Midmark Matrx Quick Reference Manual

Quick Reference Guide

Matrx™ Central Scavenger

Waste Anesthetic Gas Disposal System

Model Number:

Serial Number:

Dealer Information:

Purchase Date:

This guide highlights basic operation information for the Matrx™ Central Scavenger

System.

Refer to the Matrx™ Central Scavenger

System Installation Manual for more detailed information about the Unit.

If service is required, contact your

authorized Midmark dealer.

Maintenance Limited Warranty

© Midmark Corporation 2008

Once a year inspect the following:

• Outside Vent must be kept free of dirt, snow and

debris including bird, rodent and insect nests.

• Visually inspect the fan for dirt and dust buildup.

Vacuum if necessary.

• Visually inspect power cord and all Scavenging

Hoses for damage. Replace if necessary.

• Test the vacuum levels at each Scavenging Hose

port using the Manometer supplied with the unit.

Follow the instructions printed on the front of the

Manometer.

Vacuum levels registering outside of the pass bands

on the Manometer indicate that the fan needs to be

cleaned, replaced, or that there is a blockage in the

duct work.

Calling for Service

If service is required, contact your Midmark dealer.

To contact Midmark Corporation directly:

1-800-Midmark (1-800-643-6275)

8:00 am - 5:00 pm (EST) Monday through Friday

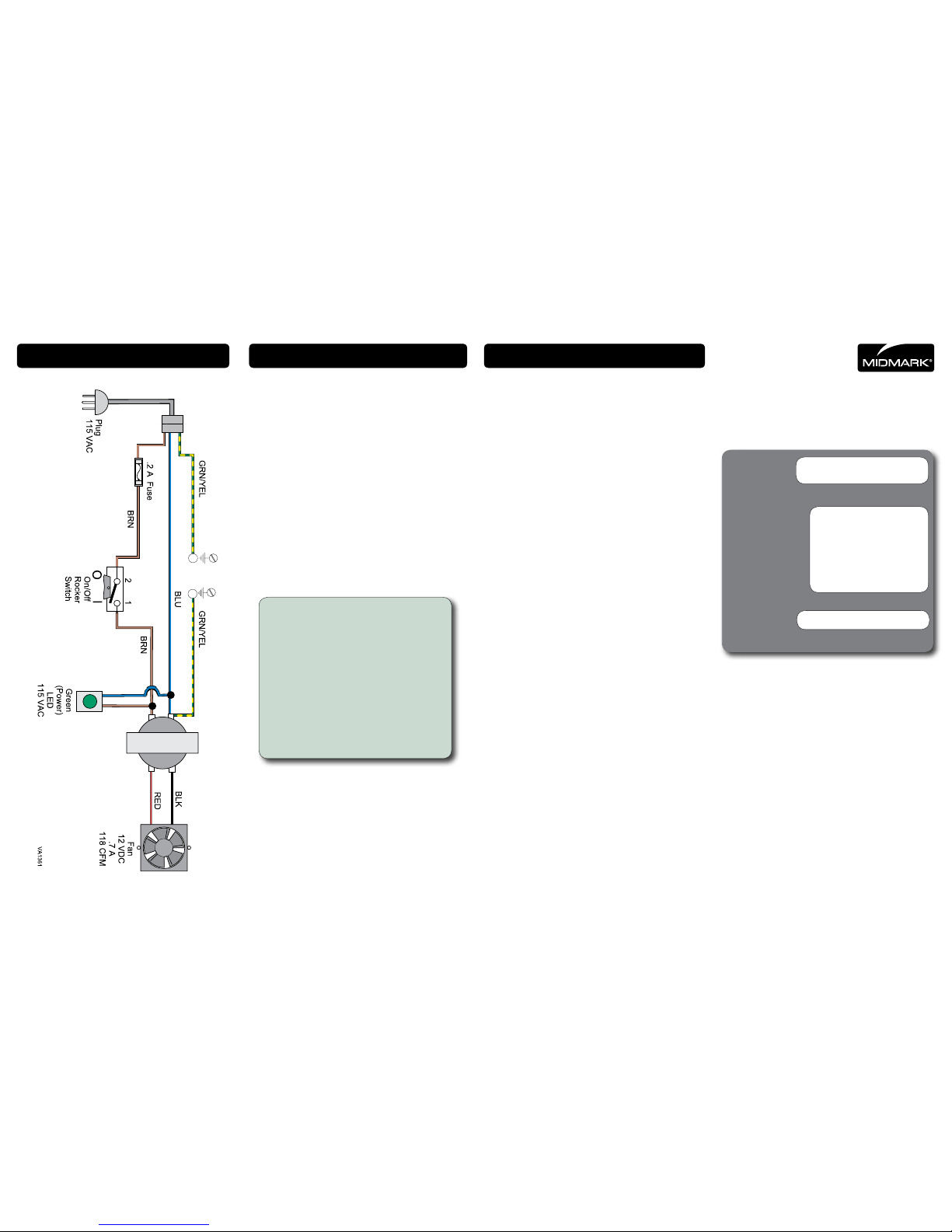

Wiring Diagram

10593300 Rev C (11/11)

Operation of the Matrx™ Central

Scavenger System is restricted to use in

veterinary procedures performed by

veterinary professionals trained in

anesthesia practice.

Test the vacuum levels at each

Scavenging Hose port using the

Manometer provided with the

product:

A) When a new line is added.

B) When any Trunk Line or Scavenging

Hose line is modified.

C) Yearly to verify performance and

functionality of the equipment.

Note: Instructions for using the Manometer are

printed on the front of the device.

Power Supply

12

VDC

115

VAC

Midmark Corporation (“Midmark”) warrants to the original

purchaser its new Matrx™ Central Scavenger products

and components (except for components not warranted

under “Exclusions”) manufactured by Midmark to be free

from defects in material and workmanship under normal

use and service. Midmark’s obligation under this warranty is limited to the repair or replacement, at Midmark’s

option, of the parts or the products the defects of which

are reported to Midmark within the applicable warranty

period and which, upon examination by Midmark, prove

to be defective.

APPLICABLE WARRANTY PERIOD

The applicable warranty period, measured from the date

of installation for the original user, shall be Five (5) years.

EXCLUSIONS

This warranty does not cover and Midmark shall not be

liable for the following: (1) repairs and replacements

because of misuse, abuse, negligence, alteration, accident, freight damage, or tampering; (2) products which

are not installed, used, and properly cleaned as required

in the Midmark Installation” manual and or “maintenance”

guide for this applicable product; (3) products considered

to be of a consumable nature; (4) accessories or parts

not manufactured by Midmark; (5) charges by anyone

for adjustments, repairs, replacement parts, installation,

or other work performed upon or in connection with such

products which is not expressly authorized in writing in

advance by Midmark.

EXCLUSIVE REMEDY

Midmark’s only obligation under this warranty is the repair

or replacement of defective parts. Midmark shall not be

liable for any direct, special, indirect, incidental, exemplary, or consequential damages or delay, including, but not

limited to, damages for loss of profits or loss of use.

NO AUTHORIZATION

No person or firm is authorized to create for Midmark any

other obligation or liability in connection with this product.

THIS WARRANTY IS MIDMARK’S ONLY WARRANTY

AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED. MIDMARK MAKES NO IMPLIED

WARRANTIES OF ANY KIND INCLUDING ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR

ANY PARTICULAR PURPOSE. THIS WARRANTY IS

LIMITED TO THE REPAIR OR REPLACEMENT OF

DEFECTIVE PARTS.

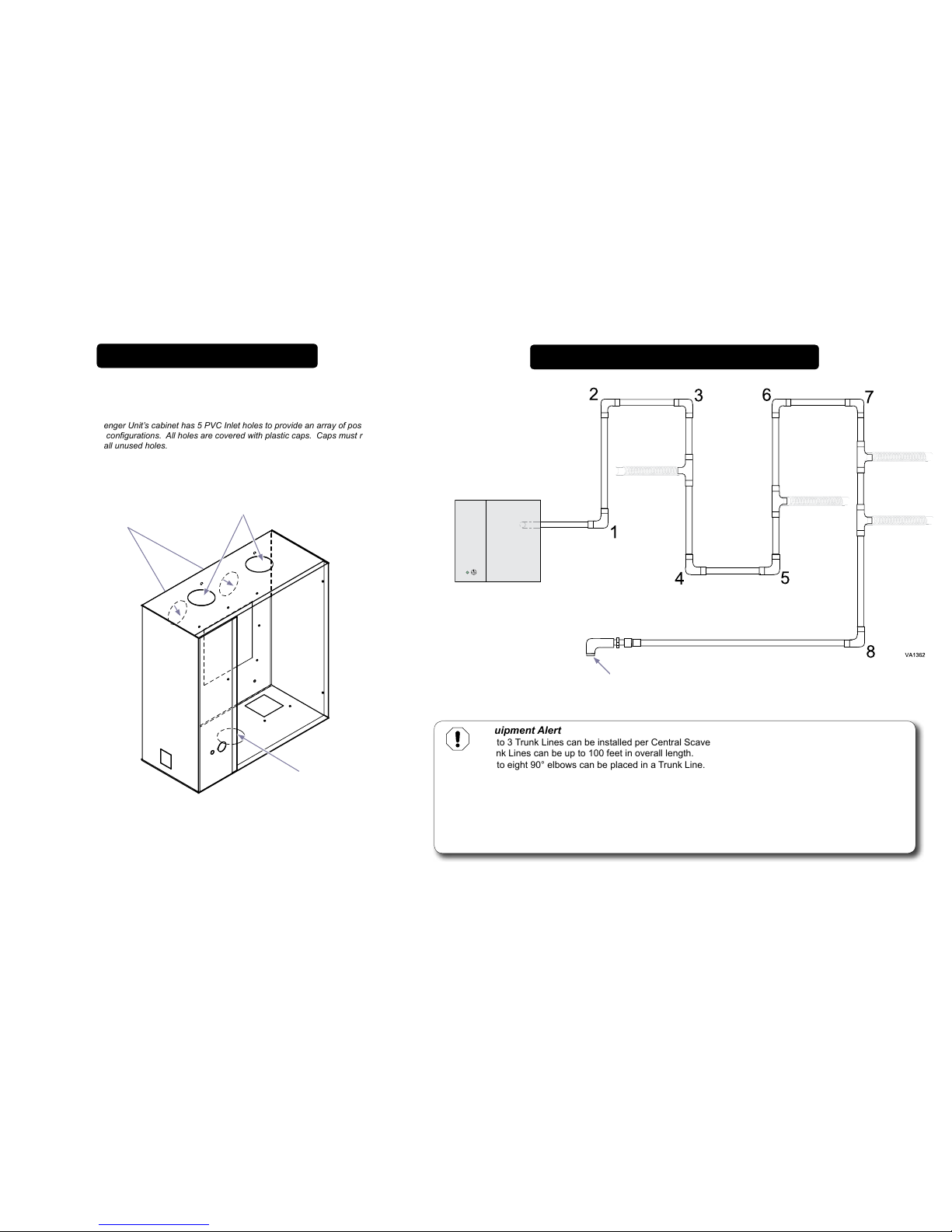

Equipment Alert

Up to 3 Trunk Lines can be installed per Central Scavenger Unit.

Trunk Lines can be up to 100 feet in overall length.

Up to eight 90° elbows can be placed in a Trunk Line.

Up to 4* Scavenging Hoses can be connected to a Trunk Line.

A Check Valve must be installed at every terminating end of a Trunk Line.

All Pipe should be mounted to a Wall or Ceiling and can be concealed inside walls if desired.

It is recommend the unit be turned off during close of business in order to extend longevity of system.

* Maximum of 3 Scavenging Lines per 100 foot Trunk Line in Canada.

© Midmark Corporation 2008

Adding Trunk Lines

PVC Inlet holes:

• The Scavenger Unit’s cabinet has 5 PVC Inlet holes to provide an array of possible

trunk line configurations. All holes are covered with plastic caps. Caps must remain in

place on all unused holes.

2 on Back

2 on Top

1 on Bottom

Sample Trunk Line Assembly

Scavenger Unit

Vacuum Inlet Assembly, installed with the Check

Valve facing downwards at the terminating end of

the Trunk Line.

3 feet

6 feet

8 feet 8 feet

14 feet

6 feet

14 feet

20 feet

20 feet

Scavenging

Hose

Scavenging

Hose

Scavenging

Hose

Scavenging

Hose

Midmark Corporation

60 Vista Drive

Versailles, OH 45380 USA

1-800-643-6275

1-937-526-3662

Loading...

Loading...