Page 1

413

Go To Table Of Contents

Place Order

To purchase a printed copy of this manual,

click on the "Place Order" button below.

-001 thru -004

Power Female Procedure

Examination Chair

Serial Number Prefixes:

BK, V, DT & FH

Service and

Parts Manual

FOR USE BY MIDMARK TRAINED TECHNICIANS ONLY

SF-1457 Part No. 004-0003-00 Rev. O (1/01/06)

413

-001

thru

-004

Page 2

Go To Table Of Contents

Page 3

TABLE OF CONTENTS

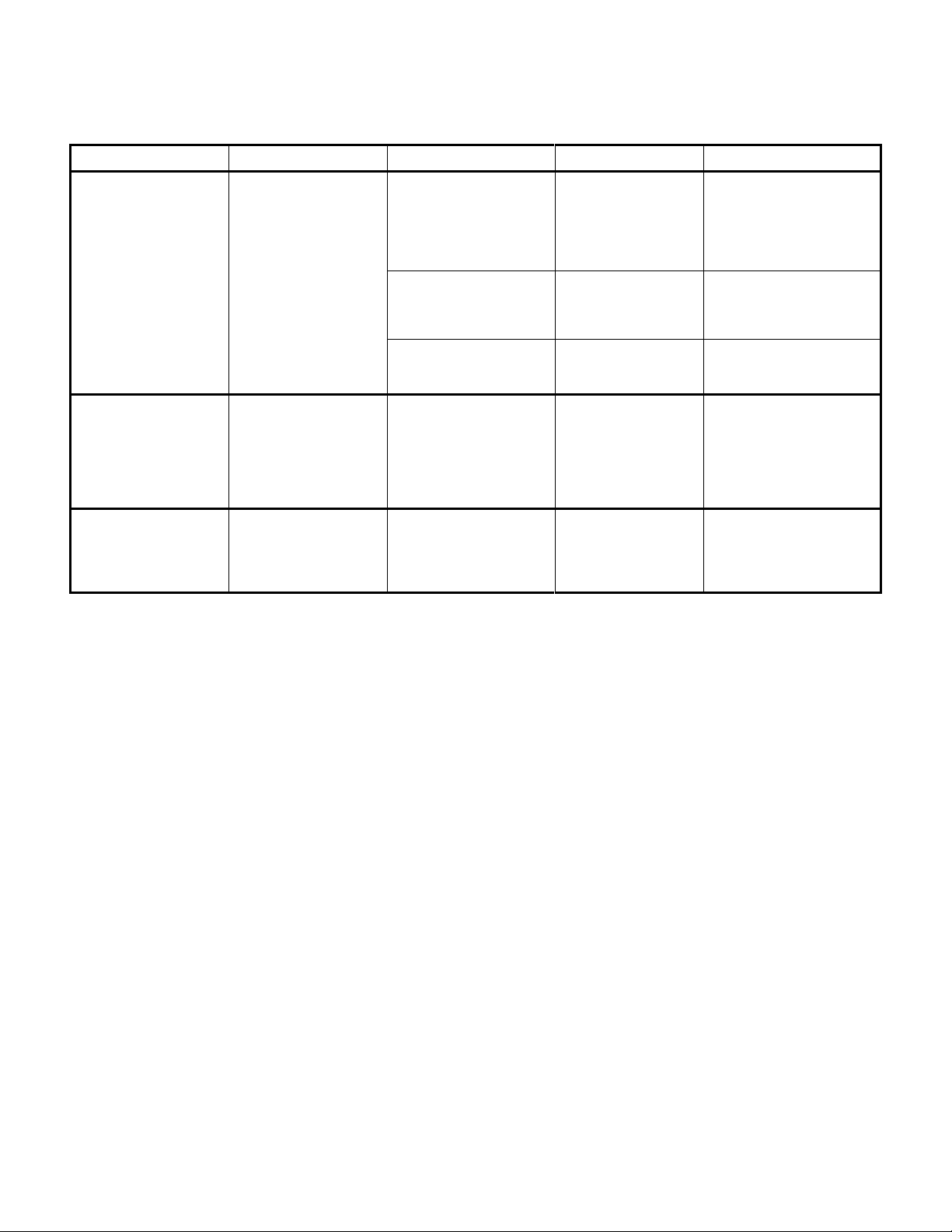

Section/Paragraph Page Section/Paragraph Page

IMPORTANT INSTRUCTIONS

General Safety Instructions......................................... ii

Safety Alert Symbols .................................................. ii

Warranty Instructions ................................................... ii

SECTION I GENERAL INFORMATION

1.1 Scope of Manual ......................................... 1-1

1.2 How to Use Manual ..................................... 1-1

1.3 Description of 413 Power Female

Procedures Chair ..................................... 1-1

1.4 Specifications ............................................. 1-3

1.5 Parts Replacement Ordering ....................... 1-5

1.6 Special Tools .............................................. 1-5

SECTION II TESTING AND TROUBLESHOOTING

2.1 Operational Test .......................................... 2-1

2.2 Troubleshooting Procedures ........................ 2-2

SECTION III SCHEDULED MAINTENANCE

3.1 Scheduled Maintenance .............................. 3-1

SECTION IV MAINTENANCE/SERVICE

INSTRUCTIONS

4.1 Introduction ................................................. 4-1

4.2 Seat Up Limit Switch Removal /

Installation ................................................ 4-1

4.3 Seat Actuator Removal / Installation ............ 4-2

4.4 Pan Safety Limit Switch Removal /

Installation ................................................ 4-4

4.5 Gas Spring Removal / Installation ................ 4-6

4.6 Base Actuator Removal / Installation ........... 4-7

4.7 Typical Capacitor Removal / Installation ...... 4-9

4.8 Typical Actuator Motor / Actuator Brake

Removal / Installation ............................. 4-10

4.9 Base Down Limit Switch or Seat Down Limit

Switch Removal / Installation .................. 4-11

4.10 Typical Foot Pedal Footswitch Removal /

Installation .............................................. 4-13

SECTION V SCHEMATICS AND DIAGRAMS

5.1 Electrical Schematics / Wiring Diagrams ..... 5-1

SECTION VI PARTS LIST

6.1 Introduction ................................................. 6-1

6.2 Description of Columns ............................... 6-1

6.3 Torque Specifications And Important

Assembly Notes ....................................... 6-1

Pictorial Index .............................................. 6-2

Labels and Decals ........................................ 6-3

Upholstery .................................................... 6-4

Main Frame Section ................................... 6-5.*

Stirrup Assembly ......................................... 6-6

Stirrups ...................................................... 6-7.*

Arm Rest Assembly ...................................6-8.*

Cross Support ............................................ 6-9.*

Base Components .................................... 6-10.*

Base Actuator .......................................... 6-11.*

Base And Panels ..................................... 6-12.*

Linkage Assembly .................................... 6-13.*

Pan Assembly.......................................... 6-14.*

Footrest Assembly ................................... 6-15.*

Seat Components ..................................... 6-16*

Seat Actuator ........................................... 6-17.*

Footswitch ................................................. 6-18

Back Panel .............................................. 6-19.*

Wiring Locations ......................................... 6-20

Export ........................................................ 6-21

COMMENTS ............................................................ 7-1

FAX ORDERING FORM .......................................... 7-2

(*) Indicates that there has been a serial number break for the illustration

and that there are additional point page(s) following the original page.

© Midmark Corporation 1995 SF-1457 Rev. 6/00 Page i Printed in U.S.A.

Page 4

IMPORT ANT INSTRUCTIONS

Return To Table Of Contents

General Safety Instructions

Safety First: The primary concern of Midmark

Corporation is that this Power Female Procedures

Chair is maintained with the safety of the patient and

staff in mind. To assure that services and repairs are

completed safely and correctly, proceed as follows:

(1) Read this entire manual before performing any

services or repairs on this chair.

(2) Be sure you understand the instructions

contained in this manual before attempting to

service or repair this chair.

Safety Alert Symbols

Throughout this manual are safety alert symbols that

call attention to particular procedures. These items are

used as follows:

DANGER

A DANGER is used for an imminently

hazardous operating procedure,

practice, or condition which, if not correctly

followed, will result in loss of life or serious

personal injury.

NOTE

A NOTE is used to amplify an operating procedure,

practice or condition.

Warranty Instructions

Refer to the Midmark “Limited Warranty” printed on the

back cover of the Installation and Operation Manual for

warranty information. Failure to follow the guidelines

listed below will void the warranty and / or render the

413 Power Female Procedures Chair unsafe for

operation.

• In the event of a malfunction, do not attempt to

operate the chair until necessary repairs have been

made.

• Do not attempt to disassemble chair, replace malfunctioning or damaged components, or perform

adjustments unless you are one of Midmark’s

authorized service technicians.

• Do not substitute parts of another manufacturer

when replacing inoperative or damaged components.

Use only Midmark replacement parts.

WARNING

A WARNING is used for a potentially

hazardous operating procedure,

practice, or condition which, if not correctly

followed, could result in loss of life or serious

personal injury.

CAUTION

A CAUTION is used for a potentially

hazardous operating procedure, practice,

or condition which, if not correctly followed, could

result in minor or moderate injury. It may also be

used to alert against unsafe practices.

EQUIPMENT ALERT

An EQUIPMENT ALERT is used for an

imminently or potentially hazardous

operating procedure, practice, or condition which, if

not correctly followed, will or could result in serious,

moderate, or minor damage to unit.

© Midmark Corporation 1995 SF-1457 Page ii Printed in U.S.A.

Page 5

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

SECTION I

GENERAL INFORMATION

1.1 Scope of Manual

This manual contains detailed troubleshooting, scheduled maintenance, maintenance, and service instructions for 413 Power Female Procedures Chair. This

manual is intended to be used by Midmark’s authorized

service technicians.

1.2 How to Use Manual

A. Manual Use When Performing Scheduled Mainte-

nance.

(1) Perform inspections and services listed in

Scheduled Maintenance Chart (Refer to

para 3.1).

(2) If a component is discovered to be faulty or out

of adjustment, replace or adjust component in

accordance with maintenance / service instructions (Refer to para 4.1).

B. Manual Use When Chair Is Malfunctioning And

Cause Is Unknown.

(1) Perform an operational test on chair (Refer to

para 2.1).

(2) Perform troubleshooting procedures listed in

Troubleshooting Guide (Refer to para 2.2).

(3) If a component is discovered to be faulty or out

of adjustment, replace or adjust component in

accordance with maintenance / service instructions (Refer to para 4.1).

examinations and procedures on female patients;

especially Lithotomy procedures.

The major serviceable components of the chair are the

seat actuator, seat capacitor, base actuator, base

capacitor, gas spring, pan safety limit switch, seat up

limit switch, seat down limit switch, base down limit

switch, and the foot control which includes four foot

switches.

B. Theory of Operation (See Figure 5-1, Sheets 1

and 2 for domestic wiring diagrams, Figure 5-2,

Sheets 1 and 2 for export wiring diagrams, Figure

5-3 for domestic electrical schematic, and Figure 54 for export electrical schematic.)

Electrical Power:

Line voltage is supplied directly to the footswitches of

the chair. Also, line voltage is always present at the

receptacle (domestic units only).

Chair Operation:

Power is present at all four foot control footswitches.

However, the BASE DOWN and SEAT UP switches

receive their power thru the BASE UP and SEAT

DOWN footswitches, respectively. So, if the BASE UP

footswitch is depressed, power is removed from the

BASE DOWN footswitch and if the SEAT DOWN

footswitch is depressed, power is removed from the

SEAT UP footswitch. This wiring setup prevents the

operator from trying to run the actuator in an up and

down direction simultaneously and causing damage to

the actuator.

C. Manual Use When Damaged Component Is Known.

(1) Replace or adjust component in accordance

with maintenance / service instructions (Refer

to para 4.1).

1.3 Description Of 413 Power Female

Procedures Chair

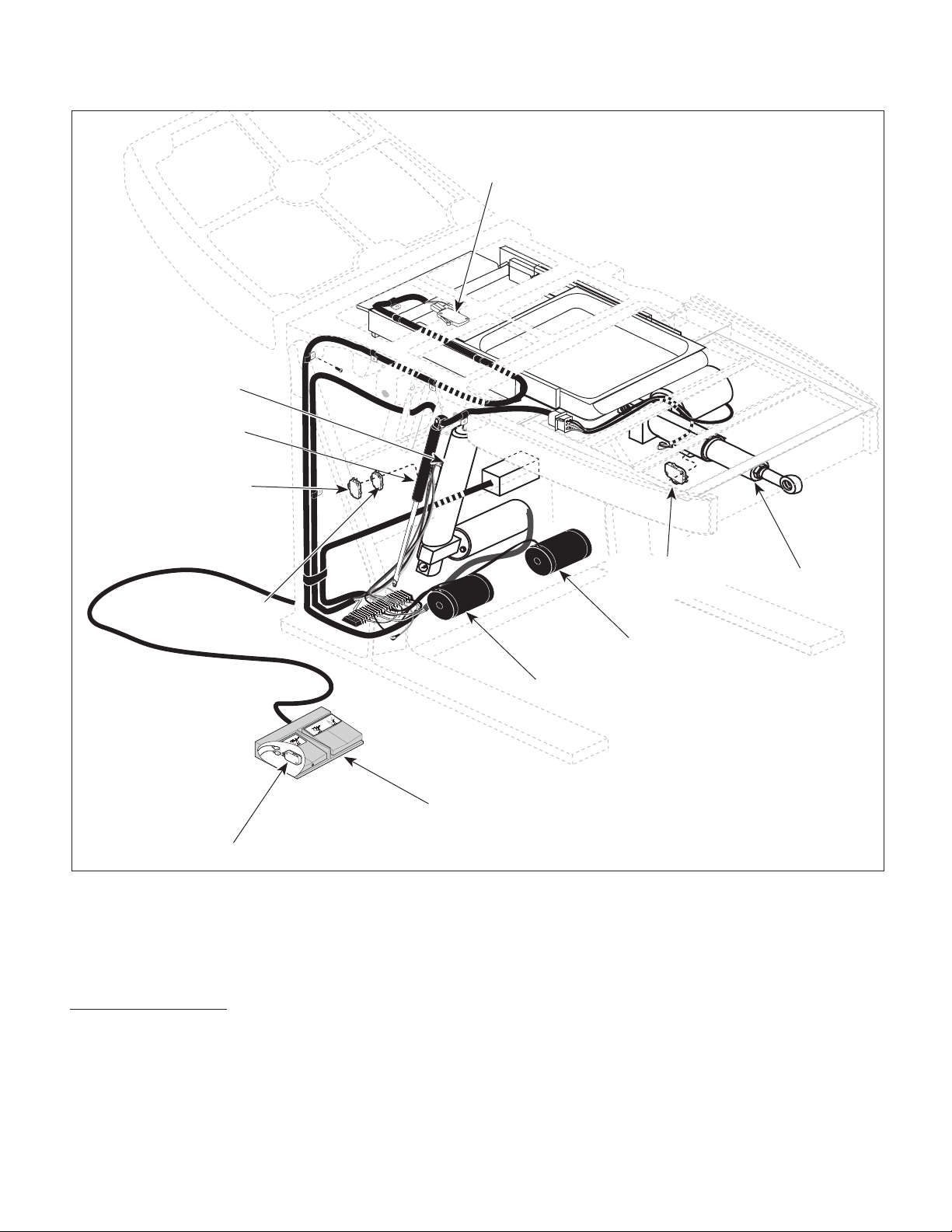

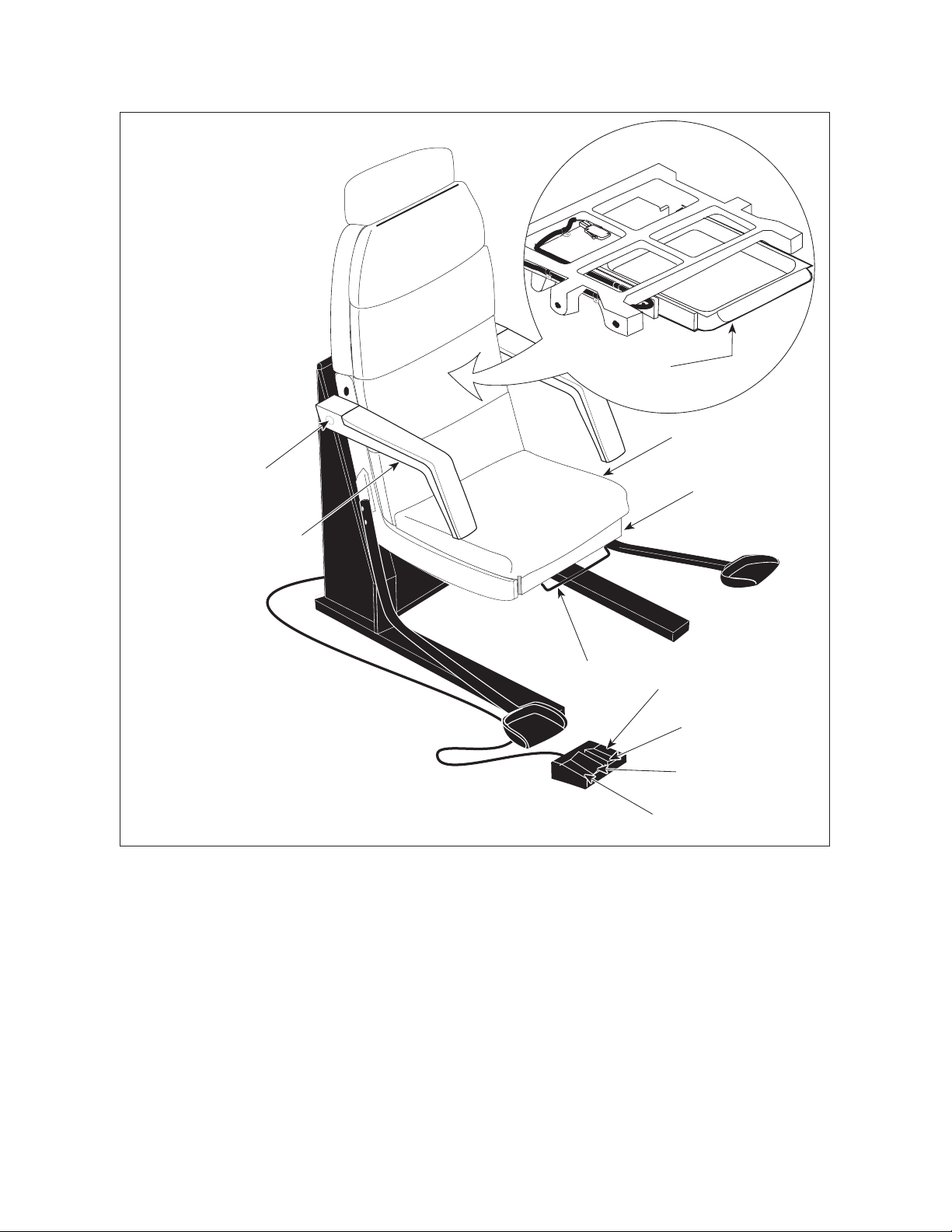

A. General Description (See Figure 1-1).

The 413 Power Female Procedures Chair is an examination chair designed for performing female specific

© Midmark Corporation 1995 SF-1457 Page 1-1 Printed in U.S.A.

SEAT UP function:

When the operator depresses the SEAT UP footswitch,

current is applied across the seat actuator motor

windings thru the normally open (N.O.) pan safety limit

switch and seat capacitor, causing the seat actuator to

run. The pan safety limit switch is a N.O switch. When

the pan assembly is in its stowed position, the pan

safety limit switch is tripped, closing the circuit and

allowing the seat actuator to run. If the pan assembly is

not in its stowed position, the pan safety limit switch is

not tripped, which opens the circuit and prevents the

seat actuator from running. This prevents the operator

Page 6

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

BASE ACTUAT OR

GAS SPRING

BASE DOWN

LIMIT SWITCH

PAN SAFETY

LIMIT SWITCH

SEAT DOWN

LIMIT SWITCH

RETURN

RETURN

AQUIRE

AQUIRE

FOOT CONTROL

FOOT SWITCH

Figure 1-1. Major Components

from running the foot section into the pan assembly and

damaging it. The seat capacitor provides motor start

and motor run power for the seat actuator.

BASE DOWN function:

When the BASE DOWN footswitch is depressed,

current is applied across the base actuator motor coil

thru either the seat up limit switch or the base down

limit switch and base capacitor, causing the base

SEAT UP

LIMIT SWITCH

SEAT ACTUATOR

SEAT CAPACITOR

BASE CAPACITOR

MA317900

actuator to run. The seat up limit switch is a normally

closed (N.C.) switch which is tripped when the seat

function is in any position, but all the way up, resulting

in an open circuit. This prevents the operator from

running the BASE DOWN function (lower than the 2/3

up position - see base down limit switch operation)

when the seat is in any position, but all the way up,

preventing an accidental seat section collision with

floor. When the seat function is raised all the way up,

the seat up limit switch untrips, closing the circuit, and

© Midmark Corporation 1995 SF-1457 Page 1-2 Printed in U.S.A.

Page 7

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

allowing the BASE DOWN function to be operated to

any position.

The base down limit switch is a N.C. switch which is

tripped when the base function is between the all the

way down position to approximately the 2/3 up position,

resulting in an open circuit. This means that the switch

is untripped only when the base function is in 2/3 up

position to all the way up position, resulting in a closed

circuit. This only allows the operator to lower the BASE

DOWN function down to the 2/3 up position. Then the

base down limit switch trips, opening the circuit, and

preventing further downward movement of the base

actuator. This prevents an accidental seat section

collision with floor. The base capacitor provides motor

start and motor run power for the base actuator.

So, if the seat up limit switch is tripped (seat function

not

in all the way up position), the base down limit

switch provides the base actuator with current; this

allows you to lower table top only 1/3 of way down. But,

if the seat up limit switch is untripped (seat function is in

all the way up position), the seat up limit switch provides the base actuator with current; this allows you to

lower table top all the way down.

BASE UP function:

When the BASE UP footswitch is depressed, current is

applied across the base actuator motor coil and base

capacitor, causing the base actuator to run. The base

capacitor provides motor start and motor run power for

the base actuator.

is

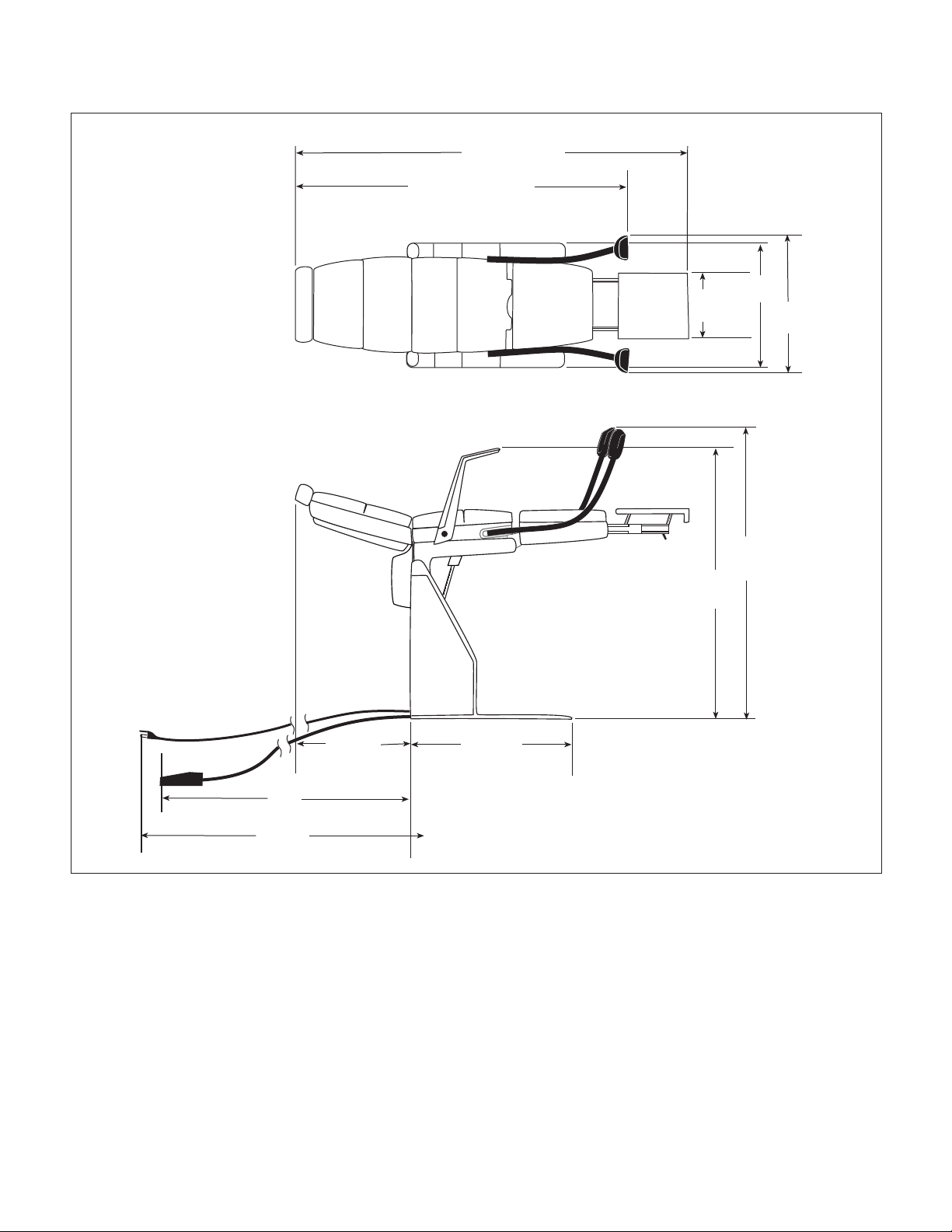

1.4 Specifications

Factual data for the 413 Female Procedures Chair is

provided in Table 1-1. Also, see Figure 1-2.

Table 1-1. Specifications

Description Data

Weight:

Without Shipping Carton ................ 374 lb (169.6 kg)

With Shipping Carton ..................... 412 lb (186.9 kg)

Shipping Carton ....... 55 in. "L" x 33 in. "W" x 44 in. "H"

(139.7 cm x 83.8 cm x 111.7 cm)

Dimensions (See Figure 1-2):

Table Top Length (w/o foot section

extended) ................................... 55.5 in. (141.0 cm)

Table Top Length (w/ foot section

fully extended) ............................ 72.7 in. (184.6 cm)

Table Top Width (w/ armrests) .......... 28 in. (71.1 cm)

Maximum width of upholstery ............. 22 in. (55.9 cm)

Overall Width ..................................... 28 in. (71.1 cm)

Chair Positioning:

Seat height in chair position ................ 19 in. (48.3 cm)

Height in table position ....................... 34 in. (86.4 cm)

Maximum pelvic area height ............... 36 in. (91.4 cm)

Chair Speeds (@ 60 Hz.):

Base Up ................................................ 9 ±1 seconds

Seat Up ................................................. 9 ±1 seconds

SEAT DOWN function

When the SEAT DOWN footswitch is depressed,

current is applied across the seat actuator motor coil

thru the seat down limit switch and seat capacitor. The

seat down limit switch is a N.C. switch which is tripped

when the base function is between the all the way down

position to approximately the 2/3 up position, resulting

in an open circuit. This means that the switch is

untripped only when the base function is in the 2/3 up

position to all the way up position, resulting in a closed

circuit. This only allows the operator to lower the SEAT

DOWN function if the base actuator is in 2/3 up position

or higher. This prevents an accidental seat section

collision with floor. The seat capacitor provides motor

start and motor run power for the seat actuator.

© Midmark Corporation 1995 SF-1457 Rev. 7/98 Page 1-3 Printed in U.S.A.

Weight Capacity (Maximum)............. 300 lb. (136.0 kg)

Electrical Requirements:

115 VAC Unit........................... 110 - 120 VAC, 60 HZ,

6 amp, single phase

230 VAC Unit...................... 220 - 240 VAC, 50/60 HZ,

5 amp, single phase

Power Consumption:

115 VAC Unit ........................................... 720 WATTS,

6 amps @ 120 VAC

230 VAC Unit........................................ 1200 WATTS,

5 amps @ 240 VAC

Recommended Circuit:

A separate (dedicated) circuit is recommended for

this chair. The chair

electrical circuit with other appliances or equipment

unless the circuit is rated for the additional load.

should not

be connected to an

Page 8

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

68 in. (172.7 cm.)

53 1/4 in. (135.2 cm.)

16 in.

40.6 cm.

22 in.

(55.9 cm.)

33 3/4 in.

(85.7 cm.)

72 in

(182.9 cm.)

100 in.

(254 cm.)

19 5/8 in.

(49.8 cm.)

30 3/4 in.

(78.1 cm.)

Figure 1-2. Chair Dimensions

50 in.

(127 cm.)

44 1/2 in.

(113 cm.)

MA318000

© Midmark Corporation 1995 SF-1457 Page 1-4 Printed in U.S.A.

Page 9

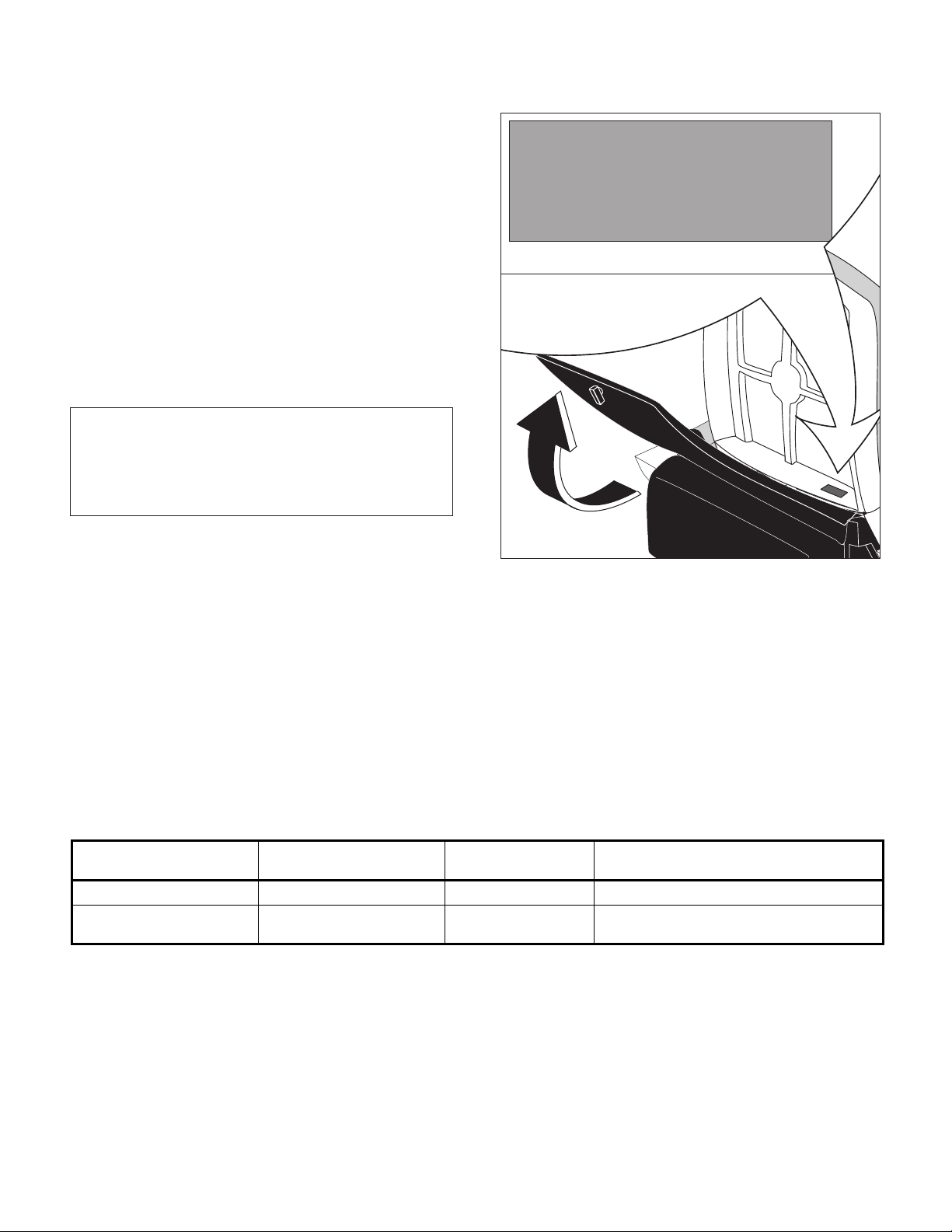

1.5 Parts Replacement Ordering

MODEL NO. 413-00X

INPUT. 120 VAC.

RATING 6 AMPS 60 Hz

SERIAL NO. XXXXXX

FOR SALES OR SERVICE CALL 1-800-XXX-XXXX MADE IN THE U.S.A.

MIDMARK

Return To Table Of Contents

If a part replacement is required, order the part directly

from the factory as follows:

(1) Refer to Figure 1-3 to determine the location of

the model number and serial number of the

chair and record this data.

(2) Refer to the Parts List to determine the item

numbers of the parts, part numbers of the

parts, descriptions of the parts, and quantities

of parts needed and record this data (Refer to

para 6.1).

NOTE

Ask the Purchasing Department of the company that

owns the chair for this information. Otherwise, this

information may be obtained from the dealer that

sold the chair.

SECTION I

GENERAL INFORMATION

(3) Determine the installation date of the chair and

record this data.

(4) Call Midmark with the recorded information and

ask for the Medical Products Technical Services Department. See back cover of this

manual for the phone number or use the Fax

Order Form (See page 7-2 for Fax Order

Form).

1.6 Special Tools

Table 1-2 lists all of the special tools needed to repair

the chair, how to obtain the special tools, and the

purpose of each special tool.

Description of Special Tool

Multimeter Commercially Available Any Type Used to perform continuity and voltage checks.

Torque Wrench Commercially Available Any Type Used to tighten hardware to specified torque

Manufacturer’s

Name / Address / Phone

MA309302

Figure 1-3. Model Number / Serial

Table 1-2. Special Tool List

Manufacturer’s

Part Number

Number Location

Purpose of Special Tool

values.

© Midmark Corporation 1995 SF-1457 Page 1-5 Printed in U.S.A.

Page 10

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

© Midmark Corporation 1995 SF-1457 Page 1-6 Printed in U.S.A.

Page 11

TESTING AND TROUBLESHOOTING

Return To Table Of Contents

SECTION II

TESTING AND TROUBLESHOOTING

SECTION II

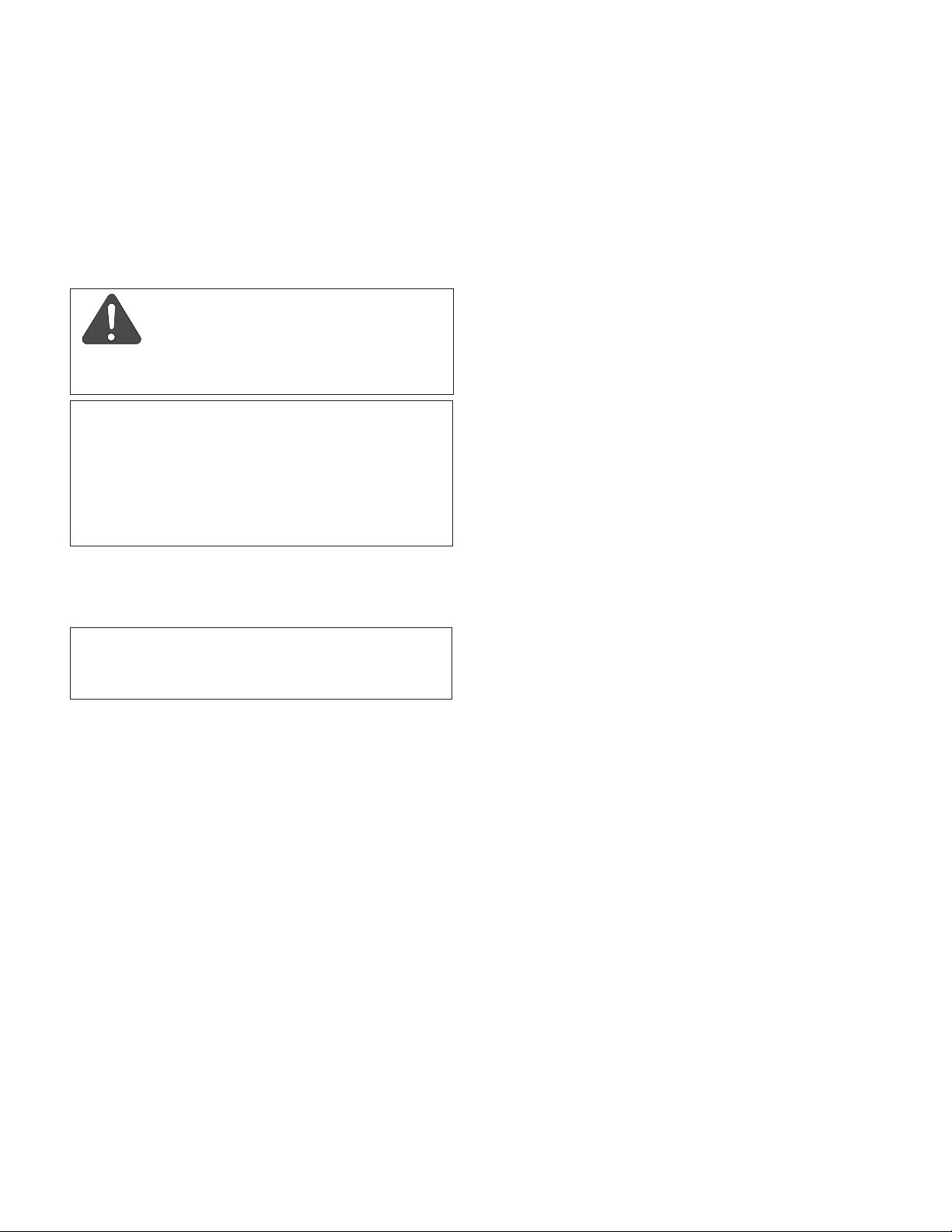

2.1 Operational Test

In order to effectively diagnose the malfunction of the

chair, it may be necessary to perform an operational

test as follows:

DANGER

Refer to the Operator Manual for

complete instructions on operating the

chair. Failure to do so could result in personal

injury.

NOTE

The Operational Test, for the most part, only describes what should happen when the chair is

operated. If the chair does something other than

described, a problem has been discovered. Refer to

the Troubleshooting Guide to determine the cause of

the problem and its correction.

(1) Plug the chair into a grounded, non-isolated,

correctly polarized outlet, that has the proper

voltage output for the chair.

(7) Depress BASE DOWN footswitch and lower

table top all the way down; then depress SEAT

DOWN footswitch.

(8) Observe. After the BASE DOWN function is

lowered all the way down, the seat actuator

should not run when the SEAT DOWN

footswitch is depressed.

(9) Run BASE UP function all the way up and then

run SEAT DOWN function all the way down.

(10) Pull the pan holder assembly outward until pan

safety limit switch is no longer tripped. Depress

SEAT UP footswitch and then SEAT DOWN

footswitch.

(11) Observe. The seat section of table top

not

move when the SEAT UP and SEAT

DOWN footswitches are depressed.

(12) Push pan holder assembly inward until pan

safety limit switch is tripped. Depress SEAT

UP and SEAT DOWN footswitches.

should

NOTE

Pan holder assembly should be pushed in fully for

the following step.

(2) Depress BASE UP, SEAT DOWN, SEAT UP,

and BASE DOWN footswitches in this order.

(3) Observe. The table top should move in the

direction corresponding to the footswitch which

is being depressed and at the speeds listed

below:

Chair Speeds (@ 60 Hz.):

Base Down to Base Up in 9 +/1 seconds

Seat Down to Seat Up in 9 +/1 seconds

The actuator assembly should not drift after the

footswitch is released. The actuator assembly

should not make excessive squealing noises.

(4) Raise BASE UP function all the way up.

(5) Depress SEAT DOWN footswitch and lower

seat section halfway. Then raise SEAT UP

function all the way up.

(6) Observe. Seat actuator should run.

(13) Observe. The seat section of table top

move when the SEAT UP and SEAT DOWN

footswitches are depressed.

(14) Lower the SEAT DOWN function all the way

down.

(15) Depress and hold the BASE DOWN footswitch.

(16) Observe. The BASE DOWN function should

lower approximately 1/3 of its travel and then

stop.

(17) Raise the SEAT UP function all the way up.

(18) Depress the BASE DOWN footswitch.

(19) Observe. The BASE DOWN function should

lower all the way down.

(20) Pull the release handle and extend the foot

extension. Then, pull the release handle and

push the foot extension back into foot section.

should

© Midmark Corporation 1995 SF-1457 Page 2-1 Printed in U.S.A.

Page 12

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

RELEASE

BUTTON

PAN HOLDER

ASSEMBLY

SEAT

SECTION

FOOT

EXTENSION

ARM

REST

Figure 2-1. Operational Test

(21) Observe. The foot extension should slide out

easily and quietly. The foot extension should

automatically lock into a fully extended position.

When the foot extension is pushed into the foot

section, the foot extension should automatically

lock into a stowed position.

RELEASE

HANDLE

BASE DOWN

SEAT UP

SEAT DOWN

BASE UP

MA316500

(24) Raise arm rest upward and then release.

(25) Observe. The arm rest should automatically

lock into its normal position.

2.2 Troubleshooting Procedures

(22) Press the arm rest release button and lower the

arm rest.

(23) Observe. When the release button is pressed,

the arm rest should be able to be lowered.

© Midmark Corporation 1995 SF-1457 Page 2-2 Printed in U.S.A.

Table 2-1 is a Troubleshooting Guide which is used to

determine the cause of the malfunction.

Page 13

TESTING AND TROUBLESHOOTING

Return To Table Of Contents

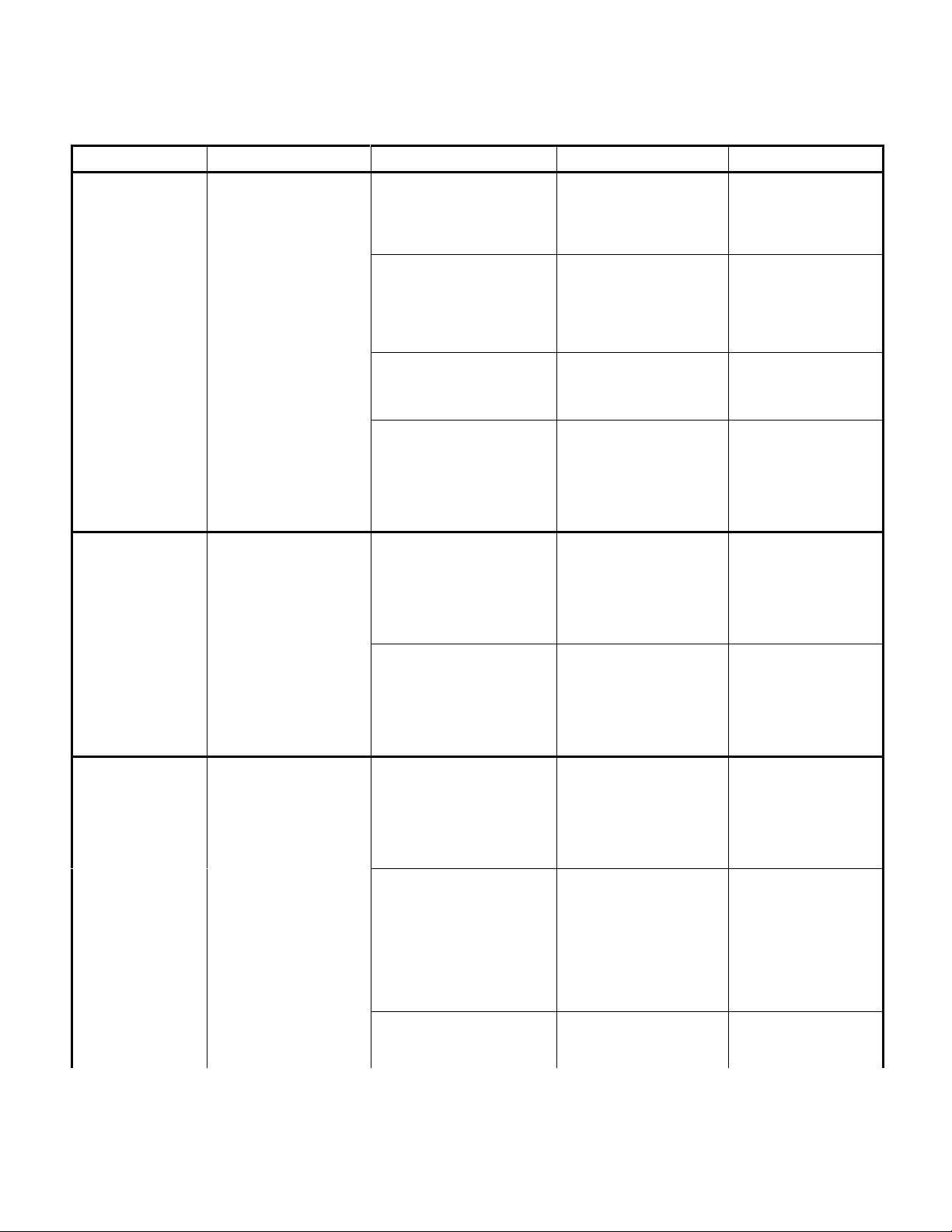

Table 2-1. Troubleshooting Guide

Problem Symptom Probable Cause Check Correction

Table will not operate

when any of the Base

or Seat up or down

functions are

selected.

SEAT UP function

does not work, but

SEAT DOWN

function does.

SEAT DOWN

function does not

work, but SEAT UP

function does.

When a foot control

footswitch is depressed,

its actuator motor does

not run or hum.

When SEAT UP

footswitch is depressed,

nothing happens.

When SEAT DOWN

footswitch is depressed,

nothing happens.

Power cord is not plugged into

facility wall outlet.

Facility circuit breaker

providing power to chair is

tripped.

One or both fuses in AC

connector receptacle is blown

(export models only).

Wire connections loose. Check all wiring

SEAT UP footswitch is

malfunctioning.

SEAT DOWN footswitch is

sticking open.

SEAT DOWN footswitch is

malfunctioning.

Seat down limit switch is

tripped.

Seat down limit switch is

malfunctioning.

Check to see if power cord

is plugged in.

Check to see if facility

circuit breaker is tripped.

One way of checking this is

to plug a lamp into wall

outlet that chair was

plugged into.

Refer to Figure 5-2, Sheets

1 or 2 for fuse information.

Perform continuity check on

fuse.

connections from power

cord to terminal block.

Perform continuity check on

wires. Use multimeter to

check for proper voltage

levels.

Perform continuity check on

SEAT UP footswitch.

When footswitch is

activated, there should be

continuity between COM.

and N.O. terminals of

footswitch.

Perform continuity check on

SEAT DOWN footswitch.

When footswitch is not

activated, there should be

continuity between COM.

and N.C. terminals of

footswitch.

Perform continuity check on

SEAT DOWN footswitch.

When footswitch is

activated, there should be

continuity between COM.

and N.O. terminals of

footswitch.

Check if seat down limit

switch is tripped. Seat

down limit switch should be

tripped when base actuator

is in all the way down

position to 2/3 up position.

This prevents operator from

accidentally colliding seat

section with floor.

Perform continuity check on

N.C. seat down limit

switch. Switch tripped =

p

Plug power cord into

facility wall outlet.

If circuit breaker is

tripped, determine what

caused circuit breaker to

trip, correct the problem,

and then reset / replace

circuit breaker.

Replace any blown

fuses.

Clean any dirty

connections. Tighten

any loose connections.

Replace any damaged

connections.

Replace SEAT UP

footswitch. Refer to

para 4.10.

Replace SEAT DOWN

footswitch. Refer to

para 4.10.

Replace SEAT DOWN

footswitch. Refer to

para 4.10.

Raise BASE UP function

until it is at least 2/3 of

the way up in its travel.

Then SEAT DOWN

function will work.

Inform operator of the

seat down limit switch

function.

Replace seat down limit

switch. Refer to para

4.9.

SECTION II

© Midmark Corporation 1995 SF-1457 Page 2-3 Printed in U.S.A.

Page 14

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

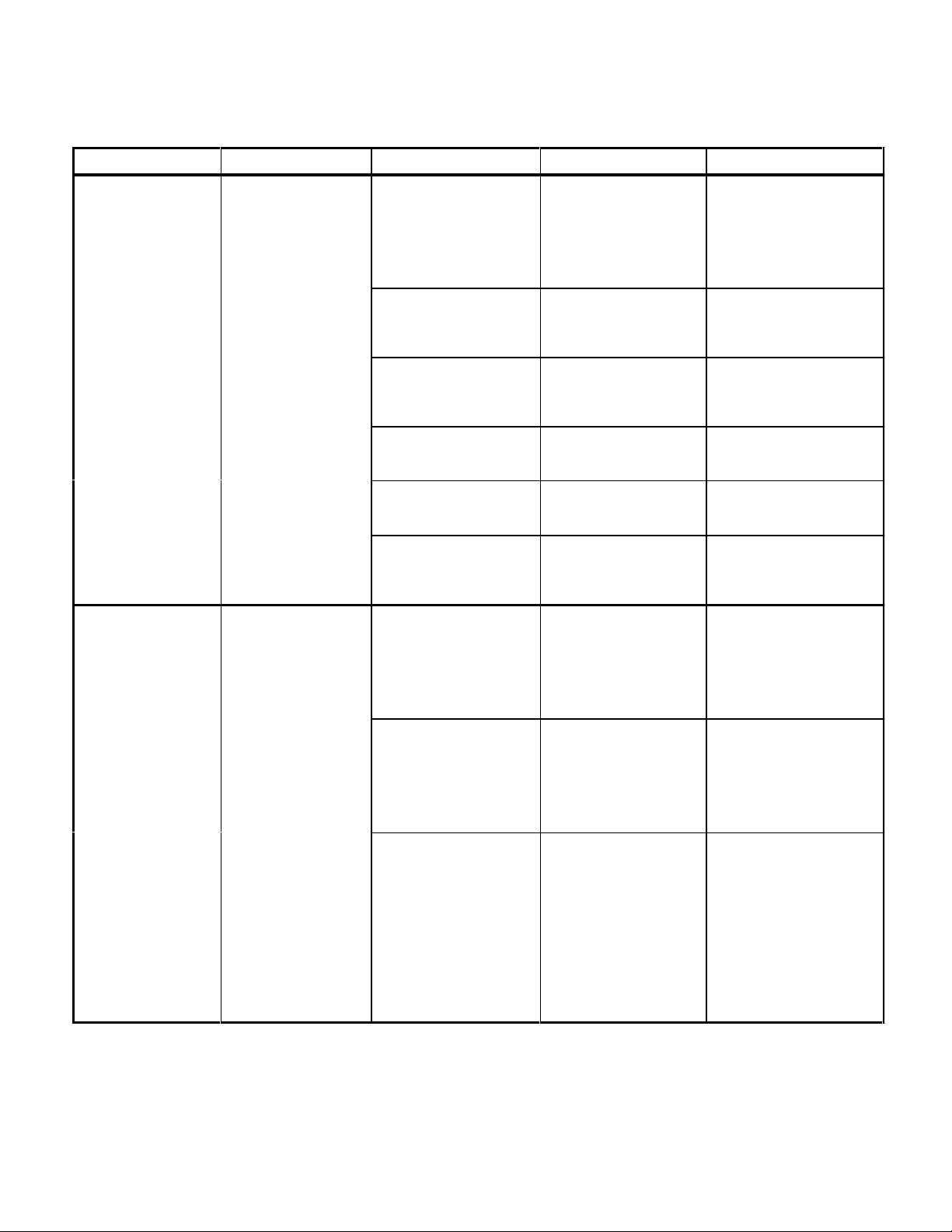

Table 2-1. Troubleshooting Guide - Continued

Problem Symptom Probable Cause Check Correction

SEAT UP and SEAT

DOWN functions do not

work.

BASE DOWN function

does not work, but BASE

UP function does.

When SEAT DOWN or

SEAT UP footswitch is

depressed, nothing

happens.

When BASE DOWN

footswitch is depressed,

nothing happens.

Wire connections loose. Check all wiring

Treatment pan assembly is

not pushed in all the way.

Pan safety limit switch is

malfunctioning.

Seat capacitor is weak or

blown.

Thermal overload switch in

seat actuator motor is

activated.

Seat actuator assembly is

malfunctioning.

BASE DOWN footswitch is

malfunctioning.

BASE UP footswitch is

sticking open.

Base down limit switch is

tripped.

connections from SEAT

DOWN footswitch to

terminal block. Perform

continuity check on wires.

Use multimeter to check for

proper voltage levels.

Check if treatment pan

assembly is pushed all the

way in to its stowed

position.

Perform continuity check on

pan safety limit switch.

Switch tripped = closed

circuit or continuity.

Replace suspect seat

capacitor with known

working seat capacitor.

__ Wait 10 to 20 minutes to allow

Replace suspect seat

actuator assembly with

known working seat

actuator assembly.

Perform continuity check on

BASE DOWN footswitch.

When footswitch is

activated, there should be

continuity between COM.

and N.O. terminals of

footswitch.

Perform continuity check on

BASE UP footswitch.

When footswitch is not

activated, there should be

continuity between COM.

and N.C. terminals of

footswitch.

Check if base down limit

switch is tripped. Base

down limit switch will be

tripped when base actuator

is lowered below the 2/3 up

position. This removes

current from base actuator if

N.C seat up limit switch is

also tripped. This prevents

operator from accidentally

colliding seat section with

floor.

Clean any dirty connections.

Tighten any loose

connections. Replace any

damaged connections.

Push treatment pan assembly

all the way in. Inform

operator on how this function

works.

Replace pan safety limit

switch. Refer to para 4.4.

Replace seat capacitor.

Refer to para 4.7.

seat actuator motor to cool.

Replace seat actuator

assembly. Refer to para 4.3.

Replace BASE DOWN

footswitch. Refer to para

4.10.

Replace BASE UP footswitch.

Refer to para 4.10.

Raise SEAT UP function all

the way up to untrip seat up

limit switch. Then BASE

DOWN function can be

lowered all the way down.

Inform the operator how this

function works.

© Midmark Corporation 1995 SF-1457 Rev. 9/97 Page 2-4 Printed in U.S.A.

Page 15

TESTING AND TROUBLESHOOTING

Return To Table Of Contents

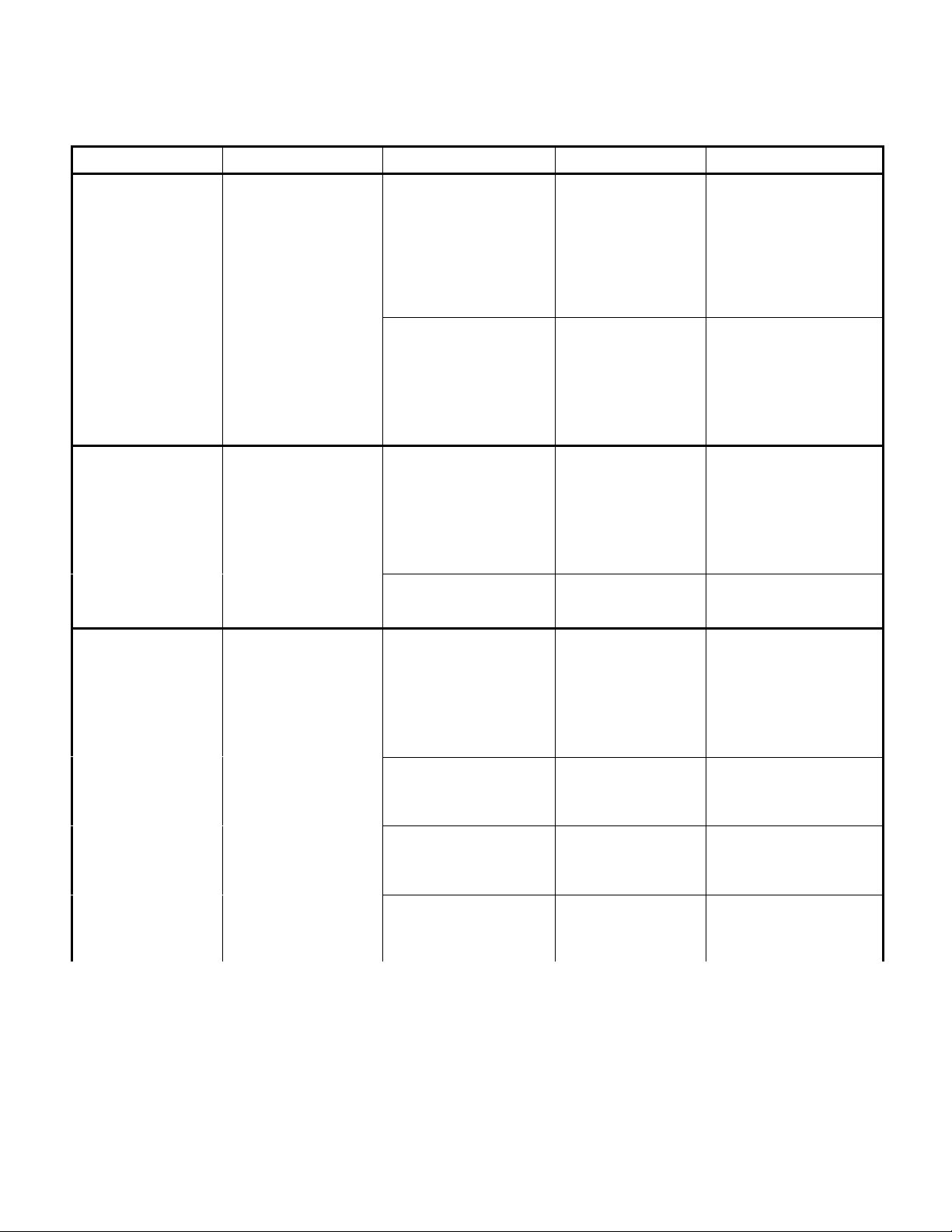

Table 2-1. Troubleshooting Guide - Continued

Problem Symptom Probable Cause Check Correction

BASE DOWN function

does not work, but

BASE UP function does

- Continued.

BASE UP function does

not work, but BASE

DOWN function does.

BASE UP and BASE

DOWN functions do not

work.

When BASE DOWN

footswitch is depressed,

nothing happens Continued.

When BASE UP

footswitch is depressed,

nothing happens.

When BASE UP or BASE

DOWN footswitch is

depressed, nothing

happens.

Base down limit switch is

malfunctioning.

Seat up limit switch is

malfunctioning.

BASE UP footswitch is

malfunctioning.

Gas spring is

malfunctioning.

Wire connections loose. Check all wiring

Base capacitor is weak or

blown.

Perform continuity

check on N.C. base

down limit switch.

Switch tripped = open

circuit. Base down limit

switch is tripped when

base actuator is in all

the way down position

to 2/3 up position.

Perform continuity

check on N.C. seat up

limit switch. Switch

tripped = open circuit.

Seat up limit switch is

untripped only when

seat section is all the

way up.

Perform continuity

check on BASE UP

footswitch. When

footswitch is activated,

there should be

continuity between

COM. and N.O.

terminals of footswitch.

Replace suspect gas

spring with known

working gas spring.

connections from BASE

UP footswitch to

terminal block. Perform

continuity check on

wires. Use multimeter

to check for proper

voltage levels.

Replace suspect base

capacitor with known

working base capacitor.

Replace base down limit

switch. Refer to para 4.9.

Replace seat up limit switch.

Refer to para 4.2.

Replace BASE UP

footswitch. Refer to para

4.10.

Replace gas spring. Refer

to para 4.5.

Clean any dirty connections.

Tighten any loose

connections. Replace any

damaged connections.

Replace base capacitor.

Refer to para 4.7.

SECTION II

© Midmark Corporation 1995 SF-1457 Page 2-5 Printed in U.S.A.

Thermal overload switch in

base actuator motor is

activated.

Base actuator assembly is

malfunctioning.

_ Wait 10 to 20 minutes to

Replace suspect base

actuator assembly with

known working base

actuator assembly.

allow base actuator motor to

cool.

Replace base actuator

assembly. Refer to para

4.6.

Page 16

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

Table 2-1. Troubleshooting Guide - Continued

Problem Symptom Probable Cause Check Correction

Chair moves fine for light

patient, but will not move

or moves slowly for very

heavy patient.

Heavy patients cause

table to malfunction.

Low voltage is being

supplied to chair.

Table overloaded with too

heavy of a patient.

Check voltage at wall

receptacle - should be

115 +/- 5 VAC for

domestic units and 230

+/- 10 VAC for export

units.

Maximum weight

capacity of table is 300

lbs (136.0 kg).

Correct low voltage situation

at wall receptacle.

Inform chair operator of

weight limitation.

Whirling or squeaking

noise is heard when an

actuator assembly is

being run.

Foot extension locking

mechanism is

malfunctioning.

Capacitor for suspect

function is weak.

Noisy actuator. Foreign matter on ball

Foot extension does not

lock into stowed position

or extended position

automatically.

screw threads and / or lack

of lubricant.

Foot extension lock /

unlock mechansim is

malfunctioning.

Replace suspect

capacitor with known

working capacitor.

Check for foreign

matter on ball screw

threads. Check for lack

of lubricant on ball

screw threads.

Check to see if return

spring is present.

Check to see if linking

rod is present.

Replace capacitor. Refer to

para 4.7.

Clean all foreign matter off

of ball screw threads. Coat

ball screw threads with STP

treatment oil or equivalent.

If actuator assembly is still

noisy, replace. Refer to

para 4.3 or 4.6.

Lubricate mechansim with a

silicone based lubricant.

Replace missing, worn, or

broken return spring or

linking rod.

© Midmark Corporation 1995 SF-1457 Page 2-6 Printed in U.S.A.

Page 17

SCHEDULED MAINTENANCE

Return To Table Of Contents

SECTION III

SCHEDULED MAINTENANCE

SECTION III

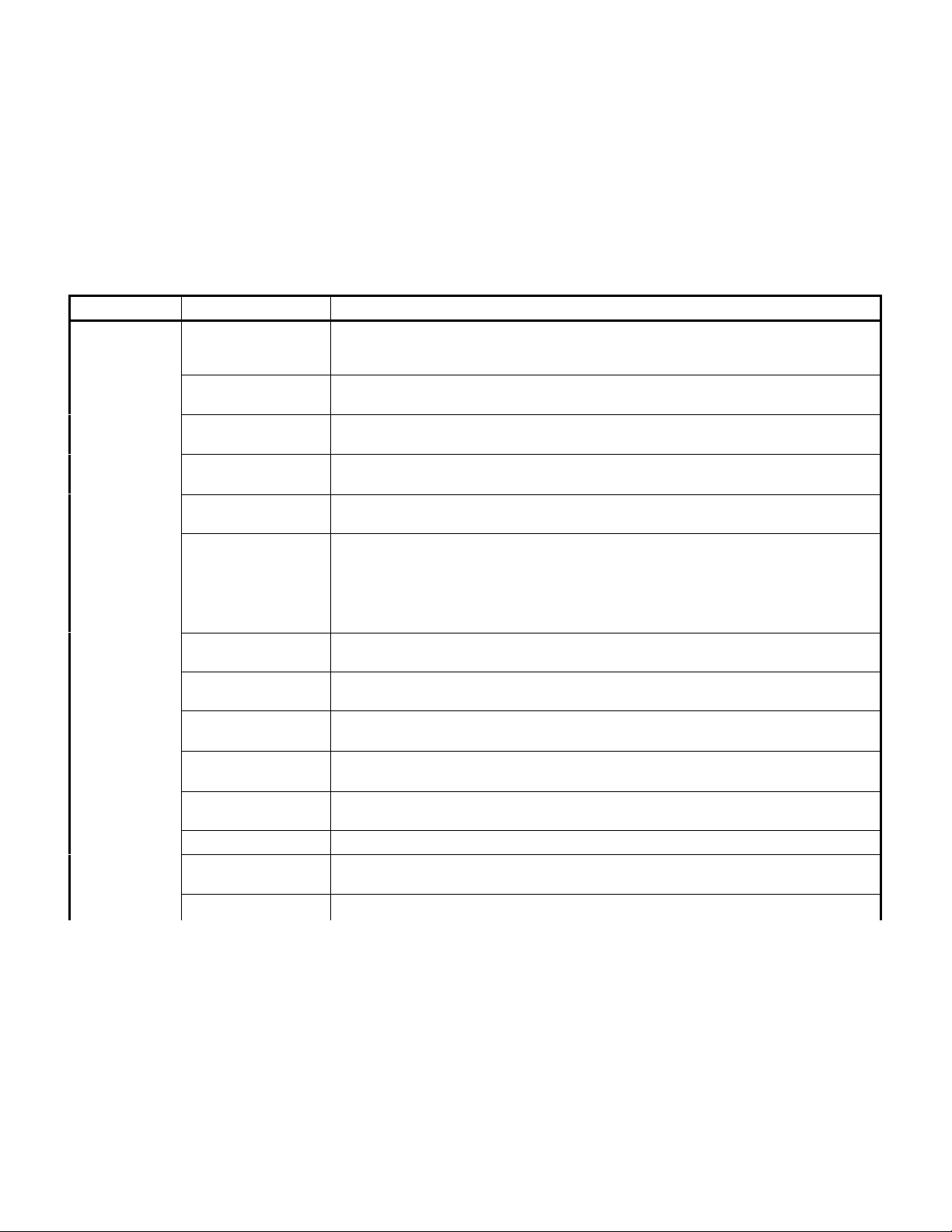

3.1 Scheduled Maintenance

periodically on the chair. These inspections and

services should be performed as often as indicated in

Table 3-1 is a Scheduled Maintenance Chart which lists

the chart.

the inspections and services that should be performed

Table 3-1. Scheduled Maintenance Chart

Interval Inspection or Service What to Do

Semi-annually Obvious damage Visually check condition of chair for obvious damage such as: cracks in components, missing

Fasteners/hardware Check chair for missing or loose fasteners / hardware. Replace any missing hardware and

Warning and

instructional decals

Pivot points / moving

parts / accessories

Foot control Check that foot control works correctly. Make sure all footswitches operate properly.

Ball screws of actuator

assemblies

Inner tube of base

actuator

Drifting of actuator

assemblies

Foot extension Check that foot extension automatically locks into stowed and extended positions. Lubricate

Pan safety limit switch Check that pan safety limit switch is tripped when pan assembly is in fully stowed position.

Electrical receptacle

(domestic units only)

Upholstery Check all upholstery for rips, tears, or excessive wear. Replace cushions as necessary.

Accessories Check that all accessories have all of their components and that they function properly. If

Operational Test Perform an Operational Test to determine if the chair is operating within its specifications

components, dents in components, or any other visible damage which would cause chair to

be unsafe to operate or would compromise its performance. Repair chair as necessary.

tighten any loose hardware as necessary.

Check for missing or illegible decals. Replace decals as necessary.

Lubricate all exposed pivot points, moving parts, and accessories with silicone based

lubricant.

Replace any malfunctioning footswitches. Refer to para 4.10.

Extend each actuator assembly and wipe ball screw threads down with a rag to remove

foreign matter. Coat as much of the ball screw threads as possible with STP treatment oil or

equivalent. Run each actuator assembly to both ends of its travel a couple of times to

spread the oil evenly over all of the ball screw threads and then remove excess oil. If oil

does not correct a squealing actuator assembly, replace actuator assembly. Refer to para

4.3 or 4.6.

Lubricate inner tube of base actuator with vaseline.

Check each actuator assembly for drift. Replace actuator assembly brake components as

necessary. Refer to para 4.8.

linkages with a silicone based lubricant.

Adjust or replace pan safety limit switch if necessary. Refer to para 4.4.

Check that the electrical receptacle is functioning properly. Replace receptacle as

necessary.

necessary, repair or replace the accessory.

p

p

p

© Midmark Corporation 1995 SF-1457 Page 3-1 Printed in U.S.A.

Page 18

SECTION III

Return To Table Of Contents

SCHEDULED MAINTENANCE

© Midmark Corporation 1995 SF-1457 Page 3-2 Printed in U.S.A.

Page 19

MAINTENANCE / SERVICE

EARLY UNITS

3A

4

5

4

6

7

1

LATER UNITS

4

3B

EARLY UNITS

3A

4

Return To Table Of Contents

SECTION IV

MAINTENANCE / SERVICE INSTRUCTIONS

SECTION IV

4.1 Introduction

DANGER

Refer to the Operator Manual for

complete instructions on operating the

chair. Failure to do so could result in personal

injury.

NOTE

Perform an operational test on the chair after the

repair is completed to confirm the repair was properly

made and that

The following paragraphs contain removal, installation, repair, and adjustment procedures for the chair.

all

malfunctions were repaired.

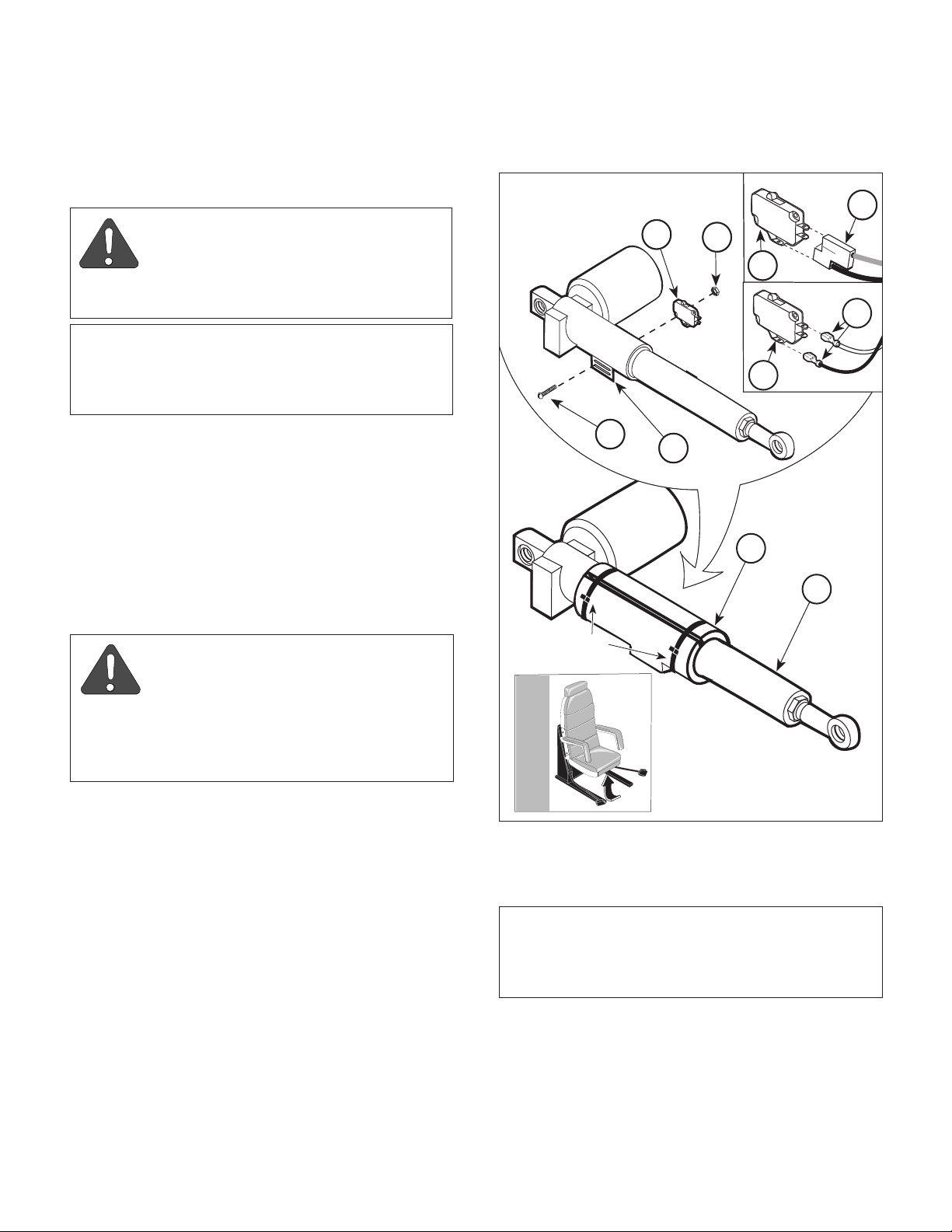

4.2 Seat Up Limit Switch Removal / Installation

A. Removal

(1) Raise TABLE UP and SEAT UP functions all

the way up.

LATER UNITS

3B

4

5

4

6

7

1

2

DANGER

Always disconnect the power cord

from the wall outlet before removing

any of the chair's covers/shrouds or making any

repairs to prevent the possibility of electrical

shock. Failure to comply with these instructions

could result in severe personal injury or death.

(2) Unplug chair power cord from wall outlet.

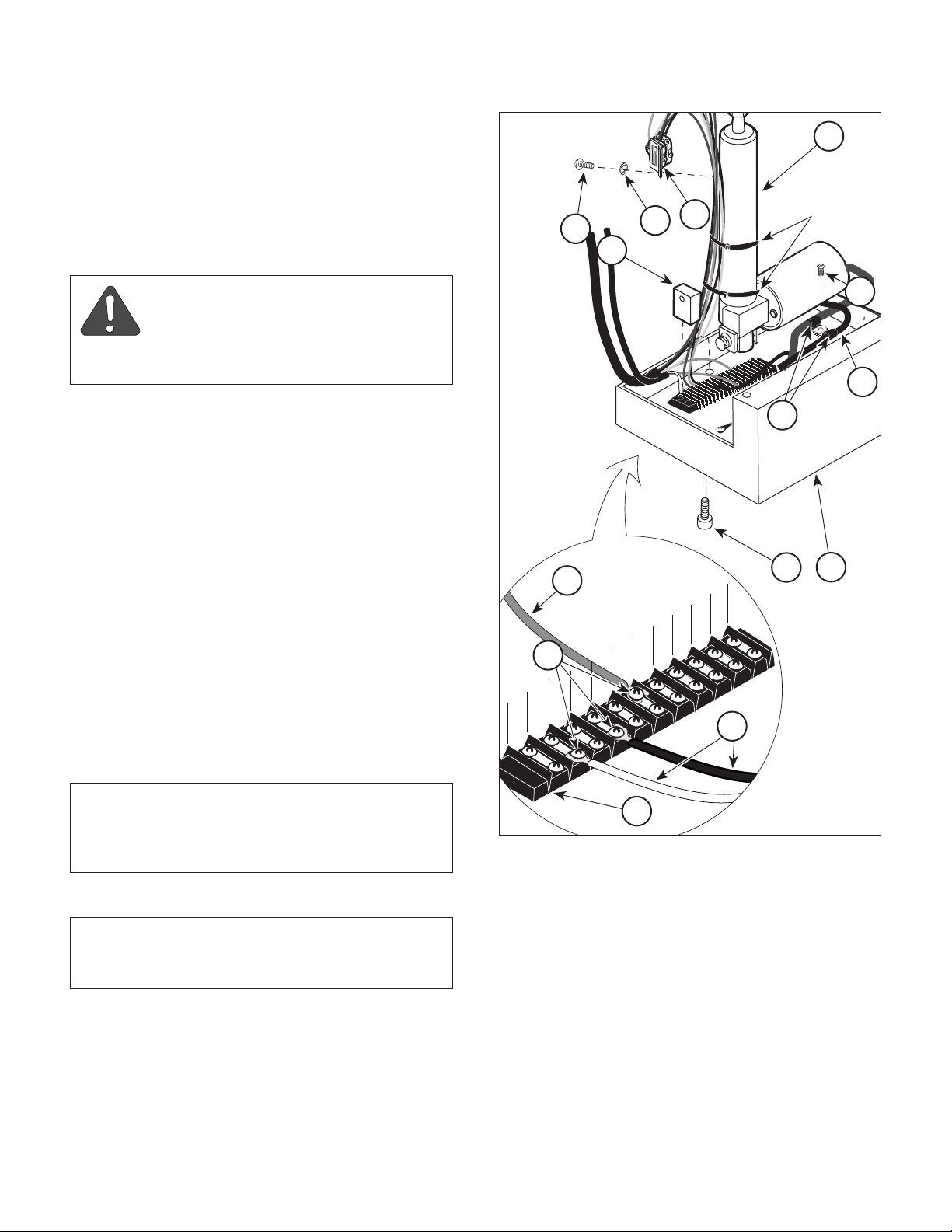

(3) Cut two cable ties and remove actuator sleeve

(1, Figure 4-1) from shaft of seat actuator (2).

(4) On early units, tag and disconnect two wires

(3A) from terminals of seat up limit switch (4).

On later units, disconnect wire harness (3B)

from seat up limit switch (4).

(5) Remove two nuts (5), screws (6), and seat up

limit switch (4) from switch bracket (7).

CABLE TIES

VIEW

MA316600

Figure 4-1. Seat Up Limit Switch

Removal / Installation

B. Installation

NOTE

With SEAT UP function all the way up, seat up limit

switch should be untripped. Make sure seat up limit

switch is installed to meet this condition.

(1) Install seat up limit switch (4) on switch bracket

(7) and secure with two screws (6) and

nuts (5), making sure trip arm of switch is in

cutout of seat actuator shaft (2).

© Midmark Corporation 1995 SF-1457 Page 4-1 Printed in U.S.A.

Page 20

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

(2) On early units, connect two wires (3A) to

terminals of seat up limit switch (4).

On later units, connect wire harness (3B) to

seat up limit switch (4).

(3) Install actuator sleeve (1) on shaft of seat

actuator (2) and secure with two cable ties.

NOTE

The following step applies to later units only.

(7) On later units, remove two screws (9) and

partially separate receptacle bracket (10) from

pivot frame (11).

(4) Plug chair power cord into wall outlet.

4.3 Seat Actuator Removal / Installation

A. Removal

(1) If possible, raise SEAT UP function all the way

up.

DANGER

Always disconnect the power cord

from the wall outlet before removing

any of the chair's covers/shrouds or making any

repairs to prevent the possibility of electrical

shock. Failure to comply with these instructions

could result in severe personal injury or death.

(2) Unplug chair power cord from wall outlet.

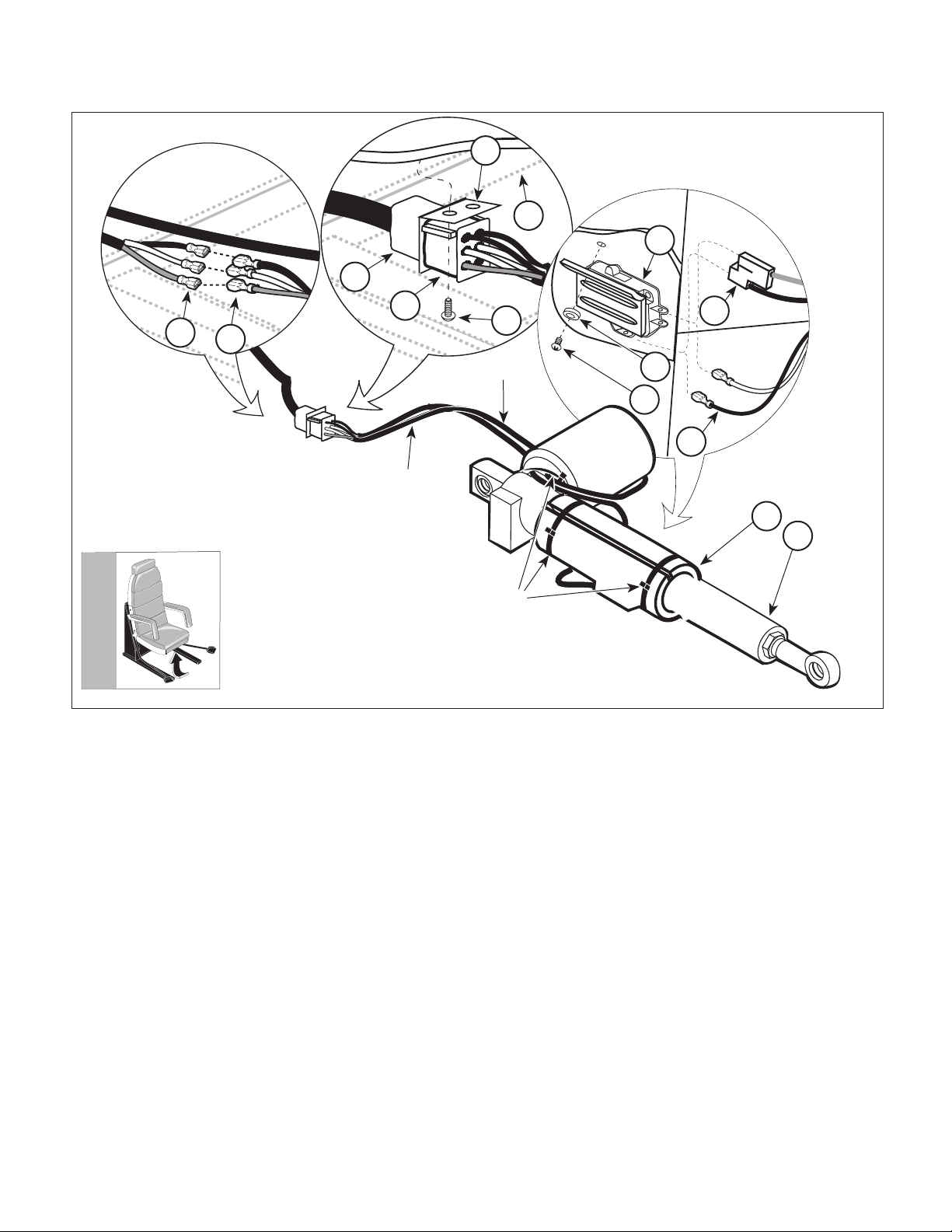

(3) Remove two cable ties and remove actuator

sleeve (1, Figure 4-2) from shaft of seat actuator (2).

(4) On early units, tag and disconnect two wires

(3A) from terminals of seat up limit switch (4).

On later units, disconnect wire harness (3B)

from seat up limit switch (4).

(5) Remove two screws (5), lockwashers (6), and

seat up limit switch assembly (4) from shaft of

seat actuator (2).

NOTE

Early units are units with Serial Numbers BK-1000

thru BK1271 and V-1000 thru V-1575. Later units

are units with Serial Numbers BK-1272, V-1576, and

FH-1000 thru Present.

(8) Cut any cable ties securing wire / wire har-

nesses to seat actuator (2).

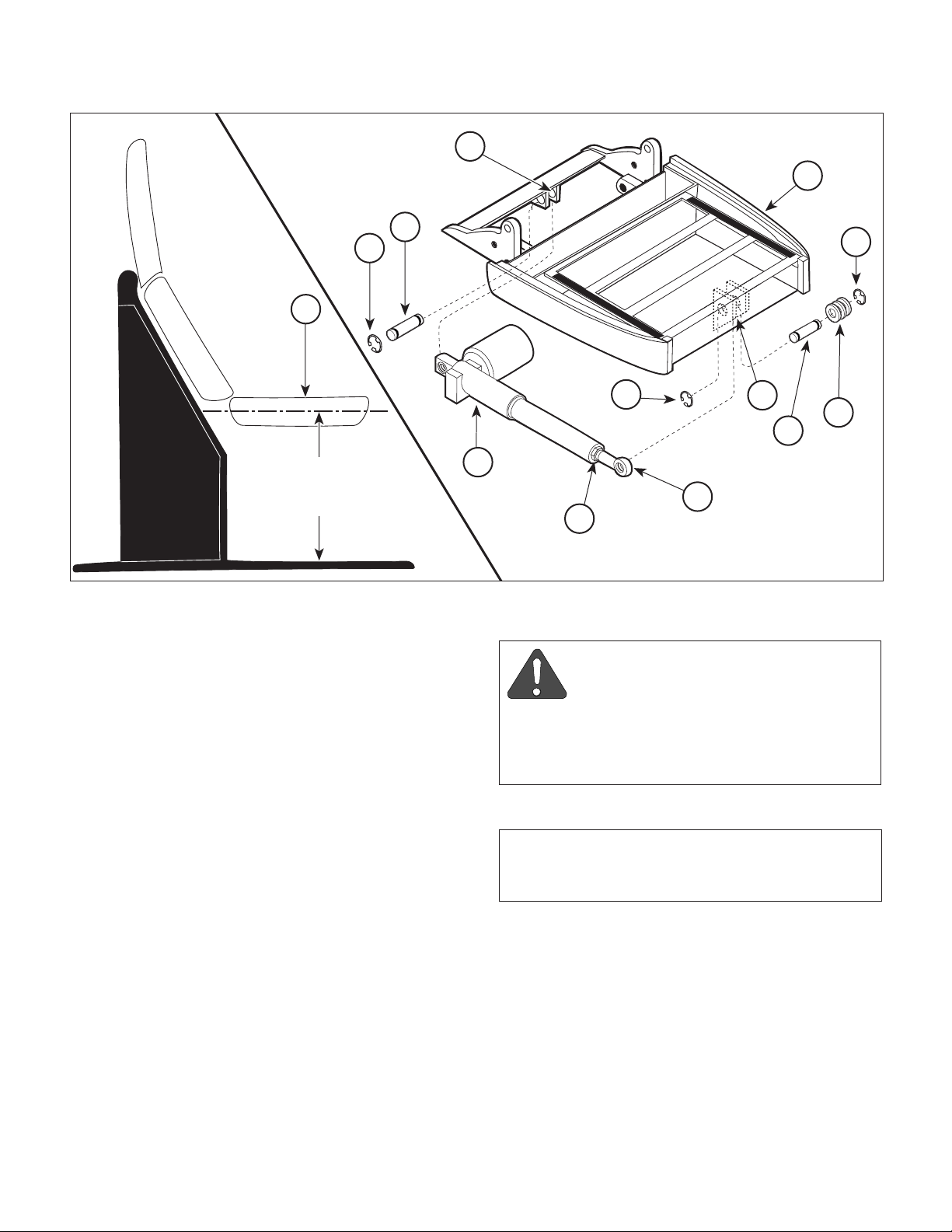

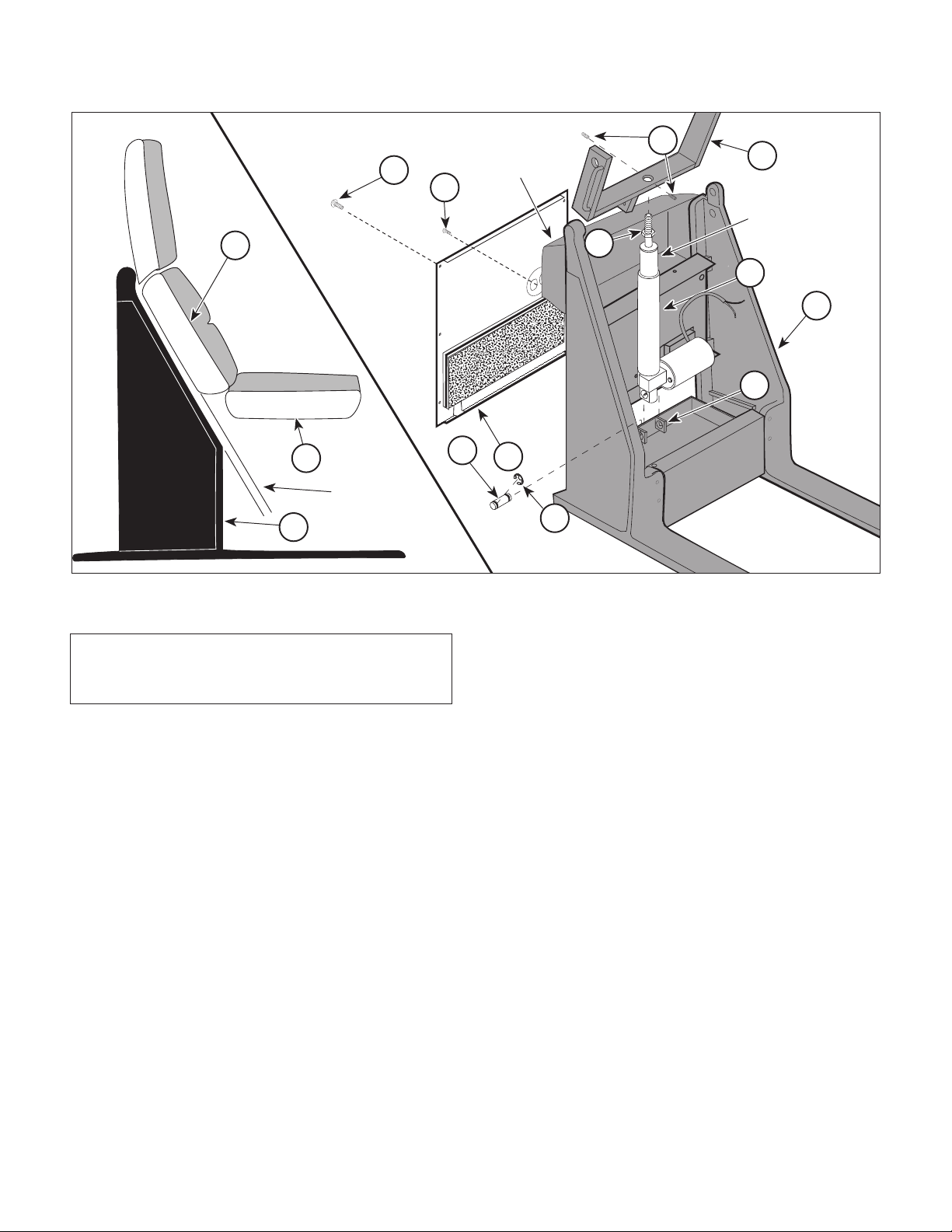

(9) While supporting seat section (1, Figure 4-3),

remove two e-rings (2), clevis pin (3), and base

of seat actuator (4) from bracket (5).

(10) While supporting seat section (1), remove two

e-rings (6), spacers (7), clevis pin (8), and seat

actuator (4) from bracket (9). Remove seat

actuator from chair.

B. Installation

NOTE

This jam nut has left hand threads.

(1) Loosen jam nut (10, Figure 4-3); then remove

swivel joint (11) from shaft of new seat actuator (4).

(2) Coat threads of swivel joint (11) with permanent

threadlocking adhesive (Loctite 262).

(3) Screw swivel joint (11) into shaft of seat

actuator (4).

(4) While supporting seat section (1), install base

of seat actuator (4) on bracket (5) and secure

with clevis pin (3) and two e-rings (2).

(5) While supporting seat section (1), install shaft

end of seat actuator (4) on bracket (9) and

secure temporarily with clevis pin (8).

NOTE

The following step applies to later units only.

(6) On early units, tag and disconnect three wires

(7A) from three actuator wires (8A).

On later units, disconnect wire harness (7B)

from connector receptacle (8B).

© Midmark Corporation 1995 SF-1457 Page 4-2 Printed in U.S.A.

(6) On later units, install receptacle bracket (10,

Figure 4-2) on pivot frame (11) and secure with

two screws (9).

Page 21

10

Return To Table Of Contents

SECTION IV

MAINTENANCE / SERVICE

VIEW

7A

8A

8B

WIRING

HARNESS

7B

WIRING HARNESS

CABLE TIES

11

LATER

UNITS

4

9

3B

EARLY UNITS

6

5

3A

1

2

Figure 4-2. Seat Actuator Wires Disconnection / Connection

(7) On early units, connect three wires (7A) to

three actuator wires (8A).

On later units, connect wire harness (7B) to

connector receptacle (8B).

(8) Install switch bracket assembly (4) on shaft of

seat actuator (2) and secure with two

lockwashers (6) and screws (5).

(9) On early units, connect two wires (3A) to

terminals of seat up limit switch (4).

On later units, connect wire harness (3B) to

seat up limit switch (4).

(10) Secure wires / wire harnesses to seat actuator

(2) with a cable tie.

MA316700

(11) Install actuator sleeve (1) on shaft of seat

actuator (2) and secure with two cable ties.

(12) Run SEAT UP function all the way up and then

run TABLE DOWN function all the way down.

(13) If seat section (1, Figure 4-3)

go to step 18. If seat section (1)

with floor, go to step 14.

(14) While supporting seat section (1), remove

clevis pin (8) securing swivel joint (11) of seat

actuator (4) to bracket (9).

(15) Screw swivel joint (11) in or out as determined

necessary in step 13.

is

level with floor,

is not

level

© Midmark Corporation 1995 SF-1457 Page 4-3 Printed in U.S.A.

Page 22

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

5

1

3

2

1

PARALLEL

SPACING

LEVEL WITH THE FLOOR

Figure 4-3. Seat Actuator Removal / Installation

(16) Connect swivel joint (11) of seat actuator (4) to

bracket (9) and secure with clevis pin (8).

(17) Repeat steps 12 thru 16 until seat section (1) is

level with floor.

(18) Install spacers (7) and two e-rings (6) on clevis

pin (8).

6

9

4

11

10

DANGER

Always disconnect the power cord

from the wall outlet before removing

any of the chair's covers/shrouds or making any

repairs to prevent the possibility of electrical

shock. Failure to comply with these instructions

could result in severe personal injury or death.

6

7

8

MA316800

(19) Tighten jam nut (10).

(20) Plug chair power cord into wall outlet.

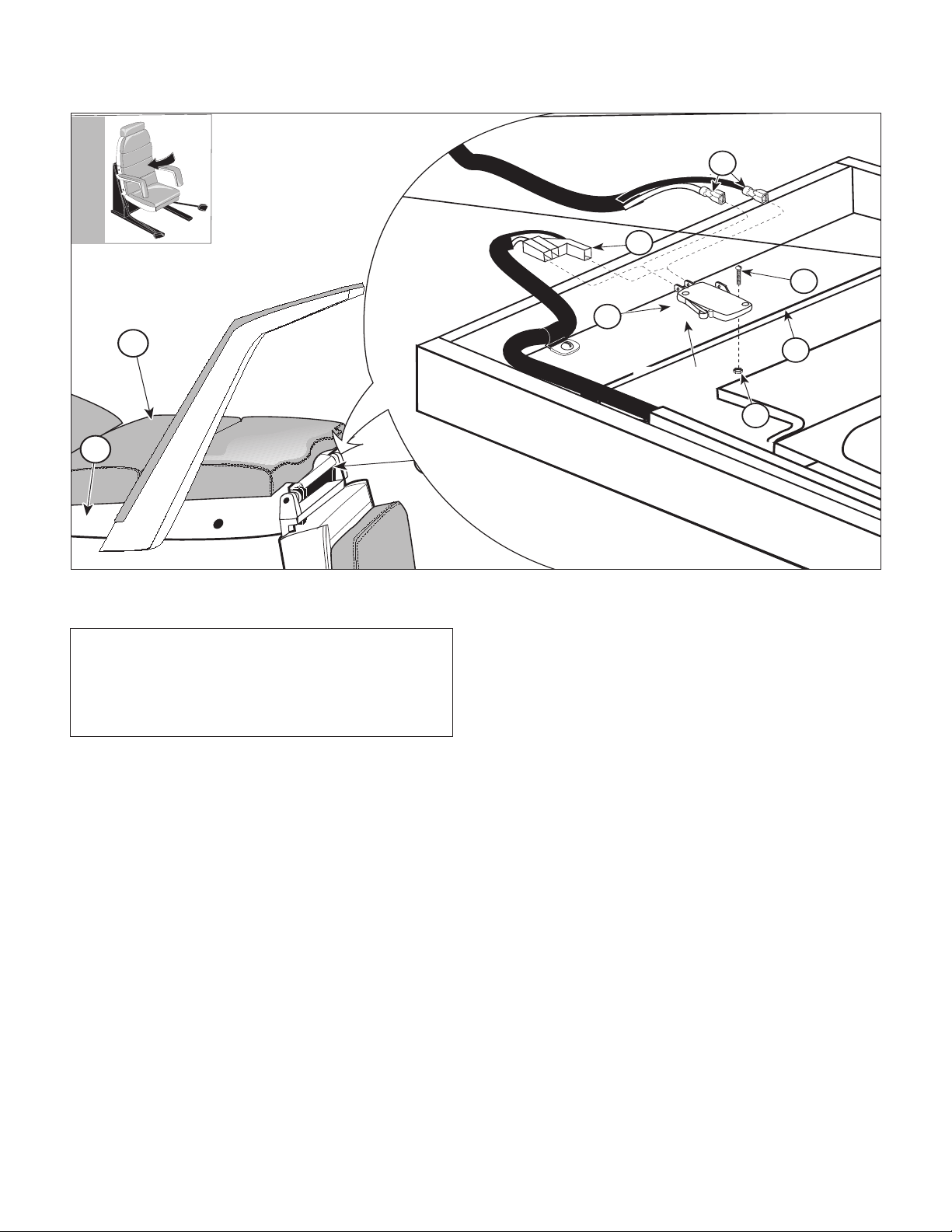

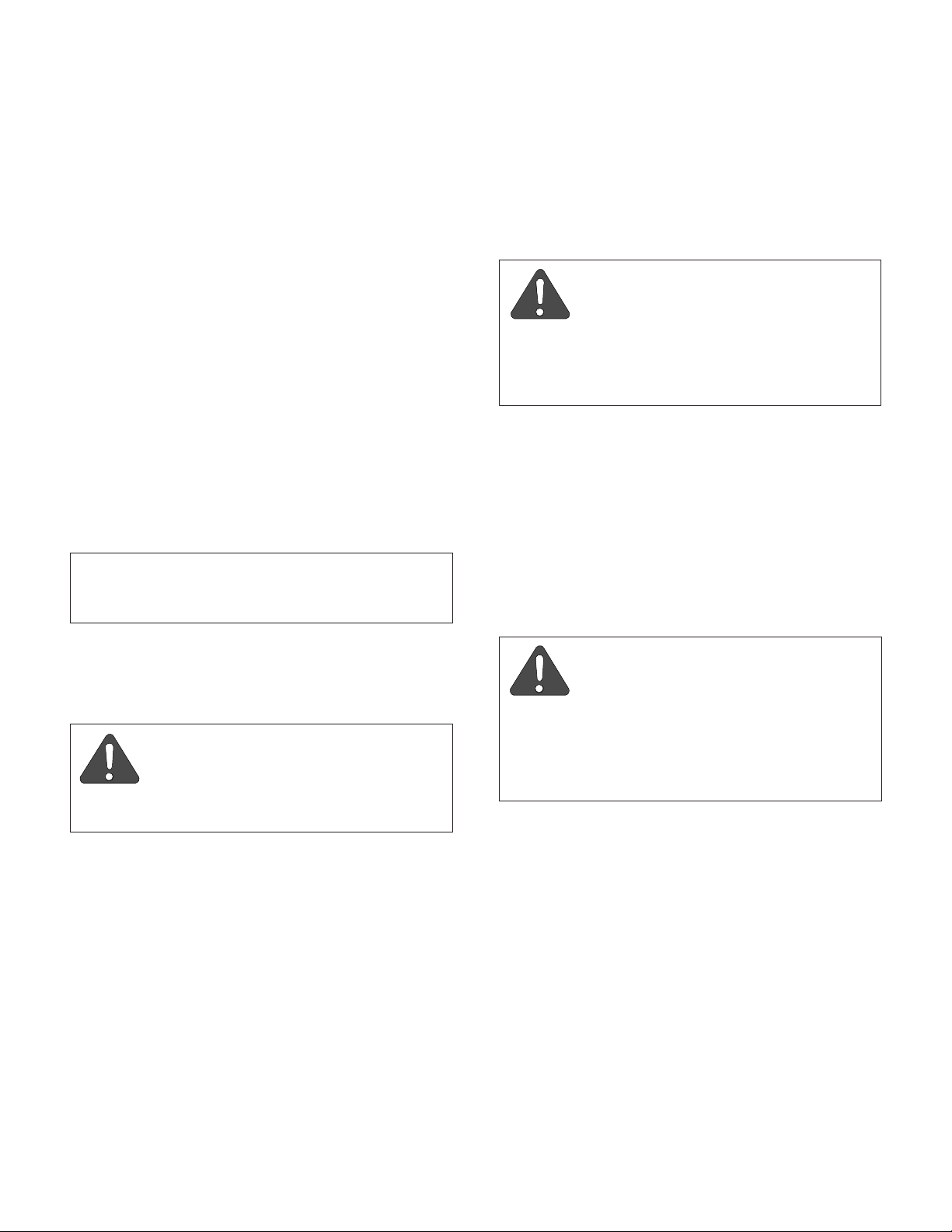

4.4 Pan Safety Limit Switch Removal /

Installation

A. Removal

(1) If possible, run seat section all the way down.

© Midmark Corporation 1995 SF-1457 Page 4-4 Printed in U.S.A.

(2) Unplug chair power cord from wall outlet.

NOTE

The upholstered lower back section is held onto the

lower back casting with velcro.

(3) Remove upholstered lower back section (1,

Figure 4-4) from lower back casting (2).

(4) Pull pan holder assembly (3) out as far as

possible.

Page 23

VIEW

LATER UNITS

7

6

8

TRIP ARM

5

4A

EARLY UNITS

MA316900

4B

Return To Table Of Contents

1

SECTION IV

MAINTENANCE / SERVICE

2

Figure 4-4. Pan Safety Limit Switch Removal / Installation

NOTE

Early units are units with Serial Numbers BK-1000

thru BK1271 and V-1000 thru V-1575. Later units

are units with Serial Numbers BK-1272, V-1576, and

FH-1000 thru Present.

(5) On early units, tag and disconnect two wires

(4A) from pan safety limit switch (5).

On later units, disconnect wire harness (4B)

from pan safety limit switch (5).

(6) Remove two nuts (6), screws (7), and pan

safety limit switch (5) from pan frame (8).

B. Installation

3

(3) Push pan holder assembly (3) all the way in

until it locks into its fully stowed position, while

observing, from under lower back casting (2),

how the pan safety limit switch (5) is being

tripped.

(4) Slide pan safety limit switch (5) inward or

outward as determined necessary, so that the

trip arm of pan safety limit switch is tripped just

before the pan holder assembly (3) locks into

its fully stowed position.

(5) Repeat steps 3 and 4 until the pan safety limit

switch (5) is positioned properly. Then secure

the pan safety limit switch (5) in position by

tightening two nuts (6).

(1) Install pan safety limit switch (5) on pan frame

(8) and secure with two screws (7) and nuts

(6). Do not tighten nuts at this time.

(2) On early units, connect one wire (4A) to N.O.

terminal and other wire (4A) to COM. terminal

of pan safety limit switch (5).

On later units, connect wire harness (4B) to

pan safety limit switch (5).

© Midmark Corporation 1995 SF-1457 Page 4-5 Printed in U.S.A.

(6) Install upholstered lower back section (1) on

lower back casting (2).

(7) Plug chair power cord into wall outlet.

Page 24

SECTION IV

6

5

7

8

Return To Table Of Contents

MAINTENANCE / SERVICE

4.5 Gas Spring Removal / Installation

A. Removal

(1) If possible, raise TABLE UP and SEAT UP

functions all the way up.

WARNING

Always disconnect the power cord

from the wall outlet before removing

any of the table's covers / shrouds or making any

repairs to prevent the possibility of electrical

shock. Failure to comply with these instructions

could result in severe personal injury or death.

(2) Unplug chair power cord from wall outlet.

1

3

(3) Remove seven screws (1, Figure 4-5), outer

shroud (2), and inner shroud (3) from base

casting (4).

WARNING

If TABLE UP function is not all the way

up, the gas spring will be under extreme pressure. Raise table all the way up before

removing gas spring mounting hardware. Failure

to do so could result in serious personal injury

or death.

(4) Remove two screws (5), four washers (6), and

gas spring (7) from brackets (8).

B. Installation

(1) Coat threads of two screws (5) with removable

threadlocking adhesive (Loctite 242).

(2) Install gas spring (7) on brackets (8) and

secure with four washers (6) and two

screws (5).

2

4

7

8

6

6

5

(3) Install inner shroud (3) and outer shroud (2) on

base casting (4) and secure with seven

screws (1).

(4) Plug chair power cord into wall outlet.

© Midmark Corporation 1995 SF-1457 Page 4-6 Printed in U.S.A.

MA317000

Figure 4-5. Gas Spring Removal / Installation

Page 25

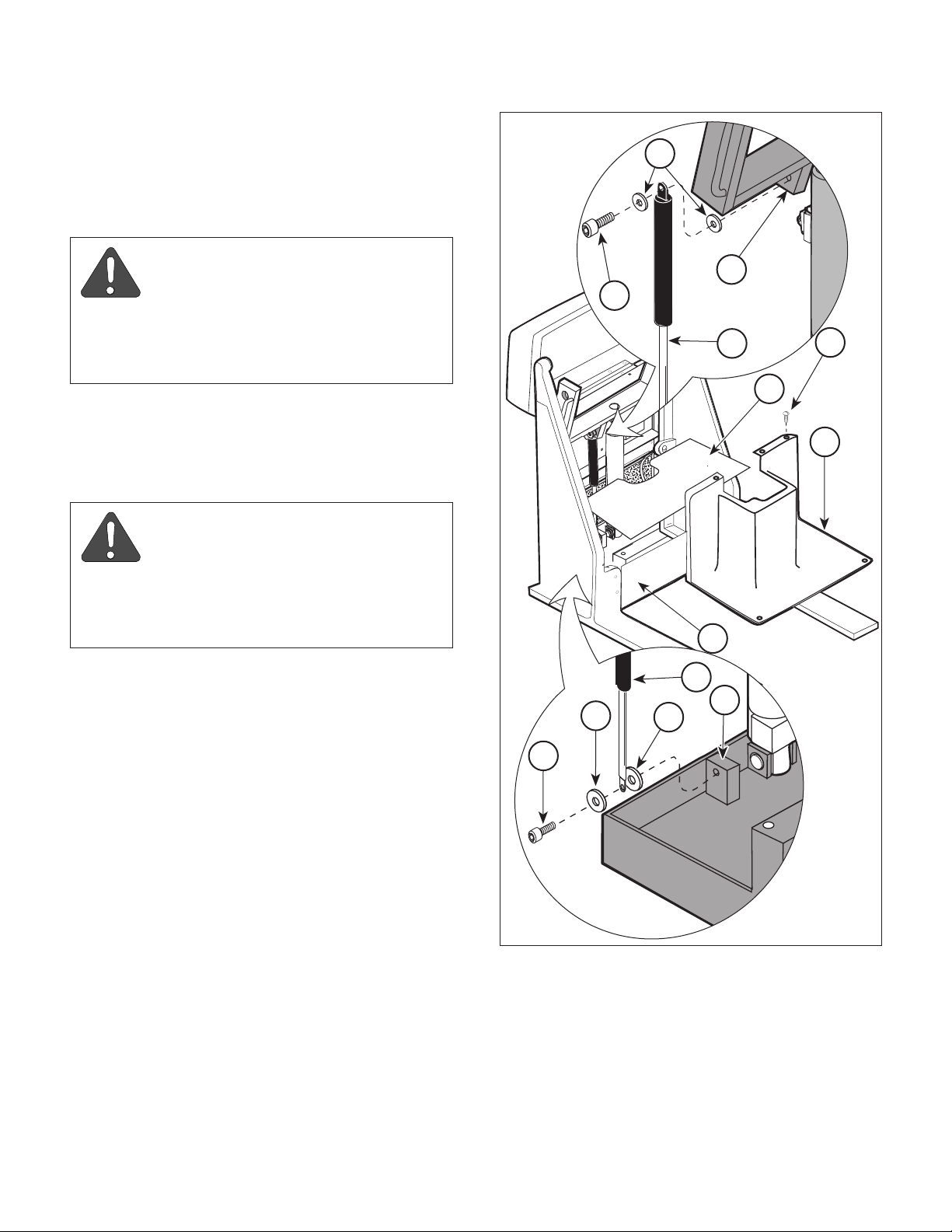

4.6 Base Actuator Removal / Installation

11

13

1

2

5

6

7

8

9

10

11

4

3

12

11

Return To Table Of Contents

A. Removal

SECTION IV

MAINTENANCE / SERVICE

7

(1) Remove gas spring (Refer to para 4.5).

(2) Remove stirrup from patient's right side of

chair.

WARNING

Chair is heavy. Use proper lifting

techniques (and an assistant if necessary) to raise and lower chair. Failure to do so

could result in back injury.

(3) Lay chair onto its right side (patients).

(4) Remove two screws (1, Figure 4-6) and gas

spring base mounting bracket (2) from base

casting (3).

(5) Remove two screws (4), lockwashers (5), and

switch bracket assembly (6) from shaft of base

actuator (7).

(6) Cut cable ties securing wires to base actu-

ator (7).

6

4

5

CABLE

TIES

2

8

10

9

3

1

(7) Remove screw (8) and two cable clamps (9)

from base casting (3). Remove cable clamp (9)

off of base actuator cable (10).

(8) Tag three actuator wires (11); then loosen three

terminal screws (12) and disconnect three

actuator wires (11) from terminal block (13).

NOTE

Access to jam nut (1) may only be possible with a

"homemade" ground down 1-1/8 in. open end

wrench.

(9) Loosen jam nut (1, Figure 4-7).

NOTE

Setscrews are only on later units. Open rear access

door to gain access to the rear setscrew.

(10) If present, loosen two setscrews (2).

Figure 4-6. Wires Disconnection / Connection

(11) Remove screw (3), six screws (4), and back

cover (5) from side uprights (6).

(12) While supporting seat section (7), remove two

e-rings (8) and clevis pin (9) securing base of

base actuator (10) to bracket (11).

MA317100

© Midmark Corporation 1995 SF-1457 Page 4-7 Printed in U.S.A.

Page 26

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

13

7

6

4

P ARALLEL

SPACING

REAR ACCESS

DOOR

3

9

5

2

12

SHAFT

1

10

6

11

8

MA317200

Figure 4-7. Base Actuator Removal / Installation

NOTE

Note how far threads of base actuator are screwed

into chair yoke frame.

(13) While supporting seat section (7), use strap

wrench or channel lock pliers with a soft cloth

to unscrew shaft of base actuator (10) from

chair yoke frame (12).

B. Installation

(1) Screw jam nut (1, Figure 4-7) onto threads of

base actuator (10) fully.

(2) If unit does not have two setscrews (2), apply

permanent threadlocking adhesive (Loctite 262)

to threads of base actuator (10).

(3) While supporting seat section (7), screw new

base actuator (10) into chair yoke frame (12)

approximately the same distance as old base

actuator used to be.

(4) While supporting seat section (7), connect base

actuator (10) to bracket (11) with clevis pin (9)

and two e-rings (8).

(5) Connect three actuator wires (11, Figure 4-6) to

terminal block (13) and secure by tightening

three terminal screws (12).

(6) Install one cable clamp (9) onto base actuator

cable (10); then secure both cable clamps (9)

to base casting (3) with screw (8).

(7) Install switch bracket (6) on shaft of base

actuator (7) and secure with two lockwashers

(5) and screws (4).

(8) Secure wires to base actuator (7) with three

cable ties.

(9) Raise chair to upright position.

© Midmark Corporation 1995 SF-1457 Page 4-8 Printed in U.S.A.

Page 27

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

(10) Plug chair power cord into wall outlet.

(11) Run SEAT UP function all the way up and

TABLE DOWN function all the way down.

(12) If lower back casting (13, Figure 4-7)

with angled surface of side upright (6), go to

step 16.

If lower back casting (13)

angled surface of side upright (6), go to

step 13.

(13) Using strap wrench or channel lock pliers with a

soft cloth, screw shaft of base actuator (10) in

or out of chair yoke frame (12) as determined

necessary in step 12.

(14) Repeat steps 11 thru 13 until lower back

casting (13)

side upright (6) when chair is in full TABLE

DOWN position.

(15) Tighten jam nut (1).

is

parallel with angled surface of

is not

is

parallel

parallel with

NOTE

Setscrews are only on later units. Open rear access

door to gain access to the rear setscrew.

4.7 Typical Capacitor Removal / Installation

A. Removal

(1) If possible, raise TABLE UP and SEAT UP

function all the way up.

WARNING

Always disconnect the power cord

from the wall outlet before removing

any of the table's covers / shrouds or making any

repairs to prevent the possibility of electrical

shock. Failure to comply with these instructions

could result in severe personal injury or death.

(2) Unplug chair power cord from wall outlet.

(3) Remove seven screws (1, Figure 4-8), outer

shroud (2), and inner shroud (3) from base

casting (4).

(4) Using a screwdriver, pry tab of capacitor

mounting bracket (5) outward and remove

capacitor (6) from capacitor mounting bracket.

(5) Remove capacitor cap (7) from capacitor (6).

(16) If present, tighten two setscrews (2).

(17) Install back cover (5) on side uprights (6) and

secure with six screws (4) and one screw (3).

WARNING

Chair is heavy. Use proper lifting

techniques (and an assistant if necessary) to raise and lower chair. Failure to do so

could result in back injury.

(18) Lay chair onto its side.

(19) Install gas spring base mounting bracket (2,

Figure 4-6) on base casting (3) and secure with

two screws (1).

(20) Raise chair to upright position.

(21) Install gas spring (Refer to para 4.5).

(22) Install stirrup.

WARNING

A capacitor contains stored electricity.

Never touch terminals of a capacitor,

even if power has been shut off or disconnected.

Always discharge capacitor before touching

capacitor terminals or wires. Failure to comply

with these instruction could result in serious

personal injury or death.

(6) Discharge capacitor (6).

(7) Disconnect two wires (8) from terminals of

capacitor (6).

B. Installation

(1) Connect two wires (8) to terminals of capaci-

tor (6).

(2) Install capacitor cap (7) on capacitor (6).

© Midmark Corporation 1995 SF-1457 Page 4-9 Printed in U.S.A.

Page 28

SECTION IV

SEAT

CAPACITOR

7

5

6

8

BASE

CAPACITOR

CATCH

TAB

1

2

3

4

VIEW

MA317300

Return To Table Of Contents

MAINTENANCE / SERVICE

(3) Position bottom of capacitor (6) on capacitor

mounting bracket (5) and then push the top of

the capacitor in. Using a screwdriver, force tab

of capacitor mounting bracket (5) down over

catch.

(4) Install inner shroud (3) and outer shroud (2) on

base casting (4) and secure with seven

screws (1).

(5) Plug chair power cord into wall outlet.

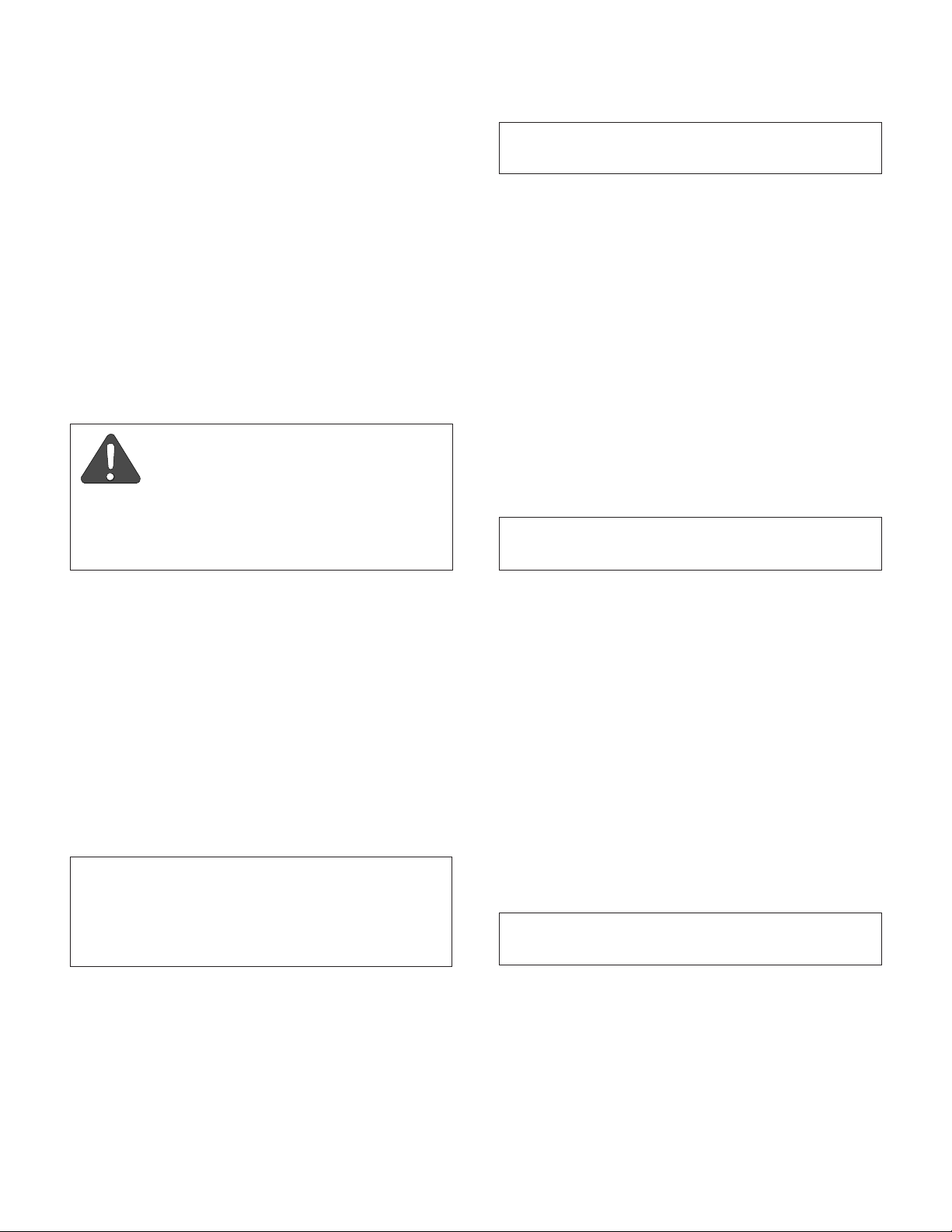

4.8 Typical Actuator Motor / Actuator

Brake Removal / Installation

A. Removal

(1) Remove malfunctioning actuator assembly:

Seat actuator assembly (Refer to para 4.3).

Base actuator assembly (Refer to para 4.6).

Figure 4-8. Typical Capacitor Removal / Installation

(2) Remove two nuts (1, Figure 4-9) and actuator

motor (2) from actuator mechanism (3).

(3) Remove two shoulder washers (4) from actua-

tor mechanism (3).

(4) Remove spacer (5) and motor coupler (6) from

shaft of actuator motor (2).

NOTE

A needle nose pliers should be used to extract the

actuator brake from the actuator mechanism. Grasp

the raised round plate of the actuator brake with the

pliers and pull.

(5) Remove actuator brake (7) and rubber damper

(8) from shaft of actuator mechanism (3).

B. Installation

NOTE

The rubber damper must be installed so its flat side

faces the inside of the actuator mechanism. The

actuator brake must be installed so its flattest side

faces outward. The shaft of the actuator mechanism

may be turned with a screwdriver to help align the

keys of the actuator mechanism shaft with the key

slots in actuator brake.

© Midmark Corporation 1995 SF-1457 Page 4-10 Printed in U.S.A.

Page 29

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

(6) Check actuator assembly for proper operation.

The actuator assembly should run normally and

should not make a grinding noise. A grinding

noise indicates that key slots of motor coupler

1

4

were not aligned properly with keys of actuator

mechanism (a grinding noise also indicates that

the motor coupler is being damaged). The

actuator assembly should brake properly.

4.9 Base Down Limit Switch or Seat Down

KEYS

7

Limit Switch Removal / Installation

6

3

KEY SLOTS

8

KEY

7

SLOT

Figure 4-9. Typical Actuator Motor / Actuator Brake

Removal / Installation

(1) Install rubber damper (8), actuator brake (7),

and spacer (5) in actuator mechanism (3).

(2) Install motor coupler (6) on shaft of actuator

motor (2).

5

2

MA317400

A. Removal

(1) If possible, raise TABLE UP and SEAT UP

functions all the way up.

WARNING

Always disconnect the power cord

from the wall outlet before removing

any of the table's covers / shrouds or making any

repairs to prevent the possibility of electrical

shock. Failure to comply with these instructions

could result in severe personal injury or death.

(2) Unplug chair power cord from wall outlet.

(3) Remove seven screws (1, Figure 4-10), outer

shroud (2), and inner shroud (3) from base

casting (4).

(4) Remove two screws (5), lockwashers (6), and

switch bracket (7) from shaft of base actuator (8).

(5) Tag and disconnect two wires (1, Figure 4-11)

from base down limit switch (2).

(3) Install two shoulder washers (4) in actuator

mechanism (3).

(4) Align keys of actuator mechanism (3) shaft with

key slots of motor coupler (6) and then install

actuator motor (2) on actuator mechanism (3)

and secure with two nuts (1).

(5) Install actuator assembly:

Base actuator assembly (Refer to para 4.6).

Seat actuator assembly (Refer to para 4.3).

© Midmark Corporation 1995 SF-1457 Page 4-11 Printed in U.S.A.

(6) Tag and disconnect two wires (3) from seat

down limit switch (4).

NOTE

Note or mark the approximate position of the limit

switches on the switch bracket. This will help during

installation.

(7) Remove two nuts (5), lockwashers (6), screws

(7), and limit switches (2 and 4) from switch

bracket (8).

Page 30

SECTION IV

MA317500

1

2

3

VIEW

4

7

6

5

8

Return To Table Of Contents

MAINTENANCE / SERVICE

3

7

6

6

5

Figure 4-11. Wires Disconnection / Connection

1

4

2

8

MA317600

(2) Connect one wire (3) to N.C. terminal and the

other wire (3) to COM. terminal of seat down

limit switch (4).

(3) Connect one wire (1) to N.C. terminal and the

other wire (1) to COM. terminal of base down

limit switch (2).

(4) Install switch bracket (7, Figure 4-10) on shaft

of base actuator (8) and secure with two

lockwashers (6) and screws (5).

Figure 4-10. Base Down Limit Switch or

Seat Down Limit Switch Removal / Installation

B. Installation

(1) Install limit switches (2 and 4, Figure 4-11) on

switch bracket (8) and secure with two screws

(7), lockwashers (6), and nuts (5), making sure

to position the limit switches in approximately

same position as they were removed.

© Midmark Corporation 1995 SF-1457 Rev. 2/99 Page 4-12 Printed in U.S.A.

(5) Install inner shroud (3) and outer shroud (2) on

base casting (4) and secure with seven

screws (1).

(6) Plug chair power cord into wall outlet.

NOTE

The trip arms of the limit switches should be tripped

when the base up function is at 2/3 of it total height.

Page 31

(7) Run TABLE UP function up until the table top is

Return To Table Of Contents

at 2/3 of its total height.

(8) If limit switches trip too early, loosen two

screws (7, Figure 4-11) and slide limit switches

(2 and 4) downward slightly; then tighten two

screws (7).

SECTION IV

MAINTENANCE / SERVICE

3

RETURN

RETURN

If limit switches trip too late, loosen two screws

(7) and slide limit switches (2 and 4) upward

slightly; then tighten two screws (7).

(9) Repeat steps 7 and 8 until limit switches are

adjusted so they trip when table top reaches 2/

3 of its total height.

4.10 Typical Foot Pedal Footswitch Removal / Installation

A. Removal

WARNING

Always disconnect the power cord

from the wall outlet before removing

any of the table's covers / shrouds or making any

repairs to prevent the possibility of electrical

shock. Failure to comply with these instructions

could result in severe personal injury or death.

(1) Unplug chair power cord from wall outlet.

(2) Remove screw (1, Figure 4-12), lockwasher

(2), and pedal (3) from foot switch bracket (4).

AQUIRE

6

AQUIRE

2

5

9

8

1

7

PIVOT

SPACER

10

4

MA317701

(3) Remove two locknuts (5), screws (6), two

insulators (7), and footswitch (8) from

footswitch bracket (4).

(4) Tag and disconnect two

terminals of footswitch (8). Remove footswitch.

B. Installation

(1) Connect two

footswitch (8).

(2) Install footswitch (8) on foot switch bracket (4)

and secure with two insulators (7), screws (6),

and locknuts (5).

© Midmark Corporation 1995 SF-1457 Rev. 2/99 Page 4-13 Printed in U.S.A.

or

three wires (9) to terminals of

or

Figure 4-12. Typical Foot Pedal Footswitch

Removal / Installation

(3) Ensure springs (10) are in position and have

not fallen off.

three wires (9) from

(4) Install pedal (3) on foot switch bracket (4) and

secure with lockwasher (2) and screw (1),

making sure pedal is mounted on pivot spacer.

(5) Plug chair power cord into wall outlet.

Page 32

SECTION IV

Return To Table Of Contents

MAINTENANCE / SERVICE

© Midmark Corporation 1995 SF-1457 Page 4-14 Printed in U.S.A.

Page 33

SCHEMATICS AND DIAGRAMS

Return To Table Of Contents

SECTION V

SCHEMATICS AND DIAGRAMS

SECTION V

5.1 Electrical Schematics / Wiring

Diagrams

Figures 5-1 and 5-2 illustrate the wiring connections

RECEPTACLE WIRING

HARNESS 015-0431-00

BASE

CAPACITOR

(41-53 MFD)

ELECTRICAL

RECECTACLE

2 AMPS. MAX.

BLACK

BLACK

BLACK

BLACK

BLACK

(DOWN)

WHITE

BASE

ACTUATOR

FOOT PEDAL

WHITE

ORANGE

RED

BLUE

GREEN

BLACK

RED (UP)

SEAT UP

BASE

DOWN

BASE UP

SEAT DOWN

ORANGE

SEAT DOWN LIMIT SWITCHES, (N.C.)

(BASE FUNCTION- ALL THE WAY DOWN

TO 2/3 WAY UP = TRIPPED = OPEN

CIRCUIT

ORANGE

BLACK

BASE DOWN LIMIT SWITCHES, (N.C.)

(BASE FUNCTION- ALL THE WAY DOWN

TO 2/3 WAY UP = TRIPPED = OPEN

CIRCUIT

SEAT FUNCTION ALL THE WAY

UP= UNTRIPPED=CLOSED CIRCUIT,

ANY OTHER POSITION=TRIPPED=OPEN CIRCUIT

Figure 5-1 Wiring Diagam (Used on Domestic Units with

Serial Numbers: BK1000 Thru BK1271)

BLACK

ORANGE

RED

BLUE

WHITE

SEAT

CAPACITOR

(41-53 MFD)

GREEN

between the electrical components in the chair. Figures

5-3 and 5-4 illustrate the logic/current flow between the

electrical components in the chair.

GREEN/YELLOW

WHITE

1

WHITE

2

BLACK

3

BLACK

4

WHITE/BLACK

5

RED

6

BLUE

7

RED

8

ORANGE

9

10

11

BLUE

WHITE/BLACK

WHITE/BLACK

SEAT

ACTUATOR

SEAT LIMIT SWITCH, N.C.

ON SEAT ACTUATOR

WHITE/BLACK

BLACK

WHITE/BLACK

BLACK

ORANGE

RED (UP)

WHITE

BLACK (DOWN)

WHITE

GREEN

BLACK

PAN SAFETY

LIMIT SWITCH, (N.O.)

(PAN IN = CLOSED

CIRCUIT)

RED

WIRING HARNESS

015-0426-00

WHITE

RED

RED

WHITE

ORANGE

MA 307403

(Applies To 115 VAC Domestic Units With Serial Numbers BK-1000 Thru BK-1271

© Midmark Corporation 1995 SF-1457 Rev. 8/96 Page 5-1 Printed in U.S.A.

Figure 5-1 (Sheet 1 of 2). Wiring Diagram

Page 34

SECTION V

Return To Table Of Contents

SCHEMATICS AND DIAGRAMS

ELECTRICAL

RECEPTACLE

RECEPTACLE WIRING

HARNESS 015-0431-00

SEAT

CAPACITOR

(41-53 MFD)

BASE

CAPACITOR

(41-53 MFD)

2 AMPS. MAX.

GREEN/YELLOW

JUMPER WIRE

015-0022-00

POWER CORD

015-0066-02

120 V.A.C., 60 Hz.

6 AMPS..

JUMPER WIRE

015-0427-00

BLACK

ORANGE

RED

BLUE

WHITE

GREEN

BLACK

BLACK

BASE

ACTUATOR

FOOT CONTROL

WHITE

ORANGE

RED

BLUE

GREEN

BLACK

BLACK

BLACK

BLACK

(DOWN)

WHITE

RED (UP)

SEAT UP

BASE

DOWN

BASE UP

SEAT DOWN

TERMINAL

BLOCK

BLACK

ORANGE

SEAT DOWN LIMIT SWITCH (N.C)

(BASE FUNCTION - ALLTHE WAY DOWN TO

2/ 3 WAY UP= TRIPPED = OPEN CIRCUIT)

ORANGE

BLACK

BASE DOWN LIMIT SWITCH (N.C.) (BASE

FUNCTION- ALL THE WAY DOWN TO 2/3

WAY UP = TRIPPED = OPEN CIRCUIT)

BLACK

SEAT FUNCTION ALL THE WAY

UP = UNTRIPPED = CLOSED CIRCUIT,

ANY OTHER POSTION = TRIPPED = OPEN CIRCUIT

WHITE

WHITE

SEAT

ACTUATOR

SEAT UP LIMIT SWITCH (N.C.)

ON SEAT ACTUATOR

WHITE

WHITE

1

WHITE

2

BLACK

3

BLACK

4

BLUE

5

RED

6

WHITE/BLACK

7

BLACK

8

ORANGE

9

RED

10

11

WHITE/BLACK

BLUE

BLUE

BLACK

BLACK (DOWN)

RED (UP)

WHITE

WHITE

GREEN

BLACK

PAN SAFETY LIMIT

SWITCH, (N.O.)

(PAN IN = CLOSED CIRCUIT)

WHITE

PAN LIMIT SWITCH

HARNESS

015-0561-00

JUMPER WIRE

015-0428-01

WIRING HARNESS

002-0484-00

WHITE

RED

BLUE

BLACK

ORANGE

RED

WHITE

ORANGE

BLACK

BLACK

WHITE

BLUE

SEAT LIMIT SWITCH HARNESS

015-0562-00

MA307400

(Applies To 115 VAC Domestic Units With Serial Numbers BK-1272 and FH-1000 Thru Present)

© Midmark Corporation 1995 SF-1457 Page 5-2 Printed in U.S.A.

Figure 5-1 (Sheet 2 of 2). Wiring Diagram

Page 35

SEAT

Return To Table Of Contents

CAPACITOR

(12.5 MFD)

BASE

CAPACITOR

(12.5 MFD)

SECTION V

SCHEMATICS AND DIAGRAMS

220 V.A.C., 50 Hz.

1.5 AMPS..

5 X 20 MM. 1.5 AMP.

SLO BLO FUSES

BLACK

ORANGE

RED

BLUE

WHITE

GREEN

BASE

ACTUAT OR

FOOT CONTROL

GREEN

BLACK

BLACK

WHITE

ORANGE

BLUE

RED

BLACK

BLACK

BLACK

BLACK

(DOWN)

WHITE

RED (UP)

SEAT UP

BASE

DOWN

BASE UP

SEAT DOWN

WHITE

1

WHITE

2

BLACK

3

BLACK

4

WHITE/BLACK

5

RED

6

BLUE

7

RED

8

ORANGE

9

10

11

WHITE

ORANGE

SEAT DOWN LIMIT SWITCHES, (N.C.)

(BASE FUNCTION- ALL THE WAY DOWN

TO 2/3 WAY UP = TRIPPED = OPEN

CIRCUIT

ORANGE

BLACK

BASE DOWN LIMIT SWITCHES, (N.C.)

(BASE FUNCTION- ALL THE WAY DOWN

TO 2/3 WAY UP = TRIPPED = OPEN

CIRCUIT

SEAT LIMIT SWITCH, N.C.

ON SEAT ACTUATOR

SEAT FUNCTION ALL THE WAY

UP= UNTRIPPED=CLOSED CIRCUIT,

ANY OTHER POSITION=TRIPPED=OPEN CIRCUIT

BLUE

WHITE/BLACK

WHITE/BLACK

SEAT

ACTUATOR

BLACK

BLACK (DOWN)

WHITE/BLACK

RED (UP)

WHITE

WHITE

GREEN

BLACK

PAN SAFETY

LIMIT SWITCH, (N.O.)

(PAN IN = CLOSED

CIRCUIT)

RED

WHITE

WHITE/BLACK

BLACK

ORANGE

RED

RED

WHITE

ORANGE

MA 307402

(Applies To 220 VAC Export Units With Serial Numbers V-1000 Thru V-1575)

© Midmark Corporation 1995 SF-1457 Page 5-3 Printed in U.S.A.

Figure 5-2 (Sheet 1 of 2). Wiring Diagram

Page 36

SECTION V

Return To Table Of Contents

SCHEMATICS AND DIAGRAMS

220 V.A.C., 50 Hz.

1.5 AMPS.

BLACK

ORANGE

RED

BLUE

WHITE

SEAT

CAPACITOR

(41-53 MFD)

BLACK

GREEN

BASE

ACTUATOR

BASE

CAPACITOR

(41-53 MFD)

BLACK

BLACK

BLACK

BLACK

(DOWN)

WHITE

RED (UP)

ORANGE

JUMPER WIRE

015-0305-02

WHITE

1

WHITE

2

BLACK

3

BLACK

4

BLUE

5

RED

6

WHITE/BLACK

7

BLACK

8

ORANGE

9

RED

10

11

WHITE

ORANGE

SEAT DOWN LIMIT SWITCH (N.C.)

(BASE FUNCTION - ALL THE WAY DOWN TO

2/3 WAY UP = TRIPPED = OPEN CIRCUIT)

WHITE/BLACK

5 X 20 MM. 1.5 AMP.

SLO BLO FUSES

JUMPER WIRE

015-0303-00

WHITE

GRN/YLW

BLACK

PAN SAFETY LIMIT SWITCH,(N.O.)

(PAN IN =CLOSED

CIRCUIT)

PAN LIMIT SWITCH HARNESS

015-0561-00

JUMPER WIRE

015-0305-03

WHITE

FOOT CONTROL

WHITE

ORANGE

RED

BLUE

GREEN

BLACK

Figure 5-2 Wiring Diagram (Used on Export Units with

Serial Numbers: V 1576 Thru Present)

BLACK

BASE DOWN LIMIT SWITCH (N.C.) (BASE

FUNCTION - ALL THE WAY DOWN TO 2/3

WAY UP = TRIPPED = OPEN CIRCUIT)

BLACK

SEAT UP

BASE

DOWN

BASE UP

SEAT LIMIT SWITCH, (N.C.)

ON SEAT ACTUATOR

SEAT DOWN

SEAT FUNCTION ALL THE WAY

UP= UNTRIPPED=CLOSED CIRCUIT,

ANY OTHER POSITION=TRIPPED=OPEN CIRCUIT

BLUE

BLUE

SEAT

ACTUATOR

WHITE

BLACK

RED (UP)

WHITE

BLACK (DOWN)

BLACK

WHITE

SEAT LIMIT SWITCH HARNESS

015-0562-00

WHITE

RED

BLUE

BLACK

ORANGE

RED

WHITE

ORANGE

BLACK

BLUE

WIRING HARNESS

002-0484-00

MA 307401

(Applies To 220 VAC Export Units With Serial Numbers V-1576 Thru Present)

© Midmark Corporation 1995 SF-1457 Rev 7/98 Page 5-4 Printed in U.S.A.

Figure 5-2 (Sheet 2 of 2). Wiring Diagram

Page 37

SCHEMATICS AND DIAGRAMS

Return To Table Of Contents

Positions:

- Pan Switch - CLOSED

- Seat Down Switch- OPEN

- Base Down Switch - OPEN

- Seat Up Switch - CLOSED

Conclusions:

- Base can power either direction.

- Seat can power up only!

ELECTRICAL

RECEPTACLE

SECTION V

WHITE

SEAT

ACTUATOR

BLACK

BASE

ACTUATOR

WHITE

RED

SEAT

CAPACITOR

SEAT UP

LIMIT SWITCH

(N.C.)

BLACK

BASE

RED

CAPACITOR

PAN SAFETY LIMIT SWITCH

WHITE

BLACK

WHITE

ORANGE

BLACK

BLACK

BLACK

SEAT DOWN

LIMIT SWITCH

(N.C.)