Page 1

Assembly

Instructions

Stools: Models 425 and 427

MODEL 425

(The above models are shown with optional items attached.)

MODEL 427

Introduction

These assembly instructions are intended to assist you

in assembling Midmark's Model #425 and #427 Stools.

Please follow these instructions to assure proper

assembly.

Unpacking

EQUIPMENT ALERT

To avoid damage, do not use a knife or any other

sharp object for opening cartons.

Assembly

Remove the stool from the carton. Depending on the

optional items that you purchased, assemble the stool

in the following order:

- Optional Lab Height Kit Assembly

- Optional Armrest Assembly

- Optional Backrest Assembly

- Seat Assembly

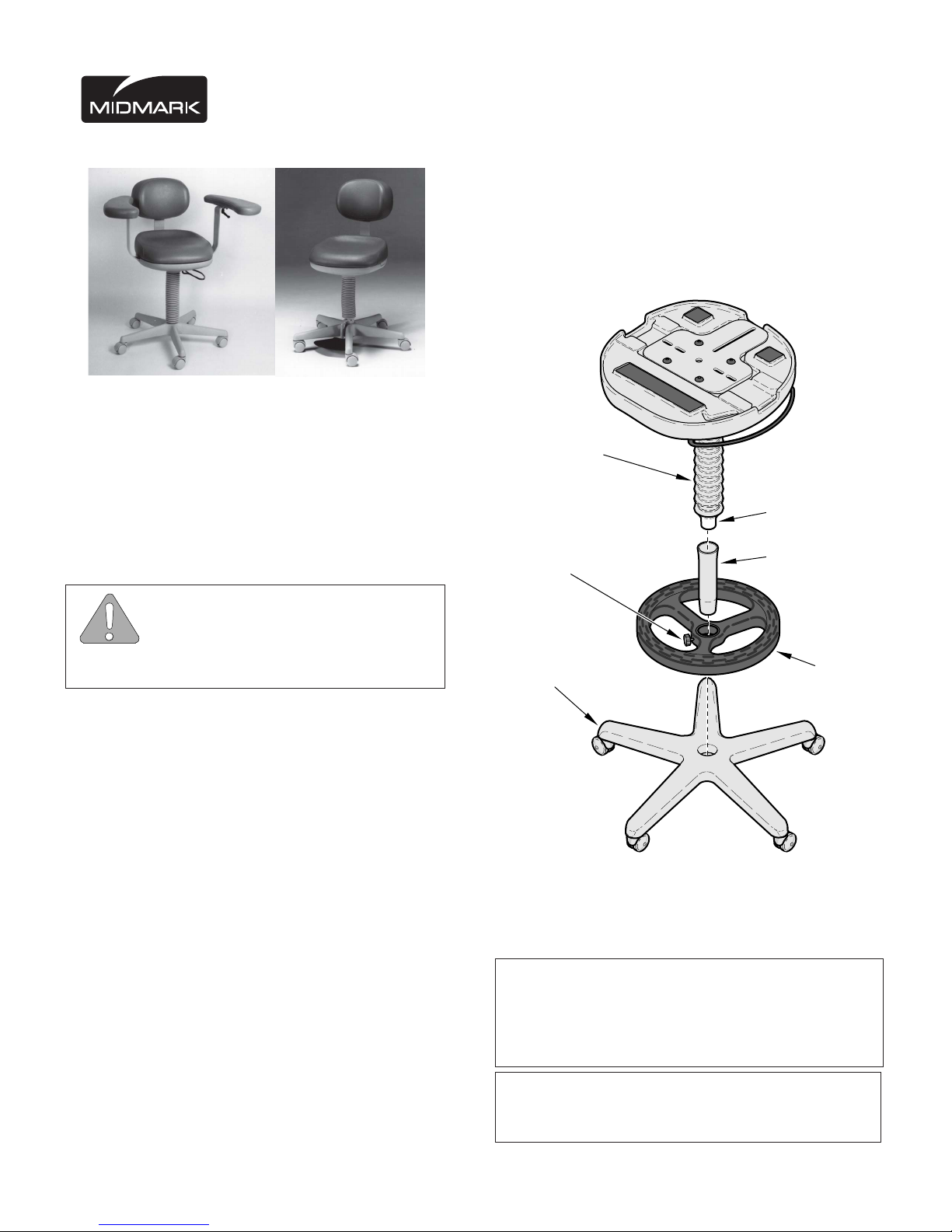

Optional Lab Height Kit Assembly

Place the base stool on its side. Remove the roller

base from the gas cylinder by using a hammer to pound

the roller base from the gas cylinder. To prevent

marking, use a piece of cardboard or wood over the

roller base before striking it. Strike as close to the gas

cylinder as possible and rotate to a different leg with

each blow. Insert extension tube thru the foot ring.

Tighten the knob firmly to prevent the foot ring from

rotating around the tube. Insert the gas cylinder into the

extension tube (see Figure 1). Finally, insert the

extension tube into the roller base.

Bellows

Gas Cylinder

Knob

Roller Base

FIGURE 1

Extension Tube

MA8374i

NOTE

If you have ordered a Lab Height Kit, please assemble the Lab Height Kit to the base stool first. We

suggest that no armrests or backrests be mounted to

the stool during the lab height assembly.

NOTE

The Lab Height Kit cannot be used on 427 Foot

Release Models.

Foot Ring

Sheet

4

1

of

Page 2

Armpad

Angular

Adjustment

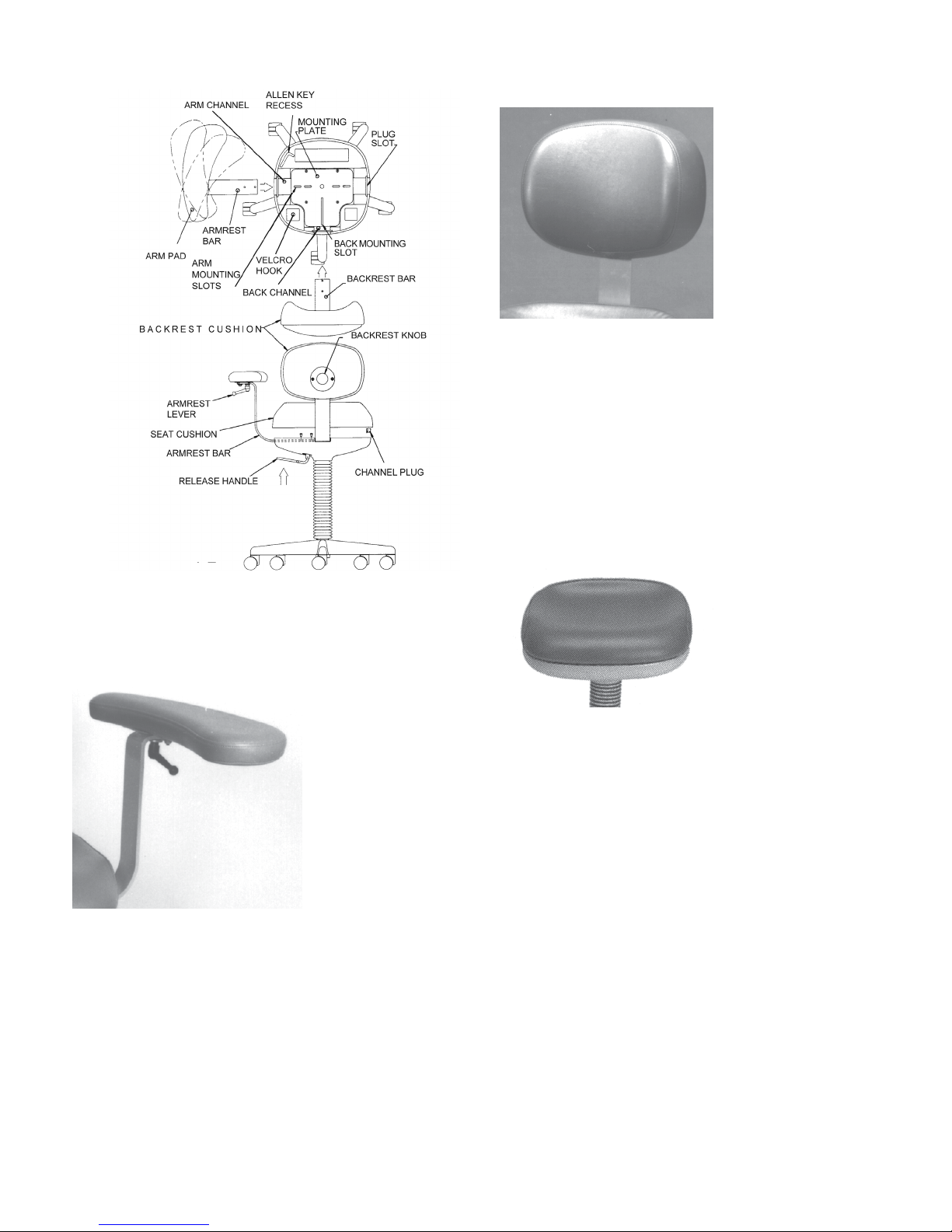

Optional Backrest Assembly

FIGURE 4

Insert the backrest bar into the back channel and under

the mounting plate (see Figure 2). Align the tapped

holes in the backrest bar with the back mounting slot in

the mounting plate. Using the supplied 5/32 Allen Key,

drive the two 1/4 - 20 x 3/8 screws through the mounting plate and into the backrest bar. Tighten the screws

and place the Allen Key into the Allen Key recess.

Seat Assembly

FIGURE 2

Optional Armrest Assembly

FIGURE 3

Insert the armrest bar into the arm channel and under

the mounting plate (see Figure 2). Align the two tapped

holes in the armrest bar with the two arm mounting

slots in the mounting plate. Using the supplied 5/32

Allen Key, drive the two 1/4-20 x 3/8 screws through the

mounting plate and into the armrest bar. Repeat the

above procedure with the other armrest. After tightening the last screw, place the Allen Key into the Allen Key

recess.

Insert the three channel plugs into the plug slots--if

FIGURE 5

needed (see Figure 2). You'll find the channel plugs in

the small parts bag.

Remove the seat cushion from its carton. Align the

three velcro patches on the bottom of the seat cushion

with the three velcro hook patches on the base stool.

Then, place the seat cushion onto the base stool. If the

cushion isn't centered on the base stool, pull the

cushion up and try again.

Sheet

4

2

of

Page 3

Adjustments

Height Adjustment of Stool

Lower the 425 stool by grasping the release handle,

(see Figure 2) and pull up. This will open the valve in

the gas cylinder. The weight of the operator will compress the gas in the cylinder allowing the stool seat to

lower. Once the desired height is reached, release the

handle. The handle will snap back to its original position locking the cylinder's vertical position.

To raise the stool, grasp the handle and pull up. While

holding the handle up, remove the operator's weight

from the stool top. By removing the weight from the

stool top, the compressed gas in the cylinder can exert

enough thrust to force the seat up to the desired

position. When the desired position is reached, release

the handle.

Cleaning

Upholstery

Wash your upholstery weekly with a mild liquid soap and

water mixture, rinse with clear water and dry completely to

remove disinfection cleaner build-up.

Disinfect your upholstery with a solution of standard bleach

and water mixed 1 in 10 (10%) or chlorine based cleaners.

Follow this with a clear water rinse and thorough drying of

material. See current CDC Guideline for Disinfection &

Sterilization in Healthcare Facilities.

To minimize damage caused by disinfectant cleaner residue

build-up, do not allow disinfectants to pool on the upholstery

surface. Once the approved contact time has been obtained,

remove and dry excess liquid remaining on the surface.

Detailed care and maintain instructions are available in your

user guide located on the CD that came with your table or by

referring to

Painted Metal / Plastic Surfaces

Upholstery Care and Maintenance.

In units with the foot release (Model 427), the valve in

the gas cylinder is opened and closed by the action of

the foot pedal instead of the release handle. The valve

is opened by pressing down on the pedal and is closed

by releasing the pedal.

Backrest Adjustment

The backrest has two adjustments: in-and-out and upand-down. Adjust in or out by removing the cushion

and loosening the two 1/4-20 x 3/8 screws with the

supplied 5/32 Allen Key. Position the backrest by

pushing or pulling the backrest bar at the base. Tighten

the two 1/4-20 x 3/8 screws when the desired position

is achieved.

Up-and-down adjustment is obtained by loosening the

backrest knob (turning counterclockwise) and lifting or

lowering the backrest cushion. When the desired

position is reached, tighten the backrest knob (turning

clockwise).

Armrest Adjustment

Each armrest has two adjustments: in-and-out and

angular. In-and-out adjustment is obtained by removing

the cushion and loosening the two 1/4-20 x 3/8 screws

using the supplied Allen Key. Position the armrest by

pushing or pulling the armrest bar at its base. When the

desired position is reached, tighten the two 1/4-20 x 3/8

screws on each arm.

Clean the painted metal and plastic surfaces weekly using a

clean soft cloth, and mild cleaner. Periodic applications of

common furniture wax will ease cleaning, and maintain the

finished luster of the surfaces.

Angular adjustment of the arm pad can be obtained by

turning the arm lever a half-turn in. Adjust the arm pad

to the desired angular position and turn the arm lever a

half-turn out to lock into place.

Sheet

4

3

of

Page 4

SCOPE OF WARRANTY

Midmark Corporation (“Midmark”) warrants to the original retail purchaser that

it will repair or replace components of the domestic and international medical

products manufactured by Midmark (except for components not warranted

under “Exclusions”) that are defective in material or workmanship under

normal use and service. Midmark’s obligation under this warranty is limited to

the repair or replacement, at Midmark’s option, of the applicable components.

This limited warranty shall only apply to defects that are reported to Midmark

within the applicable warranty period and which, upon examination by

Midmark, prove to be defective. This warranty extends only to the first retail

purchaser of a product and is not transferable or assignable.

APPLICABLE WARRANTY PERIOD

The applicable warranty period, measured from the date of delivery to the

original user, shall be one (1) year for all warranted product s and components.

OBTAINING WARRANTY SERVICE

Warranty service must be obtained through either Midmark or an authorized

dealer in the Midmark product line for which warranty service is requested.

Midmark may be contacted for warranty service inquiries or issues via email

at www.midmark.com; by phone at 1-800-MIDMARK; by facsimile at 1-800365-8631; or by mail to Midmark Corporation, 60 Vista Drive, V ersailles, Ohio

45380.

It is the retail purchaser’s obligation to arrange for delivery of a product to

Midmark or one of its authorized dealers for warranty service, which delivery

shall be at retail purchaser’s expense. It is also the retail purchaser’s

obligation to comply with the warranty service instructions provided either by

Midmark or its authorized dealer. The ret ail purchaser must provide Midmark

with completed warranty registration information within thirty (30) days after

purchase in order to obtain the benefits of this warranty .

EXCLUSIONS

This warranty does not cover, and Midmark shall not be liable, for the

following:

(1) defects, damage or other conditions caused, in whole or in part, by

misuse, abuse, negligence, alteration, accident, freight damage, tampering or

failure to seek and obtain repair or replacement in a timely manner;

(2) products which are not installed, used, and properly cleaned and

maintained as required in the Midmark “Installation” and/or “Installation/

Operation Manual” for the applicable product;

(3) products considered to be of a consumable nature;

(4) accessories or parts not manufactured by Midmark;

(5) charges by anyone for adjustments, repairs, replacement parts,

installation or other work performed upon or in connection with such products

which are not expressly authorized in writing in advance by Midmark;

(6) costs and expenses of routine maintenance and cleaning; and

(7) representations and warranties made by any person or entity other than

Midmark.

EXCLUSIVE REMEDY; CONSEQUENTIAL DAMAGES DISCLAIMER:

MIDMARK’S ONLY OBLIGATION UNDER THIS WARRANTY IS THE

REPAIR OR REPLACEMENT OF DEFECTIVE PARTS. MIDMARK SHALL

NOT BE LIABLE FOR AND HEREBY DISCLAIMS ANY DIRECT, SPECIAL,

INDIRECT , INCIDENTAL, EXEMPLARY OR CONSEQUENTIAL DAMAGES

OR DELAYS, INCLUDING, BUT NOT LIMITED T O, DAMAGES FOR LOSS

OF PROFITS OR INCOME, LOSS OF USE, DOWNTIME, COVER AND

EMPLOYEE OR INDEPENDENT CONTRACTOR WAGES, PAYMENTS AND

BENEFITS.

NO AUTHORIZATION

No person or firm is authorized to create or approve for Midmark any other

obligation or liability in connection with the products.

WARRANTY DISCLAIMER

THIS WARRANTY IS MIDMARK’S ONLY WARRANTY AND IS IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED. MIDMARK MAKES

NO IMPLIED WARRANTIES OF A N Y KIND INCLUDING ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. THIS WARRANTY IS LIMITED TO THE REPAIR OR REPLACEMENT OF DEFECTIVE PARTS.

STATUTE OF LIMITATIONS

No action may be brought against Midmark for breach of this limited warranty,

an implied warranty, if any, or for any other claim arising out of or relating to

the products, more than ninety (90) days following expiration of the limited

warranty period.

Midmark Corporation

60 Vista Drive

P .O. Box 286

Versailles, OH 45380-0286

1-800-MIDMARK

Fax 877-249-1793

www.midmark.com

© Midmark Corporation - 1995

003-0458-00 Rev. J (8/15)

Sheet

4

4

of

Loading...

Loading...