Page 1

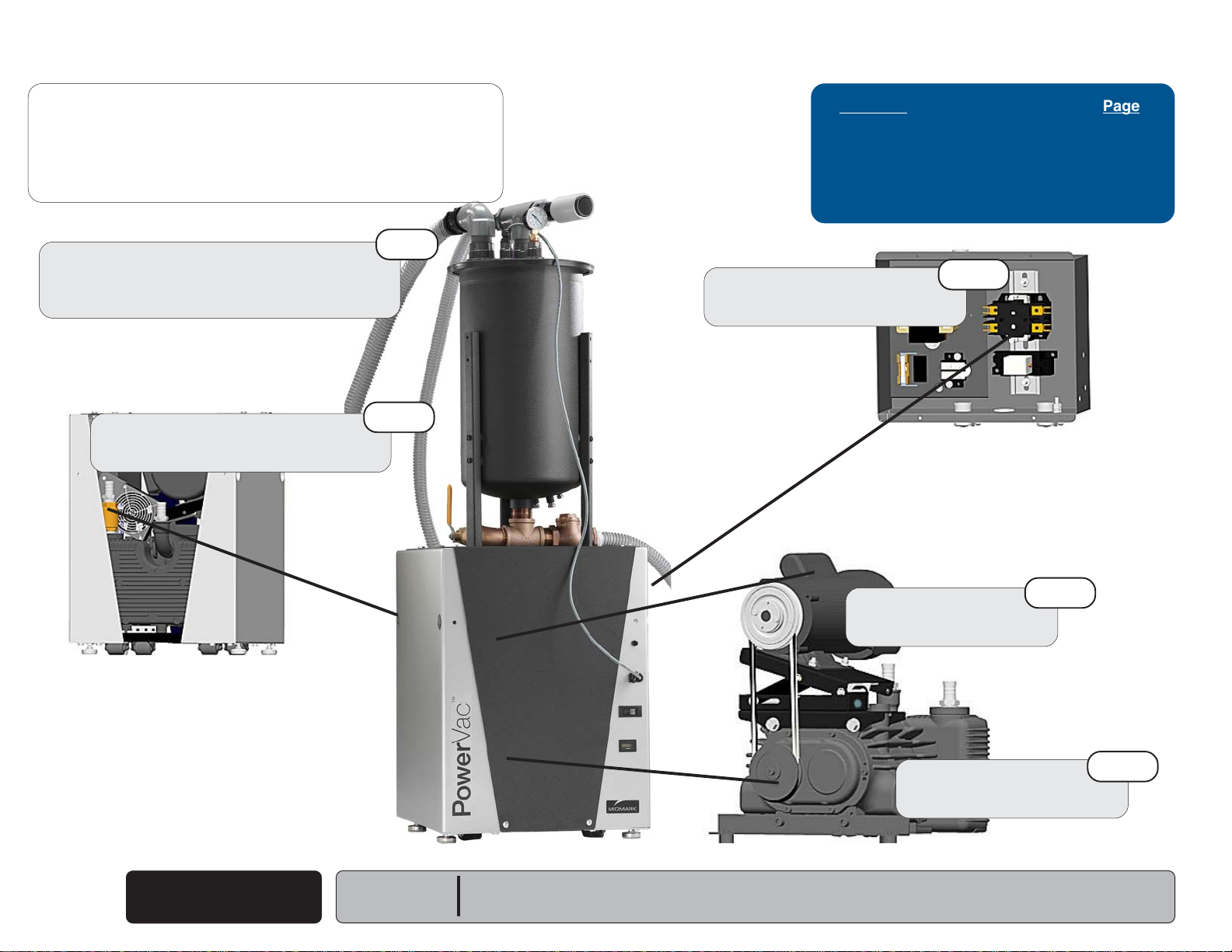

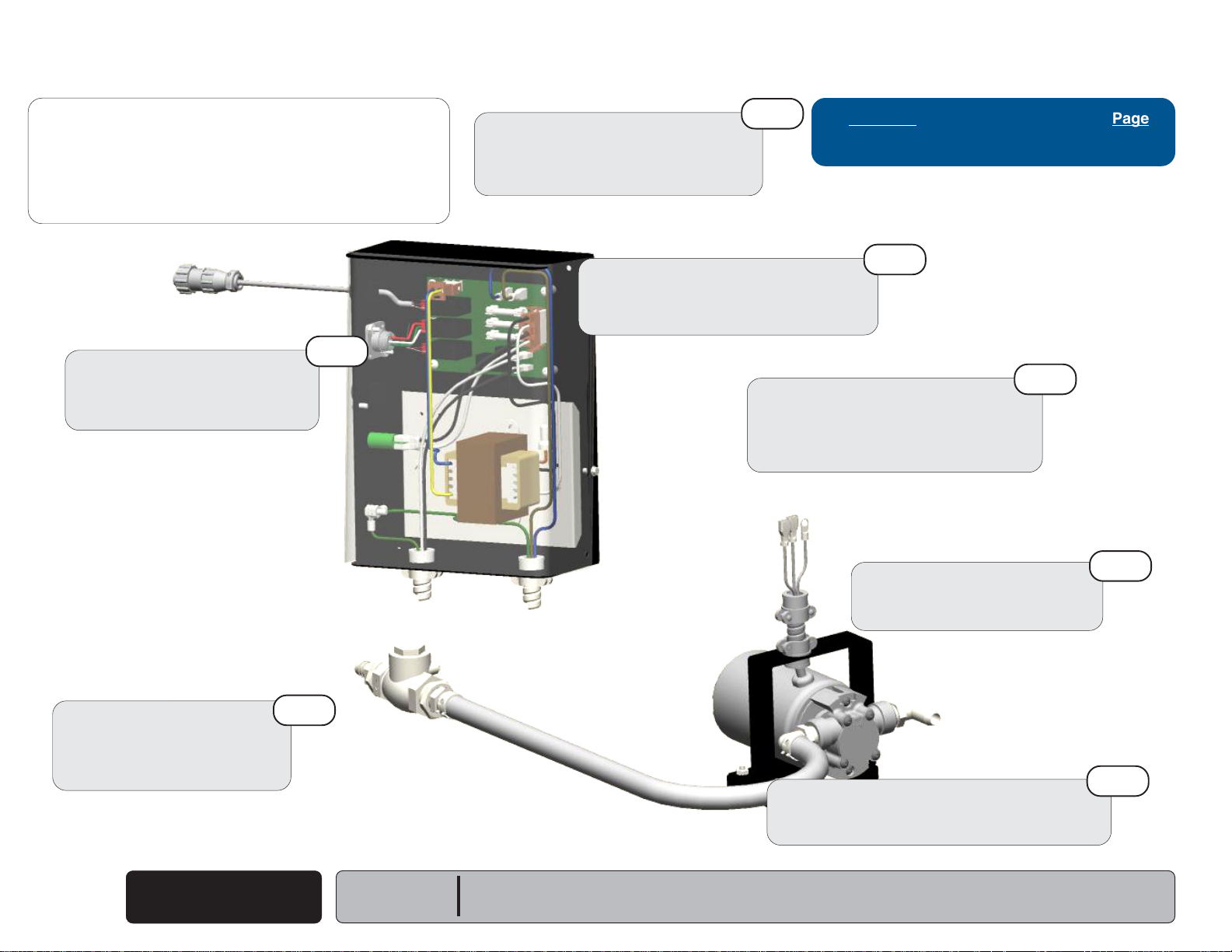

PowerVac

Go To Table Of Contents

Next

Style B

®

Model Numbers:

Single Vac Units

P3

P5

P7

Twin Vac Units

P6

P10

P14

Service and

Parts Manual

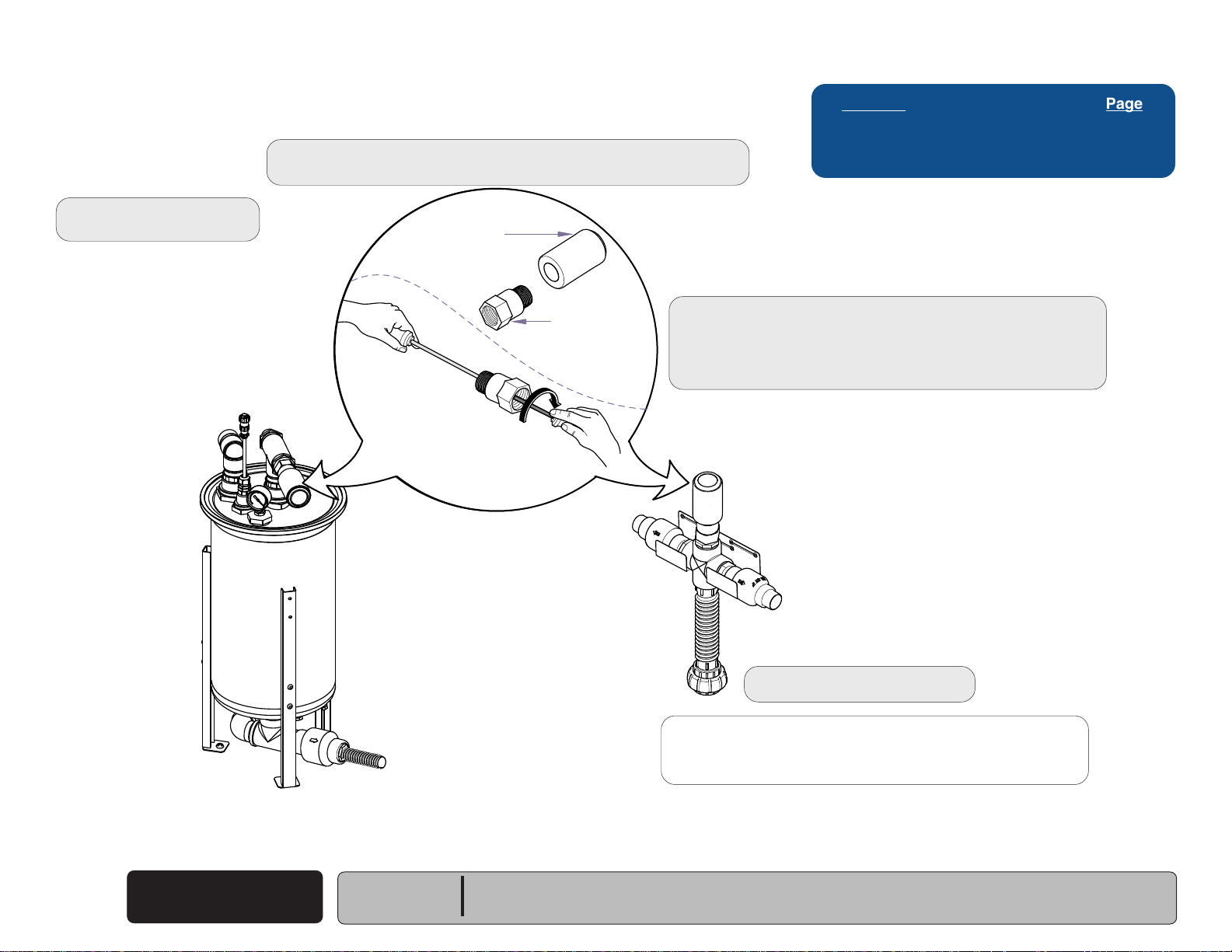

Earlier Version Current Version

FOR USE BY MIDMARK TRAINED TECHNICIANS ONLY

Part No. 004-0494-00 Rev. AA7 (5/13/19)

Page 2

GENERAL INFORMATION

Back

Next

Symbols ....................................iii

Ordering Parts ......................... iii

Serial Number Location .......... iii

Specifications ........................... iv

Model Identification /

Compliance Charts: ................. v

Warranty Information............... vi

TESTING & REPAIR - continued

cont.

Section B -

General Information

ACCESS PROCEDURES

TROUBLESHOOTING

Vacuum System ....................... A-2

Electrical System Operation

Power to System .................................

Wall Switch On ................................... A-4

Section A

Bottom Float contact Closed .............. A-5

Middle Float Contact Closed ............. A-6

Top Float Contact Closed ................... A-7

Liquid Evacuation Pump

(Accessory) ..............................

A-3

A-11

TESTING & REPAIR

Belt ............................................ B-2

Check Valve .............................. B-6

Vacuum Relief Valve................. B-9

Exhaust .....................................B-12

Float .......................................... B-15

Section B

Low Voltage .............................. B-18

Door Limit Switch &

Circuit Breaker (On/Off Switch)

.............................................. B-21

Contactor .................................. B-26

Fuse........................................... B-28

Table Of Contents

Relay.......................................... B-31

Transformer .............................. B-34

FOR USE BY MIDMARK TRAINED TECHNICIANS ONLY

Section C

WIRING DIAGRAMS

Section D

EXPLODED VIEWS / PARTS LISTS

Section E

Liquid Evacuation Pump

Section E

* Indicates multiple pages due to model / serial number break(s)

Fan..........................................B-37

Gauge ..................................... B-41

Motor ......................................B-43

Capacitor ................................B-44

Pump ......................................B-50

Liquid Evacuation Pump

(Accessory) ............................

Separator Tank ....................... B-58

Front Cover ............................ C-2

Top Cover ............................... C-3

Electrical Cover ...................... C-4

Back Cover (Previous Tank)... C-5

Back Cover (Large Tank) ........ C-6

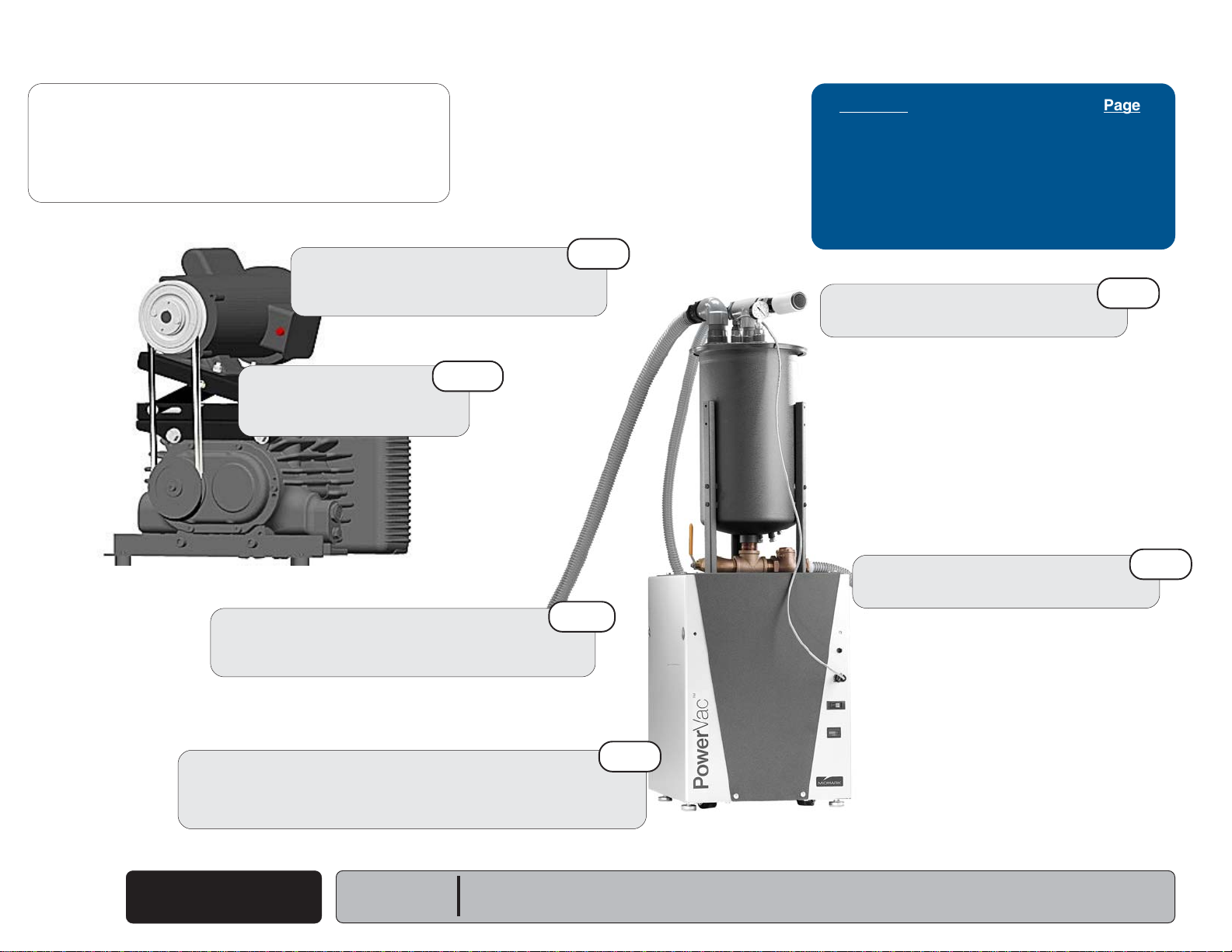

PowerVac

Liquid Evacuation Pump

(Accessory) ............................

PowerVac® Single Models

(P3, P5, P7) .............................

PowerVac ® Twin Models

(P6, P10, P14) .........................

(Accessory) ...........................

®

.................................................. D-2*

B-53

D-4

E-2*

E-3*

E-4*

Page 3

Symbols

AA158000-1i

0

5

1

0

1

5

2

0

2

5

-

3

0

Back

Go To Table Of Contents

Next

General Information

Ordering Parts

WARNING

Indicates a potentially hazardous situation which

could result in serious injury if not avoided.

The following information is required when ordering parts:

• Serial number & model number

• Part number for desired part.

[Refer to Exploded Views / Parts Lists section]

CAUTION

Indicates a potentially hazardous situation which may

result in minor or moderate injury if not avoided. It may also be

used to alert against unsafe practices.

Equipment Alert

Indicates a potentially hazardous situation which

could result in equipment damage if not avoided.

In Section A, test the components in the order indicated.

(ex.

1st

then,

The symbols below may be used in this manual to represent

the operational status of table functions and components.

Refer to Section B for component testing procedures.

Indicates the function / component is working properly.

No action required.

2nd

)

Non-warranty parts orders may be faxed to Midmark using

the Fax Order Form in the back of this manual.

For warranty parts orders, call Midmark's Technical Service

Department with the required information.

Hours: 8:00 am until 5:00 pm EST [Monday - Friday]

Phone: 1-(800)-Midmark

Model / Serial Number Location

Tank Serial

Number

General Information

Indicates the function / component is working,

but a problem exists.

Indicates the function / component is not working at all.

Base Serial

Number

© Midmark Corporation 2006 SF-1873

Rev 9/10/18

iii

Page 4

General Information

Model

P3

Model

P5

Model

P7

Model

P6

Model

P10

Model

P14

Evacuation Control

Box (Optional)

Max Users

3-5 5-7 7-10 6-10 10-14 14-20

N/A

Vac Unit

H x W x D

26" x 19.5" x 18.5" 26" x 19.5" x 18.5" 26" x 19.5" x 18.5" 26" x 39" x 18.5" 26" x 39" x 18.5" 26" x 39" x 18.5"

N/A

Separator

H x W x D

32" x 22" x 22" 32" x 22" x 22" 32" x 22" x 22" 32" x 22" x 22" 32" x 22" x 22" 32" x 22" x 22"

5" x 5.5" x 6"

Actual Weight (lbs)

Vac Unit - 355

Separator - 47

Vac Unit - 355

Separator - 47

Vac Unit - 355

Separator - 47

Vac Units - 710

Separators - 94

Vac Units - 710

Separators - 94

Vac Units - 710

Separators - 94

2

Total HP 222444N/A

Voltage 208 / 230 208 / 230 208 / 230 208 / 230 208 / 230 208 / 230 115 VAC

Amps 11.4 11.4 11.4 22.8 22.8 22.8 3

Hertz 60 60 60 60 60 60 60

Recommended

Breaker Size (Amps)

(Min. 20 Amp ea.)

30 30 30 2 x 30 2 x 30 2 x 30

15

Inlet Connection Size

(in.)

1 1/2" 1 1/2" 1 1/2" 2" 2" 2"

N/A

Fuses

1/8 A, 250V

Type T

1/8 A, 250V

Type T

1/8 A, 250V

Type T

1/8 A, 250V

Type T

1/8 A, 250V

Type T

1/8 A, 250V

Type T

1/4A, 250V, Type T

3A, 250V, Type T

Drain Connection Size

(in.)

1 1/2" 1 1/2" 1 1/2" 1 1/2" 1 1/2" 1 1/2"

N/A

Back

Go To Table Of Contents

Next

Weights, Dimensions, Electrical Specifications

Classifications: Class 1, Type B Applied Part

iv

© Midmark Corporation 2006 SF-1873

Rev. 9/10/18

Page 5

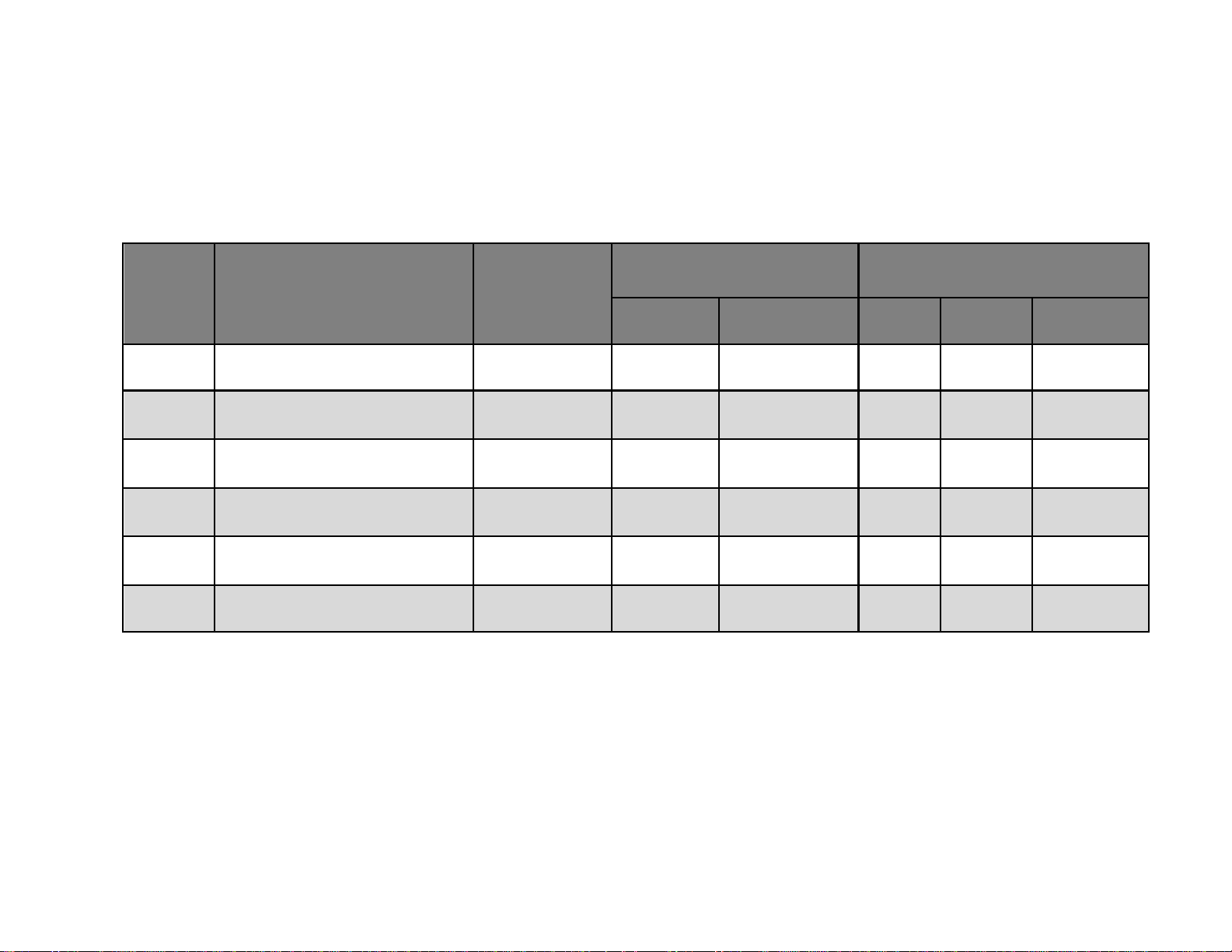

General Information

UL 60601-1

CAN/CSA 22.2,

#601.1-M90

VAC Amps Cycles (Hz)

P3

PowerVac® Dry Vacuum

System - Single - 3 - 5 User

V x x 230 11.4 60

P5

PowerVac® Dry Vacuum

System - Single - 5 - 7 User

V x x 230 11.4 60

P7

PowerVac® Dry Vacuum

System - Single - 7 - 10 User

V x x 230 11.4 60

P6

PowerVac® Dry Vacuum

System - Twin - 6 - 10 User

V x x 230 22.8 60

P10

PowerVac® Dry Vacuum

System -Twin - 10 - 14 User

V x x 230 22.8 60

P14

PowerVac® Dry Vacuum

System - Twin - 14 - 20 User

V x x 230 22.8 60

Complies To:

Model

Description

Serial Number

Prefix

Electrical Supply Requirements:

Back

Go To Table Of Contents

Next

Model Identification / Compliance Chart - PowerVac

®

© Midmark Corporation 2006 SF-1873

Rev 9/10/18

v

Page 6

General Information

Back

Go To Table Of Contents

Next

Warranty Information

LIMITED WARRANTY

SCOPE OF WARRANTY

Midmark Corporation (“Midmark”) warrants to the original purchaser its new PowerVac® products and components (except for components not warranted

under “Exclusions”) manufactured by Midmark to be free from defects in material and workmanship under normal use and service. Midmark’s obligation under

this warranty is limited to the repair or replacement, at Midmark’s option, of the parts or the products the defects of which are reported to Midmark within the

applicable warranty period and which, upon examination by Midmark, prove to be defective.

APPLICABLE WARRANTY PERIOD

The applicable warranty period, measured from the date of installation for the original user, shall be five (5) years or 10,000 usage hours (whichever comes

first) for all warranted products and components and ten (10) years or 20,000 usage hours (whichever comes first) for the pump only.

EXCLUSIONS

This warranty does not cover and Midmark shall not be liable for the following: (1) repairs and replacements because of misuse, abuse, negligence,

alteration, accident, freight damage, or tampering; (2) products which are not installed, used, and properly cleaned as required in the Midmark “Installation”

manual and or PowerVac

manufactured by Midmark; (5) charges by anyone for adjustments, repairs, replacement parts, installation, or other work performed upon or in connection

with such products which is not expressly authorized in writing in advance by Midmark.

EXCLUSIVE REMEDY

Midmark’s only obligation under this warranty is the repair or replacement of defective parts. Midmark shall not be liable for any direct, special, indirect,

incidental, exemplary, or consequential damages or delay, including, but not limited to, damages for loss of profits or loss of use.

®

Care Guide for this applicable product; (3) products considered to be of a consumable nature; (4) accessories or parts not

NO AUTHORIZATION

No person or firm is authorized to create for Midmark any other obligation or liability in connection with the products.

THIS WARRANTY IS MIDMARK’S ONLY WARRANTY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED. MIDMARK MAKES NO IMPLIED

WARRANTIES OF ANY KIND INCLUDING ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. THIS WARRANTY IS LIMITED TO

THE REPAIR OR REPLACEMENT OF DEFECTIVE PARTS.

vi

Page 7

Troubleshooting

Go To Page:

Back

Go To Table Of Contents

Next

Troubleshooting

5

1

0

2

0

1

5

2

5

0

3

0

Function / System Page

Vacuum System ................................... A-2

Electrical System Operation

Power to System......................... A-3

Wall Switch On ........................... A-4

Bottom Float Contact Closes ...... A-5

Middle Float Contact Closes ....... A-6

Top Float Contact Closes ........... A-7

Liquid Evacuation Pump.......................A-11

Models:

Serial Numbers:

AA220500

Section A

© Midmark Corporation 2006 SF-1873

Rev 2/08

A-1

Page 8

Troubleshooting

Back

Go To Table Of Contents

Next

Go To Page:

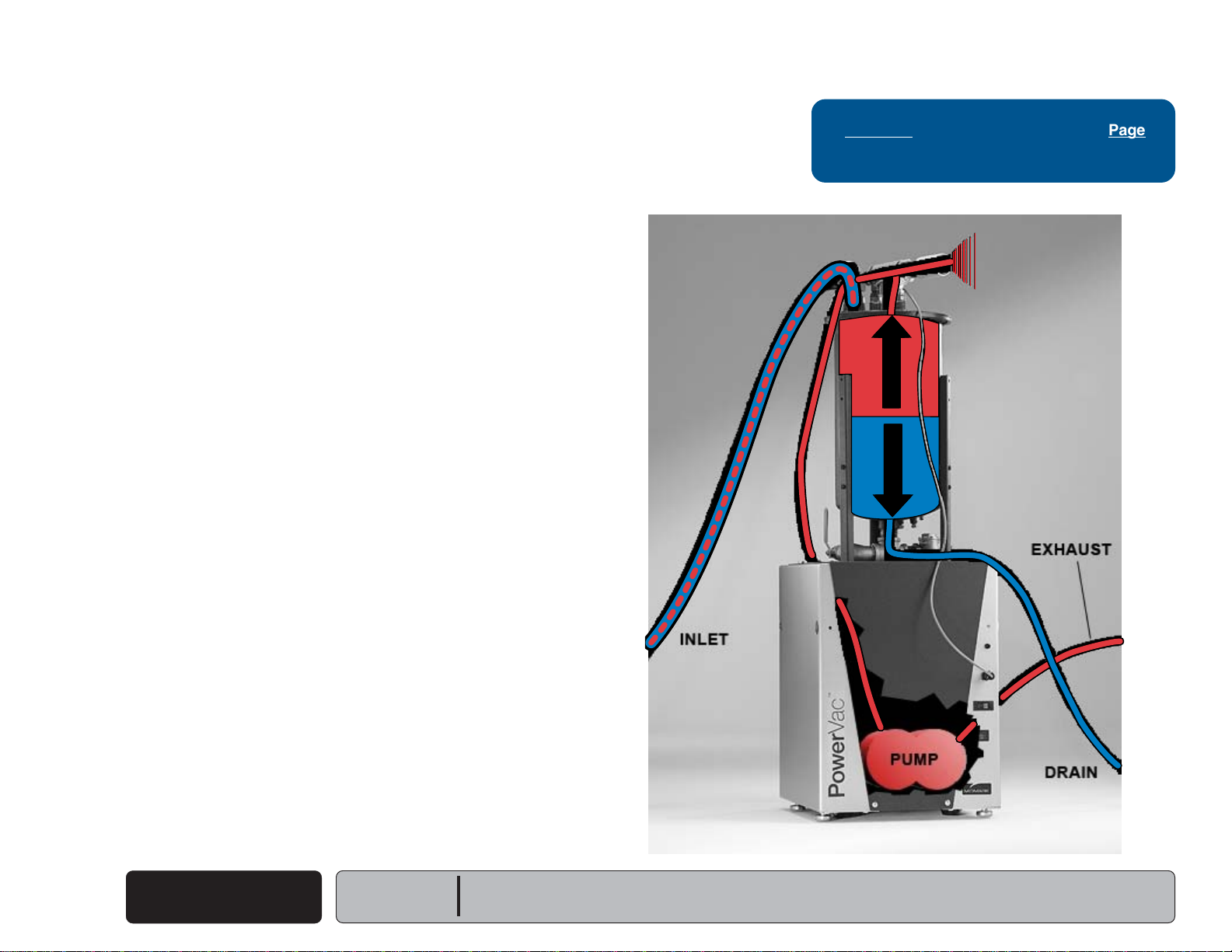

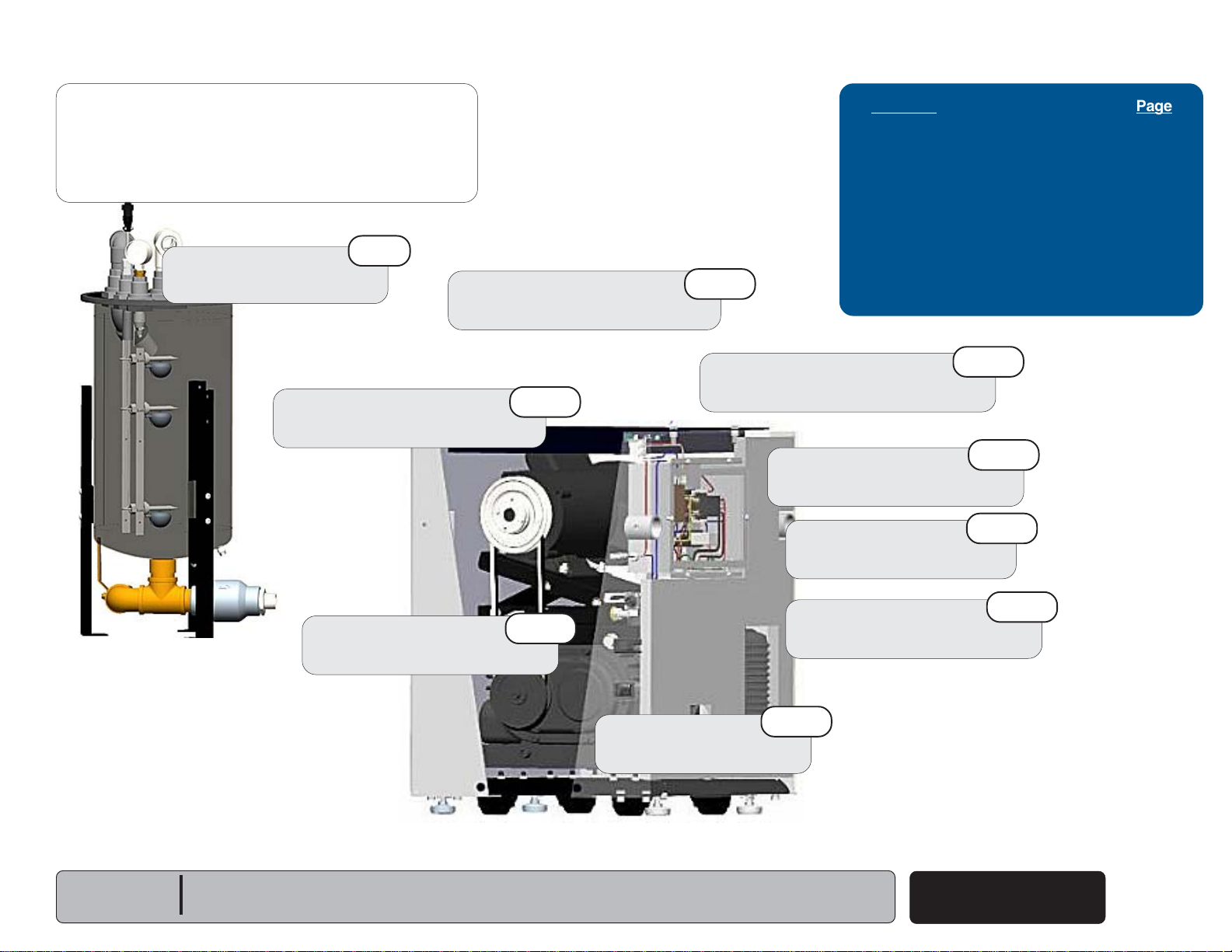

Vacuum System Operation

Operatory waste (air, solids and liquids) is pulled into the separator

through the inlet hose by the rotary claw pump in the vacuum base unit.

Air is separated from liquids and solids. Air then flows into the pump and

out through the exhaust hose.

Refer To: Page

Low or No Suction ................................ A-9

Earlier Version Shown

Fresh air is pumped in through the Vacuum Relief Valve to the pump and

out through the exhaust. (When ports are opened in the operatories the

VRV closes to compensate.)

The check valve connected below the drain port allows the unit to drain

liquids and solids upon removal of vacuum from the chamber when the

pump / motor shuts off.

The fan(s), hour meter and vacuum pump start to run when power is

supplied by the wall switch. The fan(s) and hour meter then begin to cycle

with the vacuum pump / motor. The float switches control the pump motor

by a 24 vac relay via motor contactor.

The upper and lower reed switch floats interact as a latching circuit with

the internal relay to release upon drain below the bottom float.

Air

Liquids

Fresh Air

Intake

Fr

A-2

© Midmark Corporation 2006 SF-1873

Vacuum System

Rev 9/10

Models:

Serial Numbers:

All

Page 9

Troubleshooting

Back

Go To Table Of Contents

Next

Go To Page:

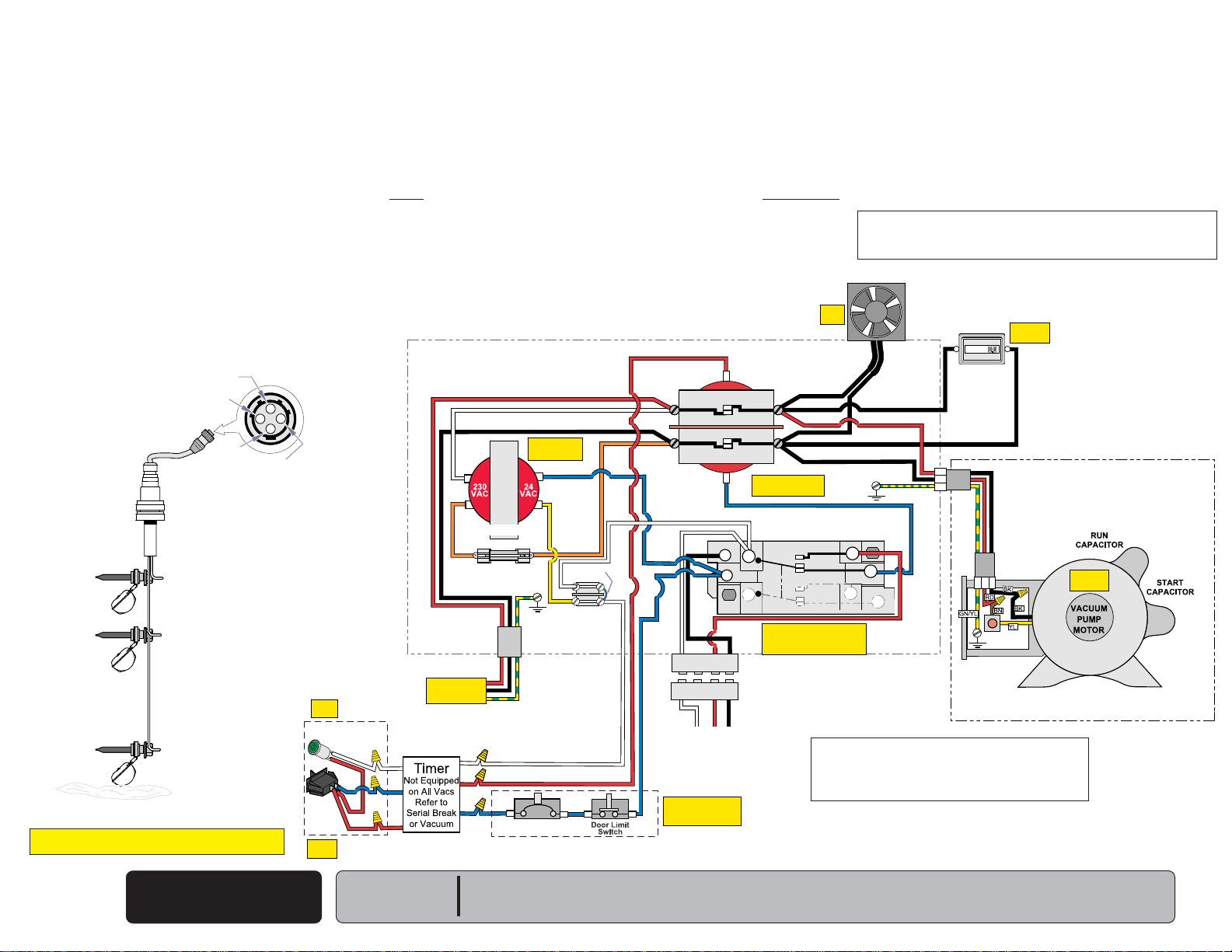

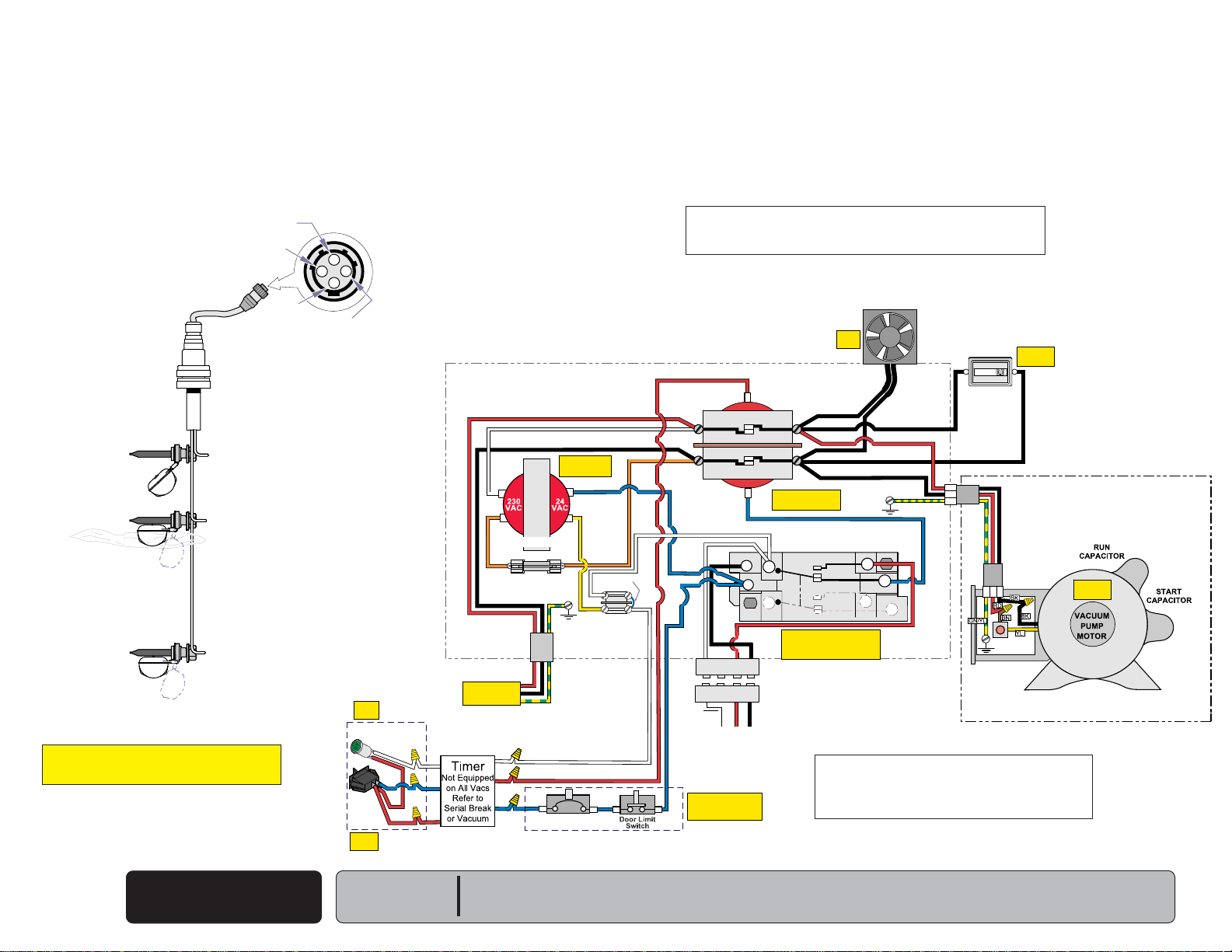

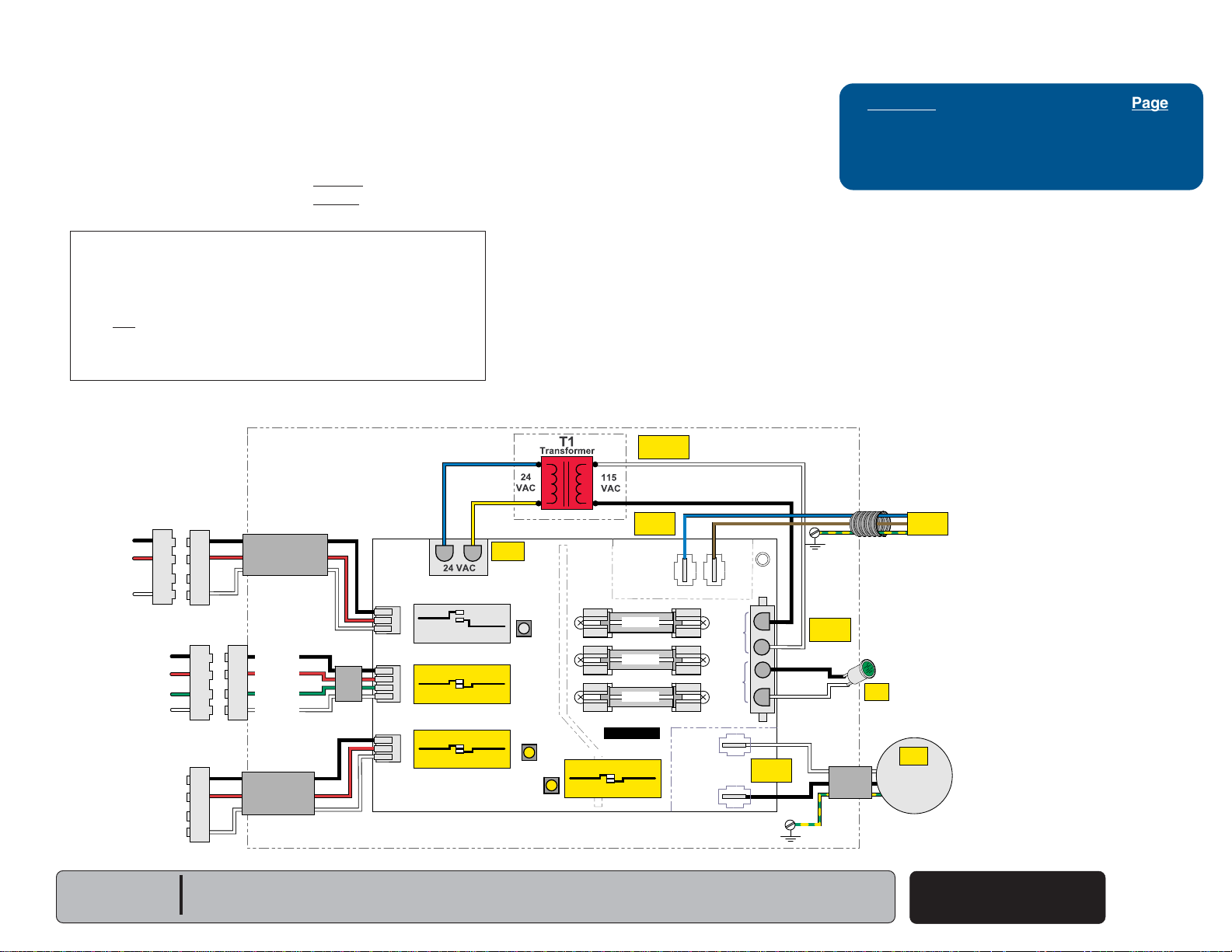

Electrical System

(Power to System Wall Switch Open All Float Switches Open)

• Power (230 VAC) is on supplying Line Voltage to the Vacuum Pump Electrical System.

• 230 V is applied to the 230 V / 24 V Transformer energizing it.

• 24 V is applied from one side of Transformer, to the Terminal Block.

• From the Terminal Block, 24 V is applied to Terminal 6 of CR1 Relay, thru CR1 normally

closed contacts (6 & 2) to one side of the coil on Contactor “C”, also to J1 & J2 Plug

(pin 1), and thru the Timer to one side of the Wall On / Off Light.

• 24 V is also applied thru the closed Door Limit Switch,Circuit Breaker & Timer to one

side of the Wall On/Off Switch.

VACUUM PUMP ELECTRICAL SYSTEM

Common

Top

Float

Middle

Float

Bottom

Float

Bottom

Float

AA160800i

Top

Float

3

Middle

Float

4

2

1

Transformer

Fuse F1

BK

RD

WH

RD

BL

Energized

GN/YL

Circuit

Breaker

YL

Light

On

On/Off

Light

Remote

Wall

Switch

Switch

On

WH

Transformer

OR

230 VAC

Power On

WH

RD

WH

BL

BL

RD

RD

RD

WH

RD

BL

SEPARATOR FLOAT

SWITCH ASSEMBLY

Earlier Version HasThree

Reed Switch Floats.

The Middle Float in

Current Version

is Not Used and

No Longer Installed

Contacts

Open

Contacts

Open

Contacts

Open

Water Level

Water Low, All Float Switches Open

BL

WH

YL

OR

Jumper

Terminal

Block

BL

Refer To: Page

Motor will not Run ................................. A-10

Motor Cutting Out ................................. A-11

NOTE:

Some units have dual fans that are wired in parallel.

FAN

Fan

Off

RD

Contacts

RD

WH

BK

OR

RD

BL

WH

BL

RD

BL

WH

WH

1

1

BL

WH

To J1 or J2 Plug on

Evacuation Board

Separation Tank

Open

WH

BK

BL

RD

2

2

RD BK

or

to Float on

CONTACTOR

"C"

Contacts

Open

Power Removed From

Coil, Contacts Open.

BL

WH

Coil

7

6

Coil

8

Coil

5

WH

BK

3

4

4

3

BK

BK

RD

BK

BK

BK

CR1 (Float Switch) RELAY

Contacts Open

CR1 Coil Not Energized

Contacts Remain in

Same Position

BK

BK

GN/YL

BL

RD

RD

4

BL

2

3

BL

1

RD

NOTE:

Circuit Breaker &

BL

Door Limit Switch

Closed

Manual reset button on earlier versions,

automatic reset on current versions.

RD

HOUR

METER

HOURS

BK BK

Thermal

Reset

Meter

Stopped

Pump

Stopped

AA2480i

Models:

Serial Numbers:

All

Power to System

© Midmark Corporation 2006 SF-1873

Rev 11/2/15

A-3

Page 10

Troubleshooting

Back

Go To Table Of Contents

Next

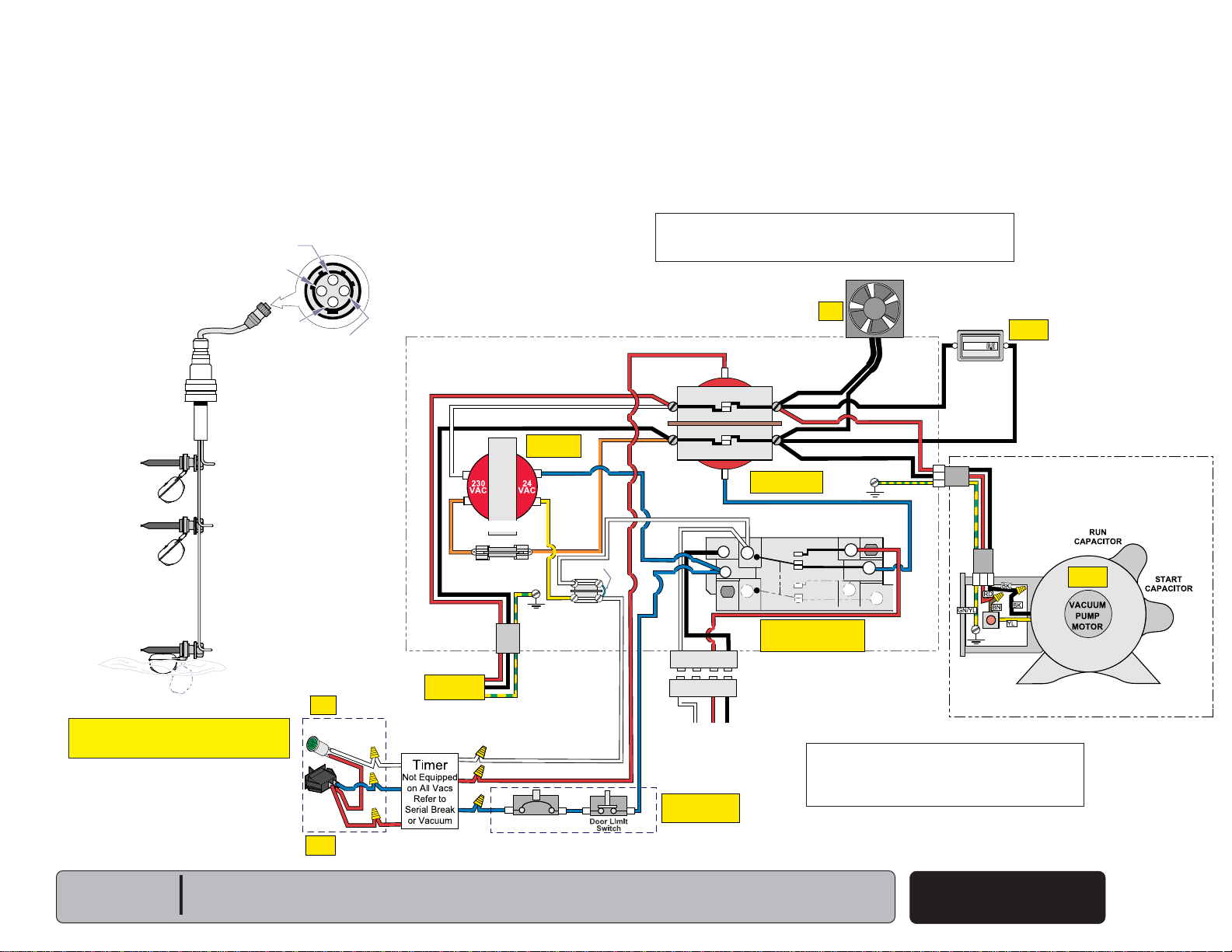

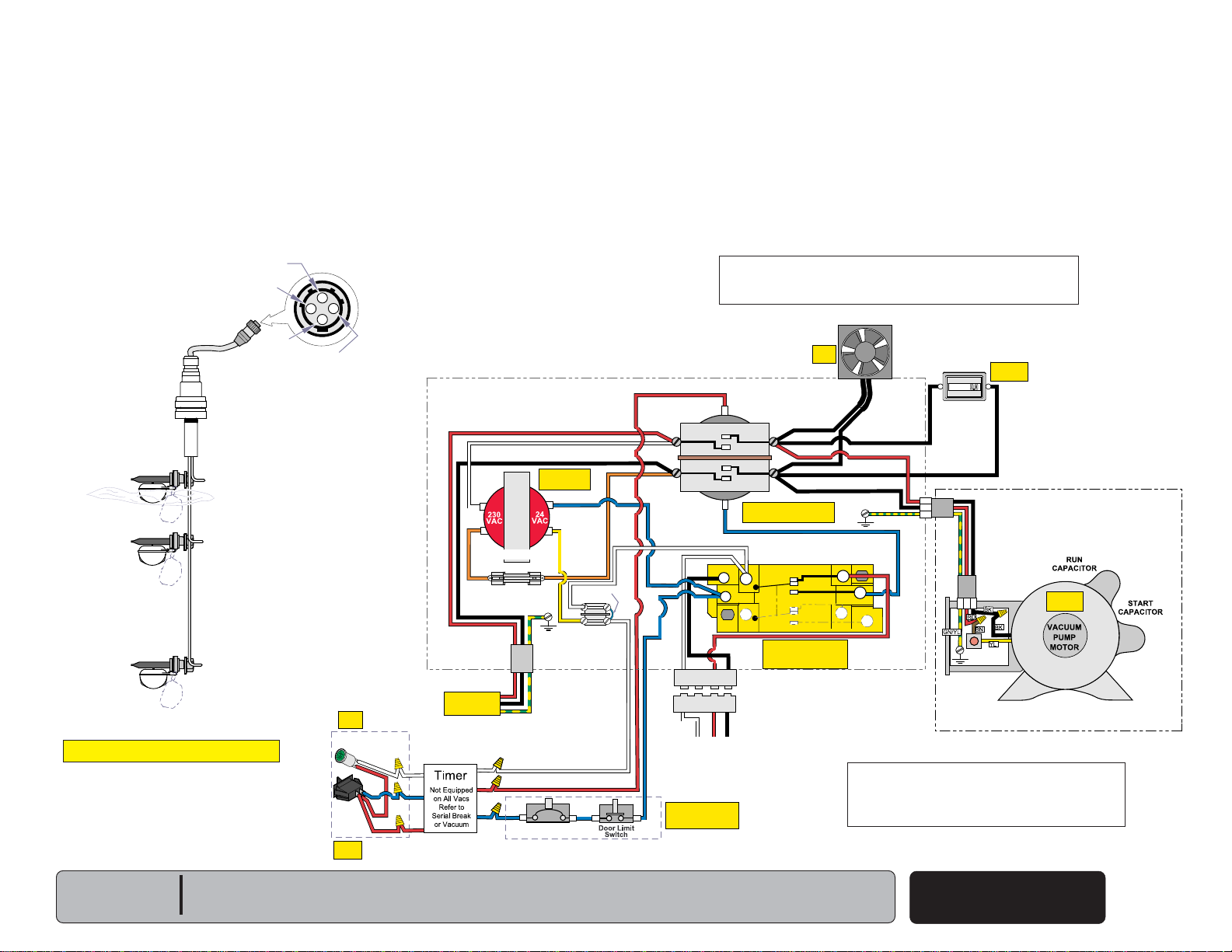

Electrical System

- continued (Wall Switch On, Power to System, All Float Switches Open)

• Remote Wall Switch is turned on, the On / Off Light comes on.

• 24 V is applied to the other side of the coil of Contactor “C”, energizing the coil and closing its

contacts.

• The Fan(s), Hour Meter, and Vacuum Pump run.

Electrical System

- continued (Wall Switch OFF

,

Power to System, All Float Switches Open, Timer ON)

• Remote Wall Switch is turned off, the Timer turns on and starts to measure two hours.

• The Timer will run the Vacuum for one minute every two hours while the Remote Wall Switch is

turned off by completing the 24 V circuit to the Contactor "C" coil.

VACUUM PUMP ELECTRICAL SYSTEM

SEPARATOR FLOAT

SWITCH ASSEMBLY

Earlier Version Shown

Earlier Version HasThree

Reed Switch Floats.

The Middle Float in

Current Version

is Not Used and

No Longer Installed

Contacts

Open

Contacts

Open

Contacts

Open

Water Level

Water Low, All Float Switches Open

Top

Float

Middle

Float

Bottom

Float

Common

Bottom

Float

AA160800i

Top

Float

3

Middle

Float

4

2

1

Transformer

Energized

BL

YL

WH

BK

YL

GN/YL

WH

RD

BL

Circuit

Breaker

OR

Jumper

Terminal

Block

BL

RD

WH

RD

WH

Light

On

On/Off

Light

Remote

Wall

Switch

Switch

On

WH

Transformer

OR

Fuse F1

RD

230 VAC

Power On

WH

RD

WH

BL

BL

RD

RD

RD

WH

RD

BL

RD

RD

WH

BK

OR

BL

BL

BL

WH

1

1

WH

To J1 or J2 Plug on

Evacuation Board

Separation Tank

Circuit Breaker &

BL

Door Limit Switch

Contacts

Closed

WH

BK

BL

RD

2

2

RD BK

or

to Float on

Closed

CONTACTOR

Contacts

BL

Coil

7

Coil

8

Coil

WH

BK

3

4

4

3

"C"

BK

BK

RD

BK

BK

Closed

Coil Energized

Contacts Closed

CR1 (Float Switch) RELAY

WH

Contacts Open

6

5

CR1 Coil Not Energized

Contacts Remain in

Same Position

NOTE:

Some units have dual fans that are wired in parallel.

FAN

Fan

On

BK

BK

BK

GN/YL

BL

RD

RD

4

BL

2

3

BL

1

RD

BK BK

RD

HOUR

METER

HOURS

Thermal

Reset

Meter

Running

NOTE:

Manual reset button on earlier versions,

automatic reset on current versions.

Pump

Running

AA2478i

Wall Switch On

A-4

© Midmark Corporation 2006 SF-1873

Rev 11/2/15

Models:

Serial Numbers:

All

Page 11

Troubleshooting

Back

Go To Table Of Contents

Next

Electrical System

- continued (Water Rises, Bottom Float Switch Closes, Middle and Top Switches Remain Open.)

• Contactor “C” contacts remain closed.

• The Fan(s), Hour Meter, and Vacuum Pump continue to run.

SEPARATOR FLOAT

SWITCH ASSEMBLY

Earlier Version Shown

Earlier Version HasThree

Reed Switch Floats.

The Middle Float in

Current Version

is Not Used and

No Longer Installed

Contacts

Open

Contacts

Open

Contacts

Closed

Water Level

Bottom Float Switch Closed,

Middle and Top Remain Open.

Top

Float

Middle

Float

Bottom

Float

Common

Bottom

Float

Top

Float

AA160801i

3

Middle

Float

Light

On

On/Off

Light

Remote

Wall

Switch

Switch

On

4

2

1

WH

RD

WH

BL

BL

RD

RD

RD

WH

OR

230 VAC

Power On

WH

RD

BL

Transformer

Fuse F1

BK

RD

GN/YL

WH

RD

BL

Breaker

NOTE:

Some units have dual fans that are wired in parallel.

VACUUM PUMP ELECTRICAL SYSTEM

Transformer

Energized

BL

YL

YL

Circuit

WH

Terminal

Block

BL

OR

Jumper

WH

WH

RD

RD

Contacts

WH

BK

OR

RD

BL

WH

BL

RD

BL

WH

1

1

WH

To J1 or J2 Plug on

Evacuation Board

Separation Tank

Circuit Breaker &

BL

Door Limit Switch

Closed

Coil

BK

BL

RD

2

3

2

3

RD BK

or

to Float on

Closed

CONTACTOR

"C"

Contacts

Closed

Contacts Closed

BL

WH

7

6

Coil

8

Coil

5

WH

BK

4

4

Coil Energized

CR1 Coil Not Energized

FAN

Fan

On

BK

BK

RD

BK

BK

BK

CR1 (Float Switch) RELAY

Contacts Open

Contacts Remain in

Same Position

RD

4

2

3

NOTE:

Manual reset button on earlier versions,

automatic reset on current versions.

HOUR

METER

BK

BK BK

RD

BK

GN/YL

BL

RD

BL

BL

1

RD

HOURS

Thermal

Reset

Meter

Running

Pump

Running

AA2478i

Models:

Serial Numbers:

All

Bottom Float

Switch Closed

© Midmark Corporation 2006 SF-1873

Rev 11/2/15

A-5

Page 12

Troubleshooting

Back

Go To Table Of Contents

Next

Electrical System

- continued (Water Reaches Middle Float, Middle and Bottom Float Switches are Closed, Top Switch Remains Open.)

• Contactor “C” contacts remain closed.

• The Fans, Hour Meter, and Vacuum Pump continue to run.

Top

Float

Middle

Float

Bottom

Float

Common

AA160802i

Bottom

Float

Top

Float

4

3

Middle

Float

1

2

Light

On

On/Off

Light

Remote

Wall

Switch

Switch

On

WH

RD

BL

RD

RD

SEPARATOR FLOAT

SWITCH ASSEMBLY

Earlier Version Shown

Earlier Version HasThree

Reed Switch Floats.

The Middle Float in

Current Version

is Not Used and

No Longer Installed

Contacts

Open

Contacts

Closed

Water Level

Contacts

Closed

Middle and Bottom Float Switches

are Closed, Top Remains Open.

NOTE:

Some units have dual fans that are wired in parallel.

Fan

On

FAN

HOUR

METER

BK

BK BK

RD

BK

GN/YL

BL

RD

RD

4

BL

2

3

BL

1

RD

HOURS

Thermal

Reset

Meter

Running

Pump

Running

AA2478i

VACUUM PUMP ELECTRICAL SYSTEM

RD

RD

WH

Transformer

Fuse F1

BK

RD

WH

RD

BL

Energized

YL

GN/YL

Circuit

Breaker

BL

WH

YL

OR

Jumper

Terminal

Block

BL

WH

WH

Transformer

OR

230 VAC

Power On

WH

BL

RD

WH

RD

BL

BK

OR

RD

BL

WH

BL

RD

BL

WH

1

1

WH

To J1 or J2 Plug on

Evacuation Board

Separation Tank

Circuit Breaker &

BL

Door Limit Switch

Contacts

Closed

WH

BK

BL

RD

2

2

RD BK

or

to Float on

Closed

CONTACTOR

Contacts

BL

Coil

7

Coil

8

Coil

WH

BK

3

4

4

3

"C"

BK

BK

BK

Closed

Coil Energized

Contacts Closed

CR1 (Float Switch) RELAY

WH

Contacts Open

6

5

CR1 Coil Not Energized

Contacts Remain in

Same Position

BK

RD

BK

NOTE:

Manual reset button on earlier versions,

automatic reset on current versions.

A-6

Switch Closed

© Midmark Corporation 2006 SF-1873

Middle Float

Rev 11/2/15

Models:

Serial Numbers:

All

Page 13

Electrical System

Back

Go To Table Of Contents

Next

- continued (Water Reaches Top Float, All Float Switches are Closed.)

• The Top Float Switch sends 24v to the coil of CR1 Float Switch Relay changing the contacts position.

• Power is removed from the coil of Contactor “C”, opening its contacts.

• The Fan(s), Hour Meter, and Vacuum Pump stop running.

• CR1 Float Switch Relay remains energized through its own normally closed tips (6&4) and the bottom float

swich (pin 3) of J1& J2

• The Collection tank starts to Drain, Pump remains off until Bottom Float Switch opens interupting 24v to the

CR1 Float Switch Relay coil.

• CR1 Float Switch Relay returns to its nornal state energizing Contactor "C", the Vacuum Pump, Fan(s) Motors,

and Hour Meter restart .

SEPARATOR FLOAT

SWITCH ASSEMBLY

Earlier Version Shown

Earlier Version HasThree

Reed Switch Floats.

The Middle Float in

Current Version

is Not Used and

No Longer Installed

Contacts

Closed

Water Level

Contacts

Closed

Contacts

Closed

All Float Switches are Closed.

Top

Float

Middle

Float

Bottom

Float

AA160803i

Common

Bottom

Float

Top

Float

3

Middle

Float

4

1

2

Light

On

On/Off

Light

Remote

Wall

Switch

Switch

On

VACUUM PUMP ELECTRICAL SYSTEM

RD

Contacts

RD

Open

WH

Transformer

Fuse F1

BK

RD

WH

RD

BL

GN/YL

Circuit

Breaker

Energized

BL

YL

YL

WH

Terminal

Block

BL

OR

Jumper

WH

WH

Transformer

OR

230 VAC

Power On

WH

RD

WH

BL

BL

RD

RD

RD

WH

RD

BL

BK

OR

RD

BL

WH

RD

BL

BL

WH

1

1

BL

WH

To J1 or J2 Plug on

Evacuation Board

Separation Tank

Circuit Breaker &

BL

Door Limit Switch

WH

Closed

NOTE:

Some units have dual fans that are wired in parallel.

CONTACTOR

Contacts

Open

BL

Coil

BK

7

Coil

8

Coil

BL

WH

RD

BK

2

3

4

4

2

3

RD BK

or

to Float on

Fan

"C"

BK

BK

RD

BK

BK

BK

Power Removed From

Coil, Contacts Open.

CR1 (Float Switch) RELAY

WH

Contacts Open

6

5

CR1 Coil

Energizes

Contacts Change

Positions

Troubleshooting

FAN

RD

HOUR

METER

HOURS

BK BK

Thermal

Reset

Meter

Stops

Off

BK

BK

GN/YL

BL

RD

RD

4

BL

2

3

BL

1

RD

NOTE:

Manual reset button on earlier versions,

automatic reset on current versions.

Pump

Stops

AA2479i

Models:

Serial Numbers:

All

Top Float

Switch Closed

© Midmark Corporation 2006 SF-1873

Rev 11/2/15

A-7

Page 14

Troubleshooting

Back

Go To Table Of Contents

Next

Go To Page:

Vacuum System

Problem: Operatory has low or no suction.

Earlier Version Shown

Will the motor start?

If motor runs go to 2nd check.

If not Refer to Section A - Motor will not run.

Check Belt Tension.

Refer to: Section B - Belt.

(Earlier Version ONLY)

2nd

1st

Refer To: Page

Motor will not Run ................................. A-9

Belt ............................................... B-2

Check Valve ......................................... B-6

Vacuum Relief Valve ............................ B-9

Exhaust ............................................... B-12

Check Vacuum Relief Valve.

Refer to: Section B - Vacuum Relief Valve.

5th

A-8

with Motor Running

© Midmark Corporation 2006 SF-1873

Check Hoses and Bulkhead Fittings.

Check for leaks, kinks and loose connections in the

hoses, bulkhead fittings and separator lid gasket.

Check Exhaust.

Remove exhaust line to see if suction increases.

Unclog or replace exhaust line if suction increased when checking.

Refer to: Section B - Exhaust

Low or No Suction

Rev 9/10/18

Models:

Serial Numbers:

3rd

All

6th

Earlier Version Shown

Check Drain Line for Suction.

Refer to: Section B - Check Valve.

4th

Page 15

Troubleshooting

Back

Go To Table Of Contents

Next

Go To Page:

Vacuum System

Problem: Motor will not run.

Check Float.

Refer to: Section B - Float

6th

Is Pump locked up?

Refer to: Section B - Pump

Reset Thermal Overload.

Refer to: Section B - Motor

2nd

Refer To: Page

Door Limit Switch................................B-20

Float...................................................B-15

Pump .................................................B-49

Low Voltage .......................................... B-18

Motor ..................................................B-42

Contactor .............................................. B-25

Fuse .................................................. B-27

1st

Check Door Limit Switch.

Refer to: Section B - Door Limit Switch

Check Fuse.

Refer to: Section B - Fuse

Check Relay.

Refer to: Section B - Relay

Relay ................................................ B-30

3rd

5th

7th

Earlier Version Shown

Models:

Serial Numbers:

All

Check Low Voltage.

Refer to: Section B - Low Voltage

4th

Check Motor.

Refer to: Section B - Motor

Earlier Version Shown

Check Contactor.

Refer to: Section B - Contactor

9th

Motor Not Running

© Midmark Corporation 2006 SF-1873

8th

Rev 9/10/18

A-9

Page 16

Troubleshooting

Back

Go To Table Of Contents

Next

Go To Page:

Vacuum System

Problem: Motor cutting out or running at a reduced speed.

RER

1st

4th

Check Equipment Room Temperature.

Temperature should be - 40° to 104° Fahrenheit

- 4 to 37 Celsius

Check Exhaust line and valve.

Refer to: Section B - Exhaust

Refer To: Page

Contactor .............................................. B-25

Pump ....................................................B-44

Exhaust ............................................... B-12

Motor ..................................................B-42

Check Contactor Voltage.

Refer to: Section B - Contactor

2nd

A-10

© Midmark Corporation 2006 SF-1873

Motor Cutting Out

Rev 9/10/18

Models:

Serial Numbers:

All

Earlier Version Shown

Check Motor.

Refer to: Section B - Motor

Is Pump locked up?

Refer to: Section B - Pump

5th

3rd

Page 17

AA158503i

HIGH

VOLTAGE

LOW

VOLTAGE

K4

C1

115

VAC

115

VAC

J4

F3 FUSE

F2 FUSE

F1 FUSE

115 VAC

Supply

Neutral

(Blue)

Line

(Black)

J7

J6

BK

GN

RD

WH

POWER

ON

LIGHT

BL

WH

WH

WH

BK

BL

YL

BK

BK

BR

GN/YL

WH

BK

BL

YL

GN/YL

Grd

J5

PLUG

4

1

2

3

4

3

2

1

K1

RELAY

VACUUM PUMP #1

Top

Float Swt.

Bottom

Float Swt.

RELAY

Contacts

Open

LED

OFF

RELAY

K2

K3

RELAY

Neutral

(Wht)

Line

(Blk)

EVAC.

PUMP

J8

J9

1

4

2

3

Middle

Float Swt.

Common

Top

Float Swt.

Bottom

Float Swt.

To

Separator

Float Assy.

1

4

2

3

BK

GN

RD

WH

Com.

Bottom

Middle

Top

WH

BK

RD

WH

BK

RD

J2

PLUG

2

3

1

1

4

2

3

BK

RD

WH

To Motor Control

(CR1 Relay)

System #2

(Same As

Above J1)

1

4

2

3

Coil (7)

N/O (4)

1

4

2

3

BK

RD

WH

To Motor Control

(CR1 Relay)

System #1

N/O

Com. (6)

WH

RD

BK

J3

Plug

1

2

J1

PLUG

2

3

1

Light

On

115 VAC

Power On

Transformer

Energized

24 VAC

On

115 VAC

Power On

Contacts

Closed

VACUUM PUMP #2

Contacts

Closed

FLOATS

Contacts

Closed

EVAC. PUMP

LED

ON

Evac.

Pump

Swt.

LED

ON

115 VAC

Power On

LIQUID

EVACUATION

PUMP

Pump

On

115 VAC

Power On

Electrical System for Accessory - Liquid Evacuation Pump

Back

Go To Table Of Contents

Next

Go To Page:

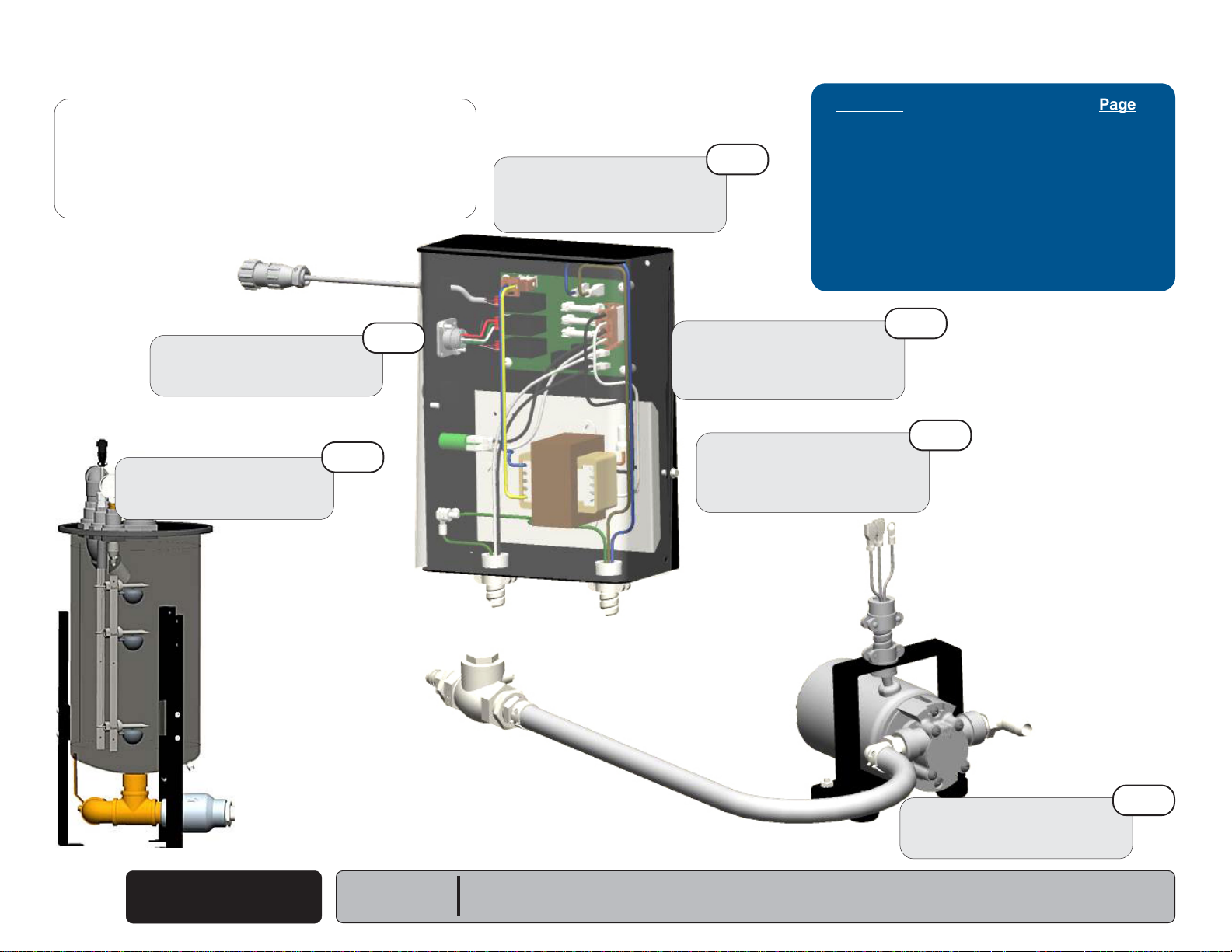

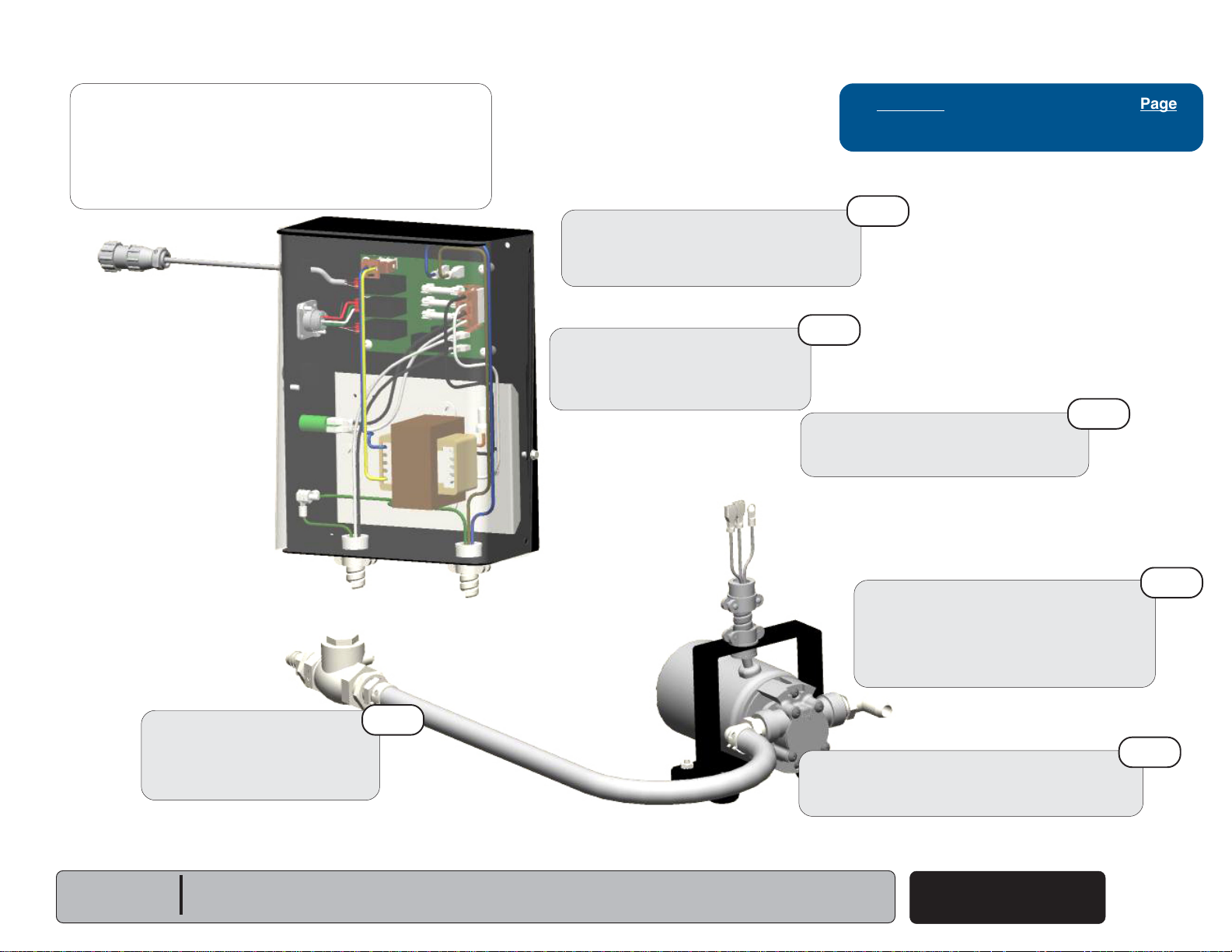

The Liquid Evacuation Pump is an optional accessory for the PowerVac®.

• 115 VAC is applied to the 115V / 24V Transformer energizing it.

• 24 VAC is applied from one side of the Transformer to the J3 plug.

• When the water level reaches the

• When the water level reaches the

Power is supplied to J8 and J9 terminals, energizing the Liquid Evacuation Pump.

NOTE:

The Liquid Evacuation Pump will continue to run until the water

level drops below the

contacts.

If the

Top

float closes, K1 relay contacts close, and its LED is on,

a problem is occurring with the system.

Check for a restriction in the lines, pump not functioning, or PC

board problem.

Liquid Evacuation Pump Electrical System shown when the Bottom & Middle Float Switches are Closed and Pump is running.

Bottom

float switch, opening K3 & K4 relay

Bottom

Middle

float switch, K3 relay contact closes.

float switch, K2 & K4 relay contact close.

(Liquid Evac Pump is Optional)

Optional Liquid Evac Pump Must use a Three Float Assembly

Troubleshooting

Refer To: Page

Evacuation Pump Will Not Run............. A-12

Pump Runs But Will Not Pump ............. A-13

Pump tripping Thermal Overload .......... A-14

Serial Numbers:

Models:

All

Liquid Evac Pump

Electrical

© Midmark Corporation 2006 SF-1873

Rev 9/10/18

A-11

Page 18

Troubleshooting

Back

Go To Table Of Contents

Next

Go To Page:

Evacuation Pump System

Problem: Evacuation Pump will not run.

Check PC Board

Refer to: Section B - Liquid

Evacuation Pump

Check Float Assembly

Refer to: Section B - Float

Assembly

3rd

5th

Check Low Voltage

to PC Board

Refer to: Section B - Liquid

Evacuation Pump

Refer To: Page

Liquid Evacuation Pump

2nd

Check Supply Voltage

to PC Board

Refer to: Section B - Liquid

Evacuation Pump

Check Thermal Motor

Protector

Refer to: Section B - Liquid

Evacuation Pump

Check Supply Voltage ...............B-53-B-56

Check Low Voltage....................B-53-B56

Check Float Assembly....................... B-15

Check Thermal Motor Protector...B-53-B-56

Check PC Board........................B-53-B-56

Check Pump Motor....................B-53-B-56

1st

4th

Earlier Version Shown

A-12

© Midmark Corporation 2006 SF-1873

Evacuation Pump

Will Not Run

Rev 9/10/18

Models:

Serial Numbers:

All

Earlier Version Shown

Check Pump Motor

Refer to: Section B - Liquid

Evacuation Pump

6th

Page 19

Troubleshooting

Back

Go To Table Of Contents

Next

Go To Page:

Evacuation Pump System

Problem: Evacuation Pump runs but does not

remove liquid from Separator.

Check Supply Voltage to Pump

Supply voltage is low.

Refer to: Section B - Liquid Evacuation

Pump

2nd

Check for Obstructions in

Outlet of Separator / Lines.

Refer to: Section B - Liquid

Evacuation Pump

Check Pump Location

Pump should be positioned as close as

possible below the separator.

Refer To: Page

Liquid Evacuation Pump..............B-53-B-56

4th

5th

Check Discharge Line

from Pump

Do not run a discharge head of

greater then 35 ft. (15 Psi).

Models:

Serial Numbers:

All

6th

Earlier Version Shown

Check Suction Line Into Pump

Check for leaks.

Avoid "looping" suction pipe as it could

trap air.

Suction line should not be more than 6 ft.

in length.

Check Evac. Pump Impeller for

Obstructions or Damage.

Refer to: Section B - Liquid Evacuation Pump

Evacuation Pump Runs

but Will Not Pump

© Midmark Corporation 2006 SF-1873

Rev 9/10/18

1st

3rd

A-13

Page 20

Troubleshooting

Back

Go To Table Of Contents

Next

Go To Page:

Evacuation Pump System

Problem: Evacuation Pump Motor keeps tripping

on Thermal Overload.

2nd

Check for Obstructions in

Discharge Line from Pump

Refer to: Section B - Liquid

Evacuation Pump

Check Ambient Temperature

at Motor

Temperature should not exceed 104° F

(40° C) around pump.

Check Supply Voltage to Pump

Supply voltage is low.

Refer to: Section B - Liquid Evacuation

Pump

6th

Check Pump Location

Pump should be positioned as close as

possible below the separator.

Suction line should not be more than 6 ft.

in length.

Refer To: Page

Liquid Evacuation Pump ....................... B-52

1st

5th

Check Discharge Line

from Pump

Do not run a discharge head of

greater then 35 ft. (15 Psi).

Evacuation Pump Keeps

Tripping on Thermal

A-14

© Midmark Corporation 2006 SF-1873

Protector

3rd

Rev 9/10/18

Models:

Serial Numbers:

Earlier Version Shown

All

Motor Thermal Protector

Weak

Replace motor pump.

Check Evac. Pump Impeller for

Obstructions or Damage.

Refer to: Section B - Liquid Evacuation Pump

7th

4th

Page 21

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Testing & Repair

Components: Page

Belt ....................................................B-2

Check Valve ......................................... B-6

Vacuum Relief Valve ............................ B-9

Exhaust ............................................... B-12

Float ..................................................... B-16

Low Voltage .......................................... B-18

Door Limit Switch &

Circuit Breaker (On/Off Switch) ........... B-21

Contactor ............................................. B-26

Fuse ..................................................... B-28

Relay .................................................... B-31

Transformer ......................................... B-34

Fan ....................................................... B-37

Gauge ................................................... B-41

Motor .................................................... B-43

Pump .................................................... B-50

Liquid Evacuation Pump (Accessory) .. B-53

Separator Tank (Rinse)....................... B-58

Models:

Serial Numbers:

Section B

© Midmark Corporation 2006 SF-1873

B-1

Page 22

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

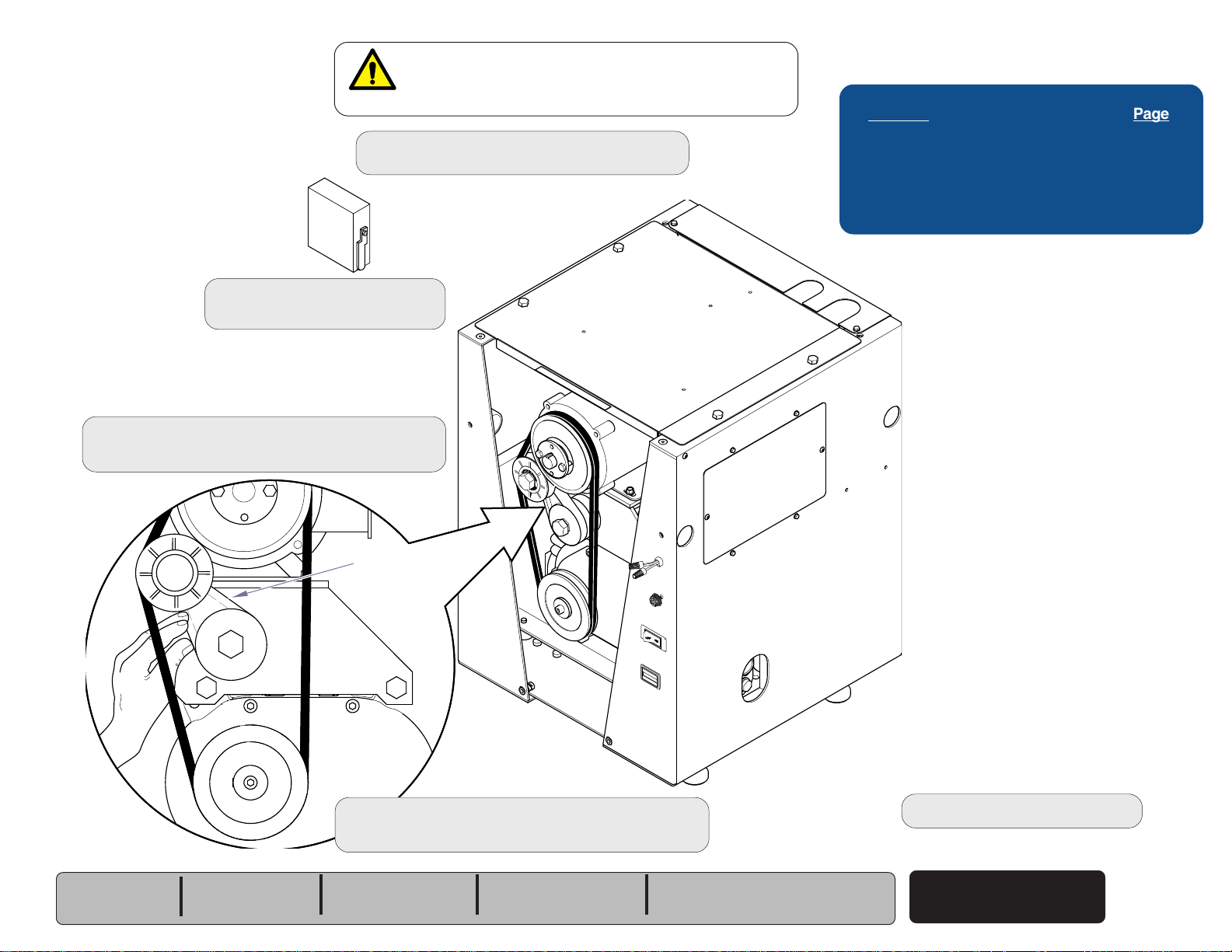

Belt

Location & Function

The Belt runs on a motor pulley system operating the pump.

Belt should never have nicks, cracks or any visible damage,

this will affect performance.

Earlier versions of the PowerVac® the belt will need adjusting

from time to time. Newer versions of the PowerVac® have an

auto tensioner.

WARNING

Motors installed after 12/08 are thermally protected

with automatic reset. Unit may start without warning.

Motor Pulley

Refer to: Page

Belt Adjustment (Tension) .................... B-3

Belt Replacement (Earlier Version) ........ B-4

Belt Replacement (New Version) ........... B-5

B-2

© Midmark Corporation 2006 SF-1873

Belt

Serial Numbers:

Rev 9/10/18

Models:

Belt

Pump Pulley

Earlier Version Shown

AA162300i

All

Page 23

Testing & Repair

10

15

20

25

Back

Go To Table Of Contents

Next

Go To Page:

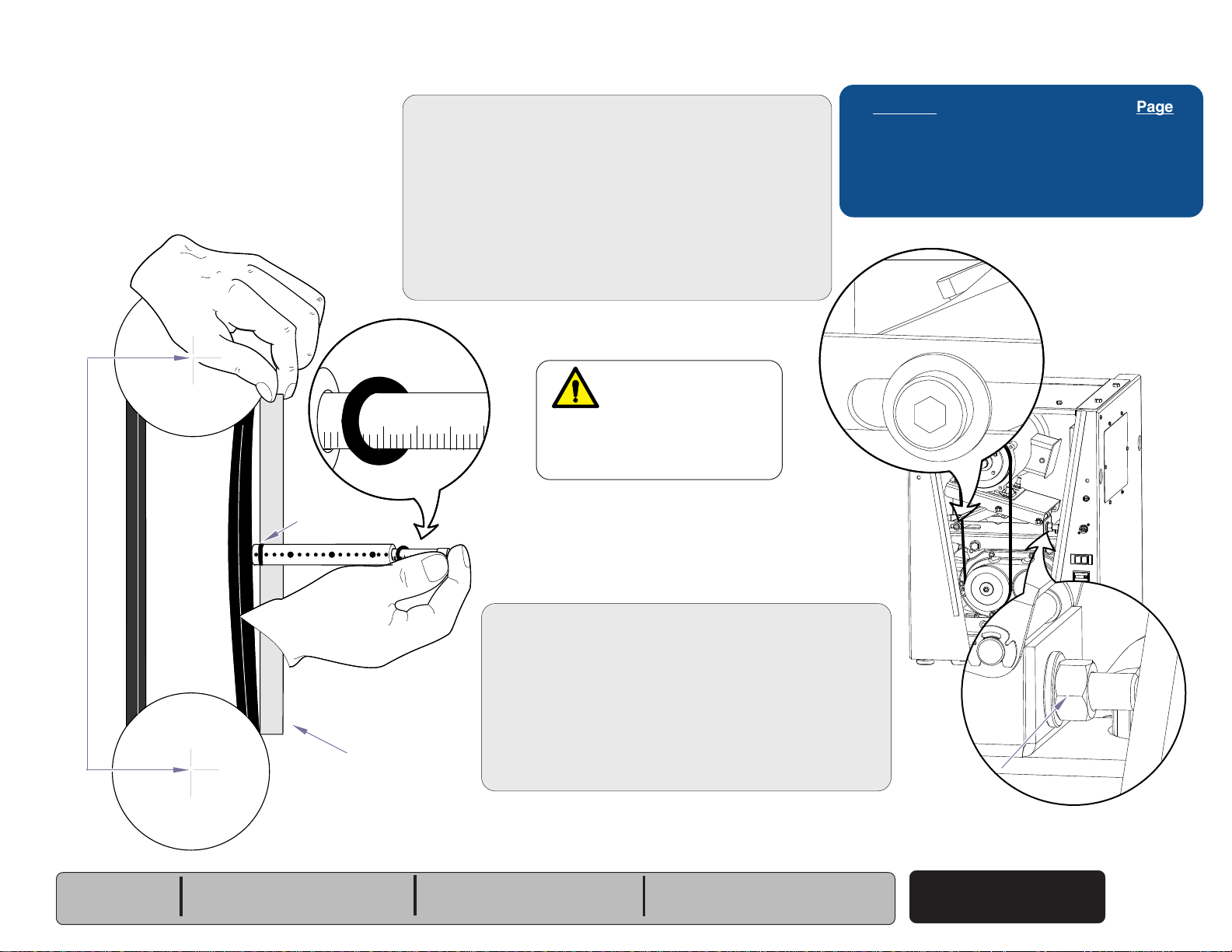

Belt

Checking and Adjusting Belt Tension

(Earlier Versions Only)

(Small End O-ring)

Large End

O-ring

12"

50

150

100

Check belt tension using belt tension checker...

A. Remove front cover. Refer to: Section C Front Cover.

B. Position o-ring on large end of tension checker to 12”

(use "Inches of Span Length" increments on checker).

C. Slide o-ring on small shaft to 0 pounds.

D. Align straight edge with belt.

E. Apply force on the plunger until o-ring on large

shaft is even with straight edge.

F. Remove the tension checker and read the defection

force the small o-ring was moved to.

Verify deflection reading is 7 lbs.

7 pounds

WARNING

Motors installed after

12/08 are thermally protected

with automatic reset. Unit may

start without warning.

15

10

25

20

30

I

f adjustment is needed...

A. Loosen Motor Mount Bolt.

B. Move adjustment nut clockwise to tighten belt.

C. Move adjustment nut counter clockwise to loosen belt

D. Use belt tension checker to recheck deflection reading.

E. Tighten motor mount bolt.

F. Replace front cover.

Refer to: Page

Belt Location and Function .................... B-2

Belt Replacement (Earlier Version) ........ B-4

Belt Replacement (New Version) ........... B-5

Front Cover ........................................... C-2

Motor Mount Bolt

ON

OFF

HOURS

AA168200i

Models:

Serial Numbers:

P3

0611P3P0000 to 0801P3P0611

V245092 to V317654

Straight Edge

If no adjustment is needed...

A. Tighten motor mount bolt.

B. Replace front cover.

0611P5P0000 to 0801P5P0240

V245092 to V317641

P5

0611P7P0000 to 0712P7P0104

V245092 to V317634

P7

Adjustment Nut

Belt

© Midmark Corporation 2006 SF-1873

Rev 9/10/18

B-3

Page 24

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Belt

Replacement

(Earlier Versions Only)

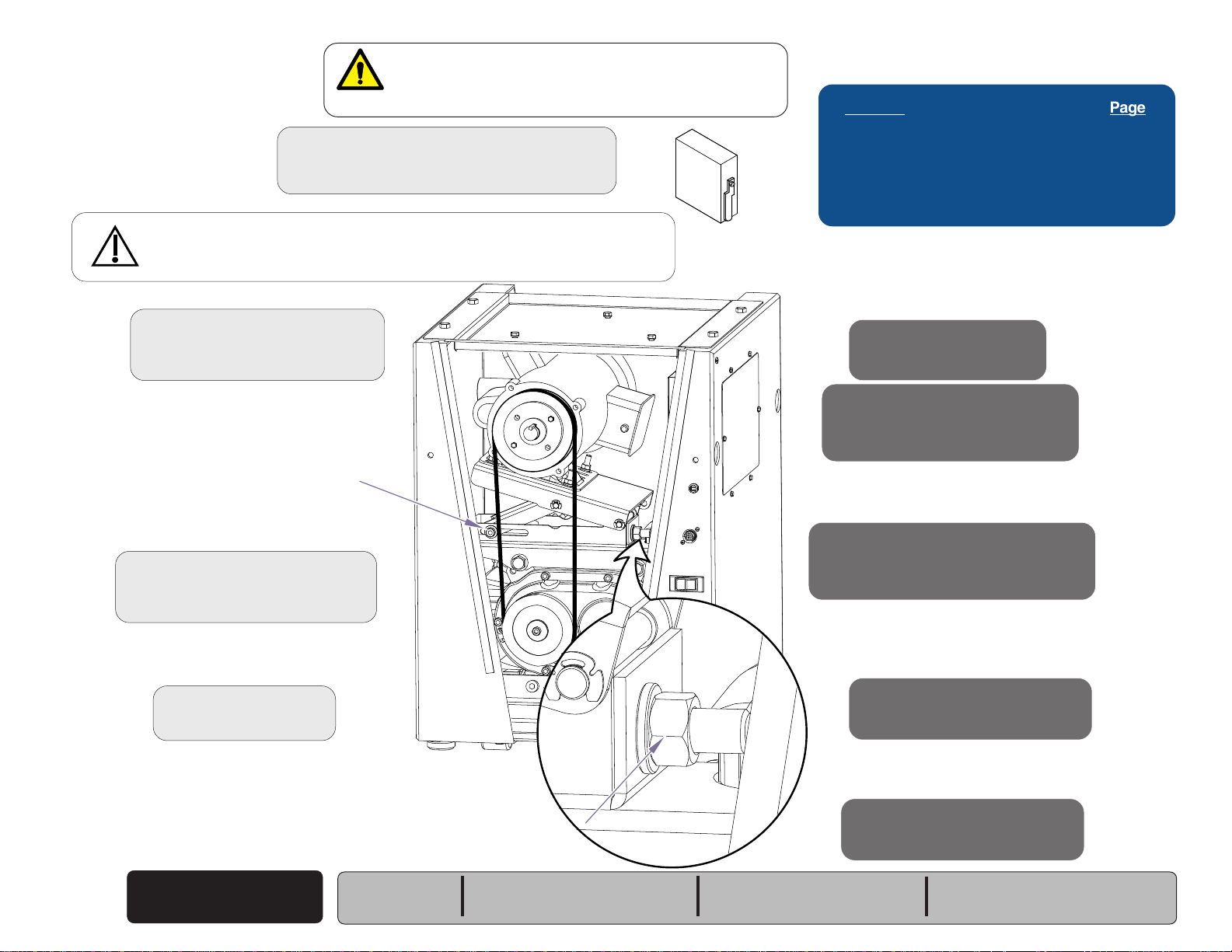

Caution

The On/Off switch controls only the secondary circuit power.

The main power source must be turned off to remove all power in the control box.

WARNING

Motors installed after 12/08 are thermally protected

with automatic reset. Unit may start without warning.

Removal

Step 1: Disconnect power at on/off switch

and main power supply box.

Refer to: Page

Belt Location and Function .................... B-2

Belt Adjustment (Earlier Version) .......... B-3

Belt Replacement (New Version) ........... B-5

Front Cover ........................................... C-2

Removal

Step 2: Remove front cover.

Refer to: Section C - Front Cover

Motor Mount Bolt

Removal

Step 3: Loosen motor mount bolt

and adjustment bolt.

Removal

Step 4: Remove belt.

Installation

Step 5: Replace belt.

Installation

Step 6: Tighten adjustment bolt

and motor mount bolt.

Installation

Step 7: Set belt tension.

ON

OFF

HOURS

Refer to: Section B - Belt Adjustment

Installation

Step 8: Replace front cover.

B-4

© Midmark Corporation 2006 SF-1873

Belt

Serial Numbers:

Rev 9/10/18

Models:

Adjustment Bolt

0611P3P0000 to 0801P3P0611

V245092 to V317654

P3

AA162700i

Installation

Step 9: Connect power.

0611P5P0000 to 0801P5P0240

V245092 to V317641

P5

0611P7P0000 to 0712P7P0104

V245092 to V317634

P7

Page 25

Belt

Back

Go To Table Of Contents

Next

Go To Page:

Replacement

with automatic reset. Unit may start without warning.

Step 1: Disconnect power at on/off switch

(Newer Versions Only)

Step 2: Remove front cover.

Refer to: Section C Front Cover

Step 3: Slightly push tension arm up toward the

pulley and remove belt with other hand.

WARNING

Motors installed after 12/08 are thermally protected

and main power supply box.

Testing & Repair

Refer to: Page

Belt Location and Function .................... B-2

Belt Adjustment (Earlier Version) .......... B-3

Belt Replacement (Earlier Version) ........ B-4

Front Cover ........................................... C-2

Models:

Serial Numbers:

P3

0802P3P0612 thru

Present

Tension Arm

Step 4: Slightly push tension arm up toward the

pulley and install new belt with other hand.

P5

0801P5P0241 thru

Present

P7

0712P7P0105 thru

Present

AA221600

All

V785000 thru

Present

Step 5: Replace front cover.

Belt

© Midmark Corporation 2006 SF-1873

Rev 9/10/18

B-5

Page 26

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

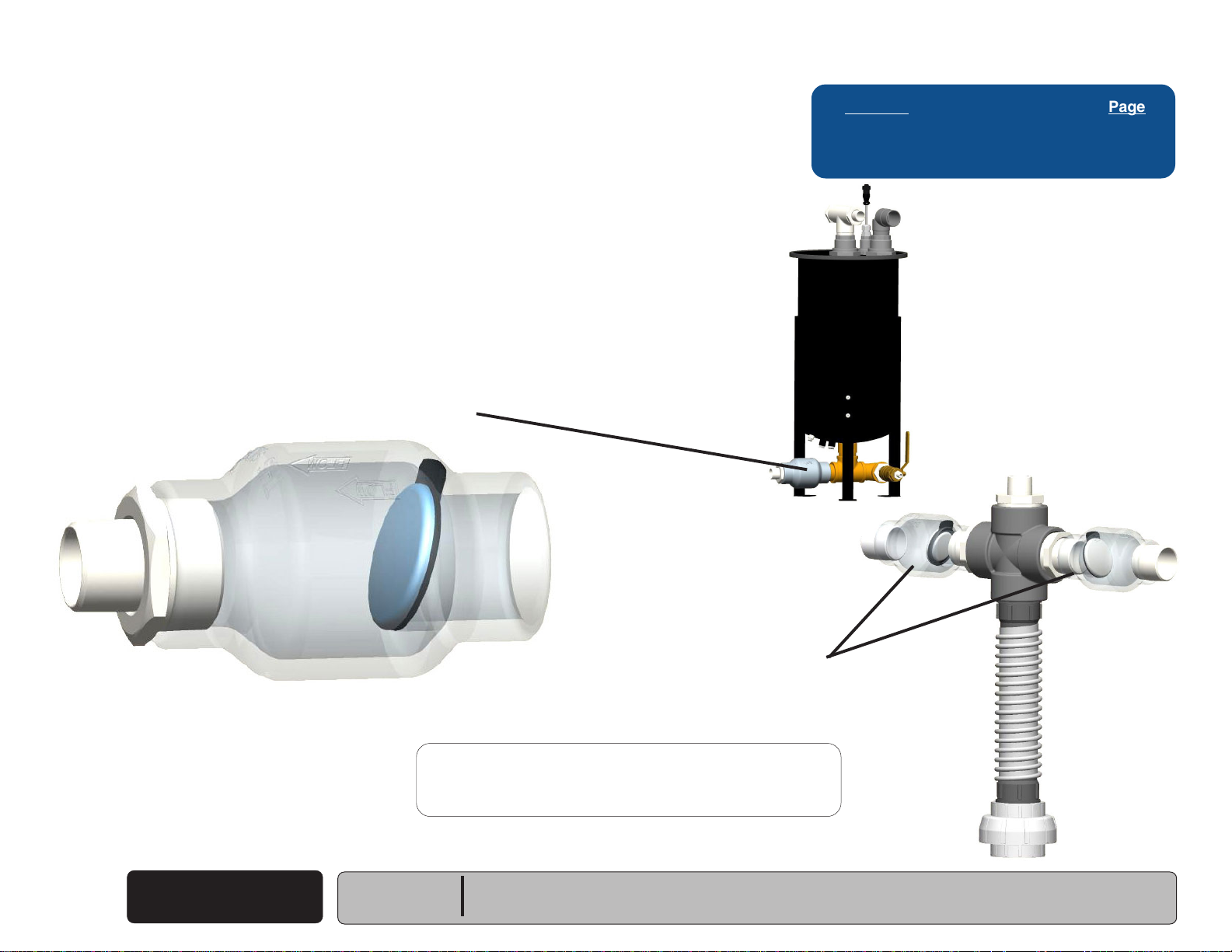

Check Valve

Location and Function

The Check Valve located in the drain allows the separator to

drain upon removal of vacuum pressure. When the pump is

not running, the valve opens, allowing liquids to drain. If the

pump is running the valve closes to keep air in the drain from

back flushing into the system.

Each vacuum pump in a multiple pump installation requires a

check valve to be installed into the intake line.

This prevents loss of suction pressure when one pump in the

system is turned off. If no check valve is present, flow will be

allowed through he "off" pump, creating a loss suction of the

rest of the system.

Vacuum Pressure keeps Valve

Closed when Pump is Running

Refer to: Page

Check Valve Test ................................. B-7

Check Valve Replacement .................... B-8

Earlier Version Shown

Located at bottom

drain on all units

B-6

© Midmark Corporation 2006 SF-1873

When Pump Stops Valve Opens

for Liquids and Solids to Drain

Check Valve

Serial Numbers:

Rev 9/10/18

Multiple Units have two additional check

valves, located in the Tee Assembly

Note: When installing check valve in horizontal position,

Models:

confirm the hinge for the flapper is on top of the valve.

All

Page 27

Testing & Repair

AA163000i

Back

Go To Table Of Contents

Next

Go To Page:

Check Valve

Testing

Equipment Room

Operatory

On / Off Switch

AA152901i

Step 2: Turn vacuum off and

ensure that water

drains from separator.

Refer to: Page

Check Valve Location and Function ...... B-6

Check Valve Replacement .................... B-8

Step 3: Turn power off.

Step 4: Allow unit to drain completely.

Step 1: Vacuum 1-2 gallons of fresh

water into system through

operatory lines.

Note: If water does not drain out, remove lid and see if valve is clogged.

Serial Numbers:

(If so flush and clean tank, if not replace valve.)

If water drains out, continue with next test on step 3.

Models:

All

Earlier Version Shown

Step 6: Turn power on and place hand over end of drain hose.

Note: If you feel suction check valve is stuck, replace check valve.

If no suction is felt then check valve is good.

© Midmark Corporation 2006 SF-1873

Step 5: Pull drain hose

Check Valve

out of drain.

Rev 9/10/18

B-7

Page 28

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

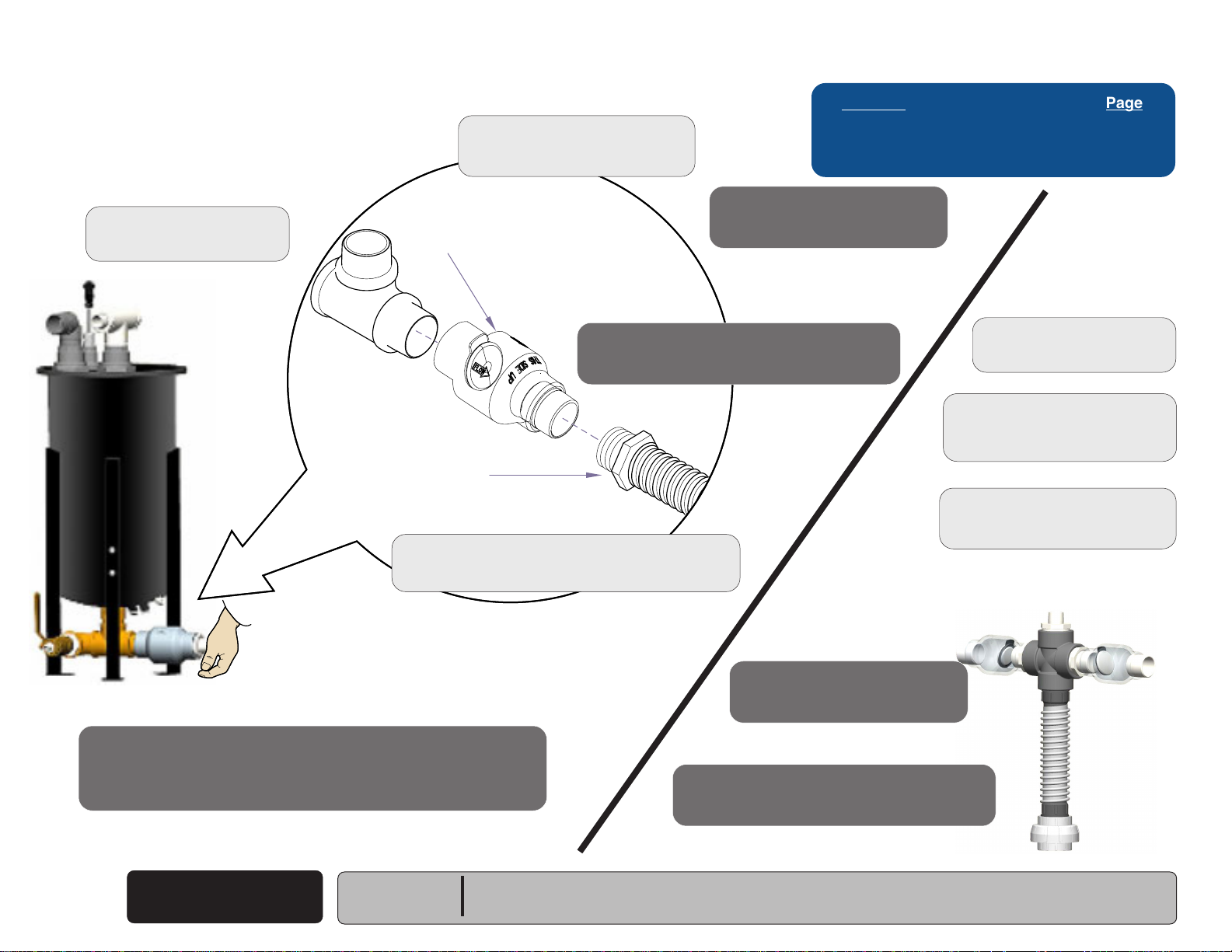

Check Valve

Replacement

Removal

Step 1: Turn power off.

All Units

Removal

Step 3: Unscrew check valve.

Check

Valve

Drain Hose

Verify criteria of valve so the

correct position is "up".

Installation

Step 5: Install drain hose to check valve.

Refer to: Page

Check Valve Location and Function ...... B-6

Check Valve Test ................................. B-7

Installation

Step 4: Install check valve.

Twin Units

Removal

Step 1: Turn power off.

Removal

Step 2: Remove drain hose

from check valve.

Removal

Step 3: Unscrew check valve.

Earlier Version Shown

Installation

Step 6: Turn power on and place hand over end of check valve.

Note: Verify you do NOT feel any suction.

B-8

© Midmark Corporation 2006 SF-1873

AA162900i

Check Valve

Serial Numbers:

Rev 9/10/18

Removal

Step 2: Remove drain hose from check valve.

Models:

All

Twin Unit Tee Assembly Check Valves

Installation

Step 4: Install check valve.

Installation

Step 5: Install drain hose to check valve.

Page 29

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

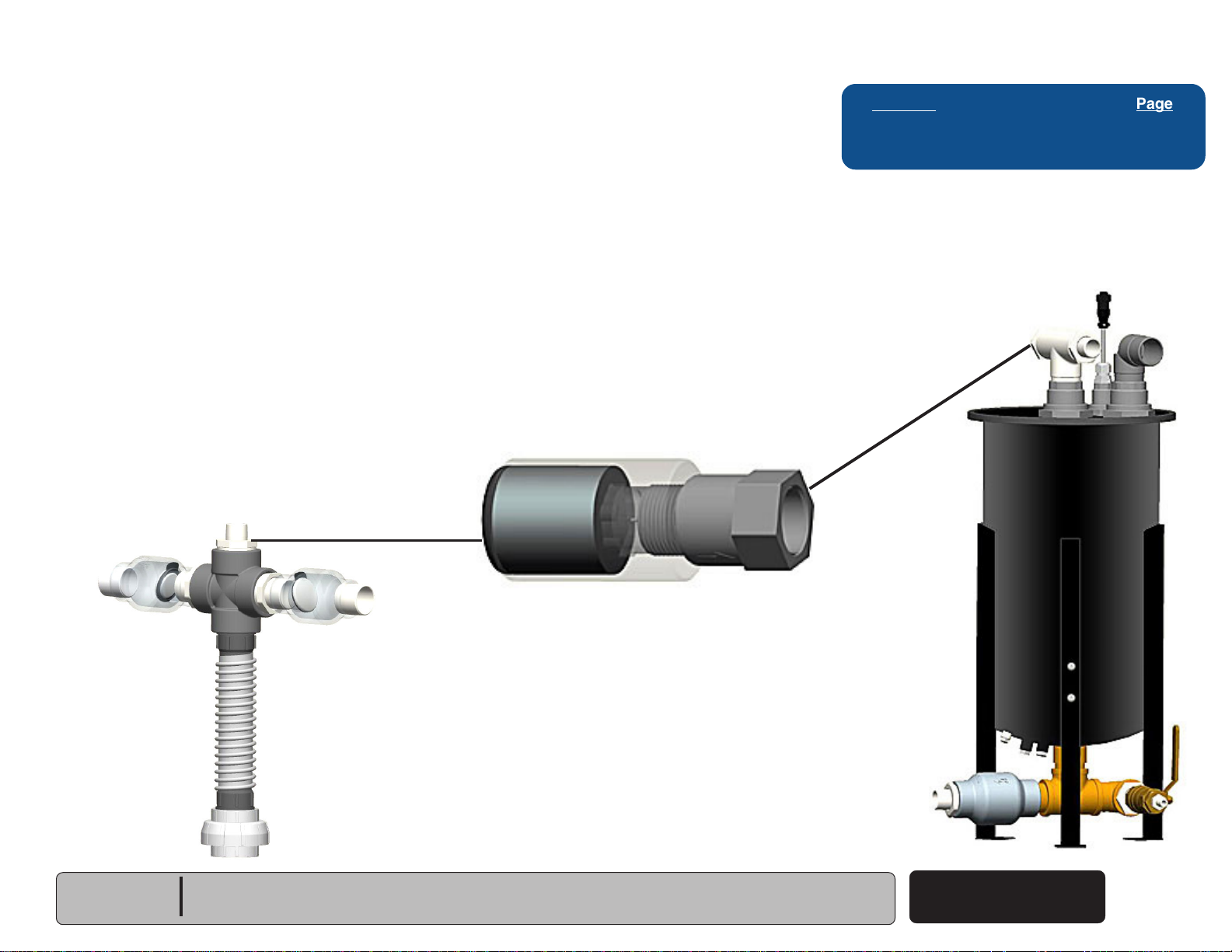

Vacuum Relief Valve

Location and Function

The Vacuum Relief Valve regulates the vacuum pressure in

the PowerVac

.

The Vacuum Relief Valve has a 1" NPT male fitting on one

side and 1" NPT female fitting on the other side.

The valve is adjustable up to 18"Hg.

Recommended range for the system vacuum is from 10" to

18"Hg. The valve is preset at the factory for 12" Hg.

The Vacuum Relief Valve is located on top of the separator

tank in the "T" Fitting on Single Models and in the center of

the mounted "T" assembly on the Twin Models.

®

Twin Unit Location

Refer to: Page

VRV Adjustment ................................... B-10

VRV Replacement ................................ B-11

Single Unit Location

Models:

Serial Numbers:

All

Earlier Version Shown

Vacuum Relief Valve

© Midmark Corporation 2006 SF-1873

Rev 9/10/18

B-9

Page 30

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Vacuum Relief Valve

Adjustment

Step 1: Turn power off.

Single Unit Location

0

2

5

2

0

3

-

Step 2: Remove the filter and valve by unscrewing from tee-fitting.

Filter

Valve

5

1

0

1

5

0

Step 3: Adjust the center mounted screw inside the valve.

Twin Unit Location

Refer to: Page

VRV Location and Function................... B-9

VRV Replacement ................................ B-11

Note: Use 1/4 inch nutdriver and phillips screwdriver.

Each full clockwise turn increases the vacuum level by

approximately 2 inch Hg.

Vacuum Relief Valve

B-10

© Midmark Corporation 2006 SF-1873

AA163100i

Earlier Version Shown

Rev 9/10/18

Models:

Serial Numbers:

Step 4: Install filter and valve.

Note: Recommended Range is 10” Hg - 18 Hg.

Vacuum is preset at 12” Hg.

If reading is low check for leaks or open operatory lines.

All

Page 31

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Vacuum Relief Valve

Replacement

Removal

Step 1: Turn power off.

Single Unit Location

Refer to: Page

VRV Location and Function................... B-9

VRV Adjustment ................................... B-10

Filter

Twin Unit Location

Valve

5

1

0

2

0

1

5

2

5

0

3

0

Removal

Step 2: Unscrew valve from tee-fitting.

Unscrew valve from filter.

Models:

Serial Numbers:

All

Installation

Step 3: Screw filter onto valve.

AA163200i

Earlier Version Shown

Screw valve assembly into tee-fitting.

Installation

Step 4: Turn power on.

Installation

Step 5: Perform Adjustment.

Refer to: Section B - VRV Adjustment

Vacuum Relief Valve

© Midmark Corporation 2006 SF-1873

Rev 9/10/18

B-11

Page 32

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Exhaust Valve

Location and Function

The exhaust check valve provides protection for the pump. It

prevents moisture from entering the pump from the exhaust

line.

Refer to: Page

Exhaust Valve Check ........................... B-13

Exhaust Valve Replacement ................. B-14

B-12

© Midmark Corporation 2006 SF-1873

Exhaust Valve

Rev 2/08

Models:

Serial Numbers:

Earlier Version Shown

All

Page 33

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Exhaust Valve

Check

Step 1: Turn power off.

Barbed Fitting

Exhaust Valve

Refer to: Page

Exhaust Valve Location and Function ... B-12

Exhaust Valve Replacement ................. B-14

Step 2: Remove exhaust hose from barbed fitting.

Remove barbed fitting.

Step 3: Remove exhaust valve from nipple.

Step 4: Shake valve and listen for movement of flap.

Note: If you are able to hear the valve flap moving, it

Models:

Serial Numbers:

is good. If valve is stuck and not moving,

remove valve and clean.

If valve will not work, replace the exhaust valve.

Refer to: Section B Replacement

All

Nipple

Earlier Version Shown

AA163400i

Exhaust Valve

© Midmark Corporation 2006 SF-1873

Rev 9/10/18

B-13

Page 34

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Exhaust Valve

Replacement

Removal

Step 1: Turn power off.

Barbed Fitting

Exhaust Valve

Refer to: Page

Exhaust Valve Location and Function .. B-12

Removal

Step 2: Remove exhaust hose from barbed fitting.

Remove barbed fitting.

Installation

Step 5: Screw barbed fitting into exhaust valve.

Connect exhaust hose to barbed fitting.

Removal

Step 3: Remove exhaust valve from nipple.

Installation

Step 4: Screw new exhaust valve onto nipple.

B-14

© Midmark Corporation 2006 SF-1873

Exhaust Valve

Rev 9/10/18

Nipple

Models:

Serial Numbers:

Earlier Version Shown

All

Installation

Step 6: Turn power on.

AA163400i

Page 35

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Float Assembly

Location and Function

The Float Assembly contains three Float (Reed) Switches

mounted on a bracket at different intervals.

The Reed Switch has contacts that remain open until the

liquid in the separator rises, causing the float to rise until the

magnet contacts the Reed Switch.

When the magnet contacts the Reed Switch, the open

contacts inside the reed close.

When the top float switch closes, the fan, hour meter and

vacuum pump stop running until the bottom float opens and

the cycle starts again.

The upper and lower floats interact as a latching circuit with

the internal relay to release upon drain below the bottom

float. The magnet in the float is to activate the reed switch

within the stem.

If the PowerVac

installed, it begins running when the middle float switch

closes, avoiding the vacuum pump shut-off that would occur if

the liquid level closed the top switch.

®

has a Liquid Evacuation Pump (Accessory)

Refer to: Page

Check Float .......................................... B-16

Replace Float ........................................ B-17

Reed Switch

Contacts are open

until

magnet closes it.

Magnet

Float

Earlier Versions had Three Reed Switch Floats. The Middle Float

was for the Liquid Evac Pump Option. If You Have a Liquid Evac

Pump Connected to the PowerVac you Must Replace Float With a

Three Reed Switch Float Assembly. If There is No Evac Pump

Connected to the PowerVac, You can Replace the Float With a Two

Reed Switch Float Assembly.

Models:

Serial Numbers:

All

Current Version Shown

AA2293

Float Assembly

© Midmark Corporation 2006 SF-1873

Earlier Version

Shown

Rev 9/11

B-15

Page 36

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Float Assembly

Earlier Versions had Three Reed Switch Floats. The Middle Float

was for the Liquid Evac Pump Option. If You Have a Liquid Evac

Pump Connected to the PowerVac you Must Replace Float With a

Three Reed Switch Float Assembly. If There is No Evac Pump

Connected to the PowerVac, You can Replace the Float With a Two

Reed Switch Float Assembly.

Check

To check float switches...

Note: If pump is not running, unplug float from base unit. If pump doesn't start running,

test relay (Section B) if pump starts running, continue with float checks...

A) Turn power off and plug float into base unit.

B) Remove gasket on separator lid.

C) Lift lid/float assembly out of tank and lay across top of tank.

D) Turn power on.

E) Move floats to down position.

F) Raise bottom float to reed swtich, then raise top float to reed swtich. Motor should stop

after top switch is raised.

G) Move top float down first, then lay bottom float down.

Motor should not start until bottom float is down.

Note: Floats should move freely, if float does not work properly, replace the float assembly.

Refer to: Page

Float Location and Function .................. B-15

Replace Float ........................................ B-17

Rinse Separator Tank .......................... B-58

Relay Test ........................................... B-32

B-16

© Midmark Corporation 2006 SF-1873

Note:

If no water in separator, but still runs when

unplugged from vacuum base unit, float maybe stuck.

Float Assembly

Rev 9/10/18

Models:

Serial Numbers:

All

Current Version Shown

AA2336

Page 37

Float Assembly

Back

Go To Table Of Contents

Next

Go To Page:

Replacement

Removal

Step 1: Turn power off.

Unplug float cord.

Earlier Versions had Three Reed Switch Floats. The Middle

Float was for the Liquid Evac Pump Option. If You Have a

Liquid Evac Pump Connected to the PowerVac you Must

Replace Float With a Three Reed Switch Float Assembly. If

There is No Evac Pump Connected to the PowerVac, You can

Replace the Float With a Two Reed Switch Float Assembly.

Float Cord Fitting

Removal

Step 3: Lift separator lid.

Hold onto float underneath lid.

Loosen float cord fitting on top of separator.

Float will come down into your hand.

Testing & Repair

Refer to: Page

Float Location and Function .................. B-15

5

1

0

2

0

1

5

2

5

0

3

0

Installation

Step 4: Insert new float assembly up through separator lid.

Check Float .......................................... B-16

Tighten float cord fitting on top of separator.

Installation

Step 6: Plug in float cord to vacuum base unit.

Turn power on.

Models:

Serial Numbers:

All

Earlier Version

Shown

Removal

Step 2: Pull gasket down off separator lid.

Installation

Step 5: Set lid on separator.

Install gasket.

AA163700i

Float Assembly

© Midmark Corporation 2006 SF-1873

Rev 9/10/18

B-17

Page 38

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Master Control Panel and Low Voltage

Location and Function

Wiring for Remote ON/OFF Switch, Master Control Panel

Low voltage (24VAC) wiring provides power for a remote ON/

OFF switch and indicator light (optional).

Refer to: Page

Master Control Panel Test ................... B-19

Low Voltage Test ................................. B-20

B-18

© Midmark Corporation 2006 SF-1873

AA163400i

Low Voltage

Earlier Version Shown

Models:

Serial Numbers:

Rev 12/10

All

Page 39

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Master Control Panel

Test

Step 1: Disconnect power at on/off switch

and main power supply box.

Caution

When testing components

with power on use care to

prevent electrical shock.

Step 2: Bypass the remote switch to verify it is not defective.

Disconnect the Red and Blue wires from the remote switch.

Connect the Blue and Red wires together.

Refer to: Page

Location and Function .......................... B-18

Low Voltage Test ................................. B-20

Models:

Serial Numbers:

Step 3: Connect power to the PowerVac

Turn the On/Off switch On.

Note: If the fan, hour meter and pump start running

then replace the remote switch.

®

All

Earlier Version Shown

© Midmark Corporation 2006 SF-1873

Low Voltage

Rev 9/10/18

B-19

Page 40

Testing & Repair

Transformer

Contactor

Back

Go To Table Of Contents

Next

Go To Page:

Low Voltage

Test

Step 1: Turn power off.

Step 2: Remove electrical cover.

Refer to: Section C Access Procedures

Caution

When testing components

with power on use care to

prevent electrical shock.

Refer to: Page

Location and Function .......................... B-18

Master Control Panel Testing .............. B-19

Access Procedrues .............................. C-1

Step 3: Set meter to V.

~

Step 4: Turn power on.

Step 5: Place probes on red low voltage wire on contactor

and yellow wire coming from transformer.

Note:

5

1

0

2

0

1

5

2

5

0

3

-

0

Verify voltage is 24 VAC.

B-20

© Midmark Corporation 2006 SF-1873

Low Voltage

Rev 9/10/18

AA2335

Models:

Serial Numbers:

All

Page 41

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Door Limit Switch &

PowerVac® Circuit Breaker (ON/OFF Switch)

Location & Function

With facility power (230 VAC) supplied to the system....

The transformer continuously supplies 24 VAC to the

normally-open door limit switch.

With the front access cover in place...

The plastic bumper on the top right side of the access cover,

trips the door limit switch causing it to close.

When the limit switch is closed, 24 VAC flows thru the switch

to the PowerVac® circuit breaker

circuit breaker switch ON, current is supplied to the remote

wall switch

Note: If the facility does not have a remote wall switch,

(if applicable)

the PowerVac

switch for the system.

.

®

circuit breaker serves as the ON/OFF

(ON / OFF Switch)

. With the

Refer to: Page

Door Limit Switch Testing .................... B-22

Circuit Breaker (On/Off) Testing .......... B-23

Door Limit Switch Replacement ........... B-24

Circuit Breaker Replacement (On/Off) B-25

When the front access cover is removed...

The door limit switch opens and stops current flow to the

PowerVac® circuit breaker. This is a safety feature that

prevents the system from operating with the cover removed.

Models:

Serial Numbers:

All

Earlier Version Shown

Door Limit Switch

On/Off Switch

© Midmark Corporation 2006 SF-1873

Rev 2/08

B-21

Page 42

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Door Limit Switch

Step 1: Turn power off.

Testing

During this step, the motor belt and pulley may spin with front cover off.

Stay clear and keep everything out of the vacuum base!

Step 3: Turn power on and depress activation button with a screwdriver.

Note: If motor starts up, quickly take pressure off switch.

Plastic bumper may be obstructed or damaged.

Check plastic bumper on door for damage.

If it is damaged, switch it with plastic bumper on opposite side of door

until a replacement can be ordered.

If motor doesn't start, continue with step 4.

Caution

Step 2: Remove front cover.

Refer to: Section C Front Cover.

Refer to: Page

Door Limit / Circuit Breaker Function .. B-21

Circuit Breaker (On/Off) Testing .......... B-23

Door Limit Switch Replacement ........... B-24

Circuit Breaker Replacement (On/Off) B-25

Section C Front Cover ......................... C-2

Caution

When testing components

with power on use care to

Mounting Screw

prevent electrical shock.

Step 5: Remove mounting screw for door limit switch.

Disconnect electrical leads.

Step 4: Turn power off.

C

O

M

NO

N

C

AA164100i

With switch 'untripped'...

OL

less than 5

ΩΩ

Ω

ΩΩ

Door Limit Switch &

B-22

© Midmark Corporation 2006 SF-1873

ON

OFF

HOURS

AA164000i

gnidaeRreteMsutatSnoitcAderiuqeR

Limit switch - OK

Circuit Breaker

Rev 9/10/18

Replace switch

Models:

Serial Numbers:

Activation

Button

Caution

Door limit switch is a safety device.

If switch is not working, do not bypass.

Warranty will be void if switch is bypassed.

If both tests fail, it must be replaced!

All

Limit Switch Test

Step 6: Test continuity. Set meter to

Place meter probes on

Note: Check switch 'tripped' and 'untripped'.

Step 7: Install front cover.

With switch 'tripped'...

gnidaeRreteMsutatSnoitcAderiuqeR

OL

less than 5

ΩΩ

Ω

ΩΩ

Ω.Ω.

Ω.

Ω.Ω.

COM and NO

Replace switch

Limit switch - OK

terminals.

Page 43

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Circuit Breaker (ON/OFF Switch)

Testing

Step 1: Turn power off.

Step 2: Remove front cover.

Refer to: Section C Front Cover.

Caution

When testing components

with power on use care to

prevent electrical shock.

Circuit Breaker Test

Step 3: Test continuity. Set meter to

Disconnect leads from switch terminals.

Place meter probes on

Note: Check switch 'tripped' and 'untripped'.

COM and NO

Ω.Ω.

Ω.

Ω.Ω.

Refer to: Page

Door Limit / Circuit Breaker Function .... B-19

Door Limit Switch Testing ..................... B-20

Door Limit Switch Replacement ............ B-22

Circuit Breaker Replacement (On/Off) .. B-23

Front Cover .......................................... C-2

terminals.

OL

less than 5

Models:

Serial Numbers:

gnidaeRreteMsutatSnoitcAderiuqeR

Circuit Breaker is Good

ΩΩ

Ω

ΩΩ

Replace Circuit Breaker

All

AA165501i

Step 4: Connect switch leads.

With switch 'tripped'...

gnidaeRreteMsutatSnoitcAderiuqeR

OL

less than 5

ΩΩ

Ω

ΩΩ

Door Limit Switch &

Circuit Breaker

© Midmark Corporation 2006 SF-1873

Install front cover.

Replace Circuit Breaker

Circuit Breaker is Good

Rev 9/10/18

B-23

Page 44

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Door Limit Switch

Replacement

Removal

Step 1: Disconnect power at on/off switch

and main power supply box.

Removal

Step 2: Remove front cover.

Refer to: Section C Front Cover

Caution

The On/Off switch controls only the secondary circuit power.

The main power source must be turned off to remove all power in the control box.

Vacuum system must not have power when front cover is off base unit.

Plunger

Mounting Screw

WARNING

Motors installed after

12/08 are thermally protected

with automatic reset. Unit may

start without warning.

Refer to: Page

Door Limit / Circuit Breaker Function .. B-21

Door Limit / Circuit Breaker Testing .... B-22

Circuit Breaker (On/Off) Testing .......... B-23

Circuit Breaker Replacement (On/Off) B-25

Front Cover .......................................... C-2

Removal

Step 3: Disconnect wires from limit switch.

Mounting Screw

Installation

Step 6: Connect wiring to limit switch.

Door Limit Switch &

B-24

© Midmark Corporation 2006 SF-1873

Circuit Breaker

ON

OFF

HOURS

Rev 9/10/18

AA165700i

Models:

Serial Numbers:

Removal

Step 4: Remove mounting screw and pull out limit switch and bracket.

Remove switch from bracket.

Installation

Step 5: Align limit switch with hole in side panel and

plunger away from mounting screws.

Install mounting screw as shown.

Installation

Step 7: Install front cover.

Installation

Step 8: Turn power source on.

All

Rev 1/09

Page 45

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Circuit Breaker (ON/OFF Switch)

Replacement

Removal

Step 1: Disconnect power at on/off switch

and main power supply box.

Removal

Step 2: Remove front cover.

Refer to: Section C Front Cover

Refer to: Page

Door Limit / Circuit Breaker Function .... B-19

Door Limit Switch Test .......................... B-20

Circuit Breaker (On/Off) Testing ........... B-21

Door Limit Switch Replacement ............ B-22

Front Cover .......................................... C-2

Removal

Step 4: Push in on both side of breaker and push forward to pull out of panel.

Installation

Step 5: Push in on both sides of breaker.

Push breaker into panel and release

sides to snap it in to place.

Removal

Step 3: Disconnect wires from back of breaker.

Models:

Serial Numbers:

All

Installation

Step 6: Install front cover and restore power.

AA165600i

Door Limit Switch &

Circuit Breaker

© Midmark Corporation 2006 SF-1873

Rev 9/10/18

B-25

Page 46

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Contactor

Location and Function

When the PowerVac® is turned on either by the remote wall

switch or vacuum unit on/off switch, the Contactor is energized. It sends current to the fan, hour meter and pump,

turning them on.

Earlier Version

Refer to: Page

Contactor Testing ................................. B-27

Current Version

B-26

© Midmark Corporation 2006 SF-1873

Contactor

Earlier Version Shown

Models:

Serial Numbers:

Rev 3/14/19

All

Page 47

Contactor

Back

Go To Table Of Contents

Next

Go To Page:

Test

Step 1: Turn power off.

Caution

When testing components

with power on use care to

prevent electrical shock.

Testing & Repair

Refer to: Page

Contactor Location and Function ......... B-26

Electrical Cover .................................... C-4

Step 3: Turn power on.

Step 2: Remove electrical cover.

Refer to Section C: Electrical Cover.

Step 5: Check voltage across contactor.

• Set meter to V.

• Place meter probes on top red wire and

bottom black wire.

Note: Verify reading is 24 volts.

AA163900

Step 4: Check high voltage on contactor.

• Set meter to V.

• Place meter probes on front, left side red

and black wires.

Note: Verify reading is line volts.

Step 6: Insert screwdriver to start manually.

Note: if system starts, replace contactor.

Step 7: Install electrical cover.

Note:

Line Voltage shoud be 208 - 230 VAC with circuit loaded

(equipment running)

gnidaeRreteMsutatSnoitcAderiuqeR

Models:

Serial Numbers:

All

Line Volts

(Left side check)

24 Volts

(Top and Bottom check)

)

Contactor OK

Contactor OK

Contactor

© Midmark Corporation 2006 SF-1873

Rev 9/10/18

B-27

Page 48

Testing & Repair

Back

Go To Table Of Contents

Next

Go To Page:

Fuse

Location and Function

The fuse limits the electrical current from the transformer to

the contactor. It interrupts the electrical currents in the case

of an overload.

Only replace fuse with 1/8 amp, 250 volt, Slo Blo, fuse.