Page 1

M9 / M9D

Go To Table Of Contents

Place Order

To purchase a printed copy of this manual,

click on the "Place Order" button below.

M11 / M11D

-001 thru -019

Self-Contained Steam Sterilizer

Serial Number Prefixes:

M9 [CZ, DA, DB, DX, DY, FK, LA, FL, OM]

M9D [FF, FG]

M 11 [ES, ET, FP, FR, GB. NP]

M11D [GC, GD]

NO LONGER IN

Some service parts may not

PR

ODUCTION

be available for this product!

M9/D

M11/D

-001 thru -019

FOR USE BY MIDMARK TRAINED TECHNICIANS ONLY

SF-1827 Part No. 004-0372-00 Rev. F (1/01/08)

Page 2

Go To Table Of Contents

Page 3

TABLE OF CONTENTS

Section/Paragraph Page

IMPORTANT INSTRUCTIONS

General Safety Instructions......................................... iii

Safety Alert Symbols .................................................. iii

Warranty Instructions .................................................. iii

SECTION I GENERAL INFORMATION

1.1 Model / Serial Number Location................... 1-1

1.2 Specifications .............................................. 1-1

1.3 Description of Normal Operation.................. 1-2

1.4 Ordering Parts............................................. 1-3

1.5 Special Tools .............................................. 1-4

SECTION II TESTING AND TROUBLESHOOTING

2.1 Operational Test.......................................... 2-1

2.2 Troubleshooting Procedures ........................ 2-1

SECTION III SCHEDULED MAINTENANCE

3.1 Scheduled Maintenance .............................. 3-1

SECTION IV MAINTENANCE/SERVICE

INSTRUCTIONS

4.1 Safety Precautions...................................... 4-1

4.2 Top Cover Removal / Installation ................ 4-1

4.3 Right Hand Side Panel Removal /

Installation .............................................. 4-1

4.4 Left Hand Side Panel Removal /

Installation .............................................. 4-2

4.5 Back Panel Removal/Installation................. 4-3

4.6 Base Inspection Cover Removal /

Installation .............................................. 4-3

4.7 Bellows Assembly Removal / Installation.... 4-4

4.8 Condensing Tank Water Level Sensor

Removal / Installation ............................. 4-5

4.9 Temperature Sensor Assembly

Removal / Installation ............................. 4-6

4.1 0 Pressure Vessel Water Level Sensor

Removal / Installation ............................. 4-6

4.1 1 Vent Solenoid Removal / Installation........... 4-7

4.1 2 Fill Solenoid Removal / Installation ............. 4-9

4.1 3 Control PC Board Removal / Installation ... 4-10

4.1 4 Door Switch Removal / Installation............ 4-13

4.1 5 Pulse Solenoid Removal / Installation ....... 4-13

4.1 6 Thermostat Removal / Installation ............. 4-14

4.1 7 Wire Tray Rack and Tray Plate

Removal / Installation ........................... 4-15

Section/Paragraph Page

4.1 8 Heating Element and Gasket

Removal / Installation ........................... 4-15

4.1 9 Filter Removal / Installation....................... 4-16

4.2 0 Door Gaskets Removal / Installation ......... 4-17

4.2 1 Display PC Board Removal / Installation ... 4-17

4.2 2 Condensing Tank Assembly

Removal / Installation ........................... 4-18

4.2 3 Pressure Relief Valve Removal /

Installation ............................................. 4-19

4.2 4 Pressure / Temperature Potentiometers

Adjustments ......................................... 4-20

4.2 5 Display PC Board Lamp / Display /

Button Check........................................ 4-23

4.2 6 Pressure Relief Valve Check..................... 4-24

4.2 7 Dry Cycle Dip Switches Adjustment........... 4-25

4.2 8 M9 / M11 Door Opening Test ..................... 4-26

SECTION V SCHEMATICS AND DIAGRAMS

5.1 Wiring Diagrams.......................................... 5-1

5.2 Flow Diagram ............................................ 5-11

5.3 Pressure / Temperature Chart .................... 5-12

SECTION VI PARTS LIST

6.1 Description of Bullets ................................... 6- 1

6.2 Torque Specifications and Important

Assembly Notes ...................................... 6-1

NOTE:

The Parts List in this manual is divided

into two sections [M9 / M9D & M11/M11D].

Verify model and refer to appropriate section.

M9 / M9D Parts List

M9 Component / Page Cross-Reference ..... 6-2

M9D Component / Page Cross-Reference .... 6 -3

Main Enclosure Components...................... 6-4*

Plumbing and Sensor Components ............ 6-5*

Pressure Vessel Components .................... 6-6*

M9 Manifold Components........................... 6-7*

M9D Manifold Components ........................ 6-8*

Electrical Components ............................... 6-9*

M9 Control PC Board ............................... 6-10*

M9D Control PC Board ............................... 6-11

M9 Labels and Decals............................... 6-12

M9D Labels and Decals ............................ 6-13

Printer Components .................................. 6-14

Racks, Trays, and Cleaner....................... 6-15*

Packaging ................................................. 6-16

(*) Indicates that there has been a serial number break for the illustration

and that there are additional point page(s) following the original page.

© Midmark Corporation 2002 SF-1827 Page i Printed in U.S.A.

Page 4

TABLE OF CONTENTS

Section/Paragraph Page

SECTION VI PARTS LIST - continued

NOTE:

The Parts List in this manual is divided

into two sections [M9 / M9D & M11/M11D].

Verify model and refer to appropriate section

M11 / M11D Parts List

M11 Component / Page

Cross-Reference ................................... 6-17

M11D Component / Page

Cross-Reference .................................... 6-18

Main Enclosure Components.................... 6-19*

Plumbing and Sensor Components .......... 6-20*

Pressure Vessel Components .................. 6-21*

M11 Manifold Components....................... 6-22*

M11D Manifold Components .................... 6-23*

Electrical Components ............................. 6-24*

M11 Control PC Board ............................. 6-25*

M11D Control PC Board ............................. 6-26

M11 Labels and Decals............................. 6-27

M11D Labels and Decals .......................... 6-28

Printer Components .................................. 6-29

Racks, Trays, and Cleaner....................... 6-30*

Packaging ................................................. 6-31

COMMENTS ............................................................ 7-1

FAX ORDERING FORM .......................................... 7-2

.

© Midmark Corporation 2002 SF-1827 Page ii Printed in U.S.A.

Page 5

IMPORTANT INSTRUCTIONS

Return To Table Of Contents

General Safety Instructions

Safety First: The primary concern of Midmark

Corporation is that this sterilizer is maintained with the

safety of the patient and staff in mind. To assure that

services and repairs are completed safely and correctly,

proceed as follows:

(1 ) Read this entire manual before performing any

services or repairs on this sterilizer.

(2 ) Be sure you understand the instructions con-

tained in this manual before attempting to

service or repair this sterilizer.

Safety Alert Symbols

Throughout this manual are safety alert symbols that

call attention to particular procedures. These items are

used as follows:

DANGER

A DANGER is used for an imminently

hazardous operating procedure, practice, or condition which, if not correctly followed,

will result in loss of life or serious personal

injury.

NOTE

A NOTE is used to amplify an operating procedure,

practice or condition.

Warranty Instructions

Refer to the Midmark “Limited Warranty” printed in the

Installation and Operation Manual for warranty information. Failure to follow the guidelines listed below will

void the warranty and/or render the M9 sterilizer unsafe

for operation.

• In the event of a malfunction, do not attempt to

operate the sterilizer until necessary repairs have

been made.

• Do not attempt to disassemble sterilizer, replace

malfunctioning or damaged components, or perform

adjustments unless you are one of Midmark’s

authorized service technicians.

• Do not substitute parts of another manufacturer when

replacing inoperative or damaged components. Use

only Midmark replacement parts.

WARNING

A WARNING is used for a potentially

hazardous operating procedure, practice, or condition which, if not correctly followed,

could result in loss of life or serious personal

injury.

CAUTION

A CAUTION is used for a potentially

hazardous operating procedure, practice,

or condition which, if not correctly followed, could

result in minor or moderate injury. It may also be

used to alert against unsafe practices.

EQUIPMENT ALERT

An EQUIPMENT ALERT is used for an

imminently or potentially hazardous

operating procedure, practice, or condition which, if

not correctly followed, will or could result in serious,

moderate, or minor damage to unit.

© Midmark Corporation 2002 SF-1827 Page iii Printed in U.S.A.

Page 6

Return To Table Of Contents

Page 7

GENERAL INFORMATION

Return To Table Of Contents

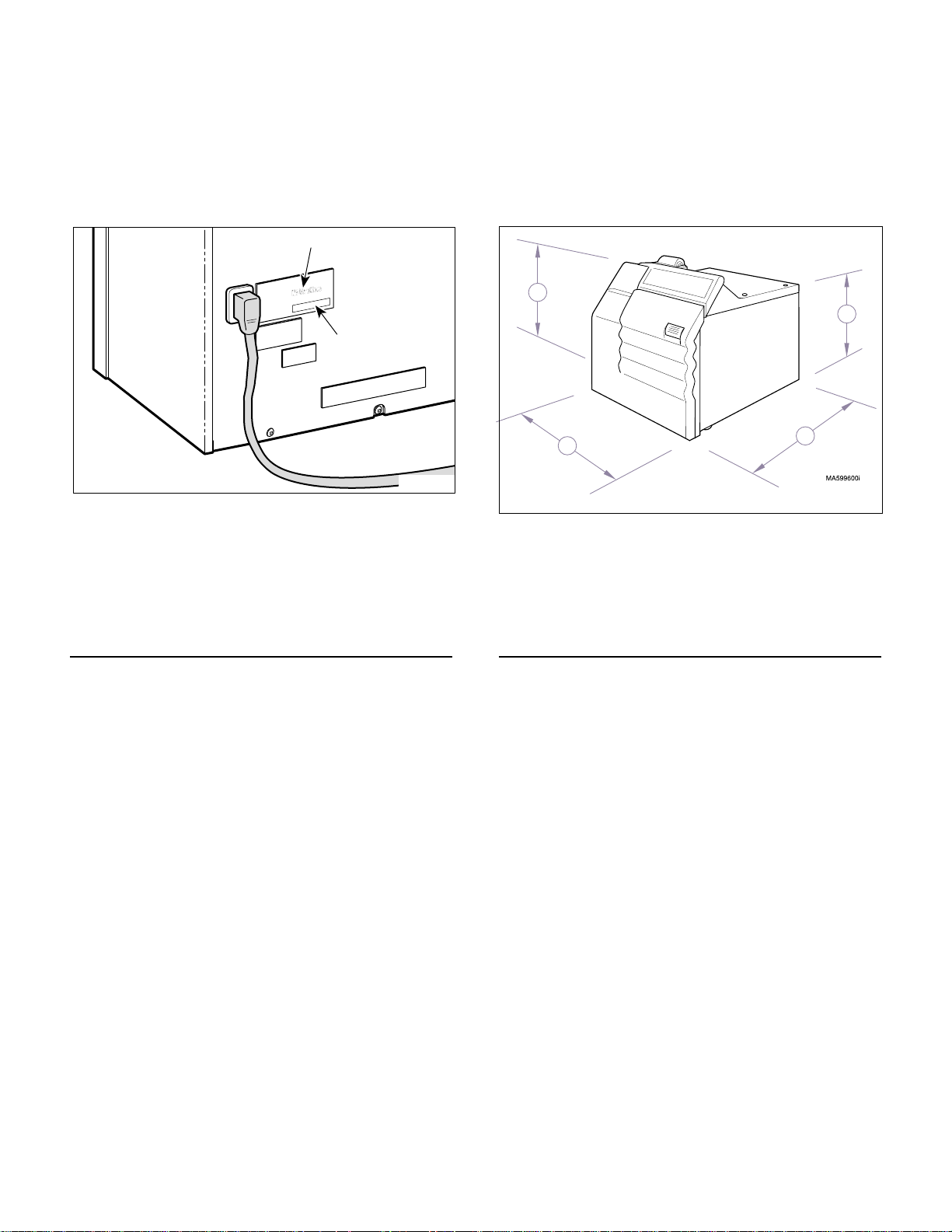

1.1 Model / Serial Number Location

MODEL NUMBER

SERIAL NUMBER

SECTION I

GENERAL INFORMATION

SECTION I

A

D

MA2071-01

Figure 1-1. Model / Serial Number Location

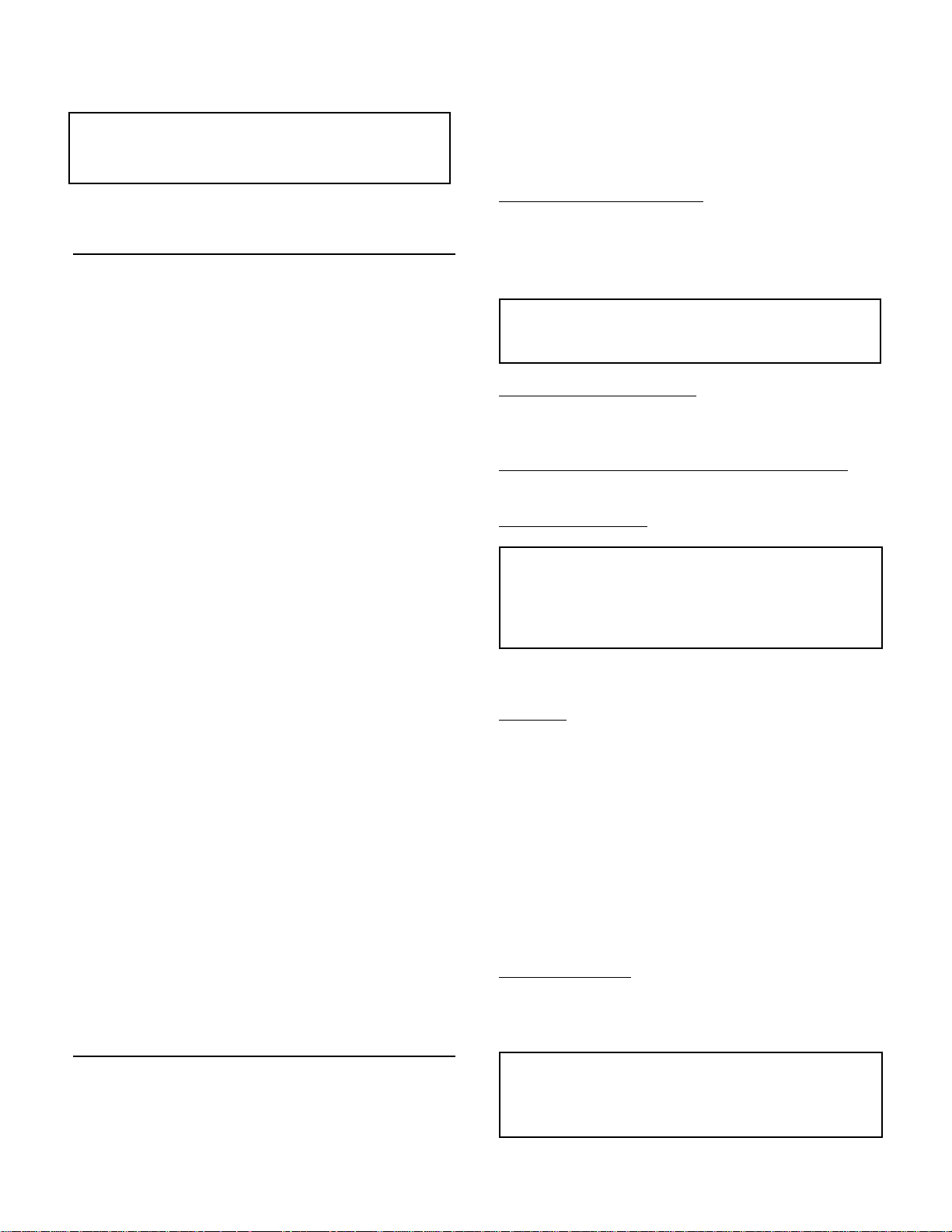

1.2 Specifications

Table 1-1. Specifications

Description Data

M9 / M9D Dimensions:

Front Height (A, Figure 1-2).............. 16.4 in (41.8 cm)

(printer adds approx. 0.5 in)

Width (B).............................................. 15 in (38.1 cm)

Depth (C) .......................................... 18.1 in (47.8 cm)

Back Height (D) ...............................13.75 in (34.9 cm)

Chamber Diameter .................................9 in. (22.8 cm)

Chamber Depth ....................................15 in. (38.1 cm)

Shipping Carton ....................... 22 in x 17.75 in x 18 in

(56 cm x 45 cm x 46 cm)

B

C

Figure 1-2. Dimensions

Description Data

M11 / M11D Dimensions:

Front Height (A, Figure 1-2).............. 17.7 in (44.9 cm)

(printer adds approx. 0.5 in)

Width (B)........................................... 17.6 in (44.8 cm)

Depth (C) .......................................... 22.4 in (56.8 cm)

Back Height (D) ...............................15.25 in (38.7 cm)

Chamber Diameter ...............................11 in. (27.9 cm)

Chamber Depth ....................................18 in. (45.7 cm)

Shipping Carton ...................... 23 in x 27.5 in x 21.5 in

(58.4 cm x 69.8 cm x 54.6 cm)

Weight:

Reservoir Empty ...................................... 70 lb (32 kg)

Reservoir Full........................................... 77 lb (35 kg)

With Shipping Carton ............................... 78 lb (36 kg)

Water Reservoir Capacity ................ Approx. 7/8 gallon

(3.31 Liters to full mark)

© Midmark Corporation 2002 SF-1827 Page 1-1 Printed in U.S.A.

Weight:

Reservoir Empty ................................... 96 lb (43.5 kg)

Reservoir Full......................................... 106 lb (48 kg)

With Shipping Carton ............................. 128 lb (58 kg)

Water Reservoir Capacity ............... Approx. 1.25 gallon

(4.7 Liters) to full mark

Page 8

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

NOTE

The following information applies to all models of the

M9 / M9D / M11 / M11D included in this manual.

Table 1-1. Specifications - continued

Description Data

M9 / M9D / M11 / M11D

Electrical Requirements:

100 VAC Unit...............................100 VAC 50 - 60 HZ,

15 amp, single phase

115 VAC Unit......................110 - 120 VAC 50 - 60 HZ,

15 amp, single phase

230 VAC Unit......................220 - 240 VAC 50 - 60 HZ,

7 amp, single phase

Power Consumption:

100 VAC Unit ......................................... 1425 WATTS,

15 amps @ 100 VAC

115 VAC Unit ......................................... 1425 WATTS,

12 amps @ 120 VAC

230 VAC Unit ......................................... 1500 WATTS,

7 amps @ 240 VAC

Recommended Circuit:

A separate (dedicated) circuit is recommended for

this sterilizer. The sterilizer should not be connected

to an electrical circuit with other appliances or

equipment unless the circuit is rated for the additional load.

Chamber Pressure:

Operating ........................... 27 - 31 psi (186 - 215 kPa)

Minimum Before Door Is Released

(M9 & M11 only) ................................ 0.7 psi (5 kPa)

Maximum Before Safety Valve

Opens (older units). .......................... 35 psi (241 kPa)

Maximum Before Safety Valve

Opens (newer units). ....................... 40 psi (275.7 kPa)

Chamber Temperature (Operating):

Unwrapped Cycle ................... 272-273 °F (133-134 °C)

Pouches Cycle ...................... 272-273 °F (133-134 °C)

Liquids Cycle ......................... 252-253 °F (122-123 °C)

Packs Cycle .......................... 252-253 °F (122-123 °C)

Maximum Before Thermostat

Energ izes ........................................... 295 °F (146 °C)

1.3 Description of Normal Operation

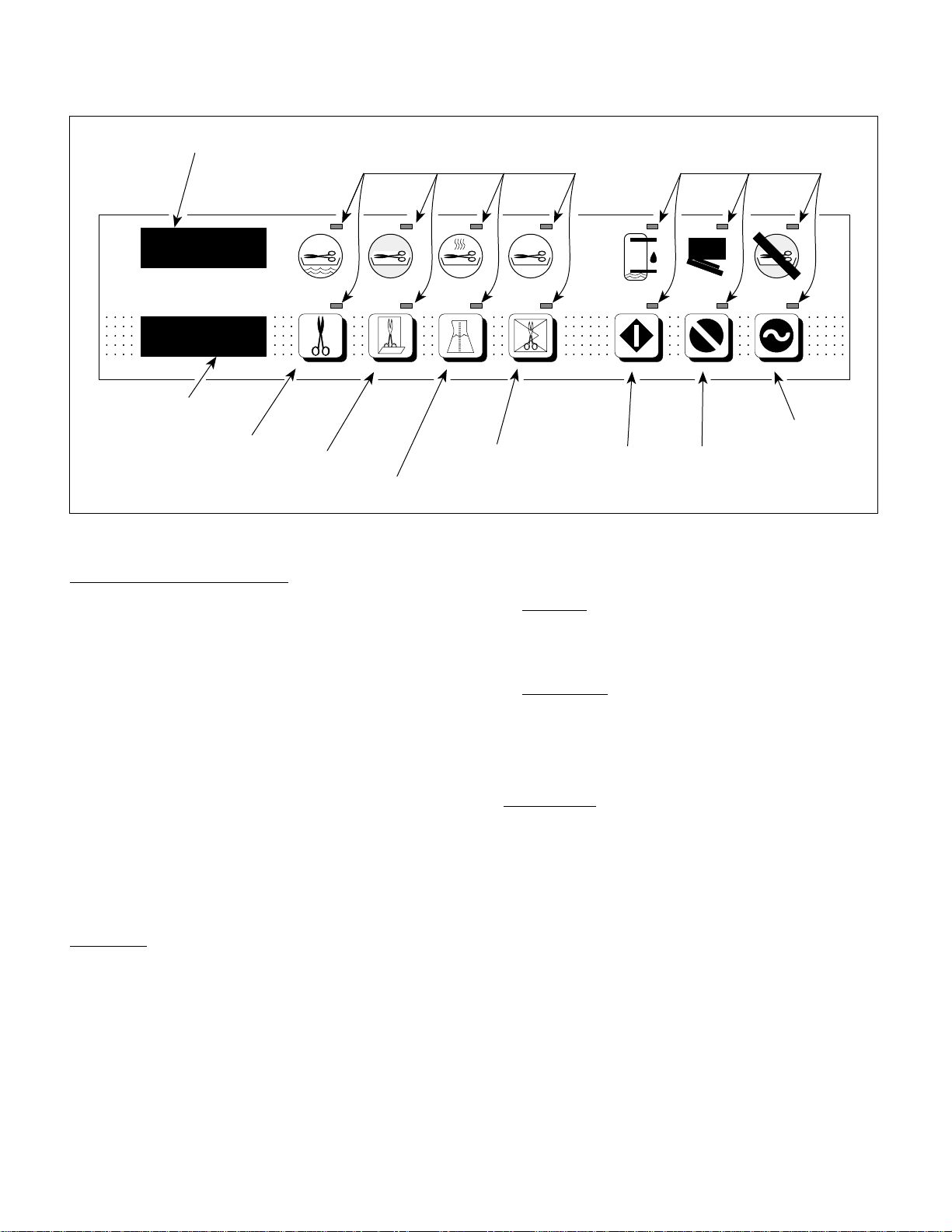

(Figure 1-3 shows Display Panel Buttons & Lamps)

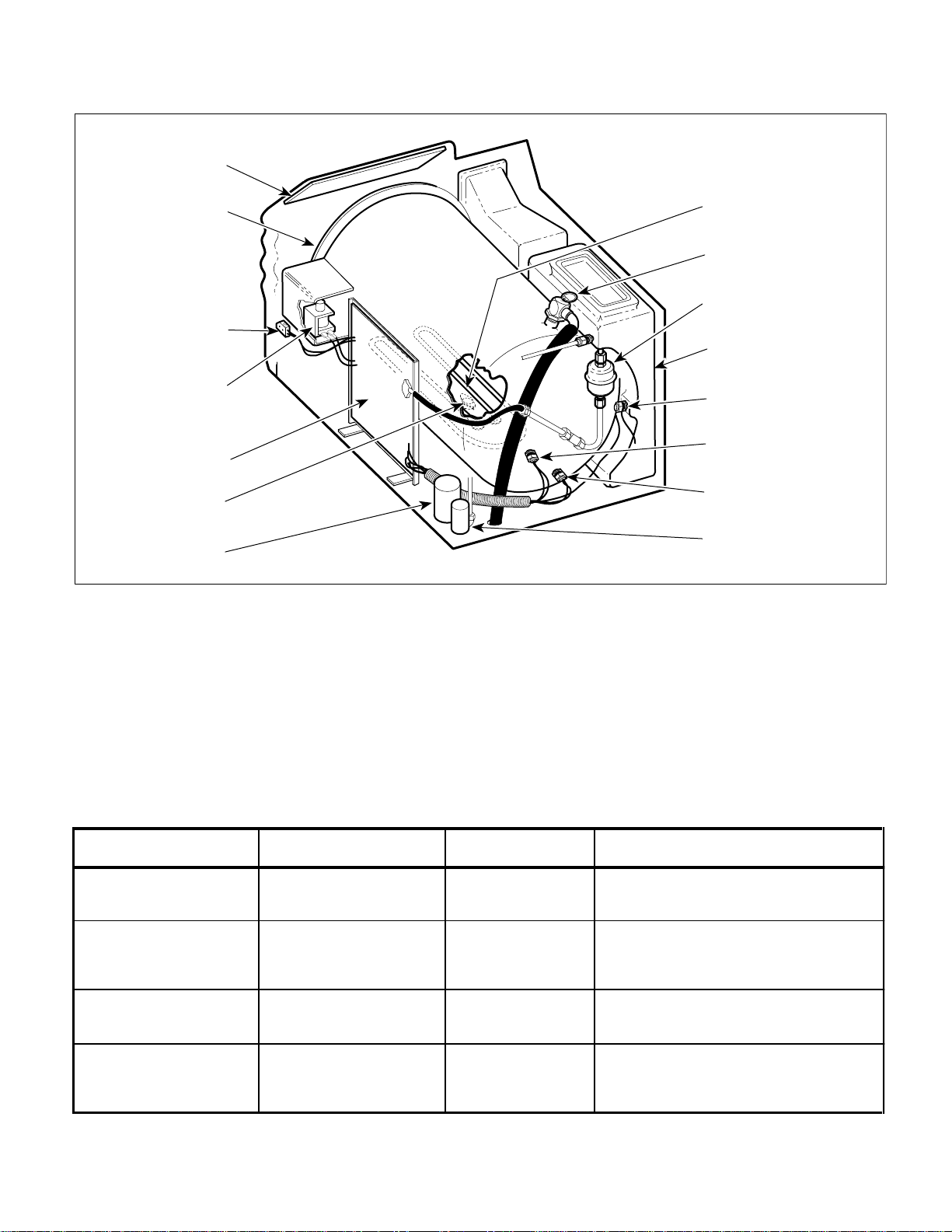

(Figure 1-4 shows location of Major Components)

Plug Power Cord Into Outlet

Display: E001 (Error lamp flashes)

1. Line voltage (100/115/230V) is supplied to Control

PC Board.

NOTE

There are two primary fuses on PC Board. Faulty

fuse(s) will disable all functions of sterilizer.

Press ON/STANDBY Button

Display: (Error lamp goes out; ON/STANDBY lamp

illuminates, & program lamps flash)

Select Cycle (Unwrapped, Pouches, Liquids, Packs)

Display: TIME/TEMP. (for the selected cycle)

Press START Button

NOTE

After the START button is pressed, the PC board

continuously monitors the Door Switch for continuity.

If continuity is not detected, the PC board stops the

cycle, and the Door Ajar lamp illuminates.

1. The Fill Cycle is initiated.

Fill Cycle

Display: (Filling lamp illuminates)

1. Line voltage from PC Board energizes Fill Solenoid;

this allows water to flow into Pressure Vessel.

2. Water fills Pressure Vessel until it makes contact

with the Pressure Vessel Water Level Sensor.

3. When water completes the ground circuit between

the Pressure Vessel Water Level Sensor & the

chassis, the PC Board de-engergizes the Fill

Solenoid & the Steriliation Cycle is initiated.

Sterilization Cycle

Display: (Sterilizing lamp illuminates)

xxx° (chamber temperature)

xx PSI [after temperature reaches 208°F (98°C)]

NOTE

During the Sterilization Cycle, the Temperature Probe

monitors the chamber temperature and the PC Board

monitors chamber pressure.

© Midmark Corporation 2002 SF-1827 Page 1-2 Printed in U.S.A.

Page 9

TEMP / TIME DISPLAY

Return To Table Of Contents

TEMP (°F) \ TIME (MIN : SECONDS)

FILLING

STERILIZING

LAMP

DRYING

COMPLETE

SECTION I

GENERAL INFORMATION

LAMP

WATER LOW

DOOR AJAR

ERROR

PRESSURE (PSI)

UNWRAPPED

POUCHES

PRESSURE

DISPLAY

UNWRAPPED

BUTTON

POUCHES

BUTTON

LIQUIDS

BUTTON

Figure 1-3. Display Panel Button / Lamp Locations

Sterilization Cycle - continued

1. Line voltage from PC Board energizes Heating

Element.

2. Air & steam flow thru Bellows as water in chamber

begins to boil. When temperature reaches approx.

215° F (101° C), the Bellows closes and pressure

begins to build.

3. When chamber reaches required temperature, Heating

Element is de-energized and sterlization time begins

to count down on Display PC Board.

4. Line voltage from PC Board energizes Heating

Element intermittantly to maintain required

temperature & pressure until time elapses.

5. When sterilization time expires, the Heating Element

de-energized & the Vent Cycle is initiated.

Vent Cycle

1. Line voltage from PC Board energizes Vent Solenoid.

[Liquids Cycle requires chamber to cool to 223° F

(106° C) before Vent Solenoid is energized]

2. Chamber pressure is released thru Vent Solenoid

until pressure drops to 0.7 psi (4.8 kPa).

LIQUIDS

PACKS

BUTTON

PACKS

START

STOP

ON/STANDBY

ON / STANDBY

BUTTON

START

BUTTON

STOP

BUTTON

MA207702

3. Control PC Board sounds 5 beeps.

4.

M9 / M11: Line voltage from PC Board energizes

Pulse Solenoid.

Door opens automatically.

Drying Cycle is initiated.

M9D / M11D: "Open the Door" Lamp illuminates.

"dddd" appears on Display PC Board.

Manually open door at this time.

Drying Cycle is initiated.

Drying Cycle

Display: (Drying lamp illuminates)

xx:xx (time counts down from 30 minutes)

(Complete lamp illuminates at end of cycle)

1. Line voltage energizes Heating Element for

45 seconds. (30 minute countdown begins on

Display PC Board).

2. Heating Element is energized intermittantly (as

shown below) until Dry Cycle is complete.

45 seconds ON - 2 minutes OFF

30 seconds ON - 2 minutes OFF

xx* seconds ON - 2 minutes OFF (until cycle ends)

*This time is adjustable. Refer to adjustment

procedure in Section IV if necessary.

© Midmark Corporation 2002 SF-1827 Page 1-3 Printed in U.S.A.

Page 10

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

DISPLAY PC

BOARD

PRESSURE

VESSEL

DOOR

SWITCH

HEATING

ELEMENT

PRESSURE

RELIEF VALUE

BELLOWS

ASSEMBLY

CONDENSING

TANK ASSEMBLY

PULSE

SOLENOID

(M9 / M11only)

CONTROL PC

BOARD

THERMOSTAT

FILL

SOLENOID

Figure 1-4. Major Components

1.4 Ordering Parts

Contact Midmark's Technical Service Department with

all necessary information (model / serial number, part

number, etc.).

Orders can be placed using the Fax Order Form ( page

7-2) or by calling the phone number on the back cover of

this manual.

Table 1-2. Special Tool List

CONDENSING TANK

WATER LEVEL SENSOR

(early M9 only)

TEMPERATURE

SENSOR ASSEMBL Y

PRESSURE VESSEL

WATER LEVEL SENSOR

VENT

SOLENOID

MA207604

1.5 Special Tools

Special tools needed to repair the sterilizer are listed

below in Table 1-2.

Description of Special Tool

Digital Multimeter (must be

capable of displaying 3 digits)

Water Level Sensor Wrench Midmark Corp.

3/32 in. Diameter Punch Commercially Available Any Type Used to remove / install two roll pins which secure

Pressure Gauge Test Harness Midmark Corp.

© Midmark Corporation 2002 SF-1827 Page 1-4 Printed in U.S.A.

Manufacturer’s

Name / Address / Phone

Commercially Available Any Type Used to check probes, switches, and connections

60 Vista Drive

Versailles, Ohio 45380

(513) 526-3662

60 Vista Drive

Versailles, Ohio 45380

(513) 526-3662

Manufacturer’s

Part Number

for proper function by performing continuity

checks.

050-2324-00 Used to hold fitting in place so the nut that holds

water level sensor can be loosened / tightened.

door switch in place or roll pin which secures latch

lever to pulse solenoid.

002-0372-00 Used to check the pressure in the pressure vessel

during a cycle to diagnose malfunctions and / or

adjust the pressure range potentiometer to a

correct setting.

Purpose of Special Tool

Page 11

TESTING AND TROUBLESHOOTING

Return To Table Of Contents

SECTION II

TESTING AND TROUBLESHOOTING

SECTION II

2.1 Operational Test

To effectively diagnose a malfunction of the sterilizer,

perform the Pressure / Temperature Potentiometers

Adjustment procedure. Refer to para 4.24.

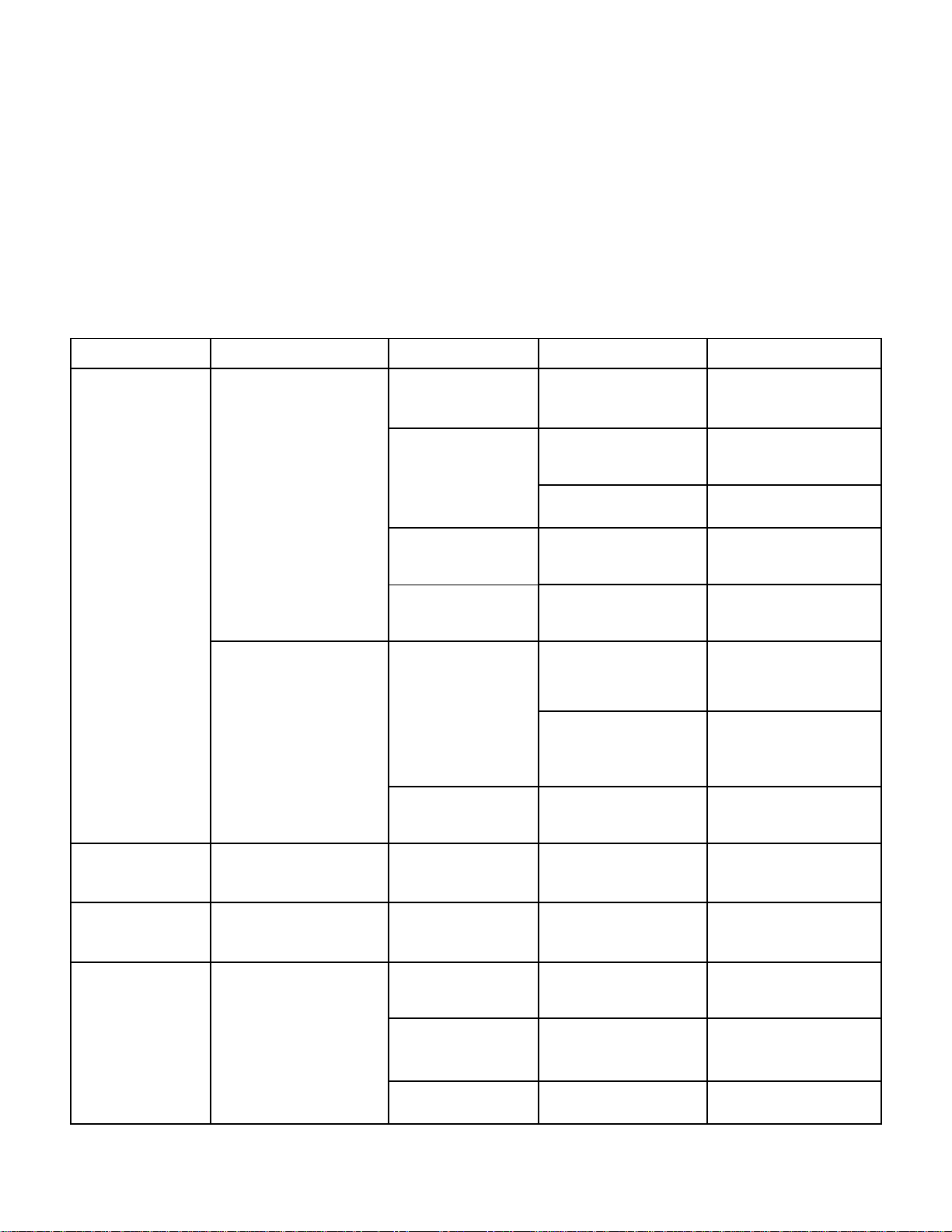

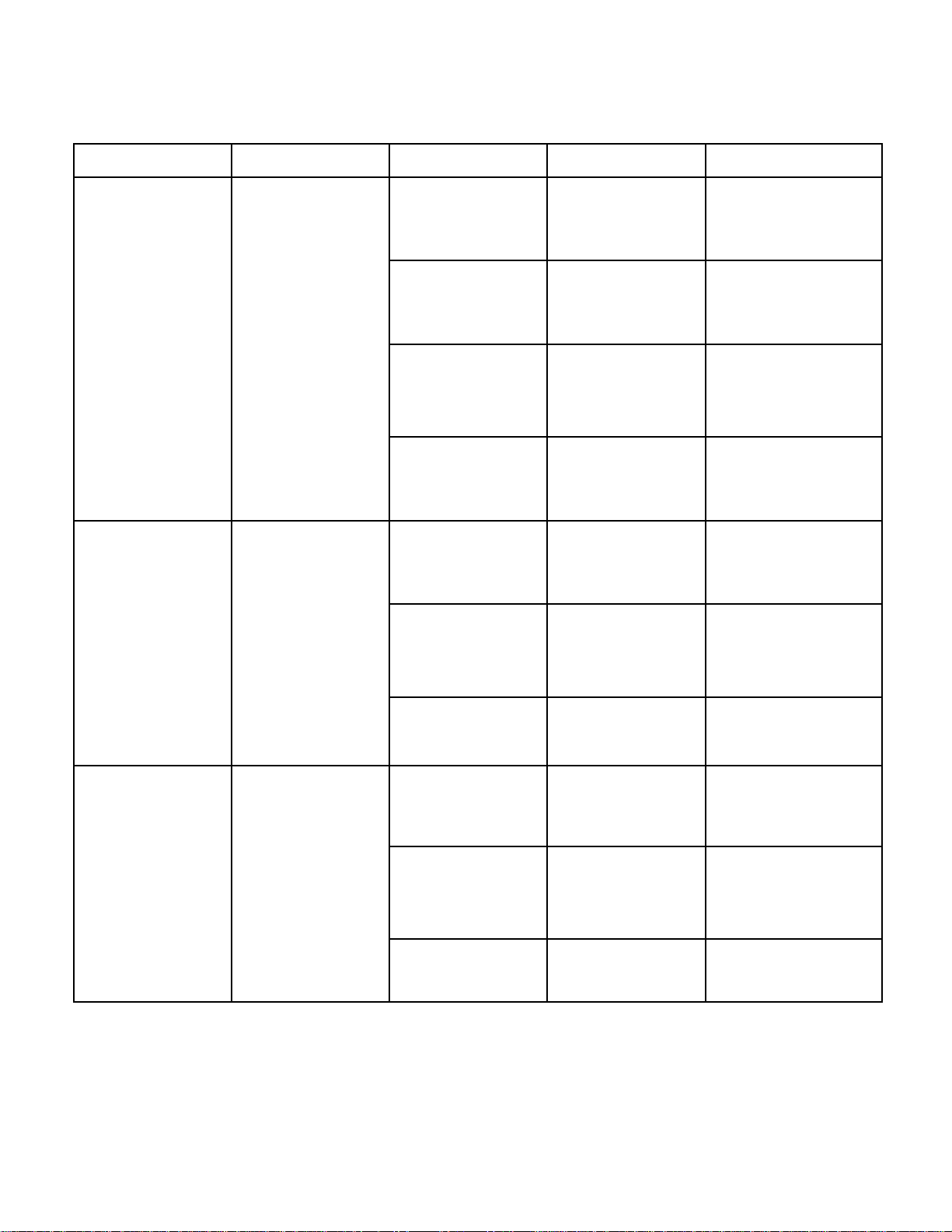

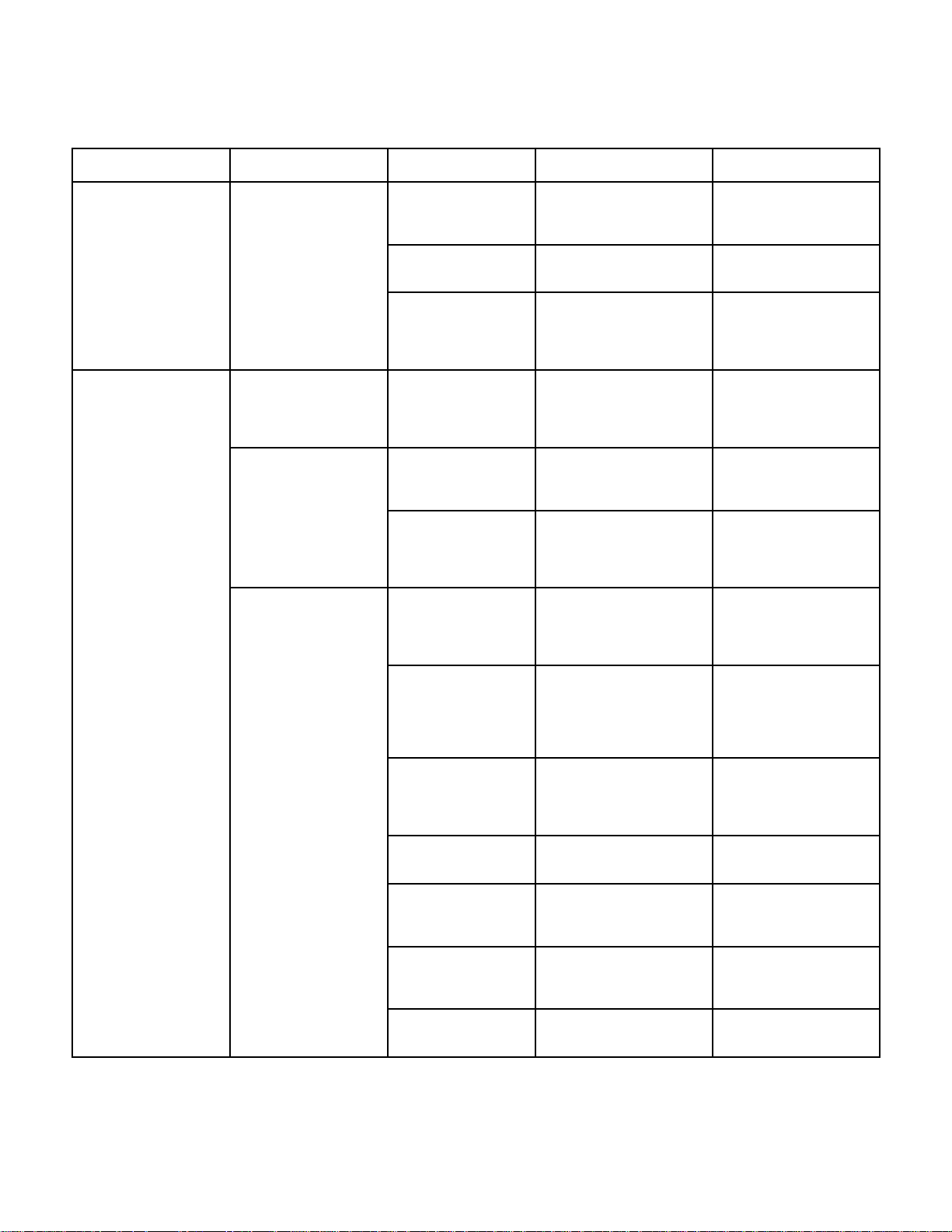

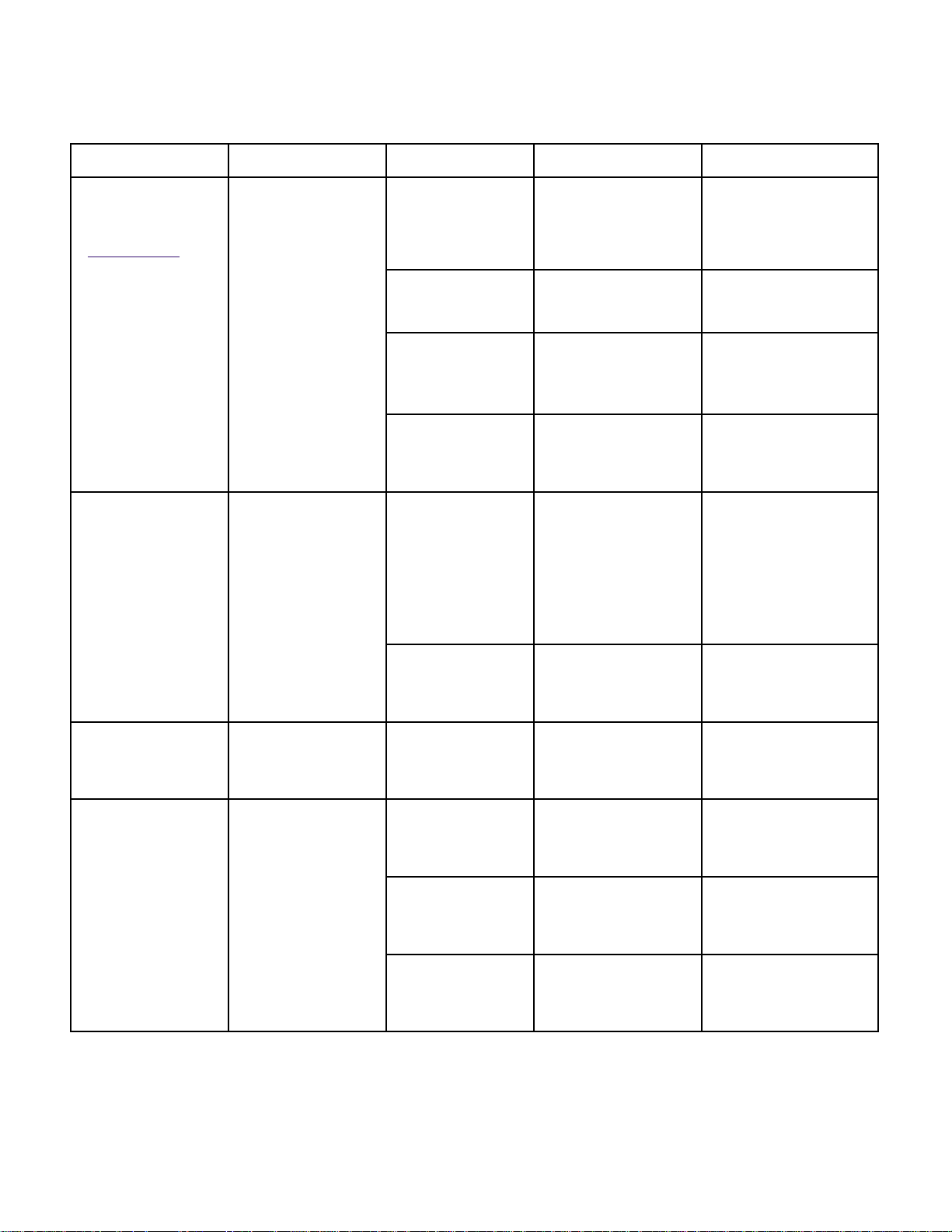

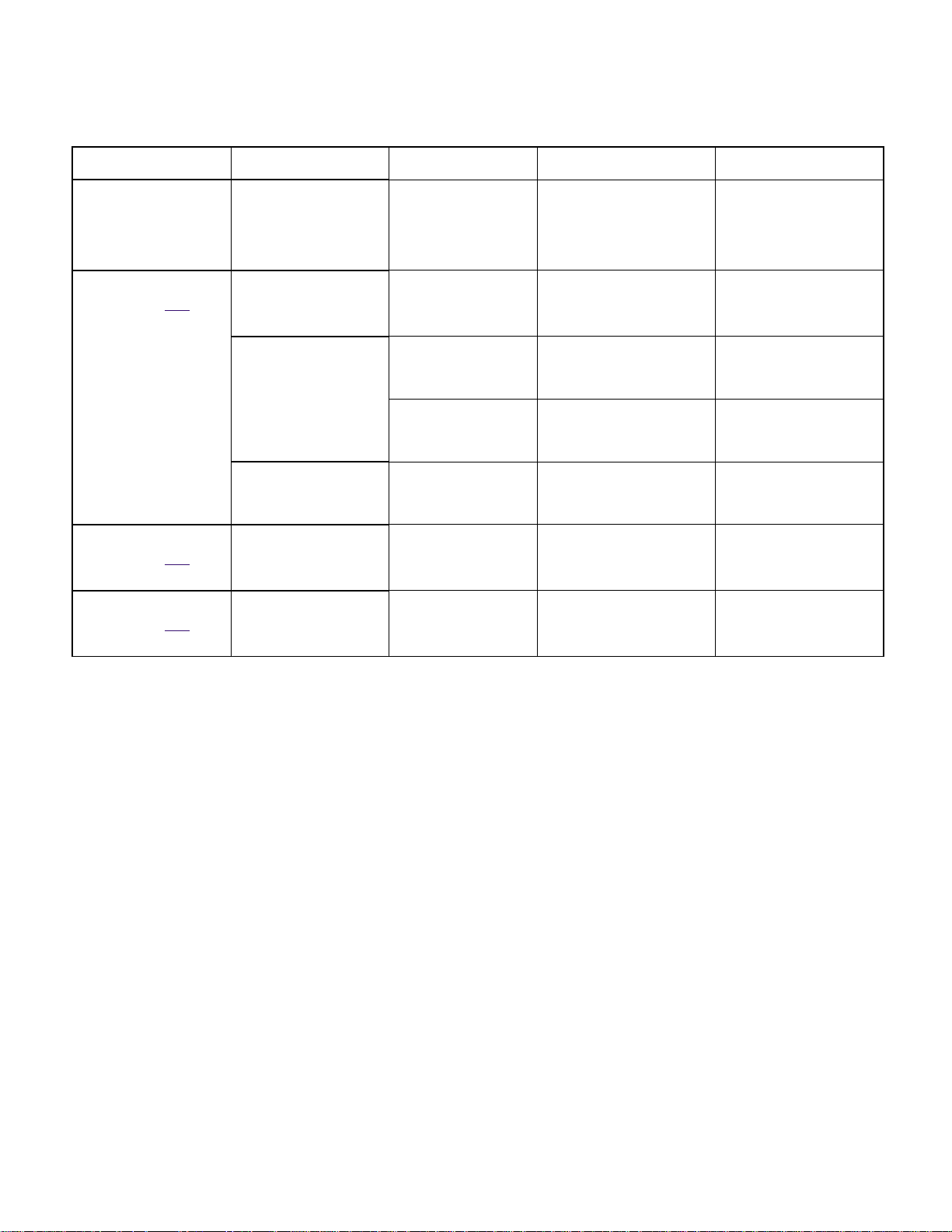

Table 2-1. Troubleshooting Guide

melborPmotpmySesuaCelbaborPkcehCnoitcerroC

1edocrorrE

otnoitpurretnirewoP(

.)draobCPlortnoc

gnirudnwodstuhS

.elcycnoitaziliretS

2.2 Troubleshooting Procedures

If a malfunction is detected, locate the Problem &

Symptom in Table 2-1. Perform the Check for each

Probable Cause indicated. Follow instructions in the

Correction column as they apply.

.detavitca

tatsomrehttaehrevO

)kaelerusserP(

tatsomrehttaehrevO

.detavitca

)ylreporpgnilliftoN(

.level

lacirtceledaB

.)s(noitcennoc

.snoitcennoc

taehrevoytluaF

.tatsomreht

)nepokcuts(

.skaelerusserprofkcehC

.2-2elbaTotrefeR

pmalgnilliFtahtkcehC

retaweruseB.setanimulli

.yrdsirosneslevel

sireziliretstahtkcehC

ytilicafdnareziliretskcehC

lacirtcelereporprof

kcehcytiunitnocmrofreP

.).C.N(tatsomrehtno

.kael

.01.4

.snoitcennoc

.61.4arapot

gninoitcnuflamecalpeR

erusserptatnenopmoc

rosneslevelretawecalpeR

arapotrefeR.yrassecenfi

.levelotreziliretstsujdA

esoolecalper/nethgiT

refeR.tatsomrehtecalpeR

gnirudnwodstuhS

.elcycgniyrD

2edocrorrE

desserpnottuBpotS(

)elcycgnirud

3edocrorrE

nottuBybdnatS/NO(

)elcycgniruddesserp

4edocrorrE

)rajArooD(

.elcycgnirudnwodstuhSdesserpnottuBpotS

elcycgnirudnwodstuhSnottuBybdnatS/nO

elcycgnirudnwodstuhS.desolctonhctalrooDsihctalroodfikcehC

.detavitca

.tatsomreht

)nepokcuts(

.esool

hctiwsrooD

tatsomrehttaehrevO

)egatlovtupnihgiH(

taehrevoytluaF

.elcycgnirud

.elcycgniruddesserp

noitcennochctiwsrooD

.gninoitcnuflam

.2.1arapnideton

.segnarecnatsiser

_repeebretfaelcyctratseR

_repeebretfaelcyctratseR

.hctiwsgnigagne

hctiwsroodkcehC

.noitcennoc

.egatlovtupniytilicafkcehC

deecxetondluohsegatloV

sastnemeriuqeRlacirtcelE

foecnatsiserkcehC

otrefeR.tnemelegnitaeh

lamronrof1.5arap

kcehcytiunitnocmrofreP

.).C.N(tatsomrehtno

kcehcytiunitnocmrofreP

.).O.N(hctiwsroodno

.72.4

.61.4arapot

.spotslangis

.spotslangis

.snipdna

.snoitcennoc

.41.4arapot

emitelcycyrdehttsujdA

arapotrefeR.sehctiwspid

,stimilfotuosiecnatsiserfI

.tnemelegnitaehecalper

.81.4arapotrefeR

refeR.tatsomrehtecalpeR

.hctalroodtsujdA

hctalroodetacirbul/naelC

esoolecalper/nethgiT

refeR.hctiwsroodecalpeR

© Midmark Corporation 2002 SF-1827 Page 2-1 Printed in U.S.A.

Page 12

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

Table 2-1. Troubleshooting Guide -

melborPmotpmySesuaCelbaborPkcehCnoitcerroC

5edocrorrE

erusserpyalpsiD[

isp53dedeecxe

])aPk142(

6edocrorrE

erutarepmetyalpsiD[

F°772dedeecxe

])C°631(

gnirudnwodstuhS

elcycnoitazilirertS

gnirudnwodstuhS

elcycnoitazilirertS

.dedaolrevoreziliretSerusserptahtkcehC

)ylraegnisolc(

rosneserutarepmeT

.gninoitcnuflam

.kaelerusserpwolSerusserprofkcehC

.gninoitcnuflamswolleB

sretemoitnetopreziliretS

ro/dnanoitarbilacfotuo

.rosneserutarepmetytrid

continued

erutarepmetnaelC

kcehcneht;rosnes

gnisufonoitarbilac

tseTeguaGerusserP

.ssenraH

.noitarbilackcehCrosneserutarepmetecalpeR

dedaolrevotonsilessev

.skcapnenilyvaehhtiw

taesolcdluohsswolleB

.)C°001(F°212.xorppa

.2-2elbaTotrefeR.skael

.ezisdaol

.7.4arap

.42.4

.9.4

ecuderotrotarepotcurtsnI

otrefeR.swollebecalpeR

/erutarepmeTmrofreP

retemoitnetoPerusserP

arapotrefeR.tnemtsujdA

arapotrefeR.ylbmessa

gninoitcnuflamecalpeR

.kaelerusserptatnenopmoc

sretemoitnetopreziliretS

ro/dnanoitarbilacfotuo

.rosneserutarepmetytrid

.ssenraH

rosneserutarepmeT

.gninoitcnuflam

7edocrorrE

erusserpyalpsiD[

isp5.42wolebdeppord

])aPk961(

gnirudnwodstuhS

elcycnoitazilirertS

.kaelerusserpwolSerusserprofkcehC

sretemoitnetopreziliretS

ro/dnanoitarbilacfotuo

.rosneserutarepmetytrid

.ssenraH

rosneserutarepmeT

.gninoitcnuflam

erutarepmetnaelC

kcehcneht;rosnes

gnisufonoitarbilac

tseTeguaGerusserP

.noitarbilackcehCrosneserutarepmetecalpeR

.2-2elbaTotrefeR.skael

erutarepmetnaelC

kcehcneht;rosnes

gnisufonoitarbilac

tseTeguaGerusserP

.noitarbilackcehCrosneserutarepmetecalpeR

/erutarepmeTmrofreP

retemoitnetoPerusserP

arapotrefeR.tnemtsujdA

.42.4

arapotrefeR.ylbmessa

.9.4

gninoitcnuflamecalpeR

.kaelerusserptatnenopmoc

/erutarepmeTmrofreP

retemoitnetoPerusserP

arapotrefeR.tnemtsujdA

.42.4

arapotrefeR.ylbmessa

.9.4

© Midmark Corporation 2002 SF-1827 Page 2-2 Printed in U.S.A.

Page 13

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

Table 2-1. Troubleshooting Guide -

melborPmotpmySesuaCelbaborPkcehCnoitcerroC

11M&9M-ylno

8edocrorrE

didhctiwsrooD[

sutatsegnahcton

dionelosroodretfa

.detavitcasaw

.elcyc

fodnetasneporooD

.elcycfodne

tanepotonseodrooD

msinahcemregnulp

.gninoitcnuflam

.noitarbilacfotuo

.gninoitcnuflamhctiwsrooDkcehcytiunitnocmrofreP

dioneloseslup&revelhctaL

tekcarbhctaldnasniprooD

.ylreporpgninoitcnufton

retemoitnetoperusserporeZ

continued

rofkcehC.hctiwsroodno

.snoitcennocesool

rooD11M/9MmrofreP

otrefeR.tseTgninepO

.82.4arap

roodnosrrubrofkcehC

nitekcarbhctaldnasnip

.rood

orezfonoitarbilackcehC

.retemoitnetoperusserp

.gninoitcnuflamdionelosesluProoD11M/9MmrofreP

otrefeR.tseTgninepO

.82.4arap

.41.4arapot

refeR.hctiwsroodecalpeR

rosirbedynaevomeR

&revelhctalmorfpudliub

.msinahcemdioneloseslup

naelcneht;srrubevomeR

desabmuihtilhtiwebuldna

.esaerg

erusserporeztsujdA

otrefeR.retemoitnetop

.42.4arap

.dioneloseslupecalpeR

.51.4arapotrefeR

.

9edocrorrE

erusserP[

isp9.0dedeecxe

gnirud)aPk2.6(

]elcycyrD

11M/9M

.elcycfodne

D11M/D9M

elcycfo

-11M/9M

.detcetedsi

tasneporooD-

sirooD-

dnetadenepoyllaunam

tonseodrooD

.elcycfodnetanepo

rorrenehwdesolcsirooD

.elcyc

.noitarbilacfotuo

msinahcemregnulp

.gninoitcnuflam

.noitarbilacfotuo

retemoitnetoperusserporeZ

dioneloseslup&revelhctaL

.82.4arap

tekcarbhctaldnasniprooD

.ylreporpgninoitcnufton

retemoitnetoperusserporeZ

yrDgniruddesolcsawrooD

.rood

-

orezfonoitarbilackcehC

.retemoitnetoperusserp

.42.4arap

rooD11M/9MmrofreP

otrefeR.tseTgninepO

roodnosrrubrofkcehC

nitekcarbhctaldnasnip

.esaerg

orezfonoitarbilackcehC

.retemoitnetoperusserp

.42.4arap

erusserporeztsujdA

otrefeR.retemoitnetop

rosirbedynaevomeR

&revelhctalmorfpudliub

.msinahcemdioneloseslup

naelcneht;srrubevomeR

desabmuihtilhtiwebuldna

erusserporeztsujdA

otrefeR.retemoitnetop

tuhsottonrotarepomrofnI

.elcycyrDgnirudrood

© Midmark Corporation 2002 SF-1827 Page 2-3 Printed in U.S.A.

Page 14

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

Table 2-1. Troubleshooting Guide -

melborPmotpmySesuaCelbaborPkcehCnoitcerroC

01edocrorrE

teserremitgodhctaW(

)rorre

11edocrorrE

21edocrorrE

)rorretsetmaR(

31edocrorrE

D11M&D9M-ylno

sutatshctiwsrooD(

tsalecnisdegnahcnu

)elcyc

.elcyc

.elcyc

)rorretpurretnierawtfoS(

.elcyc

.elcyc

sesuFnwolB

sthgiLyalpsiDoN

.sthgilsutatsDEL

thgiLretaWwoL

(

retfanosemoc

).nim5.xorppa

.rebmahc

etelpmoctonseodreziliretS

etelpmoctonseodreziliretS

.noitcnuflam

etelpmoctonseodreziliretS

.noitcnuflam

etelpmoctonseodreziliretS

nwolbdraobCPnoesufniaM.dioneloseslupnitrohSneht;dioneloseslupgulpnU

&.pmetsyalpsidtinU

wohstonseodtub,erusserp

sllifylsuounitnocretaW

sahdraobCPlortnoC

/erawtfosadah

.eruliaferawdrah

asahdraobCPlortnoC

erawdrah/erawtfos

asahdraobCPlortnoC

erawdrah/erawtfos

sihctiwsrooD

.gninoitcnuflam

--

ytridrosneslevelretaW

.gninoitcnuflamro

continued

.elcyclanoitidda

.elcyclanoitidda

.elcyclanoitidda

.hctiwsrood

.kcehc

neht;rewoptcennocsID

detcennocsidrofkcehc

.ytilicafroreziliretsnigniriw

nur&rewoptcennoC

rofrewoptcennocsiD

neht;sdnoces01.xorppa

nur&rewoptcennoc

rofrewoptcennocsiD

neht;sdnoces01.xorppa

nur&rewoptcennoc

nokcehcytiunitnocmrofreP

gninepOrooD11M/9Mnur

.82.4arapotrefeR.tseT

;rosneslevelretawnaelC

ytiunitnocmrofrepneht

.31.4arap

.31.4arap

.31.4arap

.41.4arap

.51.4arapot

.noitarepo

.01.4arapotrefeR

ecalper,stsisrepedocrorrefI

otrefeR.draobCPlortnoc

ecalper,stsisrepedocrorrefI

otrefeR.draobCPlortnoc

ecalper,stsisrepedocrorrefI

otrefeR.draobCPlortnoc

otrefeR.hctiwsroodecalpeR

refeR.dioneloseslupecalpeR

.xorpparofrewoptcennocsiD

tcennocnehT.sdnoces03

reporprofkcehcdnarewop

.rosneslevelretawecalpeR

rosneserutarepmeT

.gninoitcnuflam

.rebmahc

thgiLretaWwoL

(

nosemoc

)yletaidemmi

)ylnostinuelyts-redlO(

gniretnetonsiretaW

.dionelos

sasetanimullithgilretawwoL

.detratssielcycsanoos

.deggolc/ytridsiretliFnaelcdeepshtiwretlifnaelC

llifnideppartsirbeD

levelknatgnisnednoC

.gninoitcnuflamrosnes

.renaelc

-draobCPmorfrosnesgulpnU

rosnes.pmettcennocsiD

kcehcneht;draobCPmorf

.noitareporeporprof

cinosartlunirohsurb&

dionelosllifelbmessasiD

.sirbedynaevomerdna

.9.4arapotrefeR

.91.4arapotrefeR

.21.4arap

.rosneserutarepmetecalpeR

.yrassecenfiretlifecalpeR

otrefeR.dionelosllifecalpeR

repmujyletnanamrep&

.draobnonoitcennoc

© Midmark Corporation 2002 SF-1827 Page 2-4 Printed in U.S.A.

Page 15

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

Table 2-1. Troubleshooting Guide -

melborPmotpmySesuaCelbaborPkcehCnoitcerroC

onsahreziliretS

.rewop

elcyclliF

nehwesnopseroN

dehsupsiYBDNATS/NO

.)etanimullispmalon(

.elcycllifspikstinUtewrosneslevelretaW

.noitcnuflam

.ylwols

yrevsllifrebmahC

tonsireziliretS

.nideggulp

lortnocnonwolbesuF

.draobCP

.detavitcatatsomrehTottupnitaegatlovrofkcehC

.elcycsuoiverpmorf

.deggulpgnibut/retliFgnibutdnaretlifevomeR

retawlesseverusserP

rosneslevel

.ytridrogninoitcnuflam

continued

sidrocrewoptahtkcehC

dnareziliretsotnideggulp

.teltuo

.sesufdraobCPlortnoc

morfdraobCPlortnoc

.tatsomreht

-lesseverusserpwollA

.tcepsnidna

CPmorfrosnesgulpnU

.noitarepo

otdrocrewopnigulP

.teltuororezilirets

nokcehcytiunitnocmrofreP

noitcennocrepmuj&draob

reporprofkcehC.draobno

.sesufecalpeR

.loocotreziliretsroftiaW

,enonfI.egatlovkcehc-eR

refeR.tatsomrehtecalper

.61.4arapot

riaotrosneslevelretaw

dnahdnaevomerroyrd

.01.4arapotrefeR.yrd

retlifnaelc/ecalpeR

otrefeR.gnibutro/dna

.91.4arap

erusserpnaelc/ecalpeR

.rosneslevelretawlessev

.01.4arapotrefeR

.retaw

htiwsllifrevorebmahC

rosneslevel

dioneloslliF

.kcuts

.gnissimdraob

.gninoitcnuflam

.gninoitcnuflam

dnarosneslevel

.draobCPlortnoc

rogninoitcnuflam

draobCPlortnoC

retawlesseverusserP

.ytridrogninoitcnuflam

ytridro,nekorb,esooL

neewtebnoitcennoc

retawlesseverusserp

.leveltonsireziliretSlevelrofreziliretskcehC

CPnowercsdnuorG

rosneserutarepmeT

CPmorfrosnesgulpnU

noitcennocrepmuj&draob

.noitarepo

.rosnes

.noitallatsni

.wercs

.dionelos

llakcehC sesuaCelbaborP

.evobadetsil

reporprofkcehC.draobno

kcehcytiunitnocmrofreP

dnarotcennocneewteb

levelretawlesseverusserp

dnuorgdraobCPkcehC

rosneserutarepmetgulpnU

kcehcnehtdraobCPmorf

.noitareporeporprof

foecnatsiserkcehC

.5noitceSotrefeR

.21.4

erusserpnaelc/ecalpeR

.rosneslevelretawlessev

.01.4arapotrefeR

nekorbnaelc/ecalpeR

.snoitcennocroseriw

anoreziliretsllatsni-eR

thgiehtsujda,ecafruslevel

,sreleveltooflaudividnifo

.reziliretspumihsro

.wercsdnuorgecalpeR

erutarepmetecalpeR

.9.4arapotrefeR.rosnes

llifnaelc/ecalpeR

arapotrefeR.dionelos

.draobCPlortnocecalpeR

.31.4arapotrefeR

© Midmark Corporation 2002 SF-1827 Page 2-5 Printed in U.S.A.

Page 16

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

-ylno11M/9M

Table 2-1. Troubleshooting Guide -

melborPmotpmySesuaCelbaborPkcehCnoitcerroC

tonseodrooD

tnevretfanepo

.elcyc

tonseodrebmahC

.ylreporptnev

dionelosesluP

seodroodtub,sezigrene

.nepoton

aretfasneporooD

lamronnahtregnol

.doirepgnitnev

11M/9M-

.gnidnibrevelhctaLybrevelhctaletarepO

.gnidnibhctalrooDybhctalroodetarepO

nidehsuptonkcaryarT

otniyawehtlla

gnisuac,rebmahc

.roodhtiwecnerefretni

orezerusserP

fotuoretemoitnetop

.noitarbilac

tnevro,retlif,niarD

.deggulpgnibut

continued

rofkcehcotdnah

.ecnatsiser

rofkcehcotdnah

.ecnatsiser

htiwerefretnitonseod

.rood

-orezerusserptsujdA

.tcepsnidna

.revelhctaletacirbul/naelC

.hctalroodetacirbul/naelC

sikcaryartfieesotkcehC

sitahtosylreporpdellatsni

.rood

.42.4arap

gnibutdnaretlifevomeR

osylreporpkcaryartllatsnI

htiwerefretnitonseodtitaht

otrefeR.retemoitnetop

hsulfdna,niard,naelC

.retlifnaelc/ecalpeR.gnibut

.91.4arapotrefeR

pmalROODEHTNEPO

regnolretfasetanimulli

.doirep

seoderutarepmeT

evobaogton

gnitnevlamronnaht

D11M/D9M-

dionelostneV

.kcuts

etelpmoctonlliwtinU

.elcycnoitazilirets

rogninoitcnuflam

.5noitceS

.kaelerusserpwolS.skaelerusserprofkcehC

foecnatsiserkcehC

otrefeR.liocdionelos

.11.4

.2-2elbaTotrefeR

tnevnaelc/ecalpeR

arapotrefeR.dionelos

gninoitcnuflamecalpeR

.kaelerusserptatnenopmoc

.)C°101(F°512

tonstnemurtsnI

.gniyrd

retfatewerastnemurtsnI

.etelpmocsielcycgniyrd

.elcyc

tagninepotonsirooD

fonoitroptnevfodne

.leveltonsireziliretSlevelrofreziliretskcehC

.deggulpsiretliFtfelsiretawontahtkcehC

eeS melborP :

.noitallatsni

seodrooD

elcyctnevretfanepoton

.

anoreziliretsllatsni-eR

thgiehtsujda,ecafruslevel

.reziliretspumihs

retfalesseverusserpni

.elcycfonoitropgnitnev

.91.4arapot

ro,sreleveltooflaudividnifo

refeR.retlifnaelc/ecalpeR

© Midmark Corporation 2002 SF-1827 Page 2-6 Printed in U.S.A.

Page 17

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

Table 2-1. Troubleshooting Guide -

melborPmotpmySesuaCelbaborPkcehCnoitcerroC

ROODEHTNEPO

tonseodpmal

.etanimulli

pmalROODEHTNEPO

ehttaetanimullitonseod

.elcycnoitazilretsfodne

tnemtsujdafotuo

retemoitnetoperusserP

continued

lliwkcehcdraobCPyalpsiD

.gnitteserusserporezwohs

.52.4arapotrefeR

ylnoD11M/D9M-

"100C"edoC

D11M&D9M-ylno

)rorreretawwoL(

.retaw

"200C"edoC

D11M&D9M-ylno

)rajarooD(

.nurtonlliwelcyCnilevelretaW

.wol

.nurtonlliwelcyC

.llufsiknatgnisnednoC

htiwsllifrevorebmahC

.nurtonlliwelcyC.rajarooD-.roodesolC

dioneloslliF

.kcuts

ootsiknatgnisnednoc

rogninoitcnuflam

rosneslevelretaW

.gninoitcnuflamroytrid

.kcehc

rosneserutarepmeT

.gninoitcnuflam

nilevelretawkcehC

.knatgnisnednoc

foecnatsiserkcehC

.5noitceSotrefeR.dionelos

;rosneslevelretawnaelC

ytiunitnocmrofrepneht

erutarepmettcennocsiD

rofkcehcneht;rosnes

.noitareporeporp

erusserptsujdA

arapotrefer.retemoitnetop

.42.4

htiwknatgnisnednoclliF

.retawdellitsid

refeR.dionelosllifecalpeR

.21.4arapot

levelretawecalpeR

.01.4arapotrefeR.rosnes

erutarepmetecalpeR

.9.4arapotrefeR.rosnes

D11M&D9M-ylno

"300C"edoC

)rorreelcycyrD(

.tratstondidelcycyrDdenepotonsawrooD

retfasetunim03nihtiw

.gnitnev

-roodnepO.elcycnureR

retfasetunim03nihtiw

.gnitnev

© Midmark Corporation 2002 SF-1827 Page 2-7 Printed in U.S.A.

Page 18

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

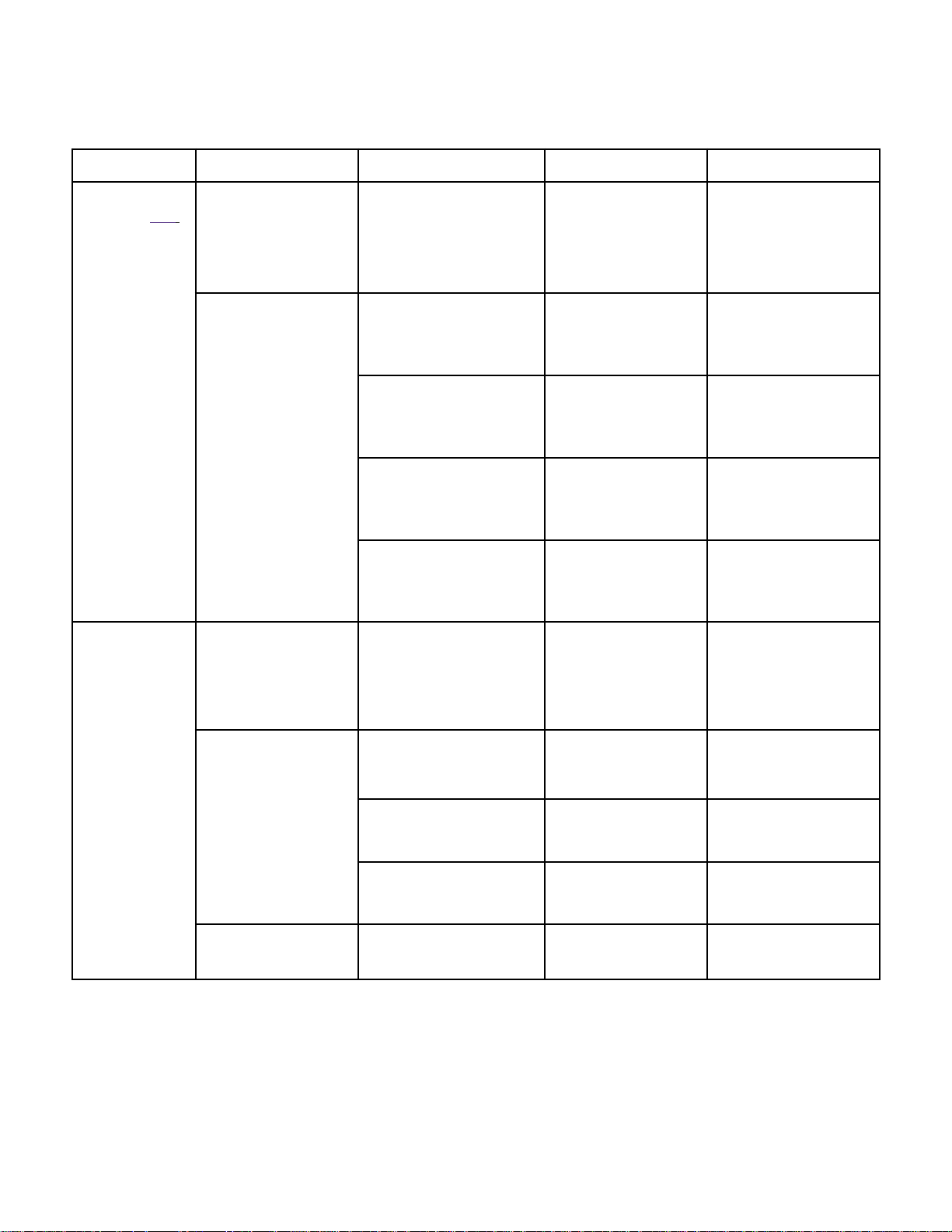

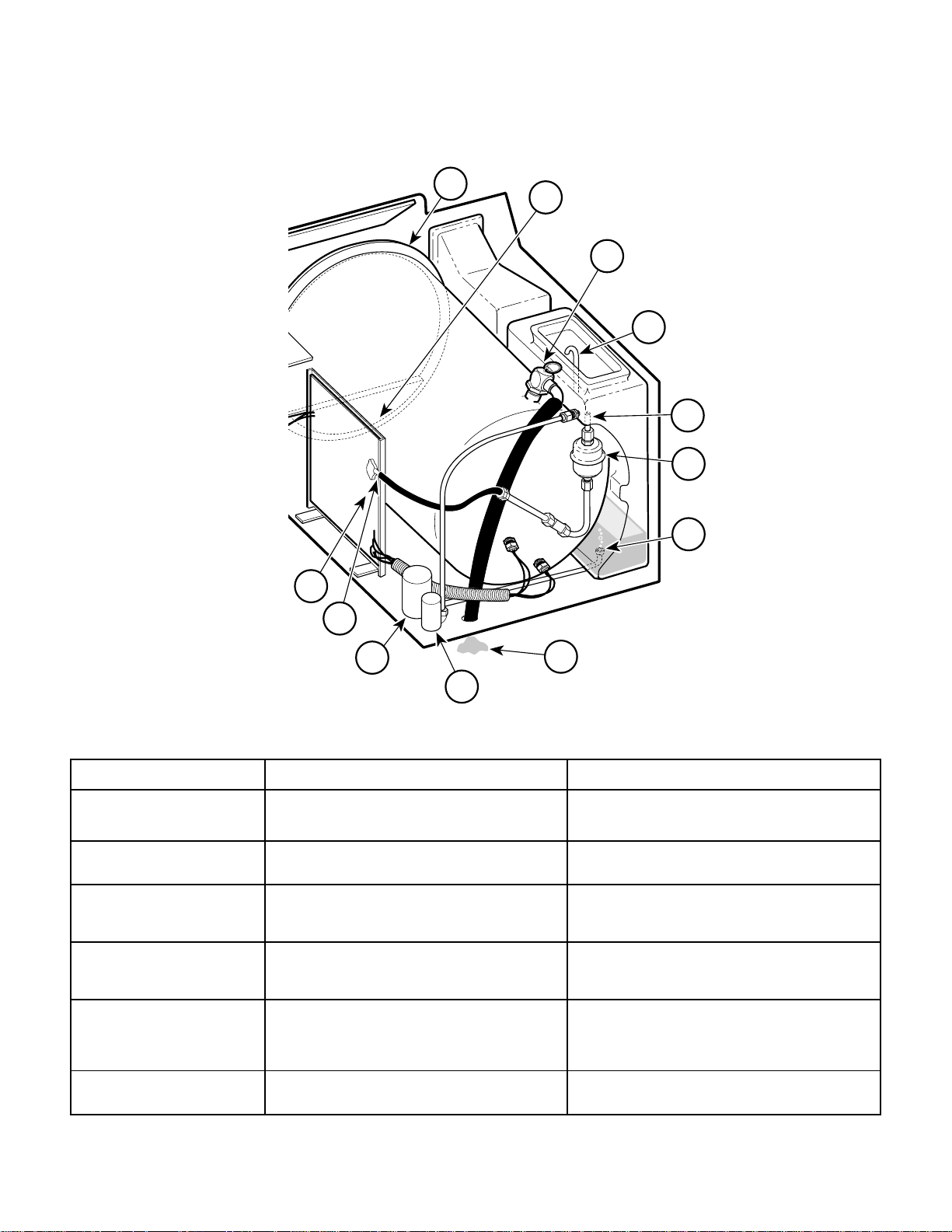

2.3 Areas To Check For Pressure Leaks

(Figure 2-1)

6a

1

1a

5

2a

4a

4

3a

6

swolleB )4(

3

5a

2

Table 2-2. Areas To Check For Pressure Leaks

tnenopmoCkcehCnoitcerroC

teksaGrooD

dioneloSlliF 3(

)1-2erugiF,1(

dioneloStneV )2(

)a1(eeS

.

.)a2(eeS

)

.)a3(eeS

.)a4(eeS

evlaVfeileRerusserP )5(

.evlavfeilererusserp

esoHrosneSerusserP )6(

.)a5(eeS

.)a6(eeS

.rooddnuoragnikaelretawrofkcehC

.liocgnisnednocurhtgnikaelretawrofkcehC

,enilllifurhtriovreserotnikcabgnikaelretawrofkcehC

.levelretawriovresergnisiar

nienilswollebmorfmaetsevissecxerofkcehC

.nommocnutonsimaetsfossihthgila:ETON.riovreser

.reziliretsfokcabhtaenebgnikaelretawrofkcehC

gniecalpererofeberusserplautcakcehc:ETON

.draobCPniamotnokaelmaetsrofkcehC

MA542300

.02.4arapotrefeR.teksagroodecalpeR

.11.4arapotrefeR.dionelostnevecalpeR

.21.4arapotrefeR.dionelosllifecalpeR

.7.4arapotrefeR.swollebecalpeR

.32.4arapotrefeR.evlavfeilererusserpecalpeR

.eitelbachtiwdraobCPotesohrosneserusserperuceS

© Midmark Corporation 2002 SF-1827 Page 2-8 Printed in U.S.A.

Page 19

SECTION III

Return To Table Of Contents

SCHEDULED MAINTENANCE

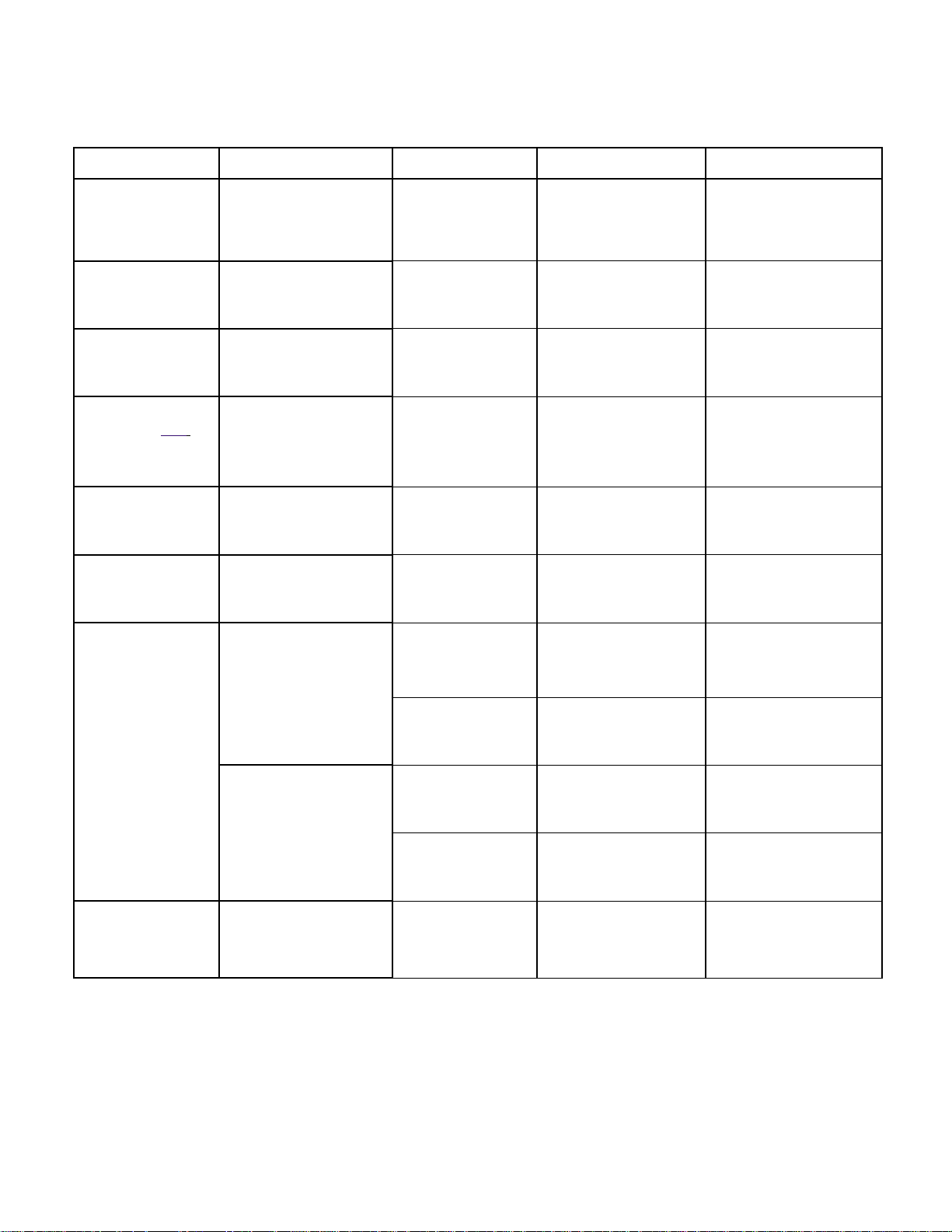

3.1 Scheduled Maintenance

Table 3-1 lists inspections and services that should be

performed periodically on the sterilizer.

Table 3-1. Scheduled Maintenance Chart

lavretnIecivreSronoitcepsnI oDottahW

SECTION III

SCHEDULED MAINTENANCE

yllaunna-imeSegamadsuoivbO ,stnenopmocniskcarc:sahcusegamadsuoivborofreziliretsfonoitidnockcehcyllausiV

erawdrah/srenetsaF dnaerawdrahgnissimynaecalpeR.erawdrah/srenetsafesoolrognissimrofreziliretskcehC

strapgnivoM .esaergerutarepmethgihhtiwdetacirbulebdluohsstrapgnivomllA

dnagninraW

slacedlanoitcurtsni

yalrevoyalpsiD .yrassecenfiyalrevoyalpsidecalpeR.yalrevoyalpsidelbigelliro,degamad,gnissimrofkcehC

snoitcennocgniriW esoolynanethgiT.snoitcennocytridllanaelC.snoitcennocgniriwllafoytirgetniehtkcehC

roodfotnemevomeerF

hctal

roodfotnemevomeerF

gnirpshctiws

revelhctaL

)ylno11M/9M(

steksagmaDdnarooD .steksagnisdiovro,steksagfonoitaroireted,steksagnotridrofkcehcdnasteksagevomeR

retliF arapotrefeR.yrassecenfiretlifecalpeR.noitulosretawdnapaosdlimagnisuretlifnaelC

dluowhcihwegamadelbisivrehtoynaro,skael,stnenopmocnistned,stnenopmocgnissim

.reziliretsehtfoecnamrofrepehtesimorpmocdluowroetarepootefasnuebotreziliretsesuac

.yrassecenfireziliretsriapeR

.yrassecenfi172etitcoLgnisuyrassecensaerawdrahesoolynanethgit

.yrassecensaslacedecalpeR.slacedelbigellirognissimrofkcehC

.snoitcennocdegamadynaecalpeR.snoitcennoc

.esaergerutarepmethgihhtiwsniprooddnahctalroodetacirbuL.hctalroodnaelC

ecalpeR.esaergerutarepmethgihhtiwgnirpshctiwsroodetacirbuL.gnirpshctiwsroodnaelC

.yrassecenfignirpshctiwsrood

htiwrevelhctaletacirbuL.revelhctalnaelC.ecnatsiserrofkcehcotdnahybrevelhctaletarepO

.esaergerutarepmethgih

otrefeR.yrassecenfisteksagecalpeR.noitulosretawdnapaosdlimagnisusteksagnaelC

.02.4arap

.91.4

rosneslevel

)ylnostinu

gnibuT fignibutecalpeR.gnibuthsulfdna,niard,naelC.pudliubroftcepsnidnagnibutevomeR

)tnempiuqe

© Midmark Corporation 2002 SF-1827 Page 3-1 Printed in U.S.A.

retawlesseverusserP

retawknatgnisnednoC

ylrae(rosneslevel

draobCPyalpsiD yalpsidecalpeR.52.4arapotrefeR.kcehcnottub/yalpsid/pmaldraobCPyalpsidehtmrofreP

evlavfeilererusserP fievlavfeilererusserpecalpeR.62.4arapotrefeR.kcehcevlavfeilererusserpamrofreP

lanoitpo(retnirP

tsetlanoitarepO snoitacificepsstinihtiwgnitareposireziliretsehtfienimretedottsetlanoitareponamrofreP

.01.4arapotrefeR

.8.4arapotrefeR

.yrassecen

.yrassecenfidraobCP

.32.4arapotrefeR.yrassecen

.yrassecen

.42.4arapotrefeR.yrassecenfisretemoitnetop

.yrassecenfirosnesecalpeR.srosneslevelretawlesseverusserpmorfpu-dliubynaevomeR

.yrassecenfirosnesecalpeR.rosneslevelretawknatgnisnednocmorfpu-dliubynaevomeR

firetnirpecalpeR.yrassecenfiegdirtracnobbirecalpeR.ylreporpstnirpretnirptahtkcehC

draobCPlortnocehttsujdA.stnenopmocgninoitcnuflamynaecalpeR.)1.2arapotrefeR(

Page 20

SECTION III

Return To Table Of Contents

SCHEDULED MAINTENANCE

© Midmark Corporation 2002 SF-1827 Page 3-2 Printed in U.S.A.

Page 21

MAINTENANCE / SERVICE

Return To Table Of Contents

SECTION IV

MAINTENANCE / SERVICE INSTRUCTIONS

SECTION IV

4.1 Safety Precautions

WARNING

Always disconnect the power cord

from the outlet before removing any of

the sterilizer covers/panels or making any repairs

to prevent the possibility of electrical shock.

Also, drain the sterilizer to prevent spills during

repairs. Failure to comply with these instructions

could result in serious personal injury or death.

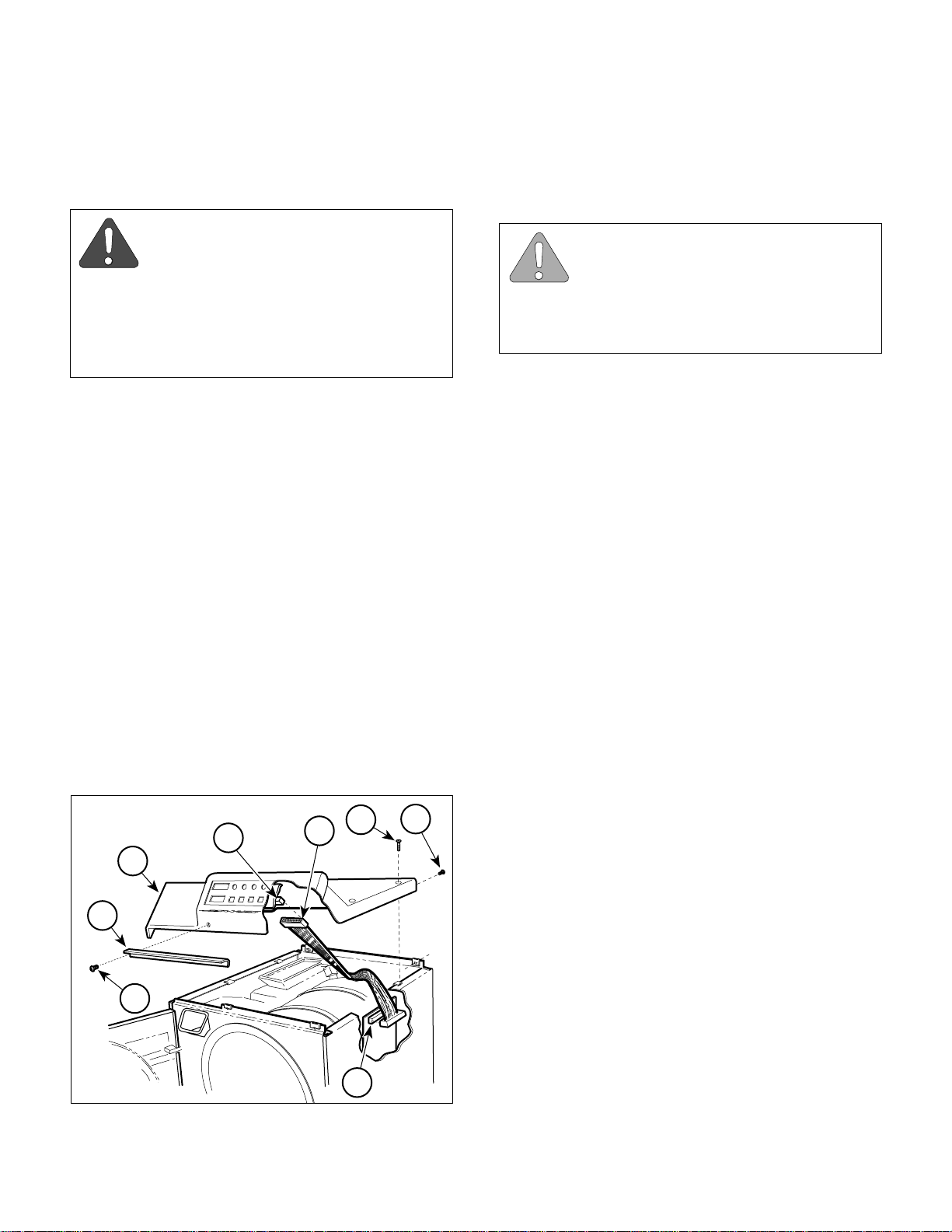

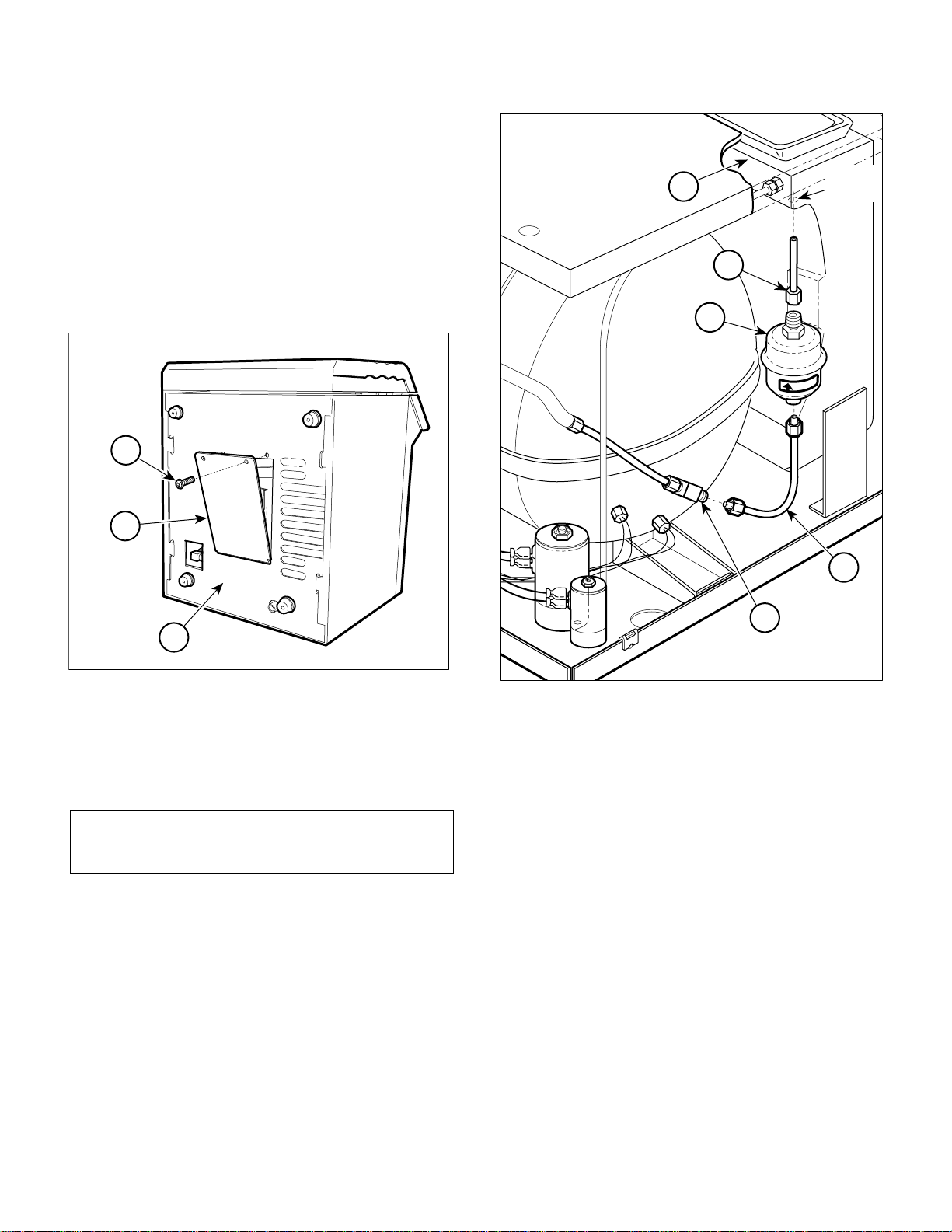

4.2 Top Cover Removal / Installation

A. Removal

(1 ) Disconnect power cord from the outlet.

(2 ) If the sterilizer contains a printer, remove printer

(Refer to Operation Manual).

(3 ) Open sterilizer door.

(4 ) Remove two screws (1, Figure 4-1) and steam

block (2) from top cover (3).

(5 ) Remove four screws (4) and two screws (5)

from top cover (3).

(6 ) On units which apply, carefully break front of

top cover (3) loose from silicone sealant.

EQUIPMENT ALERT

Lift top cover carefully and slowly. Rib-

bon connector is still connected to display

PC board and any excess pressure exerted on it

could result in a damaged ribbon connector or display

PC board.

(7 ) Lift rear of top cover (3) and disconnect ribbon

connector (6) from display PC board (7A) or

control PC board (7B) (depending on whether

ribbon connector (6) is part of display PC board

or is a separate component).

(8 ) Remove top cover (3) from sterilizer.

B. Installation

(1 ) Coat mating surfaces of front panel lip and top

cover (3) with silicone sealant.

(2 ) Position top cover (3) over sterilizer, with rear of

top cover raised, and connect ribbon connector

(6) to display PC board (7A) or control PC

board (7B).

(3 ) Install top cover (3) on sterilizer and secure

using two screws (5) and four screws (4).

(4 ) Install steam block (2) on top cover (3) and

secure using two screws (1).

5

7A

4

6

3

2

(5 ) Close sterilizer door.

(6 ) If the sterilizer contains a printer, install printer

(Refer to Operation Manual).

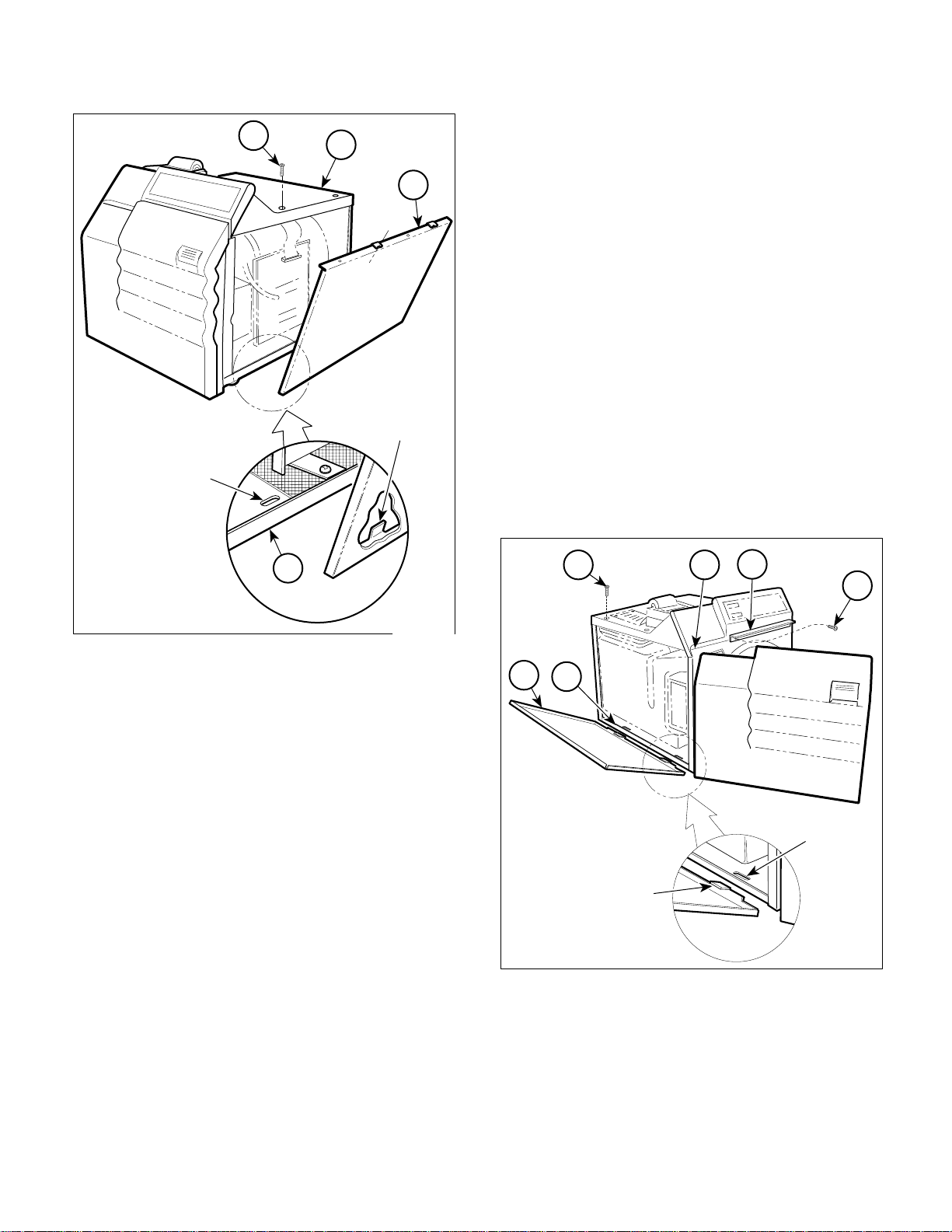

4.3 Right Hand Side Panel Removal /

Installation

A. Removal

1

7B

Figure 4-1. Top Cover Removal / Installation

© Midmark Corporation 2002 SF-1827 Page 4-1 Printed in U.S.A.

MA204802

(1 ) Disconnect power cord from the outlet.

(2 ) Remove two screws (1, Figure 4-2) from top

cover (2).

Page 22

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

1

2

(3 ) Remove left screw (1, Figure 4-3) from steam

block (2).

SLOT

3

TAB

4

(4 ) Remove two screws (3) from top cover (4).

(5 ) Lift up the left hand corner of top cover (4), pull

outward and down on the top edge of the left

hand side panel (5), and remove left hand side

panel from sterilizer.

B. Installation

(1 ) Insert two tabs of left hand side panel (5) into

two slots of base (6).

(2 ) Lift up the left hand corner of top cover (4), raise

the top edge of left hand side panel (5) into

position, and secure using two screws (3).

(3) Install left screw (1) on steam block (2).

(4 ) Close sterilizer door.

3 4

2

1

MA2049-01

Figure 4-2. Right Hand Side Panel

Removal / Installation

(3 ) Pull outward and down on the top edge of the

right hand side panel (3) and remove right hand

side panel from sterilizer.

B. Installation

(1 ) Insert two tabs of right hand side panel (3) into

two slots of base (4).

(2 ) Raise top edge of right hand side panel (3) into

position and secure using two screws (1).

4.4 Left Hand Side Panel Removal / Installation

A. Removal

(1 ) Disconnect power cord from the outlet.

(2 ) Open sterilizer door.

5

6

SLOT

TAB

MA2050-01

Figure 4-3. Left Hand Side Panel

Removal / Installation

© Midmark Corporation 2002 SF-1827 Page 4-2 Printed in U.S.A.

Page 23

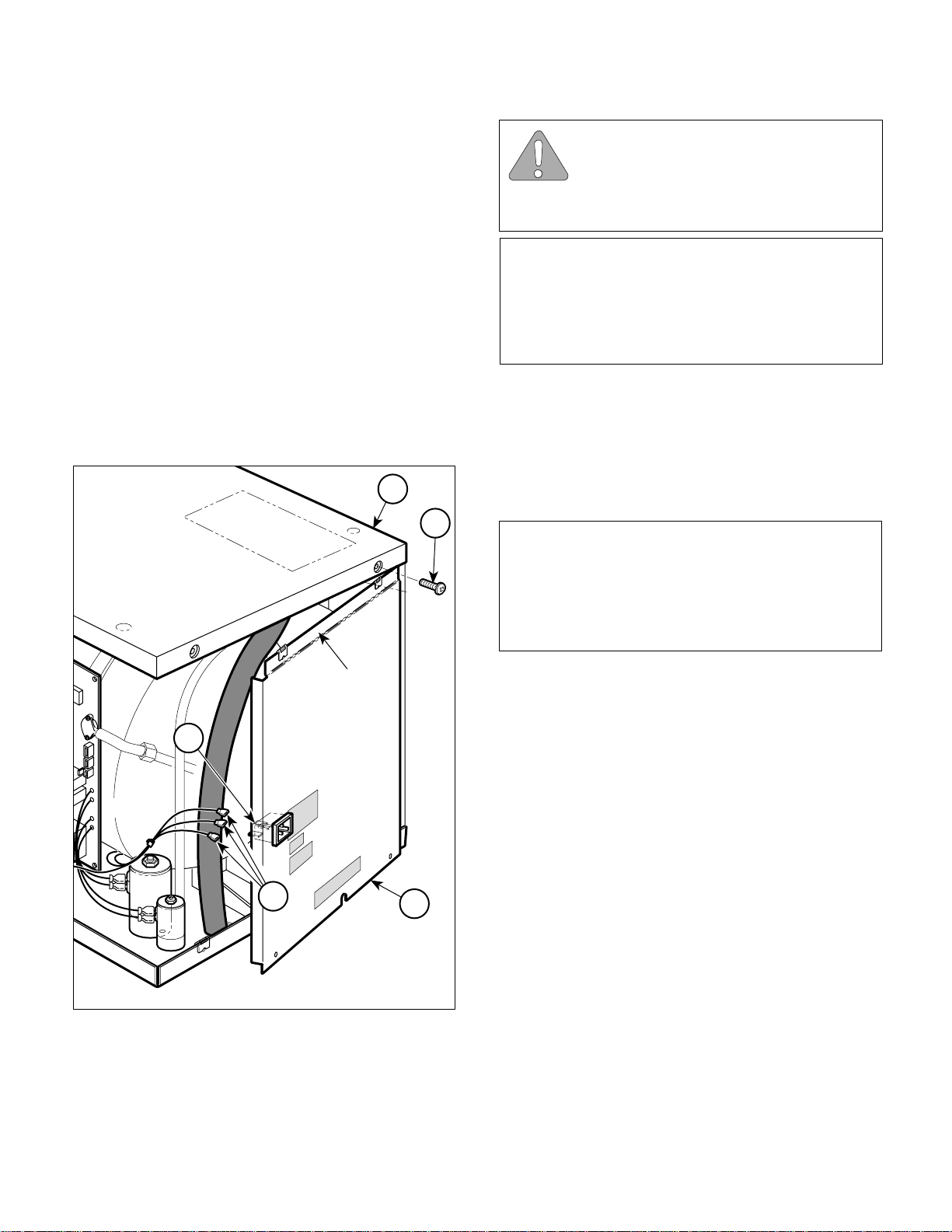

4.5 Back Panel Removal / Installation

Return To Table Of Contents

A. Removal

(1 ) Disconnect power cord from sterilizer.

(2 ) Remove right hand side panel (Refer to

para 4.3).

(3 ) Remove left hand side panel (Refer to

para 4.4).

(4 ) Remove four screws (1, Figure 4-4) from back

panel (2).

(5 ) Partially remove back panel (2) by simulta-

neously pulling downward and outward on back

panel.

SECTION IV

MAINTENANCE / SERVICE

EQUIPMENT ALERT

Ensure that wires are completely discon-

nected before attempting to remove back

panel. Failure to do so could result in damage to

sterilizer.

NOTE

Units prior to serial number CZ1110/OM1000 have a

fuse holder attached to the back panel. On these

sterilizers, tag and disconnect two wires from the

receptacle and one wire from the fuse holder instead

of performing step 6.

(6 ) On older units, tag and disconnect three wires

(3) from terminals of receptacle (4) and remove

back panel (2) from sterilizer. On newer units,

separate back panel (2) from unit as far as

possible and lay it on its side.

5

B. Installation

1

NOTE

Units prior to serial number CZ1110/OM1000 have a

fuse holder attached to the back panel. On these

sterilizers, remove tags and connect two wires to the

receptacle and one wire to the fuse holder instead of

performing step 1.

FLAP

4

(1 ) On older units, remove tags and connect three

wires (3) to terminals of receptacle (4).

(2 ) Position flap of back panel (2) behind top cover

(5) and secure back panel in place using four

screws (1).

(3 ) Install left hand side panel (Refer to para 4.4).

(4 ) Install right hand side panel (Refer to para 4.3).

4.6 Base Inspection Cover Removal /

3

2

Installation

A. Removal

(1 ) Disconnect power cord from outlet.

MA2051-01

(2 ) Drain water from condensing tank.

Figure 4-4. Back Panel Removal / Installation

(3) Turn sterilizer onto its back.

© Midmark Corporation 2002 SF-1827 Page 4-3 Printed in U.S.A.

Page 24

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

(4 ) Remove two screws (1, Figure 4-5) and base

inspection cover (2) from base (3).

B. Installation

(1 ) Install base inspection cover (2) on base (3) and

secure using two screws (1).

(2 ) Turn sterilizer upright.

(3 ) Refill condensing tank with distilled water.

1

2

3

Figure 4-5. Base Inspection Cover

Removal / Installation

MA2052-01

4

5

3

2

Figure 4-6. Bellows Assembly

Removal / Installation

TUBE

HOLE

1

MA2053-01

4.7 Bellows Assembly Removal /

B. Installation

Installation

(1 ) Connect tubes (1 and 5) to bellows assem-

NOTE

Figure 4-6 shows old-style bellows. The procedure for

the new-style is the same.

A. Removal

(1 ) Remove back panel (Refer to para 4.5).

(2 ) Disconnect tube (1, Figure 4-6) from tee (2).

(3 ) Pull downward on bellows assembly (3) to

remove bellows assembly from condensing

tank (4).

(4 ) Loosen and remove tubes (1 and 5) from

bellows assembly (3).

© Midmark Corporation 2002 SF-1827 Page 4-4 Printed in U.S.A.

bly (3).

(2 ) Position bellows assembly (3) and insert tube

(5) into tube hole of condensing tank (4).

(3 ) Connect tube (1) to tee (2).

(4 ) Install back panel (Refer to para 4.5).

Page 25

4.8 Condensing Tank Water Level Sensor

Return To Table Of Contents

Removal / Installation (Applies only to

Units with old style Control PC Board

with EPROM Version M or Before)

SECTION IV

MAINTENANCE / SERVICE

NOTE

Units with old style control PC board with EPROM

version N or after or new style control PC board do

not have a condensing tank water level sensor.

A. Removal

(1 ) Drain water from condensing tank.

(2 ) Remove back panel (Refer to para 4.5).

(3 ) Remove bellows assembly (Refer to para 4.7).

(4 ) Disconnect wire (1, Figure 4-7) from termi- nal

(2).

(5 ) Using Water Level Sensor Wrench to hold fitting

(3), loosen nut (4) (Refer to Table 1-2 for special

tool).

(6 ) Pull assembled level sensor rod (5) from

fitting (3).

(7 ) Remove nut (4), silicone tube (6), and crimp (7)

from level sensor rod (5). Discard silicone tube

and crimp.

(8 ) Using vise grips to hold level sensor rod (5),

remove nut (8) and terminal (2) from level

sensor rod.

B. Installation

(1 ) Using vise grips to hold level sensor rod (5),

install terminal (2) on level sensor rod and

secure using nut (8).

3

6

4

2

8

7

5

1

MA2054-01

Figure 4-7. Condensing Tank Water Level

Sensor Removal / Installation

(3) Install assembled level sensor rod (5) in fit-

ting (3).

(4 ) Using Water Level Sensor Wrench to hold fitting

(3), tighten nut (4) (Refer to Table 1-2 for special

tool).

(5 ) Connect wire (1) to terminal (2).

(6 ) Install bellows assembly (Refer to para 4.7).

(7 ) Install back panel (Refer to para 4.5).

(8 ) Refill condensing tank with distilled water.

EQUIPMENT ALERT

The end of the silicone tube must extend

past nut (4) after nut is installed. If it is

not, the level sensor rod will not function properly

because the terminal will be in contact with nut (4).

(2 ) Install crimp (7), nut (4), and silicone tube (6) on

level sensor rod (5) and secure by crimping

crimp (7).

© Midmark Corporation 2002 SF-1827 Page 4-5 Printed in U.S.A.

Page 26

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

4.9 Temperature Sensor Assembly

Removal / Installation

A. Removal

(1 ) Remove back panel (Refer to para 4.5).

NOTE

Units with old style control PC board with EPROM

version N or after or new style control PC board will

only have two wire harnesses to disconnect instead

of three.

(2 ) Disconnect two / three wire harnesses (1, Figure

4-8) from two / three terminals (2).

(3 ) Remove flex guard tubing (3) from two / three

wire harnesses (1).

(4 ) Remove temperature sensor assembly (4) from

pressure vessel (5).

B. Installation

(3 ) Install flex guard tubing (3) on three wire

harnesses (1).

(4 ) Connect three wire harnesses (1) to three

terminals (2).

(5 ) Install back panel (Refer to para 4.5).

4.10 Pressure Vessel Water Level Sensor

Removal / Installation

A. Removal

(1 ) Remove back panel (Refer to para 4.5).

(2 ) Remove wire tray rack and tray plate (Refer to

para (4-17).

(3 ) Disconnect wire (1, Figure 4-9) from termi- nal

(2).

(4 ) Remove nut (3) and terminal (2) from level

sensor rod (4).

(1 ) Coat threads of temperature sensor assembly

(4) with teflon tape.

(2 ) Install temperature sensor assembly (4) in

pressure vessel (5).

2

5

4

1

3

(5 ) Remove nut (5).

EQUIPMENT ALERT

Do not try to pull level sensor rod out of

back side of pressure vessel. Doing so

will damage level sensor rod.

(6 ) Push level sensor rod (4) thru fitting (6) and into

pressure vessel (7) and remove level sensor

rod.

(7 ) Remove spacer (8) from level sensor rod (4).

(8 ) Remove silicone tube (9) from fitting (6).

Discard silicone tube (9) and crimp (10).

(9 ) If damaged, remove fitting (6) from pressure

vessel (7).

B. Installation

(1 ) If removed, coat fitting (6) with teflon tape and

install fitting in pressure vessel (7).

(2 ) Install silicone tube (9) and spacer (8) on level

sensor rod (4).

MA2074-01

Figure 4-8. Temperature Sensor Assembly

Removal / Installation

© Midmark Corporation 2002 SF-1827 Page 4-6 Printed in U.S.A.

Page 27

MAINTENANCE / SERVICE

Return To Table Of Contents

4.11 Vent Solenoid Removal /

Installation

SECTION IV

7

8

4

6

9

10

5

1

MA2055-01

Figure 4-9. Pressure Vessel Water Level

Sensor Removal / Installation

NOTE

The assembled level sensor rod must be installed

from the inside of the pressure vessel.

(3) Install assembled level sensor rod (4) in fit-

ting (6).

EQUIPMENT ALERT

The end of the silicone tube must extend

past nut (5) after nut is installed. If it is

not, the level sensor rod will not function properly

because the terminal will be in contact with nut (5).

(4 ) Install and crimp crimp (10) on silicone

tube (9).

(5 ) Install nut (5).

NOTE

Steps will vary slightly for M9D / M11D units. Use

this procedure as a guide.

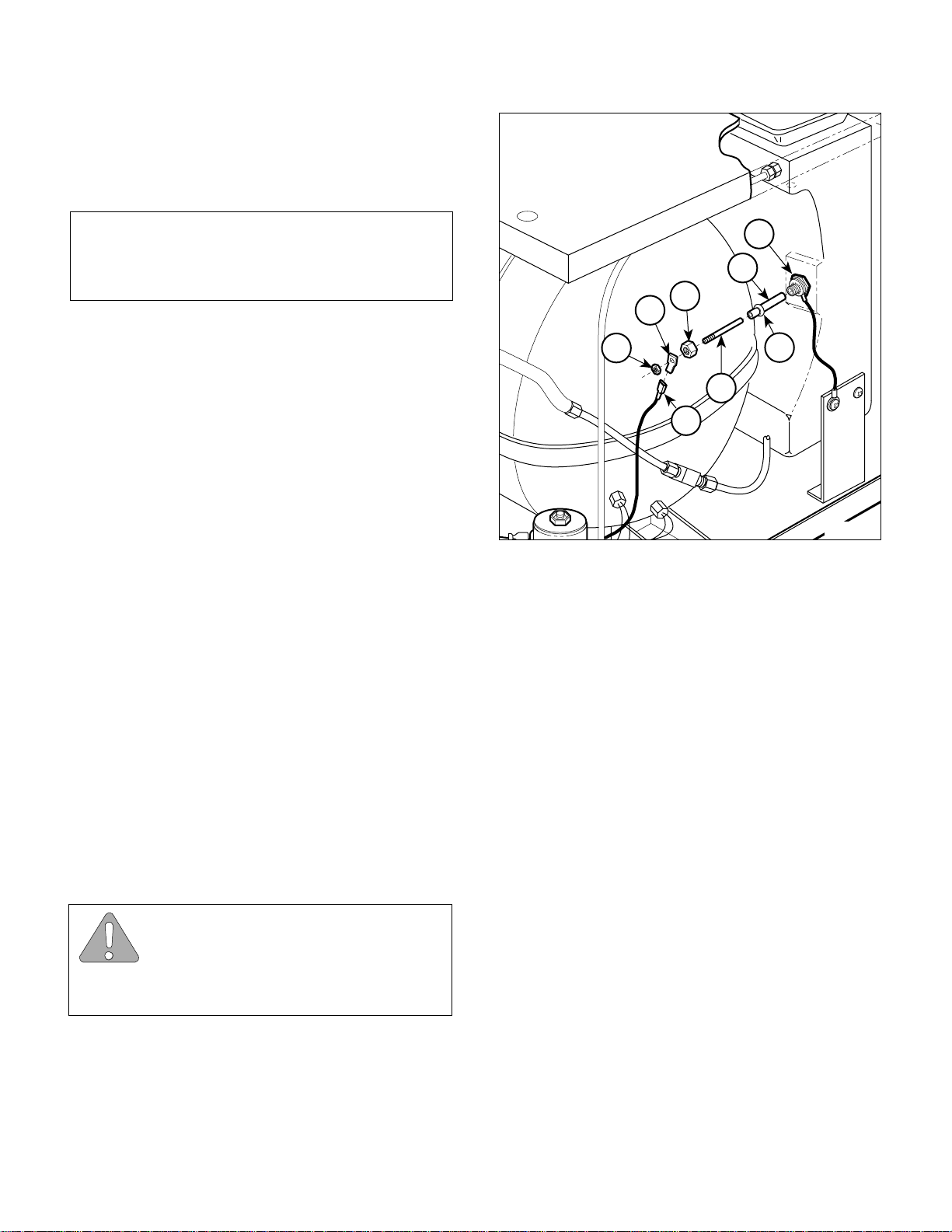

A. Removal

NOTE

Units prior to serial number CZ1110/OM1000 have a

manifold assembly which secures the vent solenoid.

Refer to the parts list to remove the vent solenoid on

2

3

these sterilizers.

(1 ) Drain water from condensing tank.

(2 ) Remove back panel (Refer to para 4.5).

(3 ) Tag and disconnect two wires (1, Figure 4-10)

from terminals (3).

(4 ) Tag and disconnect two wires (2) from terminals

(4).

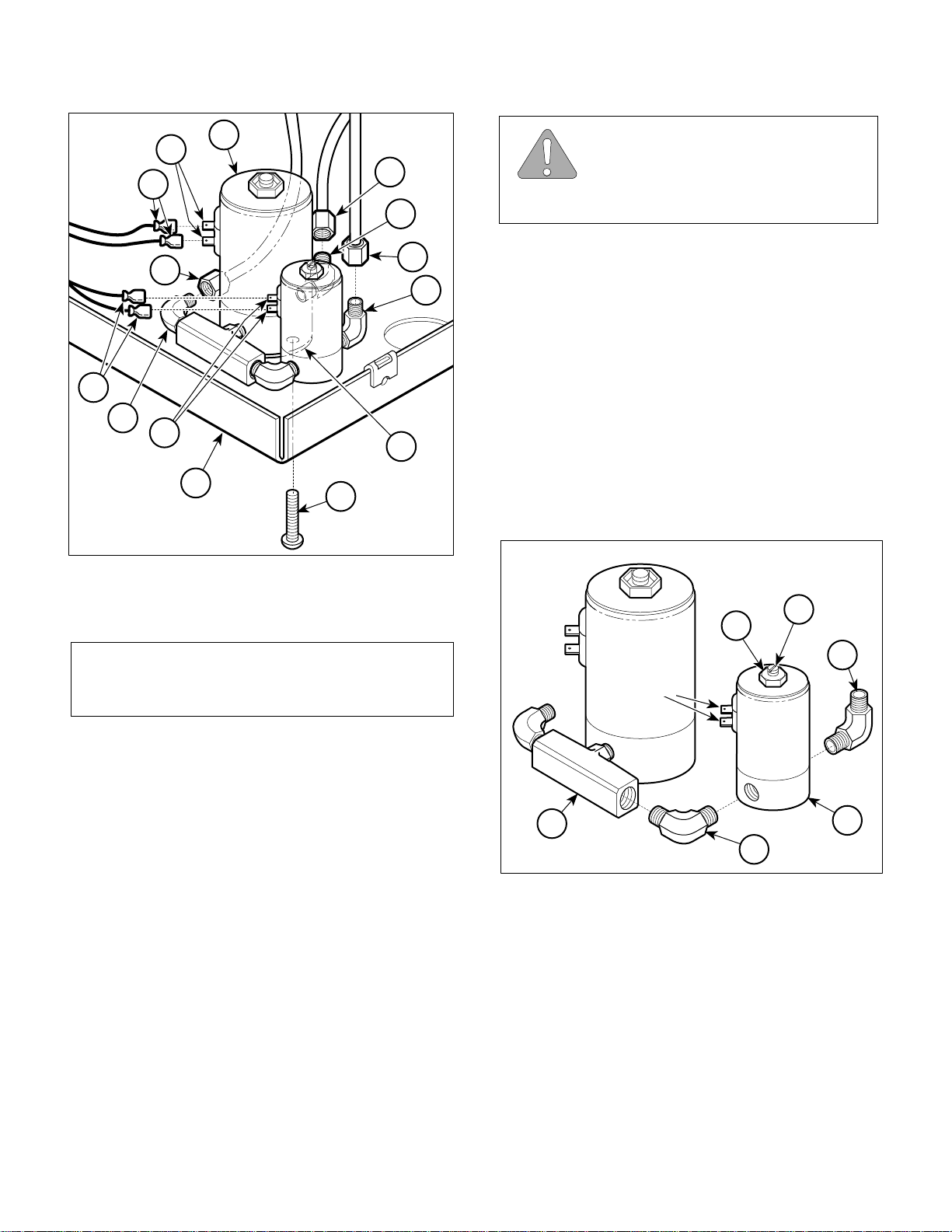

(5 ) Disconnect three tubes (5 thru 7) from elbows (8

thru 10).

(6 ) Remove two screws (11) from bottom of

manifold assembly (12).

NOTE

Spacer (12A) is only on newer units.

(7 ) Remove manifold assembly (12) and spacer

(12A) from base (13).

(8 ) Hold screw (1, Figure 4-11) and loosen nut (2).

Turn terminals out of the way.

(9 ) Remove assembled vent solenoid (3) and elbow

(4) from tee (5).

(6 ) Install terminal (2) on level sensor rod (4) and

secure using nut (3).

(7 ) Connect wire (1) to terminal (2).

(8 ) Install wire tray rack and tray plate (Refer to

para 4.17).

(9 ) Install back panel (Refer to para 4.5).

© Midmark Corporation 2002 SF-1827 Page 4-7 Printed in U.S.A.

(1 0) Remove elbows (4 and 6) from vent sole-

noid (3).

Page 28

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

3

12

1

7

10

6

5

9

2

8

4

12A

13

11

MA2056-0

Figure 4-10. Vent Solenoid Removal / Installation

EQUIPMENT ALERT

When installing the vent solenoid, the

side of the solenoid marked IN needs to

be connected to the pressure line. Reversing vent

solenoid will cause system failure.

(7 ) Install spacer (12A, Figure 4-10) and manifold

assembly (12) on base (13) and secure using

two screws (11).

(8 ) Connect three tubes (5 thru 7) to elbows (8 thru

10).

(9 ) Connect two wires (2) to terminals (4).

(10) Connect two wires (1) to terminals (3).

(11) Install back panel (Refer to para 4.5).

(12) Refill condensing tank with distilled water.

2

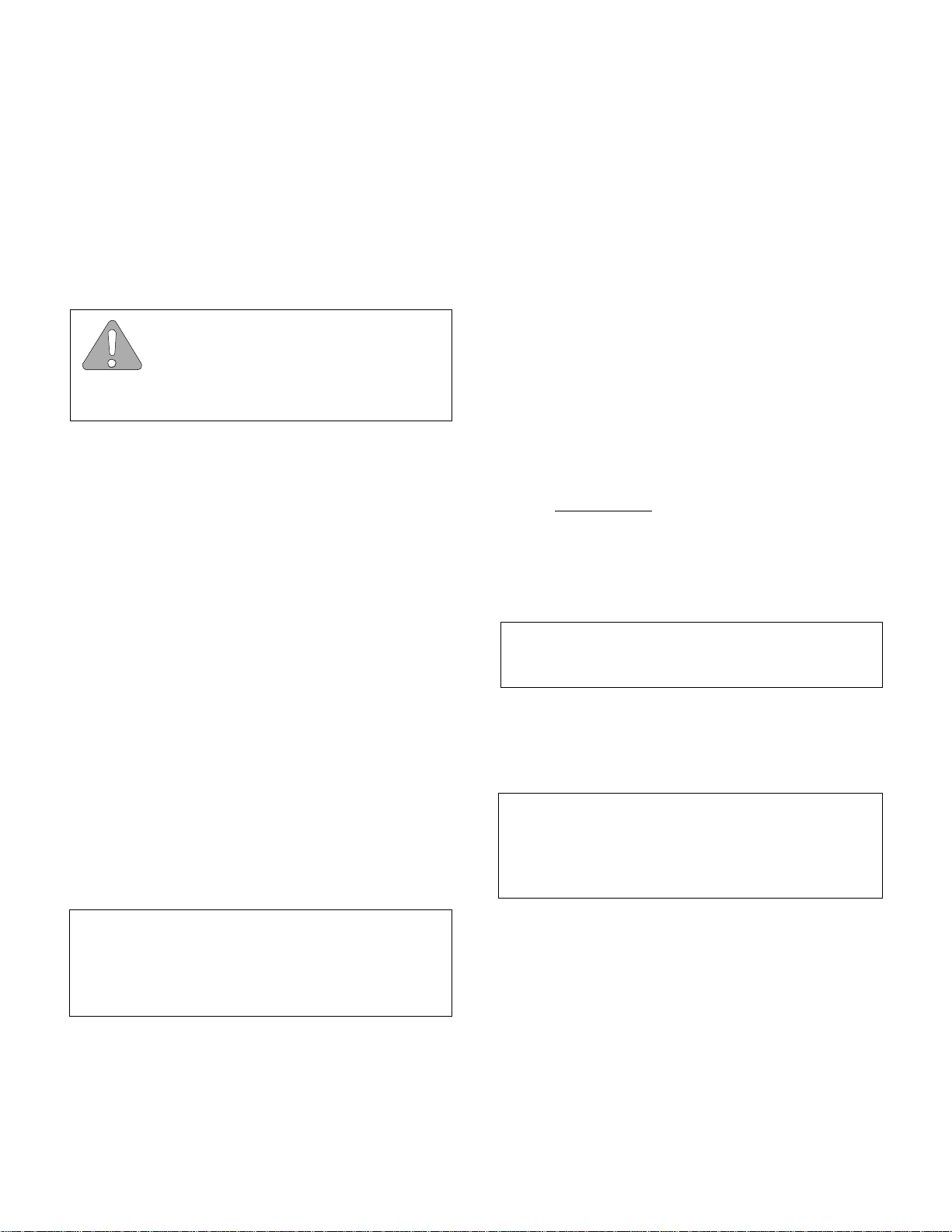

B. Installation

NOTE

The end of elbow (6) which receives a tube does not

get coated with teflon tape.

(1 ) Coat the threads of elbows (4 and 6, Figure 4-

11) with teflon tape.

(2 ) Install elbows (4 and 6) on vent solenoid (3).

(3 ) Hold screw (1) and loosen nut (2). Turn termi-

nals out of the way.

(4 ) Install assembled elbow (4) and vent solenoid

(3) on tee (5).

(5 ) Turn terminals of vent solenoid (3) so wires will

connect easily to vent solenoid.

(6 ) Hold screw (1) and tighten nut (2).

2

TERMINALS

5

4

Figure 4-11. Vent Solenoid Fittings

Removal / Installation

1

6

3

MA205701

© Midmark Corporation 2002 SF-1827 Page 4-8 Printed in U.S.A.

Page 29

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

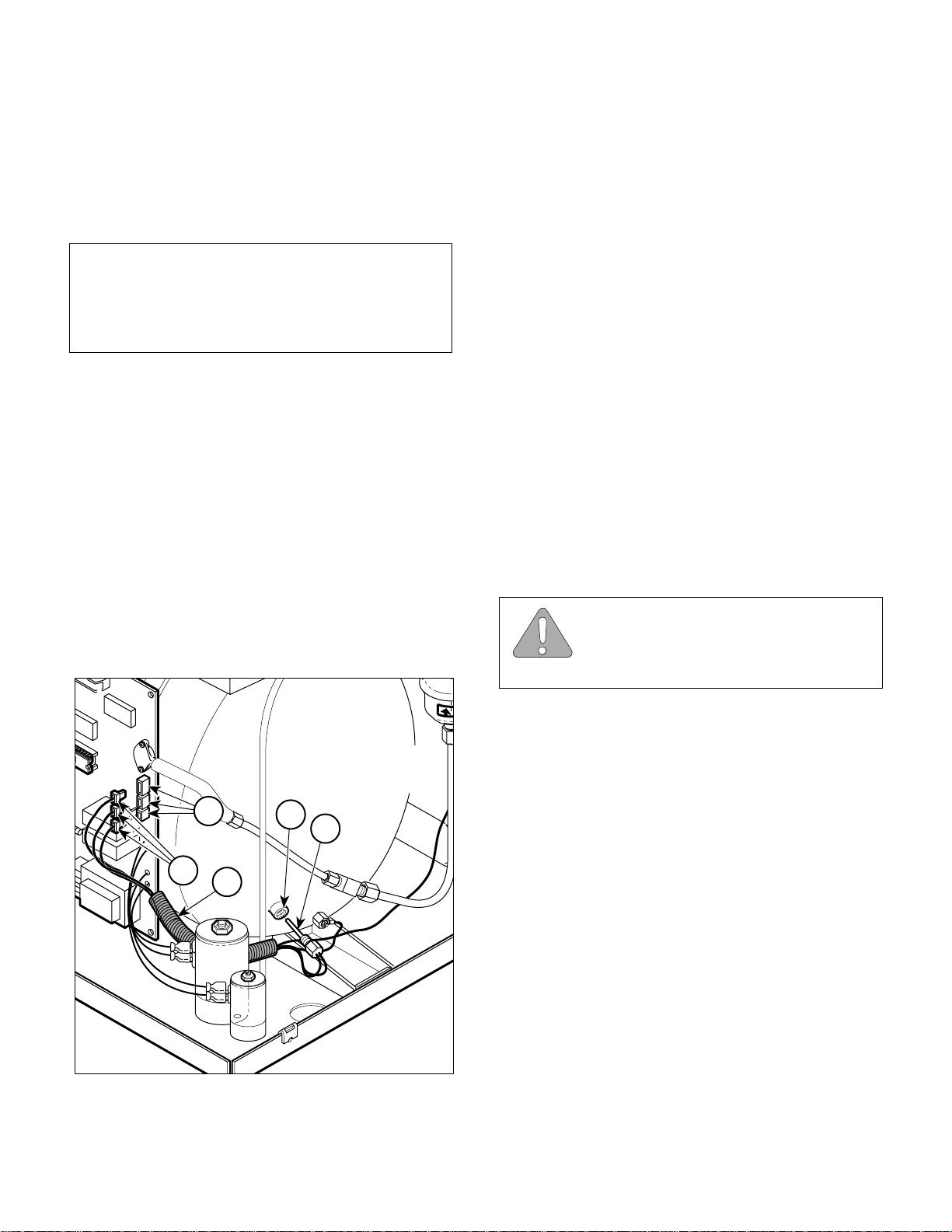

4.12 Fill Solenoid Removal / Installation

NOTE

Steps will vary slightly for M9D / M11D units. Use

this procedure as a guide.

A. Removal

NOTE

Units prior to serial number CZ1110/OM1000 have a

manifold assembly which secures the fill solenoid.

Refer to the parts list to remove the fill solenoid on

these sterilizers.

(1 ) Drain water from condensing tank.

(2 ) Remove back panel (Refer to para 4.5).

(3 ) Tag and disconnect two wires (1, Figure 4-12)

from terminals (3).

(4 ) Tag and disconnect two wires (2) from

terminals (4).

NOTE

Spacer (12A) is only on newer units.

(7 ) Remove manifold assembly (12) and spacer

(12A) from base (13).

(8 ) Hold screw (1, Figure 4-13) and loosen nut (2).

Turn terminals out of the way.

(9 ) Remove assembled vent solenoid (3) and elbow

(4) from tee (5).

(1 0) Remove elbow (6) and tee (5) from fill

solenoid (7).

(1 1) Remove elbow (8) from fill solenoid (7).

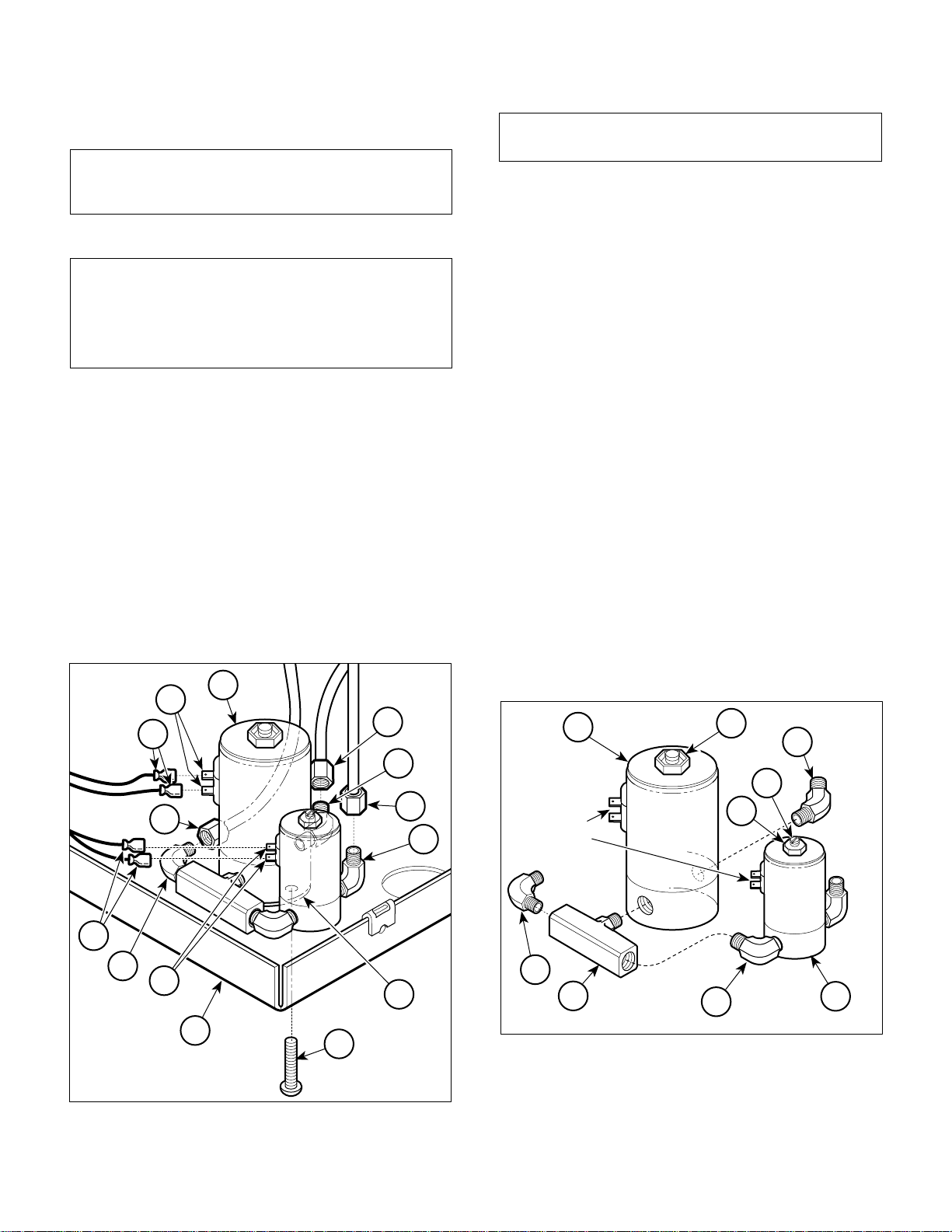

B. Installation

(1 ) Coat threads of tee (5, Figure 4-13) and elbows

(6 and 8) with teflon tape.

(2 ) Install elbow (8) on fill solenoid (7).

(5 ) Disconnect three tubes (5 thru 7) from elbows (8

thru 10).

(6 ) Remove two screws (11) from bottom of

manifold assembly (12).

12

3

1

7

10

6

5

9

2

8

4

12A

13

11

MA2056-0

Figure 4-12. Fill Solenoid Removal / Installation

(3 ) Install elbow (6) and tee (5) on fill solenoid (7).

(4 ) Loosen nut (9). Turn terminals of fill solenoid

(7) so wires will connect easily to fill solenoid.

Tighten nut (9).

(5 ) Coat threads of elbow (4) with teflon tape.

7

9

8

1

2

TERMINALS

6

5

Figure 4-13. Fill Solenoid Fittings

Removal / Installation

2

4

3

MA205801

© Midmark Corporation 2002 SF-1827 Page 4-9 Printed in U.S.A.

Page 30

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

(6 ) Hold screw (1) and loosen nut (2). Turn termi-

nals out of the way.

(7 ) Install assembled elbow (4) and vent solenoid

(3) on tee (5).

(8 ) Turn terminals of vent solenoid (3) so wires will

connect easily to vent solenoid.

(9 ) Hold screw (1) and tighten nut (2).

EQUIPMENT ALERT

When installing the vent solenoid and the

fill solenoid, the side of the solenoids

marked "IN" need to be connected to the pressure

lines. Reversing solenoids will cause system failure.

(10) Install spacer (12A, Figure 4-12) and manifold

assembly (12) on base (13) and secure using

two screws (11).

(11) Connect three tubes (5 thru 7) to elbows (8

thru 10).

(12) Connect two wires (2) to terminals (4).

(13) Connect two wires (1) to terminals (3).

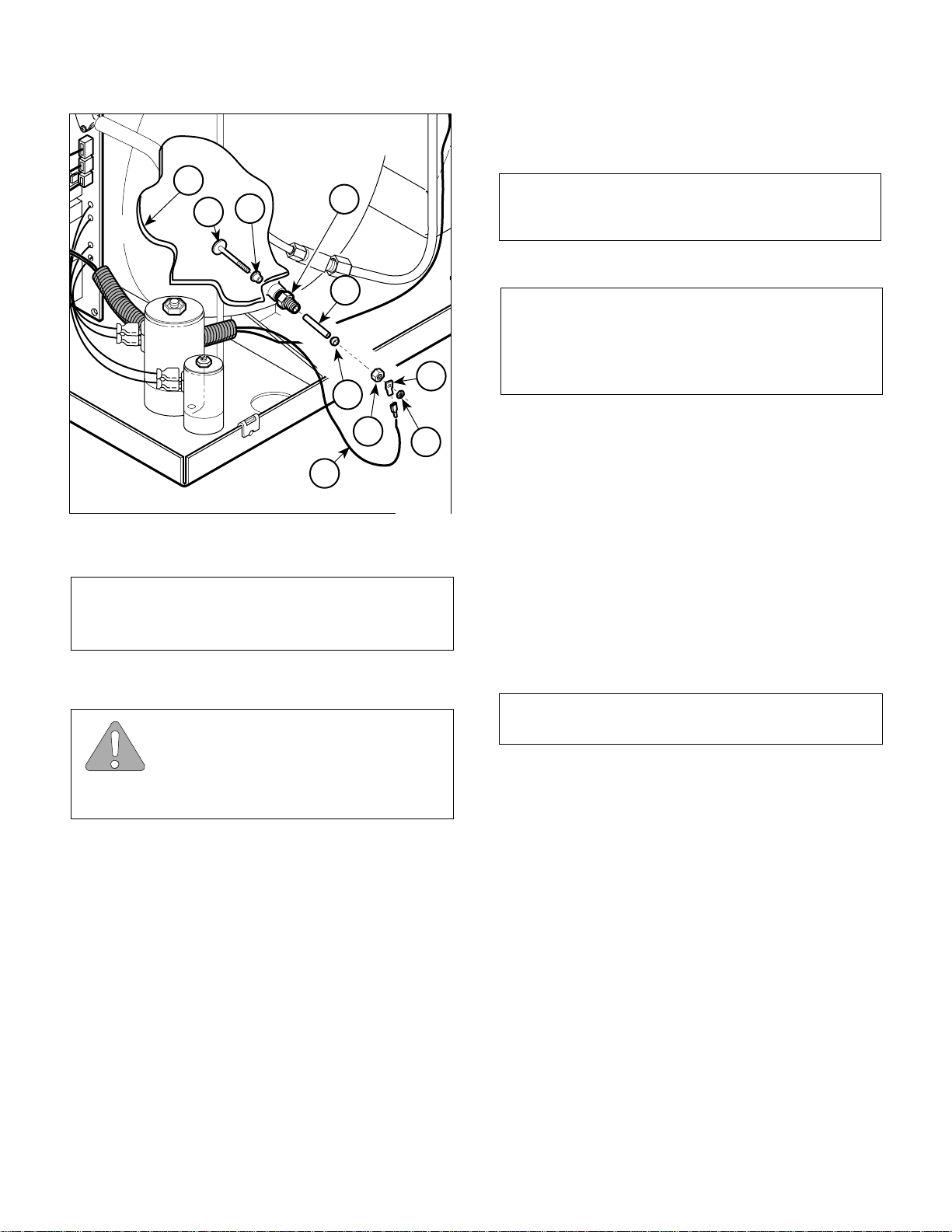

(4 ) Tag and disconnect two wires (5) from terminals

(6).

(5 ) Tag and disconnect two wires (7) from

terminals (8).

(6 ) Disconnect ribbon connector (9) from connec-

tor (10).

(7 ) Tag and disconnect neutral wire (11) from

terminal (12).

(8 ) Tag and disconnect hot wire (13) from termi- nal

(14).

(9 ) Disconnect printer cable (15) from connec- tor

(16).

(1 0) Disconnect door switch harness (17) from

connector (18).

M9 / M11 only

(1 1) Tag and disconnect two wires (19) from pulse

solenoid terminals (20).

(1 2) Disconnect heater element wire (21) from

connector (22).

(14) Install back panel (Refer to para 4.5).

(15) Refill condensing tank with distilled water.

4.13 Control PC Board Removal /

Installation

A. Removal

(1 ) Remove right hand side panel (Refer to

para 4.3).

(2 ) Disconnect pressure tube (1, Figure 4-14) from

pressure sensor (2).

NOTE

Units with old style control PC board with EPROM

version N or after or new style control PC board will

only have two wire harnesses (3) to disconnect

instead of three.

(3 ) Disconnect two / three wire harnesses (3) from

two / three connectors (4).

NOTE

Positions of locknuts (1) and screws (2) are reversed

on newer units.

(1 3) Remove two locknuts (1, Figure 4-15), screws

(2), and control PC board (3) and control PC

board bracket (4) as an assembly from

base (5).

NOTE

Units prior to serial number CZ1110/OM1000 have the

ground wire attached to the control PC board bracket.

When nut (6), starwasher (7), and screw (8) are

removed, ground wire will also be removed.

(1 4) Remove nut (6), starwasher (7), and screw (8)

from control PC board bracket (4).

(1 5 ) Turn three standoff screws (9) 1/4 turn in the

counter-clockwise direction and remove control

PC board (3) and insulator (10) from control PC

board bracket (4).

© Midmark Corporation 2002 SF-1827 Page 4-10 Printed in U.S.A.

Page 31

OLD STYLE

Return To Table Of Contents

PC BOARD

17

SECTION IV

MAINTENANCE / SERVICE

10

18

20

21

17

19

15

11

14

16

9

2

1

3

4

12

5

7

2

1

8

6

NEW STYLE

PC BOARD

4

20

22

21

9

18

15

19

13

10

16

3

13

22

12

14

11

5

7

8

6

Figure 4-14. Control PC Board Connections

© Midmark Corporation 2002 SF-1827 Page 4-11 Printed in U.S.A.

MA207505

Page 32

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

9

(3 ) Install control PC board (3) and control PC

board bracket (4) as an assembly on base (5)

and secure using two screws (2) and lock- nuts

(1).

10

4

2

6

7

3

8

5

1

Figure 4-15. Control PC Board Removal / Installation

MA2073-01

(4 ) Connect heater element wire (21, Figure 4-14) to

connector (22).

M9 / M11 only

(5 ) Connect two wires (19) on pulse solenoid

terminals (20).

(6 ) Connect wire harness (17) to connector (18).

(7 ) Connect printer cable (15) to connector (16).

(8 ) Connect hot wire (13) to terminal (14).

(9 ) Connect neutral wire (11) to terminal (12).

(1 0) Connect ribbon connector (9) to connec tor (10).

(1 1) Connect two wires (7) to terminals (8).

(1 2 ) Connect two wires (5) to terminals (6).

NOTE

Units with old style control PC board with EPROM

version N or after or new style control PC board will

only have two wire harnesses (3) to connect instead

of three.

B. Installation

(1 ) Install insulator (10, Figure 4-15) and control PC

board (3) on control PC board bracket (4) and

secure by turning three standoff screws (9) 1/4

turn in the clockwise direction.

NOTE

Units prior to serial number CZ1110/OM1000 have the

ground wire attached to the control PC board bracket.

When nut (6), starwasher (7), and screw (8) are

removed, ground wire will also be removed. Make

sure ground wire is re-installed upon installation.

(2 ) Install screw (8), starwasher (7), and nut (6) on

control PC board bracket (4).

NOTE

Positions of locknuts (1) and screws (2) are reversed

on newer units.

(1 3 ) Connect two / three wire harnesses (3) to two /

three connectors (4).

(1 4) Connect pressure tube (1) to pressure

sensor (2).

(1 5) Install right hand side panel (Refer to para 4.3).

© Midmark Corporation 2002 SF-1827 Page 4-12 Printed in U.S.A.

Page 33

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

4.14 Door Switch Removal / Installation

A. Removal

NOTE

Units prior to serial number CZ1110/OM1000 have a

different switch weldment. Since this procedure

tampers with the pressure vessel integrity, it should

not be attempted until a Midmark service representative has been contacted.

(1 ) Open sterilizer door.

(2 ) Remove right hand side panel (Refer to para

4.3).

(3 ) Disconnect wire harness (1, Figure 4-16) from

connector (2).

(4 ) Using 3/32 in. punch, remove two roll pins (3)

from door switch bracket (4) (Refer to Table 1-2

for special tool).

(5 ) Remove door switch (5) from door switch

bracket (4).

B. Installation

(1 ) Position door switch (5) in door switch

bracket (4).

(2 ) Using 3/32 in. punch, install two roll pins (3) in

door switch bracket (4) (Refer to Table 1-2 for

special tool).

(3 ) Connect wire harness (1) to connector (2).

(4 ) Install right hand side panel (Refer to

para 4.3).

(5 ) Close sterilizer door.

4.15 Pulse Solenoid Removal /

Installation

A. Removal

(1 ) Remove control PC board (Refer to para 4.13).

(2 ) Remove two screws (1, Figure 4-17) from pulse

solenoid (2).

(M9 / M11 only)

2

1

5

4

3

Figure 4-16. Door Switch Removal / Installation

MA2059-02

(3 ) Remove nut (3) and shoulder screw (4), and

then remove pulse solenoid (2) and latch lever

(5) as an assembly from pressure vessel

bracket (6).

(4 ) Using 3/32 in. punch, remove roll pin (7) and

latch lever (5) from plunger of pulse solenoid (2)

(Refer to Table 1-2 for special tool).

B. Installation

(1 ) Using 3/32 in. punch, install latch lever (5) on

plunger of pulse solenoid (2) and secure using

roll pin (7) (Refer to Table 1-2 for special tool).

(2 ) Coat shoulder screw (4) with Loctite 271.

(3 ) Install latch lever (5) and pulse solenoid (2) as

an assembly on pressure vessel bracket (6).

Secure using shoulder screw (4) and nut (3).

© Midmark Corporation 2002 SF-1827 Page 4-13 Printed in U.S.A.

Page 34

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

B. Installation

(1 ) Slide thermostat (8) into bracket (6) and rotate

terminals (3 and 4) to a horizontal position.

PLUNGER

4

5

3

7

1

2

6

Figure 4-17. Pulse Solenoid Removal / Installation

MA2060-01

NOTE

The holes for the two screws (1) are oblong. Install

screws at the top of each hole first, then adjust

downward as necessary if door will not open.

(4 ) Position pulse solenoid (2) on pressure vessel

bracket (6) and secure in position using two

screws (1).

(2 ) Position bracket (6) against pressure vessel (7)

and secure by tightening two nuts (5).

(3 ) Connect wires (1 and 2) to terminals (3 and 4).

(4 ) Install base inspection cover (Refer to

para 4.6).

(5 ) Refill condensing tank with distilled water.

8

1

4

3

2

7

6

5

(5 ) Install control PC board (Refer to para 4.13).

4.16 Thermostat Removal / Installation

A. Removal

(1 ) Drain water from condensing tank.

(2 ) Remove base inspection cover (Refer to para

4.6).

(3 ) Tag and disconnect wires (1 and 2, Figure 4-18)

from terminals (3 and 4).

(4 ) Loosen two nuts (5) and pull top of bracket (6)

approximately 1 in. from pressure vessel (7).

(5 ) Rotate terminals (3 and 4) to a vertical position

and slide thermostat (8) upward and out of

bracket (6).

MA2062-01

Figure 4-18. Thermostat Removal / Installation

© Midmark Corporation 2002 SF-1827 Page 4-14 Printed in U.S.A.

Page 35

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

4.17 Wire Tray Rack and Tray Plate

Removal / Installation

A. Removal

(1 ) Open sterilizer door.

(2 ) Remove trays.

(3 ) Pull wire tray rack (1, Figure 4-19) and tray plate

(2) from pressure vessel (3).

B. Installation

(1 ) Position two rear posts of wire tray rack (1) in

rack holes of tray plate (2).

(2 ) Hold front end of wire tray rack (1) at approxi-

mately a 30° angle from tray plate (2).

NOTE

If wire tray rack is not raised, installation is very

difficult.

(4) Install trays.

(5 ) Close sterilizer door.

4.18 Heating Element and Gasket

Removal / Installation

A. Removal

(1 ) Drain water from condensing tank.

(2 ) Remove base inspection cover (Refer to para

4.6).

(3 ) Tag and disconnect two wires (1, Figure 4-20)

from terminals (2).

(4 ) Remove two nuts (3), lock washers (4), and

brass washers (5).

EQUIPMENT ALERT

Over bending may result in broken or

cracked terminals.

(3 ) Insert rear end of wire tray rack (1) and tray

plate (2) as an assembly in pressure vessel (3).

Push wire tray rack and tray plate as far as they

will go.

1

2

30°

HOLE

3

MA2047-01

NOTE

The following step is necessary to remove the

heating element from the pressure vessel.

(5 ) Straighten terminals (2) slightly from the present

90° position to approximately a 10° straighter

position.

(6 ) Remove bracket (6) from pressure vessel (7)

and position out-of-way.

(7 ) Turn sterilizer upright.

(8 ) Remove wire tray rack and tray plate (Refer to

para 4.17).

(9 ) Remove heating element (8) and spacer assem-

bly (9) from pressure vessel (7).

NOTE

Perform the following step only if the heating element

is

not

being replaced, but damaged gaskets

(1 0) Remove two gaskets (10) from heating ele-ment

(8).

are

.

Figure 4-19. Wire Tray Rack and Tray Plate

Removal / Installation

© Midmark Corporation 2002 SF-1827 Page 4-15 Printed in U.S.A.

Page 36

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

7

9

2

EQUIPMENT ALERT

Hold heating element firmly in position

while tightening nuts. Otherwise, damage

to heating element or improper positioning of heating

element may result. Also, spacer assembly must

remain above gaskets. If spacer assembly is

installed under gasket, leaking will result.

6

4

3

5

1

Figure 4-20. Heating Element and Gasket

Removal / Installation

B. Installation

(1 ) Install two gaskets (10) on heating element (8).

EQUIPMENT ALERT

Over bending may result in broken or

cracked terminals.

8

10

MA2061-01

(6 ) Install two brass washers (5), lock washers (4),

and nuts (3) on heating element (8).

EQUIPMENT ALERT

Over bending may result in broken or

cracked terminals.

(7 ) Bend terminals (2) slightly, back to their original

90° position.

(8 ) Connect two wires (1) to terminals (2).

(9 ) Turn sterilizer upright.

(1 0 ) Install wire tray rack and tray plate (Refer to

para 4.17).

(1 1 ) Install base inspection cover (Refer to

para 4.6).

(1 2) Refill condensing tank with distilled water.

4.19 Filter Removal / Installation

NOTE

The following step is necessary to install the heating

element in the pressure vessel.

(2 ) Straighten terminals (2) slightly from the present

90° position to approximately a 10° straighter

position.

(3 ) Install spacer assembly (9) and heating element

(8) in pressure vessel (7).

(4) Turn sterilizer on its back.

(5 ) Position bracket (6) on pressure vessel (7).

© Midmark Corporation 2002 SF-1827 Page 4-16 Printed in U.S.A.

A. Removal

(1 ) Remove wire tray rack and tray plate (Refer to

para 4.17).

NOTE

Turn filter in a circular motion while pulling upward to

remove.

(2 ) Using vise grips, remove filter (1, Figure 4-21)

from pressure vessel (2).

B. Installation

(1 ) Position filter (1) in pressure vessel (2).

Page 37

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

GROOVE

3

1

SLOT

2

MA2063-01

2

Figure 4-21. Filter Removal / Installation

(2 ) Using rubber hammer, tap filter (1) lightly into

pressure vessel (2).

(3 ) Install wire tray rack and tray plate (Refer to

para 4.17).

4.20 Door Gaskets Removal / Installation

A. Removal

(1 ) Open sterilizer door.

(2 ) Remove dam gasket (1, Figure 4-22) and door

gasket (2) from door (3).

B. Installation