Midmark 416-001, 416-002 Parts Manual

416

-001 thru -002

Power Podiatry Examination Chair

Serial Number Prefixes:

BN & V

Service and

Parts Manual

416

-001

thru

-002

FOR USE BY MIDMARK TRAINED TECHNICIANS ONLY

SF-1428 Part No. 003-0708-00 Rev. P (4/04/08)

TABLE OF CONTENTS

Section/Paragraph Page Section/Paragraph Page

IMPORTANT INSTRUCTIONS

General Safety Instructions......................................... ii

Warnings ..................................................................... ii

Warranty Instructions .................................................. ii

SECTION I GENERAL INFORMATION

1.1 Scope of Manual ......................................... 1-1

1.2 Description of 416 Power Podiatry

Examination Chair .................................... 1-1

1.3 Specifications ............................................. 1-5

1.4 Parts Replacement Ordering ....................... 1-5

1.5 Special Tools .............................................. 1-6

SECTION II TESTING AND TROUBLESHOOTING

2.1 Operational Test .......................................... 2-1

2.2 Troubleshooting Procedures ........................ 2-3

SECTION III SCHEDULED MAINTENANCE

3.1 Scheduled Maintenance .............................. 3-1

SECTION IV MAINTENANCE/SERVICE

INSTRUCTIONS

4.1 Introduction ................................................. 4-1

4.2 Reinitialization Procedure ............................ 4-1

4.3 Table Top Removal / Installation ................. 4-1

4.4 Shrouds Removal / Installation .................... 4-2

4.5 Control Disable Switch Removal /

Installation ............................................... 4-3

4.6 Hand Control Plug-In Port Removal /

Installation ............................................... 4-3

4.7 PC Control Board / Program PC Board

Removal / Installation .............................. 4-4

4.8 Actuator Motor / Actuator Brake

Removal / Installation .............................. 4-5

4.9 Tilt Actuator Assembly Removal /

Installation ............................................... 4-6

4.10 Tilt Capacitor Removal / Installation ............ 4-7

4.11 Back Actuator Assembly Removal /

Installation ............................................... 4-8

4.12 Back Capacitor Removal / Installation ......... 4-9

4.13 Arm Rest Adjustment ................................ 4-10

4.14 Foot Extension Brake Lever Adjustment ... 4-11

4.15 Hand Control Panel Or Interface Board

Removal / Installation ............................ 4-11

4.16 Plastic Foot Section Removal /

Installation ............................................. 4-12

4.17 Plastic Back Section Removal /

Installation ............................................. 4-12

4.18 Plastic Seat Section Removal /

Installation ............................................. 4-13

4.19 Foot Extension Removal /

Installation .............................................. 4-15

SECTION V SCHEMATICS AND DIAGRAMS

5.1 Electrical Schematics / Wiring Diagrams ..... 5-1

5.2 Audible Signal Guide Chart ......................... 5-4

SECTION VI PARTS LIST

6.1 Introduction ................................................. 6-1

6.2 Description of Columns ............................... 6-1

Pictorial Index ............................................. 6-2

Upholstery Set (Standard) .......................... 6-3.*

Back Section Components ......................... 6-4.*

Seat Section Components ........................... 6-5

Actuator Assembly .................................... 6-6.*

Foot Section Components ........................... 6-7

Upper Chair Electrical Components ........... 6-8.*

Fixed Base Assembly ................................ 6-9*

Hand Control Accessory............................ 6-10

COMMENTS ............................................................ 7-1

FAX ORDERING FORM .......................................... 7-2

(*) Indicates that there has been a serial number break for the illustration

and that there are additional point page(s) following the original page.

© Midmark 1994 SF-1428 Rev. 12/03 Printed in U.S.A.

Page i

IMPORTANT INSTRUCTIONS

General Safety Instructions

Safety First: The primary concern of Midmark

Corporation is that this examination chair is main-

tained with the safety of the patient and staff in mind.

To assure that services and repairs are completed

safely and correctly, proceed as follows:

(1) Read this entire manual before performing any

services or repairs on this chair.

(2) Be sure you understand the instructions

contained in this manual before attempting to

service or repair this chair.

Warnings

Throughout this manual are Note, Caution, and Danger

paragraphs that call attention to particular procedures.

These items are used as follows:

NOTE

A note is used to amplify an operating procedure,

practice or condition.

Warranty Instructions

Refer to the Midmark “Limited Warranty” printed on the

back cover of the Installation and Operation Manual for

warranty information. Failure to follow the guidelines

listed below will void the warranty and/or render the 416

Power Podiatry Examination Chair unsafe for operation.

• In the event of a malfunction, do not attempt to

operate the chair until necessary repairs have been

made.

• Do not attempt to disassemble chair, replace malfunctioning or damaged components, or perform

adjustments unless you are one of Midmark’s

authorized service technicians.

• Do not substitute parts of another manufacturer

when replacing inoperative or damaged components.

Use only Midmark replacement parts.

CAUTION

!!

not correctly followed, could result in equipment

damage.

A CAUTION is used for an operating

procedure, practice, or condition which, if

DANGER

!!

which, if not correctly followed, could result in

loss of life or serious personal injury.

A DANGER is used for an operating

procedure, practice, or condition

© Midmark 1994 SF-1428 Page ii Printed in U.S.A.

SECTION I

GENERAL INFORMATION

SECTION I

GENERAL INFORMATION

1.1 Scope of Manual

This manual contains detailed troubleshooting, scheduled maintenance, maintenance, and service instructions for 416 Power Podiatry Examination Chair. This

manual is intended to be used by Midmark’s authorized

service technicians.

1.2 Description Of 416 Power Podiatry

Examination Chair

A. General Description

The 416 Power Podiatry Examination Chair is an

examination chair designed specifically for performing

general podiatric examinations and minor podiatric

procedures (Podiatry - treatment of foot ailments).

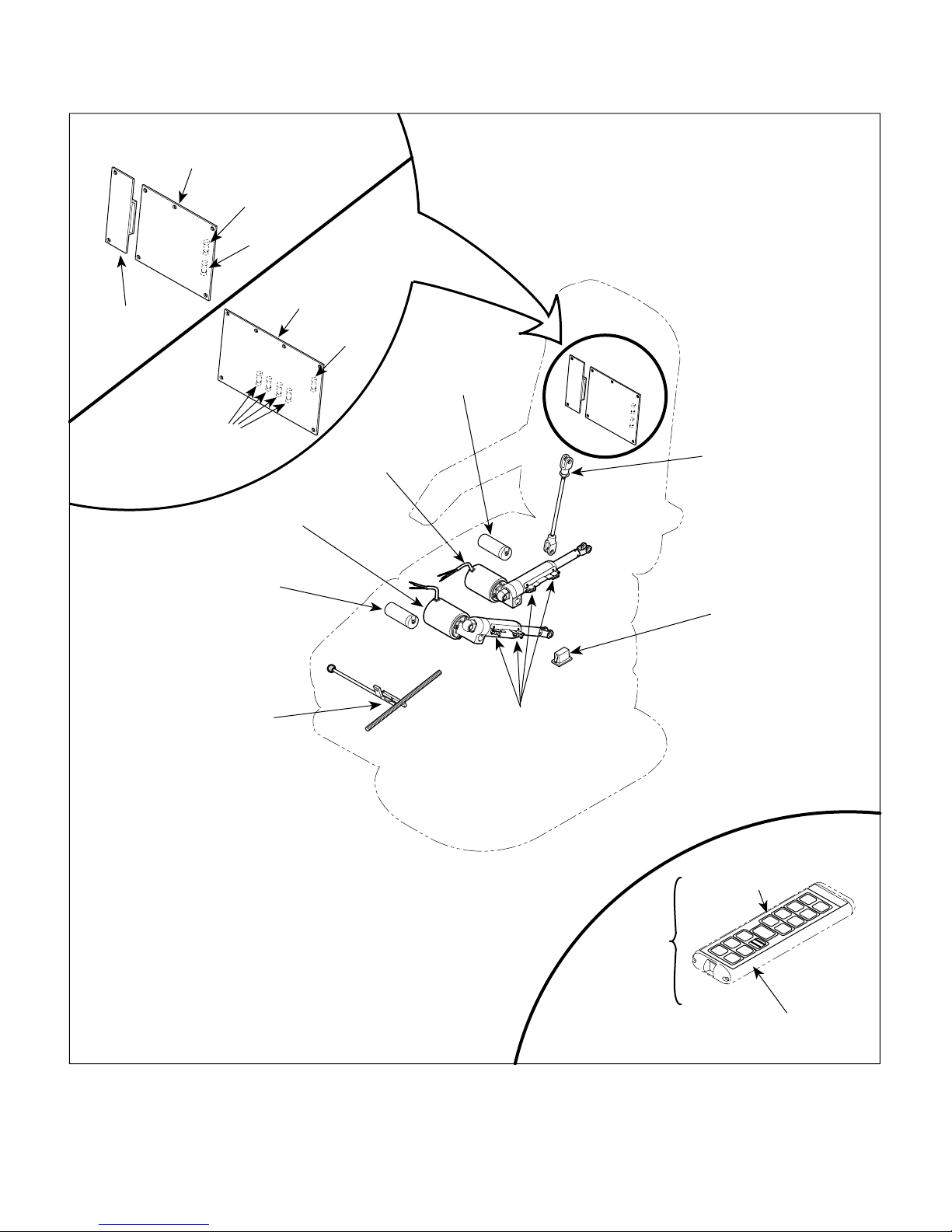

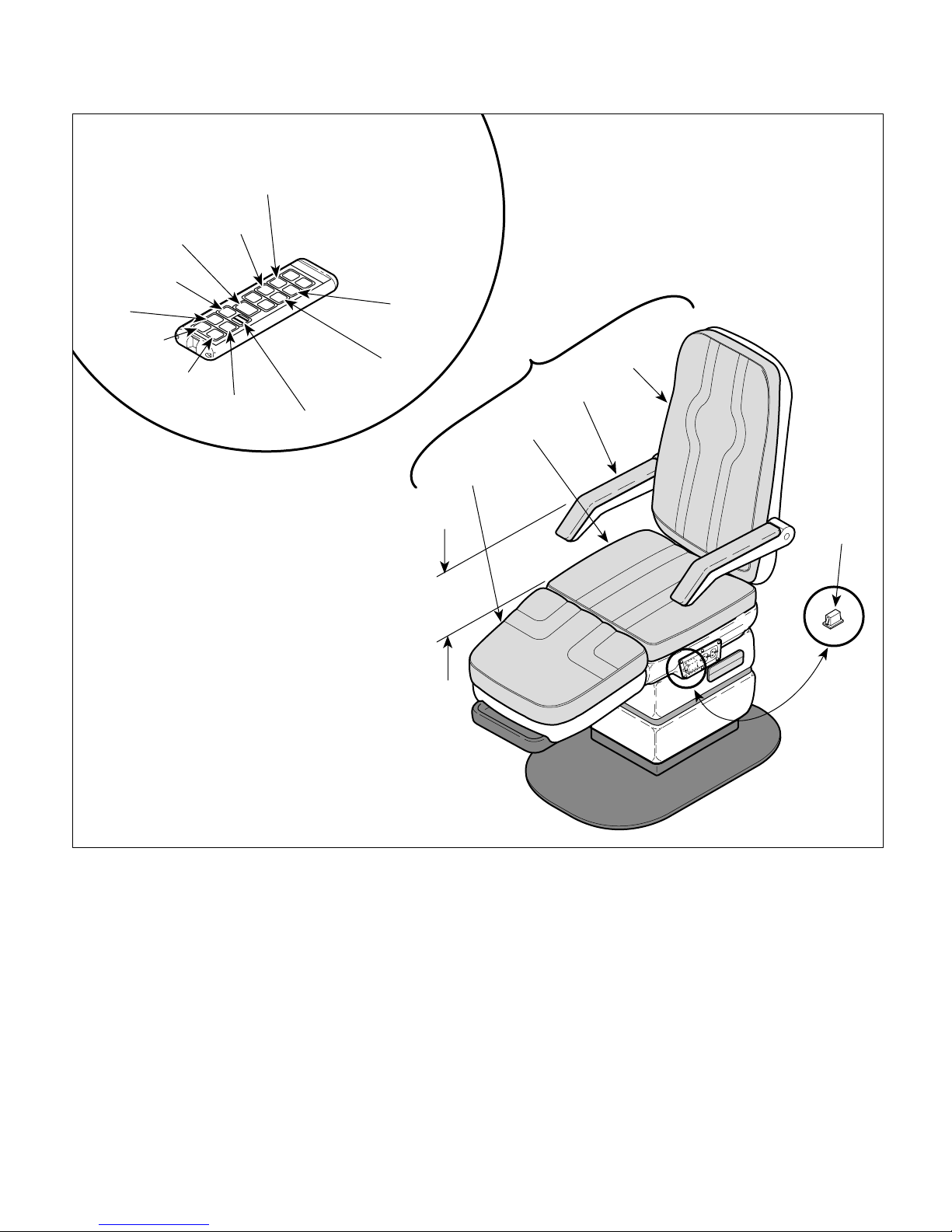

B. Major Serviceable Components (See Figure 1-1).

The major serviceable components of the chair are the

arm casting linkage assembly, back actuator capacitor,

back actuator assembly, tilt actuator capacitor, tilt

actuator assembly, foot extension brake assembly, PC

control board, PC program board (a new style PC control

board is now being used which combines the PC control

board and PC program board together into one board),

0.5 amp fuse & 20 amp fuse for old style PC control

board or 0.125 amp & 5 amp fuse for new style PC

control board, control disable switch, hand control which

includes hand control panel and hand control interface

board.

C. Theory of Operation (See Figures 5-1 thru 5-3 for

electrical schematic / wiring diagram)

115 VAC is supplied directly to the PC control board and

to the two electrical outlets.

Power:

Line voltage is supplied to the the fuses on the PC

board.

The old style board has one (1) each 20 amp and 0.5

amp fuse.

The newer style board has four (4) 5 amp and one (1)

0.125 amp fuses.

This current is applied to one side of the Normally Open

contacts of the Actuator relays on the PC board.

There are two relays per actuator assembly; one for

each direction.

There are two relays on the PC control board for a foot

actuator assembly and two relays for a base actuator

assembly, which are not used by the 416 model.

115 VAC is also applied across the 0.5 amp fuse or

0.125 amp fuse, depending on version of PC board to

the transformer. The transformer and some associated

circuitry reduce the 115 VAC to a +5 VDC output and

+12 VDC output. Both voltages are used to power

circuitry on the PC control board and PC program board.

The newer PC board, has a green "

L.E.D.

".

BOARD FAIL

• If the L.E.D. is flashing, normal operation is being

indicated.

• If the L.E.D. is not flashing, the PC control board is

malfunctioning.

• Loss of power or blown fuses can also cause the

green L.E.D. to not flash.

Actuators:

• On older units (before SN BN3404) both Back and Tilt

actuators contain a pivot point on the end of the ball

screw. If an actuator is run to the end of its stroke

(mechanical home position), the ball screw shaft spins

inside the nut, allowing the actuator to run without

damaging or advancing the nut.

• On present units (after SN BN3403) both the Back and

Tilt actuators have limit switches to prevent overextending or retracting the actuator. Should the actuator

reach the maximum extended or minimum retracted

travel the specific limit switch contacts will Open,

removing power from the actuator motor. This prevents

the actuator from over-extending or over-retracting.

• All the actuator motors have a normally closed,

thermal overload switch which will open if the actuator

assembly is run continuously and overheats.

The actuator motor was not designed for continuous

operation. The normal cool off period for the thermal

overload switches is 10 - 20 minutes.

Normal Operation:

Pressing a function key on the hand control sends a

signal to the PC control board. The PC control board

energizes the relay, closing the Normally Open contacts

of the selected function.

Current is now applied to the actuator assembly motor

causing the actuator assembly to run.

There is a diagnostic L.E.D. in each relay circuit. When

a relay coil is energized, the related L.E.D. illuminates,

indicating that there is power at the relay's coil and the

PC control board is working properly.

© Midmark 1994 SF-1428 Rev.12/03 Page 1-1 Printed in U.S.A.

SECTION I

GENERAL INFORMATION

PC CONTROL

PC PROGRAM

BOARD

BOARD

(1) FUSE

(0.5 Amp.)

(1) FUSE

(20 Amp.)

(4) FUSE

(5 Amp.)

TILT ACTUATOR

ASSEMBLY

TILT ACTUATOR

CAPACITOR

OLD STYLE

NEW STYLE

PC CONTROL

BOARD

(1) FUSE

(0.125 Amp.)

BACK ACTUATOR

ASSEMBLY

BACK ACTUATOR

CAPACITOR

ARM CASTING

LINKAGE ASSEMBLY

CONTROL

DISABLE

SWITCH

FOOT EXTENSION

BRAKE ASSEMBLY

LIMIT

SWITCHES

(NEWER UNITS)

Figure 1-1. Major Components

HAND

CONTROL

HAND CONTROL

PANEL

B

AC

U

P

T

I

U

T

P

F

T

O

O

D

IL

OW

U

P

F

O

D

O

O

T

W

S

O

A

R

U

TU

R

E

T

O

P

TIO

P

TIO

OSI

OSI

1

P

P

TIO

TIO

OSI

OSI

2

3

P

TIO

OSI

4

HAND CONTROL

INTERFACE BOARD

MIDMARK

T

A

BL

U

P

T

A

D

OW

B

A

D

C

O

K

W

T

MA257201i

B

L

E

© Midmark 1994 SF-1428 Rev. 12/03 Page 1-2 Printed in U.S.A.

SECTION I

GENERAL INFORMATION

When the PC control board receives a function signal

from a hand control, the microprocessor on the PC

control board does several things;

• It monitors the current draw of the running actuator

assembly motor (this is important because different

patient loads affect the amount of current drawn by the

motor as well as its speed - meaning monitoring current

draw can let the PC control board calculate an actuator

assembly's speed).

• The PC control board also keeps track of how long an

actuator assembly's relay has been energized (how long

actuator assembly motor has been running). By comparing the current draw of the running actuator motor and

the time period that an actuator assembly's relay has

been energized, against an on-board data base, the PC

control board can determine how far, in its range of

motion, an actuator assembly has traveled. The PC

control board records this positional information in its

memory. The PC control board continuously calculates

an actuator assembly's position and stores that information in memory for future use.

• If the current draw of an actuator assembly exceeds a

predetermined level for more than 0.5 seconds, the PC

control board shuts down the actuator assembly, until

the button is released and depressed again.

• When an operator selects a function, the PC control

board calculates the maximum run time that it will take

the actuator assembly to reach the end of its travel

range.

• If the operator holds down the function button longer

than the maximum run time, the PC control board will

de-energize the relay of the actuator assembly when the

maximum run time is reached, causing the actuator

assembly motor to stop running. This prevents excessive wear on an actuator assembly due to a switch

sticking or an operator continuously holding down a

function switch.

• When a function (this is true for only for a few of the

functions) is reselected, after its actuator assembly has

been stopped by the PC control board because it

reached its maximum run time, the PC control board will

allow the actuator assembly to run for 2 seconds before

de-energizing its relay.

This allows the mechanical "home" position of the

actuator assembly to be synchronized with the PC

control board's software "home" position.

Programmed Positions:

The operator positions the chair into a position he/she

would like to store into memory.

• When the PROGRAM button is pressed and held for

0.2 seconds for old style PC control board or 1 second

for new style PC control board, the PC control board is

in program mode and is ready to store a position into

memory.

• Then, when one of the four program position buttons

("1", "2", "3", or "4") on the hand control is pressed, the

position of the chair is stored into the PC control board's

memory. The operator has five seconds in which to

select a programmed position button. After five seconds, the PC control board cancels the program mode.

• Also, if any buttons other than the program position

buttons "1", "2", "3", or "4" are pressed, the program

mode is canceled.

• The PC control board stores the chair's position which

has been calculated and stored in the PC control boards

memory as described in the "normal operation" of a

function.

• When an operator presses a programmed position

button, the PC control board determines which functions

need to move and energizes the relays for the actuator

assemblies of those functions.

• The PC control board uses the method described in

"normal operation" to determine when an actuator

assembly of a function has reached its programmed

position.

• When an actuator assembly of a function reaches its

position, its relay is de-energized. This continues until

all actuator assemblies of affected functions have

reached their position.

• If the operator wishes to stop the chair, for any reason,

before all functions have reached their programmed

position, the STOP button may be pressed.

• When the STOP button is pressed, the PC control

board immediately de-energizes all relays, causing the

chair to stop. The STOP button overrides all other

commands.

• When a programmed position button is selected, it can

be pressed and then released; it does not need to be

held down.

• However, there is a selector switch; S1 on the old

style PC control board and SW2-4 on new style PC

control board, that can be switched to change this.

Then the programmed position button must be pressed

and held until the chair reaches its programmed position;

if the button is released, the chair will stop moving.

• The switch (S1) works as follows:

When the switch S1 is pushed in, the programmed

position button can be pressed and released.

When the switch S1 is pulled out, the programmed

position button must be pressed and held.

• The Switch SW2-4 works as follows:

When switch is ON, programmed position buttons can

be pressed and released.

When switch SW2-4 is OFF, programmed position

buttons must be pressed and held.

© Midmark 1994 SF-1428 Rev. 12/03 Page 1-3 Printed in U.S.A.

SECTION I

GENERAL INFORMATION

Auto Return Function Operation:

When the operator presses the AUTO RETURN button,

the PC control board determines which functions need to

move and energizes the relays for the actuator assemblies of those functions. The PC control board uses the

method described in "normal operation" to determine

when an actuator assembly of a function has reached

the mechanical home position. When an actuator

assembly of a function reaches its home position, its

relay is de-energized. This continues until both actuator

assemblies have reached their mechanical home

position.

The PC control board adds a slight overrun time to each

function during the AUTO RETURN mode to ensure both

actuator assemblies reach their mechanical home

position and freewheel. This allows the mechanical

"home" position of the actuator assemblies to be

synchronized with the PC control board's software

"home" position, which is important if correct program

positioning of chair is to be achieved.

If the operator wishes to stop the chair for any reason,

before all functions have reached their programmed

position, the STOP button may be pressed. When the

STOP button is pressed, the PC control board immediately de-energizes all relays, causing the chair to stop.

The STOP button overrides all other commands.

Re-initialization:

If a PC control board loses power for approximately 3

days or longer, the chair must be re-initialized. If the

chair does not move to correct programmed positions

even after an AUTO RETURN has been initiated, the PC

control board probably needs re-initialized. To reinitialize the PC control board, the PROGRAM, POSITION "1", and POSITION "2" buttons on the hand

control must be pressed and held for at least 2 seconds.

The PC control board makes all buttons inactive, except

for the AUTO RETURN button and STOP button. The

AUTO RETURN button should now be pressed which

will cause the chair to run each actuator assembly to its

mechanical home position. The reinitialization procedure must be fully completed before normal operation of

the chair can be resumed. The reinitialization routine

takes approximately 18 seconds to complete.

General Information:

A capacitor is in each actuator assembly circuit. The

capacitor provides start up power and run power for the

actuator motor.

The PC control board constantly monitors the control

disable switch for +12 VDC. If 0.0 VDC is detected (the

control disable switch is ON, meaning the chair is

disabled), the PC control board disables the relays of all

functions and removes power from the foot control or

hand control. If +12 VDC is detected (the control

disable switch is OFF, meaning the chair is enabled),

the PC control board operates normally. The control

disable switch is located under the left electrical outlet.

This function allows the controls to be disabled, preventing unauthorized personnel from operating the chair,

such as a patient.

The maximum number of buttons that can be pressed at

one time is three; if any more than three buttons are

pressed at one time, the PC control board forces the

STOP function to be executed.

There is either a capacitor or a battery on the old style

PC control board that provides power to retain the

board's memory. The PC control board will retain its

memory for approximately 3 days. On new style PC

control boards, there is a EEPROM chip which retains

the board's memory indefinitely.

Audible Alert Tones: (See Table 5-1)

The new style PC control board has audible tones to

provide feedback to the operator. SW2-1 controls

whether the tones are activated or deactivated; if SW2-1

is ON, tones are activated. If SW2-1 is OFF, tones are

deactivated.

© Midmark 1994 SF-1428 Rev. 12/03 Page 1-4 Printed in U.S.A.

SECTION I

GENERAL INFORMATION

1.3 SPECIFICATIONS

Factual data for the 416 Power Podiatry Examination

Chair is provided in Table 1-1.

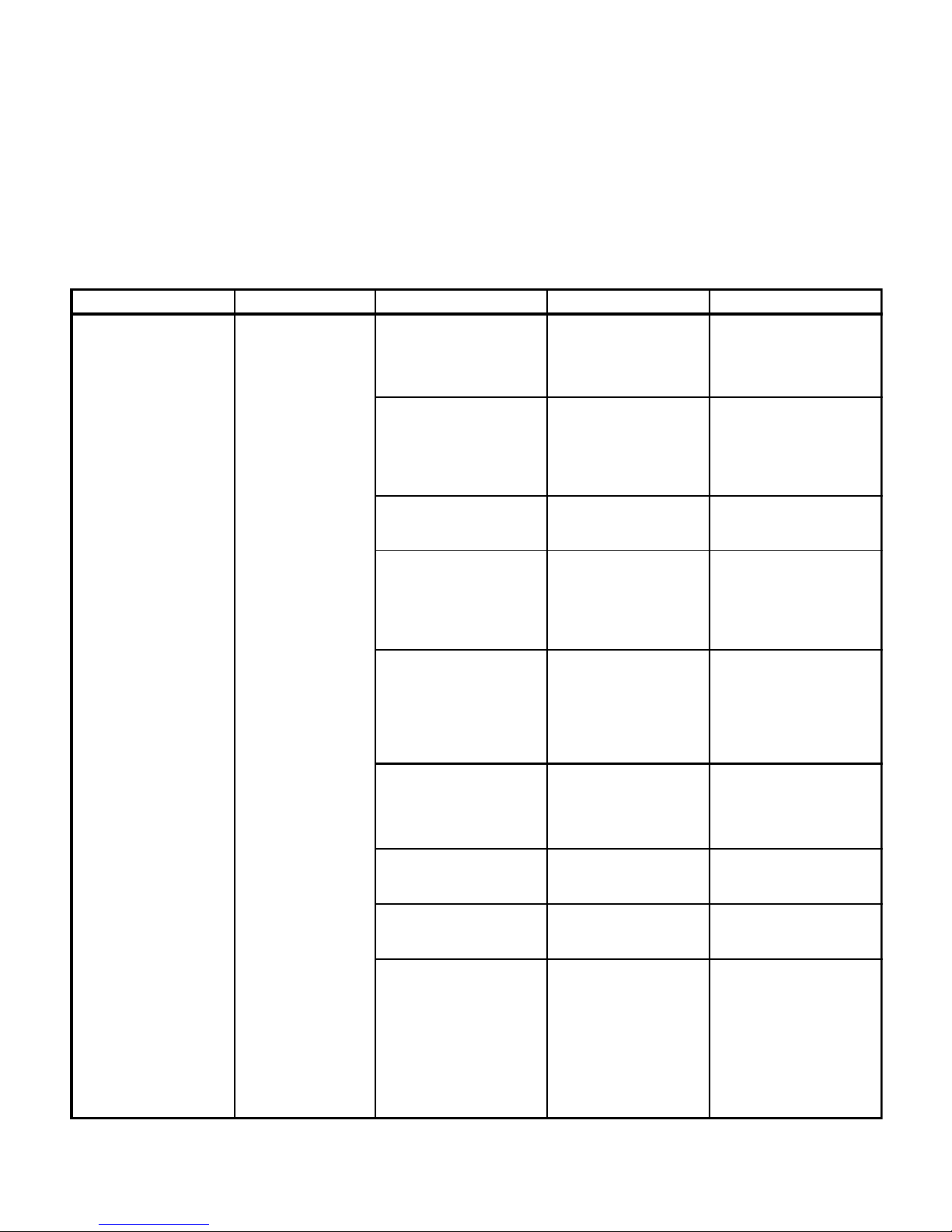

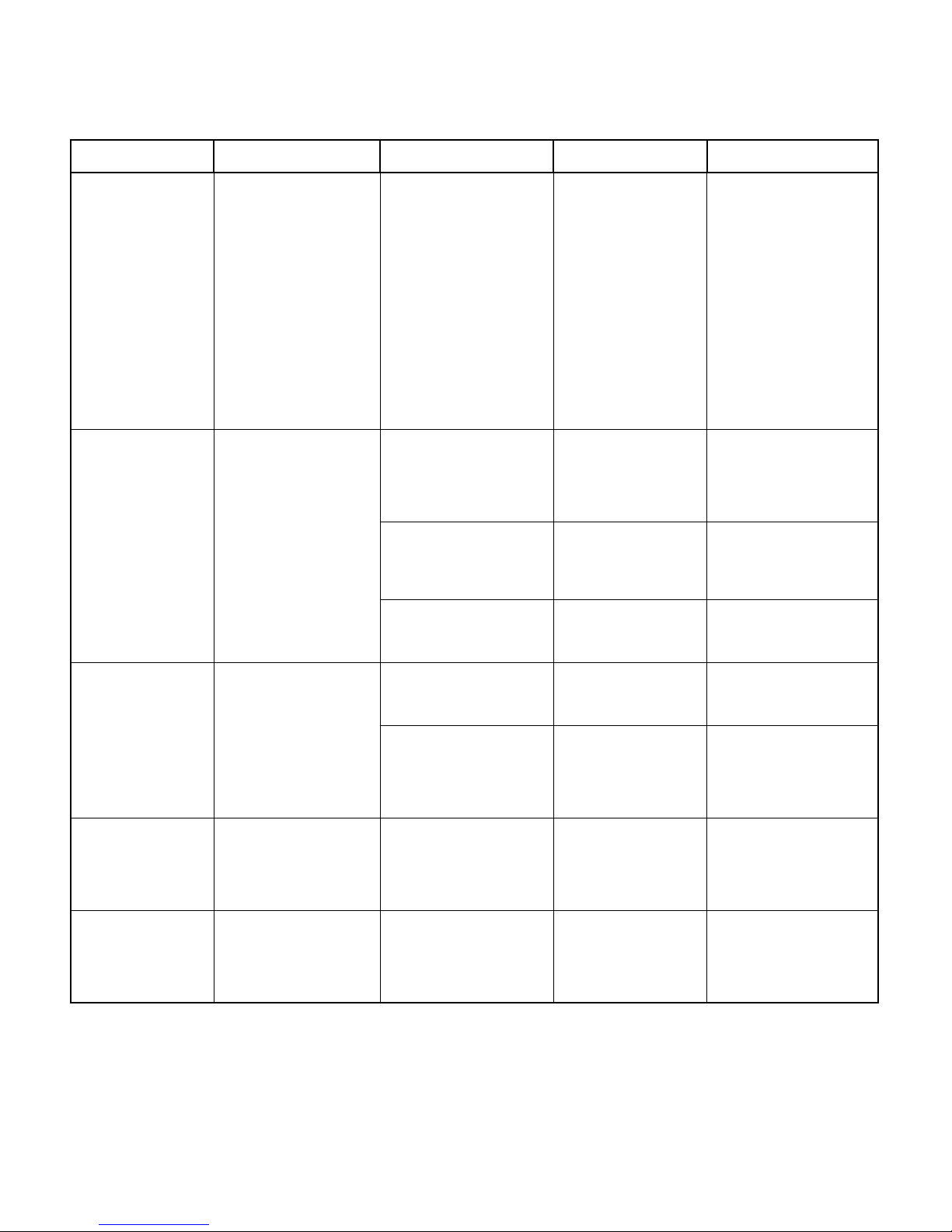

Table 1-1. Specifications

Description Data

Weight:

Without Shipping Carton ................. 500 lb (226.8 kg)

With Shipping Carton ...................... 550 lb (249.5 kg)

Shipping Carton ...... 76 in. "L" x 35 in. "W" x 36 in. "H"

(193 cm x 88.9 cm x 91.4 cm)

Dimensions:

Table Top Length .............................. 70 in. (177.8 cm)

Table Top Length with foot

section fully extended .............. 78 11/16 in. (199.9 cm)

Table Top Width (including arms) ... 28 1/8 in. (71.4 cm)

Chair Positioning:

Table Top Height (Fixed) .................. 22.5 in. (57.2 cm)

Back Down to Back Up .................................. 16° - 83°

Tilt Down to Tilt Up ......................................... 0° - 30°

Recommended Circuit:

A separate (dedicated) circuit is recommended for

this chair. The chair

should not

be connected to an

electrical circuit with other appliances or equipment

unless the circuit is rated for the additional load.

1.4 Parts Replacement Ordering

If a part replacement is required, order the part directly

from the factory as follows:

(1) Refer to Figure 1-2 to determine the location of

the model number and serial number of the chair

and record this data.

(2) Refer to the Parts List to determine the item

numbers of the parts, part numbers of the parts,

descriptions of the parts, and quantities of parts

needed and record this data (Refer to para 6.1).

Chair Speed:

Back Down to Back Up ............................... 8 seconds

Tilt Down to Tilt Up ..................................... 8 seconds

Debris Tray ......................... Extends 8 3/4 in (22.2 cm)

beyond foot section

Minimum Height at foot

section w/o tilt ............................... 19.5 in. (49.5 cm)

Maximum Height at foot

section with maximum tilt ............ 36 3/4 in. (93.3 cm)

Maximum Height at foot

section with maximum tilt,

and foot section fully extended .. 39 1/2 in. (100.3 cm)

Weight Capacity (Normal Operation) ...... 300 lb (136 kg)

Weight Capacity (Overweight

Operation) ............................................... 350 lb (159 kg)

Electrical Requirements:

115 VAC Unit ............................ 110 - 120 VAC, 60 HZ,

15 amp, single phase

Power Consumption:

115 VAC Unit ......................................... 1440 WATTS,

12 amps @ 120 VAC

MODEL

NUMBER

MIDMARK

MODEL

INPUT

RATING

SERIAL NO.

115 VAC 60 HZ

416

12 AMP

BNXXXXX

MIDMARK

M

O

DEL

INPU

RATING

SERIAL NO

T

115 VAC

.

417

12 AMP

60 H

BPXXXXX

Z

SERIAL

NUMBER

416

MIDMARK

MA2476-01

Figure 1-2. Model Number / Serial

Number Location

NOTE

Ask the Purchasing Department of the company that

owns the chair for this information. Otherwise, this

information may be obtained from the dealer that sold

the chair.

(3) Determine the installation date of the chair and

record this data.

(4) Call Midmark with the recorded information and

ask for the Medical Products Technical Services Department. See back cover of this

manual for the phone number or use the Fax

Order Form (See page 7-2 for Fax Order Form).

© Midmark 1994 SF-1428 Rev. 8/07 Page 1-5 Printed in U.S.A.

SECTION I

GENERAL INFORMATION

1.5 Special Tools

Table 1-2 lists all of the special tools needed to repair the chair, how to obtain the special tools, and the purpose of each

special tool.

Table 1-2. Special Tool List

Description of Special Tool

Multimeter Commercially Available Any Type Used to perform continuity and voltage checks.

Torque Wrench Commercially Available Any Type Used to tighten hardware to specified torque

Manufacturer's

Name / Address / Phone

Manufacturer's

Part Number

Purpose of Special Tool

values.

© Midmark 1994 SF-1428 Rev. 12/03 Page 1-6 Printed in U.S.A.

TESTING AND TROUBLESHOOTING

!

SECTION II

TESTING AND TROUBLESHOOTING

SECTION II

2.1 Operational Test (See Figure 2-1)

In order to effectively diagnose the malfunction of the

chair, it may be necessary to perform an operational test

as follows:

DANGER

Refer to the Operator Manual for

complete instructions on operating the

chair. Failure to do so could result in personal

injury.

NOTE

The Operational Test, for the most part, only describes what should happen when the chair is operated. If the chair does something other than described, a problem has been discovered. Refer to the

Troubleshooting Guide to determine the cause of the

problem and its correction.

(1) Plug the chair into a grounded, non-isolated,

correctly polarized outlet that has the proper

voltage output for the chair.

NOTE

To disable the chair, the control disable switch must

be thrown toward foot end of chair.

(2) Switch the CONTROL DISABLE switch to the

disable position (See Figure 2-1).

(7) Observe. The table top should move in the

direction corresponding to the button which is

being depressed. Each function should have

the following range of motion:

TILT DOWN to TILT UP - 0° to 30°

BACK DOWN to BACK UP - 16° to -83°

Function speeds should be as follows:

BACK DOWN to BACK UP - 8 seconds

TILT DOWN to TILT UP - 8 seconds.

When an actuator assembly reaches its limit,

the PC control board or limit switches should

automatically stop the function from freewheeling after a short time. The arm rests should be

parallel with the seat section of the table top

when the back section is all the way up.

(8) Depress the AUTO RETURN button. After the

table top starts to move, depress the STOP

button.

(9) Observe. When the AUTO RETURN button is

depressed, the table top should begin to move.

When the STOP button is depressed, the table

top should stop moving.

(10) Depress the AUTO RETURN button and allow

the table top to move to its home position

completely.

(3) Depress BACK UP, BACK DOWN, TILT UP,

and TILT DOWN buttons on hand control.

(4) Observe. No functions should operate.

NOTE

To enable the chair, the control disable switch must

be thrown toward head end of chair.

(5) Switch the CONTROL DISABLE switch to

enable position.

(6) Depress BACK UP, BACK DOWN, TILT UP,

and TILT DOWN buttons on hand control and

run each function to its limit.

© Midmark Corporation 1994 SF-1428 Rev.12/03 Page 2-1 Printed in U.S.A.

(11) Observe. The table top should move until it

reaches the home position. The entire routine

should take approximately 18 seconds to

complete.

(12) Depress the PROGRAM button on hand control

- one second for new style board and 0.2

seconds for old style board.

NOTE

A program position button must be depressed within 5

seconds of depressing the PROGRAM button.

(13) Depress the POSITION "1" button.

SECTION II

TESTING AND TROUBLESHOOTING

HAND CONTROL BUTTONS

BACK

UP

TILT

STOP

AUTO

RETURN

POSITION

"1"

POSITION

"3"

POSITION

"4"

UP

A

R

U

E

T

T

O

U

R

N

POSITIO

POSITION

1

N

POSITION

POSITION

3

2

POSITION

4

POSITION

"2"

F

O

O

U

P

STOP

B

A

C

U

K

P

T

ILT

D

U

P

T

D

ILT

O

T

W

N

F

O

D

O

O

T

W

N

PROGRAM

MIDMARK

T

A

B

U

L

E

P

T

A

D

B

O

L

W

E

N

B

A

C

O

K

W

N

BACK

DOWN

TILT

DOWN

FOOT

SECTION

TABLE

TOP

SEAT

SECTION

BACK

SECTION

ARM

REST

PARALLEL

Figure 2-1. Operational Test

MIDMARK

CONTROL

DISABLE

SWITCH

416

MA2474-01

© Midmark Corporation 1994 SF-1428 Page 2-2 Printed in U.S.A.

SECTION II

TESTING AND TROUBLESHOOTING

(14) Use any of the single function buttons to move

the table top to a new position.

(15) Depress the POSITION "1" button.

(16) Observe. The table top should move back to

the position programmed in steps 12 and 13.

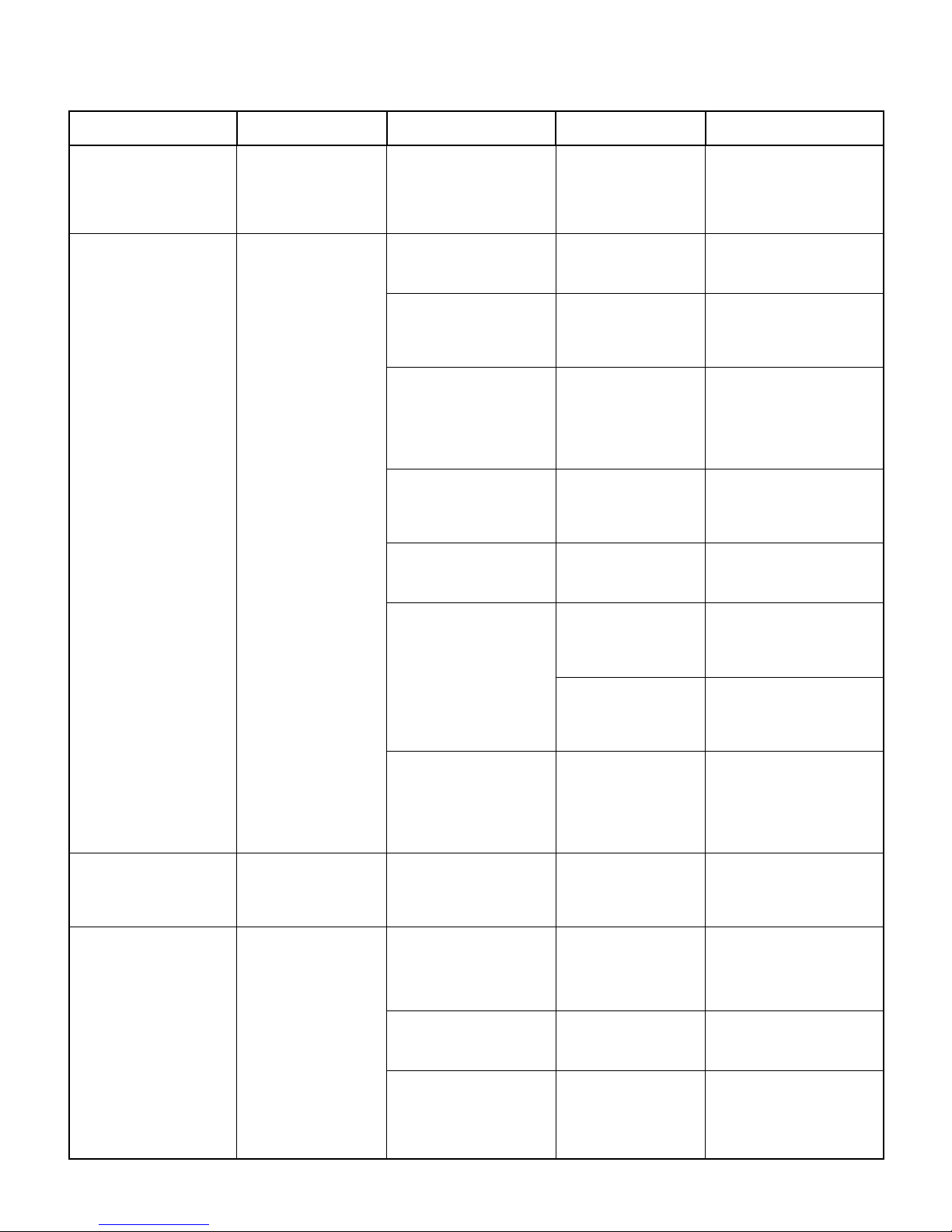

Table 2-1. Troubleshooting Guide

Problem Symptom Probable Cause Check Correction

Chair will not operate when

any of the four up and down

functions, program function,

or auto return function are

selected.

When a hand control

button is depressed, its

actuator does not run

or hum.

Power cord is not plugged

into facility wall outlet.

Control disable switch is

turned to "OFF" position.

Control disable switch is

malfunctioning.

Facility circuit breaker

providing power to chair is

tripped.

Wire connections loose. Check all wiring

0.5 amp fuse or 20 amp fuse

on old style PC control board

or 0.125 amp fuse on new

style PC control board is

blown.

The supply voltage for the

PC control board is below

normal limits.

PC control board is locked

up and needs to be

reinitialized.

PC control board is

malfunctioning.

(17) Repeat steps 12 thru 16 for the POSITION "2",

"3", and "4" buttons.

2.2 Troubleshooting Procedures

Table 2-1 is a Troubleshooting Guide which is used to

determine the cause of the malfunction.

Check to see if power cord

is plugged in.

Check to see if control

disable switch is in the

"OFF" position (located on

bottom side of one of the

chair's two electrical

outlets).

Perform a continuity check

on the control disable

switch.

Check to see if facility

circuit breaker is tripped.

One way of checking this is

to plug a lamp into wall

outlet that chair was

plugged into.

connections from power

cord to connector J1 on the

PC control board. Perform

continuity check on wires.

Use multimeter to check for

proper voltage levels.

Refer to Figure 2-2 for this

check. Perform continuity

check on fuses.

Check facility power source

for voltage between 110 120 VAC.

— Reinitialize the PC control

Replace suspect PC

control board with known

working PC control board.

On new style PC control

boards, check if green

Board Fail L.E.D. is

flashing. Flashing

indicates normal operation,

while not flashing indicates

a malfunction.

Plug power cord into facility

wall outlet and/or connector

receptacle on chair.

Switch the control disable

switch to "ON" position.

Replace the control disable

switch. Refer to para 4.5.

If circuit breaker is tripped,

determine what caused

circuit breaker to trip, correct

the problem, and then

reset/replace circuit breaker.

Clean any dirty connections.

Tighten any loose

connections. Replace any

damaged connections.

Replace any blown fuses.

If volatge is below 110 VAC,

correct low voltage problem

of facility power source.

board. Refer to para 4.2.

Replace PC control board.

Refer to para 4.7.

© Midmark Corporation 1994 SF-1428 Rev. 1/97 Page 2-3 Printed in U.S.A.

SECTION II

TESTING AND TROUBLESHOOTING

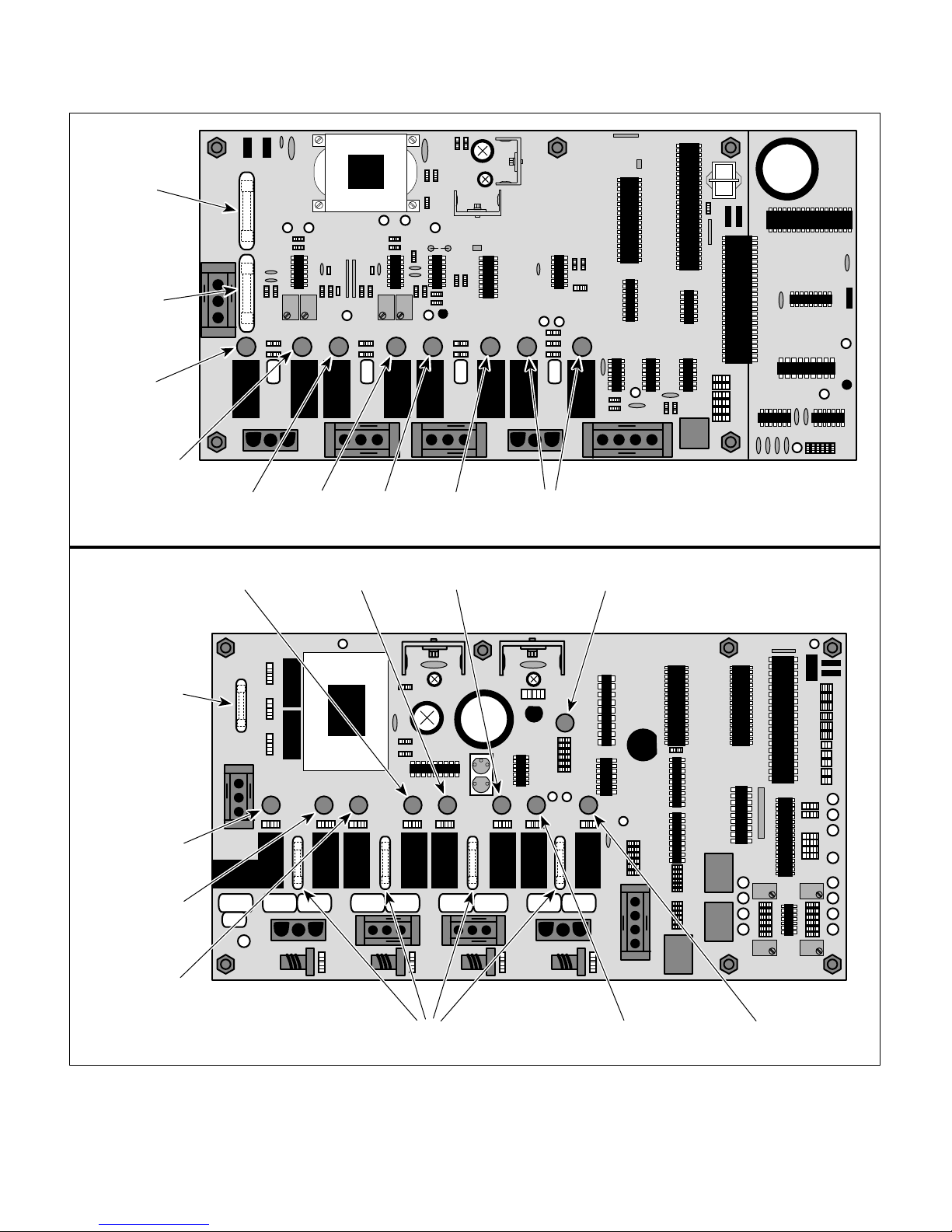

OLD

STYLE

0.5 amp.

FUSE

20 amp.

FUSE

L.E.D. NOT

USED ON

416 MODEL

L.E.D. NOT

USED ON

416 MODEL

BACK

UP

L.E.D.

BACK

DOWN

L.E.D.

TILT

UP

L.E.D.

TILT

DOWN

L.E.D.

L.E.D.'S NOT

USED ON

416 MODEL

NEW

STYLE

L.E.D. NOT

USED ON

416 MODEL

L.E.D. NOT

USED ON

416 MODEL

0.125 amp.

FUSE

BACK

UP

L.E.D.

BACK

DOWN

L.E.D.

TILT

UP

L.E.D.

DOWN

L.E.D.

5 amp.

FUSES

TILT

BOARD

FAIL

L.E.D.

L.E.D. NOT

USED ON

416 MODEL

L.E.D. NOT

USED ON

416 MODEL

MA2475-01

Figure 2-2. Indicator L.E.D.'s For Use With Troubleshooting Guide

© Midmark Corporation 1994 SF-1428 Page 2-4 Printed in U.S.A.

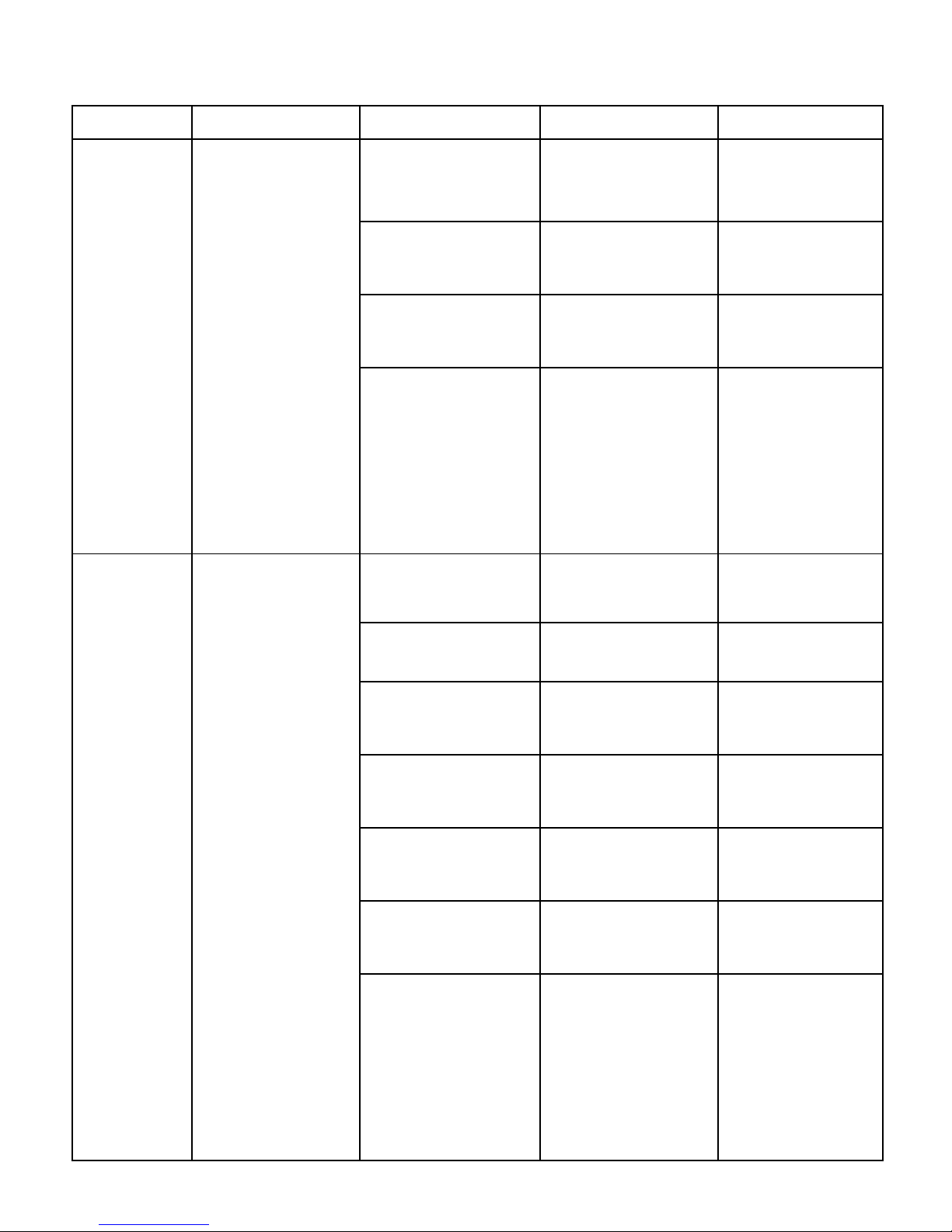

TESTING AND TROUBLESHOOTING

Table 2-1. Troubleshooting Guide - Continued

melborPmotpmySesuaCelbaborPkcehCnoitcerroC

SECTION II

nehwetarepotonlliwriahC

nwoddnapuruofehtfoyna

,noitcnufmargorp,snoitcnuf

eranoitcnufnruterotuaro

.deunitnoC-detceles

detaitiniebnacsnoitcaoN

.lortnocdnahmorf

lortnocdnahanehW

sti,desserpedsinottub

ronurtonseodrotautca

.deunitnoC-muh

ontub,rewopsahriahC

detaitiniebnacsnoitcnuf

.lortnocdnahmorf

drocliocrolortnocdnaH

.gninoitcnuflam

otnideggulptonsidroclioC

elcatpecerrolortnocdnah

.ylreporpriahcno

dnahmorfrotcennocnobbiR

emocebsahlenaplortnoc

ehtmorfdetcennocsid

.draobecafretni

riahcnoelcatpecerdroclioC

.gninoitcnuflamsi

trapsi(elcatpecerdroclioC

dnahno)draobecafretnifo

.gninoitcnuflamsilortnoc

.draob

.gninoitcnuflamsidroclioCotretemitlumaesU

tcepsusecalpeR

nwonkhtiwtnenopmoc

.tnenopmocgnikrow

sidrocliocfikcehC

.ylreporpnideggulp

nobbirfikcehC

detcennocsirotcennoc

draobecafretniehtot

.ylreporp

otnilortnocdnahgulP

edisrehtonoelcatpecer

tpmettanehtdnariahcfo

skrowfI.riahcetarepoot

sawelcatpecer,won

.gninoitcnuflam

tcepsusecalpeR

htiwdraobecafretni

ecafretnignikrownwonk

ytiunitnocamrofrep

.drocliocehtnokcehc

.tnenopmoc

gninoitcnuflamecalpeR

dnahotnidrocliocgulP

.riahcnoelcatpecerrolortnoc

.snoitcennocytridynanaelC

forotcennocnobbirtcennoC

ecafretniotlenaplortnocdnah

.51.4arapotrefeR.draob

.elcatpecerecalpeR

.draobecafretniecalpeR

.51.4arapotrefeR

.drocliocecalpeR

silortnocdnaH

.gninoitcnuflam

.draob

.lenap

sawenituornoitazilaitinieR

.detelpmocyllufton

snoitcnuferomroenO

morfdetaitiniebtonnac

.lortnocdnah

.ton

KCABdnaPUKCAB

tonodsnoitcnufNWOD

.krow

ebyamsnoitcnufemoS

dnahhtiwdetaitini

yamemostub,lortnoc

dnaPUKCABnehW

snottubNWODKCAB

riahceht,desserpera

rehtolla(evomtonlliw

.)krowsnoitcnuf

.nwolb

.)gninoitcnuflam

.detavitca

dnahfolenaplortnocdnaH

gninoitcnuflamsilortnoc

sienarbmemhctiws(

.lenap

rokaewsiroticapackcaB

nihctiwsdaolrevolamrehT

siylbmessarotautcakcab

tcepsusecalpeR

htiwdraobecafretni

ecafretnignikrownwonk

dnahtcepsusecalpeR

nwonkhtiwlenaplortnoc

lortnocdnahgnikrow

— noitazilaitinierrehtonanuR

dnahtcepsusecalpeR

nwonkhtiwlenaplortnoc

lortnocdnahgnikrow

kcabtcepsusecalpeR

nwonkhtiwroticapac

.roticapackcabgnikrow

— wollaotsetunim02ot01tiaW

.draobecafretniecalpeR

.51.4arapotrefeR

.lenaplortnocdnahecalpeR

.51.4arapotrefeR

,krowt'nseodtifI.erudecorp

eriwrotautcallagulpnu

dnadraobCPmorfsessenrah

noitazilaitinidrihtanur

.2.4arapotrefeR.erudecorp

.lenaplortnocdnahecalpeR

.51.4arapotrefeR

refeR.roticapackcabecalpeR

.21.4arapot

otylbmessarotautcakcab

.looc

© Midmark Corporation 1994 SF-1428 Rev. 10/99 Page 2-5 Printed in U.S.A.

.gninoitcnuflam

siylbmessarotautcakcaB

.ylbmessa

kcabtcepsusecalpeR

roylbmessarotautca

ahtiwrotomrotautca

gnikrownwonk

rorotomrotautcaecalpeR

refeR.ylbmessarotautcakcab

.11.4ro8.4arapot

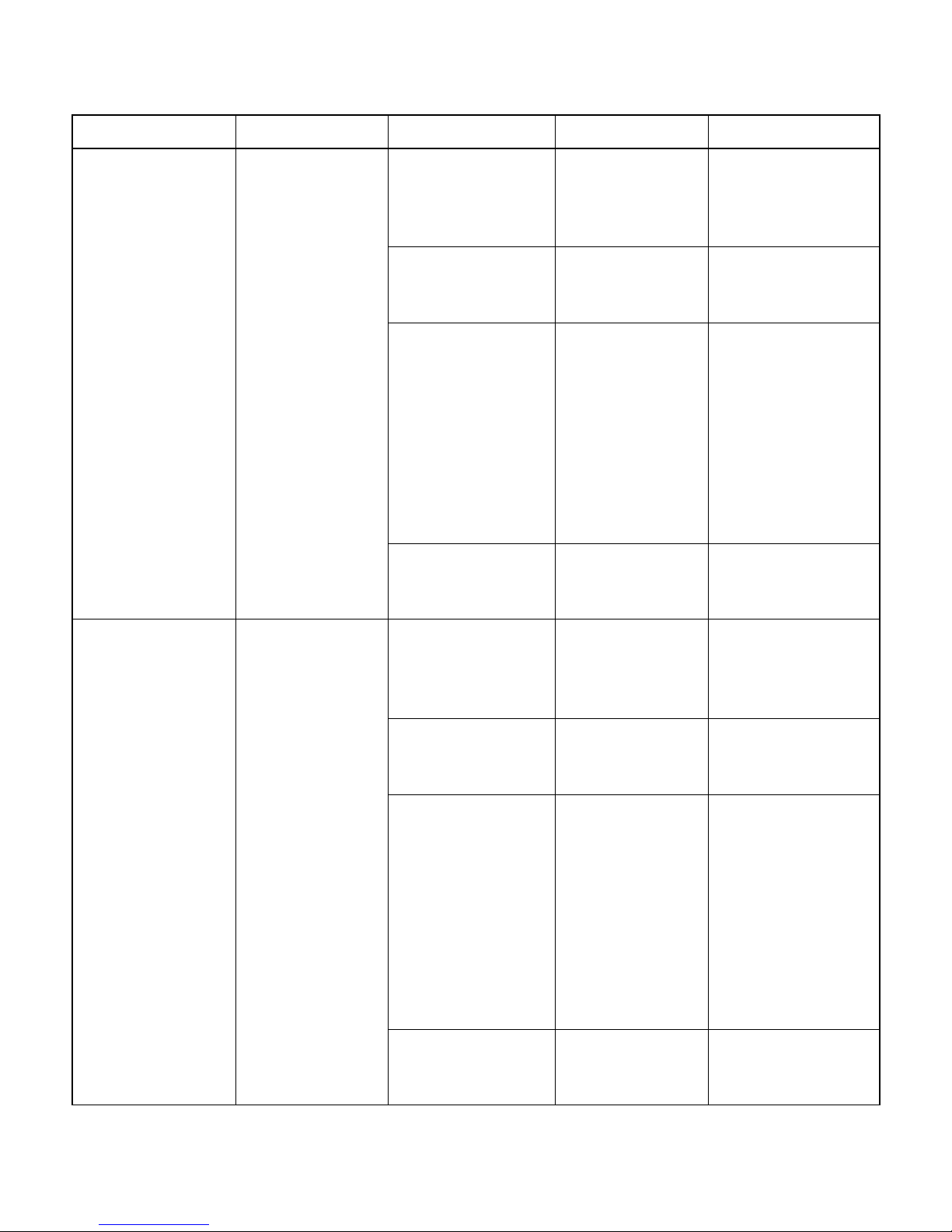

SECTION II

TESTING AND TROUBLESHOOTING

Table 2-1. Troubleshooting Guide - Continued

melborPmotpmySesuaCelbaborPkcehCnoitcerroC

dnaPUKCAB

NWODKCAB

tonodsnoitcnuf

.deunitnoC-krow

.deunitnoC

TLITdnaPUTLIT

snoitcnufNWOD

.krowtonod

KCABdnaPUKCABnehW

,desserperasnottubNWOD

lla(evomtonlliwriahceht

-)krowsnoitcnufrehto

TLITdnaPUTLITnehW

,desserperasnottubNWOD

lla(evomtonlliwriahceht

.)krowsnoitcnufrehto

.)ylnodraob

.sdnoces5.0

sidraoblortnocCP

.gninoitcnuflam

dnaPUKCABrofesufpma5

sisnoitcnufNWODKCAB

CPelytswenotseilppa(nwolb

.esoolsnoitcennoceriWotsnoitcennocgniriwllakcehC

gniwardsirotautcakcaB

nahteromroftnerrucevissecxe

.nwolbrokaewsiroticapactliTroticapactlittcepsusecalpeR

sihtrof2-2erugiFotrefeR

ytiunitnocmrofreP.kcehc

.esufnokcehc

.ylbmessarotautcakcab

nur,nehT.snottubllaesaeleR

tifieesotniagarotautcakcab

.niagagninnurspots

sihtrof2-2erugiFotrefeR

dnaPUKCABsserP.kcehc

nottubNWODKCABehtneht

lortnocCPehtgnivresboelihw

.D.E.LPUKCABehT.draob

ehtnehwetanimullidluohs

desserpsinottubPUKCAB

.D.E.LNWODKCABehtdna

ehtnehwetanimullidluohs

sinottubNWODKCAB

lortnocCPeht,tonfI.desserp

.gninoitcnuflamsidraob

tlitgnikrownwonkhtiw

.roticapac

.esufnwolbecalpeR

.snoitcennocytridynanaelC

esoolynanethgiT

ynaecalpeR.snoitcennoc

.snoitcennocdegamad

ecalper,staepermelborpfI

rotautca,roticapackcab

otrefeR.rotautcaro,rotom

.11.4ro,8.4,21.4arap

.draoblortnocCPecalpeR

.7.4arapotrefeR

refeR.roticapactlitecalpeR

.01.4arapot

tlitnihctiwsdaolrevolamrehT

.detavitcasiylbmessarotautca

siylbmessarotautcatliT

.gninoitcnuflam

dnaPUTLITrofesufpma5

nwolbsisnoitcnufNWODTLIT

draobCPelytswenotseilppa(

.)ylno

.esoolsnoitcennoceriWotsnoitcennocgniriwllakcehC

gniwardsirotautcatliT

nahteromroftnerrucevissecxe

.sdnoces5.0

sidraoblortnocCP

.gninoitcnuflam

— otsetunim02ot01tiaW

gnikrownwonkahtiw

.ylbmessa

.esufnokcehc

.ylbmessarotautcatlit

.niagagninnurspots

TLITehtnehwetanimulli

.gninoitcnuflam

.loocot

rotautcatlittcepsusecalpeR

rotomrotautcaroylbmessa

sihtrof2-2erugiFotrefeR

ytiunitnocmrofreP.kcehc

esoolynanethgiT

nur,nehT.snottubllaesaeleR

tifieesotniagarotautcatlit

9.4ro,8.4,01.4

sihtrof2-2erugiFotrefeR

dnaPUTLITsserP.kcehc

nottubNWODTLITehtneht

lortnocCPehtgnivresboelihw

.D.E.LPUTLITehT.draob

ehtnehwetanimullidluohs

dnadesserpsinottubPUTLIT

dluohs.D.E.LNWODTLITeht

fI.desserpsinottubNWOD

sidraoblortnocCPeht,ton

.7.4arapotrefeR

ylbmessarotautcatlitwolla

rorotomrotautcaecalpeR

refeR.ylbmessarotautcatlit

.9.4ro8.4arapot

.esufnwolbecalpeR

.snoitcennocytridynanaelC

ynaecalpeR.snoitcennoc

.snoitcennocdegamad

ecalper,staepermelborpfI

,rotomrotautca,roticapactlit

arapotrefeR.rotautcaro

.draoblortnocCPecalpeR

© Midmark Corporation 1994 SF-1428 Rev. 1/97 Page 2-6 Printed in U.S.A.

TESTING AND TROUBLESHOOTING

Table 2-1. Troubleshooting Guide - Continued

melborPmotpmySesuaCelbaborPkcehCnoitcerroC

SECTION II

,skrownoitcnufPUKCAB

noitcnufNWODKCABtub

NWODKCABrotonseod

KCABtub,skrownoitcnuf

llA.tonseodnoitcnufPU

.krowsnoitcnufrehto

snurnoitcnufenO

rehtoehttub,ylreporp

.tonseod

.detcennocsid

.gninoitcnuflam

.esoolsnoitcennoceriWgniriwllakcehC

timiLpUronwoDkcaB

desolCyllamroN,hctiwS

eriwronepoera,stcatnoc

sidraoblortnocCP

dnahfolenaplortnocdnaH

gninoitcnuflamsilortnoc

sienarbmemhctiws(

.)gninoitcnuflam

.lenap

esabotsnoitcennoc

.ylbmessarotautca

kcaBfonoitidnockcehC

hctiwStimiLpUronwoD

dnastcatnoc

.snoitcennoc

rof2-2erugiFotrefeR

KCABsserP.kcehcsiht

KCABehtnehtdnaPU

elihwnottubNWOD

lortnocCPehtgnivresbo

PUKCABehT.draob

etanimullidluohs.D.E.L

PUKCABehtnehw

dnadesserpsinottub

.D.E.LNWODKCABeht

nehwetanimullidluohs

nottubNWODKCABeht

eht,tonfI.desserpsi

.dabsidraoblortnocCP

dnahtcepsusecalpeR

nwonkhtiwlenaplortnoc

lortnocdnahgnikrow

esoolynanethgiT

.11.

4arapotrefeR

.7.4arapotrefeR

.51.4arapotrefeR

.snoitcennocytridynanaelC

ynaecalpeR.snoitcennoc

.snoitcennocdegamad

kcaBecalperroriapeR

.hctiwStimiLpUronwoD

.draoblortnocCPecalpeR

.lenaplortnocdnahecalpeR

,skrownoitcnufPUTLIT

noitcnufNWODTLITtub

NWODTLITrotonseod

TLITtub,skrownoitcnuf

llA.tonseodnoitcnufPU

.krowsnoitcnufrehto

snurnoitcnufenO

rehtoehttub,ylreporp

.tonseod

.detcennocsid

.gninoitcnuflam

.esoolsnoitcennoceriWgniriwllakcehC

timiLpUronwoDtliT

desolCyllamroNhctiwS

eriwronepoerastcatnoc

sidraoblortnocCP

dnahfolenaplortnocdnaH

gninoitcnuflamsilortnoc

sienarbmemhctiws(

.)gninoitcnuflam

.lenap

tlitotsnoitcennoc

.ylbmessarotautca

tliTfonoitidnockcehC

hctiwStimiLpUronwoD

dnastcatnoc

.snoitcennoc

rof2-2erugiFotrefeR

TLITsserP.kcehcsiht

TLITehtnehtdnaPU

elihwnottubNWOD

lortnocCPehtgnivresbo

PUTLITehT.draob

etanimullidluohs.D.E.L

nottubPUTLITehtnehw

TLITehtdnadesserpsi

dluohs.D.E.LNWOD

TLITehtnehwetanimulli

sinottubNWOD

CPeht,tonfI.desserp

sidraoblortnoc

.gninoitcnuflam

dnahtcepsusecalpeR

nwonkhtiwlenaplortnoc

lortnocdnahgnikrow

esoolynanethgiT

.hctiwStimiLpUro

.9

.4arapotrefeR

.7.4arapotrefeR

.51.4arapotrefeR

.snoitcennocytridynanaelC

ynaecalpeR.snoitcennoc

.snoitcennocdegamad

nwoDtliTecalperroriapeR

.draoblortnocCPecalpeR

.lenaplortnocdnahecalpeR

© Midmark Corporation 1994 SF-1428 Rev. 12/03 Page 2-7 Printed in U.S.A.

SECTION II

TESTING AND TROUBLESHOOTING

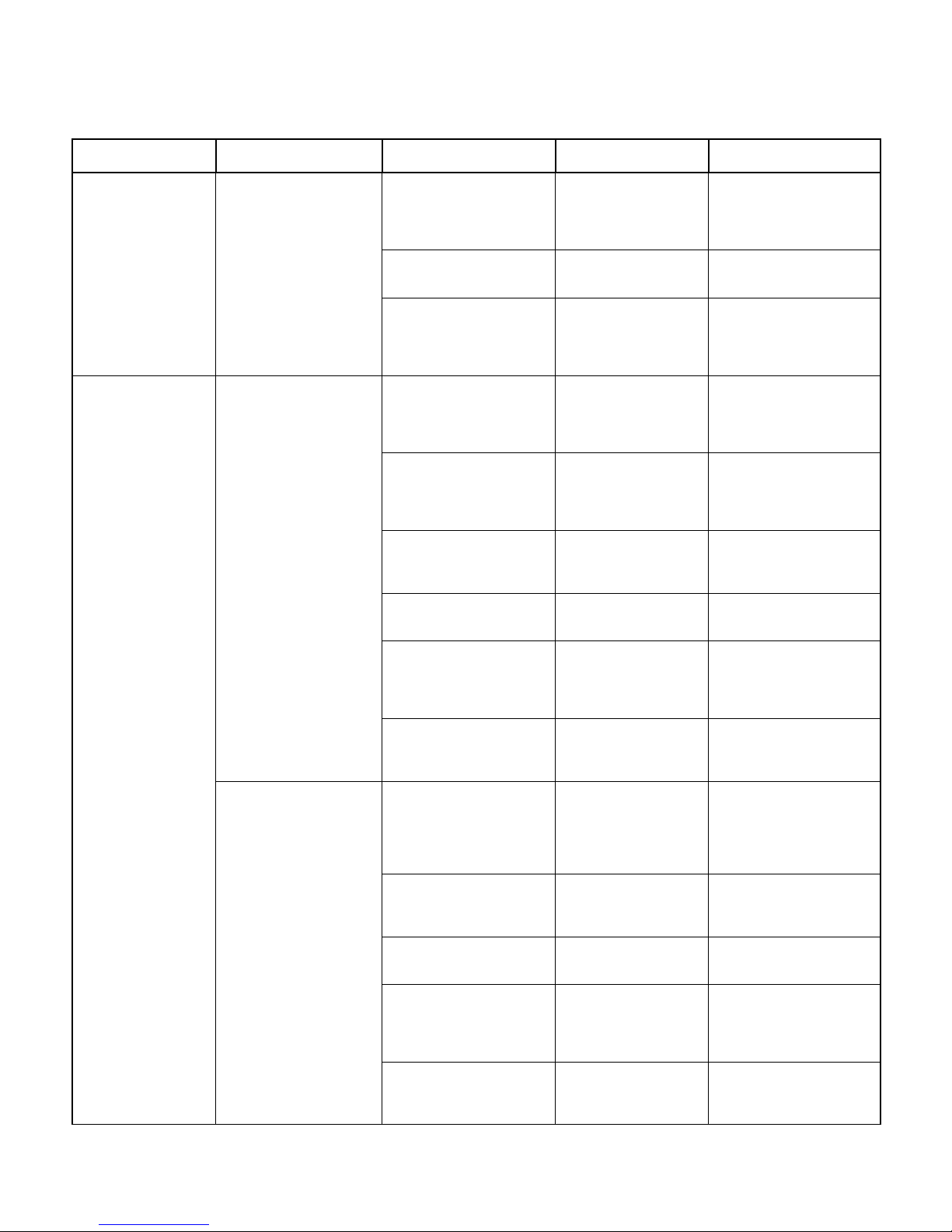

Table 2-1. Troubleshooting Guide - Continued

melborPmotpmySesuaCelbaborPkcehCnoitcerroC

noitcnufnruterotuA

etarepotonseod

.ylreporp

s'riahcehT

.ylreporp

noitcnufMARGORP

krowtonseod

.noitisop

nehwsneppahgnihtoN

NRUTEROTUAeht

.desserpsinottub

/draobmargorpCPehT

tonseoddraoblortnocCP

demmargorpadloh

sidraoblortnocCP

.gninoitcnuflam

sdeendraoblortnocCP

.dezilaitinier

dnahfolenaplortnocdnaH

gninoitcnuflamsilortnoc

sienarbmemhctiws(

.)gninoitcnuflam

rofnekatspetstcerrocnI

.noitisopfoyrtne

.erudecorp

tonsidraobmargorpCP

lortnocCPotnidetaesylluf

dlohtiwstinuno(draob

.)ylnosdraobelyts

deggulpnuneebsahriahC

eromrofrewoptuohtiwro

.syadeerhtnaht

sdeendraoblortnocCP

.dezilaitinier

CPtcepsusecalpeR

htiwdraoblortnoc

CPgnikrownwonk

.draoblortnoc

— lortnocCPehtezilaitinieR

dnahtcepsusecalpeR

htiwlenaplortnoc

dnahgnikrownwonk

.lenaplortnoc

s'rotarepoehtotrefeR

reporproflaunam

CPfieesotkcehC

.esoolsidraobmargorp

— lortnocCPehtezilaitinieR

— lortnocCPehtezilaitinieR

.7.4arapotrefeR

.draoblortnocCPecalpeR

.2.4arapotrefeR.draob

lortnocdnahecalpeR

.51.4arapotrefeR.lenap

s'rotarepoehtotrefeR

reporproflaunam

.erudecorp

draobmargorpCPtaeS

.draoblortnocCPotniylluf

.7.4arapotrefeR

.2.4arapotrefeR.draob

.2.4arapotrefeR.draob

dnahfolenaplortnocdnaH

gninoitcnuflamsilortnoc

sienarbmemhctiws(

.)gninoitcnuflam

CP/draobmargorpCP

sidraoblortnoc

.gninoitcnuflam

stiotevomtonseodriahC

demmargorptcerroc

NOITISOPnehwnoitisop

.desserpsi

nottub"4"ro,"3","2","1"

.)ylno

.dezilaitinier

.)gninoitcnuflam

sidraoblortnoc

.gninoitcnuflam

tonsidraobmargorpCP

lortnocCPotnidetaesylluf

htiwstinuotseilppa(draob

draoblortnocCPelytsdlo

deggulpnuneebsahriahC

eromrofrewoptuohtiwro

.syadeerhtnaht

sdeendraoblortnocCP

dnahfolenaplortnocdnaH

gninoitcnuflamsilortnoc

sienarbmemhctiws(

CP/draobmargorpCP

— draobmargorpCPecalpeR

— lortnocCPehtezilaitinieR

— lortnocCPehtezilaitinieR

— draobmargorpCPecalpeR

dnahtcepsusecalpeR

htiwlenaplortnoc

dnahgnikrownwonk

.lenaplortnoc

.7.4arapot

CPfieesotkcehC

.esoolsidraobmargorp

dnahtcepsusecalpeR

htiwlenaplortnoc

dnahgnikrownwonk

.lenaplortnoc

.7.4arapot

lortnocdnahecalpeR

.51.4arapotrefeR.lenap

refeR.draoblortnocCP/

draobmargorpCPtaeS

.draoblortnocCPotniylluf

.2.4arapotrefeR.draob

.2.4arapotrefeR.draob

lortnocdnahecalpeR

.51.4arapotrefeR.lenap

refeR.draoblortnocCP/

© Midmark Corporation 1994 SF-1428 Rev. 12/03 Page 2-8 Printed in U.S.A.

TESTING AND TROUBLESHOOTING

Table 2-1. Troubleshooting Guide - Continued

melborPmotpmySesuaCelbaborPkcehCnoitcerroC

SECTION II

s'riahcehT

noitcnufMARGORP

krowtonseod

.ylreporp

rofenifsevomriahC

lliwtub,tneitapthgil

sevomroevomton

yvaehyrevrofylwols

.tneitap

stiotevomtonlliwriahC

noitisopdemmargorp

demmargorpsselnu

dlehsinottubNOITISOP

fi;evomeritnerofnwod

gniruddesaelersinottub

.spotsriahc,evom

puehthtobrofsruccO

.snoitcnufnwodehtdna

.kaew

lortnocCPelytsdlofI

,1Shctiwsrotceles,draob

lortnocCPehtnodetacol

nehw(tuodellupsi,draob

tuodellupnisihctiws1S

demmargorpeht,noitisop

ebtsumhctiwsNOITISOP

wenfI.)dlehdnadesserp

,draoblortnocCPelyts

,4-2WShctiwsrotceles

lortnocCPehtnodetacol

noitisopFFOnisi,draob

FFOnisihctiwsnehw(

demmargorpeht,noitisop

ebtsumhctiwsNOITISOP

.)dlehdnadesserp

gniebsiegatlovwoL

.riahcotdeilppus

oothtiwdedaolrevoriahC

.tneitapafoyvaeh

sinoitcnufrofroticapaC

.noitisop

no,1ShctiwSfikcehC

lortnocCPelytsdlo

tuodellupnisi,draob

hctiwsfironoitisop

CPelytswenno4-2WS

FFOnisidraoblortnoc

llawtaegatlovkcehC

ebdluohS.elcatpecer

.CAV5±CAV511

thgiewmumixaM

053siriahcrofyticapac

tneitapfikcehC.sbl

.thgiewsihtdedeecxe

tcepsusecalpeR

nwonkhtiwroticapac

.roticapacgnikrow

yawehtlla1ShctiwshsuP

ot4-2WShctiwsevomroni

wollalliwsiht(noitisopNO

NOITISOPdemmargorp

dnadesserpebotnottub

fodaetsnidesaeler

.)dlehdnadesserp

egatlovwoltcerroC

.elcatpecerllawtanoitautis

forotareporiahcmrofnI

.riahcfonoitatimilthgiew

ehtrofroticapacecalpeR

otrefeR.noitcnufkaew

.21.4ro01.4arap

lliwnoitcnufriahcA

.emit

.nur

trohsarofnurylno

snoitcnufehtfoynA

.sevlesmehtybtfird

gnikaeuqsrognilrihW

nehwdraehsiesion

gniebsirotautcana

.esiwrehto

nurdnoces2/1aretfA

noitcnufdetceleseht,emit

.gninnurspots

ylreporpsnoitcnufriahC

.rotautcaysioNllabnorettamngieroF

gniebsiwardtnerrucrevO

lortnocCPybdetceted

.draob

rotcelesV022/V011ehT

lortnocCPehtnohctiws

tloV022ehtottessidraob

.gnittes

siekarbrotautcarotoM

tahtrofgninoitcnuflam

.noitcnuf

fokcaldnasdaerhtwercs

.tnacirbul

— rorotomrotautcaecalpeR

.gnittestloV

.ekarb

.sdaerht

.roticapac

ehtfieesotkcehC

rotcelesV022/V011

lortnocCPehtnohctiws

022ehtottessidraob

tcepsusecalpeR

ehtniekarbrotautca

htiwrotautcarotom

rotautcagnikrownwonk

rettamngierofrofkcehC

.sdaerhtwercsllabno

fokcalrofkcehC

wercsllabnotnacirbul

.gnittestloV

.tnelaviuqe

V022/V011ehthctiwS

CPehtnohctiwsrotceles

011ehtotdraoblortnoc

.ekarbrotautcaecalpeR

.8.4arapotrefeR

fforettamngierofllanaelC

taoC.sdaerhtwercsllabfo

htiwsdaerhtwercsllab

roliotnemtaertPTS

© Midmark Corporation 1994 SF-1428 Rev. 12/03 Page 2-9 Printed in U.S.A.

SECTION II

TESTING AND TROUBLESHOOTING

© Midmark Corporation 1994 SF-1428 Page 2-10 Printed in U.S.A.

SCHEDULED MAINTENANCE

SECTION III

SCHEDULED MAINTENANCE

SECTION III

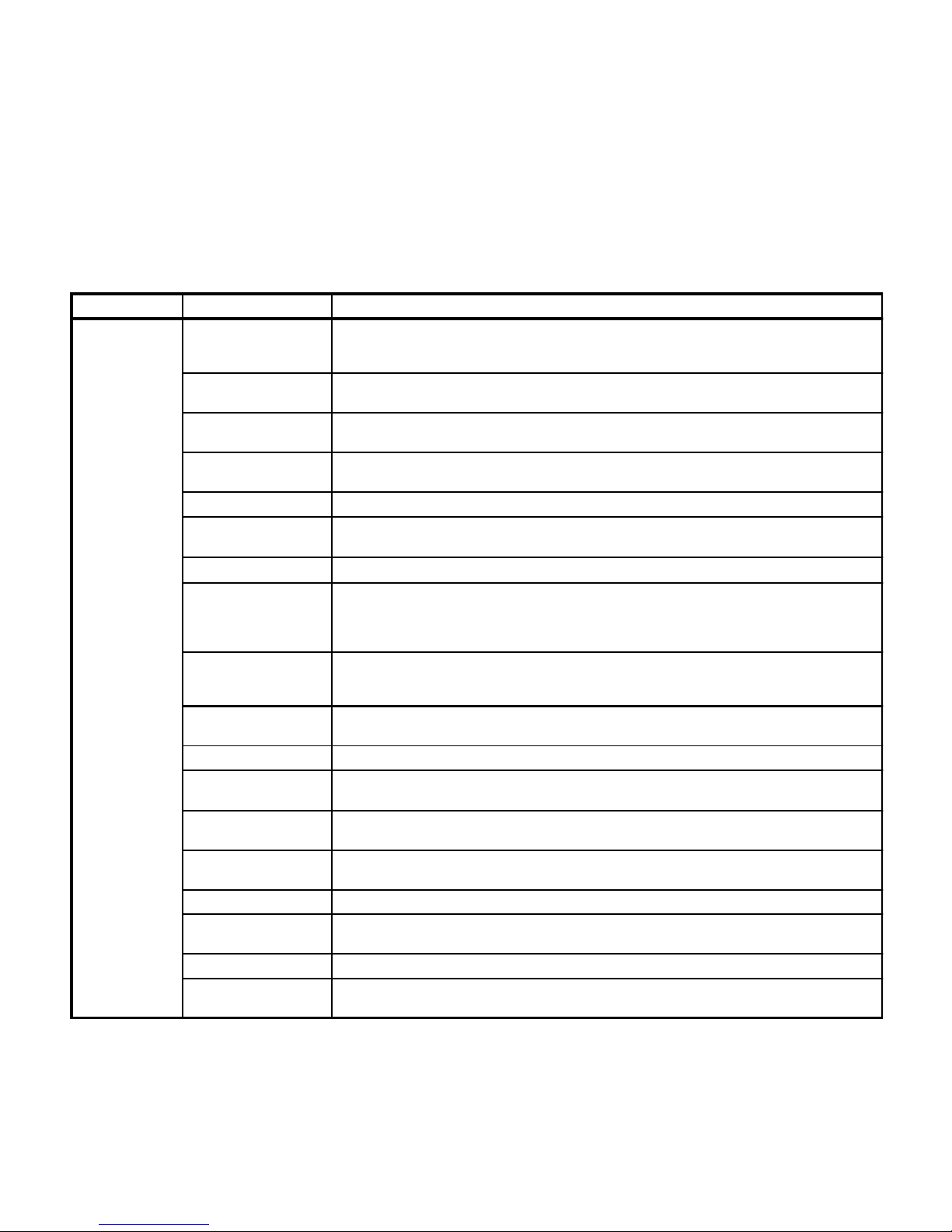

3.1 Scheduled Maintenance

periodically on the chair. These inspections and

services should be performed as often as indicated in

Table 3-1 is a Scheduled Maintenance Chart which lists

the chart.

the inspections and services that should be performed

Table 3-1. Scheduled Maintenance Chart

Interval Inspection or Service What to Do

Semi-annually Obvious damage Visually check condition of chair for obvious damage such as: cracks in components, missing

Fasteners/hardware Check chair for missing or loose fasteners/hardware. Replace any missing hardware and tighten

Warning and

instructional decals

Pivot points/moving

parts/accessories

Hand Control Check that hand control works correctly. Make sure all switch membranes work correctly.

PROGRAM function Check that the PROGRAM function works properly. Check that programmed positions can be

AUTO RETURN function Check that the AUTO RETURN function works correctly.

Ball screws of actuator

assemblies

Actuator assemblies Operate each function and listen for squealing noises, indicating a bad actuator assembly. Coat

Drift in chair Check each actuator assembly to see if it drifts. Replace actuator assembly brake if necessary.

Control disable switch Check operation of control disable switch. Replace switch if necessary. Refer to para 4.5.

Arm Rests Check that arm rests are parallel to the seat section of chair when the back section is all the way

Foot section Check operation of foot section and foot section brake lever. Make sure brake lever holds foot

Electrical receptacles Check that the electrical receptacles are functioning properly. Replace electrical receptacles as

Upholstery Check all upholstery for rips, tears, or excessive wear. Replace cushions as necessary.

Accessories Check that all accessories have all of their components and that they function properly. If

Reinitialization Reinitialize the PC control board. Refer to para 4.2.

Operational Test Perform an Operational Test to determine if the chair is operating within its specifications (Refer

components, dents in components, or any other visible damage which would cause chair to be

unsafe to operate or would compromise its performance. Repair chair as necessary.

any loose hardware as necessary.

Check for missing or illegible decals. Replace decals as necessary.

Lubricate all exposed pivot points, moving parts, and accessories with silicone based lubricant.

stored and used.

Extend each actuator assembly and wipe ball screw threads down with a rag to remove foreign

matter. Coat as much of the ball screw threads as possible with STP treatment oil or equivalent.

Run each actuator assembly to both ends of its travel a couple of times to spread the oil evenly

over all of the ball screw threads and then remove excess oil.

ball screw of noisy actuator assembly with STP treatment oil or equivalent. If oil does not correct

the problem, replace the noisy actuator. Refer to para 4.9 or 4.11.

Refer to para 4.8.

up. If not adjust arm rests. Refer to para 4.13.

section securely in place when released. Adjust if necessary. Refer to para 4.14.

necessary.

necessary, repair or replace the accessory.

to para 2.1). Replace or adjust any malfunctioning components.

© Midmark 1994 SF-1428 Page 3-1 Printed in U.S.A.

Loading...

Loading...