M9 / M9D / M11

Self -Contained Steam Sterilizer

English

Español

Français

For Models:

M9 (-040 / -041 / -042)

M9D (-042)

M11 (-040 / -041 / -042)

User Guide

TP202 20-42-FO-00014 Rev A1 C2169

TP202 20-42-FO-00014 Rev A1 C2169 TP202 20-42-FO-00014 Rev A1 C2169

Style U

003-2915-99 Rev AA8 (12/30/19)

Product Information

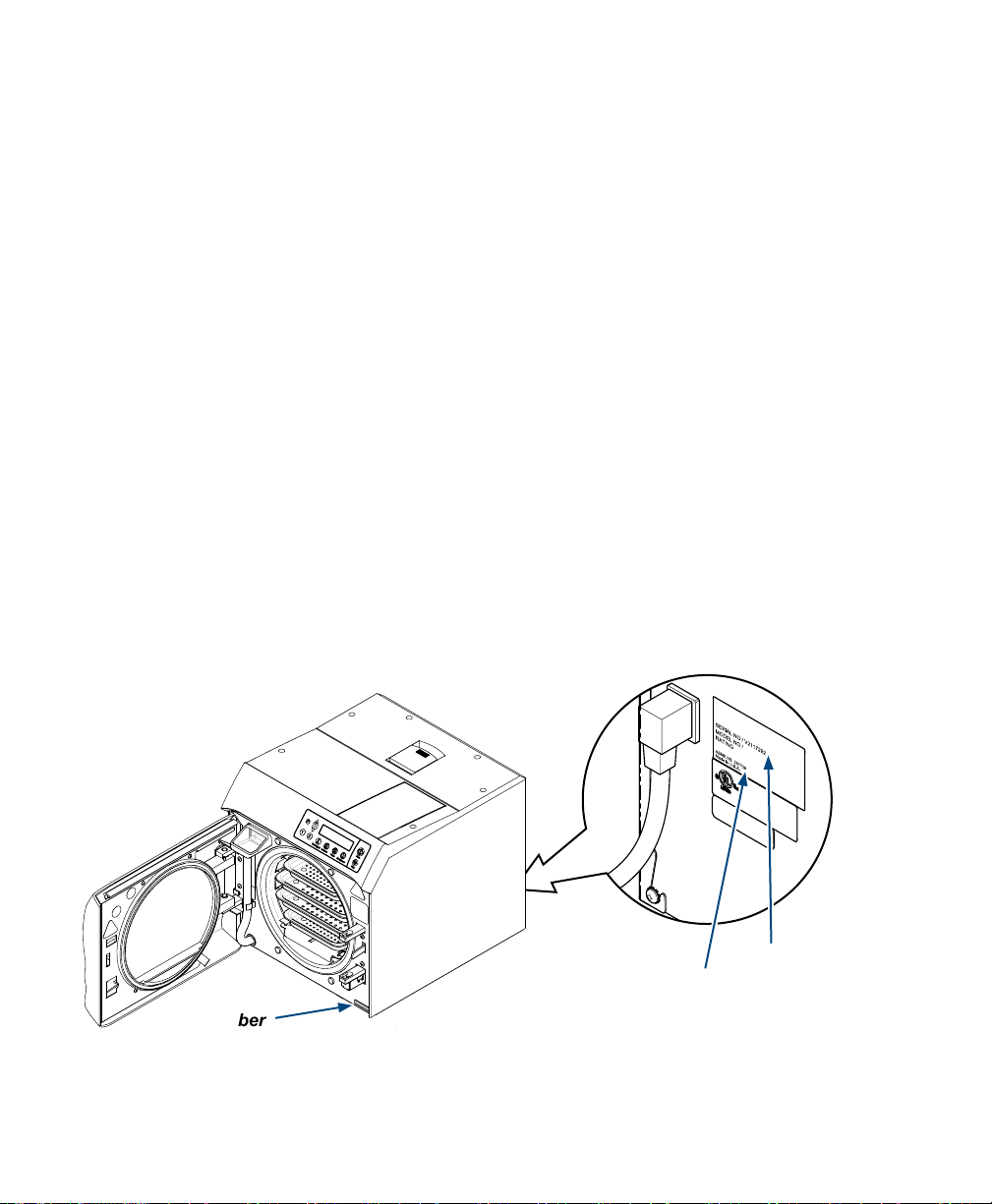

Attention Canadian Users - Action Required!

Thank you for purchasing an M9/M11 Steam Sterilizer.

To comply with changes in Canadian regulatory requirements you must now provide documentation, a

Manufacturer’s Data Report (MDR), to your appropriate provincial regulatory agency when purchasing and

using a steam sterilizer.

To obtain the MDR from Midmark, record the sterilizer Serial Number and the ASME National Board Number

of your sterilizer. See the illustration below for the location of these numbers. Then, contact Midmark

customer service at 1.800.MIDMARK and provide the recorded numbers.

Midmark will then complete the MDR and send it to you. Once you have the MDR, you must submit it to the

appropriate provincial regulatory agency.

We apologize for any inconvenience and appreciate your assistance in helping maintain compliance

to Canadian regulations for sterilizers. If you have any questions or concerns, please contact 1.800.

MIDMARK.

Serial Number

003-2915-99

ASME National Board

Number Location

English - 2

Product Serial

Number Location

© Midmark Corporation 2018

Table of Contents

Important Information

Safety Instructions ...........................................4

Intended Use....................................................4

Sterilization Technology ...................................4

Electromagnetic Interference ...........................4

Safety Symbols ................................................4

Shipping Symbols ............................................5

Transportation / Storage Conditions ................5

Accessories, Tools and Service Parts. .............5

Included with Sterilizer .....................................6

Component Location ........................................7

Controls and Indicators ....................................8

Sterilization Monitoring Guidelines.................10

Installation

Operating Environment .................................. 11

Location Requirements .................................. 11

Electrical Requirements .................................12

Connecting the Power Cord ...........................13

User Settings .................................................14

Operation

Before Operating the Sterilizer.......................15

Filling the Reservoir .......................................15

Qualication Testing .......................................16

Guidelines for Loading ...................................16

Standard Cycle Parameters ...........................24

Cycle Operation .............................................25

Post-Sterilization Processing .........................28

Programmable Cycle Buttons ........................29

Thermal Printer (Optional)

Operating the Printer......................................38

Printer Tape Description ................................38

Example of Typical Printout

of a Program Cycle ........................................39

Paper Roll Removal / Installation ...................40

Tray and Cassette Tool (optional)

Using the Optional Tray / Cassette Tool.........41

Troubleshooting

Troubleshooting Chart ....................................42

Informational Messages .................................43

Accessing the last 5 Error Codes ..................43

Error Messages..............................................43

Calling for Service ..........................................45

Specications / Compliance

Specications Chart:

M9 / M9D .................................................46

M11 .........................................................47

Water Purity Specications ............................48

Warranty Information

Scope of Warranty .........................................49

Maintenance

Maintenance Messages .................................31

Daily Maintenance .........................................32

Weekly Maintenance ......................................33

Monthly Maintenance .....................................35

Extended Use Maintenance ...........................37

003-2915-99

English - 3

© Midmark Corporation 2018

Important Information

Safety Instructions

The primary concern of Midmark is that this equipment is operated and maintained with the safety of the

patient and sta in mind. To assure safe and reliable operation:

• Read and understand this manual before attempting to install or operate the sterilizer.

• Assure that the appropriate personnel are informed on the contents of this manual.

(This is the responsibility of the purchaser).

• Assure that this manual is located near the sterilizer, or if possible, permanently axed

to the sterilizer.

Intended Use

The Midmark and Ritter M9, M9D and M11 Steam Sterilizers can be used in medical and dental oces,

hospitals, clinics, nursing homes, laboratories, and other facilities to sterilize heat and moisture stable

reusable items (including dental handpieces) that are compatible with steam sterilization. Refer to Guidelines

for loading and Standard Cycle Parameters in this manual for detailed information.

Sterilization Technology

The Midmark M9 / M9D and M11 utilize a dynamic air removal system called Steam Flush Pressure Pulse to

remove air from the chamber.

Electromagnetic Interference

This sterilizer is designed and built to minimize electromagnetic interference with other devices. However, if

interference is noticed between another device and this product:

• Remove interfering device from room

• Plug sterilizer into isolated circuit

• Increase separation between sterilizer and interfering device

• Contact Midmark if interference persists

Safety Symbols

WARNING

Indicates a potentially hazardous situation which could result in serious injury.

Caution

Indicates a potentially hazardous situation which may result in minor or moderate injury.

It may also be used to alert against unsafe practices

Equipment Alert

Indicates a potentially hazardous situation which could result in equipment damage.

003-2915-99

English - 4

© Midmark Corporation 2018

Shipping Symbols

Caution Shipping Damage

Keep dry

Proper shipping orientation

Max. stacking height

Fragile

(Refer to “n” number on package)

Transportation / Storage Conditions

Equipment Alert

Water must be drained from the unit’s reservoir before transporting / storing below +32°F (0°C).

Ambient Temperature Range: -22°F to 140°F (-30°C to +60°C)

Relative Humidity: 10% to 90% (non-condensing)

Atmospheric Pressure: 7.2 psia to 15.4 psia (49.6 kPa to 106.4 kPa)

Accessories, Tools and Service Parts

Unless noted, items can be used on the M9 / M9D and M11.

Accessories Order Number

Speed-Clean, 1 (16oz. [.47 liter]) bottle 002-0396-00

Speed-Clean, 1 case (12 - 16oz. [.47 liter]) bottles 002-0396-05

Thermal Printer 9A599001

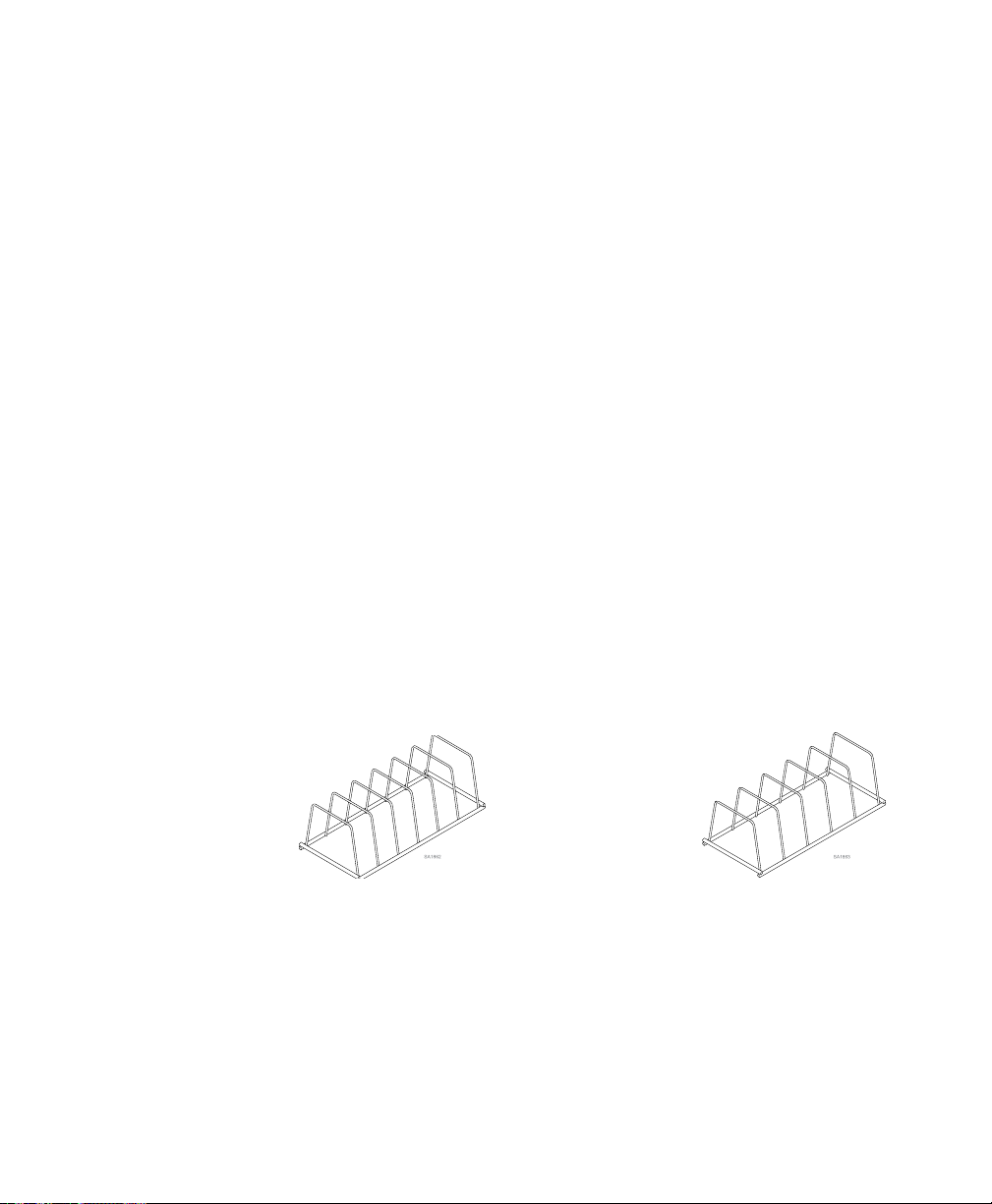

Cassette Rack (Horizontal) 9A215001 (M11 only)

Cassette Rack (Vertical) 9A215002 (M11 only)

Printer Thermal Paper Roll (Rell) 060-0016-00

Printer Stick-able Thermal Paper (Rell) 060-0016-01

Door and Dam Gasket Kit (M11 only) 002-0504-00

Door and Dam Gasket Kit (M9 / M9D only) 002-0361-01

Pouch Rack Kit (M11 only) 002-2108-00

Pouch Rack Kit (M9 / M9D only) 002-2108-01

Tray/Cassette Tool 9A307001

VistaCool ™ direct-to-drain thermal reduction system 9A586002 (Dual)

003-2915-99

Common Service Parts / Tools Order Number

English - 5

© Midmark Corporation 2018

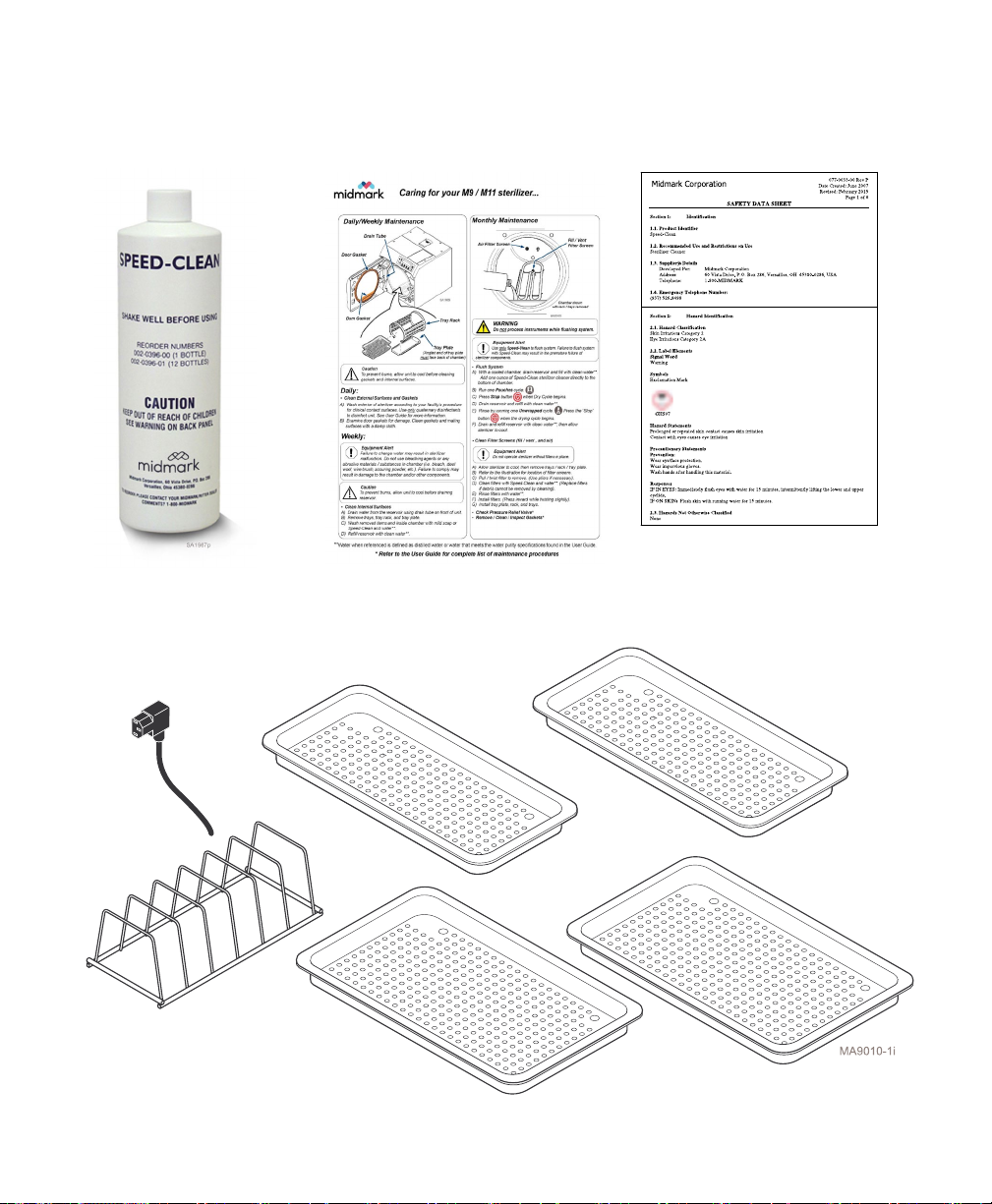

Included with Sterilizer

Speed-Clean

Power Cord

Speed-Clean SDS SheetCare / Operation Card

2 Small Trays

Pouch Rack

(M11 Rack Shown)

003-2915-99

English - 6

2 Large Trays

© Midmark Corporation 2018

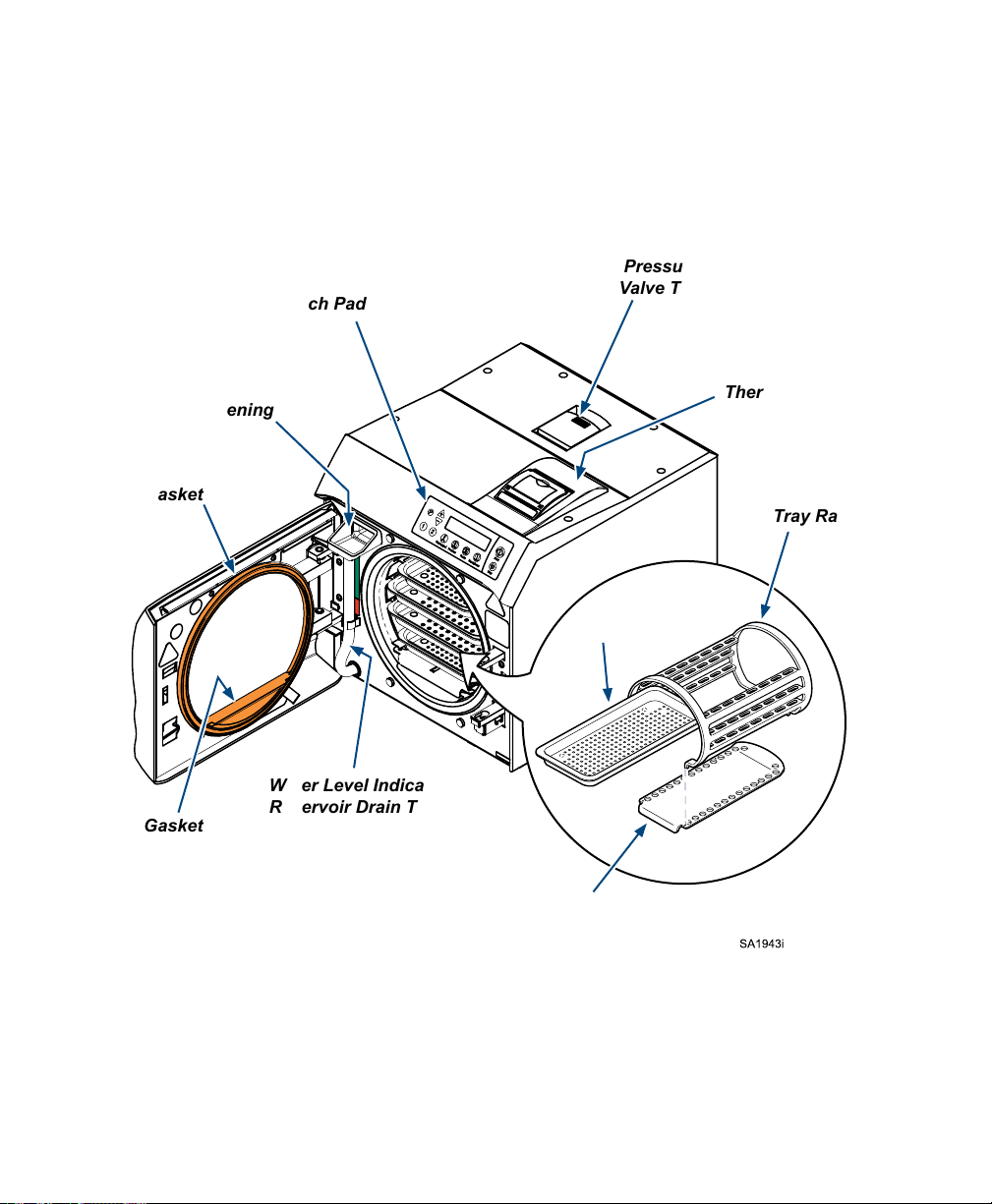

Component Location

Display / Touch Pad

Pressure Relief

Valve Test Lever

Fill Opening

Door Gasket

Dam Gasket

Thermal Printer

(optional)

Tray Rack

Tray(s)

Water Level Indicator /

Reservoir Drain Tube

Tray Plate

003-2915-99

English - 7

© Midmark Corporation 2018

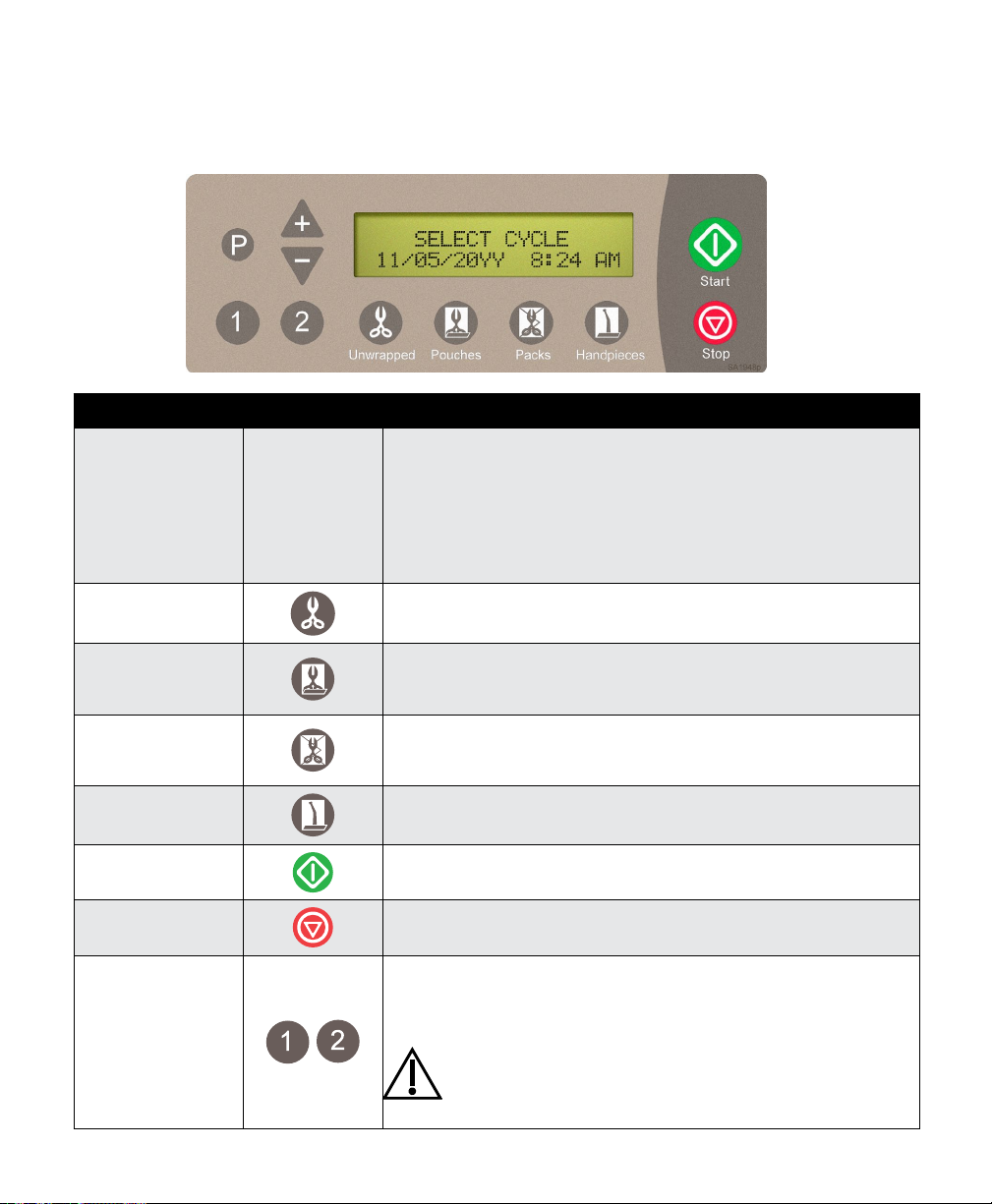

Controls and Indicators

The sterilizer controls and indicators are shown in the illustrations on this, and the following page.

The accompanying tables describe the function of each control / indicator.

Control Function

Display See illustration Indicates cycle selected, cycle temperature and exposure time

for the selected cycle. During the cycle, display shows messages

describing status of cycle. When cycle enters sterilization mode,

remaining cycle time is displayed as well as temperature and

pressure. Display also shows error message if a malfunction

occurs. Refer to the Troubleshooting section of this manual for a

detailed explanation of Informational / Error Messages.

Unwrapped button

A program cycle designed to process unwrapped instruments at:

270°F (132°C) for 3:00 minutes / 30 minute drying cycle.

Pouches button

Packs button

Handpieces

button

Start button

Stop button

1 or 2 buttons

NOTE: All material

run in these cycles

must be validated

for sterilization by

the user.

003-2915-99

A program cycle designed to process instruments in combination

paper / plastic sterilization pouches or wrapped instruments

at: 270°F (132°C) for 4 minutes / 30 minute drying cycle.

A Program cycle designed to process packs of instruments or

textiles at: 250°F (121°C) for 30 minutes / 30 minute drying

cycle.

A program cycle for dental handpieces which runs at:

270°F (132°C) for 4 minutes / 30 minute drying cycle.

Initiates selected program or, when SELECT CYCLE is displayed,

pressing Start will activate heater for 10 minutes.

Terminates selected program or function.

Programmable cycle buttons that allow an operator to create two

dierent programmed cycles for special applications. Sterilization

time and temperature, along with drying time and venting procedure can be adjusted or changed.

Caution

These cycles are not FDA cleared and validation of sterility

of items processed using them is the responsibility of the

user.

English - 8

© Midmark Corporation 2018

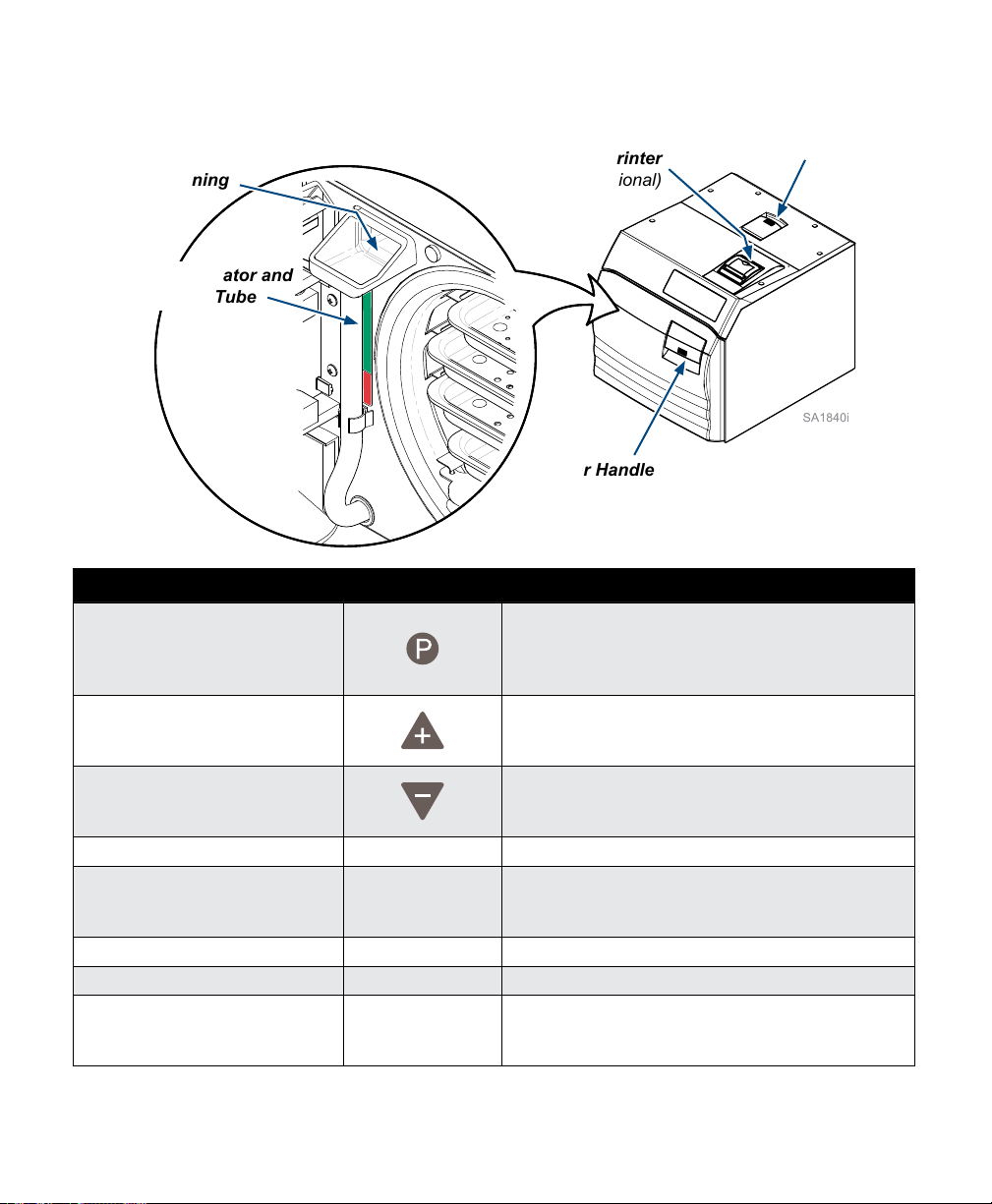

Controls and Indicators - continued...

Pressure Relief

Thermal Printer

Fill Opening

Water Level Indicator and

Reservoir Drain Tube

(optional)

Door Handle

Control Function

P button Programming mode button that allows operator to

change temperature, time, dry time and/or venting

procedure. Used in conjunction with buttons 1 or 2.

(Refer to Programming Mode).

+ (plus) button

- (minus) button

Door Handle refer to illustration For latching / opening door.

Water Level Indicator /

Reservoir Drain Tube refer to illustration

Fill Opening refer to illustration Access for lling reservoir with water.

Pressure Relief Valve Test Lever refer to illustration Allows operator to check pressure relief valve.

Thermal Printer (Optional) refer to illustration The printer (optional equipment) can be used to

Allows temperature, time, vent mode or dry time to

be increased or changed when in location 1 or 2

and the P (programming) mode is activated.

Allows temperature, time, vent mode or dry time to

be decreased or changed when in location 1 or 2

and the P (programming) mode is activated.

Shows amount of water in reservoir. Tube also

used for drainage of reservoir into suitable

container.

provide a permanent record of time, temperature,

and pressure during a cycle.

Valve Test Lever

003-2915-99

English - 9

© Midmark Corporation 2018

Sterilization Monitoring Guidelines

Note

This information below is provided for reference only. Contact appropriate state/local agencies for

specific sterilization guidelines for your office. Additional information on infection control is available

from the Centers for Disease Control and Prevention (CDC), Organization for Safety and Asepsis

Procedures (OSAP) ), Association for the Advancement of Medical Instrumentation (AAMI), and

Association for Professionals in Infection Control and Epidemiology (APIC).

Physical Monitors

Temperature and pressure measuring devices can help detect sterilizer malfunctions. The sterilizer’s control

system aborts the cycle and displays a message if physical conditions go outside established limits. The

optional thermal printer can be used to create a record of each load’s actual cycle time, temperature, and

pressure.

Note

Use only FDA cleared chemical and biological indicators designed for steam sterilization that are

compatible with the particular sterilization cycle temperature and exposure time being monitored.

Use sterility monitors with each sterilization load. If a sterilizing cycle is terminated prematurely,

reprocess instruments to ensure sterility of the load. Follow manufacturer’s instructions for proper

disposal of used indicators.

Chemical Indicators

Chemical indicators are designed to verify that conditions in the sterilizer chamber were adequate to achieve

sterilization. They do not validate that a processed item is sterile. If a chemical indicator shows a failure,

items in that load are considered non-sterile. Potential causes for sterilization failure include: improper

cleaning, packing, loading, or a sterilizer malfunction. Determine the cause of any sterilization failure, and

remedy the situation before running the next cycle. Only FDA cleared chemical indicators labeled for use

with the steam sterilization cycle parameters. e.g. temperature and exposure time, of the M9 / M9D / M11

Sterilizers should be used for monitoring the cycles. Follow the chemical indicator’s instructions for proper

storage, use, interpretation, and disposal.

Biological Indicators

Biological indicators are microbiological devices designed to accompany items being sterilized to monitor

adequacy of the sterilization process. If a biological indicator shows a failure, items in that load are

considered non-sterile. Potential causes for sterilization failure include: improper cleaning, packing, loading,

or a sterilizer malfunction. Determine the cause of any sterilization failure, and remedy the situation before

running the next cycle. Only FDA cleared biological indicators labeled for use with the steam sterilization

cycle parameters. e.g. temperature and exposure time, of the M9 / M9D / M11 Sterilizers should be used for

monitoring the cycles. Follow the biological indicators instructions for proper storage, use, interpretation, and

disposal.

003-2915-99

English - 10

© Midmark Corporation 2018

Installation

Operating Environment

Ambient Temperature Range: 68°F to 104°F (+20°C to +40°C)

Relative Humidity: < 80% (non-condensing)

(Pollution Degree 2, in accordance to IEC664)

Normal Operating Altitude: < 9842 ft. (3000 m) above sea level

Device approved for INDOOR USE ONLY.

Device to be operated in a relatively dust-free environment.

(Pollution Degree 2, in accordance to IEC664)

Device should be connected to a power source with over-voltage limits less than 1500 watts from

mains to ground. (Installation Category II in accordance to IEC664)

The M9 / M9D and M11 will emit 5000 BTU / HR during operation.

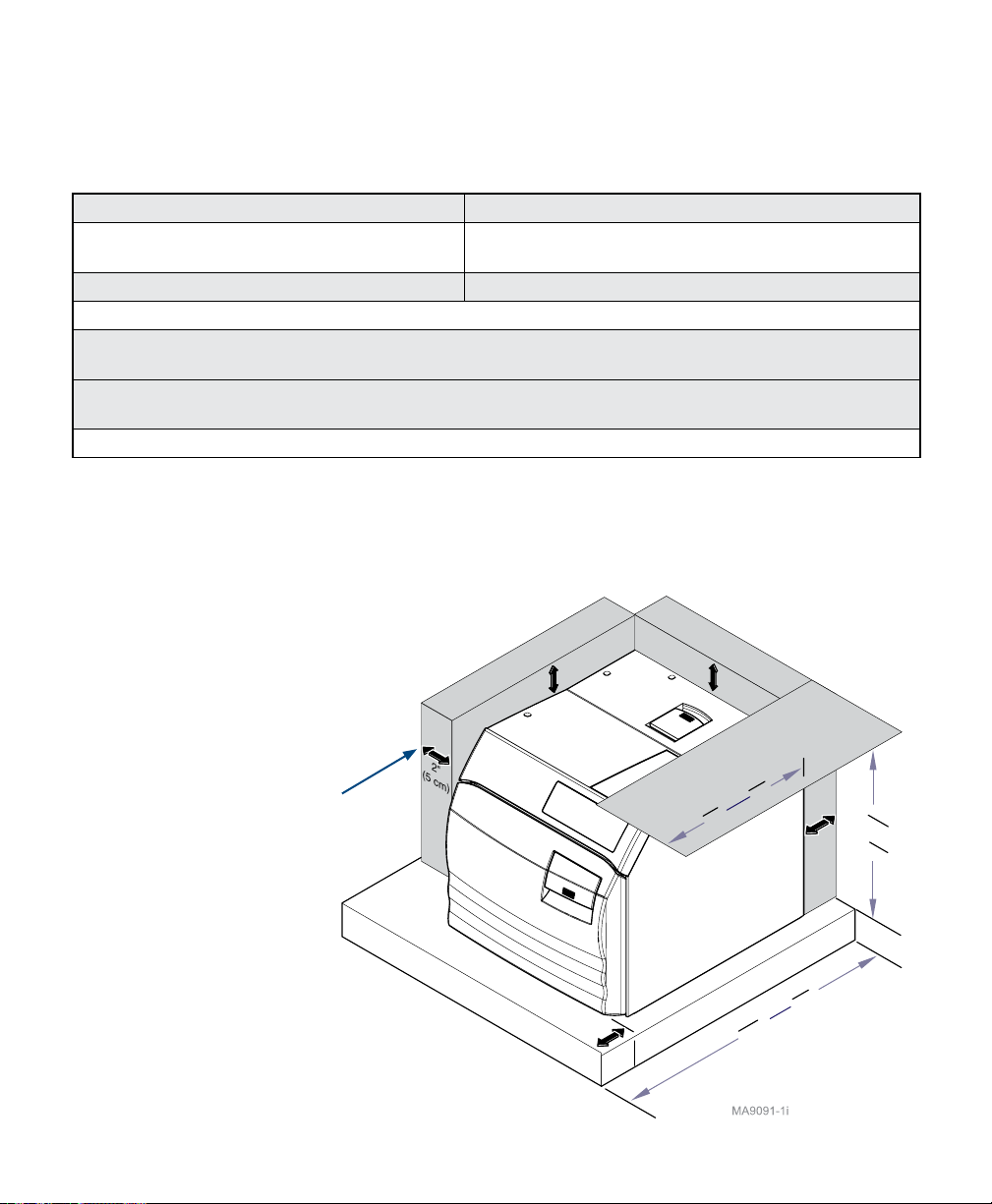

Location Requirements

Allow Clearance

on Both Sides

003-2915-99

Clearance

5"

(13 cm)

2"

(5 cm)

Support Surface

English - 11

1"

(3 cm)

Requirements

5"

(13 cm)

Overhang/Shelf

M9/M9D

15"

(38 cm)

M11

18"

(46 cm)

M9/M9D

M11

21"

(53 cm)

© Midmark Corporation 2018

2"

(5 cm)

18"

(46 cm)

M11

23" (58 cm)

M9/M9D

22" (56)

Location Requirements - continued...

Support Surface

• Material should be water-resistant material. (Ex. laminate, stainless steel, stone, etc.)

• Surface must be level to ensure chamber lls with correct water level.

Improper water level in the chamber could cause a sterilizer malfunction.

• Surface should meet minimum dimensions listed below:

Dimensions

Depth (front to back) M11 - 21” (53 cm) M9 / M9D - 18” (46 cm)

Clearance Requirements

To ensure proper air circulation, and to allow access to the reservoir ll port and drain coupling,

adhere to the minimum clearance requirements listed below. If the sterilizer will be operated

in continuous cycles, locate sterilizer where steam will not damage materials or equipment in

the surrounding area.

Back of Unit - Back Wall ................................. 2” (5 cm)

Front Support Surface - Front Sterilizer ........ 1” (3 cm)

Sides of Unit - Side Wall ................................ 2” (5 cm)

Distance above Unit for Printer Access .......... 5” (13 cm)

Maximum Upper Cabinet Shelf Overhang ..... M11 - 18” (46 cm) M9 / M9D - 15” (38 cm)

Under Cabinet or Shelf................................... M11 - 23” (58 cm) M9 / M9D - 22” (56 cm)

Relocation Requirements for Sterilizer

Disconnect power cord from electrical outlet and allow sterilizer to cool.

Drain water from reservoir or do not tip sterilizer, allowing water to spill.

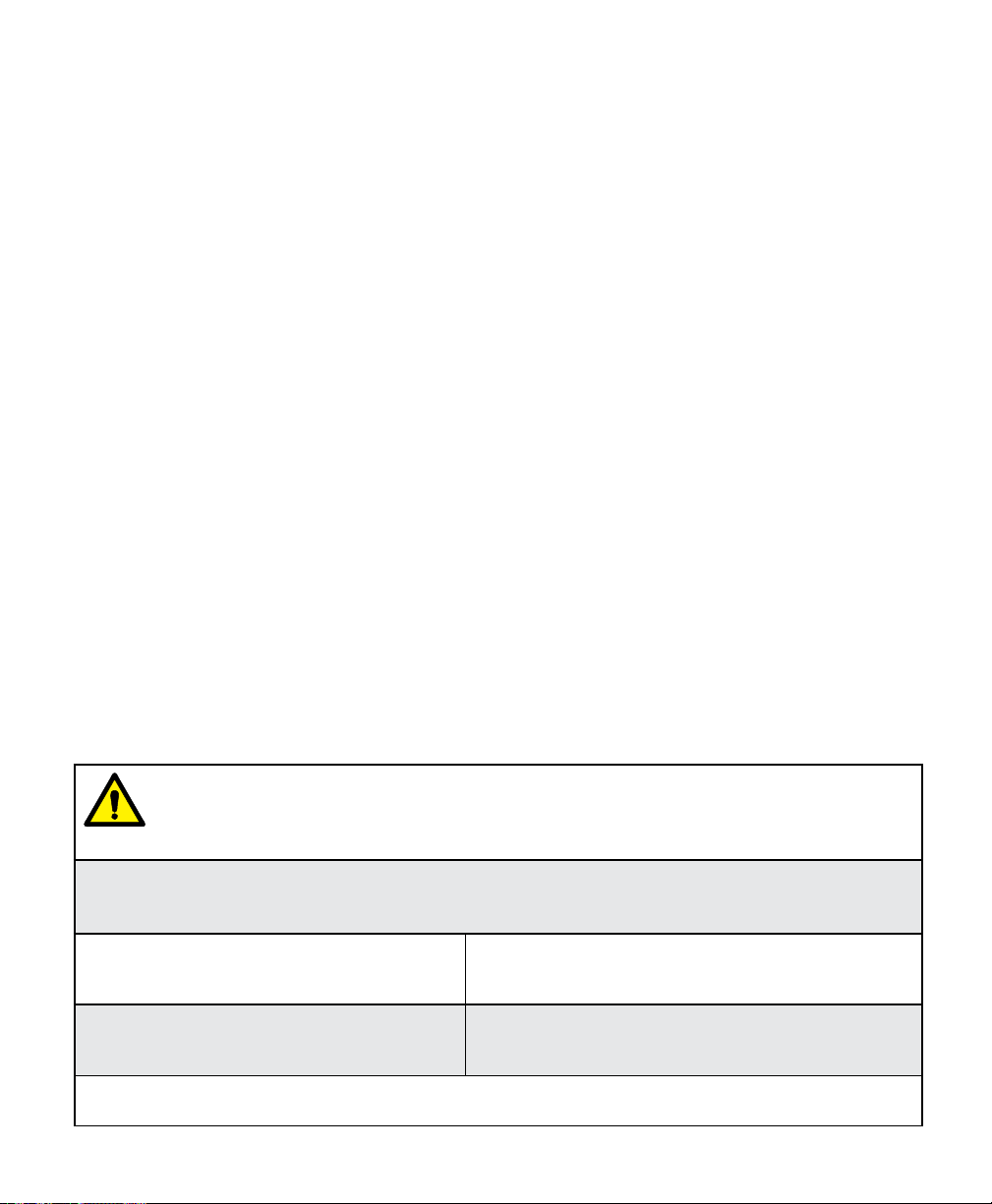

Electrical Requirements

WARNING

For 115 VAC models: Use 104 - 127 VAC, 50/60 Hz alternating current only.

For 230 VAC models: Use 207 - 253 VAC, 50/60 Hz alternating current only.

Failure to do so may result in electric shock to personnel and / or damage to sterilizer.

Note

For safety, the unit must be connected to a properly polarized and grounded receptacle. Always use a

power cord with grounding connections that match the receptacles in your location.

115 VAC Unit: 115 VAC, 50/60 Hz, 12 amp

Dedicated Supply Circuit*: 120 VAC, 50/60 Hz, 15 amp

Max. Power Consumption: 1425 Watts

230 VAC Unit: 230 VAC, 50/60 Hz, 6.4 amp

Dedicated Supply Circuit*: 230 VAC, 50/60 Hz, 10 amp

Max. Power Consumption: 1500 Watts

* Power source must have over-voltage limits less than 1500 watts from mains to ground.

(Installation Category II in accordance to IEC664)

003-2915-99

English - 12

© Midmark Corporation 2018

Connecting the Power Cord

WARNING

Equipment is not suitable for use in the presence of a flammable anesthetic mixture

with oxygen, air, or nitrous oxide.

Clarification: Equipment is suitable for use in the presence of oxygen, air, or nitrous oxide.

WARNING

Check the serial number label on back panel of sterilizer to verify voltage rating for

the unit. Failure to connect sterilizer to an appropriate power supply could result in

damage to the unit, and electrical shock to personnel.

Equipment Alert

For optimal performance, allow sterilizer to reach room temperature before operating.

To connect the power cord...

A) Plug power cord into receptacle on back of sterilizer.

B) Plug power cord into a properly polarized and grounded receptacle rated for a

minimum of 15 amps. A dedicated circuit only used for the sterilizer is recommended.

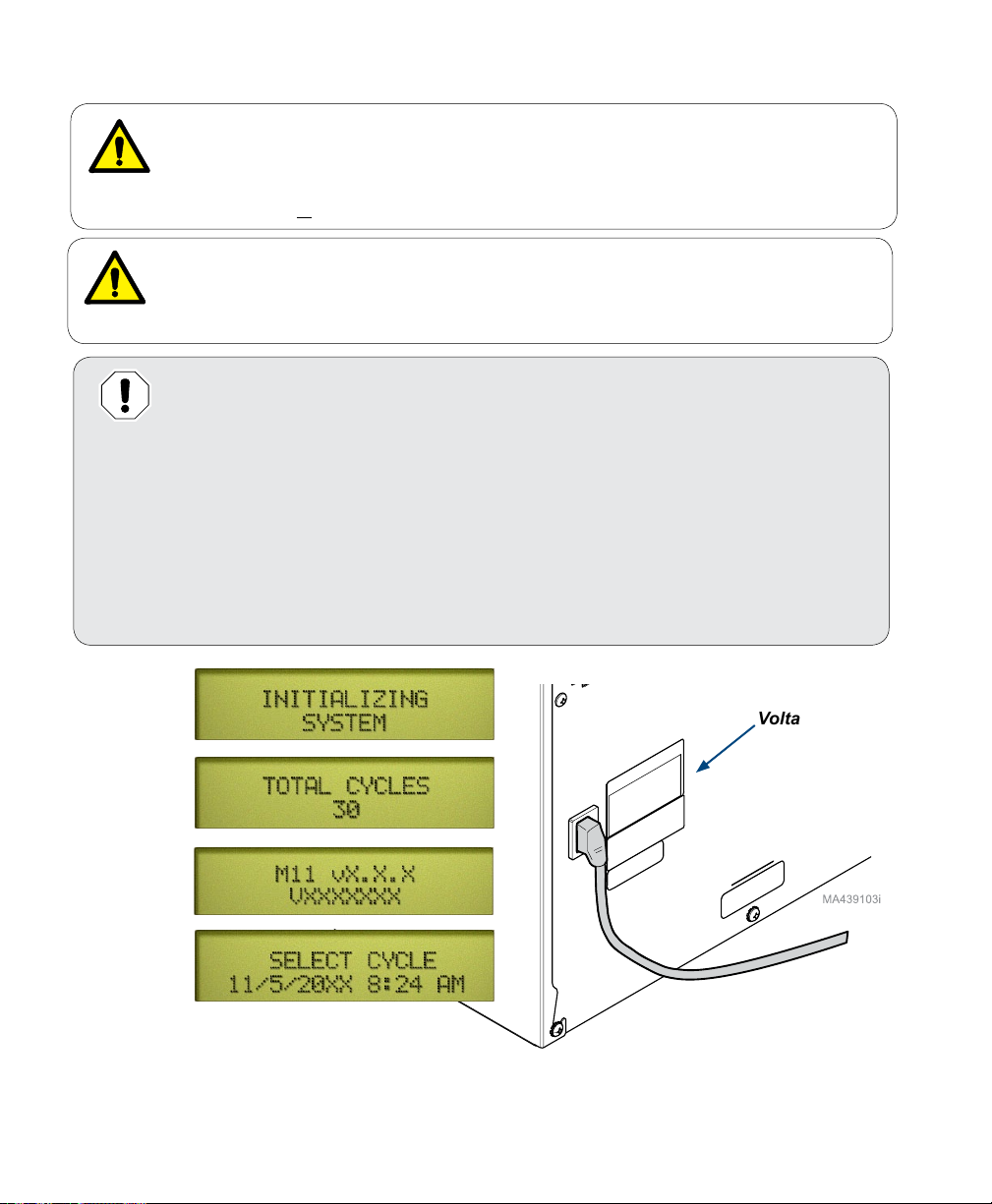

C) M9 / M9D and M11 are not equipped with an on/off switch, the display operates off

very low power. (example: microwave oven display)

Note: When power is connected, the messages shown below will appear on the display.

Display:

Voltage Rating

*

*

* These screens will display the total number of cycles run on the unit, the model number

(M9 / M9D or M11), the software version number, serial number date, and time.

003-2915-99

English - 13

© Midmark Corporation 2018

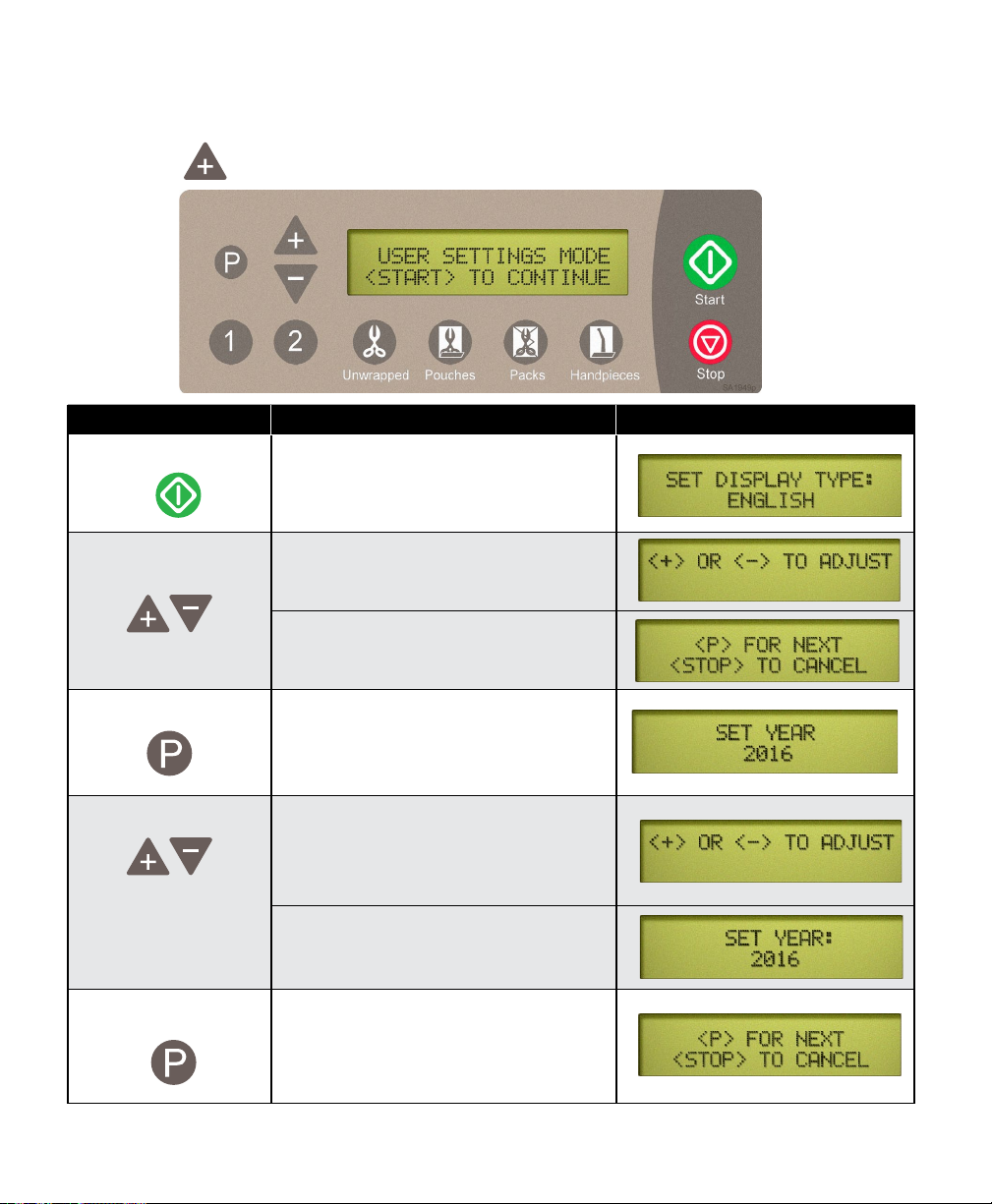

User Settings

User setting mode will enable the user to set the desired unit of measure and adjust the time

clock. To enter the user settings mode, unplug and replug the power cord while pressing and

holding the button until the User Settings screen below appears.

Action Description Display

Press Press start to initialize the User Settings

menus.

Adjust Units of

Measure

Press

Adjust Time Clock The “+“ and “-” buttons will adjust the

Press To store setting and bring up the next

NOTE: User Settings for Date and Clock must be updated manually for day light savings.

003-2915-99

The “+” and “-” buttons alternate the

setting between English or Metric

When the desired Units of Measure

appear on the display...

To store the desired Units of Measure

This brings up the Time Clock programing

display

values of the following settings

- Year / Month / Day / Hour / AM or PM /

Minute.

When the desired values appear on the

display...

setting in the list. Repeat as necessary

for all settings. When all settings are

completed pressing the “P” will initiate

normal power up.

English - 14

© Midmark Corporation 2018

Operation

Before Operating the Sterilizer

WARNING

Do not use this sterilizer for sterilizing volatile substances or for any purpose other

than its intended design. Burns and toxic or explosive conditions could result.

Do not force door handle at any time. Chamber pressure may cause door to open with

extreme force. If door handle does not move freely, allow unit to cool and depressurize for 40

minutes before opening door. Failure to adhere could result in serious personal injury.

Do not run the sterilizer without the tray plate in place. If the sterilizer malfunctions,

immediately unplug sterilizer, and call for service; do not attempt to repair the sterilizer

yourself. Doing so could result in serious injury.

Caution

Programmable cycles 1 and 2 are provided for those applications requiring sterilization

parameters different than the preset cycles. These cycles are not FDA cleared for medical

use. All material processed in these cycles must be validated by the user to ensure sterility of the

processed load.

For optimal performance, allow the sterilizer to reach room temperature before operating.

Equipment Alert

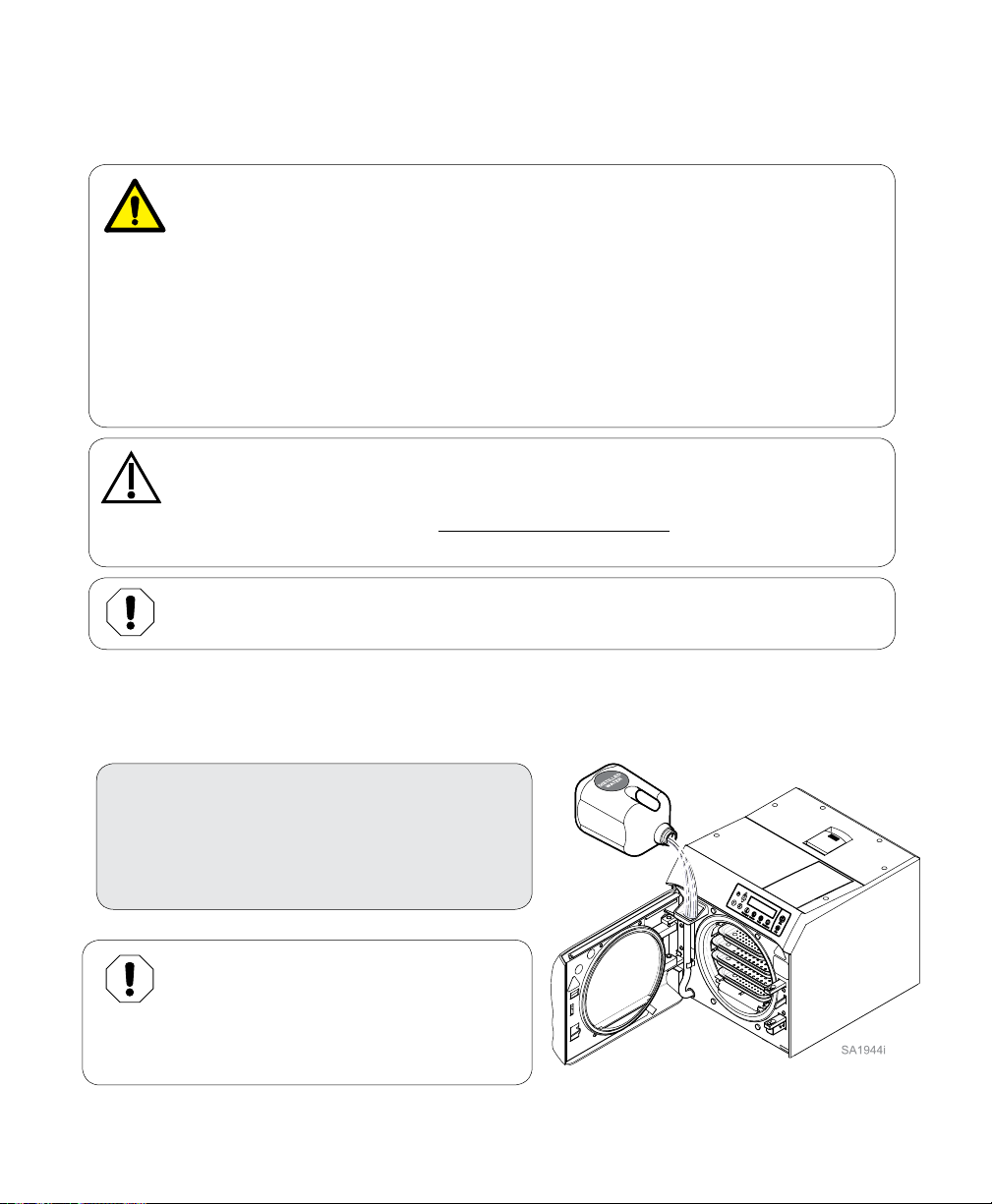

Filling the Reservoir

To fill reservoir...

A) Open door to unit.

B) Pour distilled water into fill opening until

water level reaches the top of the fill level

label on the water level indicator tube.

Equipment Alert

Use distilled water or water that meets the

referenced water purity specifications.

Failure to comply may result in sterilizer

malfunction and/or premature failure due

to excessive corrosion.

003-2915-99

English - 15

© Midmark Corporation 2018

Qualication Testing

Your sterilizer should be tested after sterilizer installation, malfunctions, relocation, major repairs, and

after sterilization process failure. Qualication testing should be performed prior to placing the sterilizer in

service. If multiple cycle types are used, e.g. “Pouches” and “Packs” each cycle type should be qualied.

Qualication testing should include at least one Biological Indicator (BI) (sometimes referred to as Spore

Tests) and one Chemical Indicator (CI). The test pack should be placed on the bottom tray near the chamber

door and performed with items routinely processed and considered to be the most dicult to sterilize.

Additional items should be placed in the chamber along with the Biological Indicator and Chemical Indicator

so that chamber is fully loaded (don’t exceed the maximum capacities listed in the tables under “Guidelines

for Loading” in this manual). Three consecutive test runs, for each cycle type tested, with negative results

from the BIs, and the appropriate readings from all physical monitors and chemical indicators demonstrating

complete sterilization, provide verication that the sterilizer has been properly installed (or reinstalled after

relocation) or repaired to the manufacturer’s specications and that it will function eectively in the facility in

which it is installed. All items processed during qualication testing should be quarantined until the results of

the biological testing for all three test runs are available.

Guidelines for Loading

All items must be processed in accordance with Centers for Disease Control and Prevention (CDC),

“Guidelines for Infection Control in Dental Healthcare Settings” – 2003, MMWR; 52 (no.RR-17), and

“Guidelines for Disinfection and Sterilization in Healthcare Facilities” – 2008, which states:

“Items to be sterilized should be arranged to permit free circulation of the sterilizing agent (e.g.,

steam, chemical vapor, or dry heat); manufacturer’s instructions for loading the sterilizer should

be followed.”

Equipment Alert

Loads must be placed on trays at all times – unless the optional cassette racks are

used – otherwise, serious instrument or equipment damage may occur.

Types of Items that can be processed in the M9 / M9D and M11

Before placing any instrument in the M9 / M9D or M11, check with the instrument manufacturer to be sure

the

materials are compatible with steam sterilization, and to verify the acceptability of sterilization parameters.

The M9 / M9D and M11 are designed to sterilize the following:

• Metal instruments

• Rubber / plastic devices (ex. suction cannulas, impression trays, etc.)

• Wrapping / bundling materials (ex. CSR wrap, instrument pouches, etc.)

• Cassettes (which t in the sterilizer trays or the cassette rack accessories)

• High / low speed handpieces

• Surgical instruments (ex. opthalmologic instruments)

003-2915-99

English - 16

© Midmark Corporation 2018

Types of Items that can be processed in the M9 / M9D and M11 - Continued...

Equipment Alert

Do not sterilize items composed of any of the following materials in the M9 / M9D or M11.

• Corrosion sensitive metal (ex. carbon steel, iron, etc.)

• Fragile items susceptible to breaking under pressure / high temperature

• Biomedical waste

• Plastics that may break down or produce residue when exposed to steam / high

temperatures.

Examples

Polyethylene, Styrene, Cellulosics, ABS, PVC, Acrylic (Plexiglass™), PPO (Noryl™),

Latex, and Neoprene

Preparing Items for Sterilization

WARNING

Clean and dry instruments thoroughly before placing them into tray. Improper cleaning may

result in non-sterile instruments or damage to the unit. Follow instrument manufacturer’s

guidelines and CDC recommendations for handling and cleaning instruments prior to sterilization.

Instruments must be thoroughly cleaned to remove all residual matter, such as debris, disinfectant

residuals, blood, organic tissue, etc. General cleaning guidelines are listed below but the device

manufacturer’s instructions for proper cleaning and preparation of the device for sterilization should always

be followed:

• Clean instruments immediately after use to avoid drying of residual matter.

• The use of automated cleaning equipment (e.g. ultrasonic cleaner or washer-disinfector) is

recommended over manual cleaning for clinician safety and cleaning eectiveness.

• After cleaning, thoroughly rinse instruments with tap water to remove any loosened debris or

residual cleaning uid. The purity of tap water varies signicantly thus, it’s recommended the nal

rinse be done with water of adequate quality to avoid instrument staining. After rinsing

instruments should be inspected for damage, debris, detergent residue and then dried before

packaging.

• If the instrument manufacturer’s instructions require lubrication of the instruments after cleaning,

wipe o excess lubricant before packing for sterilization or loading into the sterilizer.

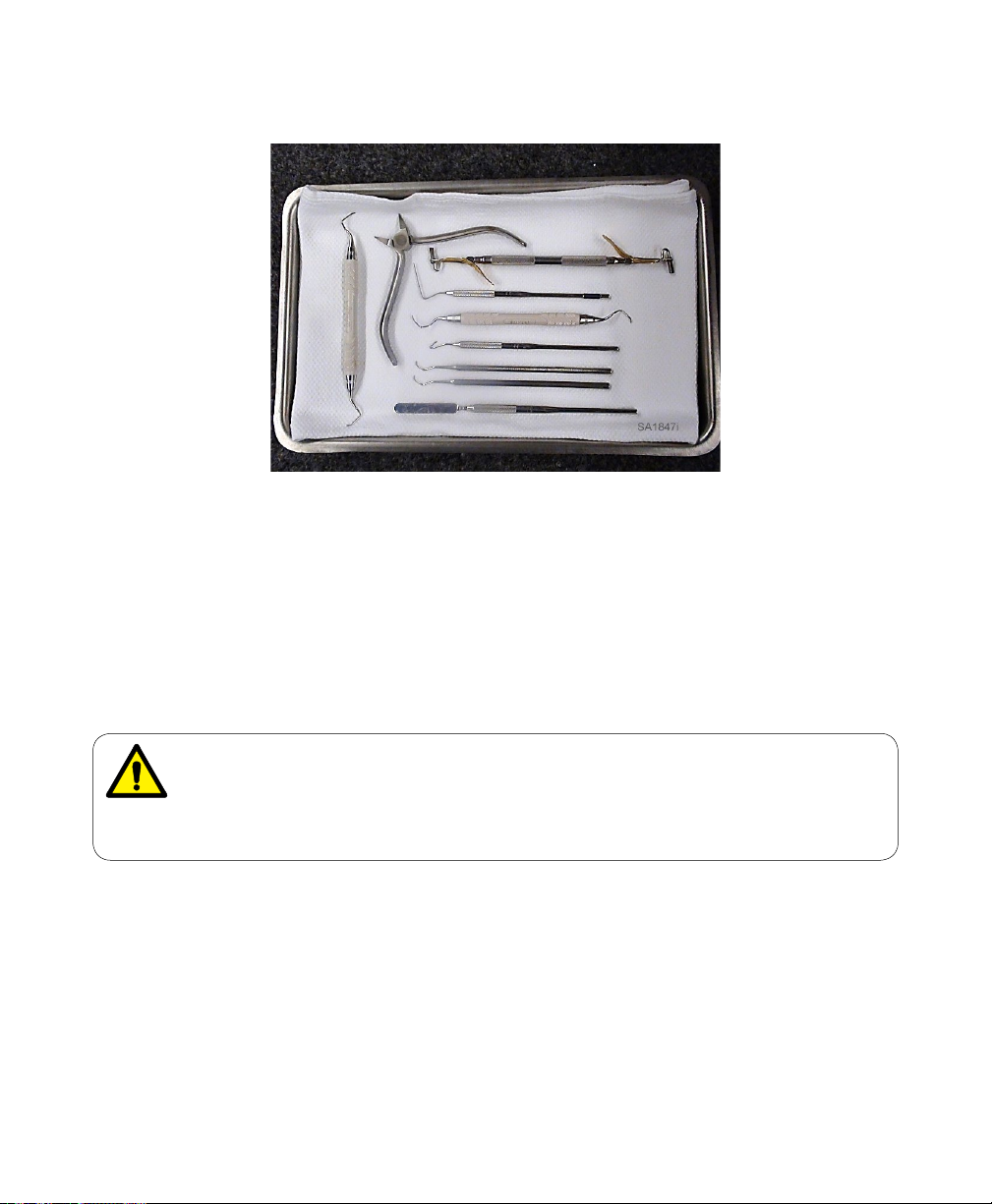

Immediate Use Sterilization

The M9 / M9D and M11 are capable of Immediate Use sterilization - sterilizing unwrapped instruments for

immediate use. Place a surgical cotton towel, paper tray liner or CSR wrap folded to t on the tray bottom

before putting unwrapped items in the tray. Arrange unwrapped items on the towel so they do not touch one

another (See Photo 1).

003-2915-99

English - 17

© Midmark Corporation 2018

Immediate Use Sterilization - Continued...

Photo 1

Please consider the following when choosing whether or not to sterilize your instruments unwrapped:

• The sterility of unwrapped instruments is compromised upon exposure to a non-sterile

environment. Follow CDC guidelines for using unwrapped, sterilized instruments.

• Due to the sensitive nature of some types of surgery (including, but not limited to

ophthalmological), instruments used in such procedures must be wrapped or pouched in order

to reduce their exposure to sterilization process residues. The water reservoir should also be

drained and relled with fresh distilled water on a daily basis when processing instruments for

these procedures on a routine basis

WARNING

Do not overload the chamber! Adequate space is required around items in trays for

steam circulation and drying. Failure to allow adequate space will compromise

sterilization and drying. Items and packaging should be completely dry when removed from

the sterilizer to minimize the potential for recontamination.

General Guidelines

• Use only M9 / M9D and M11 trays in their appropriate sterilizer. Using other trays could restrict air

/steam ow to items resulting in inadequate sterilization and drying.

• All items must t within the tray and not extend over the lip of the sterilizer tray. Instruments

must not scrape the chamber walls when sliding the tray into the chamber.

• Jointed items must be sterilized in an open position so all surfaces are exposed to the steam

(See Photo 2).

003-2915-99

English - 18

© Midmark Corporation 2018

General Guidelines - Continued...

Photo 2

• Handpieces and instruments must be arranged in a single layer on the trays (not piled or

stacked), to permit proper steam ow and drying.

• Glassware or utensils capable of holding water, e.g. bottles, basins, beakers, etc., should be

positioned on the tray with the open side down so any water condensate drains from the

container (See Photo 3). When sterilizing glassware check with the manufacturer to make sure

it is compatible with steam sterilization.

Photo 3

• Rinse tubing with distilled water or water that meets the referenced water purity specications

and do not dry prior to sterilizing. Arrange tubing on the tray so there are no sharp bends and

the tubing ends are open and unobstructed (See Photo 4).

Photo 4

003-2915-99

English - 19

© Midmark Corporation 2018

General Guidelines - Continued...

• Follow the device manufacturer’s instructions for disassembly of multi-part instruments prior to

packaging / sterilization to assure all parts are adequately exposed to the steam.

• If items are being sterilized and stored for later use they must be packaged, e.g. pouched,

wrapped, etc., and completely dry when removed from the sterilizer chamber to avoid potential

recontamination.

• Variations in load conguration, size, wrapping materials, and the environment may require the

operator to increase the default drying time to assure all packaging and instruments are

completely dry. See “Cycle Operation” section of this manual for instructions on adjusting drying

time.

• When sterilizing a load that contains one or more handpieces, utilize the hand piece cycle, not

Pouches or Unwrapped Cycle.

Pouching and Wrapping Items

The M9 / M9D and M11 are capable of sterilizing pouched or wrapped items to preserve sterility

after processing.

• When pouching or wrapping items, use only sterilization pouches and wraps that have been

cleared by the FDA and labeled for use with the steam sterilization cycle being used. Follow the

manufacturer’s instructions for use.

• Instruments made from dierent materials (stainless steel, carbon steel, plastic, etc.) should not

be mixed in the same pouch or wrapped pack to avoid potential instrument damage.

• Pouches, wraps and the included instruments should not touch the chamber wall to allow proper

steam circulation and avoid potential instrument damage.

• For proper steam circulation and drying the preferred orientation of pouches is resting on their

edge, best accomplished using the Midmark Pouch Rack supplied with the M9 / M9D / M11

sterilizer. If additional pouch racks are needed order kit P.N. 002-2108-00 (M11- 6 slot) or

002-2108-01 (M9 / M9D - 5 slot). If more than two (2) pouch racks are used in a single load

additional dry time may be required.

M11 Pouch Rack

002-2108-00

• The use of the Pouch Rack requires the removal of some of the sterilizer trays. When using the

Pouch Rack load a single pouch per rack slot. When using paper / plastic sterilization pouches

the pouches should be oriented in the rack so the plastic side of one pouch faces the paper side

of the adjacent pouch.

• Pouches loaded directly in the trays will dry best if loaded with plastic side up.

• Do not layer pouches in the trays. Pouches should be loosely packed with handpieces and

instruments single height loaded (not piled or stacked), to permit proper steam ow and

penetration to the items (See Photo 2).

003-2915-99

English - 20

M9 / M9D Pouch Rack

002-2108-01

© Midmark Corporation 2018

Pouching and Wrapping Items - Continued...

• If pouches or wrapped packs are labeled using a marking pen the ink should be nontoxic. On

paper-plastic pouches only mark on the plastic side of the pouch. On wrapped packs mark the

labeling information on the indicator tape or apply a separate label.

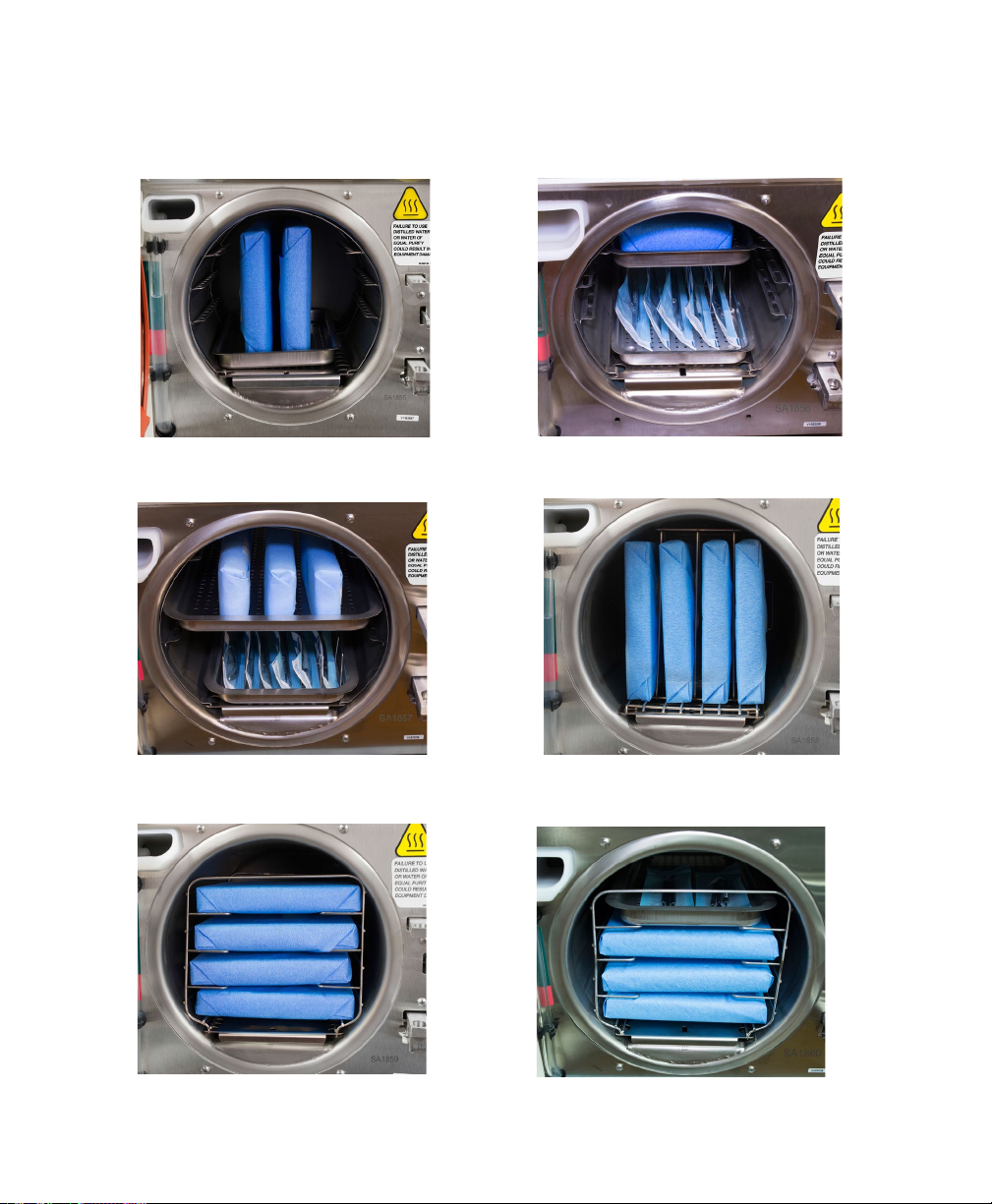

Shown below are some recommended pouch load congurations for the M9 / M9D (Photo 5 and 6)

and M11 (Photo 7 and 8):

M9 / M9D Pouches with Pouch Rack

Photo 5

M11 Pouches with Pouch Rack

Photo 7

M9 / M9D Pouches Mixed

Photo 6

M11 Pouches Mixed

Photo 8

• When using cassettes in the M9 / M9D / M11, follow the cassette manufacturer’s instructions for

use.

• Do not wrap items too tightly. Sterilization can be compromised if an item is excessively

wrapped and the wrap is more likely to tear if wrapped too tightly.

• Cassettes can be loaded on the trays but they must t within the boundaries of the tray and they

should not touch each other, the tray above, or the chamber wall to allow proper steam

circulation. The total instrument load, including the cassettes, should not exceed the limits listed

in maximum capacities tables.

• When using the optional Horizontal and Vertical cassette racks (9A215001 and 9A215002) in

the M11 the maximum load including the cassettes can be increased to 12 lbs. (5.44 kg).

Additional dry time may be required.

003-2915-99

English - 21

© Midmark Corporation 2018

Pouching and Wrapping Items - Continued...

Shown below are some recommended cassette load congurations for the M9 / M9D (Photos 9 and10) and

M11 (Photos 11, 12, 13, and 14):

M9 / M9D Large Cassette

Photo 9

M11 Mixed Load with Cassette and Pouches

Photo 11

M9 / M9D Mixed Load with Small Cassette and Pouches

Photo 10

M11 with Vertical Cassette Rack

Photo 12

003-2915-99

M11 with Horizontal Cassette Rack

Photo 13

English - 22

M11 with Horizontal Cassette Rack and Top Tray

Photo 14

© Midmark Corporation 2018

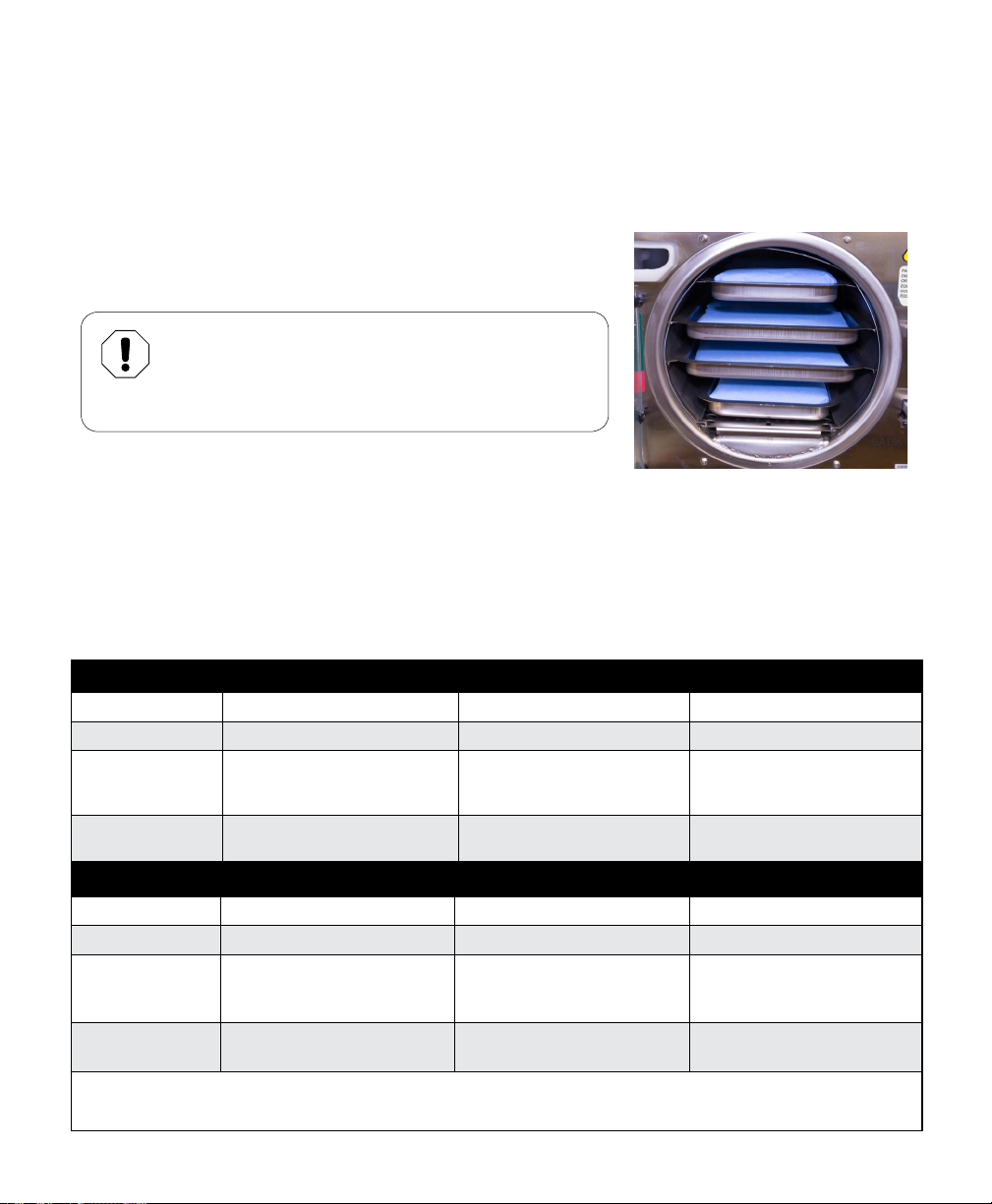

Textile Loads

• Clean textiles recommended for steam sterilization can be processed in the Packs cycle. Verify the

acceptability of the Packs cycle sterilization parameters with the textile manufacturer to assure the

textiles are compatible.

• All textile packs must not exceed the thickness limits specied in the maximum capacity tables below

and must t within the boundaries of the sterilizer trays.

• If multiple packs are placed on a single tray maintain a minimum of 1/4” (6.4 mm) between packs for

proper steam circulation and drying. (Photo 15)

Equipment Alert

Do not use towels or packaging containing chlorine bleach

residue. Failure to comply may cause rusting or discoloration

of the chamber / trays, and significantly shorten the life of the

sterilizer.

Textile load

Photo 15

Load Size

Successful sterilization is dependent on correct loading of the sterilizer. Do not overload the sterilizer

chamber! Adequate space must be maintained around all items placed in the chamber to assure proper

steam circulation and adequate drying. The charts below are provided as a reference regarding the

maximum loads that can be processed in the sterilizers but maintaining proper spacing between all items

processed to assure good steam circulation and drying should be the guiding factor in determining the

maximum load that can be processed.

M9 / M9D Maximum Capacities **

Load Type Large Tray Small Tray Total

Solid Instruments 2.4 lbs. (1089 grams) or 1.6 lbs. (726 grams) or 8.0 lbs. (3629 grams) or

Handpieces 2 handpieces with other

Packs* 90 in

instruments

2.4 lbs. (1089 grams) or

3

≤ 1.25 in. thick

(1475 cm3 ≤ 3.2 cm thick)

2 handpieces with other

instruments

1.6 lbs. (726 grams) or

55 in3 ≤ .75 in. thick

(901 cm3 ≤ 1.9 cm thick)

8 handpieces with other

instruments

8.0 lbs. (3629 grams) or

3

290 in

(4752 cm3)

M11 Maximum Capacities **

Load Type Large Tray Small Tray Total

Solid Instruments 2.7 lbs., (1225 grams) or 1.8 lbs., (816 grams) or 9.0 lbs., (4082 grams) or

Handpieces 2 handpieces with other

Packs* 145 in

* Allow a minimum of 1/4” (6.4 mm) space between each pack, and from the chamber wall.

** The default dry time may need increased due to variations in load conguration, wrapping materials, and the environment to

completely dry the chamber contents at these capacities.

003-2915-99

instruments

2.7 lbs. (1225 grams) or

3

≤ 1.5 in. thick

(2376 cm3 ≤ 3.8 cm thick)

English - 23

2 handpieces with other

instruments

1.8 lbs. (816 grams) or

108 in3 ≤ 1.5 in. thick

(1770 cm3 ≤ 3.8 cm thick)

8 handpieces with other

instruments

9.0 lbs. (4082 grams) or

3

505 in

(8275 cm3)

© Midmark Corporation 2018

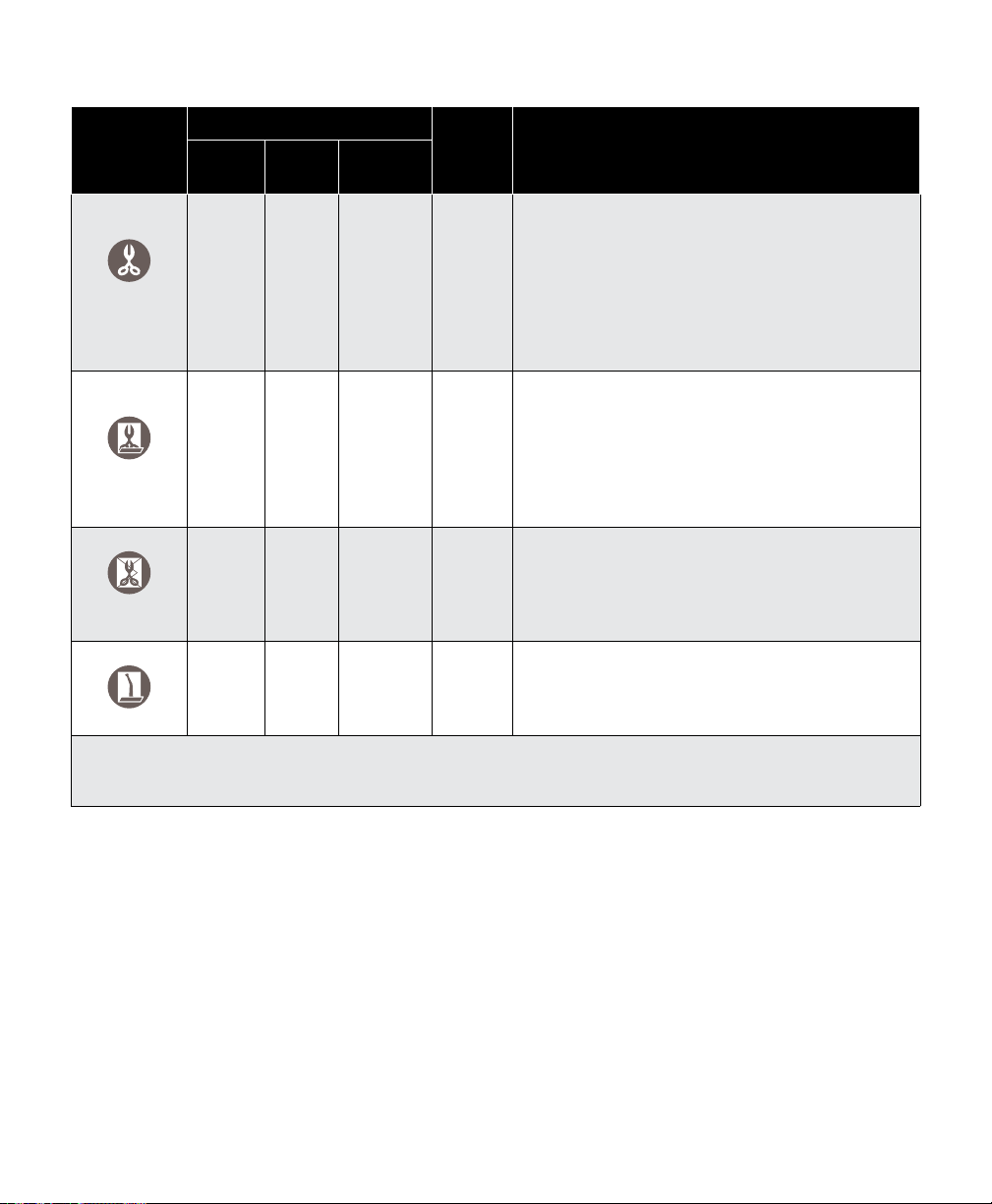

Standard Cycle Parameters

Cycle Parameters

Drying

(Ref.)

1

Time

30 min. • Instruments loose on a tray.

30 min. • Pouched or loosely wrapped instruments.

30 min. • Textiles and surgical packs wrapped for

30 min. • Dental handpieces (wrapped or unwrapped).

Cycle Type

Temp.

Time Press.

(Min.)

270°F

(132°C)

Unwrapped

Pouches

Packs

Handpieces

1. The pressure shown in this table is for reference only. It’s the ideal pressure of saturated steam

at the sterilization temperature. The pressure shown on the sterilizer display may be higher.

2. Dry time can be changed from 0 to 60 minutes. Refer to Cycle Operation.

270°F

(132°C)

250°F

(121°C)

270°F

(132°C)

3 min. 27.1 psi

(186 kPa)

4 min. 27.1 psi

(186 kPa)

30 min. 15 psi

(104 kPa)

4 min. 27.1 psi

(186 kPa)

(Always consult the item manufacturer’s

2

• Open glass or metal canisters.

• Tubing not used in surgical procedures.

(Max. length - 40” and Min. inside diameter - .187”)

• Loose items manufacturers recommend for

exposure at 270°F (132°C) for 3 minutes.

Note: The sterility of unwrapped items is compromised on exposure to a non-sterile environment.

• Multiple layers of instruments separated by

fabric.

• Wrapped trays of loose instruments.

• Wrapped cassettes.

• Wrapped items manufactures recommend for

exposure at 270°F (132°C) for 4 minutes.

sterilization.

• Items, except liquids, manufacturers

recommend for exposure at 250°F (121°C) for

30 minutes.

Note: Verify acceptability of sterilization

parameters with handpiece manufacturer.

Items to be Sterilized

recommendations for sterilization.)

003-2915-99

English - 24

© Midmark Corporation 2018

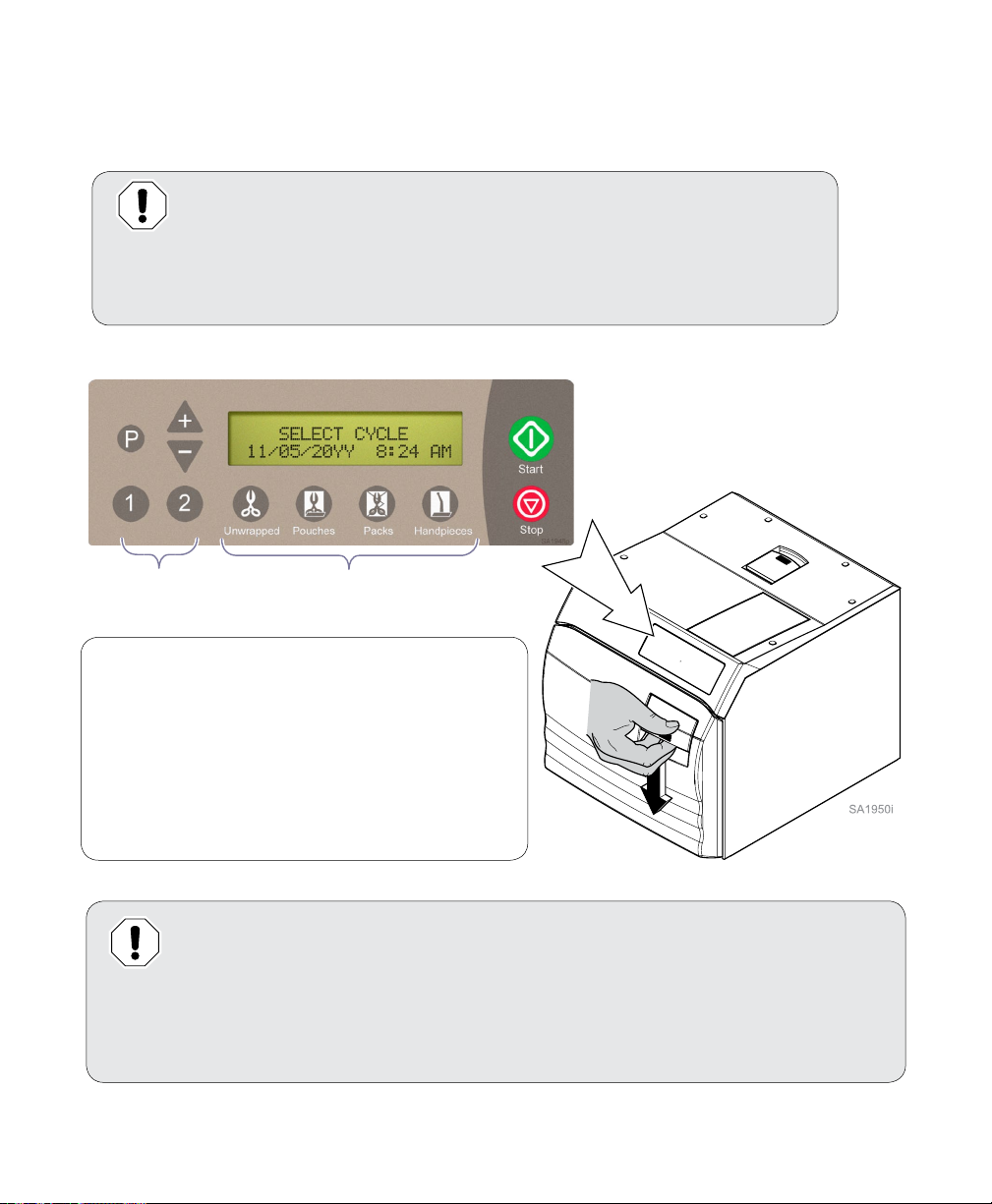

Cycle Operation

Refer to the following steps for a detailed description of cycle operation:

Equipment Alert

The sterilizer will not operate unless the door is closed and latched properly.

Step 1: Close and latch the door.

A) Lift the door handle, then push the door closed.

B) While pushing in on the door, slide the door handle down to engage the latch.

Cycle Buttons

(Programmable)

Cycle Buttons

(Pre-set)

Note

Pressing the Start button when ‘SELECT CYCLE’ is

displayed, at beginning or end of a cycle, activates

the heater for 10 minutes. The display flashes

‘ADDITIONAL HEAT’. This allows the operator to

preheat the chamber before starting a cycle or to

add additional time to the Dry mode at the end of a

cycle. Pressing the Stop button will end the

‘ADDITIONAL HEAT’ time.

Equipment Alert

Using an incorrect sterilization program could result in non-sterile goods and may

damage instruments. Consult instrument manufacturer for specific sterilization instructions.

Step 2: Select the desired cycle.

A) Press the appropriate cycle button on the display panel.

(Refer to “Cycle Parameters” chart for time / temperature specifications).

003-2915-99

English - 25

© Midmark Corporation 2018

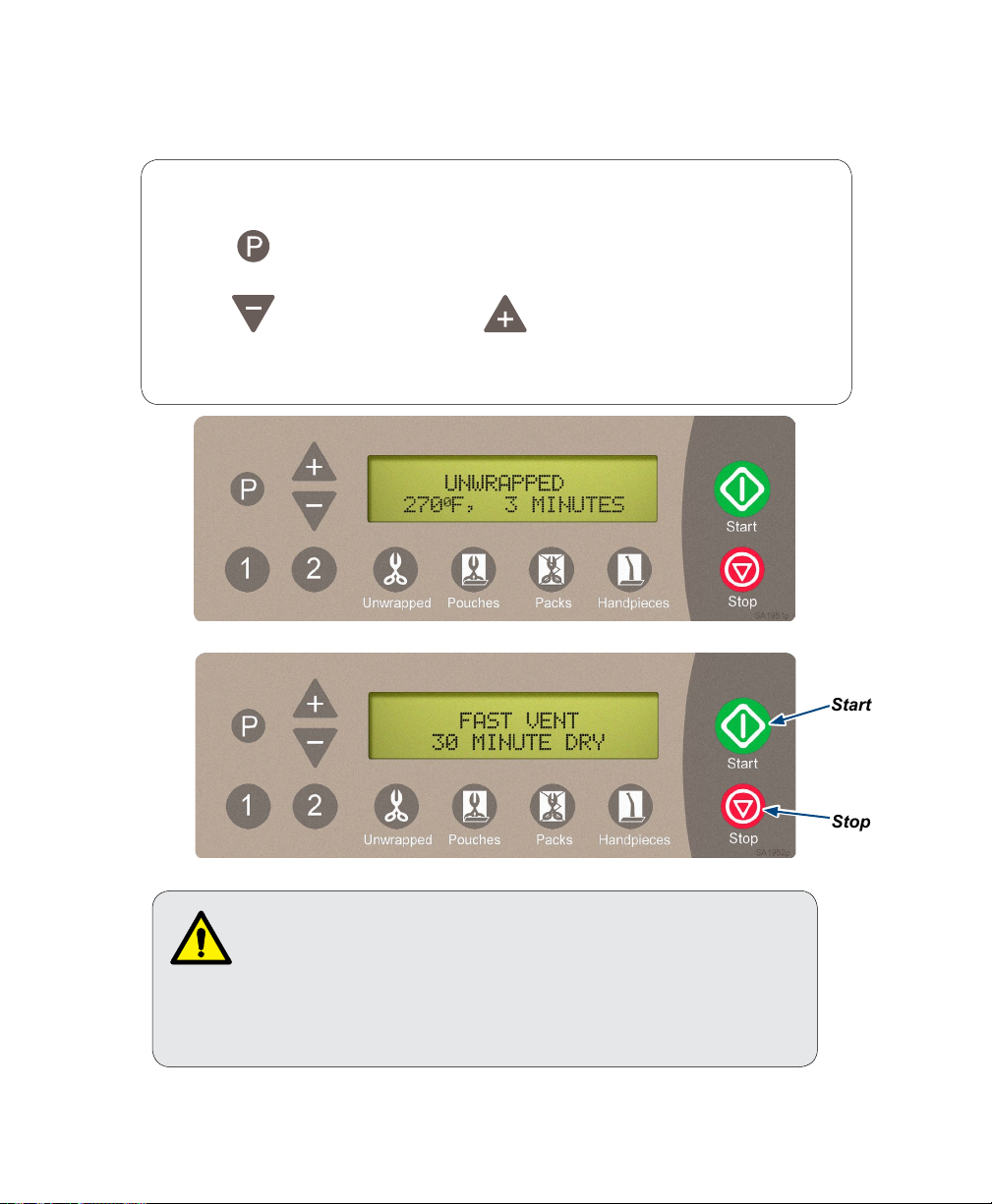

Cycle Operation - continued...

After the cycle button is pressed, the parameters for that cycle will appear on the display.

Note

On units using the metric display,°F will display as°C and PSI will display as KPA.

Pressing enables operator to change DRY time from 0 to 60 minutes in 1 minute

increments on a pre-set cycle.

Pressing decreases time. Pressing increases time.

If the new Drying Time is desired on a regular basis pressing “P” after adjusting the dry time will

store the new time as the default dry time for the selected cycle.

003-2915-99

WARNING

STOP button may be pressed at any time to stop or interrupt

a cycle. Goods must not be considered sterile if this occurs

before the Dry Cycle. Sterilizer will return to SELECT CYCLE mode.

Step 3: Press ‘Start’ button to initiate cycle.

You will hear a “beep” for two seconds, indicating the cycle has started.

English - 26

© Midmark Corporation 2018

Start

Stop

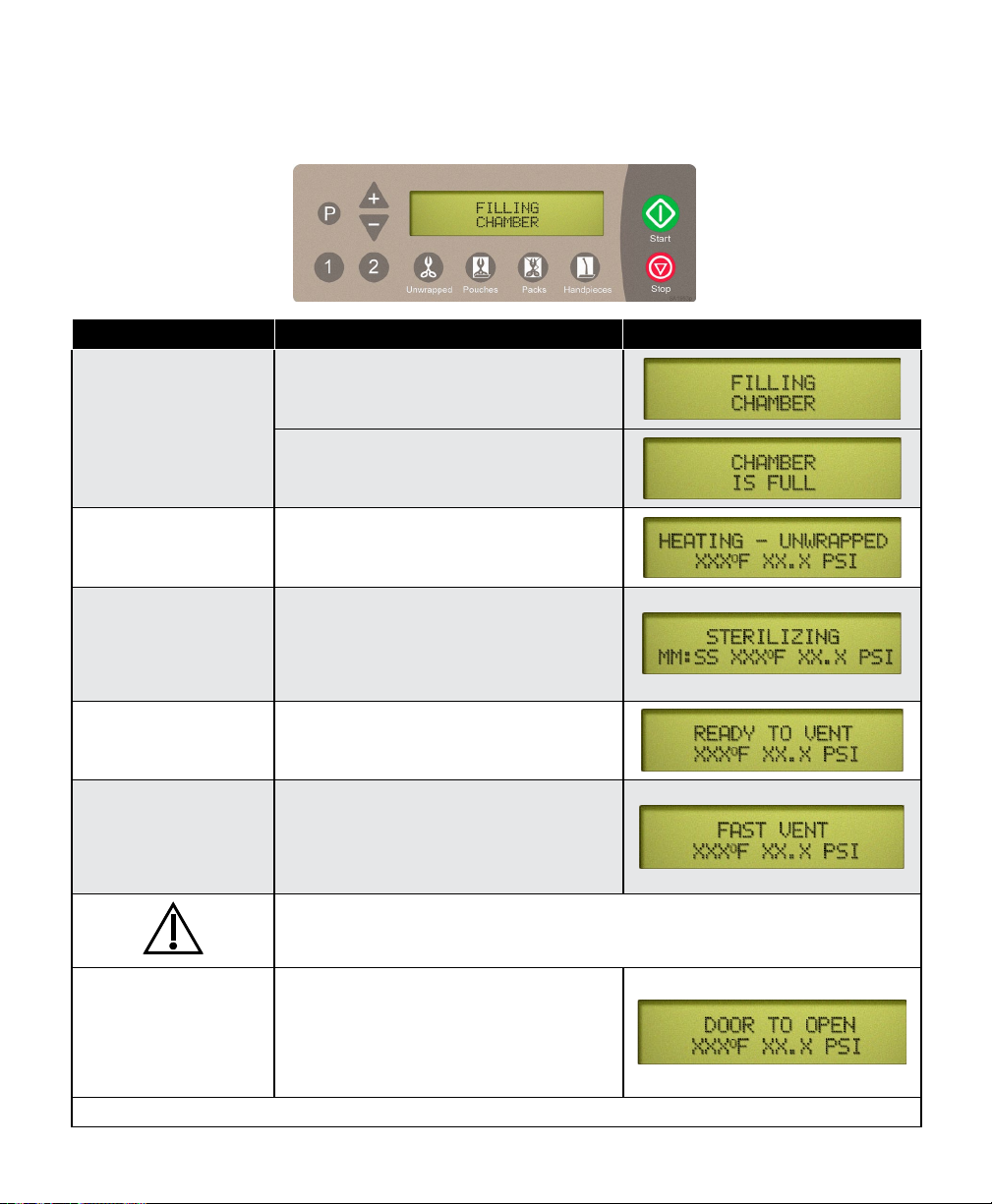

Cycle Operation - continued...

After the ‘Start’ button is pressed, the stage / status of the current cycle will appear on the display.

The chart below illustrates the display messages that will appear during each stage of the cycle.

Stage of Cycle Description Display

Filling Chamber begins lling with water.

When water reaches the proper level...

Heating Display changes as temperature and

pressure in chamber changes.

(Metric units may be displayed if desired).

Sterilizing Sterilizing begins when correct

temperature / pressure is reached.

Time remaining in cycle counts down

while current temperature / pressure in

chamber is continuously updated.

Ready to Vent ‘READY TO VENT’ is displayed when

10 seconds remain in sterilization cycle.

Fast Vent When time runs out in sterilizing mode,

Door To Open

(automatic)

Pertains only to

M9/M11 Steam Sterilizers

003-2915-99

the vent valve opens. Steam / water are

released back into the reservoir.

The display changes as temperature and

pressure in chamber changes.

Caution

Keep clear when M9 / M11 door is ready to open!

Failure to do so could result in severe burns from steam being released.

An audible signal is emitted to indicate

that the door is about to open.

When pressure in chamber reaches zero,

the door actuates to partially open (drying

mode) position.

This chart continues on the following page...

English - 27

© Midmark Corporation 2018

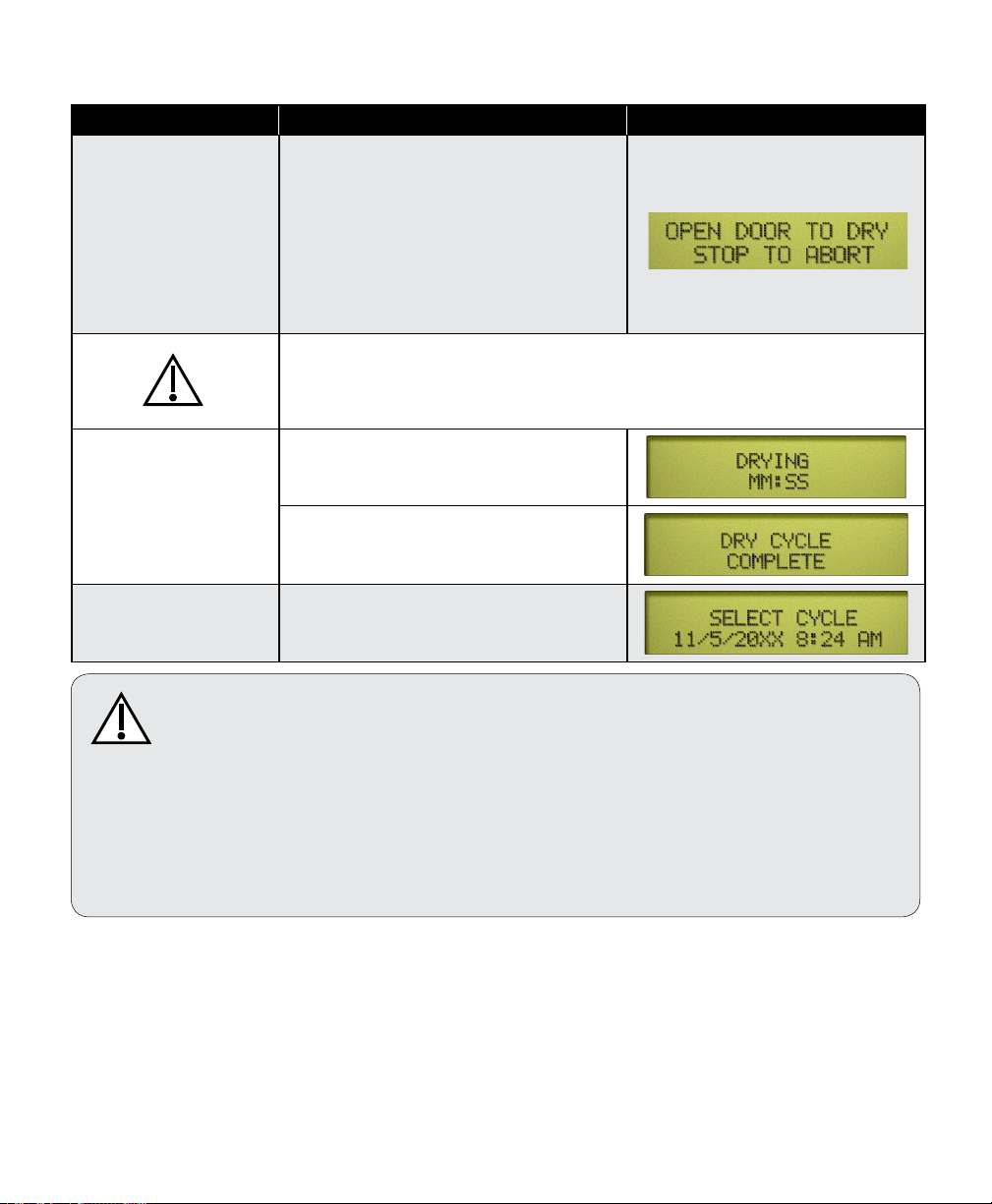

Cycle Operation - continued...

Stage of Cycle Description Display

Manual Door Open

Pertains only to

M9D Steam Sterilizer

Drying Time of Dry Cycle is counted down. If

Cycle Complete An audible signal is emitted for 10

An Audible signal is emitted when

pressure inside chambers reaches zero

to indicate Operator to open door. The

door should be opened to the rst stop

(drying mode) position. The audible signal

will continue to repeat every minute until

either the door is opened to the DRY

(partially opened) position, or by pressing

the STOP button, aborting the DRY cycle.

Caution

The processed loads may still be wet if the Dry Cycle is aborted

prior to completion. Always allow processed loads to dry in the

sterilizer before they are handled to avoid re-contamination.

desired, the Dry Cycle can be aborted by

pressing the STOP button.

When Drying time reaches 0:00...

seconds.

Caution

• The processed load and inner surfaces will be hot. Avoid contact with hot surfaces. Failure

to do so could result in serious burns.

• Do not apply downward pressure to the open sterilizer door while unloading the chamber.

Doing so could cause the sterilizer to tip resulting in serious burns or injury from the trays or

instruments sliding out of the chamber.

Step 4: Remove processed load from the chamber.

A) Refer to “Using the Optional Tray/Cassette Tool” later in this manual.

B) Sterilizer is now ready for another cycle.

Post-Sterilization Processing

After sterilization is complete, all items must be handled in accordance with accepted and documented

standards, such as the Centers for Disease Control and Prevention (CDC) documents, “Guidelines for

Infection Control in Dental Healthcare Settings” - 2003, MMWR; 52 (no. RR-17), and “Guidelines for

Disinfection and Sterilization in Healthcare Facilities” - 2008, as well as any local requirements that may

apply.

Qualied personnel responsible for infection control should prepare a protocol for handling sterilized items.

This protocol should be followed by all personnel responsible for handling sterilized items.

003-2915-99

English - 28

© Midmark Corporation 2018

Programmable Cycle Buttons

Cycle buttons can be used for custom applications that are not covered by standard cycle

programs. These cycles have not been FDA cleared for medical use. The programmable cycles allow the

user to adjust cycle parameters in order to sterilize items that cannot be sterilized in any of the standard

pre-programmed cycles. Once a custom program has been stored, it can be used just by pushing the

or button. Use the instructions in the chart below to set time / temperature parameters for these

buttons. (If you wish to change the settings, these buttons may be reprogrammed at any time).

Note:

The programmable cycles can

be programmed for the monthly

cleaning cycles with no dry time

to expedite monthly maintenance.

NOTE:

Pressing the STOP button during this procedure will abort the changes, and revert to the original settings.

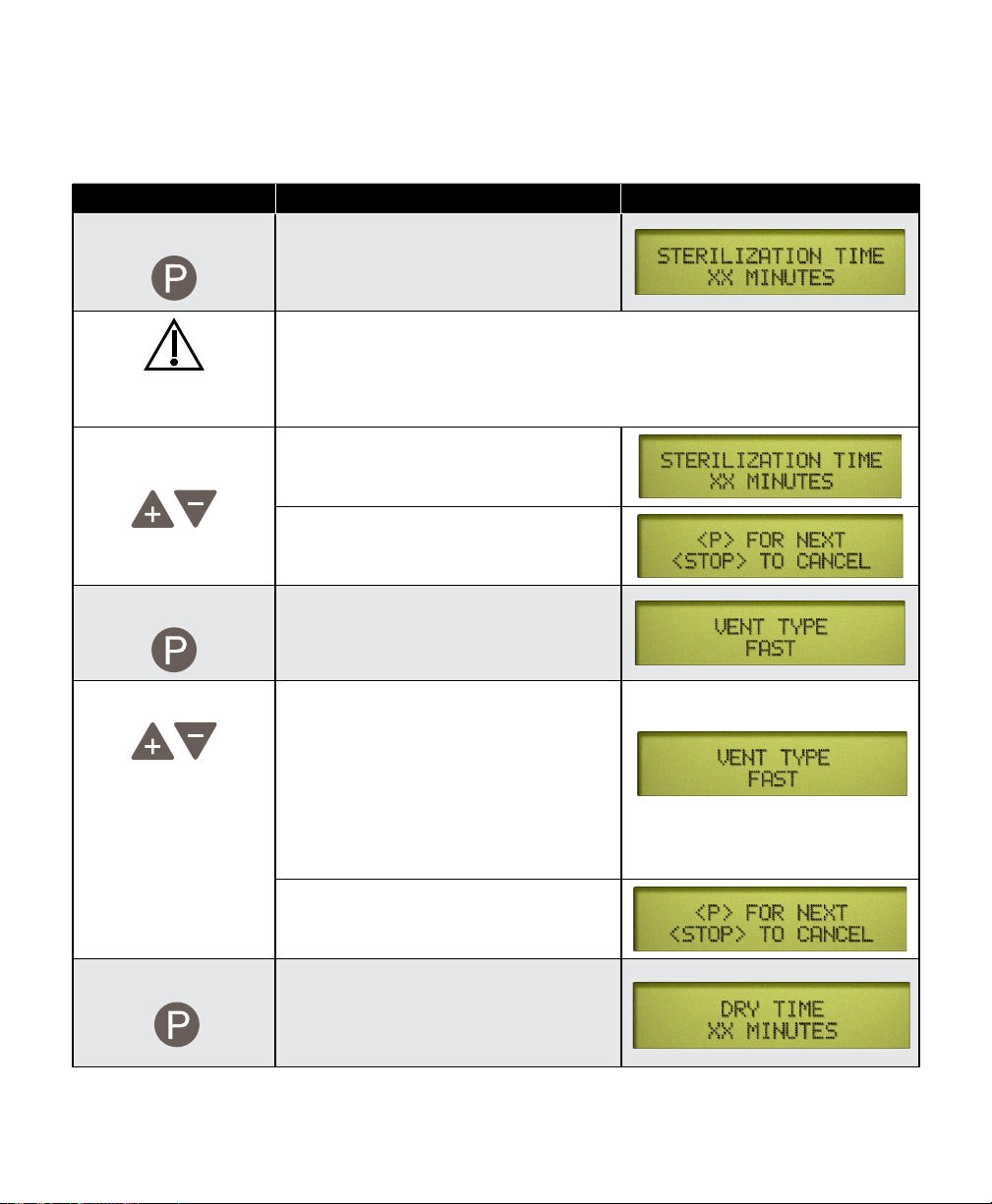

Action Description Display

Press desired

button

This selects the button that will be

programmed.

Press This brings up the sterilization

Adjust Sterilization

Temperature

003-2915-99

temperature programing display.

Caution

Sterilization temperature can be adjusted from a minimum of 250°F (121°C) to

a maximum of 275°F (135°C). At high altitudes sterilization temperatures above

270° F (132° C) may cause the pressure relief valve to leak.

The “+” and “-” buttons adjust the

temperature by 1°increments.

When the desired temperature appears

on the display...

This continues on the following page...

English - 29

© Midmark Corporation 2018

Programmable Cycle Buttons - continued...

NOTE:

Pressing the STOP button during this procedure will abort the changes, and revert to the original settings.

Action Description Display

Press To store the temperature. This brings up

the sterilization time programing display

showing the current value.

Caution

Sterilization time can be adjusted from a minimum of 3 minutes to a maximum

of 45 minutes. Because it is important to properly coordinate the cycle time with

the sterilization temperature the minimum selectable time will be determined by

the temperature setting.

Adjust Sterilization

Time

Press To store the sterilization time. This brings

The “+” and “-” buttons adjust the

time by 1 minute increments.

When the desired time appears on the

display...

up the vent speed programing display and

the current value.

Adjust Vent Speed In FAST vent, the valve fully opens and

vents the chamber.

In SLOW vent, the valve opens for a

fraction of a second (once per minute)

to slowly vent the chamber.

Pressing “+” sets it to: FAST

Pressing “-” sets it to: SLOW

When the desired setting appears on the

display...

Press To store the setting and bring up the dry

time programing display and the current

value.

This chart continues on the following page...

003-2915-99

English - 30

© Midmark Corporation 2018

Programmable Cycle Buttons - continued...

NOTE:

Pressing the STOP button during this procedure will abort the changes, and revert to the original settings.

Action Description Display

Adjust Dry Time Dry time can be adjusted from 0 to 60

minutes.

The “+” and “-” buttons adjust the

time by 1 minute increments.

When the desired time appears on the

display...

Press To store the setting and complete the

programming process. The display will

show the new cycle parameters.

Note

The programmed settings are retained under Program # button <1> or <2>.

Even if power is interrupted, or the unit is unplugged the setting will be retained.

Caution

All materials processed using these cycles must be validated by the user.

Failure to do so could result in incomplete sterilization.

Maintenance

Maintenance Messages

To assure proper operation and maximum sterilizer life, carefully follow all recommendations for periodic

maintenance. Recommended maintenance is easy to do and takes very little time.

One of the MOST important steps you can take to prevent problems with your sterilizer, is to ensure that

ONLY distilled water or water that meets the referenced water purity specifications - NOT TAP WATER is used in the sterilizer. Since the sterilizer operates with high water temperatures, any minerals dissolved

in the water will form mineral deposits. This can prevent valves from opening or closing properly and can

also lead to corrosion in the chamber and tubing.

Maintenance reminders will be displayed on the screen at the appropriate intervals to assist the operator.

These reminders are removed from the display screen once a cycle is started.

The user is responsible for establishing a periodic maintenance procedure to assure correct operation of

equipment and reliable sterilization of loads. Contact your local Midmark distributor or service representative

to develop a program for planned maintenance.

003-2915-99

English - 31

© Midmark Corporation 2018

Daily Maintenance

Equipment Alert

If the sterilizer is used frequently to process dental handpieces that have been

lubricated or dipped in dental milks, drain the water from the reservoir daily.

Refill the reservoir with distilled water or water that meets the referenced water

purity specifications.

Clean External Surfaces

A) Wash the exterior of the sterilizer each day according to your facility’s procedure for clinical contact

surfaces, noting the following: (Use only quaternary disinfectants to disinfect unit. Staining, pitting,

discoloration, or softening could occur if phenolic, iodophor, or glutaraldehyde-based disinfectant is

used on plastic surfaces of the unit. Also, use of alcohol or aerosol spray cleaner / disinfectant

containing substantial amounts of alcohol in the formula can damage the faceplate).

B) Wring excess solution from the cloth.

C) Using soft cloth, wipe all external surfaces.

D) Follow the instructions provided with the cleaner / disinfectant used regarding rinsing and drying

of the external surfaces.

Clean sterilizer door / dam gaskets

Caution

To prevent burns, allow unit to cool before

cleaning gaskets and mating surfaces.

A) Examine gaskets for possible damage.

B) Clean gaskets and mating surfaces with a damp cloth.

003-2915-99

Door Gasket

Dam Gasket

English - 32

© Midmark Corporation 2018

Weekly Maintenance

Equipment Alert

Failure to change water may result in sterilizer malfunction. Do not use bleaching

agents or any abrasive materials / substances in chamber (i.e. bleach, steel wool, wire

brush, scouring powder, etc.). Failure to comply may result in damage to the chamber and/or

other components.

Note

Every seven days, the autoclave will automatically display the PERFORM WEEKLY MAINTENANCE

message. If power is disconnected, the cycle of weekly messages will be reset.

Caution

To prevent burns, allow unit to cool before

draining reservoir.

Clean Chamber / Trays (including Rack and Plate)

A) Disconnect the upper portion of the reservoir drain tube from the panel clips, bend it downward,

and drain the reservoir water into a suitable container, e.g. a bucket, and dispose of the water.

B) Remove the trays, tray rack, and tray plate from the sterilizer.

(Refer to the following page for instructions on removing / installing the tray rack and tray plate).

C) Wash trays, rack, plate, and inside of chamber with mild soap or Speed-Clean and distilled water or

water that meets the referenced water purity specifications.

D) Refill reservoir with distilled water or water that meets the referenced water purity specifications.

003-2915-99

Trays

English - 33

Tray Rack

Tray Plate

© Midmark Corporation 2018

Weekly Maintenance - continued...

WARNING

Allow unit to cool before removing or installing tray rack and plate.

Handle metal tray rack carefully to avoid injury. Do not run sterilizer without

tray plate in place.

To remove tray rack / plate...

A) Remove trays.

B) Using a screwdriver, pry plate up while pulling tray rack / plate out of chamber.

Tray Rack

003-2915-99

Tray Plate

(Angled end must face back of chamber)

Equipment Alert

Install tray rack / plate with angled end of plate

toward the back of the chamber.

Do not allow plate to contact the water level sensor.

To install tray rack / plate...

A) Insert the tray rack into the tray plate.

B) Place back of tray plate in chamber.

C) Press down on tray rack, while sliding into chamber.

English - 34

© Midmark Corporation 2018

Monthly Maintenance

WARNING

Do not process instruments while flushing system.

Equipment Alert

Use only Speed-Clean to flush system. Failure to flush system with Speed-Clean may result in the

premature failure of sterilizer components.

Note

Every 28 days, the sterilizer will automatically display the PERFORM MONTHLY MAINTENANCE

message. If power is disconnected, the cycle of monthly messages will be reset.

Caution

Clean Chamber / Plumbing

A) With a cooled chamber, drain the sterilizer’s reservoir and refill with clean distilled water or water that

meets the referenced water purity specifications. Add one ounce of Speed-Clean sterilizer cleaner

directly to the bottom of chamber.

B) Run one Pouches cycle.

C) Press Stop button when Dry Cycle begins. (Dry Cycle is not needed during maintenance.)

D) Drain reservoir and refill a second time with clean distilled water or water that meets the referenced

water purity specifications. .

E) Rinse by running one Unwrapped cycle

begins.

F) Drain and refill reservoir with clean distilled water or water that meets the referenced water purity

specifications, then allow sterilizer to cool.

G) Remove tray plate, rack, and trays. Wipe off with a damp cloth.

To prevent burns, allow unit to cool before

draining reservoir.

. Push the “Stop” button when the drying cycle

Sterilizer Cleaner

003-2915-99

Air Filter Screen

Fill / Vent

Filter Screen

Speed-Clean

English - 35

MA8195-1i

Steam Temperature Probe

Level Sensor Probe

Heating Element

© Midmark Corporation 2018

Clean Chamber / Plumbing - continued...

Equipment Alert

Use care when wiping the inside of the chamber. Failure to comply may result in

damage to the heating element, steam temperature probe, and/or level sensor probe.

Equipment Alert

Do not operate sterilizer without filters in place.

H) Remove and clean filters. The filters are intended to prevent debris from causing valve failures.

Between regular monthly cleanings if the fill or vent times become too long or items will not dry the

filters should be cleaned. (Refer to the illustration for location of filter screens.)

I) Grasp filter and gently pull away from chamber wall while twisting slightly.

(If necessary, pliers may be used to remove filters)

J) Clean filters with Speed-Clean and distilled water. A small stiff bristled brush or ultrasonic cleaner

may be helpful. Rinse filters with distilled water. Replace filter(s) if debris cannot be removed by

cleaning.

K) Wipe out the inside of chamber.

L) Install filters. (Press inward, toward chamber wall while twisting slightly).

M) Install tray plate, rack, and trays.

Remove / Clean Door and Dam Gaskets

A) Remove door and dam gaskets from chamber door,

then remove the gasket ring from the door gasket.

B) Clean gaskets and ring with Speed-Clean,

distilled water, and a soft brush.

C) Inspect gaskets for damage / shrinking / swelling.

Replace gaskets if damage is apparent.

D) Press gasket ring into the channel in the

door gasket and reinstall the gasket in the door.

E) Install dam gasket.

003-2915-99

English - 36

© Midmark Corporation 2018

Check Pressure Relief Valve

(must be checked each month to assure it functions properly)

A) Press Unwrapped button

B) Press Start button

During the pressure relief valve check, steam will be vented from under the sterilizer. To keep

from being burned, place a steam barrier (a rolled up towel) around the bottom of the sterilizer.

C) Wait until pressure in chamber

reaches 20 PSI (138 kPa).

D) Pull upward firmly on the pressure relief lever for approximately 3 seconds, then release.

(Steam should discharge freely from beneath rear of unit when lever is pulled.

If the valve does not close completely when lever is released,

pull lever again and release quickly so that it snaps closed.

Repeat this until valve seats properly).

E) Press Stop button

(This aborts the cycle to prevent overheating).

Caution

Pressure Relief

Lever

Equipment Alert

If excessive force is required to open the

pressure relief valve, or if the valve will

not reseat properly, the valve must be replaced.

(Refer to “Calling for Service” in this manual).

MA601301i

Extended Use Maintenance

The M9 / M9D and M11 are designed and tested to provide exceptional reliability throughout their

service life. However, like all electro-mechanical devices they are subject to wear and degradation with use.

To ensure the integrity, performance, and safety of all major components it is the responsibility of the user to

have the sterilizer performance / operation veried by a Midmark Authorized Service Provider at least every

10 years or 10,000 cycles, which ever comes rst. After 10 years or 10,000 cycles of use, an annual

inspection by a Midmark Authorized Service Provider is recommended.

003-2915-99

English - 37

© Midmark Corporation 2018

Thermal Printer (Optional)

Operating the Printer

After the optional printer is installed and the sterilizer is plugged in, the printer is automatically powered up

and initialized. No user intervention or setup is required.

Printer Tape Description

The printer will print the following information for each sterilizer cycle:

• Model Number: indicates sterilizer model and software version.

• Cycle Number: reects actual cycle count of sterilizer.

• Sterilizer ID: Serial Number of sterilizer.

• Operator: a line is printed so the operator’s signature can be recorded on the printer tape.

• Date and Time: of start of each cycle

• “BEGIN selected CYCLE”: to indicate the beginning of the cycle selected by the operator.

• Summary of selected cycle set points.

Once the cycle starts, the printer will print the words “FILLING CHAMBER” to show that the sterilizer is ling

with water.

Once the sterilizer begins the Heating Phase of the sterilization cycle, the word “HEATING” is printed and

the printer will print the chamber temperature, pressure, and elapsed time in 2 minute increments until the

heating phase is completed.

When the sterilizer enters the sterilization phase, the word “STERILIZING” is printed and the printer will print

the chamber temperature, pressure, and elapsed time in 1 minute increments until the sterilization phase is

completed.

When the sterilizer has completed the sterilization phase of the program cycle, the printer will print the words

“VENTING CHAMBER” to show that the steam pressure is being exhausted from the chamber.

When the sterilizer enters the drying phase, the word “DRYING” is printed and the printer will print the

words “DRYING START” and show temperature, pressure, and elapsed time in 5 minute increments starting

with 5:00. The printer continues to print the elapsed time in 5 minute increments until the drying phase

is completed. The nal record for the drying phase will include the words “DRYING COMPLETE”. In the

event the drying time is programmed to a time that isn’t divisible by 5, the nal printed record for the drying

phase will reect the actual programmed drying time in 1 minute increments, e.g. a programmed dry time of

12 minutes will have 5,10,and 12 minutes printed on the printer tape.

When the sterilizer has completed the drying phase of the sterilization cycle, the printer will print a summary

of the sterilization cycle with the duration of each phase of the cycle and the Total Cycle Time. Following the

summary the printer will print “CYCLE COMPLETE”.

[NOTE: If drying cycle is aborted, “DRYING COMPLETE” and “CYCLE COMPLETE” will not print].

003-2915-99

English - 38

© Midmark Corporation 2018

Example of Typical Printout of a Program Cycle

Sterilizer Identication

(Serial Number)

Date and Time

of cycle start

Sterilization temperature,

time, and dry time settings

During Heat-Up phase, the

printer records chamber

temperature and pressure

in 2 minute increments

During Sterilization phase,

the printer records chamber

temperature and pressure in

1 minute increments

Indicates Venting

phase initiated

During Drying phase,

the printer records time in

5-minute increments

These lines will show the

total dry time completed

STERILIZING: 3:00

TOTAL CYCLE 00:51:44

Midmark M9 - v0.1.1

Total Cycles: 10

Sterilizer ID: V0000000

--------------------------------------------

Operator

1/27/2016 8:08 AM

BEGIN UNWRAPPED CYCLE

Temp: 270 Degrees F

Time: 3 Minutes

Dry: 30 Minutes

FILLING CHAMBER

HEATING

mm:ss Degrees PSI

0:00 77.2F 0.0

2:00 82.7F 0.7

4:00 152.2F 5.4

STERILIZING

mm:ss Degrees PSI

0:00 272.1 F 28.0

1:00 273.0 F 28.7

2:00 272.2 F 27.9

3:00 272.4 F 28.7

Min 272.0 F 27.9

Max 273.1 F 29.0

VENTING CHAMBER

DRYING

Drying Start

mm:ss Degrees PSI

5:00 192.8 F 0.0

10:00 192.7 F 0.0

30:00 192.8 F 0.0

Drying Complete

FILLING: 0:36

HEATING: 15:40

VENTING: 2:28

DRYING: 30:00

CYCLE COMPLETE

Summary of

Sterilization phase

Cycle summary

Model # and

Software Version

Total # of cycles

run on unit

Line provided for

operator signature

Selected Cycle

Indicates Filling

phase initiated

These lines will not print

if Dry Cycle is aborted

before it completes

003-2915-99

English - 39

© Midmark Corporation 2018

Paper Roll Removal / Installation

Equipment Alert

Use only thermal paper rolls with a maximum diameter of 1.89” (48 mm) and

width of 2.28” (58mm).

To remove paper...

A) Insert finger into groove at the back of the small cover and lift upward until

lid is released from locked position. To avoid damage do not use excessive

force.

B) The printer lid will hinge up towards the back of the printer.

C) Remove any remaining paper.

To install the paper roll...

A) Unroll 3” to 4” (7.6 to 10.2 cm) of paper.

B) Place the paper roll into cradle, unrolled side down.

C) Hold unrolled edge of paper out the front of the printer and shut the lid by

applying equal amounts of pressure on each side of lid until it latches.

D) Press the paper feed button for additional paper.

Note

A pink stripe that gets progressively darker on the paper indicates when paper is low.

Printer Paper Rell Order Number

Printer Thermal Paper Roll 060-0016-00

Printer Stick-able Thermal Paper 060-0016-01

Paper Feed Button

Paper Slot

003-2915-99

English - 40

Status Light

SA1841i

Printer Housing

© Midmark Corporation 2018

Using the Optional Tray / Cassette Tool

Equipment Alert

Only use the 9A307001 Tray / Cassette Tool with Midmark manufactured

trays. Slide the proper plate into the handle as shown.

Note: There are three plates included. Each plate is designed for a specific purpose.

(M9 / M9D trays, M11 trays, cassettes)

To remove M9 / M9D / M11 trays and cassettes...

A) Hook the top, saw-toothed tab of tool to top center of tray lip / cassette.

B) Rotate tool downward until the tool plate is completely under tray / cassette.

C) Check to ensure tray / cassette is being held securely and then remove from chamber.

Note: Cassette tool can handle cassettes up to 1 1/2” (3.8 cm) thick.

Caution

Trays / cassettes may be HOT - use care when removing or transporting. Hold the tray level

and slightly elevated to prevent it from shifting and becoming dislodged. Failure to comply

may result in personal injury due to burns.

003-2915-99

English - 41

© Midmark Corporation 2018

Troubleshooting

Troubleshooting Chart

Use the following chart to assist in correcting minor problems with the sterilizer.

Problem Possible Cause Solution

Sterilizer does not

operate (no display).

Steam escaping from

pressure relief valve.

Sterilization

failure evidence from

process monitor

(chemical indicator,

biological indicator,

etc.).

Door gasket leaks. Door gasket is damaged or dirty. Clean or replace door gasket.

Items are not dry at

end of Dry Cycle.

Printer not printing. Printer cables are not connected

Display goes blank /

black / is non legible

003-2915-99

Sterilizer power cord came loose from

supply outlet or back of sterilizer.

No power at Sterilizer supply outlet. Check circuit breaker for supply outlet. If problem

Fuse open on main P.C. Board. Unplug unit power cord and contact an authorized

Pressure relief valve not properly

seated.

Sterilization conditions were not

present at location of the indicator.

Indicator is out-of-date, is inappropriate

for sterilization cycle, or has otherwise

malfunctioned.

Sterilizer is improperly loaded. Reload sterilizer in accordance with guidelines for

Filter screen(s) clogged. Clean or replace lter screen(s).

properly.

Printer malfunction. (status light ashes

multiple times per second)

Printer is out of paper. (status light

ashes once per second)

Wrong paper Assure printer paper is thermal paper

Electromagnetic Interference Press any key except Stop on the keypad to reset

Assure Sterilizer power cord is plugged into outlet

and sterilizer.

recurs, unplug unit power cord and contact an

authorized service technician.

(see “Calling for Service”)

service technician. (see “Calling for Service”)

Reseat pressure relief valve.

(see “Monthly Maintenance”)

Reload sterilizer in accordance with guidelines for

loading the M9 / M9D or M11. If problem recurs,

unplug unit power cord and contact an authorized

service technician. (see “Calling for Service”)

Use an indicator, appropriate for the load and cycle

selected, that has been stored properly. Contact the

indicator manufacturer for additional information on

proper selection, use, storage, and potential misapplication or malfunction.

(see “Weekly Maintenance”)

loading the M9 / M9D or M11.

If the particular load conguration being used is

consistently not dry at the end of the dry cycle

increase the cycle drying time (see note on page 26)

or reduce the load.

(see “Monthly Maintenance”)

Ensure that printer cables are connected to printer.

Unplug sterilizer power cord, wait 15 seconds, and

then plug sterilizer power cord back in.

Insert a new paper roll. (see paper roll removal and

installation section)

the display without aborting the cycle. Pressing stop

will also reset the display but will also abort the cycle

in process.

English - 42

© Midmark Corporation 2018

Informational Messages

The chart below lists the informational messages that may appear during operation.

Message Possible Cause Solution

INITIALIZING SYSTEM

TOTAL CYCLES XXX

M9, VX.X.X

MM/DD/YYYY 8:07 Am

VXXXXXXX

PERFORM WEEKLY

MAINTENANCE

PERFORM MONTHLY

MAINTENANCE

Unit power cord was just plugged in standard informational

message.

Unit power cord was just plugged

in - standard informational message.

(Displays # of cycles, model number

(M9 / M9D or M11) and software

version)

Unit power cord was just plugged

in - standard informational message.

(Displays date, time, and serial number.)

This message is displayed every 7, 14,

and 21 days after the unit is plugged

into a power source to prompt the

operator to perform weekly maintenance

described in this manual.

This message is displayed every 28

days to prompt operator to perform

monthly maintenance described in this

manual.

Normal operation will occur after a

4 second pause.

Normal operation will occur after this

message.

Normal operation will occur after this

message.

Perform weekly maintenance.

The message will automatically clear

after the next cycle is completed.

Perform monthly maintenance.

The message will automatically clear

after the next cycle is completed.

Accessing the last 5 Error Codes

Action Description Display

Press and hold

during power up

Press the “stop” button

This menu shows the last ve error

codes displayed on the unit.

NOTE: “1” is the most recent

error code; “5” is the oldest.

To exit the error code menu press

the stop button.

Error Messages

The chart below and on the following pages, lists the error messages that may appear during operation.

Caution

If an error occurs more than once, stop using the sterilizer. Record the message or error

code, unplug unit, then call an authorized service representative. (see “Calling for Service”)

If an error message includes: “Items Not Sterile”, the items in sterilizer shall not be considered sterile;

they must be run through a successful sterilization cycle.

003-2915-99

English - 43

© Midmark Corporation 2018

Error Messages - continued...

Message Possible Cause Solution

C010: POWER UP MODE

SYSTEM PWR LOSS

ITEMS NOT STERILE

PUSH STOP TO RESTART

CO60: POWER UP MODE

SYSTEM HARDWARE

C102: FILL MODE

STOP PRESSED

C103: THROUGH C105

HEATUP, STERILIZE OR

VENT MODE

STOP PRESSED

C106: DOOR MODE

STOP PRESSED

C232: FILL MODE

WATER LOW

C326: DOOR MODE DOOR

CLOSED

C382: FILL

DOOR OPEN

C383: HEATUP MODE

DOOR OPEN

C384: STERILIZE MODE

DOOR OPEN

C533 through C633:

STEAM TEMP LOW

or

STEAM TEMP HARDWARE

or

PRESSURE LOW

Unit had loss of power

during cycle.

Power was interrupted

briey or an internal

glitch.

STOP button was pressed

during cycle.

STOP button was pressed

during cycle.

STOP button was pressed

during cycle.

Water level in

reservoir is too low.

Fill / Vent lter (in bottom

of chamber) is clogged.

Door latch safety switch is

still making contact after

door motor operated.

Sterilizer detects that door

safety switch contacts

opened.

Sterilizer detects that door

safety switch contacts

opened.

Sterilizer detects that door

safety switch contacts

opened.

Sterilizer detects that

temperature and / or

pressure is outside the

limits for normal

operation.

This chart continues on the following page...

Press STOP button to restart.

Unplug unit power cord for 1 minute and then plug

back in. If problem persists, contact an authorized

service representative. (see “Calling For Service”)

Press STOP button to restart.

Wait briey (up to one minute) while chamber pressure

/ temperature dissipates. Press STOP button to return

to select cycle mode where a new cycle may be

initiated.

Press STOP button to restart.

Rell water reservoir with distilled water, or water

that meets the referenced water purity specications.

Wait briey (up to one minute). Press STOP button to

return to select cycle mode where a new cycle may be

initiated.

Clean Fill / Vent lter.

(see “Monthly Maintenance”)

Open door.

Close the sterilizer door.

(Cycle will continue where left o.)