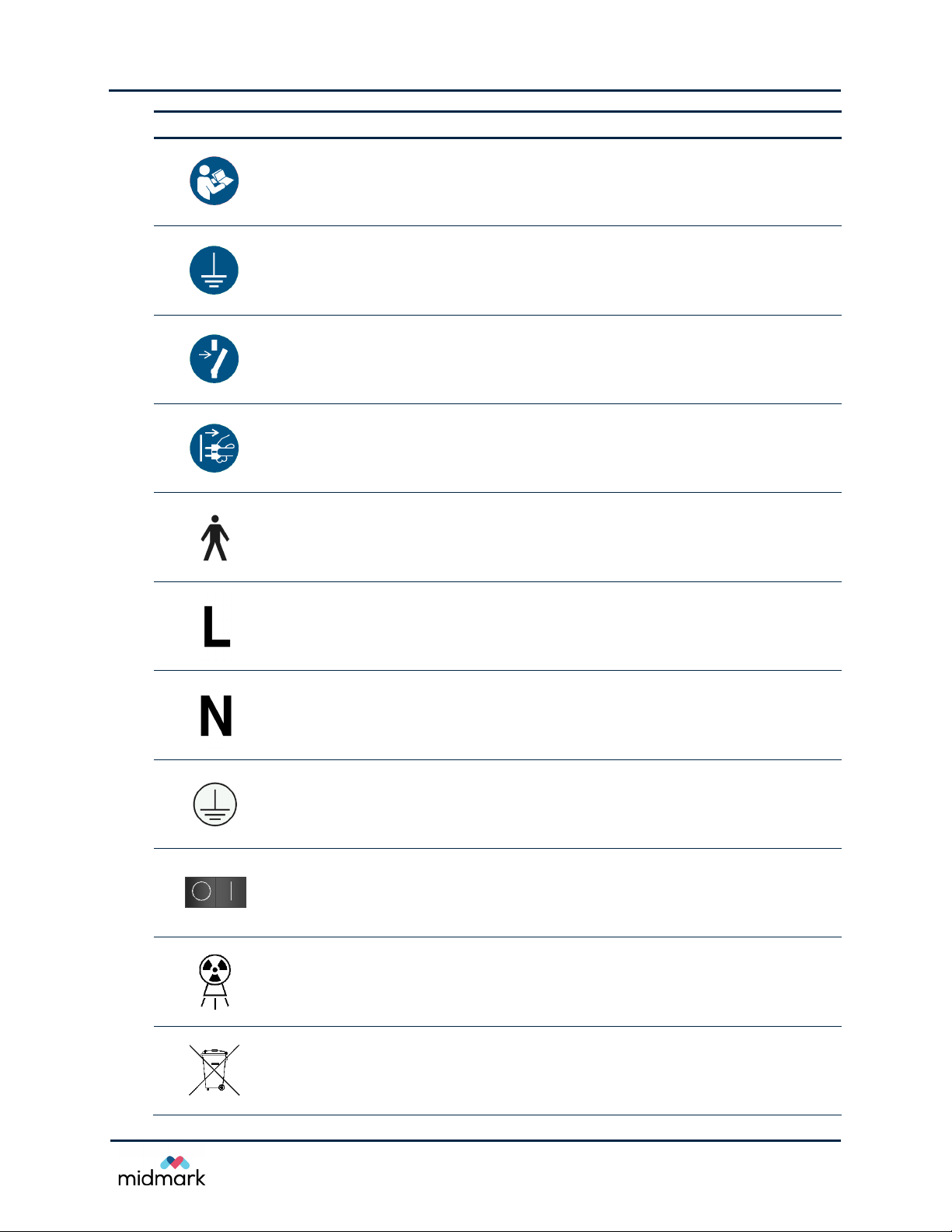

Symbol

Explanation

Refer to instructio

Advice that the operator must r

as the

Connect an earth terminal to the ground

Advice

conductor of power

Disconnect before carrying out maintenance or repair

Advice

disconnected from all sources of power before carrying out maintenance or repair.

Disconnect mains plug from electrical outlet

Adv

outlet for the purposes of maintenance of electrical equipment, in the case of

malfunction or when left unattended.

Type B applied part (IEC 60601

T

ap

Connection point for the line conductor

Shows the connection point for the

mains

Connection point for the neutral conductor

Shows the connection point for the

mains

Protective Earth (Ground)

Shows the connection point for the protective earth (ground) conductor.

Indicate connection to the power

X

Indicates the emission of X

Separate collection for electrical and electronic equipment according

Directive

Advice

2002/96/EC (WEEE) and

therefore must be disposed as electrical or electronic equipment in E.U.

n manual/booklet

ead and understand all enclosed documents such

User Guide, Installation Manual, and Service Manual.

that this equipment must be connected to a protective earth (ground)

supply mains.

that the equipment, which is not connected to mains by a plug, has to be

ice that the mains plug of the equipment must be disconnected from electrical

-1)

his device provides protection against electric shock as required for Type B

plied parts per IEC 60601-1.

ungrounded conductor of the power supply

(a.k.a. line or hot wire).

grounded conductor of the power supply

(a.k.a. neutral wire).

Terminal

mains:

• Power OFF (circle)

• Power ON (line)

-ray source assembly, emitting

-radiation.

2002/96/EC (WEEE)

that this Progeny Vantage® is subject to Directive

12

Progey Vantage® Panoramic X-ray System

Technical Service Manual

How to Use This Manual

Parameter

Specification

X

Constant potential

and current

X

Canon (

Focal spot size

0.5

Total Filtration

Anode Voltage

(internal control)

50

Regulated to ±

Anode Current

4

Regulated to ±

anode power of 1140

Exposure

Panoramic:

Cephalometric:

Precision

Cooldown Time

Automatically controlled based

SID

Panoramic:

Cephalometric:

Magnification

Panoramic:

Cephalometric:

Image pixel size

96

CCD active area

Panoramic:

Cephalometric:

Image field

Panoramic:

Cephalometric:

Pixels

Panoramic:

Cephalometric:

Specifications

-ray source

-ray Tube

Time

(DC), with microprocessor controlled time, voltage,

.

Toshiba) D-054SB, rated max 1750 W

mm2 (IEC 60336:2005)

min 3.2 mm Al

kV to 84 kV

10% of the indicated value.

mA to 14 mA

20% of the indicated value and limited by the total

W.

2.5 s to 16 s

9 s to 15.6 s

: 50 ms plus ± 5% of the indicated value.

per exposure

500 mm (approx. 20 in.)

left, 1645 mm (approx. 64.75 in.)

right, 1670 mm (approx. 65.75 in.)

1.2 ± 0.05 in horizontal and vertical direction

1.1 ± 0.05 in horizontal and vertical direction

μm × 96 μm (after 2 × 2 binning)

6 mm × 147 mm (approx. 0.24 in. × 5.8 in.)

6 mm × 221 mm (approx. 0.24 in. × 8.7 in.)

14 cm × 30 cm (approx. 5.8 in. × 12 in.)

21 cm × 30 cm (approx. 8.2 in. × 12 in.)

1509 lines x 3180 columns, 16-bits per pixel

2288 lines x 3180 columns, 16-bits per pixel

on the X-ray tube heat load.

13

Progey Vantage® Panoramic X-ray System

Technical Service Manual

How to Use This Manual

Parameter

Specification

Image Transfer Time

Panoramic:

Cephalometric:

Image data size

Panoramic:

Cephalometric

Attenuation Equivalent

of Image Receptor

max 0.4

Electrical Safety

Classification

Class I, Type B

Rated

max 20

Duty Cycle

Approx.

Heat Dissipation into

Surrounding Air

max 320

Operating Temperature

+10

Storage Temperature

-

Maximum Altitude

3000

Line Voltage

max 30 s

max 45 s

average 11.8 MB

: average 17.4 MB

mm Al

110 V – 240 V, 50 Hz or 60 Hz

A (long term 1 A) measured at 110 V

1:30

J (approx. 0.3 BTU)

°C to +35 °C (+50 °F to +95 °F)

35 °C to +66 °C (-31 °F to +150 °F)

m (approx. 9842 ft.)

Obtaining Technical Support

For technical support, contact:

MIDMARK CORPORATION

1001 Asbury Drive

Buffalo Grove, Illinois 60089 U.S.A.

Phone: 800-MIDMARK (1-800-643-6275)

+1 847-415-9800, ext. 108126

Fax: 847-415-9801

imagingtechsupport@midmark.com

Hours: 8:00 a.m. – 5:00 p.m. Central Time

14

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Theory of Operations

2 Theory of Operations

In this Chapter

• System Overview

•

About the Components

•

Operational Systems

System Overview

Panoramic radiography is a branch of tomography, particularly a branch of rotational tomography.

Images of internal structures of the jaw are created by moving the source and receptor in such a way

as to cause the foreground and background structures to blur, leaving a defined focal trough.

Cephalometric radiography is craniofacial radiography of the bony parts and soft tissue of the head.

It uses parallel X-ray technique to preserve the distance and angle relationship between the anatomic

landmarks.

System Description

The Progeny Vantage® panoramic X-ray system is a computer-controlled multi-axis dental panoramic

and cephalometric radiographic device incorporating:

• X-ray source

• Digital X-ray receptor

• Distributed processing

• WVGA LCD touch screen based operator panel

®

The Progeny Vantage

motorized, 3-speed, telescoping column. Multiple lasers are used to locate the patient and configure

the device to the patient’s morphology.

The outer portion of the column, the fixed column, is mounted to the wall and/or floor. It supports the

inner, moving, or telescoping portion of the column. This inner, telescoping column supports both the

patient positioning table and the overhead arm. The overhead arm supports the C-arm, which in turn

supports the X-ray source, or tubehead, and the panoramic X-ray receptor, or panoramic sensor. The

cephalometric attachment is an accessory that is installed to the highest point of the column. It

contains a cephalometric support arm and a cephalometric scanning mechanism. The scanning

mechanism supports the cephalometric sensor and the cephalometric scanning mechanism.

panoramic X-ray device is adjustable to the patient’s height with the

Powering the panoramic X-ray system

The Progeny Vantage® system employs a universal power supply with automatic input voltage

selection and is suitable for most dental offices worldwide. The Progeny Vantage

connected to power supply mains with voltage in the range of 110 V to 240 V and frequency 50 Hz or

60 Hz. The device should be connected also to protective earth (ground) through dedicated wire

incorporated in the power cable or provided separately.

®

device should be

Network Communications

The Progeny Vantage® device employs a fixed, dedicated network between the components inside

of the machine. The Progeny Vantage

®

also uses connection to an external Ethernet based Local

15

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Theory of Operations

Area Network (LAN) that allows images to be transferred from the device to any client computer

connected to that network and running the client software. At least one client computer should be

designated to receive the acquired radiographic image at any given time.

Distributed Processing

The Progeny Vantage® is a multi-processor system. Each system monitors itself and reports errors

to the Operator Panel.

The separate processing systems are:

• Real Time Controller (RTC, or system controller) together with the combined X-ray power and

logic boards, and all motor controllers

• Image sensors

• Operator panel

Inter-module communications utilize Ethernet based network, with power over Ethernet (PoE) switch

being located below the patient positioning table.

Movement profiles and the X-ray technique factors are stored in the Real Time Controller and initiated

by communications from the Operator Panel and by the exposure switch. The RTC controls the

motion produced by the individual motors via commands send thru a dedicated serial link. The RTC

also controls the X-ray generation by commands send to the power and logic boards via a second

serial interface.

Software Architecture

The three separate processing systems run a software to control all aspects of device operation. The

operator panel keeps track of overall system operation, communicating with all subsidiary processors.

The remaining processing systems (RTC and X-ray sensors) all report status to the operator panel,

where the appropriate operations are initiated. Movement and X-ray control are handled by the RTC,

under the parameters communicated to it by the operator panel. The sensor performs all initial

collection and processing of the image before delivering it to the operator panel, wherein secondary

image processing is applied. All system user settings are maintained on the operator panel.

Mechanical and X-ray calibration information are maintained on the RTC and X-ray controller

respectively. The sensor calibration information is maintained on the operator panel and on the

sensor, depending on the level of the calibration information (high vs. low). The processing systems

move together through the various states used to produce the device functions.

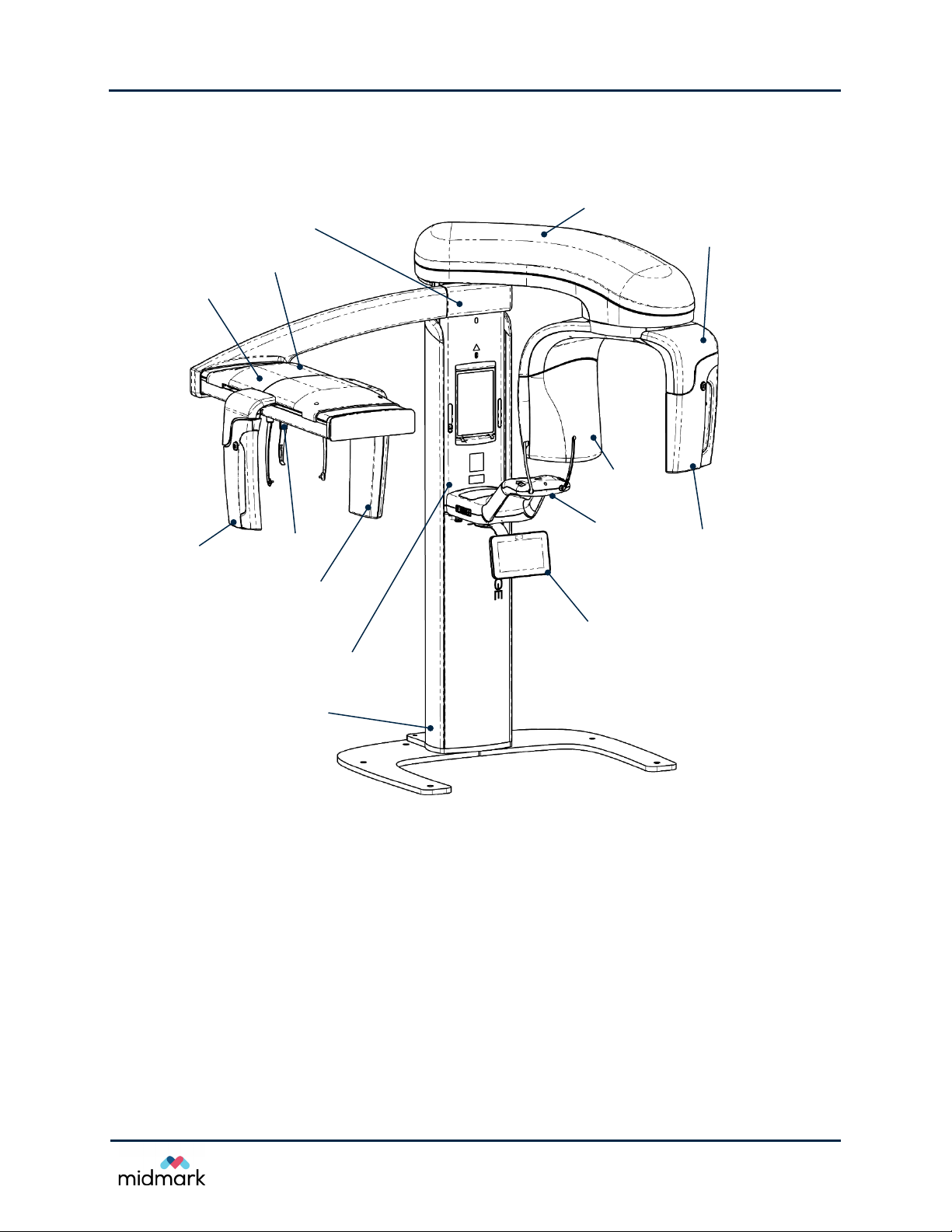

About the Components

The Progeny Vantage® panoramic X-ray system includes the following components.

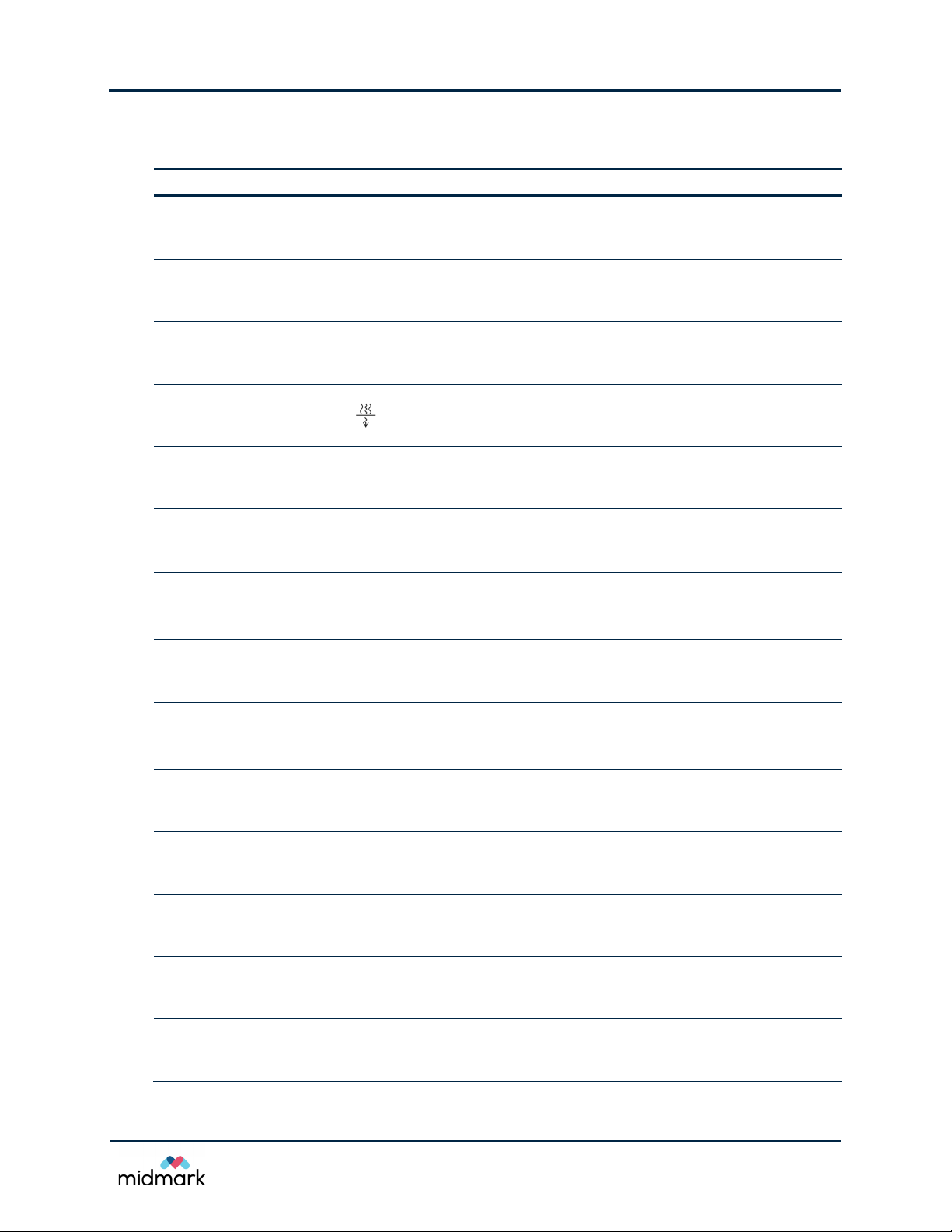

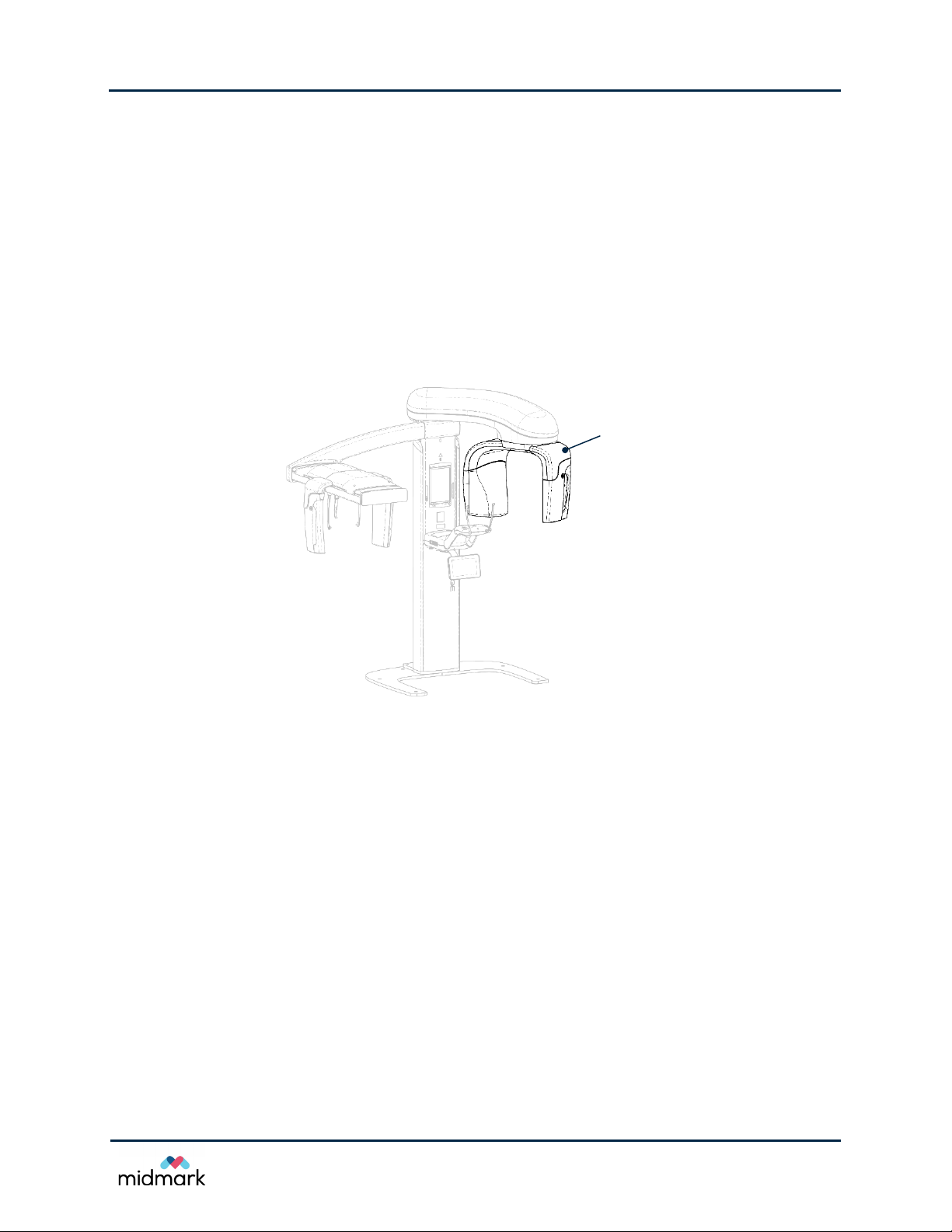

Vertical Column

The vertical column has two main parts: the fixed section and the moving, or telescoping, section.

The fixed section contains the actuator to control up and down movement of the panoramic X-ray

device. The telescoping section contains the positioning lasers. Optical sensors in the telescoping

section define the maximum and minimum extension of the column.

16

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Theory of Operations

Telescoping Section

Fixed

Patient Table

The column is comprised of two extrusions, connected by bearings and a linear actuator. The

bearings are adjustable to align the extrusions to each other, and to minimize slop. The linear actuator

is a gear driven screw with integral brake. The column, actuated by a push button operator panel

located on the side of the patient positioning table, moves at three progressively faster speeds, with

a smooth transition between speeds.

Vertical column

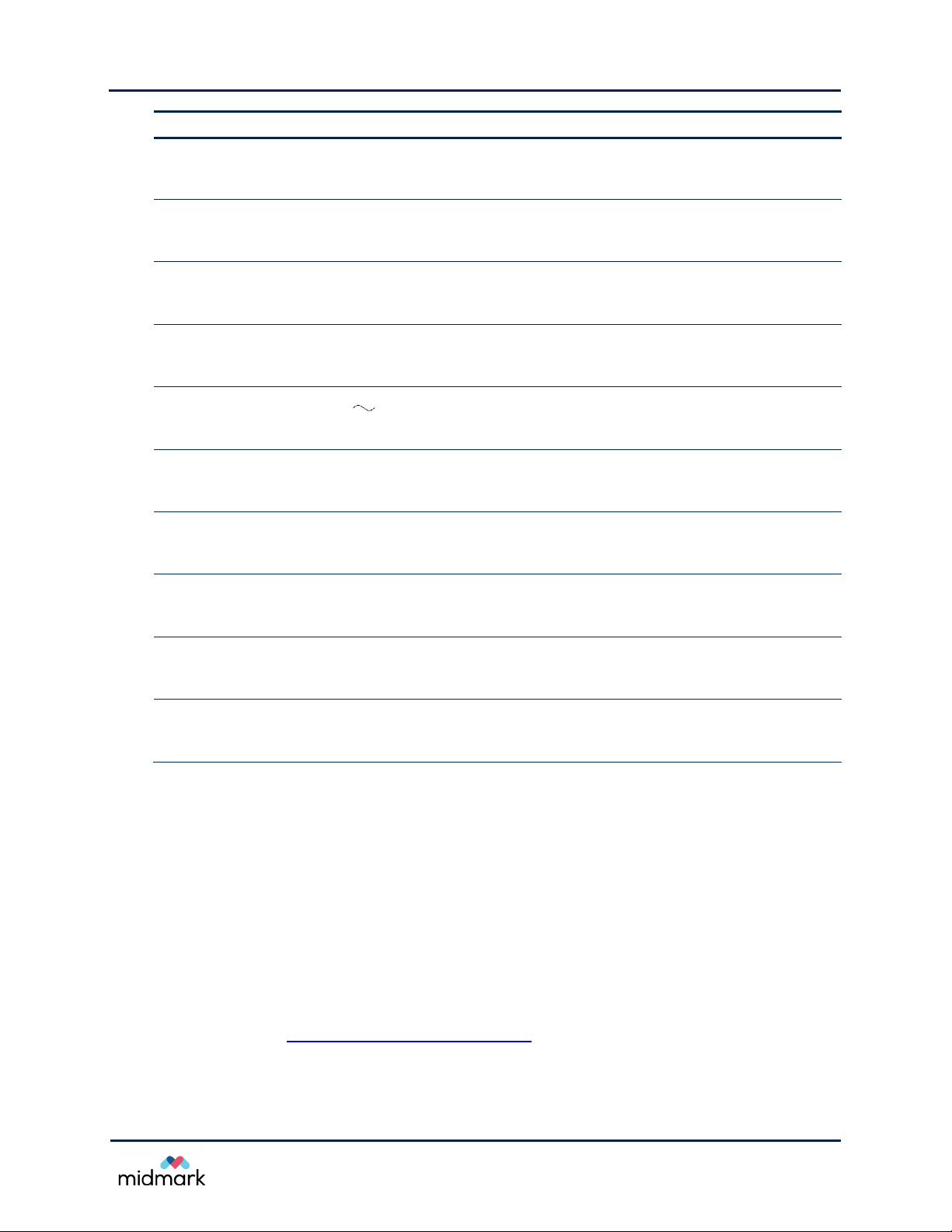

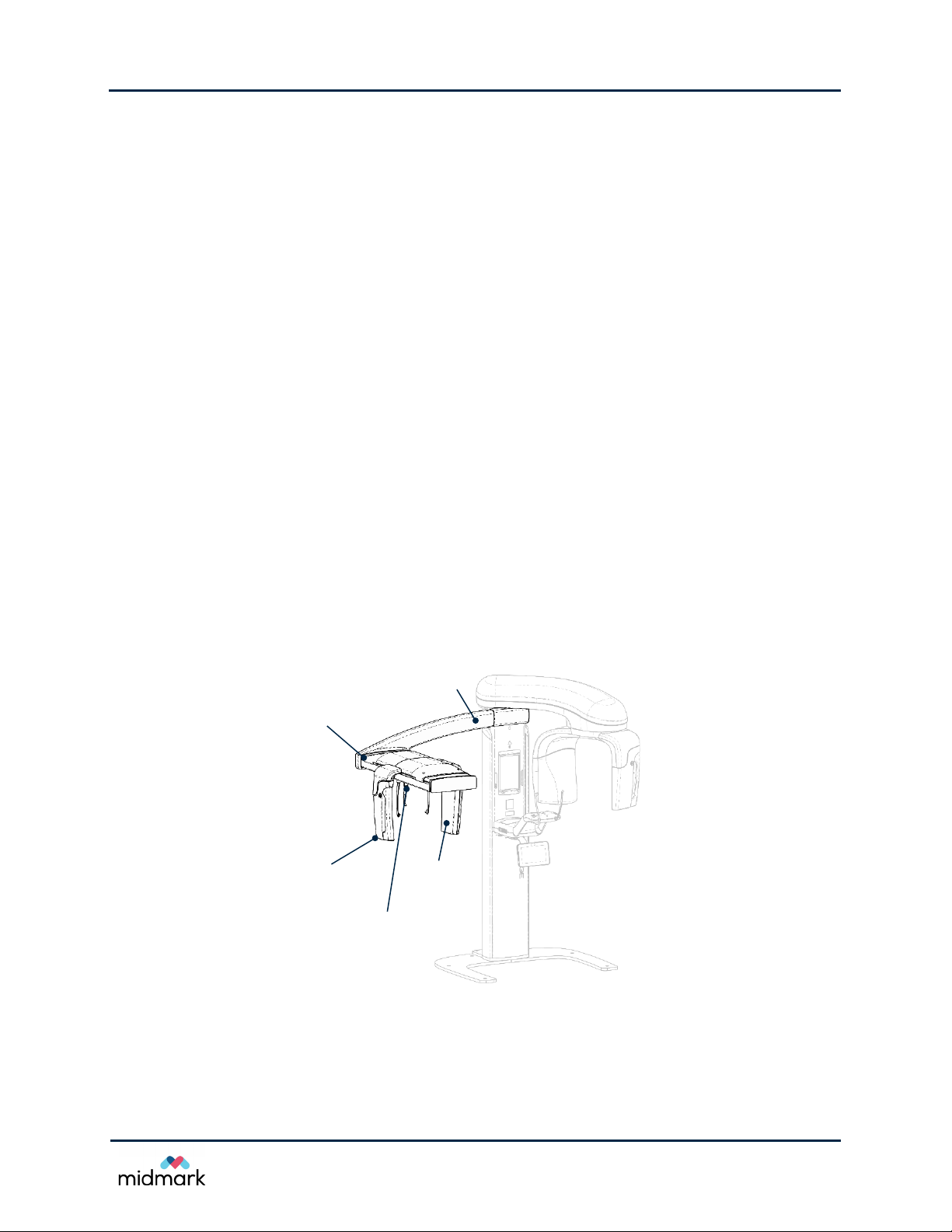

Patient Positioning Table

The patient positioning table guides and supports the patient during acquisition of panoramic X-ray

images by means of the chin rest, bite guide, and positioning wands.

Correct and repeatable patient positioning is essential to producing a clinical-quality image. Patient

positioning is accomplished by the telescoping column, the temple wands, and the reference lasers.

All of these subsystems are actuated by a push-button panel located on the left and the right sides of

the patient positioning table.

The temple wands are located on either side of the chinrest/bite piece assembly. The wands use a

spring to close against the patient’s head, and a motor to open. The maximum opening is controlled

by an optical sensor mounted inside the positioning platform. At any point, the wands can be manually

opened further against the spring.

Patient positioning table

17

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Theory of Operations

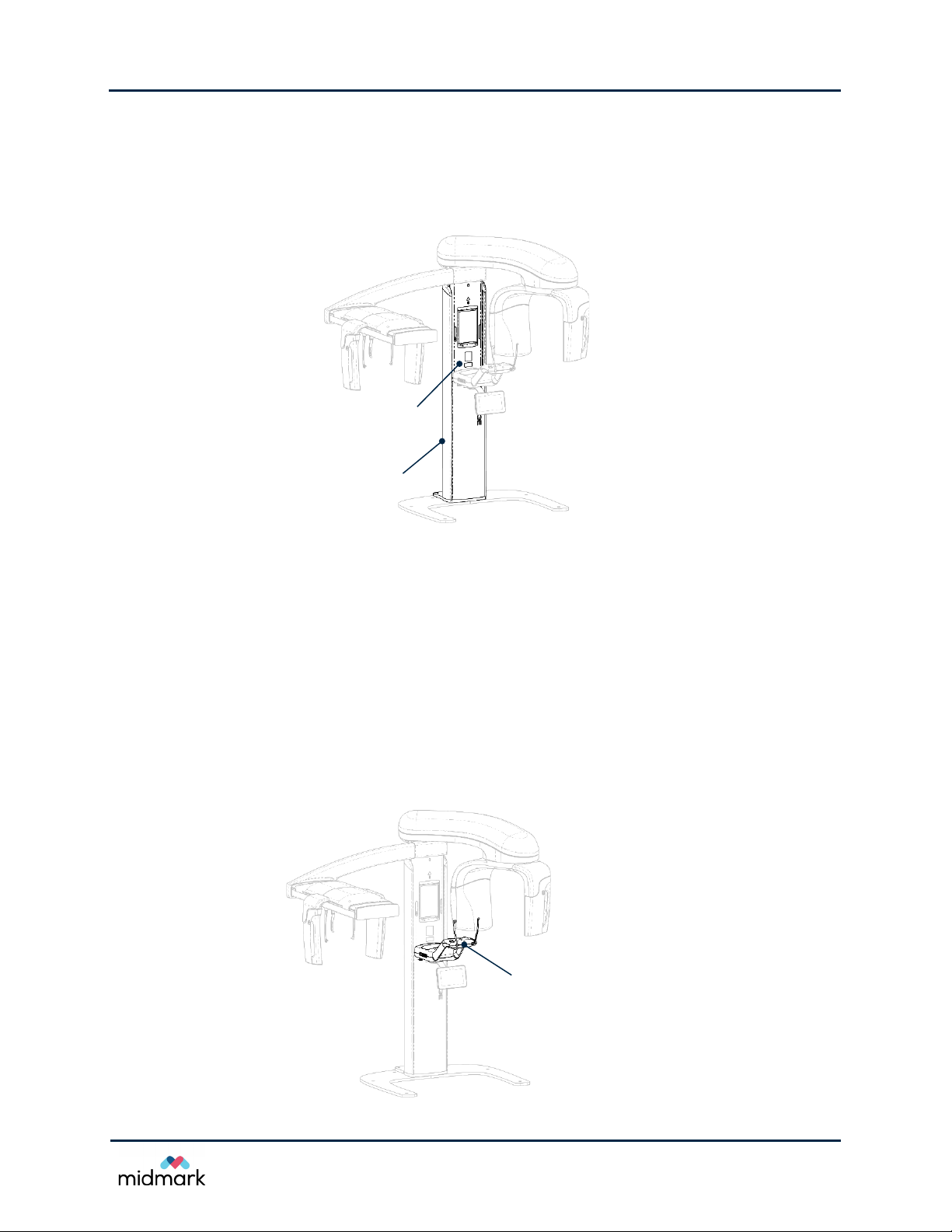

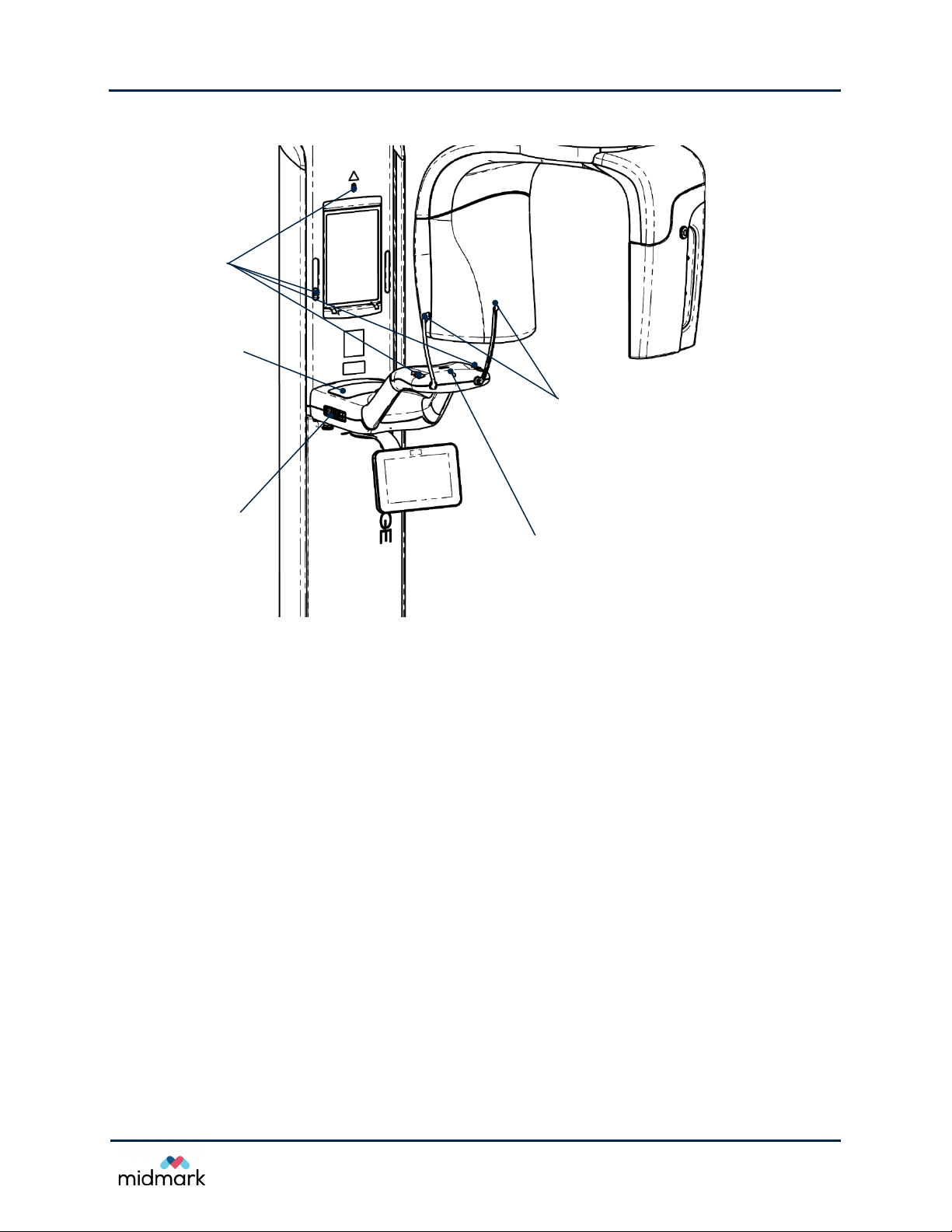

Operator Panel

Operator Panel

The operator panel, mounted under the patient positioning table, acts as the user interface for the

device. It is connected to and powered from the column computer. The operator panel and the column

computer, together, provide top-level control on the Progeny Vantage

commands given via touch screen interface in the operator panel.

Operator panel

®

device based on user

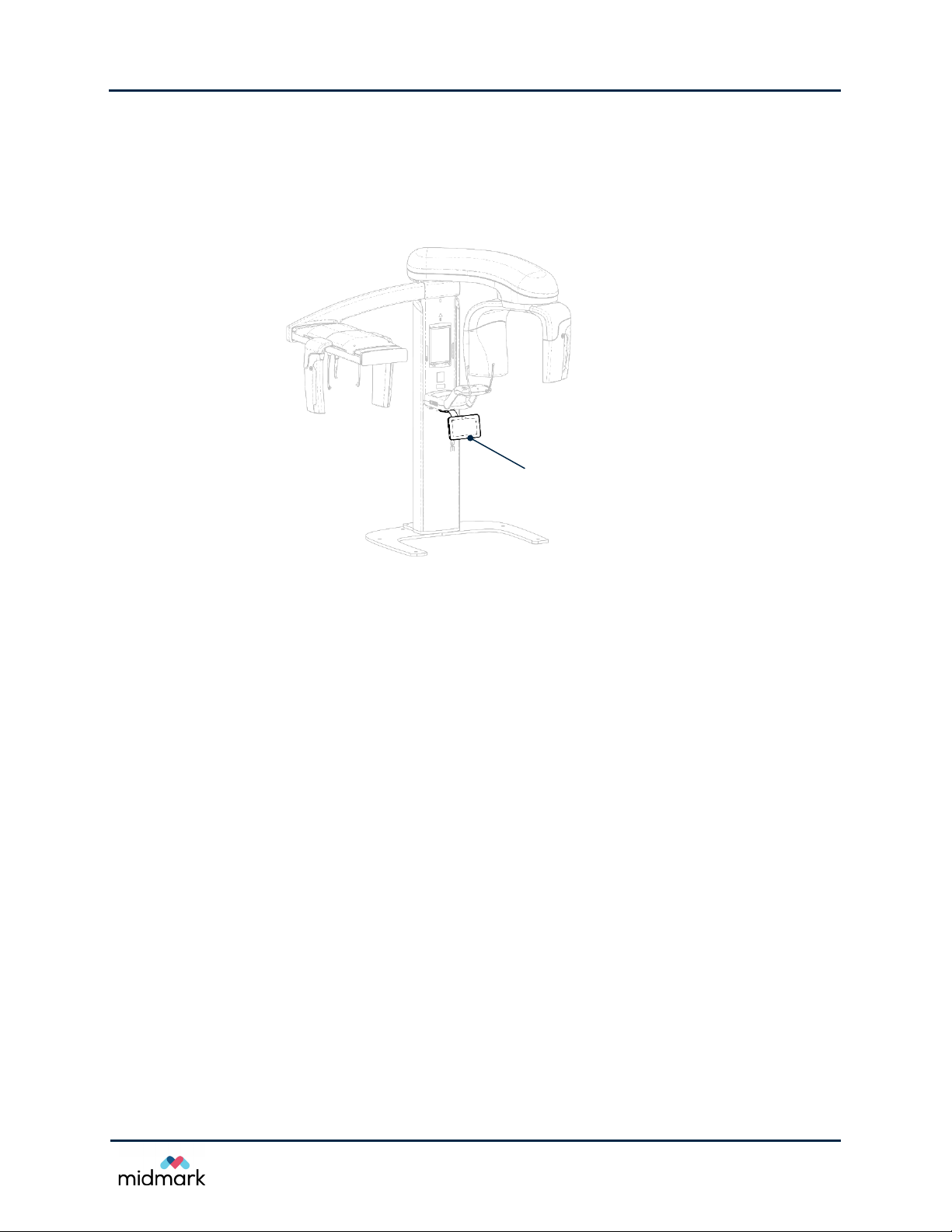

Column Computer

The column computer, mounted on the lower half of the telescoping section of the column, acts as

interface controller to the machine and provides the basic image processing. It has two network

interfaces, one connected to the in-machine network, and the other connected to the office LAN. The

column computer is powered through the 48 V power supply embedded in the column carrier board

located below the patient positioning table.

The column computer is a PC with x86 compatible processor and Windows operating system.

®

Progeny Vantage

software comes installed on the column computer, as do the sensor calibration

files. The software on the column computer provides top-level control on the Progeny Vantage

based on the touch screen commands given by the operator panel. The software also transfers the

image to the Client computer for further processing and storage.

Lasers

There are four reference lasers for locating the patient’s head relative to the device: the Median

(midsagittal) plane, the Frankfort plane, and two Cuspid plane lasers.

The Median (midsagittal) plane provides the vertical center plane reference. It is a fixed laser and is

located on the telescoping section of the column behind the upper cover.

The Frankfort plane provides a horizontal planar reference, and is adjustable vertically to correspond

to the patient’s physiognomy. It is mounted to the inside of the upper column cover, and is mountable

to either the left or the right side of the column upper cover.

The Cuspid lasers are mounted within the patient positioning table and are directed by mirrors up to

the patient’s mouth. The Cuspid lasers are carried on a transit that moves fore and aft. The transit

movement is reported to the real-time controller (RTC) by a slide potentiometer. To define the zero

position for the Cuspid lasers, a hole in the transit is aligned with a similar hole in the patient table

using a precision pin.

®

device

18

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Theory of Operations

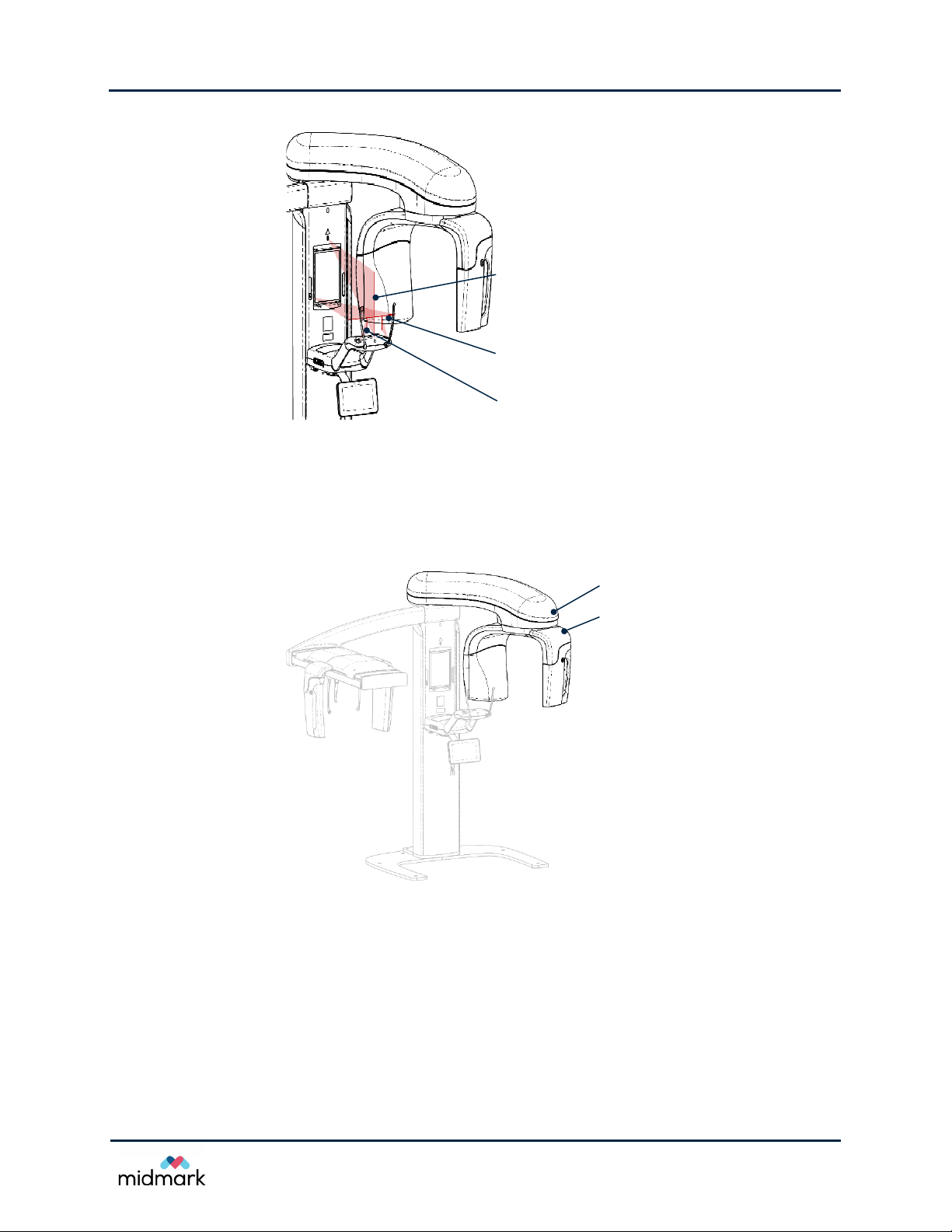

Median (midsagittal) plane

Frankfort plane

Cuspid plane

Overhead Arm

C-arm

Lasers

Overhead Assembly

The overhead assembly consists of an overhead (swing) arm and C-arm. The overhead arm supports

the C-arm, which rotates. The C-arm includes the tubehead and the removable sensor. The tubehead

produces the X-ray beam, and the sensor is a digital image receptor.

Overhead assembly

Overhead Arm – Y-axis

For the lateral Y-axis motion, the overhead arm pivots about bearings located in the mounting casting

fastened at the top of the column. Its motion is produced by a ball screw drive with one end connected

to the mounting casting and other end to the overhead arm itself. The stepper motor is near the

column. Both mechanical connections of the drive assembly are through ball bearing assemblies.

An optical sensor on the mounting casting engages a flag on the overhead arm to define a home

reference for the system. Motion is monitored by a potentiometer connected to the ball bearings at

the column end of the drive assembly. To define the zero position for the system, a hole in the swing

arm is aligned with a similar hole in the mounting casting using a precision pin.

19

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Theory of Operations

C-arm

Overhead Arm – X-axis

For the in-and-out X-axis motion, the translation drive of the overhead arm (X-axis) is comprised of a

plate mounted on linear bearings attached to the overhead arm casting. The plate is moved by a

backlashless screw drive with a stepper motor on the fixed end. Position feedback is via a linear

potentiometer with an optical sensor and flag for home reference. A hole in the plate aligns with a

hole in the overhead arm casting using a precision pin to define a system zero position.

C-arm

The C-arm is suspended on a pair of bearings mounted to the underside of the X-axis translation

plate. The C-arm casting incorporates an internal tooth ring gear that meshes with a pinion gear on a

stepper motor mounted on the X-axis translation plate. The motor is spring loaded to maintain positive

mesh and minimize slop.

C-arm

X-ray Source

The X-ray tubehead contains a high-frequency X-ray source that uses a stationary anode X-ray tube

(See Appendix in Progeny Vantage

that is comprised of a power board and a logic board controls and monitors the operation of the X-ray

tubehead. The operation of this circuit is governed by the RTC and is locally controlled by

microprocessor on the logic board. Power for the X-ray source is derived directly from the power

supply mains.

There are no serviceable parts inside of the X-ray tubehead and it must not be opened in the field.

Opening the X-ray tubehead will compromise the high-voltage and X-ray protections embedded

inside of the device and may endanger patient and operator.

The primary collimator is mounted on the output port of the X-ray tubehead. The collimator is a 2-axis

motorized automatic beam-limiting device, whose operation is governed by the RTC and locally

controlled by a motor controller. The two axes are controlled by a single motor controller in sequential

manner. A relay mounted the collimator (motor controller) carrier board directs the motor drive current

as appropriate for the controlled collimator axis.

®

User Guide for X-ray tube information). The X-ray control unit

20

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Theory of Operations

X-ray Control Unit

X-ray Tubehead

Primary Collimator

Cephalometric Sensor

Panoramic Sensor

X-ray source

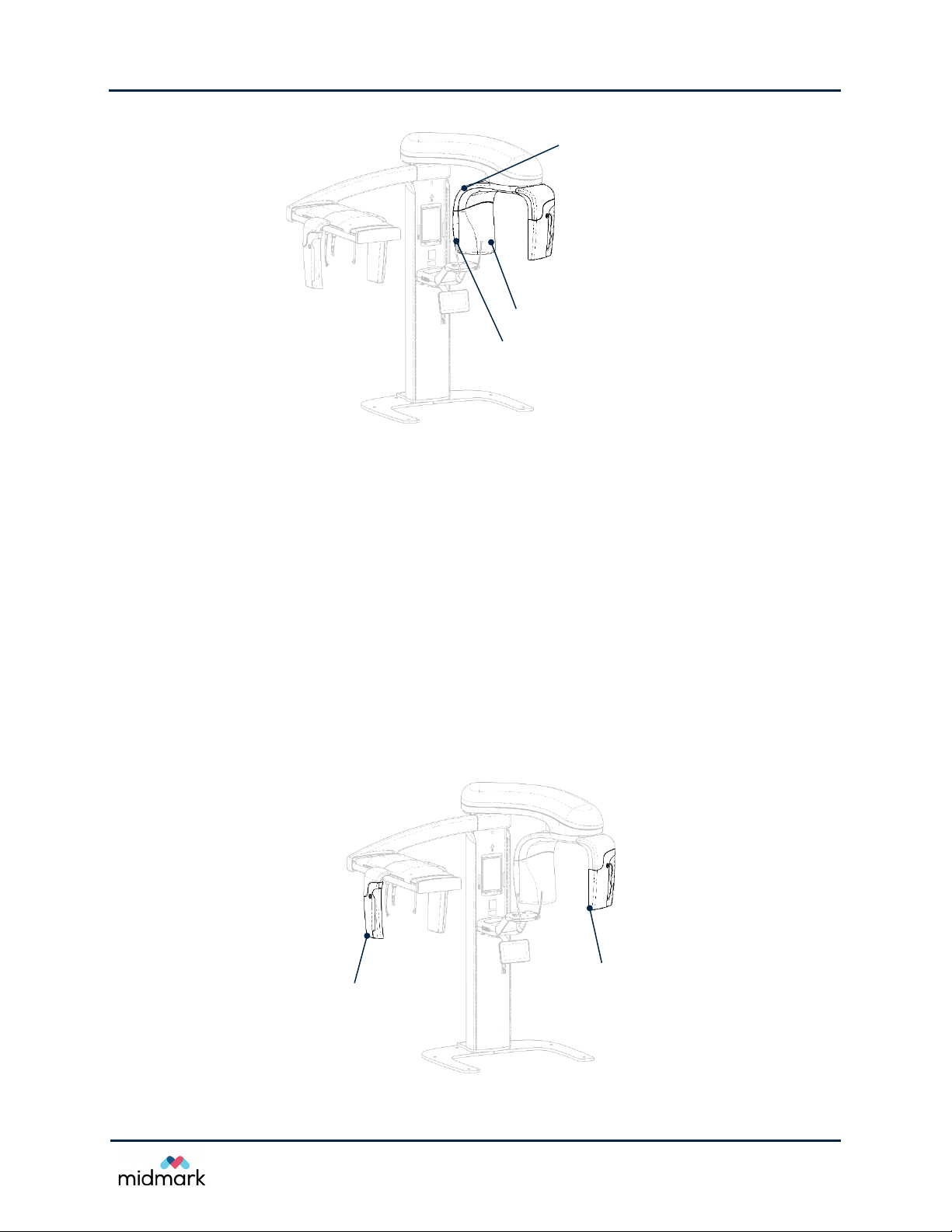

X-ray Sensors

The image sensor detects X-rays and manipulates the detection to produce an image. It contains a

very large X-ray camera that converts the X-ray to electrical signals, precise circuitry that processes

these signals, frame memory that stores the image between the imaging sessions, and

microprocessor that controls the sensor operation and communicates with the column computer via

an Ethernet connection. The device is powered through the Ethernet connection from the PoE switch

located below the patient table.

The X-ray sensor circuitry is sensitive to impact and the device must be handled with care. There are

no serviceable parts inside of the X-ray sensor and it must not be opened in the field. Opening the

sensor will compromise the X-ray performance of the device and may endanger the patient.

®

The Progeny Vantage

sensor. The difference between the two types is the size of the X-ray active area. The cephalometric

sensor has 50% larger active area than panoramic sensor and therefore the cephalometric sensor

may be used as a panoramic sensor, but the panoramic sensor cannot be used as a cephalometric

sensor.

supports two types of X-ray sensors – panoramic sensor and cephalometric

X-ray sensors

21

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Theory of Operations

Cephalometric

Sensor

Secondary

Collimator

Cephalostat

Support Arm

Scanning

Mechanism

The X-ray sensor implementation automatically converts the cephalometric sensor to panoramic

sensor based on the position ID reported from the floating connector board embedded in the sensor

mount on the C-arm or on the cephalometric transit. In addition, the sensor mount on the

cephalometric transit and the cephalometric sensor contain a mechanical key that do not allow a

panoramic sensor to be attached to the cephalometric accessory. This mechanical key consists of a

pin attached to the sensor mount on the cephalometric transit and a hole embedded in the

cephalometric sensor.

Cephalometric Attachment

The Cephalometric Extension consists of the support arm, the cephalometric scanning mechanism,

and the cephalometric sensor.

Support Arm

The support arm is an aluminum casting that mounts to the panoramic column’s inner (mobile)

component. It mounts via a support casting that allows vertical adjustment of the position of the

cephalometric mechanism. The arm can be mounted either to the right, or to the left of the column.

Cephalometric Scanning Mechanism

The cephalometric scanning mechanism is comprised of the rail and the transit assembly. The rail

supports the transit mechanism, and houses the motor and bearings that cause the transit mechanism

to move. The transit assembly mounts the cephalometric sensor and the secondary collimator,

maintaining the alignment of the sensor and secondary collimator to the X-ray tubehead.

The rail also supports the cephalostat, used to position the patient. The cephalostat is comprised of

two earposts that adjust to conform to the width of the patient’s head, and a nasion locator, which

adjusts vertically and laterally to align the patient’s head. The entire cephalostat rotates in 45°

increments to support many cephalometric imaging positions.

Cephalometric attachment

Client Computer

The client computer is a computer connected to the same local network where the Progeny Vantage®

device is connected. The client computer executes the Client software designed by Midmark and

exclusively communicates with the operator panel in the process of radiographic image acquisition in

order to obtain, process, and store the acquired image.

22

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Theory of Operations

The client computer could be installed either in close proximity to the Progeny Vantage® machine or

could be located in a dental operatory or other suitable and accessible location. It could be also

permanently or temporary assigned. In case of temporary assigned client computer, multiple

computers could act as client computer, one at a given time.

Operational Systems

The various processing systems in the Progeny Vantage® panoramic X-ray system are stand-alone

modules, each with their own diagnostic procedures.

User Interface

The user interface is provided by a tablet-style operator panel that is connected to the column

computer running the Progeny Vantage

indirect views of the Progeny Vantage

sliding, on the operator panel to interact with the Progeny Vantage

X-ray Generation

For the generation of X-rays, parameters are passed from the operator panel to the RTC defining the

desired technique factors and exposure time. Upon actuation of the exposure switch, the RTC passes

the necessary information to the X-ray controller to produce the desired exposure. The exposure

switch is also connected to the X-ray controller. Upon receipt of the exposure parameters from the

RTC, and the signal from the exposure switch, the X-ray controller then initiates, controls, and

terminates the exposure.

The exposure switch is routed through the emergency stop switch, before it reaches any control

functionality in RTC or the X-ray controller. That will cause the X-ray generation to be interrupted in

case of activation of the emergency stop switch by the operator.

®

interface software. The operator panel provides direct and

®

system. Users use gesture controls, such as swiping and

®

system.

Motion Control

The Progeny Vantage® utilizes eight motors:

• Telescoping column drive motor

• Patient positioning wand motor

• Primary collimator x-axis motor

• Primary collimator y-axis motor

• Swing arm motor (overhead assembly)

• Transition drive motor (overhead assembly)

• C-arm drive motor (overhead assembly)

• Cephalometric transit motor

The column drive is an integral DC linear actuator embedded in the telescoping column. Limit of

motion is governed by flags, mounted on the fixed portion of the column, which are sensed by two

optical sensors mounted on the telescoping portion of the column. The column drive uses a motor

controller board similar to the others, but it is designed to operate a brushless DC motor instead of a

stepper motor.

The positioning wands use a stepper motor to open the wands. Closure of the wands is produced

using a spring. In any position defined by the motor, the wands are free to open against the spring.

The open position of the wands is defined by an optical sensor.

23

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Theory of Operations

The collimator is a 2-axis motorized beam-limiting device. The two axes are controlled by a single

controller in sequential manner. A relay mounted the collimator (motor controller) carrier board directs

the motor drive current as appropriate for the controlled collimator axis.

The tomographic effect needed for panoramic image is produced by a 3-axis, computer-controlled

assembly resident completely in the swing arm of the overhead assembly. The three axes are:

• Y-axis – the swing arm of the overhead assembly, which produces the side-to-side motion

• X-axis – the translation drive of the overhead assembly, which produces the in and out motion

• R-axis – the C-arm drive which produces the rotational motion

®

The cephalometric image in the Progeny Vantage

is produced by 5-axis, computer-controlled motion

– the 3-axis of the swing arm, one additional axis in the cephalometric scanning mechanism, and the

x-axis motion of the collimator.

All motion components except the primary collimator are controlled by separate motor controller

boards and the two axis of the primary collimator are controlled by a single motor controller board.

The boards are linked to the main system controller (RTC) via dedicated serial communication

channel, which addresses each of the motor controllers by their unique address.

All motors are powered by a dedicated motor power supply line (24 V), called motor power, that is

enabled or disabled by RTC also. Each motor controller is set to a power level that corresponds to

the needs of the motor driven.

The motor power is routed through the emergency stop switch. That allows the motion to be stopped

immediately at any time when the emergency stop switch is activated by the operator.

System Diagnostics

The Progeny Vantage® incorporates an extensive diagnostic system to aid in recording and

troubleshooting system errors.

Errors generated by any subsystem are reported to the column computer, which records them in a

log. The errors are reported to the user via a pop-up window. Within the pop-up window is a link to

the system Message Center where the detailed message can be reviewed. The Message Center can

sort system error messages by date, subsystem, and content. Error messages contain a high-level

error number, which identifies the subsystem, and a low-level error number to identify the exact error.

Image Acquisition and Transfer

To produce an image, the motion profile and X-ray technique factors are selected on the operator

panel, and the column computer communicates them to the RTC. When the column computer

receives a command to move to the Ready for imaging (RFI) position, it passes the profile and

technique factors to the RTC, and commands the RTC to move to RFI. After moving to RFI, the RTC

arms itself and arms the X-ray controller. Meanwhile, the column computer has also commanded the

sensor to prepare to receive X-rays.

Upon closure of the exposure switch, the RTC begins providing motion parameters to the various

motor controllers and X-ray parameters to the X-ray controller. This continues for as long as the

exposure switch remains closed, or until the parameters of the profile are exhausted.

When the sensor detects X-rays, it begins recording the image. The sensor continues recording for a

time sufficient for the longest exposure. The sensor transfers a preview image (low resolution) and

final image (high resolution) to the operator panel. The preview image is used to generate progress

indication for the image acquisition. When the operator panel receives the complete final image, it

then processes it with the relevant calibration data and sends the final image to the client computer

for further processing with the user-selected filters. The client computer then stores the image and

passes the image to the imaging application.

If, at any time during the creation of the image, the exposure switch is released (opened), the RTC

immediately ceases transmitting parameters and instead transmits a stop command to the motor

controllers and deactivates the X-ray controller. It also advises the column computer of the

24

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Theory of Operations

Cephalometric

Sensor

Secondary

Collimator

Cephalostat

Overhead Arm

C-arm

Cephalometric Attachment

Scanning Mechanism

Transit

Panoramic

Sensor

X-ray

Tubehead

Operator Panel

Column,

Fixed Section

Patient

Positioning

Tabl e

Column,

Telescoping

occurrence. The X-ray controller detects the release of the exposure switch simultaneously and

independently from the RTC, and terminates the X-ray power immediately even if the stop command

from RTC is not received.

®

Progeny Vantage

panoramic X-ray system

25

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Theory of Operations

Bite Guide and Chin Rest

Attachment Points

Patient Positioning

Controls

Storage

Compartment

Positioning Wands

Positioning

Lasers

Progeny Vantage® patient positioning table

26

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Troubleshooting Resources

3 Troubleshooting Resources

In this Chapter

• Obtaining Assistance through Remote Access

•

Service Kit

•

Message Center

•

Error Logs

Wiring Diagrams

•

•

Printed Circuit Boards

•

Troubleshooting with Printed Circuit Boards

•

Network Communications

Obtaining Assistance through Remote Access

Remote access enables technical support to have access to a Progeny Vantage® panoramic X-ray

system while the service technician is present at the machine.

®

1. Permission from the user is required for access to the Progeny Vantage

®

2. In order to gain access, a connection from the Progeny Vantage

to the Internet is necessary.

.

3. The service engineer must be present at the location.

4. With the active participation of technical support, the “on-site” person will use the operator panel

to gain access to the Internet and log on to a remote access website. Remote access may require

the downloading and activation of a short application program from the website.

5. Once communications are established, technical support will be able to review the content of the

Progeny Vantage

device. Technical support will not be able to facilitate all manner of repairs remotely. Technical

support will be able to review historical events and make recommendations as to the next course

of action. The “on-site” participant must be able to perform the repairs or adjustments in order to

complete the task.

®

Message Center, see images, and make limited changes in the settings of the

Service Kit

Midmark offers a service kit for the alignment and image evaluation of the Progeny Vantage®

panoramic X-ray system that is available through the technical support. The service kit contains the

following fixtures and tools:

• Positioning Laser Alignment Fixture

• X-ray Source Alignment Fixture

• C-arm Calibration Setup Fixture

• Copper Filter

• Zero Position Pins

• Laser Module Assembly

27

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Troubleshooting Resources

• Projection Head Kit

• Molteni Phantom

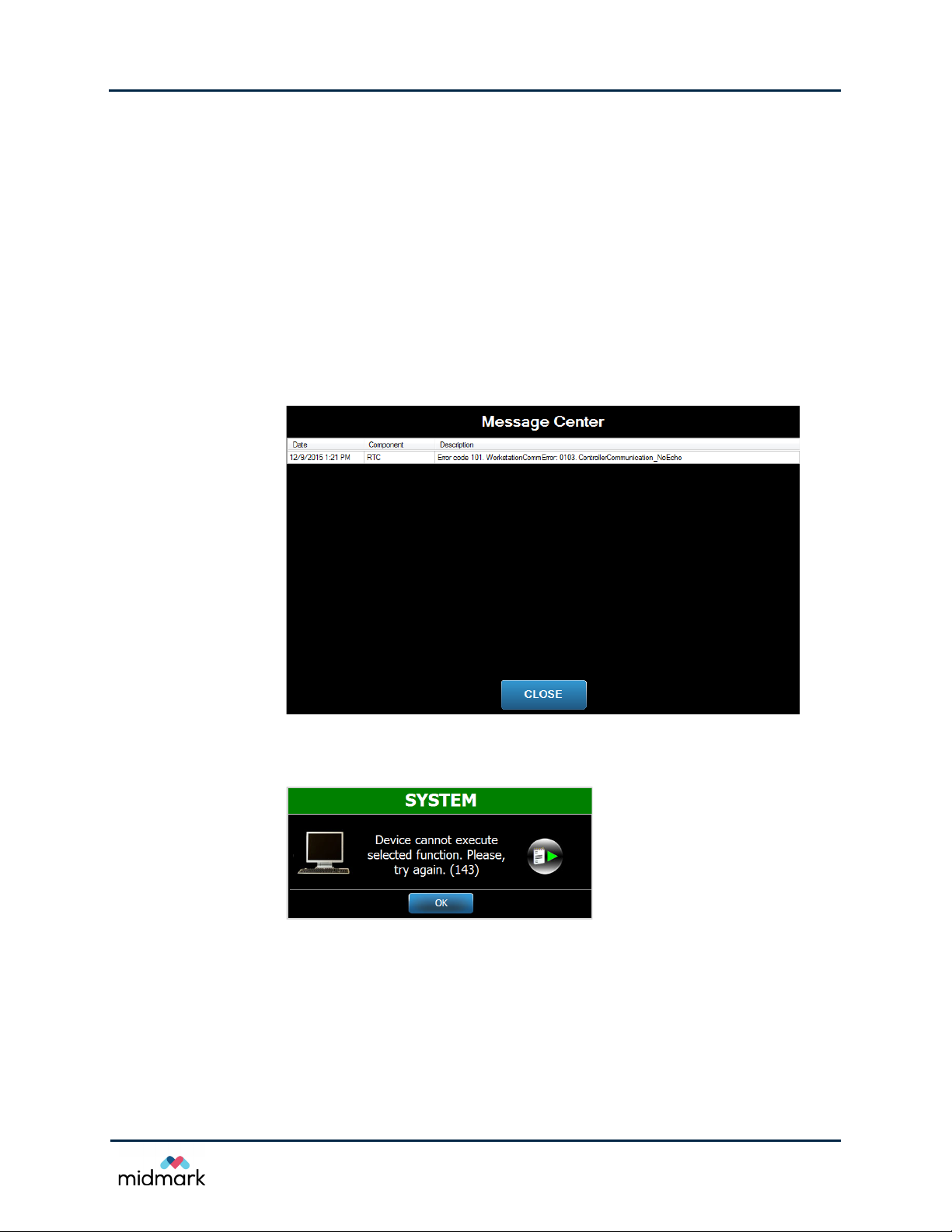

Message Center

The Message Center screen is an interactive screen on the operator panel that displays up to

100 error messages for the components of the Progeny Vantage

are sorted by time, with the most recent at the top of the list.

Tapping a column heading, such as Component, sorts the messages by that heading. Tapping a

Progeny Vantage

component.

®

component, for example the telescoping column, highlights all messages for the

Message Center Screen

®

Panoramic system. The messages

Messages also appear as pop-ups on the operator panel, as illustrated below.

Pop-up Message

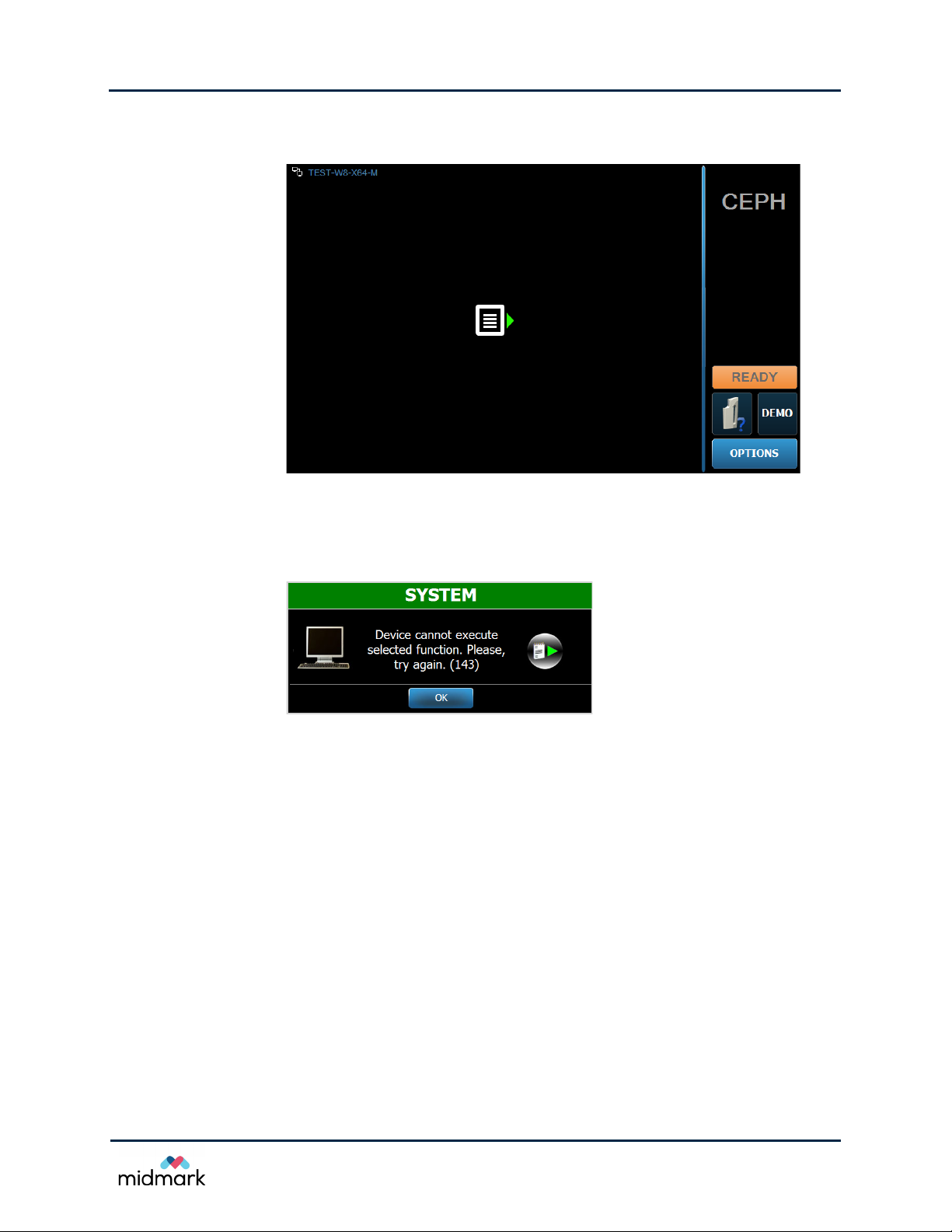

Accessing the Message Center

The Message Center is accessed from the Options screen, from the SAFE or OFFLINE screens, and from

a pop-up message screen.

28

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Troubleshooting Resources

To Access the Message Center from the Options Screen

1. On the Acquisition Setup screen, tap Options to display the Options screen.

Options Screen

2. Tap the Message Center button.

To Access the Message Center from the SAFE or OFFLINE Screens

The SAFE and OFFLINE screens are not directly accessible. The SAFE screen is transitional and

appears when the Progeny Vantage

the operator panel is disconnected from the computer workstation.

On the SAFE screen, tap the Message Center icon to display the Message Center screen.

SAFE Screen

®

system is trying to recover. The OFFLINE screen appears when

29

Progey Vantage® Panoramic X-ray System

Technical Service Manual

Troubleshooting Resources

On the OFFLINE screen, tap the Message Center icon to display the Message Center screen.

OFFLINE Screen

To Access the Message Center from a Message Screen

On the message screen, tap the Message Center icon.

Message Screen

Error Codes

This section lists all the Progeny Vantage® error codes, including system and subsystem errors for

the RTC. These codes help in troubleshooting when trying to pinpoint the source of a problem.

Error codes will either state a condition or offer a direction to investigate. In the case of directly stated

conditions, follow the instruction. In the case of coded messages that indicate a direction to

investigate, review the content of the Message Center for guidance.

Error messages may refer to a node number based on the assigned motor controller address for

communication with RTC as listed below:

• C-arm arm motor is referenced as Node 0.

• X-axis motor is referenced as Node 1.

• Y-axis motor is referenced as Node 2.

• Collimator motors are referenced as Node 3.

• Wand motor is referenced as Node 4.

• Cephalometric motor is referenced as Node 5.

30

Loading...

Loading...